Study on the Rheological Properties of Recycled Plastic and Waste Cooking Oil Composite Modified Asphalt

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Orthogonal Test

2.2.2. Preparation Process of Modified Asphalt

2.2.3. Physical Property Tests

2.2.4. Rheological Tests

2.2.5. FTIR Test

2.2.6. TLC/FID Test

3. Results

3.1. Development of Modified Asphalt

3.2. Rheological Tests

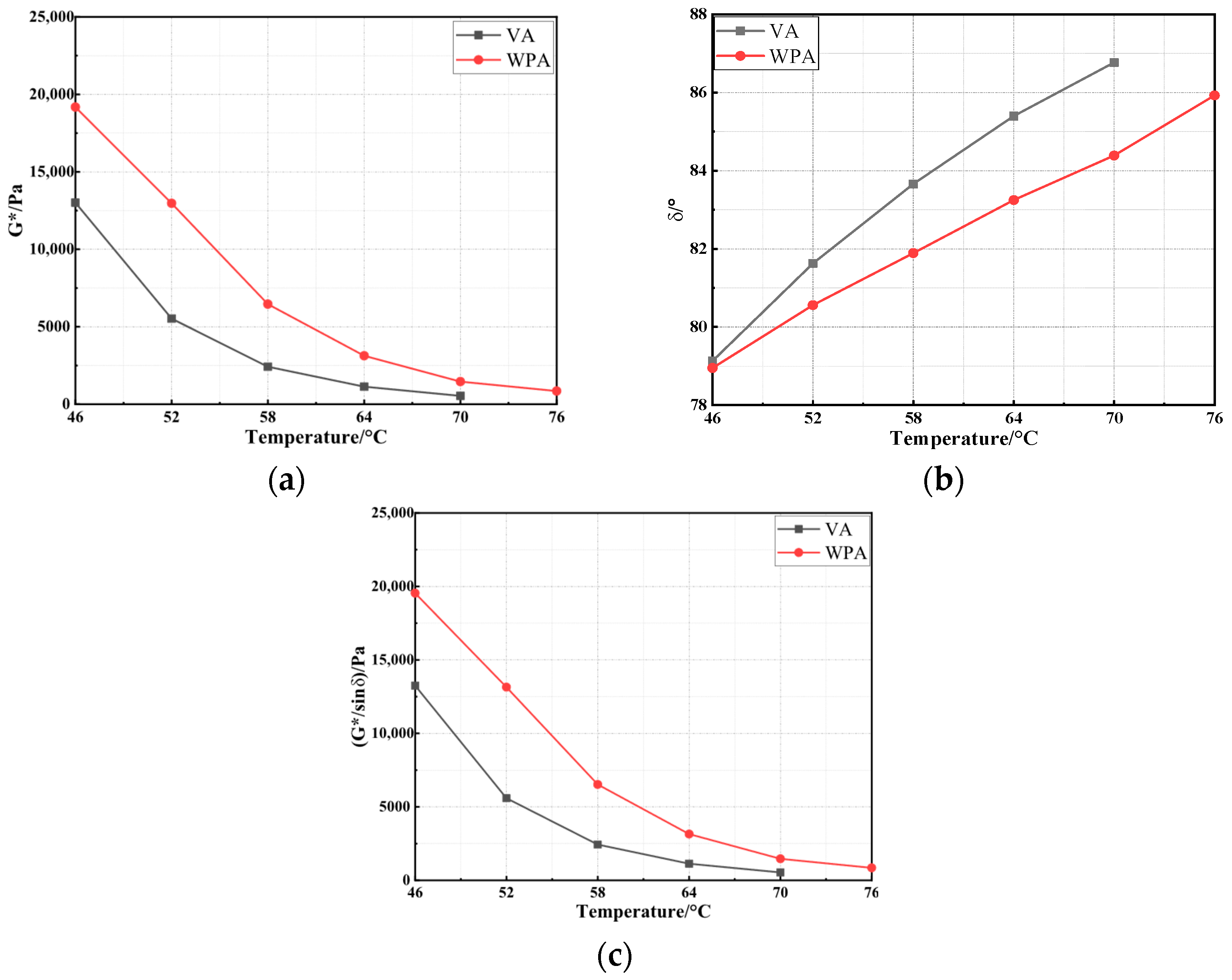

3.2.1. Temperature Sweep Test

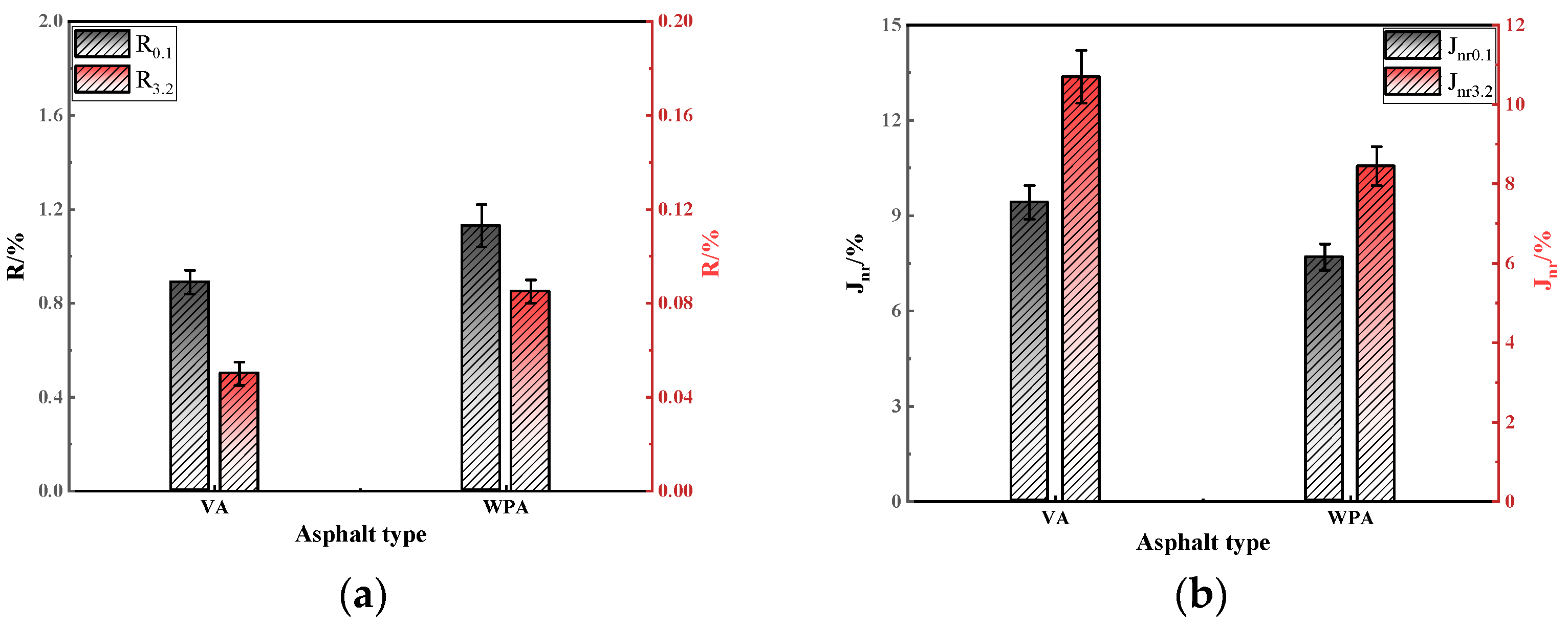

3.2.2. MSCR TEST

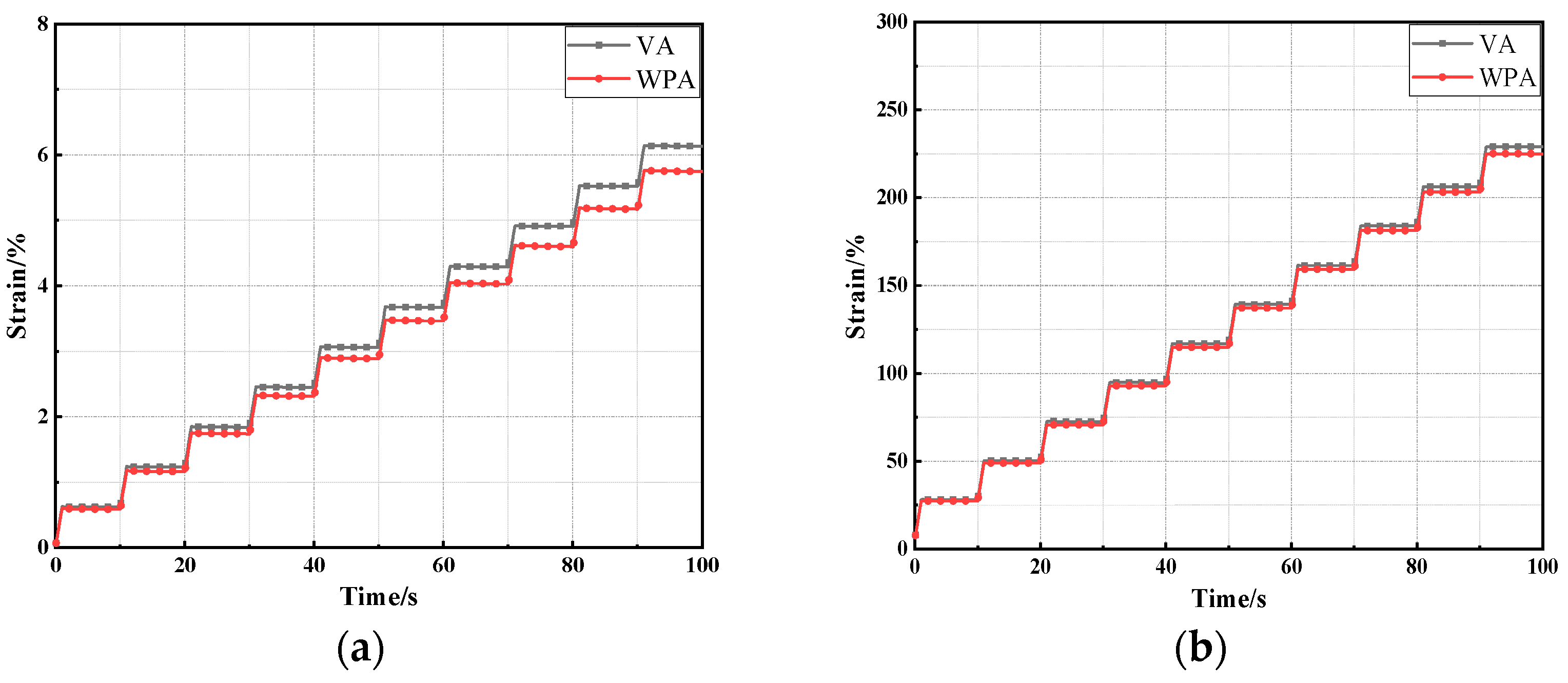

3.2.3. LAS Test

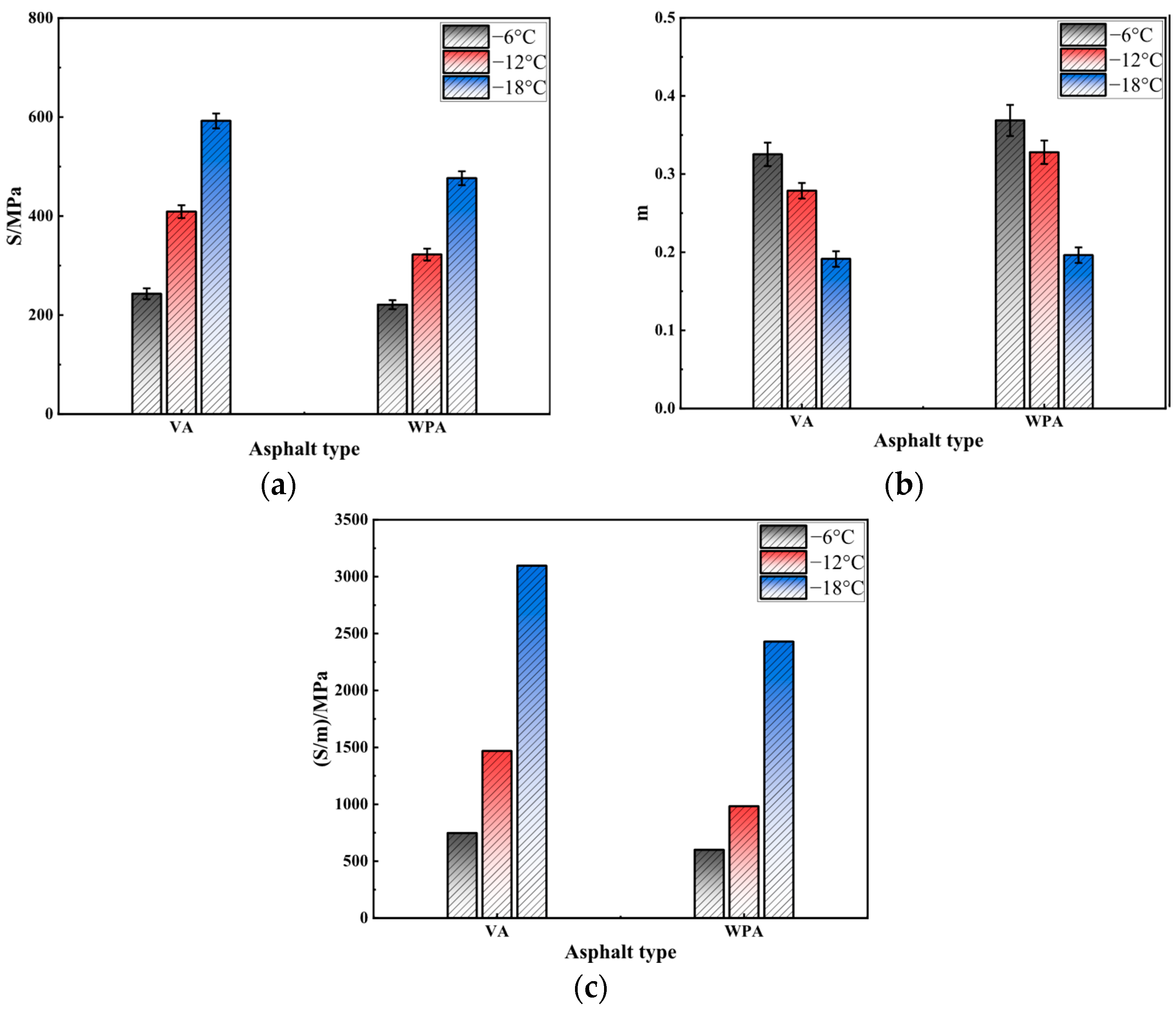

3.2.4. BBR Test

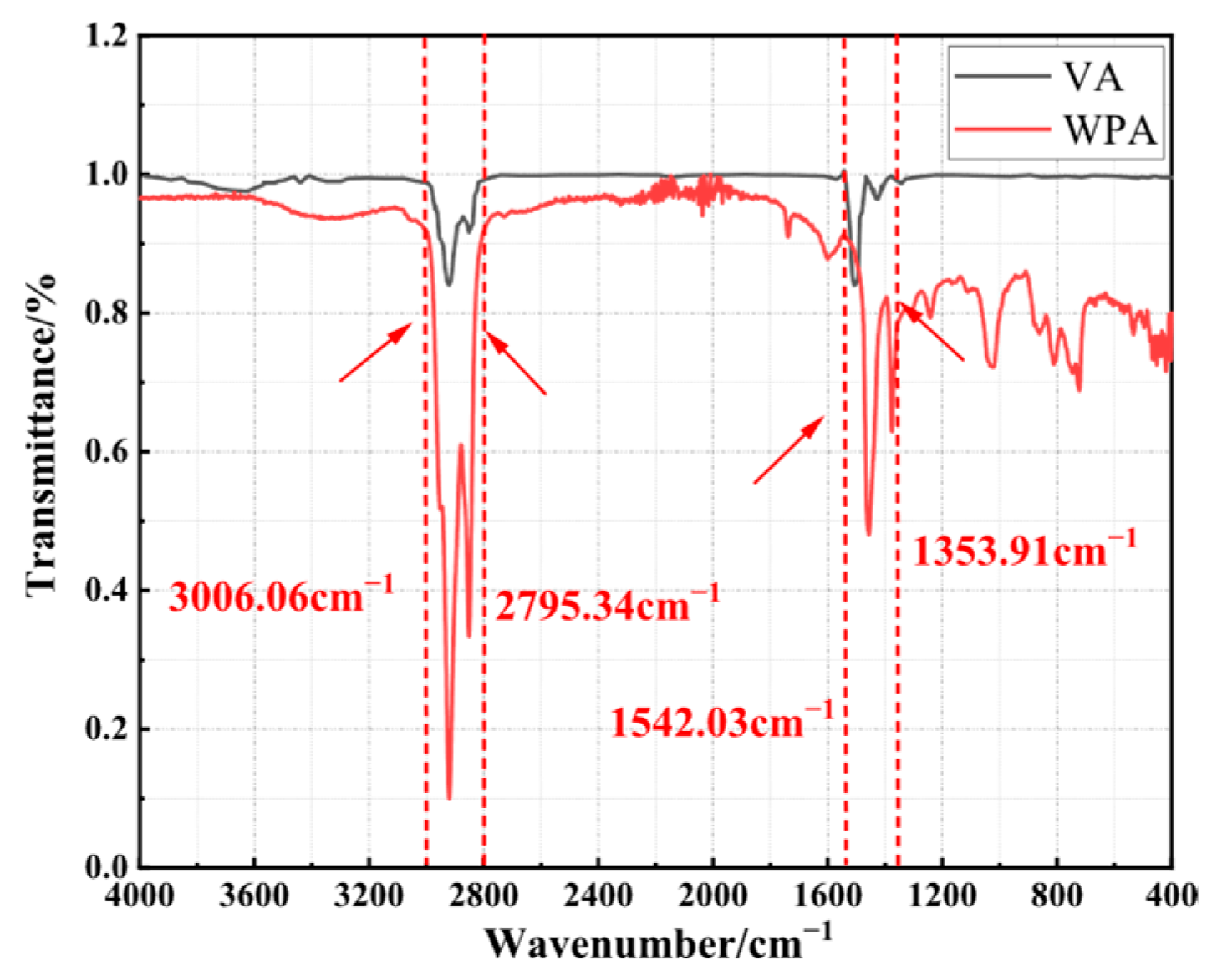

3.3. FTIR Test

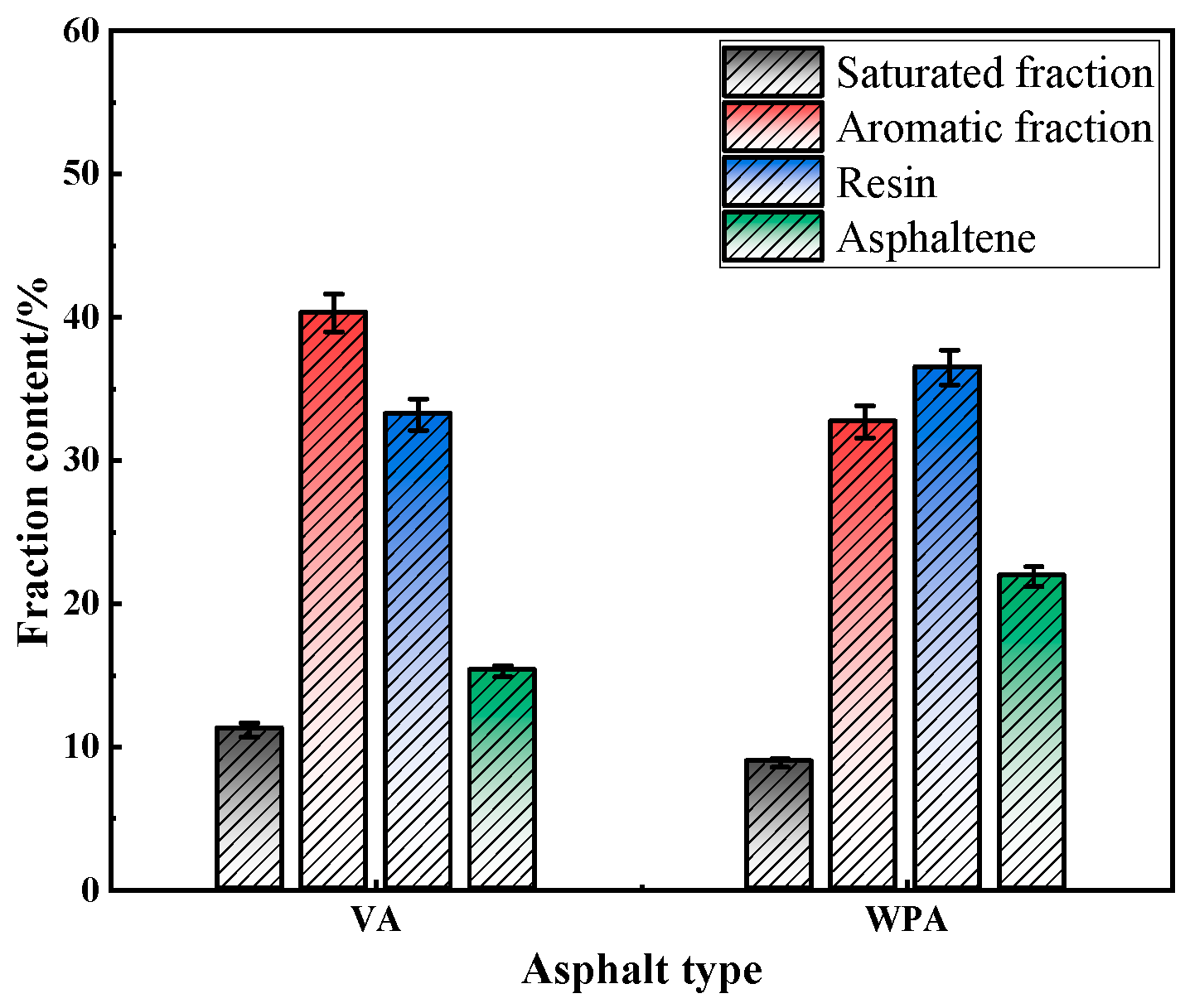

3.4. TLC-FID Test

4. Conclusions

- (1)

- Orthogonal tests were conducted to analyze the formula of composite modified asphalt, and the recommended dosage was determined as 5% WCO, 5% EVA, and 5% PE.

- (2)

- Compared with VA, the high-temperature complex modulus of WPA is increased, the phase angle is decreased, and its high-temperature performance grade reaches PG 70. In addition, WPA shows improvements in rutting resistance, fatigue performance, and low-temperature performance. The modification effectively optimizes the rheological properties of asphalt.

- (3)

- The incorporation of several modified materials causes changes in the internal components of asphalt, the contents of light components in asphalt decrease, while the proportion of heavy components increases. This component change further improves asphalt’s performance in terms of high-temperature stability, fatigue resistance, and low-temperature crack resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.; Li, J.; Liu, G.; Yang, T.; Zhao, Y. Recycling aged asphalt using hard asphalt binder for hot-mixing recycled asphalt mixture. Appl. Sci. 2021, 11, 5698. [Google Scholar] [CrossRef]

- Fry, J.; Schandl, H. Simulating waste plastic flows in Australia. Resources. Conserv. Recycl. 2024, 209, 107747. [Google Scholar]

- Ishimura, Y.; Nomura, K.; Ichinose, D. Does simplification of plastic waste separation promote plastic recycling? J. Mater. Cycles Waste Manag. 2025, 27, 316–329. [Google Scholar]

- Briassoulis, D.; Babou, E.; Hiskakis, M.; Scarascia, G.; Picuno, P.; Guarde, D.; Dejean, C. Review, mapping and analysis of the agricultural plastic waste generation and consolidation in Europe. Waste Manag. Res. 2013, 31, 1262–1278. [Google Scholar] [CrossRef] [PubMed]

- Kumi-Larbi Jnr, A.; Galpin, R.; Manjula, S.; Lenkiewicz, Z.; Cheeseman, C. Reuse of waste plastics in developing countries: Properties of waste plastic-sand composites. Waste Biomass Valorization 2022, 13, 3821–3834. [Google Scholar] [CrossRef]

- Sharma, D.K.; Bapat, S.; Brandes, W.F.; Rice, E.; Castaldi, M.J. Technical feasibility of zero waste for paper and plastic wastes. Waste Biomass Valorization 2019, 10, 1355–1363. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, X.; He, Z.; Zhang, X. Modified Asphalt From Domestic Waste Old Plastic. Intell. Autom. Soft Comput. 2010, 16, 823–831. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Abdul Wahhab, H. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357. [Google Scholar]

- Boom, Y.J.; Enfrin, M.; Swaney, M.; Masood, H.; Pramanik, B.K.; Robert, D.; Giustozzi, F. Engineering properties, microplastics and emissions assessment of recycled plastic modified asphalt mixtures. Sci. Total Environ. 2023, 893, 164869. [Google Scholar]

- Lu, D.X.; Enfrin, M.; Boom, Y.J.; Giustozzi, F. Future recyclability of hot mix asphalt containing recycled plastics. Constr. Build. Mater. 2023, 368, 130396. [Google Scholar] [CrossRef]

- Dalhat, M.; Al-Abdul Wahhab, H.I.; Al-Adham, K. Recycled plastic waste asphalt concrete via mineral aggregate substitution and binder modification. J. Mater. Civ. Eng. 2019, 31, 04019134. [Google Scholar] [CrossRef]

- Hao, G.; He, M.; Lim, S.M.; Ong, G.P.; Zulkati, A.; Kapilan, S. Recycling of plastic waste in porous asphalt pavement: Engineering, environmental, and economic implications. J. Clean. Prod. 2024, 440, 140865. [Google Scholar] [CrossRef]

- de Melo, J.V.S.; Tonial, M.; Manfro, A.L. Impact of incorporating latex glove fragments on the rheological and mechanical properties of a conventional asphalt matrix. Constr. Build. Mater. 2025, 476, 141295. [Google Scholar] [CrossRef]

- Ma, Y.; Demchuk, Z.; Polaczyk, P.; Zhou, H.; He, Q.; Baumgardner, G.L.; Huang, B. Reactive extrusion of waste plastics with compatibilizer and lightly pyrolyzed crumb rubber for asphalt modification. Transp. Res. Rec. 2025, 2679, 1052–1063. [Google Scholar] [CrossRef]

- Mamun, A.A.; Al-Abdul Wahhab, H.; Dalhat, M. Comparative evaluation of waste cooking oil and waste engine oil rejuvenated asphalt concrete mixtures. Arab. J. Sci. Eng. 2020, 45, 7987–7997. [Google Scholar] [CrossRef]

- Li, H.; Zhang, F.; Feng, Z.; Li, W.; Zou, X. Study on waste engine oil and waste cooking oil on performance improvement of aged asphalt and application in reclaimed asphalt mixture. Constr. Build. Mater. 2021, 276, 122138. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhang, H.; Sun, J.; Zhu, J.; Fan, X. Optimizing asphalt recycling through characterization of waste cooking oils. Constr. Build. Mater. 2025, 491, 142647. [Google Scholar] [CrossRef]

- Bardella, N.; Facchin, M.; Fabris, E.; Baldan, M.; Beghetto, V. Waste cooking oil as eco-friendly rejuvenator for reclaimed asphalt pavement. Materials 2024, 17, 1477. [Google Scholar] [CrossRef] [PubMed]

- Mamun, A.A.; Al-Abdul Wahhab, H. Comparative laboratory evaluation of waste cooking oil rejuvenated asphalt concrete mixtures for high contents of reclaimed asphalt pavement. Int. J. Pavement Eng. 2020, 21, 1297–1308. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Traffic Press: Beijing, China, 2011.

- GB/T 5526-2024; Animal and Vegetable Fats and Oils—Determination of Relative Density. National Standardization Administration Committee: Beijing, China, 2024.

- GB/T 22235-2008; Determination for Viscosity of Liquids. National Standardization Administration Committee: Beijing, China, 2008.

- GB/T 21789-2025; Determination of Flash Point—Abel Closed-Cup Method. National Standardization Administration Committee: Beijing, China, 2025.

- GB 5009.236-2016; National Food Safety Standard—Determination of Moisture and Volatile Substances in Animal and Vegetable Oils and Fats. National Health and Family Planning Commission of the People’s Republic of China: Beijing, China, 2016.

- GB/T 1033.1-2008; Plastics. Methods for Determining Density of Non-Celluar Plastics. Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method. National Standardization Administration Committee: Beijing, China, 2008.

- YY/T 0815-2010; Standard Test Method for Measurement of Enthalpy of Fusion, Percent Crystallinity, and Melting Point of Ultra-High-Molecular Weight Polyethylene by Means of Differential Scanning Calorimetry. State Food and Drug Administration: Beijing, China, 2010.

- GB/T 9343-2008; Test Method for Flammability of Plastics. Determination of Flash-Ignition Temperature and Self-Ignition Temperature. National Standardization Administration Committee: Beijing, China, 2008.

- GB/T 15182-2020; Linear Low Density Polyethylene Resin. State Bureau of Technical Supervision: Beijing, China, 2020.

- GB/T 33047.1-2016; Plastics-Thermogravimetry(TG) of Polymers Part 1: General Principles. National Standardization Administration Committee: Beijing, China, 2016.

- Cong, P.; Hao, H.; Luo, W. Investigation of carbonyl of asphalt binders containing antiaging agents and waste cooking oil using FTIR spectroscopy. J. Test. Eval. 2019, 47, 1147–1162. [Google Scholar] [CrossRef]

- Yuechao, Z.; Meizhu, C.; Shaopeng, W.; Qi, J. Rheological properties and microscopic characteristics of rejuvenated asphalt using different components from waste cooking oil. J. Clean. Prod. 2022, 370, 133556. [Google Scholar] [CrossRef]

- Zhong, L.; Zhang, Y.; Wang, T.; Ji, Y.; Norris, P.; Pan, W.-P. Optimized methods for preparing activated carbon from rock asphalt using orthogonal experimental design. J. Therm. Anal. Calorim. 2019, 136, 1989–1999. [Google Scholar] [CrossRef]

- Wei, H.; Wang, Y.; Li, J.; Zhang, Y.; Qian, G. Optimization design of cold patching asphalt liquid based on performance experiments and statistical methods. Constr. Build. Mater. 2023, 391, 131881. [Google Scholar] [CrossRef]

- AASHTO T 350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2019.

- AASHTO TP 101; Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep. AASHTO: Washington, DC, USA, 2012.

- AASHTO T 313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). AASHTO: Washington, DC, USA, 2019.

- GB/T 6040-2019; General Rules for Infrared Analysis. Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- JTG 3410-2025; Standard Test Methods of Asphalt And Asphalt Mixture for Highway Engineering. Standardization Administration of the People’s Republic of China: Beijing, China, 2025.

- Al-Khateeb, G.G.; Ramadan, K.Z. Investigation of the effect of rubber on rheological properties of asphalt binders using superpave DSR. KSCE J. Civ. Eng. 2015, 19, 127–135. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, T.; Xu, G.; Huang, X.; Ling, M.; Chen, X.; Xue, J. Fatigue resistance evaluation of modified asphalt using a multiple stress creep and recovery (MSCR) test. Appl. Sci. 2018, 8, 417. [Google Scholar] [CrossRef]

- Yan, C.; Yuan, L.; Yu, X.; Ji, S.; Zhou, Z. Characterizing the fatigue resistance of multiple modified asphalts using time sweep test, LAS test and elastic recovery test. Constr. Build. Mater. 2022, 322, 125806. [Google Scholar] [CrossRef]

- Yu, H.; Wu, S.; Chen, A.; Li, Y. Modification mechanism and technical performance of recycled PE-modified asphalt. Sustainability 2023, 15, 12273. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Xie, J.; Yang, C.; Yang, X.; Chen, S.; Liu, Q. Recycle of waste tire rubber powder in a novel asphalt rubber pellets for asphalt performance enhancement. Constr. Build. Mater. 2023, 399, 132572. [Google Scholar] [CrossRef]

- Alghrafy, Y.M.; Abd Alla, E.S.M.; El-Badawy, S.M. Rheological properties and aging performance of sulfur extended asphalt modified with recycled polyethylene waste. Constr. Build. Mater. 2021, 273, 121771. [Google Scholar] [CrossRef]

- Meng, F.; Ma, S.; Muhammad, Y.; Li, J.; Sahibzada, M.; Chi, F. Analysis of virgin asphalt brands via the integrated application of FTIR and gel permeation chromatography. Arab. J. Sci. Eng. 2020, 45, 7999–8009. [Google Scholar] [CrossRef]

- Zeiada, W.; Al-Khateeb, G.; Hajj, E.Y.; Ezzat, H. Rheological properties of plastic-modified asphalt binders using diverse plastic wastes for enhanced pavement performance in the UAE. Constr. Build. Mater. 2024, 452, 138922. [Google Scholar] [CrossRef]

- Shen, B.X.; Zhao, L.M.; Liu, F.X. TLC/FID group compositional analytical method of micro-amounts of asphalts and its application. Fuel Sci. Technol. Int. 1994, 12, 665–673. [Google Scholar]

- Bastola, N.R.; Teixeira, J.E.S.L. Low-temperature cracking assessment of high-RAP mixtures modified with waste plastics and vegetable oil using multi-test performance-based parameters. Constr. Build. Mater. 2025, 485, 141813. [Google Scholar] [CrossRef]

| Test | Index | Value | Requirement | Test Method |

|---|---|---|---|---|

| Penetration | 0.1 mm | 83.1 | 80~100 | JTG E20-2011 T 0604 [20] |

| Ductility | cm | >100 | >100 | JTG E20-2011 T 0605 |

| Softening point | °C | 44.5 | >44 | JTG E20-2011 T 0606 |

| RTFOT (163 °C, 85 min) | Mass loss rate/% | −0.35 | ≤±0.8 | JTG E20-2011 T 0603 |

| Penetration ratio/% | 73.1 | ≥57 | JTG E20-2011 T 0610 | |

| Residual ductility/cm | 56.5 | ≥20 | JTG E20-2011 T 0604 |

| Material Type | Properties | Test Value | Test Method |

|---|---|---|---|

| WCO | Density, g/cm−3 | 0.94 | GB/T 5526-2024 [21] |

| Viscosity, Pa·s | 0.05 | GB/T 22235-2008 [22] | |

| Flash point, °C | 243 | GB/T 21789-2025 [23] | |

| Moisture content, % | 0.15 | GB 5009.236-2016 [24] | |

| Exterior | Brown oily liquid | ||

| PE | Density, g/cm−3 | 1.05 | GB/T 1033.1-2008 [25] |

| Melting point, °C | 105 | YY/T 0815-2010 [26] | |

| Flash point, °C | 270 | GB/T 9343-2008 [27] | |

| Exterior | Colorless transparent particle | ||

| EVA | Density, g/cm−3 | 0.945 | GB/T 1033.1-2008 |

| Melting point, °C | 103 | GB/T 15182-2020 [28] | |

| Thermal decomposition temperature, °C | 241 | GB/T 33047.1-2016 [29] | |

| Exterior | Transparent particle |

| Level | (A) WCO/% | (B) EVA/% | (C) PE/% |

|---|---|---|---|

| 1 | 5 | 3 | 4 |

| 2 | 7 | 4 | 5 |

| 3 | 9 | 5 | 6 |

| Number | Factor | Evaluation Indexes | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | Penetration/0.1 mm | Softening Point/°C | Ductility/cm | Viscosity/Pa·s | |

| 1 | 1 | 1 | 1 | 83.5 | 45.1 | 7 | 0.367 |

| 2 | 1 | 2 | 3 | 79.6 | 48.3 | 9.1 | 0.765 |

| 3 | 1 | 3 | 2 | 77.4 | 50.1 | 11.2 | 0.931 |

| 4 | 2 | 1 | 3 | 82.6 | 45.7 | 7.3 | 0.389 |

| 5 | 2 | 2 | 2 | 83.8 | 44.9 | 6.8 | 0.351 |

| 6 | 2 | 3 | 1 | 81.6 | 46.2 | 7.9 | 0.422 |

| 7 | 3 | 1 | 2 | 85.7 | 43.5 | 6.1 | 0.339 |

| 8 | 3 | 2 | 1 | 84.1 | 44.7 | 6.6 | 0.347 |

| 9 | 3 | 3 | 3 | 83.6 | 45.1 | 6.9 | 0.369 |

| K1 | 80.2 | 83.9 | 83.1 | Intuitive analysis of penetration | |||

| K2 | 82.7 | 82.5 | 82.3 | ||||

| K3 | 84.5 | 80.9 | 81.9 | ||||

| R | 4.3 | 3.1 | 1.1 | ||||

| Solution | A3 | B1 | C1 | ||||

| K1 | 47.8 | 44.8 | 45.3 | Intuitive analysis of softening point | |||

| K2 | 45.6 | 46.0 | 46.2 | ||||

| K3 | 44.4 | 47.1 | 46.4 | ||||

| R | 3.4 | 2.4 | 1.0 | ||||

| Solution | A1 | B3 | C3 | ||||

| K1 | 9.1 | 6.8 | 7.2 | Intuitive analysis of ductility | |||

| K2 | 7.3 | 7.5 | 8.0 | ||||

| K3 | 6.5 | 8.7 | 7.8 | ||||

| R | 2.6 | 1.9 | 0.9 | ||||

| Solution | A1 | B3 | C2 | ||||

| K1 | 0.7 | 0.4 | 0.4 | Intuitive analysis of viscosity | |||

| K2 | 0.4 | 0.5 | 0.5 | ||||

| K3 | 0.4 | 0.6 | 0.5 | ||||

| R | 0.3 | 0.2 | 0.2 | ||||

| Solution | A1 | B3 | C2 | ||||

| Properties | Index | A1B3C1 | A1B3C2 | A1B3C3 |

|---|---|---|---|---|

| Penetration | (25 °C)/0.1 mm | 79.1 | 77.4 | 76.2 |

| Ductility | (5 °C)/cm | 48.3 | 50.1 | 51.1 |

| Softening point | °C | 9.9 | 11.2 | 11.6 |

| Viscosity | Pa·s | 0.797 | 0.931 | 1.012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zheng, P.; Pu, C.; Xu, D.; Litifu, W.; Ma, Z.; Yin, P. Study on the Rheological Properties of Recycled Plastic and Waste Cooking Oil Composite Modified Asphalt. Materials 2025, 18, 4762. https://doi.org/10.3390/ma18204762

Li M, Zheng P, Pu C, Xu D, Litifu W, Ma Z, Yin P. Study on the Rheological Properties of Recycled Plastic and Waste Cooking Oil Composite Modified Asphalt. Materials. 2025; 18(20):4762. https://doi.org/10.3390/ma18204762

Chicago/Turabian StyleLi, Maowen, Ping Zheng, Chao Pu, Dongxu Xu, Waiti Litifu, Zhe Ma, and Peng Yin. 2025. "Study on the Rheological Properties of Recycled Plastic and Waste Cooking Oil Composite Modified Asphalt" Materials 18, no. 20: 4762. https://doi.org/10.3390/ma18204762

APA StyleLi, M., Zheng, P., Pu, C., Xu, D., Litifu, W., Ma, Z., & Yin, P. (2025). Study on the Rheological Properties of Recycled Plastic and Waste Cooking Oil Composite Modified Asphalt. Materials, 18(20), 4762. https://doi.org/10.3390/ma18204762