The Effect of Process Parameters on the Performance of the RFSSW of ZK61M-T5 Magnesium Alloy

Abstract

1. Introduction

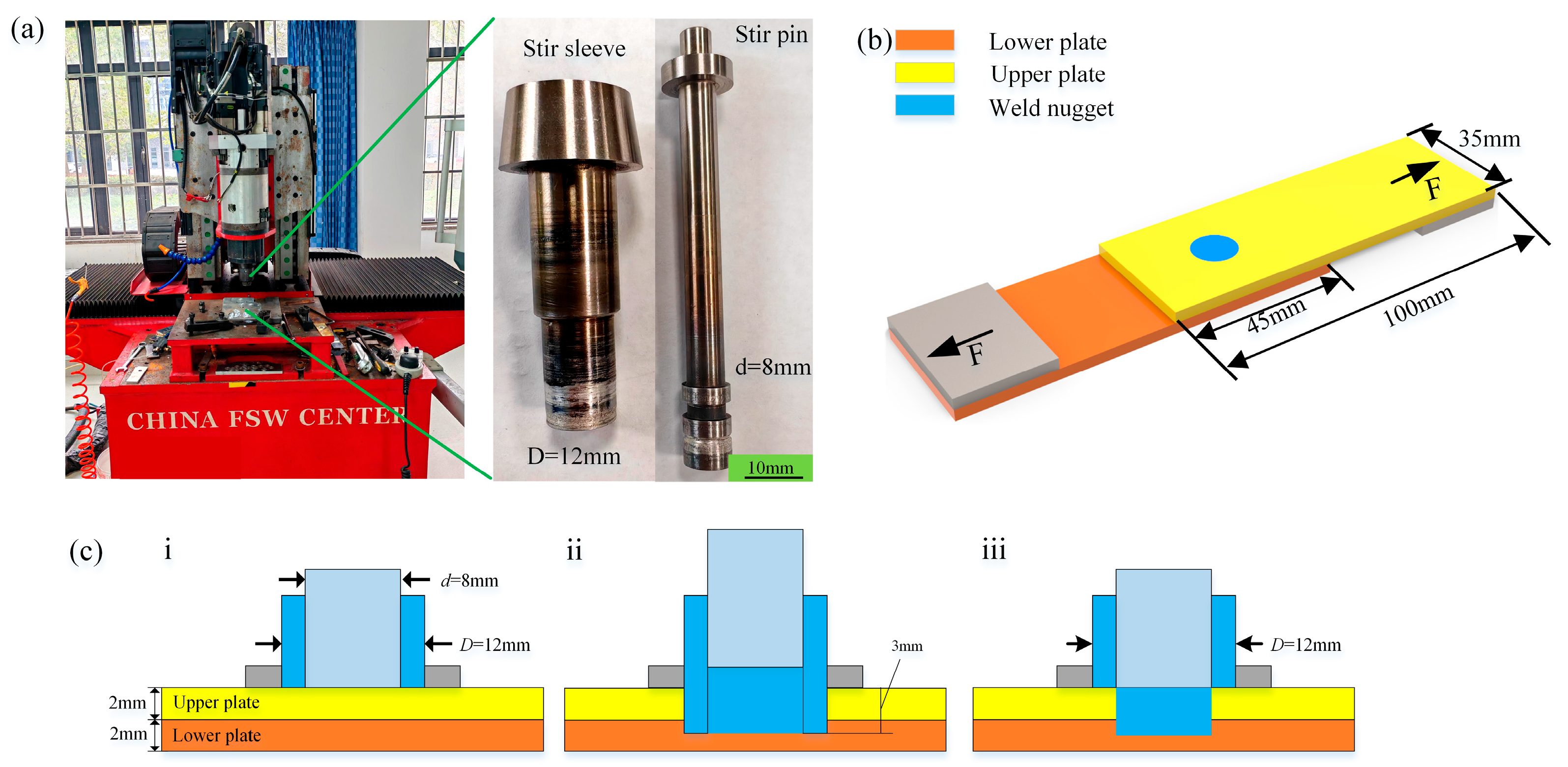

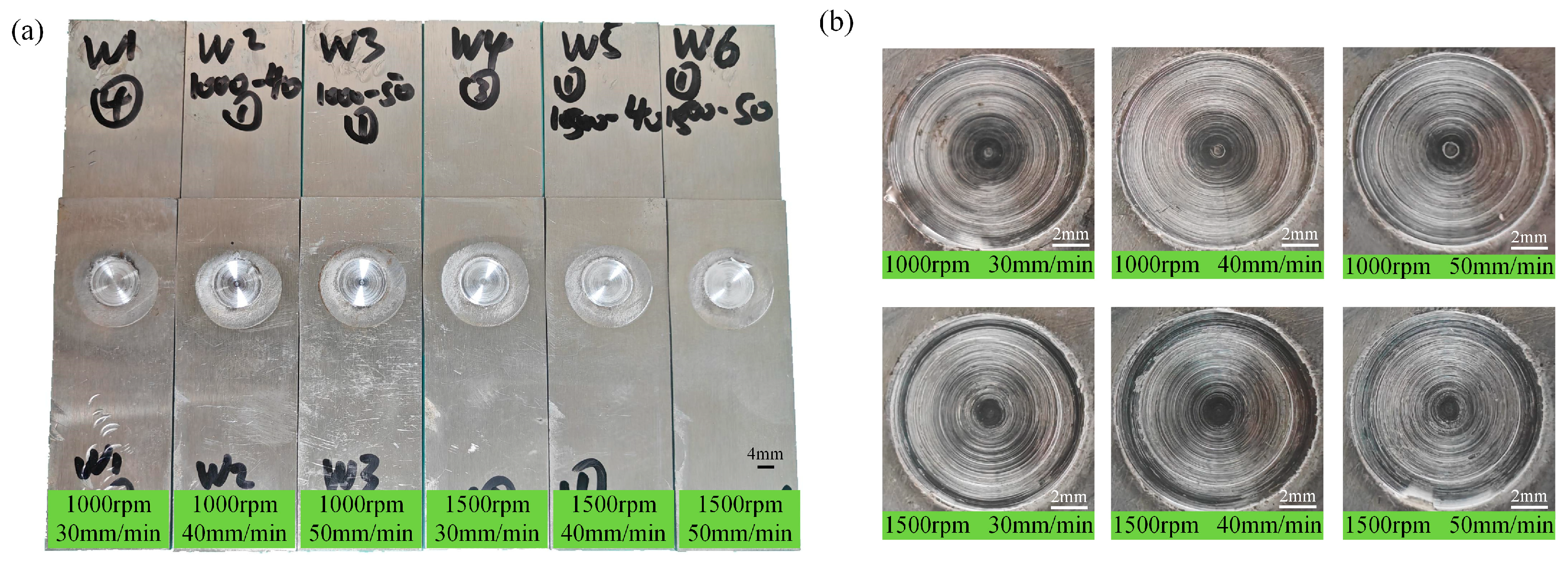

2. Test Methods

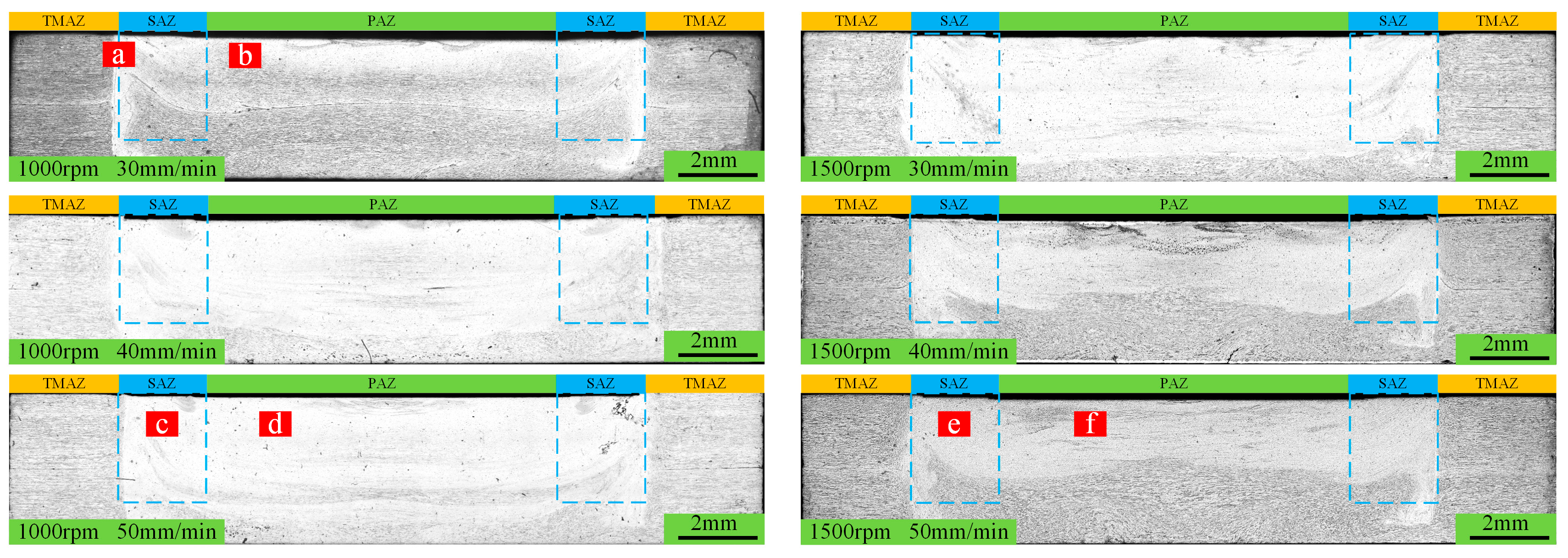

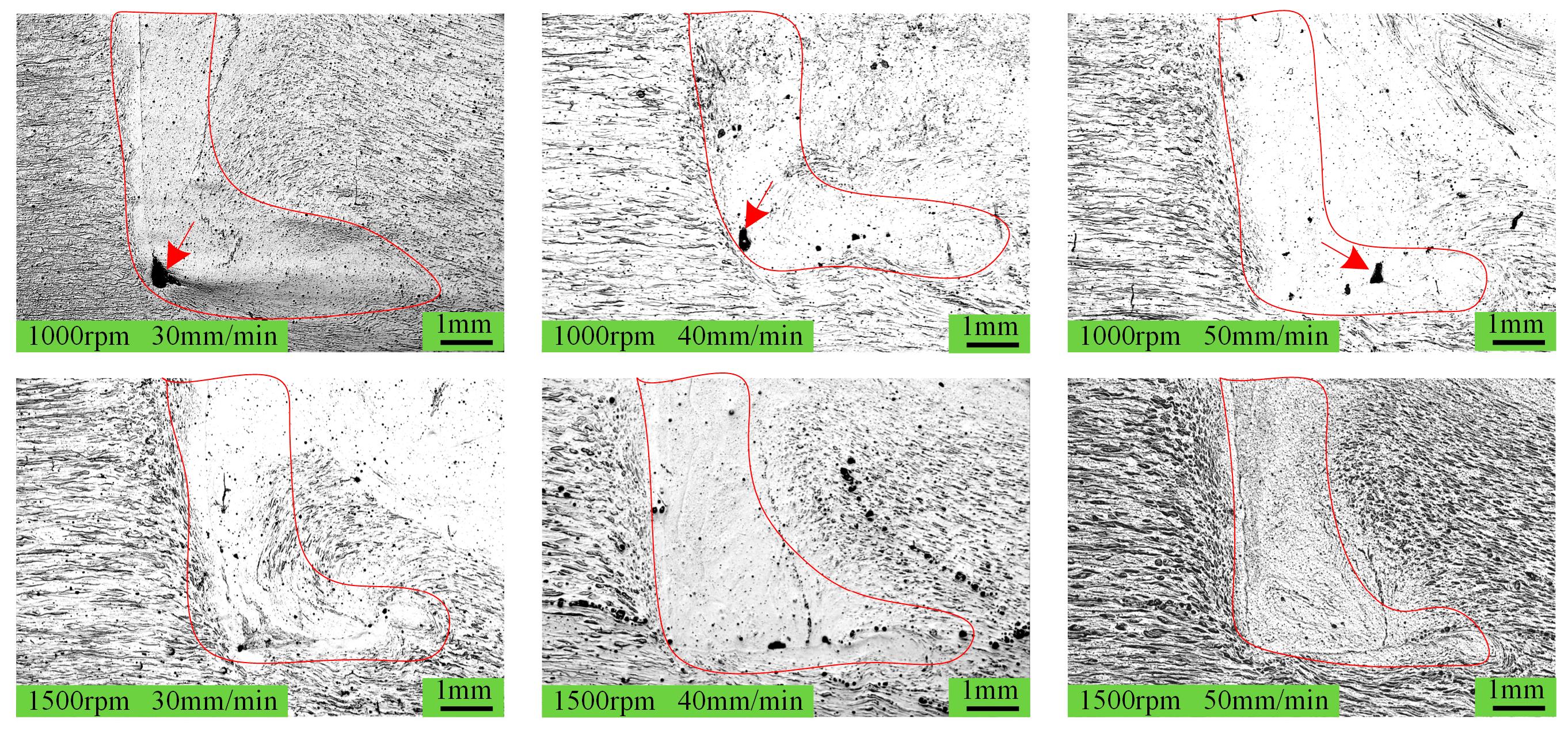

3. Results and Discussion

4. Conclusions

- (1)

- At a rotational speed of 1000 rpm, micro-pores were observed at the bottom of the sleeve-affected zone regardless of welding speed. In contrast, no such defects occurred at 1500 rpm. This indicates that higher rotational speeds can provide better plastic flowability for the magnesium alloy, resulting in a defect-free spot-welding zone.

- (2)

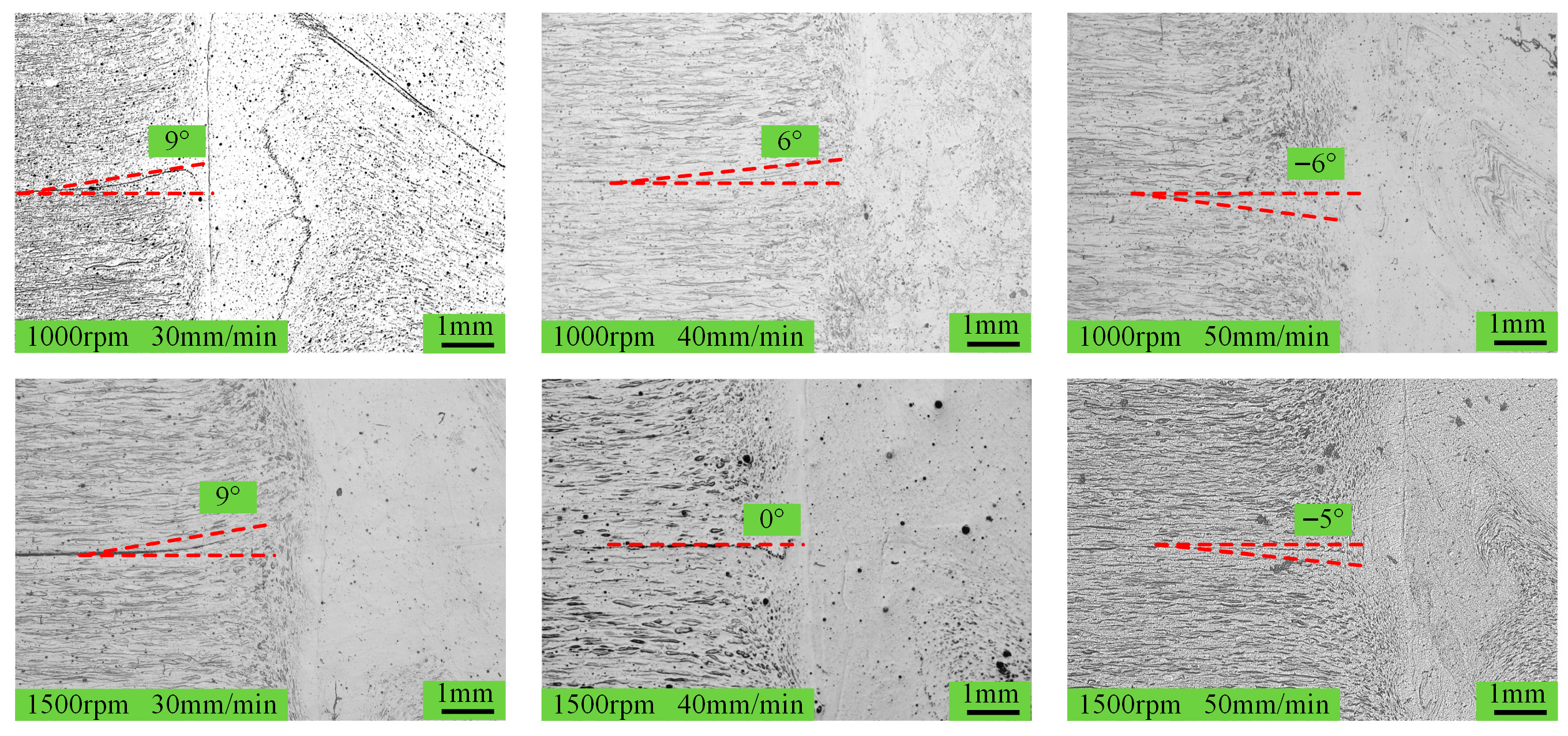

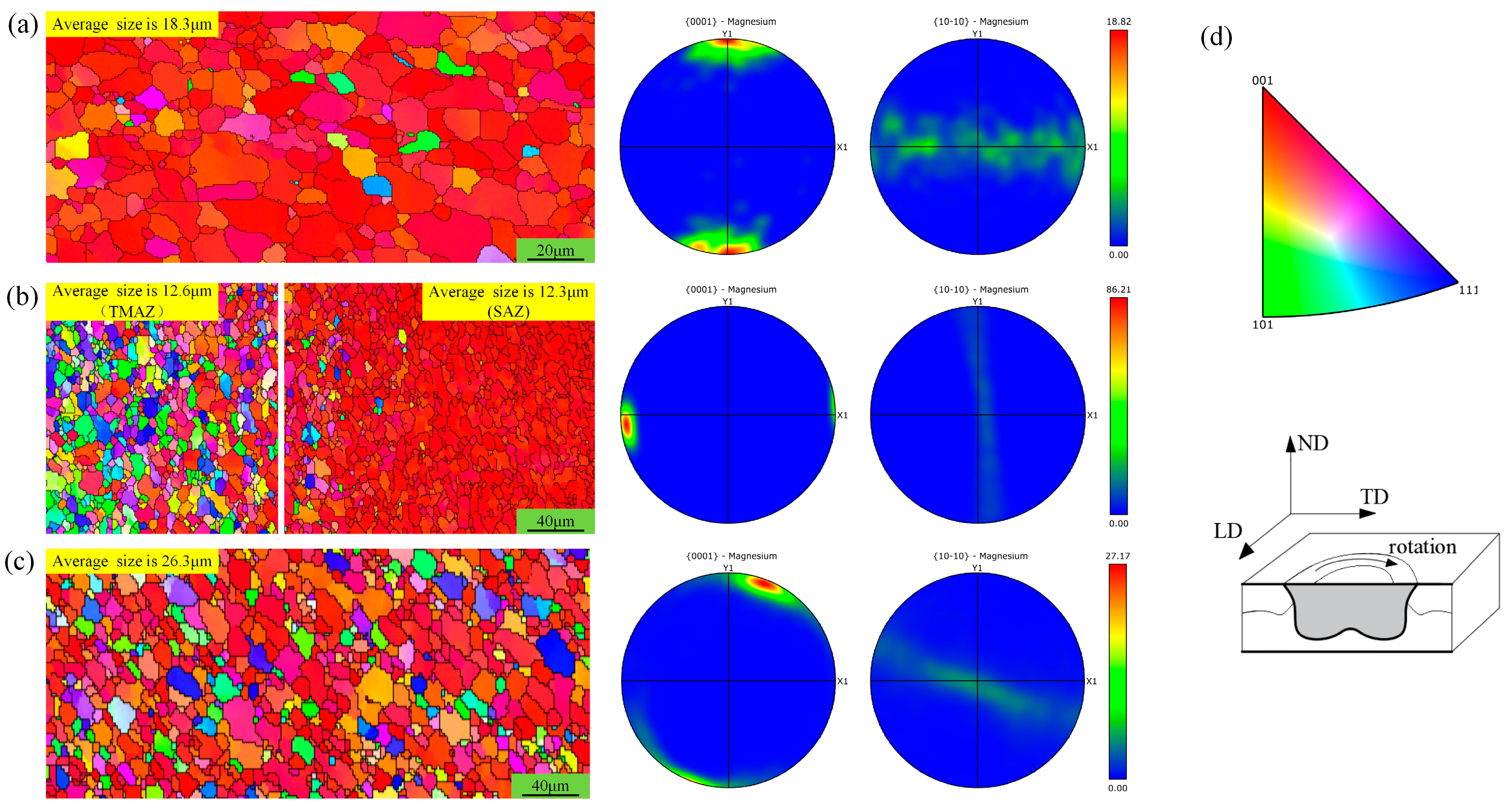

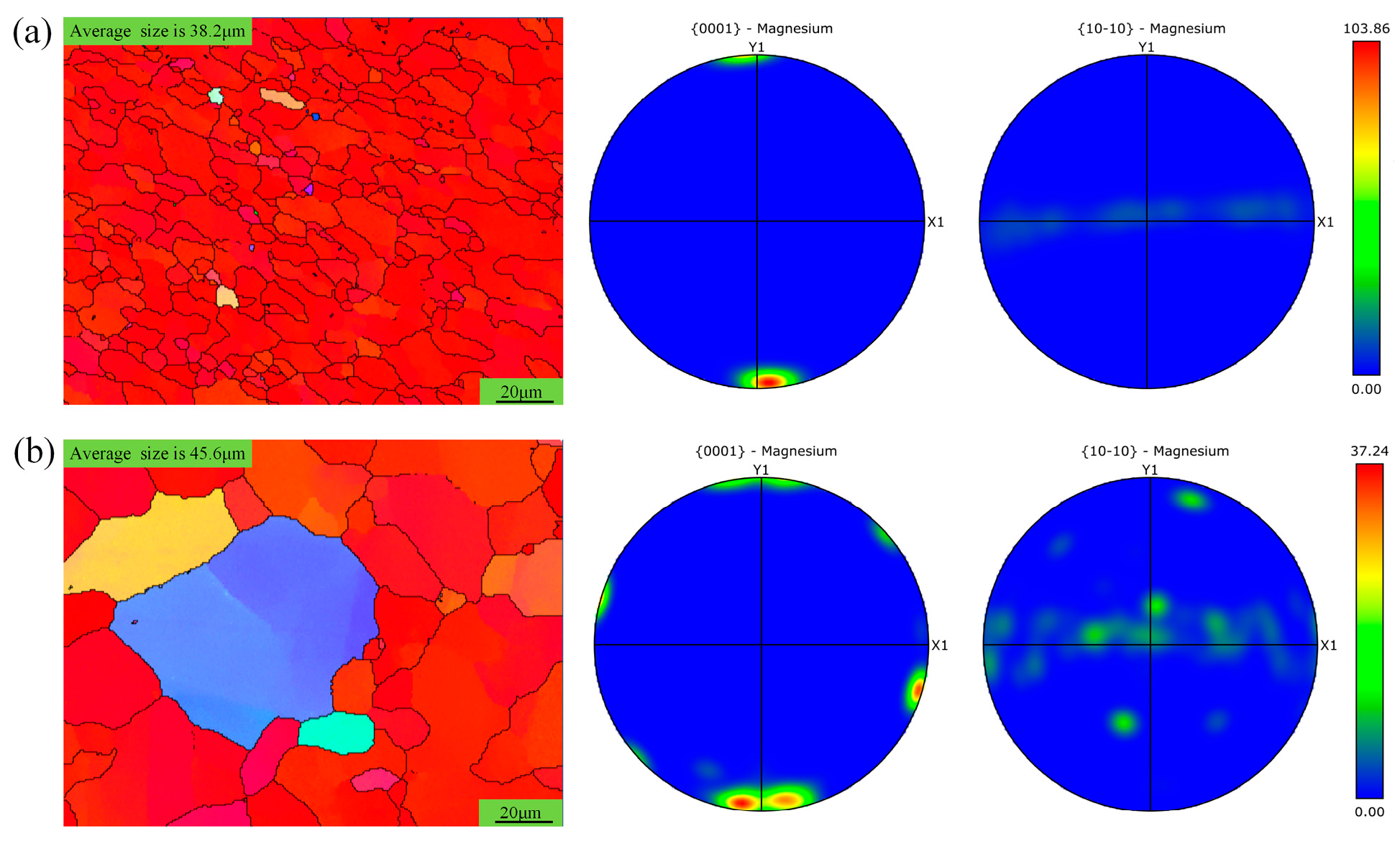

- Regardless of the rotational speed, increasing the welding speed caused the ‘Hook’ to change from an upward to a downward orientation, with reduced curvature observed at 1500 rpm. The grain size in the thermomechanically affected zone and sleeve-affected zone was finer than those of the base material, but the grains in the pin-affected zone were coarser and increased in size with the increase in rotational speed. Additionally, the grain orientation in the sleeve-affected zone was rotated by 90 degrees compared to the base material, with stronger orientation, whereas the grain orientation in the pin-affected zone was rotated by about 15 degrees. These results confirm that higher rotational speeds introduce greater heat input, causing the grains in the pin-affected zone to become larger.

- (3)

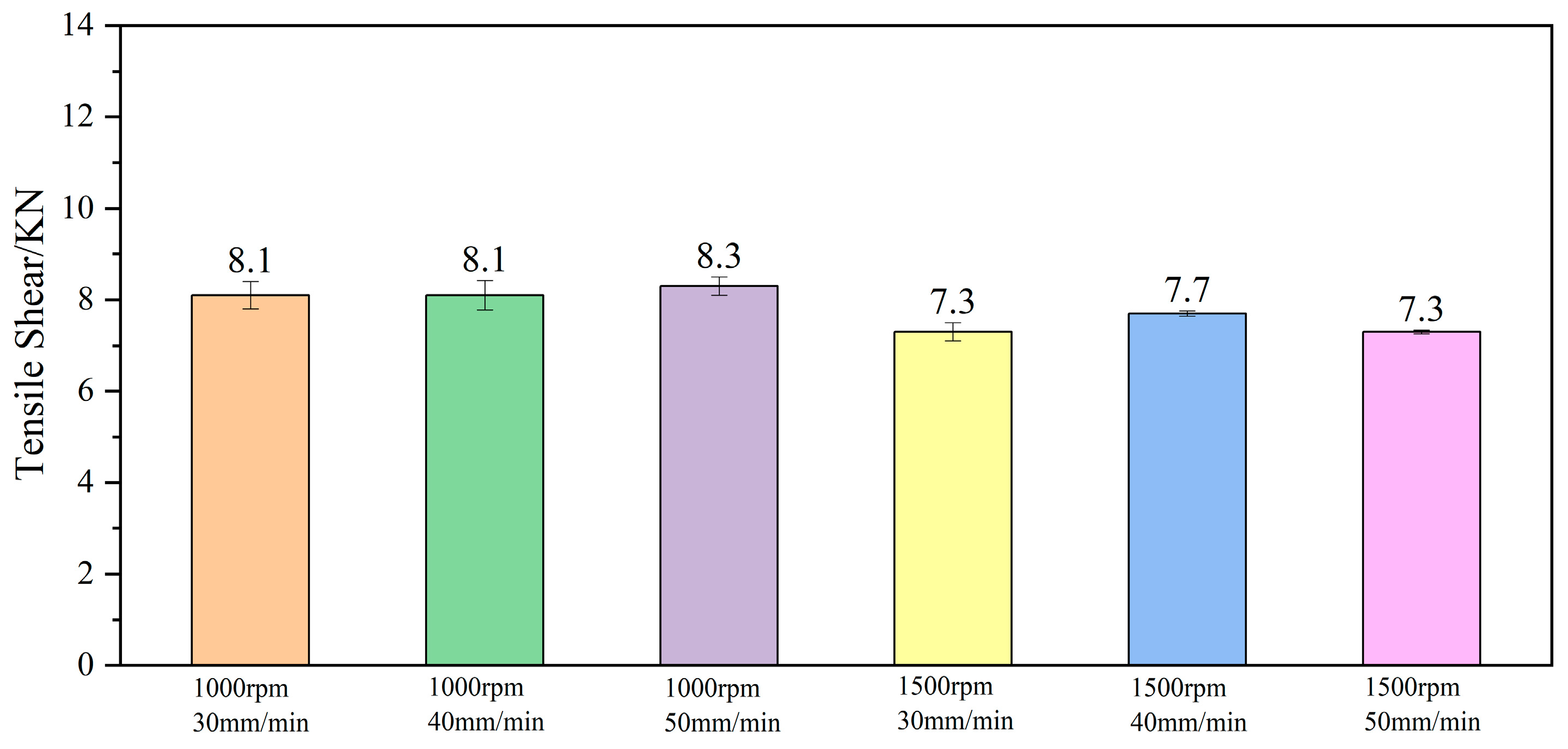

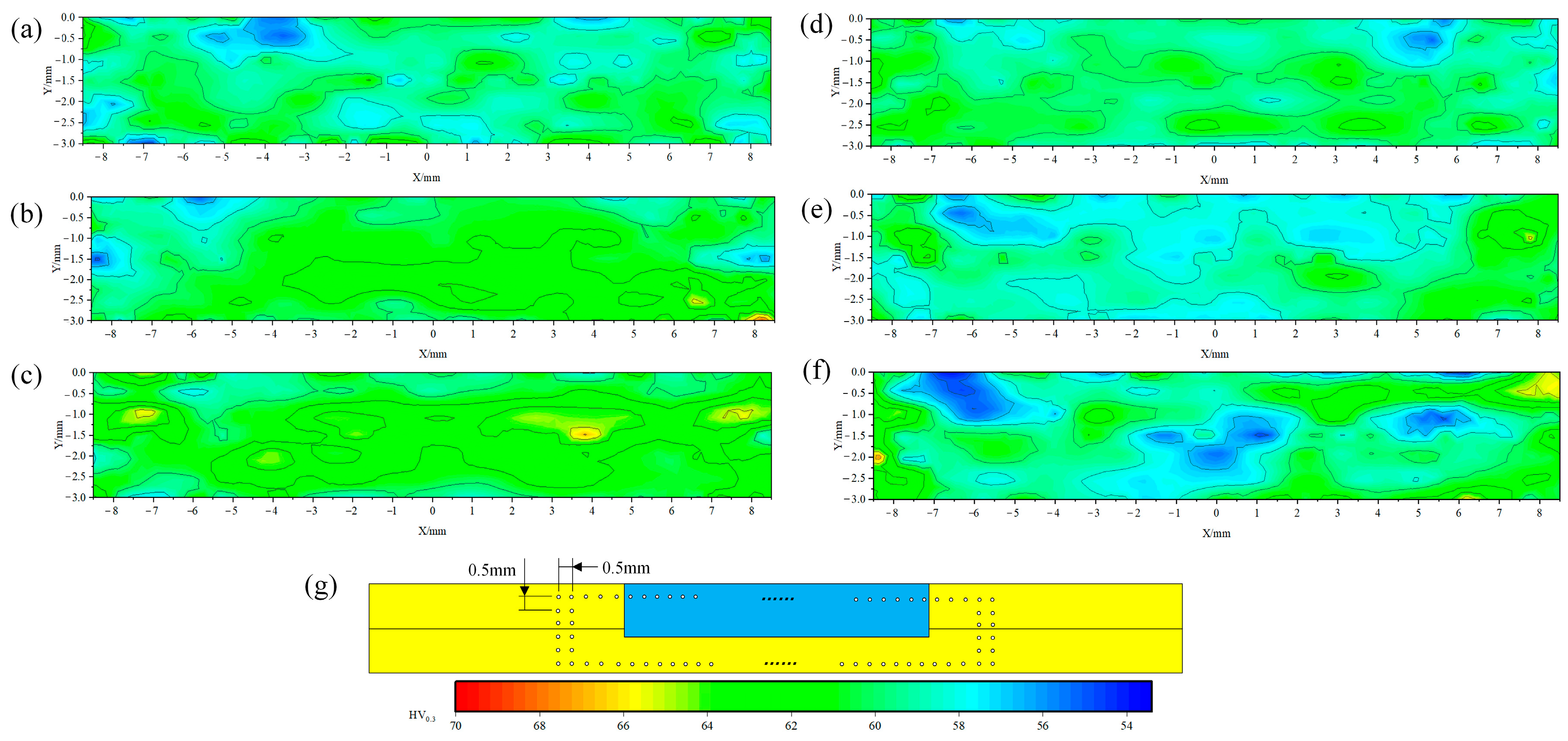

- At a rotational speed of 1000 rpm, the tensile shear fracture was basically complete protrusion fracture, while it was mostly partial protrusion fracture at 1500 rpm in the pin-affected zone. Such a difference was due to the varying bending morphologies of the ‘Hook’. At a rotational speed of 1000 rpm, the average ULSF L was 1.1 times higher than that at 1500 rpm. The spot-welding speed and internal defects had little effect on this finding because higher rotational speeds result in greater heat input, causing grain growth and reducing its performance. This was also evident in the microhardness distribution in the spot welding zone, where greater heat input led to pronounced annealing and uneven distribution of Zr, thus reducing the overall mechanical performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jayasathyakawin, S.; Ravichandran, M.; Baskar, N.; Chairman, C.A.; Balasundaram, R. Mechanical properties and applications of Magnesium alloy—Review. Mater. Today Proc. 2020, 27, 909–913. [Google Scholar] [CrossRef]

- Bai, J.; Yang, Y.; Wen, C.; Chen, J.; Zhou, G.; Jiang, B.; Peng, X.; Pan, F. Applications of magnesium alloys for aerospace: A review. J. Magnes. Alloys 2023, 11, 3609–3619. [Google Scholar] [CrossRef]

- Liu, B.; Yang, J.; Zhang, X.; Yang, Q.; Zhang, J.; Li, X. Development and application of magnesium alloy parts for automotive OEMs: A review. J. Magnes. Alloys 2023, 11, 15–47. [Google Scholar] [CrossRef]

- Wang, G.G.; Weiler, J.P. Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications. J. Magnes. Alloys 2023, 11, 78–87. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Z.; Han, S.; Li, Y. Review on joining processes of magnesium alloy sheets. Int. J. Adv. Manuf. Technol. 2022, 118, 2787–2803. [Google Scholar] [CrossRef]

- Arya, P.K.; Jain, N.K.; Murugesan, J.; Patel, V.K. Developments in friction stir welding of aluminium to magnesium alloy. J. Adhes. Sci. Technol. 2022, 36, 1365–1402. [Google Scholar] [CrossRef]

- Raval, S.K.; Judal, K.B. Recent advances in dissimilar friction stir welding of aluminum to magnesium alloys. Mater. Today Proc. 2020, 22, 2665–2675. [Google Scholar] [CrossRef]

- Jiang, D.; Kolupaev, I.N.; Wang, H.; Ge, X. Effect of tool diameter on the performance of 6061-T6 aluminum alloy in refill friction stir spot welding zone. Weld. World 2025, 69, 2075–2093. [Google Scholar] [CrossRef]

- Jiang, D.; Kolupaev, I.; Wang, H.; Ge, X. Effect of tool ratio on the performance of 6061-T6 aluminum alloy refill friction stir spot welded zone. Mater. Sci. Technol. 2025, 02670836251345981. [Google Scholar] [CrossRef]

- Jiang, D.; Kolupaev, I.N.; Wang, H.; Xiaole, G. Process optimization of refill friction spot stir of AA6061-T6 aluminum alloy for thick plate. J. Adhes. Sci. Technol. 2025, 39, 555–573. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, L.; Li, W.; Li, G.-H.; Tang, Y.-T.; Guo, N.; Feng, J.-C. Effect of tool plunge depth on the microstructure and fracture behavior of refill friction stir spot welded AZ91 magnesium alloy joints. Int. J. Miner. Metall. Mater. 2021, 28, 699–709. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, Z.; Liu, L.; Miao, S.; Lin, Z.; Wang, C.; Zhao, Y.; Xin, R.; Dong, C. Refill friction stir spot welding of AZ31 magnesium alloy sheets: Metallurgical features, microstructure, texture and mechanical properties. J. Mater. Res. Technol. 2023, 23, 3337–3350. [Google Scholar] [CrossRef]

- Campanelli, L.C.; Suhuddin, U.F.H.; Antonialli, A.Í.S.; dos Santos, J.F.; de Alcântara, N.G.; Bolfarini, C. Metallurgy and mechanical performance of AZ31 magnesium alloy friction spot welds. J. Mater. Process. Technol. 2013, 213, 515–521. [Google Scholar] [CrossRef]

- Fu, B.; Shen, J.; Suhuddin, U.F.H.R.; Chen, T.; dos Santos, J.F.; Klusemann, B.; Rethmeier, M. Improved mechanical properties of cast Mg alloy welds via texture weakening by differential rotation refill friction stir spot welding. Scr. Mater. 2021, 203, 114113. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhou, L.; Li, G.H.; Tang, Y.T.; Li, W.L.; Wang, R. Prediction and validation of temperature distribution and material flow during refill friction stir spot welding of AZ91D magnesium alloy. Sci. Technol. Weld. Join. 2021, 26, 153–160. [Google Scholar] [CrossRef]

- Solanki, K.N.; Jordon, J.B.; Whittington, W.; Rao, H.; Hubbard, C. Structure–property relationships and residual stress quantification of a friction stir spot welded magnesium alloy. Scr. Mater. 2012, 66, 797–800. [Google Scholar] [CrossRef]

- Li, G.; Zhou, L.; Luo, S.; Dong, F.; Guo, N. Microstructure and mechanical properties of bobbin tool friction stir welded ZK60 magnesium alloy. Mater. Sci. Eng. A 2020, 776, 138953. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, J.; Shirzadi, A.A. Refill Friction Stir Spot Welding (Refill FSSW) of magnesium lithium alloys: Effects of air and argon cooling. Sci. Technol. Weld. Join. 2021, 26, 236–243. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.I.; Kim, Y.R.; Baek, S.; Kim, D. Solid-State Mg Heat Sink Direct Cooling Bonding with Refill Friction Stir Spot Bonding for Power Inverters. In Proceedings of the 2025 International Conference on Electronics Packaging and iMAPS All Asia Conference (ICEP-IAAC), Nagano, Japan, 15–19 April 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 349–350. [Google Scholar] [CrossRef]

- Ekinci, O. Effect of tool rotational speed on friction stir spot welds of AZ31B Mg alloy to AISI 304 stainless steel. Mater. Test. 2024, 66, 534–543. [Google Scholar] [CrossRef]

- ASTM E8/E8M-23; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- Rosendo, T.; Parra, B.; Tier, M.A.D.; da Silva, A.; dos Santos, J.; Strohaecker, T.; Alcântara, N. Mechanical and microstructural investigation of friction spot welded AA6181-T4 aluminium alloy. Mater. Des. 2011, 32, 1094–1100. [Google Scholar] [CrossRef]

- Ji, S.; Wang, Y.; Zhang, J.; Li, Z. Influence of rotating speed on microstructure and peel strength of friction spot welded 2024-T4 aluminum alloy. Int. J. Adv. Manuf. Technol. 2017, 90, 717–723. [Google Scholar] [CrossRef]

- Wang, Y.; Chai, P.; Ma, H.; Cao, X.; Zhang, Y. Formation mechanism and fracture behavior in extra-filling refill friction stir spot weld for Al–Cu–Mg aluminum alloy. J. Mater. Sci. 2020, 55, 358–374. [Google Scholar] [CrossRef]

- ASTM E384-23; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2023.

| Each Element’s Composition (wt) % | |||||||

|---|---|---|---|---|---|---|---|

| Zn | Zr | Al | Si | Fe | Cu | Ni | Mg |

| 5.45 | 0.64 | 0.01 | 0.01 | 0.008 | 0.007 | 0.004 | Others |

| Tensile Strength/MPa | Elongation/% | Hardness/HV0.3 | Average Grains/μm |

|---|---|---|---|

| 320 | 9 | 75 | 18.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, D.; Ji, L.; Wang, H.; Ge, X. The Effect of Process Parameters on the Performance of the RFSSW of ZK61M-T5 Magnesium Alloy. Materials 2025, 18, 4743. https://doi.org/10.3390/ma18204743

Jiang D, Ji L, Wang H, Ge X. The Effect of Process Parameters on the Performance of the RFSSW of ZK61M-T5 Magnesium Alloy. Materials. 2025; 18(20):4743. https://doi.org/10.3390/ma18204743

Chicago/Turabian StyleJiang, Di, Ling Ji, Hongfeng Wang, and Xiaole Ge. 2025. "The Effect of Process Parameters on the Performance of the RFSSW of ZK61M-T5 Magnesium Alloy" Materials 18, no. 20: 4743. https://doi.org/10.3390/ma18204743

APA StyleJiang, D., Ji, L., Wang, H., & Ge, X. (2025). The Effect of Process Parameters on the Performance of the RFSSW of ZK61M-T5 Magnesium Alloy. Materials, 18(20), 4743. https://doi.org/10.3390/ma18204743