Large Platform Growth Effect of Single-Crystal Diamond on the Regulation of Its Dielectric Properties and Stress for THz Applications

Abstract

1. Introduction

2. Experimental Section

2.1. Diamond Deposition Growth

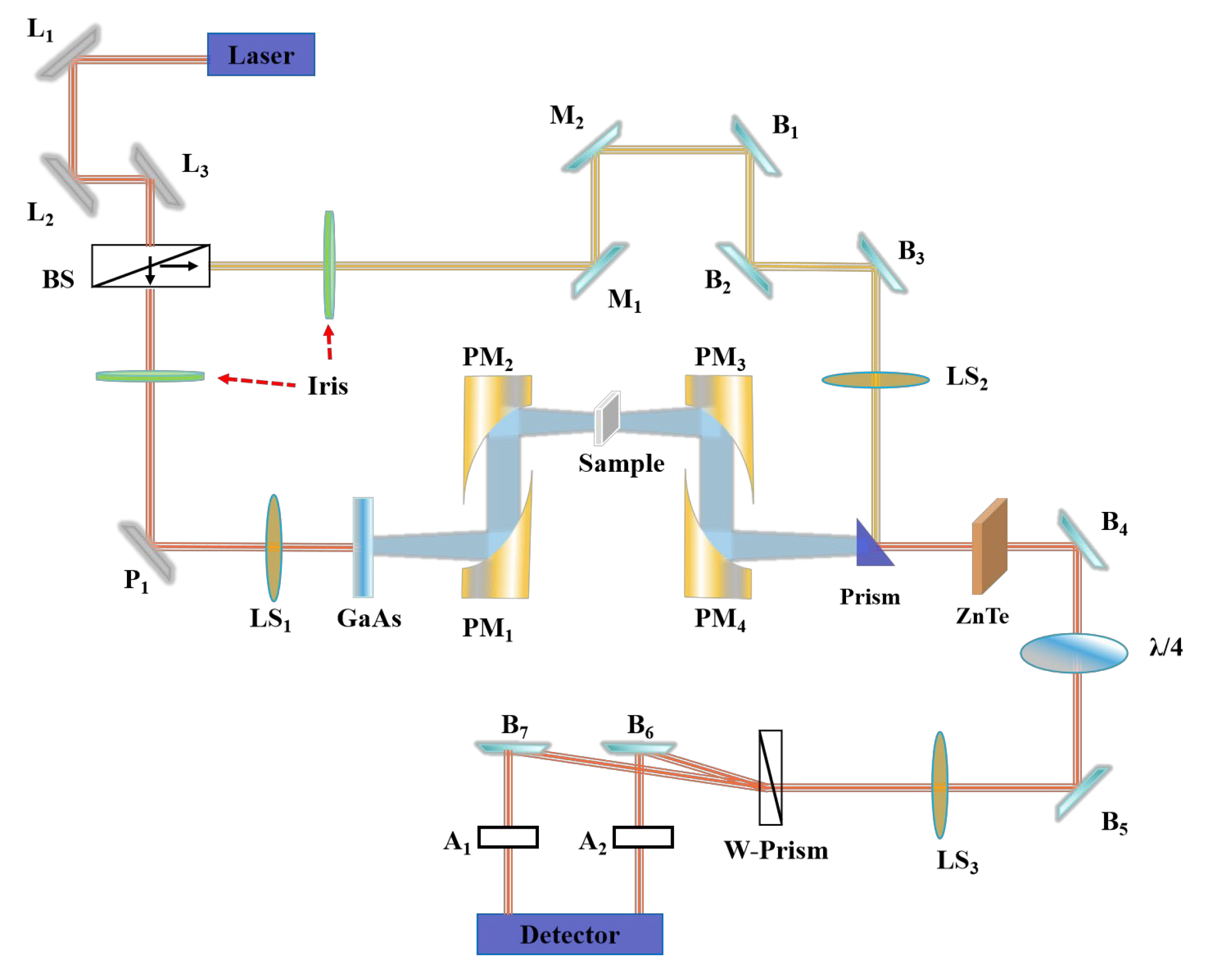

2.2. Characterization

3. Results and Discussion

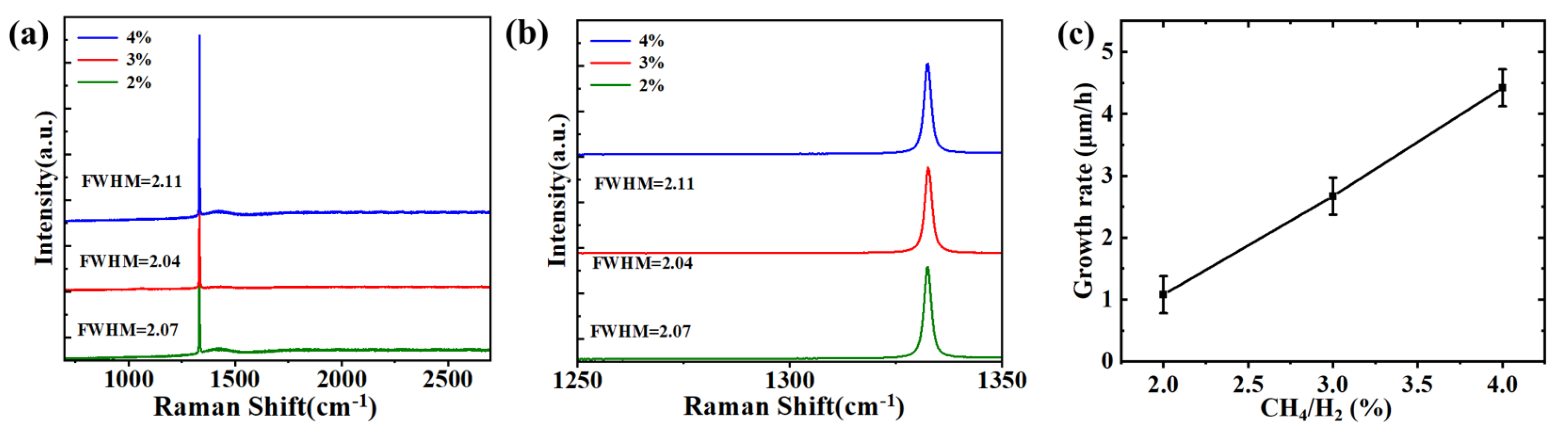

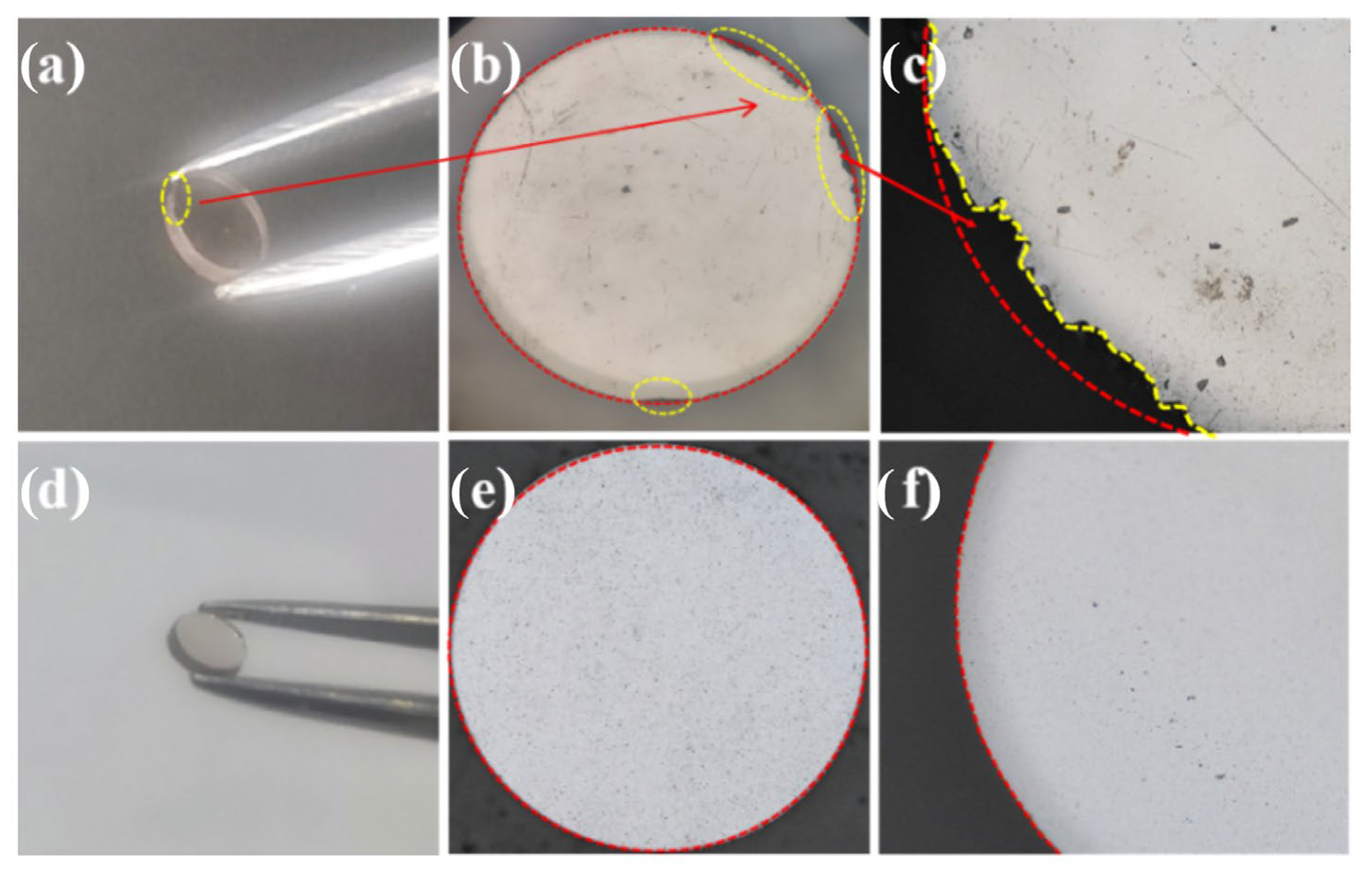

3.1. The Growth Regulation of SCD by “Two-Step Method”

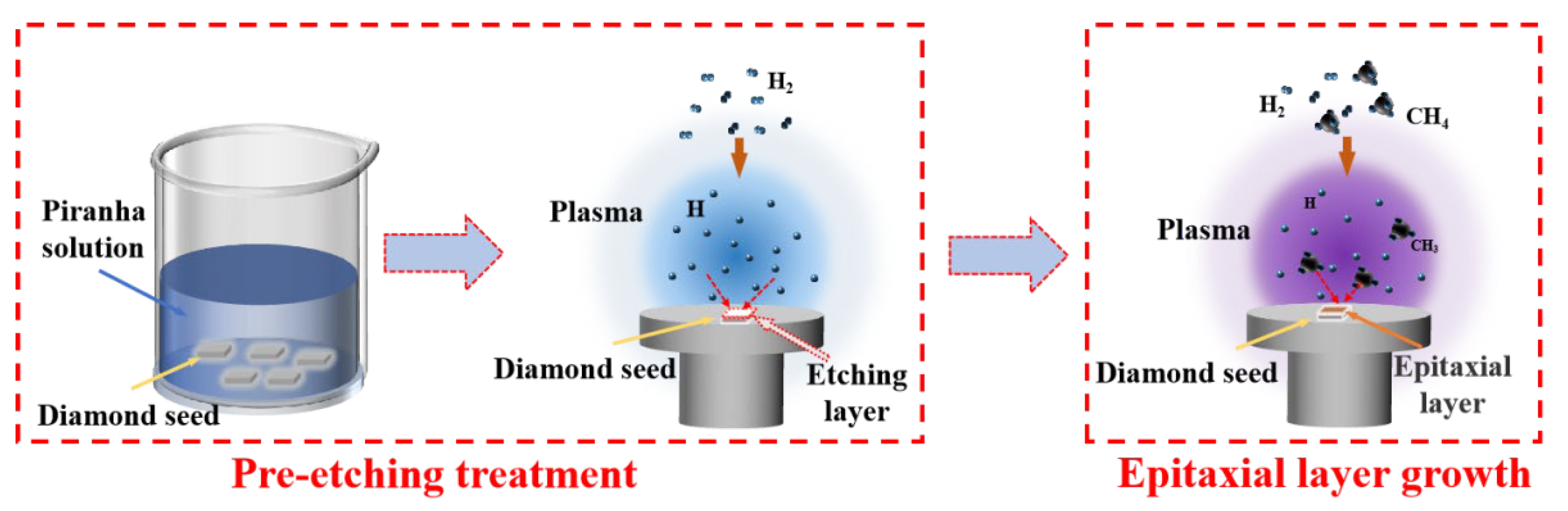

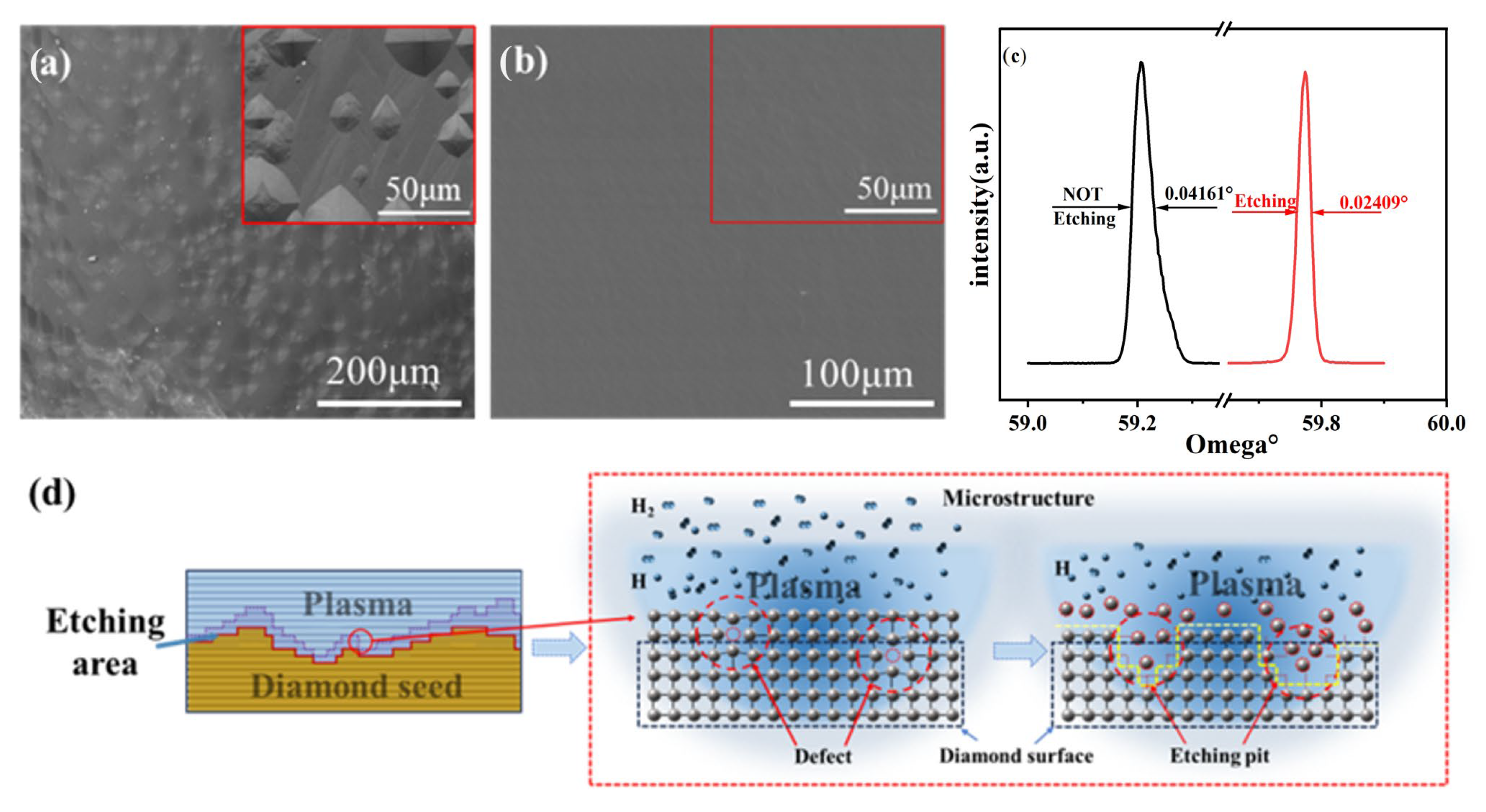

3.1.1. First Step: Optimization of Single Crystal Diamond Seed

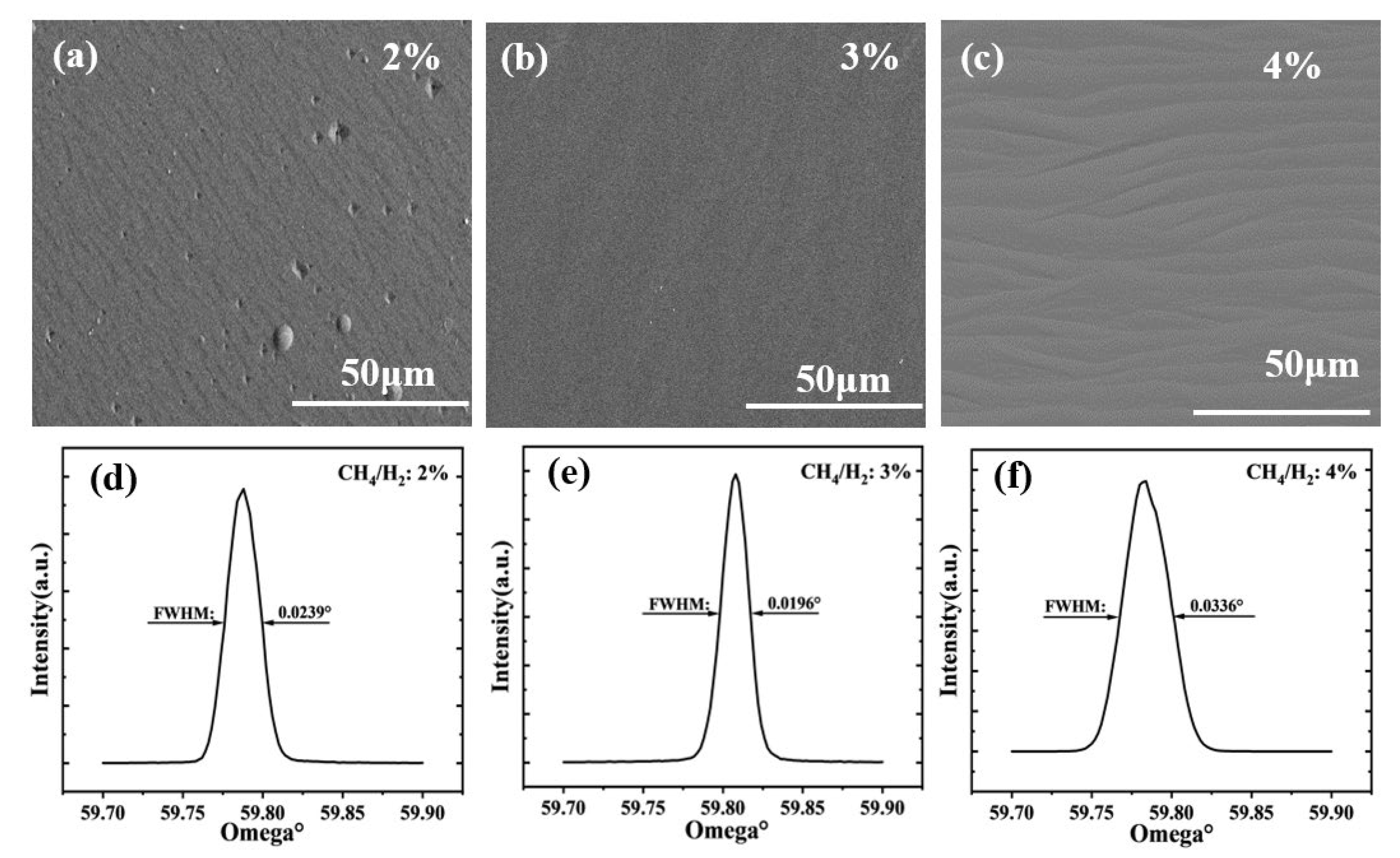

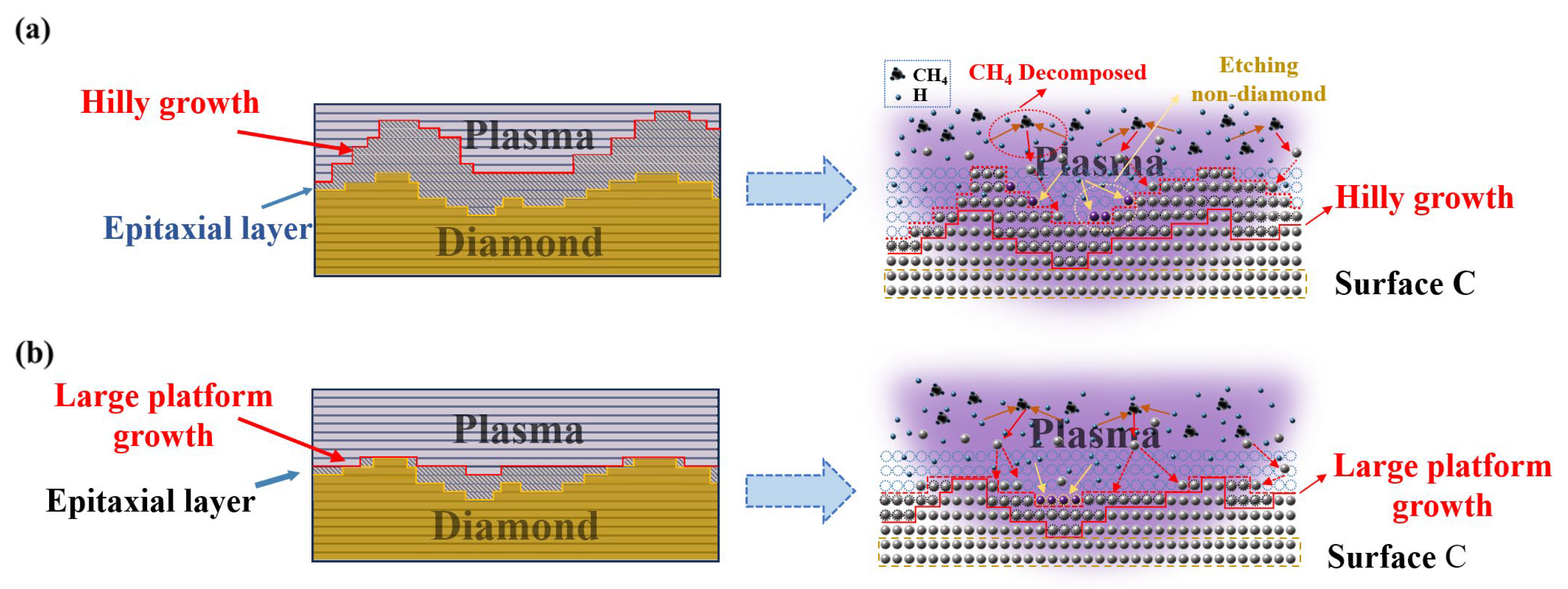

3.1.2. Step Two: Regulation of External Layer Growth

3.2. Comparison of Performance of SCD Prepared Under Two DIFFERENT Growth Patterns

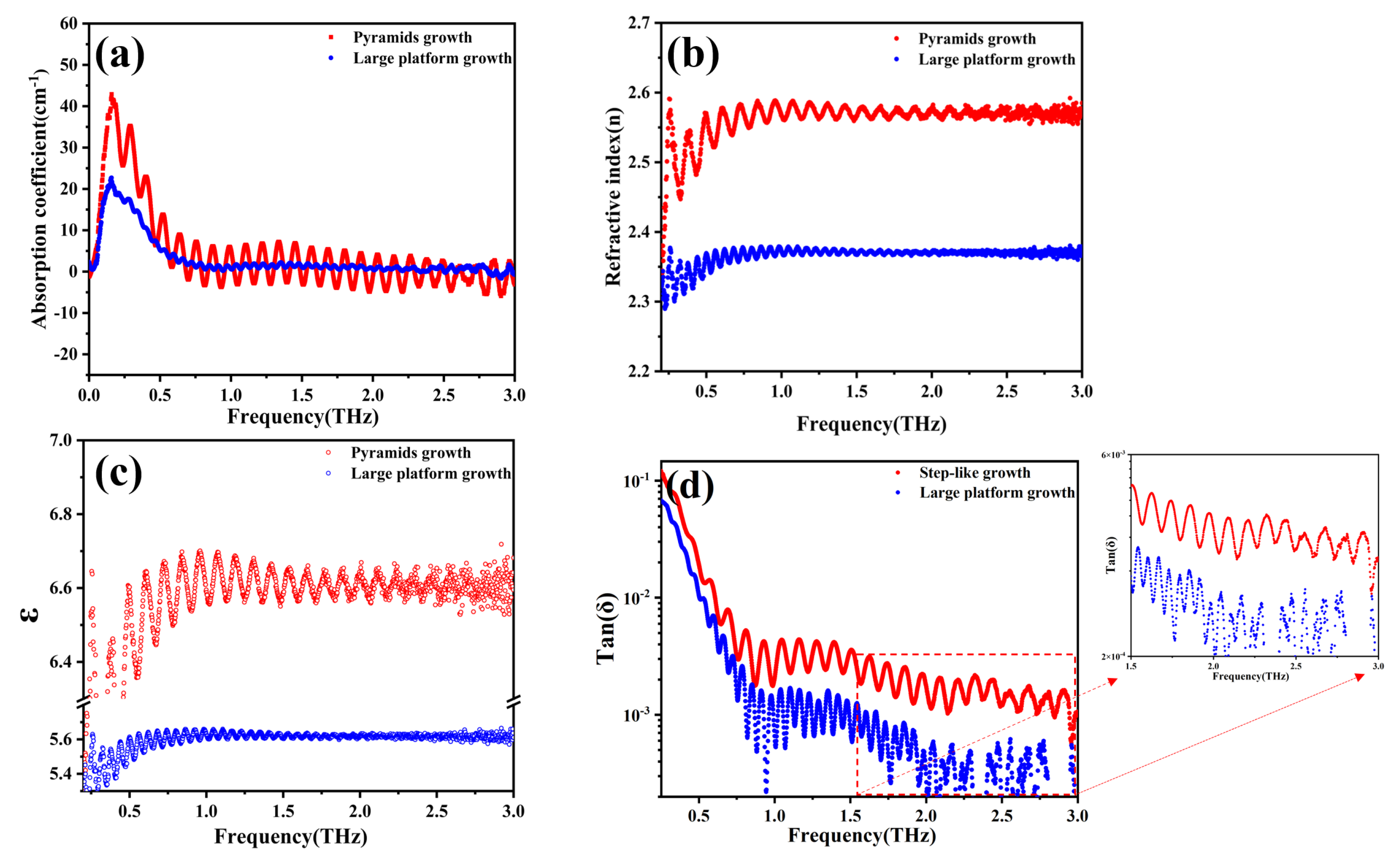

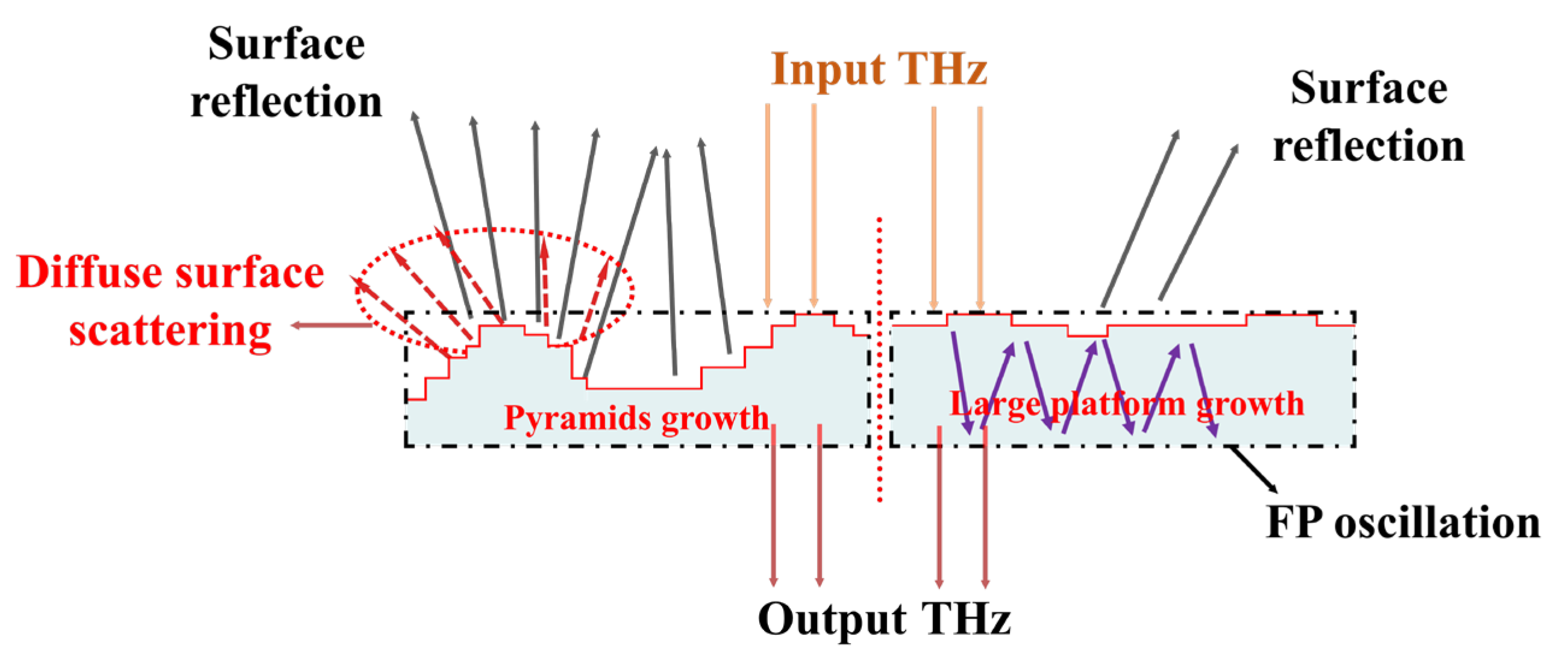

3.2.1. Effect of SCD Growth Patterns on the Dielectric Properties in the THz Band

3.2.2. Effect of SCD Growth Patterns on Stress

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fleming, J.W. High-Resolution Submillimeter-Wave Fourier-Transform Spectrometry of Gases. IEEE Trans. Microw. Theory Techn. 1974, 22, 1023–1025. [Google Scholar] [CrossRef]

- Cao, J.C.; Chen, Z.; Zhou, T.; Tan, Z.Y.; Zhang, R.; Han, Y.J.; Li, H.; Guo, X.G.; Feng, W.; Wang, C.; et al. Terahertz Semiconductor Quantum Devices and Their Applications. In Proceedings of the 2012 37th International Conference on Infrared, Millimeter, and Terahertz Waves, Wollongong, NSW, Australia, 23–28 September 2012; IEEE: New York, NY, USA; pp. 1–2. [Google Scholar]

- Chaccour, C.; Soorki, M.N.; Saad, W.; Bennis, M.; Popovski, P.; Debbah, M. Seven Defining Features of Terahertz (THz) Wireless Systems: A Fellowship of Communication and Sensing. IEEE Commun. Surv. Tuts. 2022, 24, 967–993. [Google Scholar] [CrossRef]

- Yan, F. Application on Non-Destructive Inspection of Terahertz Wave. In Proceedings of the 10th World Congress on Intelligent Control and Automation, Beijing, China, 6–8 July 2012; IEEE: New York, NY, USA; pp. 1570–1573. [Google Scholar]

- Armakavicius, N.; Bouhafs, C.; Stanishev, V.; Kühne, P.; Yakimova, R.; Knight, S.; Hofmann, T.; Schubert, M.; Darakchieva, V. Cavity-Enhanced Optical Hall Effect in Epitaxial Graphene Detected at Terahertz Frequencies. Appl. Surf. Sci. 2017, 421, 357–360. [Google Scholar] [CrossRef]

- Booske, J.H. Plasma Physics and Related Challenges of Millimeter-Wave-to-Terahertz and High Power Microwave Generation. Phys. Plasmas 2008, 15, 55502. [Google Scholar] [CrossRef]

- Dhillon, S.S.; Vitiello, M.S.; Linfield, E.H.; Davies, A.G.; Hoffmann, M.C.; Booske, J.; Paoloni, C.; Gensch, M.; Weightman, P.; Williams, G.P.; et al. The 2017 Terahertz Science and Technology Roadmap. J. Phys. D Appl. Phys. 2017, 50, 43001. [Google Scholar] [CrossRef]

- Wang, G.; Shao, S.; Huang, H.; Su, B.; He, J.; Zhang, C. Terahertz Absorption Characteristics of Liquid Water in the Range of 6~−2 °C. In Proceedings of the 2021 46th International Conference on Infrared, Millimeter and Terahertz Waves (IRMMW-THz), Chengdu, China, 29 August–3 September 2021; IEEE: New York, NY, USA; pp. 1–2. [Google Scholar]

- Dua, A.K.; Roy, M.; Nuwad, J.; George, V.C.; Sawant, S.N. Enhanced Nucleation and Post-Growth Investigations on HFCVD Diamond Films Grown on Silicon Single Crystals Pretreated with Zr:Diamond Mixed Slurry. Appl. Surf. Sci. 2004, 229, 254–262. [Google Scholar] [CrossRef]

- Liu, J.; Lin, L.; Zhao, Y.; Zheng, Y.; An, K.; Wei, J.; Chen, L.; Hei, L.; Wang, J.; Feng, Z.; et al. Homo-Epitaxial Growth of Single Crystal Diamond in the Purified Environment by Active O Atoms. Vacuum 2018, 155, 391–397. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Zhang, G.; Huo, Z.; Huang, Z.; Wu, L. A Review of Diamond Synthesis, Modification Technology, and Cutting Tool Application in Ultra-Precision Machining. Mater. Des. 2024, 237, 112577. [Google Scholar] [CrossRef]

- Ding, M.Q.; Li, L.; Feng, J. A Study of High-Quality Freestanding Diamond Films Grown by MPCVD. Appl. Surf. Sci. 2012, 258, 5987–5991. [Google Scholar] [CrossRef]

- Li, L.; Ding, M.; Cai, J.; Du, Y.; Wu, X.; Feng, J. Development of Diamond Windows for Traveling Wave Tube Harmonic Amplifier in Terahertz. In Proceedings of the 2015 IEEE International Vacuum Electronics Conference (IVEC), Beijing, China, 27–29 April 2015; IEEE: New York, NY, USA; pp. 1–3. [Google Scholar]

- Pasagadagula, M.; Chandel, A.; Sirigiri, J.R.; Zheng, Y.; Luhmann, N.C. Design of a 693 GHz Folded-Waveguide Traveling-Wave Tube Amplifier. In Proceedings of the 2020 IEEE 21st International Conference on Vacuum Electronics (IVEC), Monterey, CA, USA, 19–22 October 2020; IEEE: New York, NY, USA; pp. 151–152. [Google Scholar]

- Ding, M.Q.; Li, L.; Feng, J. Composite Diamond Films for Short-Mm Wave and THz Traveling Wave Tube Windows. Diam. Relat. Mater. 2014, 50, 129–134. [Google Scholar] [CrossRef]

- Ding, M.Q.; Li, L.; Du, Y.; Wu, X.; Cai, J.; Feng, J. Development of an Extremely Thin-Diamond Window for Terahertz Traveling Wave Tubes. Diam. Relat. Mater. 2017, 79, 173–178. [Google Scholar] [CrossRef]

- Kimura, T.; Atkinson, J.; Forrest, S.; Grant, T.; Hunter, T.; Field, M.; Borwick, R.; Brar, B. Design and Fabrication of Components for a 220 GHz 50 W Sheet Beam Travelling Wave Tube Amplifier. In Proceedings of the IVEC 2012, Monterey, CA, USA, 24–26 April 2012; IEEE: New York, NY, USA; pp. 195–196. [Google Scholar]

- Su, S.; Zhang, C.; Li, Y.; Pan, P.; Cai, J.; Feng, J. Investigation of 0.22 THz Window for THz Traveling Wave Tube Amplifier. In Proceedings of the 2021 22nd International Vacuum Electronics Conference (IVEC), Rotterdam, The Netherlands, 28–30 April 2021; IEEE: New York, NY, USA; pp. 1–2. [Google Scholar]

- Jiang, Y.; Lei, W.; Hu, P.; Song, R.; Luqi, Z.; Guowu, M.; Chen, H.; Jin, X. A Novel Slow-Wave Structure for 0.22 THz TWT. In Proceedings of the 2021 14th UK-Europe-China Workshop on Millimetre-waves and Terahertz Technologies (UCMMT), Lancaster, UK, 13–15 September 2021; IEEE: New York, NY, USA; pp. 1–2. [Google Scholar]

- Shu, G.; Dai, B.; Ralchenko, V.G.; Bolshakov, A.P.; Khomich, A.A.; Ashkinazi, E.E.; Han, J.; Zhu, J. Growth of Three-Dimensional Diamond Mosaics by Microwave Plasma-Assisted Chemical Vapor Deposition. CrystEngComm 2018, 20, 198–203. [Google Scholar] [CrossRef]

- Zhang, Y.; Shur, M.S. Collision Dominated, Ballistic, and Viscous Regimes of Terahertz Plasmonic Detection by Graphene. J. Appl. Phys. 2021, 129, 53102. [Google Scholar] [CrossRef]

- Sivarajah, P.; Steinbacher, A.; Dastrup, B.; Lu, J.; Xiang, M.; Ren, W.; Kamba, S.; Cao, S.; Nelson, K.A. THz-Frequency Magnon-Phonon-Polaritons in the Collective Strong-Coupling Regime. J. Appl. Phys. 2019, 125, 213103. [Google Scholar] [CrossRef]

- Amoruso, S.; Andreone, A.; Bellucci, A.; Koral, C.; Girolami, M.; Mastellone, M.; Mou, S.; Orlando, S.; Papari, G.P.; Paparo, D.; et al. All-Carbon THz Components Based on Laser-Treated Diamond. Carbon 2020, 163, 197–201. [Google Scholar] [CrossRef]

- Bulgakova, V.; Chizhov, P.; Ushakov, A.; Ratnikov, P.; Goncharov, Y.; Martyanov, A.; Kononenko, V.; Savin, S.; Golovnin, I.; Konov, V.; et al. Optical Pump–Terahertz Probe Diagnostics of the Carrier Dynamics in Diamonds. Materials 2023, 17, 119. [Google Scholar] [CrossRef]

- Ando, Y.; Nishibayashi, Y.; Kobashi, K.; Hirao, T.; Oura, K. Smooth and High-Rate Reactive Ion Etching of Diamond. Diam. Relat. Mater. 2002, 11, 824–827. [Google Scholar] [CrossRef]

- Yang, G.; Sun, P.; Zhu, T.; Wang, Y.; Li, S.; Liu, C.; Yang, G.; Yang, K.; Yang, X.; Lian, W.; et al. Fabrication, Microstructure and Optical Properties of <110> Textured CVD Polycrystalline Diamond Infrared Materials. Diam. Relat. Mater. 2024, 141, 110600. [Google Scholar] [CrossRef]

- Fischer, M.; Gsell, S.; Schreck, M.; Bergmaier, A. Growth Sector Dependence and Mechanism of Stress Formation in Epitaxial Diamond Growth. Appl. Phys. Lett. 2012, 100, 41906. [Google Scholar] [CrossRef]

- Nie, S.; Qiao, Y.; Chen, S.; Wang, X. Mechanistic Insights into the Formation of Dislocation-Related Pits on Diamond Surface under Plasma Etching Treatment: A Combined Simulation and Experimental Approach. Int. J. Refract. Met. Hard Mater. 2024, 118, 106452. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, Z.; Xu, W.; Wang, Q.; Xiao, Y.; Ding, L.; Huang, J.; Li, H.; He, B.; Peeters, F.M. Terahertz Optoelectronic Properties of Synthetic Single Crystal Diamond. Diam. Relat. Mater. 2023, 139, 110266. [Google Scholar] [CrossRef]

- Scheuring, A.; Probst, P.; Stockhausen, A.; Ilin, K.; Siegel, M.; Scherer, T.A.; Meier, A.; Strauss, D. Dielectric RF Properties of CVD Diamond Disks from Sub-Mm Wave to THz Frequencies. In Proceedings of the 35th International Conference on Infrared, Millimeter, and Terahertz Waves, Rome, Italy, 5–10 September 2010; pp. 1–2. [Google Scholar]

- Zheng, Y.; Zhang, R.; Chen, X.; Hing, P.; Liu, J.; Wei, J.; Wang, J.; Li, C.; Ye, H. Doomed Couple of Diamond with Terahertz Frequency: Hyperfine Quality Discrimination and Complex Dielectric Responses of Diamond in the Terahertz Waveband. ACS Appl. Electron. Mater. 2020, 2, 1459–1469. [Google Scholar] [CrossRef]

- Nix, W.D.; Clemens, B.M. Crystallite Coalescence: A Mechanism for Intrinsic Tensile Stresses in Thin Films. J. Mater. Res. 1999, 14, 3467–3473. [Google Scholar] [CrossRef]

| Substrate | Pretreatment | Growth Parameter | ||

|---|---|---|---|---|

| H2/sccm | CH4/sccm | Other Conditions | ||

| E1 | ----- | 400 | 12 | Power: 3.8 kW Pressure: 16 kPa 10 °C Time: 12 h |

| E2 | H2: 400 sccm Power: 2 kW Pressure: 8 kPa Temperature: 700–800 °C Time: 30 min | |||

| G1 | 8 | |||

| G2 | 12 | |||

| G3 | 16 | |||

| G1 | G2 | G3 | |

|---|---|---|---|

| Pre-depositional thickness | 498.37 µm | 499.70 µm | 509.23 µm |

| Thickness after deposition | 511.33 µm | 531.74 µm | 562.27 µm |

| Growth thickness | 12.96 µm | 32.04 µm | 53.04 µm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhou, J.; Song, H.; Liu, C.; Li, H.; Yang, G.; Sun, P.; Nan, Y.; Yi, J.; Bai, H.; et al. Large Platform Growth Effect of Single-Crystal Diamond on the Regulation of Its Dielectric Properties and Stress for THz Applications. Materials 2025, 18, 4745. https://doi.org/10.3390/ma18204745

Zhang P, Zhou J, Song H, Liu C, Li H, Yang G, Sun P, Nan Y, Yi J, Bai H, et al. Large Platform Growth Effect of Single-Crystal Diamond on the Regulation of Its Dielectric Properties and Stress for THz Applications. Materials. 2025; 18(20):4745. https://doi.org/10.3390/ma18204745

Chicago/Turabian StyleZhang, Pengwei, Jun Zhou, Hui Song, Chenxi Liu, He Li, Guoyong Yang, Peng Sun, Yiming Nan, Jian Yi, Huiping Bai, and et al. 2025. "Large Platform Growth Effect of Single-Crystal Diamond on the Regulation of Its Dielectric Properties and Stress for THz Applications" Materials 18, no. 20: 4745. https://doi.org/10.3390/ma18204745

APA StyleZhang, P., Zhou, J., Song, H., Liu, C., Li, H., Yang, G., Sun, P., Nan, Y., Yi, J., Bai, H., Wang, Y., Jiang, N., & Nishimura, K. (2025). Large Platform Growth Effect of Single-Crystal Diamond on the Regulation of Its Dielectric Properties and Stress for THz Applications. Materials, 18(20), 4745. https://doi.org/10.3390/ma18204745