Concurrent Multiscale Modelling of Thermomechanical Responses of Heterogeneous Partition Walls

Abstract

1. Introduction

2. Theory of Concurrent Multiscale Modeling

2.1. Governing Equations for Coupled Thermomechanical Problems

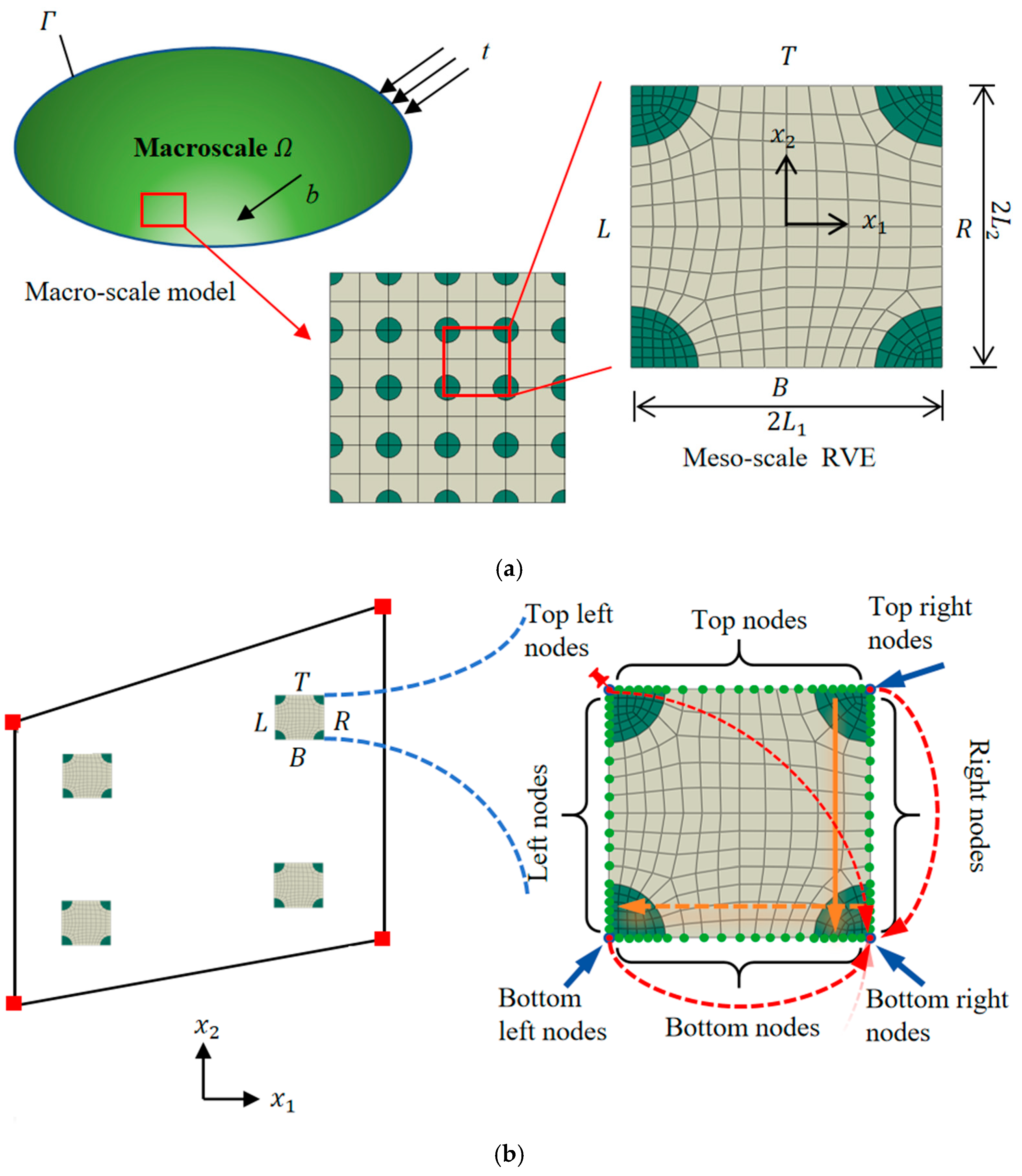

2.2. Concurrent Multiscale Modeling

2.3. Transition from Macro- to Meso-Scale

2.4. Transition from Meso- to Macro-Scale

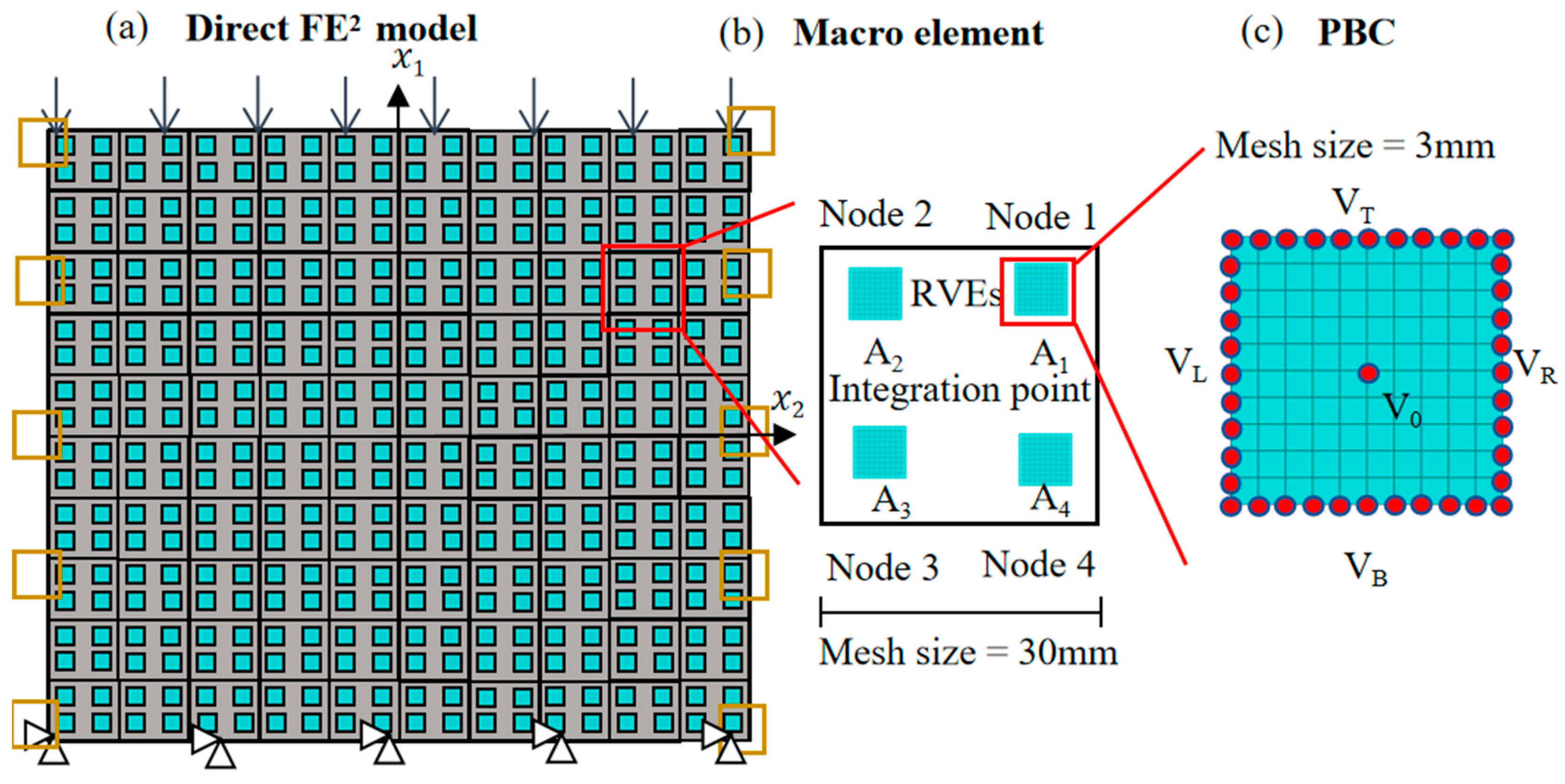

3. Numerical Implementation

3.1. Boundary Conditions

3.2. Enforcement of the Hill-Mandel Condition

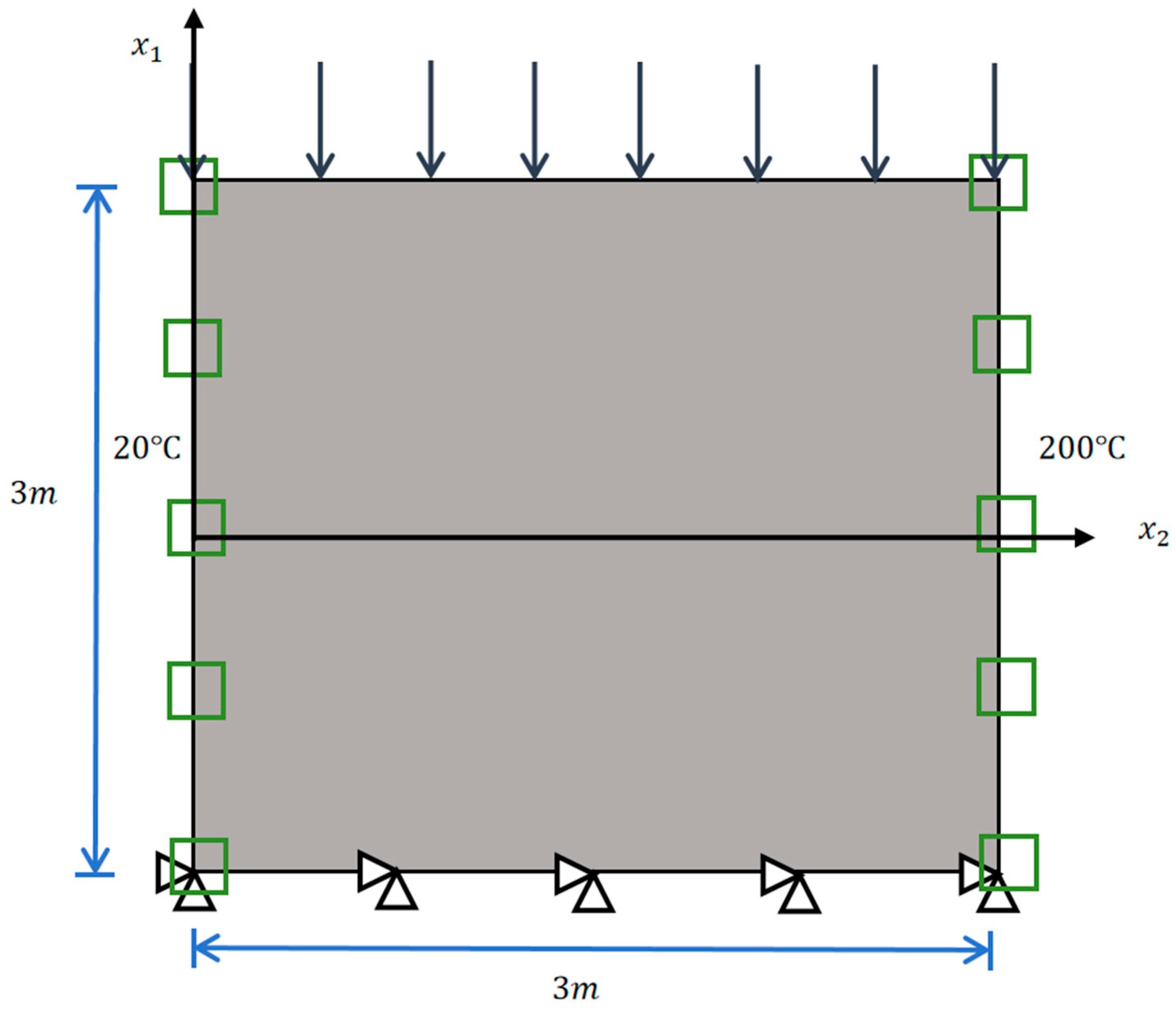

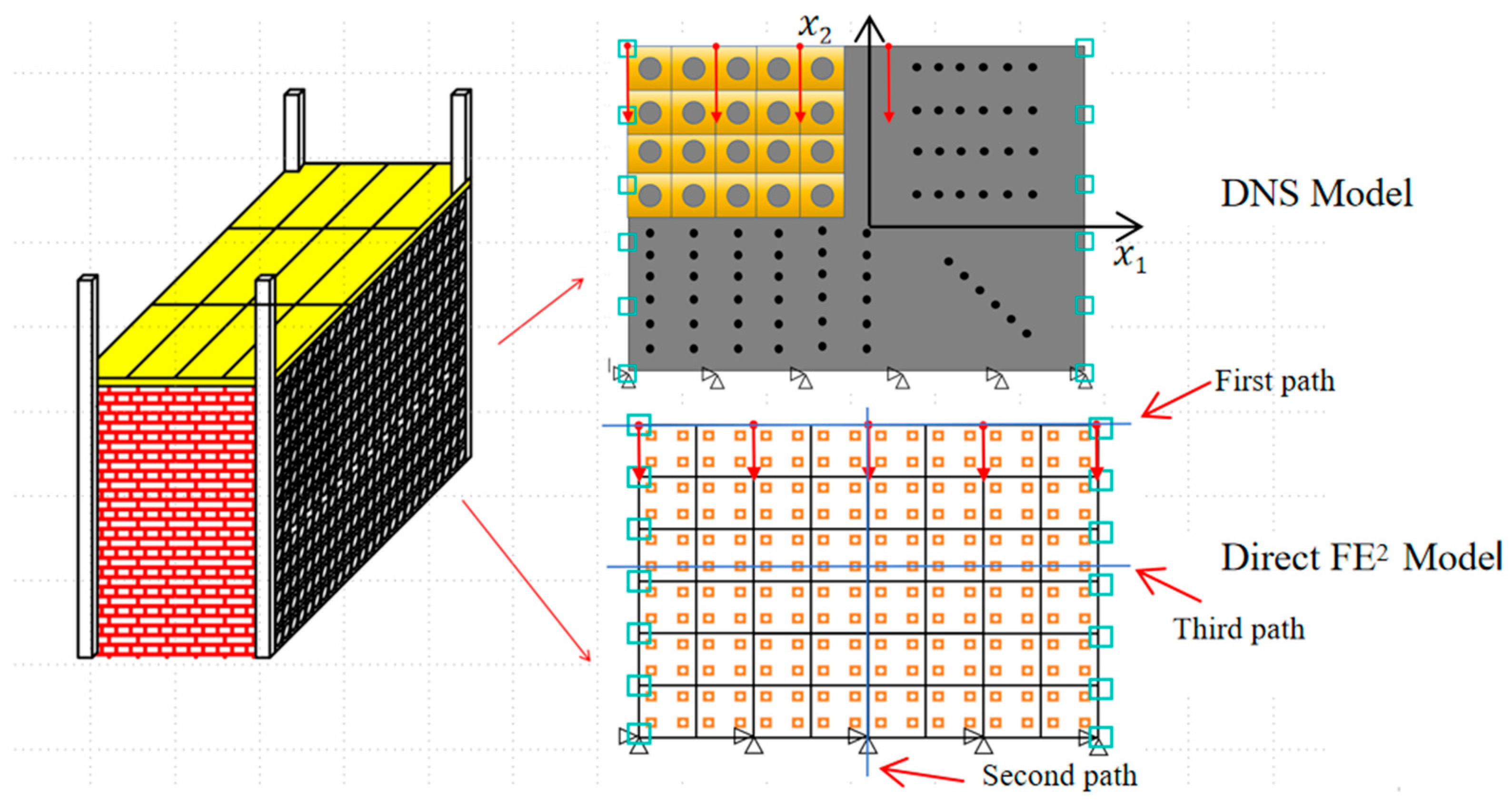

4. Applications for Partition Walls

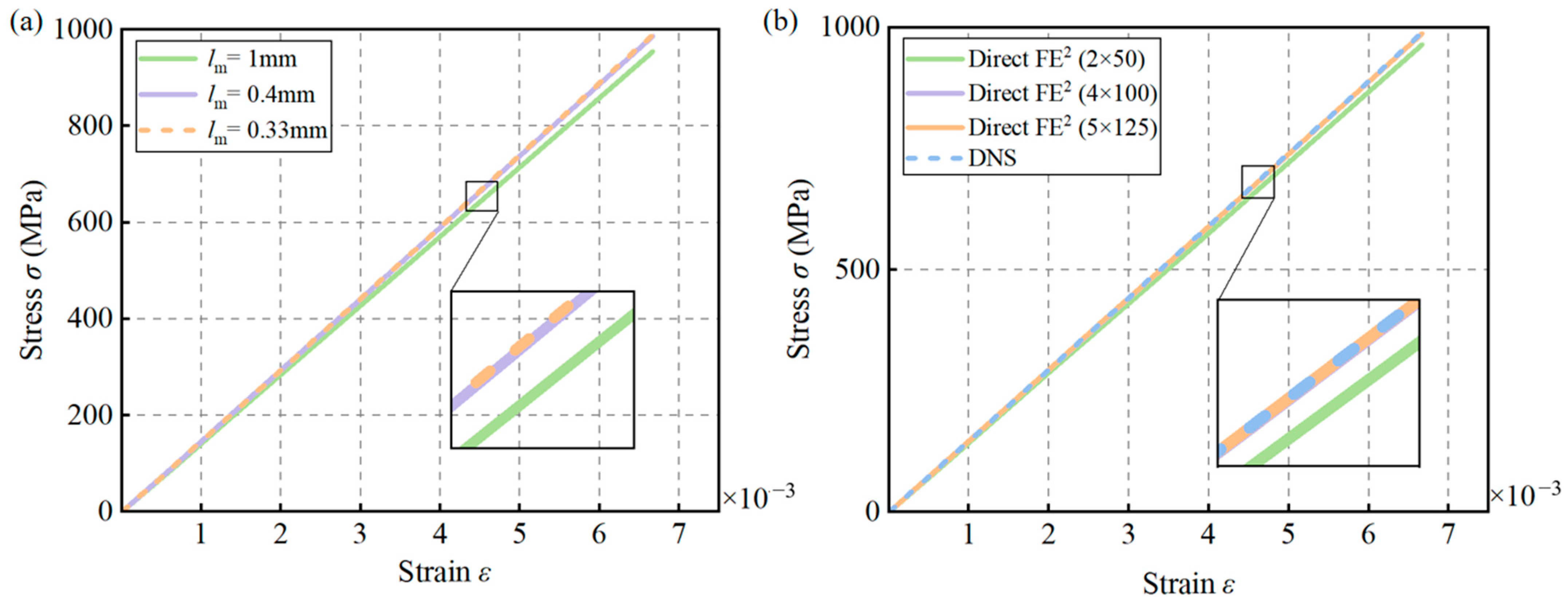

4.1. Solid Steel Plate

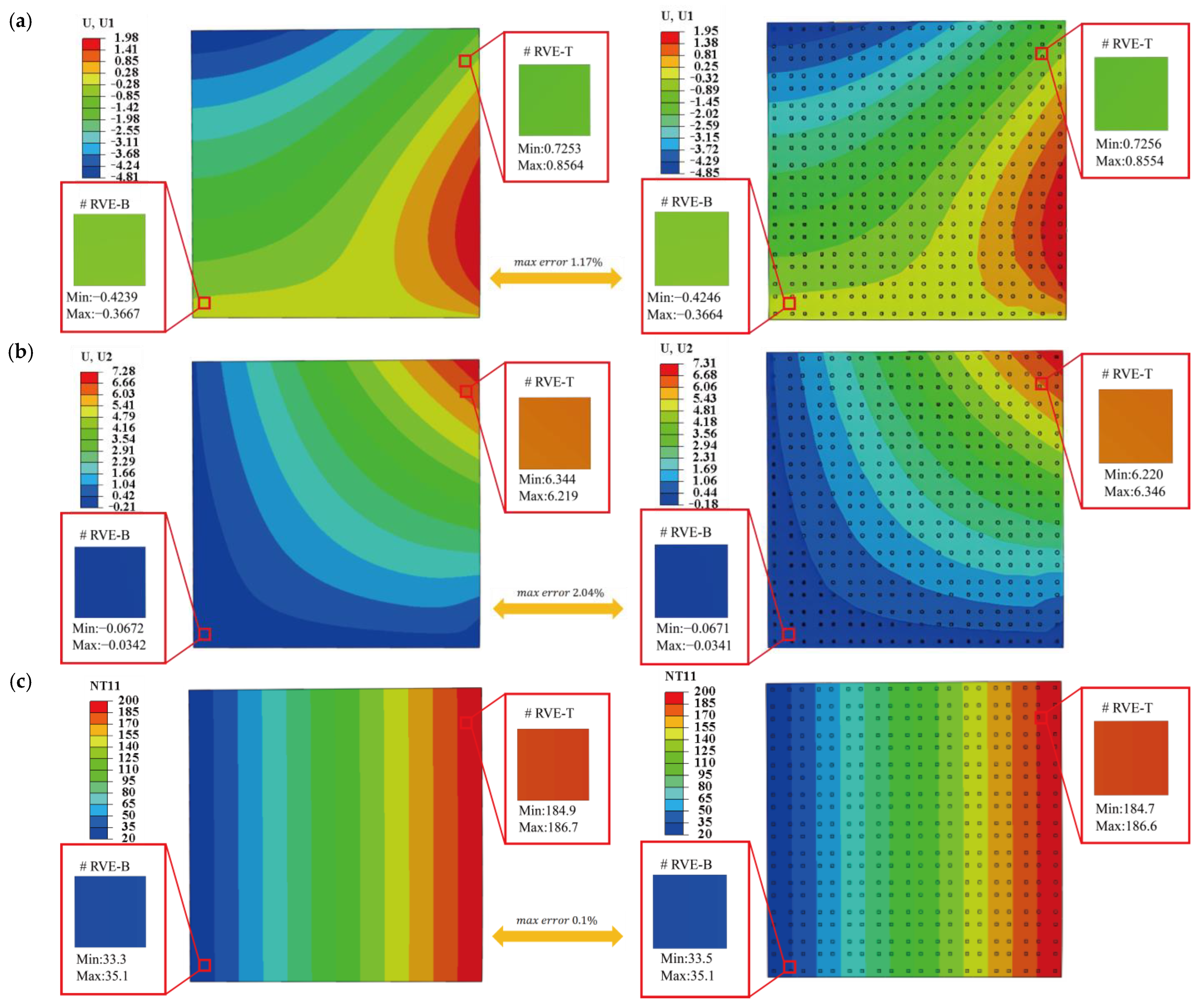

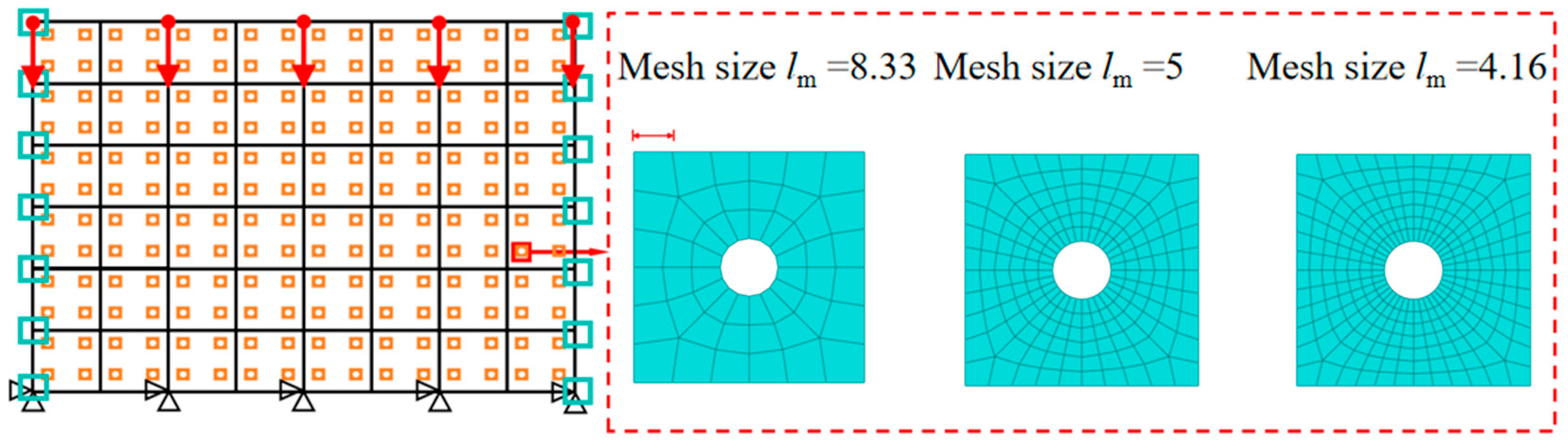

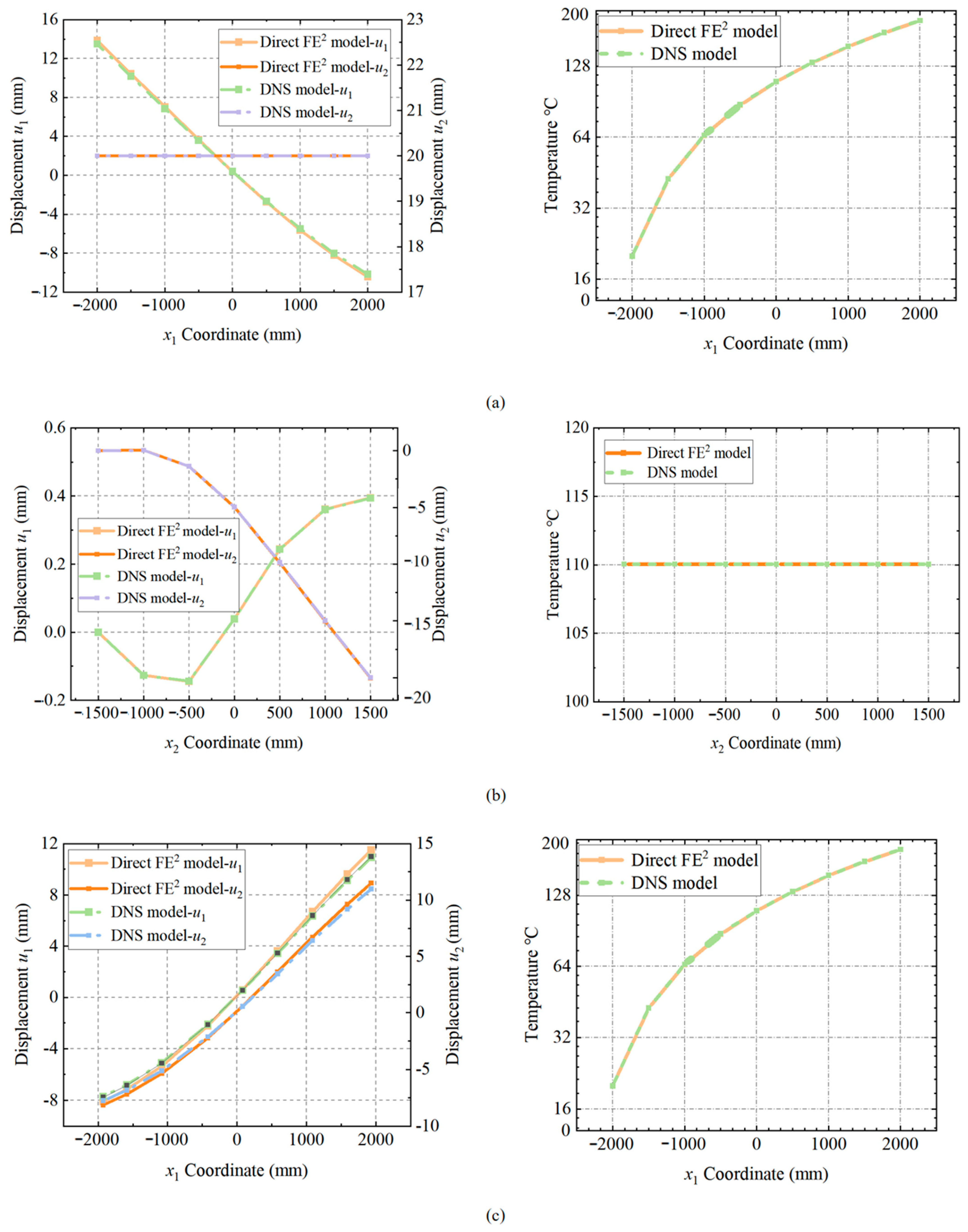

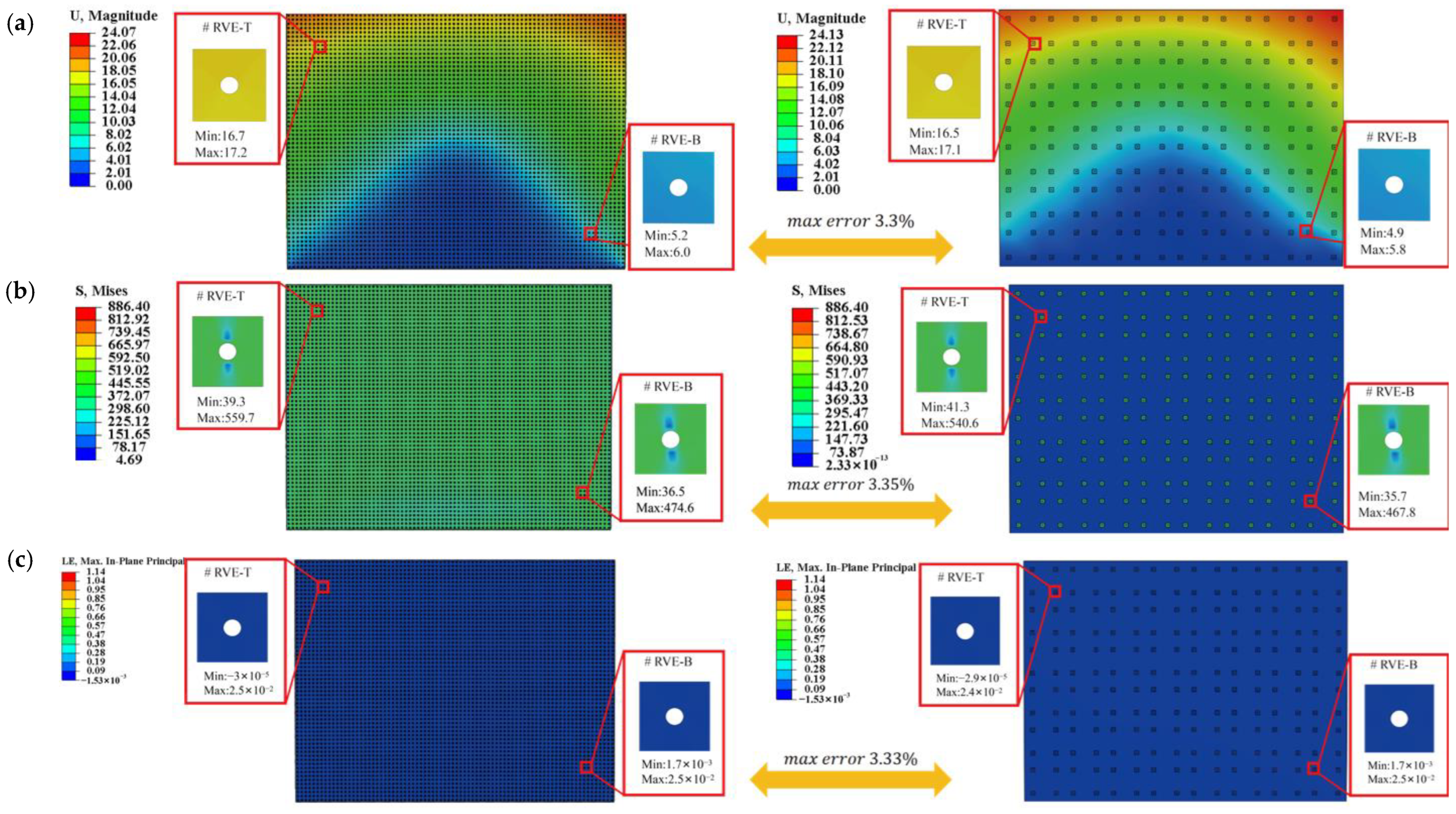

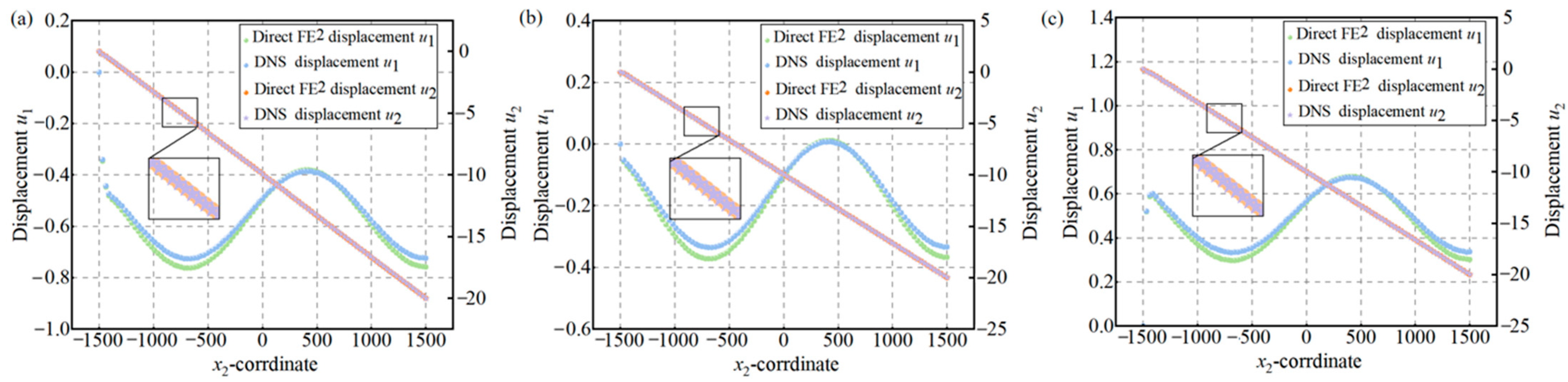

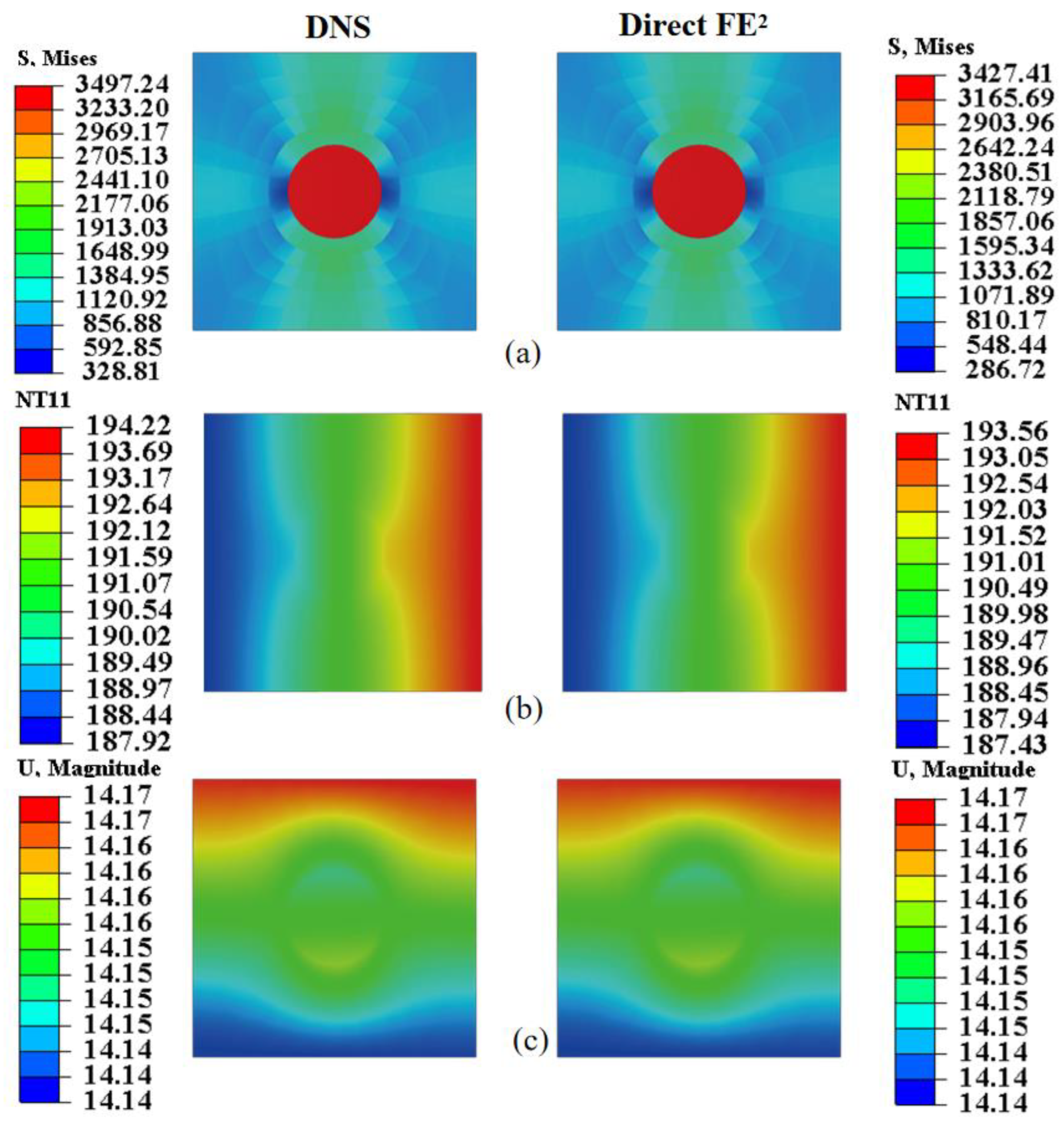

4.2. Circular Hole Steel Plate

4.3. Fiber-Reinforced Composite Plate

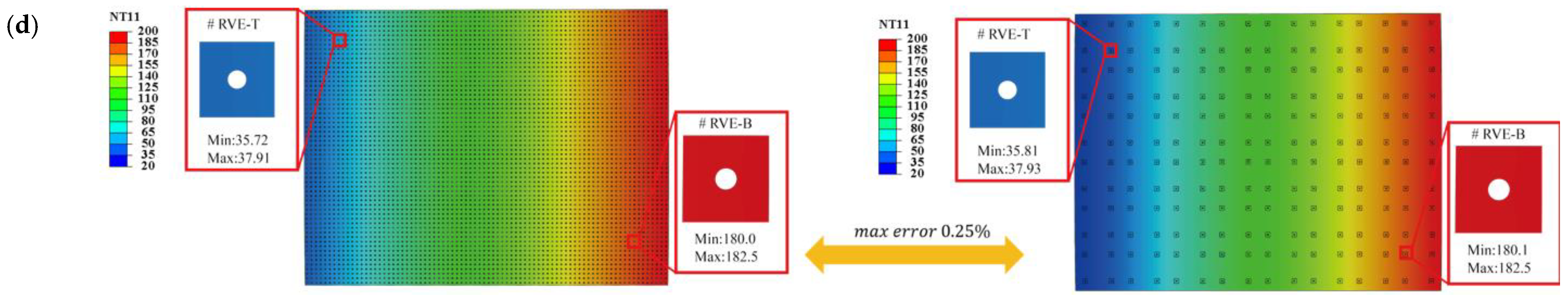

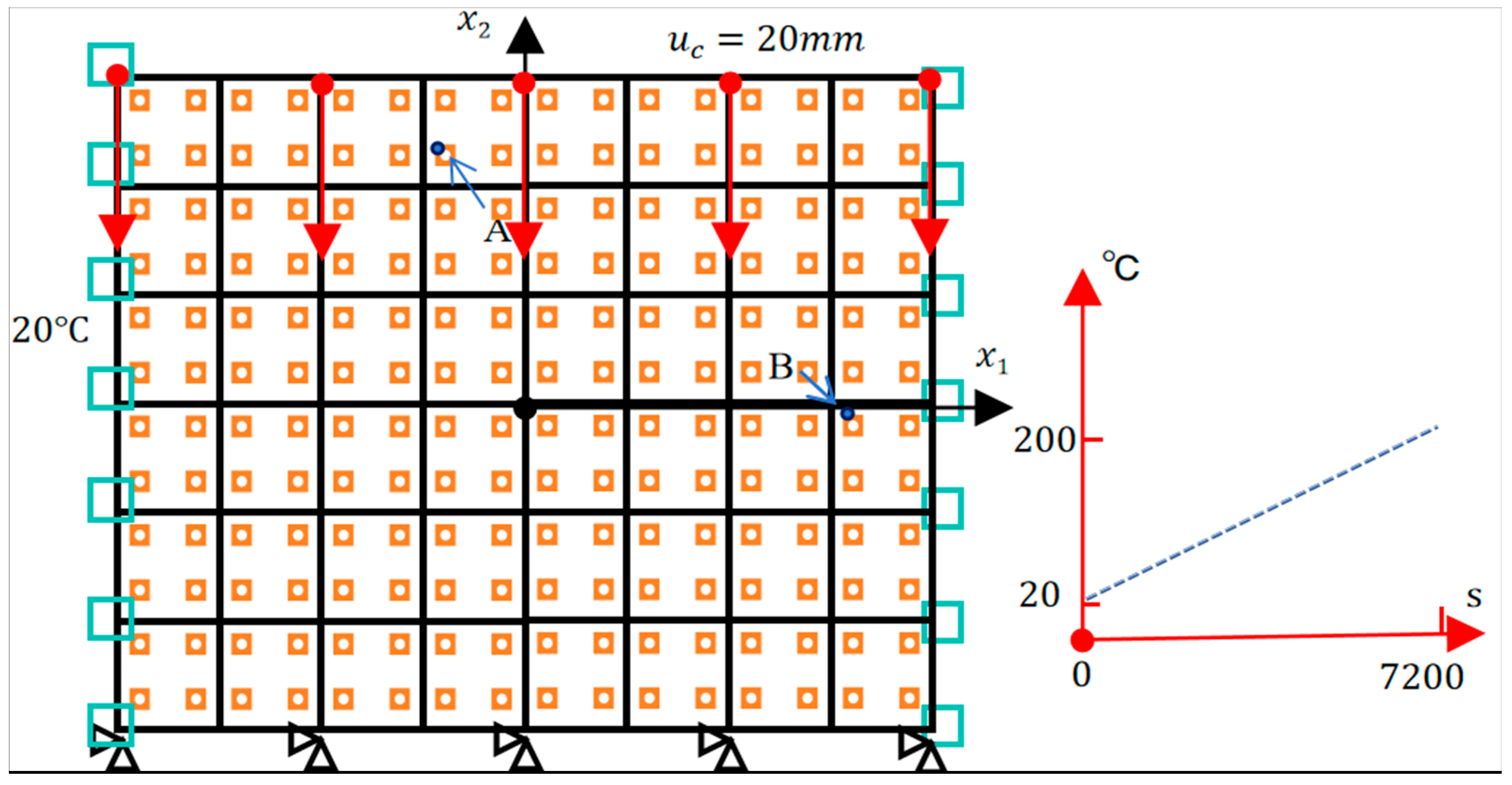

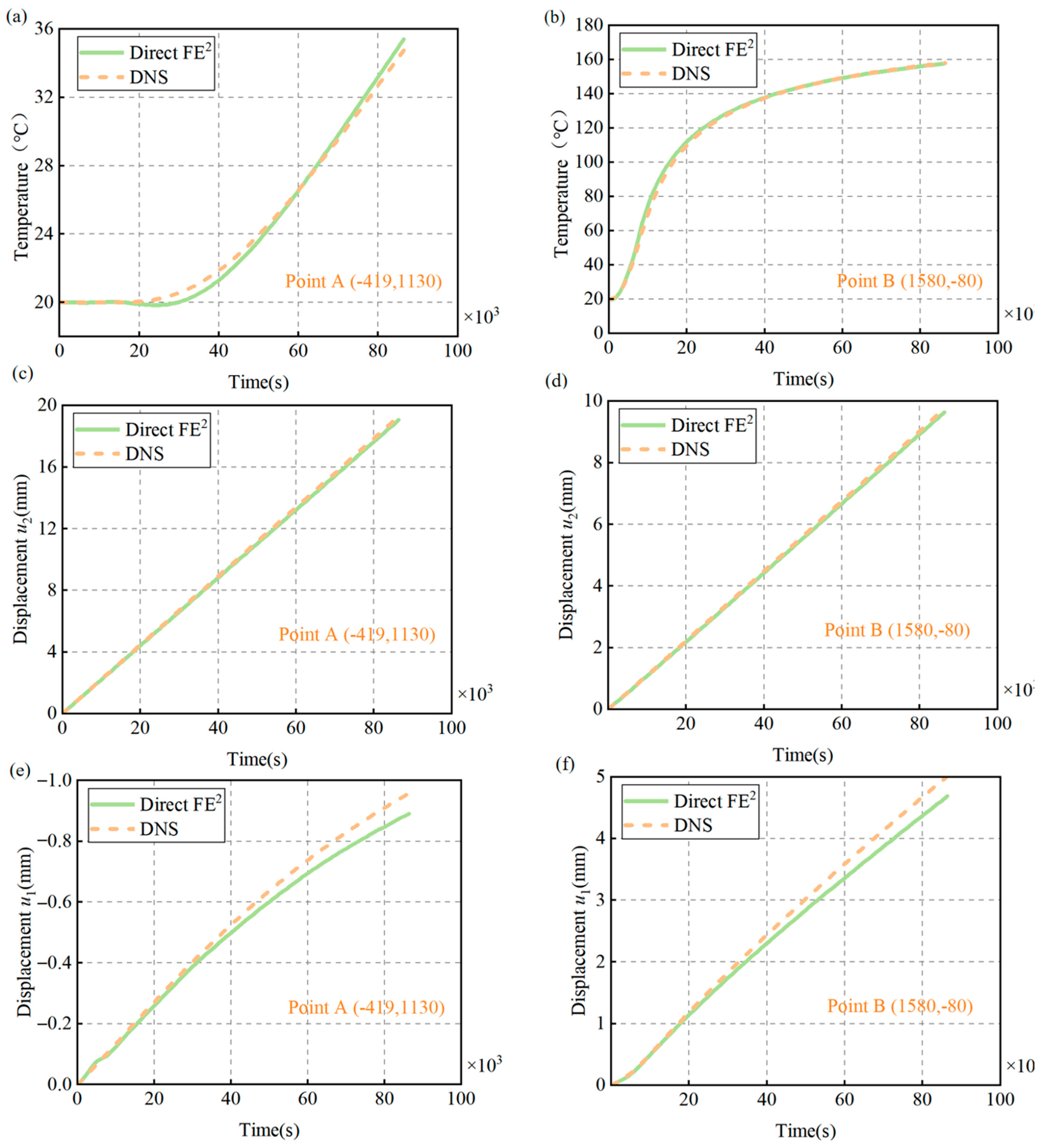

4.4. Transient Thermo-Mechanical Coupling Analysis

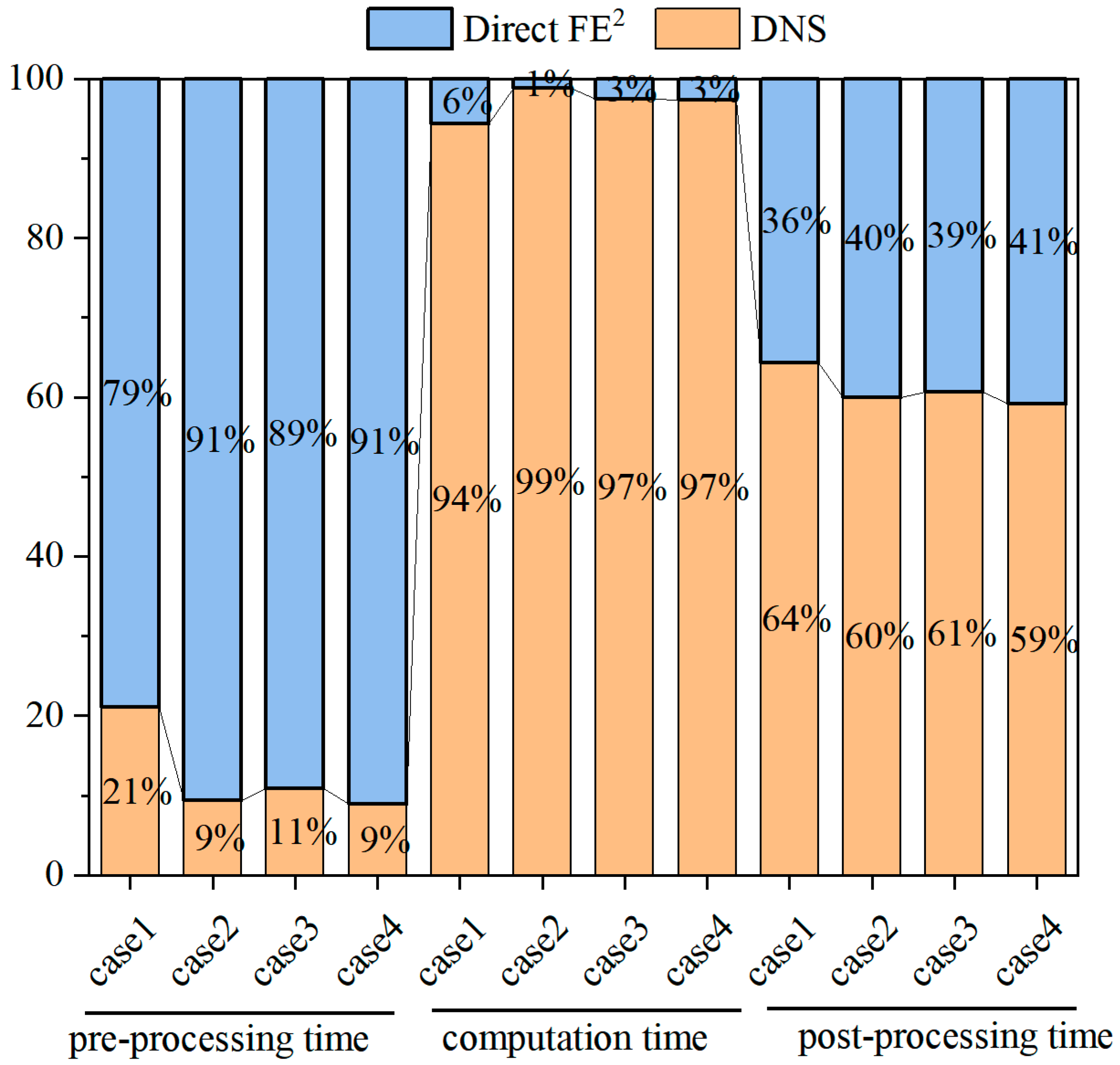

5. Computational Efficiency of the Direct FE2 Method

6. Discussion of Engineering Implications and Limitations

7. Conclusions

- (a)

- A practical framework was established for static and transient thermomechanical analysis within common commercial finite element software.

- (b)

- The Direct FE2 method showed less than 5% deviation from DNS results in both displacement and temperature, while achieving a computational efficiency improvement of approximately one order of magnitude.

- (c)

- The simplified preprocessing requirements and high efficiency highlight its suitability for a wide range of engineering applications.

- (a)

- Evaluation and design of partition walls in high-rise buildings and industrial facilities.

- (b)

- Optimization of lightweight and perforated wall systems through accurate prediction of thermal stress redistribution and local failure.

- (c)

- Performance-based evaluation of fiber-reinforced composite walls under thermal loading, supporting the development of advanced structural materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kodur, V.; Sultan, M. Effect of temperature on thermal properties of high-strength concrete. J. Mater. Civ. Eng. 2003, 15, 101–107. [Google Scholar] [CrossRef]

- Chen, L.; Liu, C.; Lian, H.; Gu, W. Electromagnetic scattering sensitivity analysis for perfectly conducting objects in TM polarization with isogeometric BEM. Eng. Anal. Bound. Elem. 2025, 172, 106126. [Google Scholar] [CrossRef]

- Chen, L.; Pei, Q.; Fei, Z.; Zhou, Z.; Hu, Z. Deep-neural-network-based framework for the accelerating uncertainty quantification of a structural–acoustic fully coupled system in a shallow sea. Eng. Anal. Bound. Elem. 2025, 171, 106112. [Google Scholar] [CrossRef]

- Chen, L.; Huo, R.; Lian, H.; Yu, B.; Zhang, M.; Natarajan, S.; Bordas, S.P. Uncertainty quantification of 3D acoustic shape sensitivities with generalized nth-order perturbation boundary element methods. Comput. Methods Appl. Mech. Eng. 2025, 433, 117464. [Google Scholar] [CrossRef]

- Lian, H.; Li, X.; Qu, Y.; Du, J.; Meng, Z.; Liu, J.; Chen, L. Bayesian uncertainty analysis for underwater 3D reconstruction with neural radiance fields. Appl. Math. Model. 2025, 138, 115806. [Google Scholar] [CrossRef]

- Chen, L.; Lian, H.; Pei, Q.; Meng, Z.; Jiang, S.; Dong, H.-W.; Yu, P. FEM-BEM analysis of acoustic interaction with submerged thin-shell structures under seabed reflection conditions. Ocean Eng. 2024, 309, 118554. [Google Scholar] [CrossRef]

- Chen, J.Z. The Finite Element Method: Its Fundamentals and Applications in Engineering; World Scientific Publishing Company: Singapore, 2011. [Google Scholar]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Minkina, W.; Dudzik, S. Infrared Thermography: Errors and Uncertainties; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Sutton, M.A.; Orteu, J.J.; Schreier, H. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Ezekoye, O.A. Conduction of heat in solids. In SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2016; pp. 25–52. [Google Scholar]

- Green, A.E.; Lindsay, K.A. Thermoelasticity. J. Elast. 1972, 2, 1–7. [Google Scholar] [CrossRef]

- Bergman, T.L. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Byström, A. Large-Scale Test on a Steel Column Exposed to Localized Fire. Fire Saf. J. 2011, 46, 235–244. [Google Scholar] [CrossRef]

- Choe, L.; Gross, J.L.; McAllister, T.P. Full-Scale Fire Tests on a Steel-Framed Building. J. Struct. Eng. 2011, 137, 180–190. [Google Scholar]

- Jia, B.; Rusinek, A.; Pesci, R.; Børvik, T.; Alves, M. Perforation Behavior of 304 Stainless Steel Plates at Various Temperatures. J. Dyn. Behav. Mater. 2019, 5, 314–325. [Google Scholar] [CrossRef]

- Blanco, J.M.; Coello, P.; Vega, J.M. Experimental Study on the Thermal Behavior of Perforated Sheet-Metal Panels. Energy Build. 2014, 75, 337–345. [Google Scholar]

- Bazli, M.; Abolfazli, M.; Ashrafi, H. Mechanical Properties of Fibre Reinforced Polymers under Elevated Temperatures: Experimental Review. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar]

- Liang, J.; Wang, Y.; Zhao, D.; Wang, Y. Experimental Study of Curing Temperature Effects on the Thermomechanical Properties of Carbon-Fiber Epoxy Composites. Compos. Part B Eng. 2023, 258, 110654. [Google Scholar]

- Hughes, T.J. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis; Courier Corporation: North Chelmsford, MA, USA, 2003. [Google Scholar]

- Müller, C.; Smith, R.; Wang, Z. Challenges in experimental repeatability and generalizability: The impact of sensor precision and environmental factors. J. Exp. Mech. 2018, 45, 1123–1135. [Google Scholar]

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Watts, J.M., Jr.; Wieczorek, C.J. SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2015. [Google Scholar]

- Geers, M.G.; Kouznetsova, V.G.; Brekelmans, W. Multi-scale computational homogenization: Trends and challenges. J. Comput. Appl. Math. 2010, 234, 2175–2182. [Google Scholar] [CrossRef]

- Feyel, F. Multiscale FE2 elastoviscoplastic analysis of composite structures. Comput. Mater. Sci. 1999, 16, 344–354. [Google Scholar] [CrossRef]

- Mandel, J. Contribution théorique à l’étude de l’écrouissage et des lois de l’écoulement plastique. In Proceedings of the Applied Mechanics: Proceedings of the Eleventh International Congress of Applied Mechanics, Munich, Germany, 1–5 September 1964; pp. 502–509. [Google Scholar]

- Miehe, C.; Schröder, J.; Becker, M. Computational homogenization analysis in finite elasticity: Material and structural instabilities on the micro-and macro-scales of periodic composites and their interaction. Comput. Methods Appl. Mech. Eng. 2002, 191, 4971–5005. [Google Scholar] [CrossRef]

- Raju, K.; Tay, T.-E.; Tan, V.B.C. A review of the FE2 method for composites. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 1–24. [Google Scholar] [CrossRef]

- Tan, V.B.C.; Raju, K.; Lee, H.P. Direct FE2 for concurrent multilevel modelling of heterogeneous structures. Comput. Methods Appl. Mech. Eng. 2020, 360, 112694. [Google Scholar] [CrossRef]

- Terada, K.; Kikuchi, N. A class of general algorithms for multi-scale analyses of heterogeneous media. Comput. Methods Appl. Mech. Eng. 2001, 190, 5427–5464. [Google Scholar] [CrossRef]

- Xu, J.; Li, P.; Poh, L.H.; Zhang, Y.; Tan, V.B.C. Direct FE2 for concurrent multilevel modeling of heterogeneous thin plate structures. Comput. Methods Appl. Mech. Eng. 2022, 392, 114658. [Google Scholar] [CrossRef]

- Zhi, J.; Raju, K.; Tay, T.-E.; Tan, V.B.C. Transient multi-scale analysis with micro-inertia effects using Direct FE 2 method. Comput. Mech. 2021, 67, 1645–1660. [Google Scholar] [CrossRef]

- Yeoh, K.; Poh, L.; Tay, T.; Tan, V. Multiscale computational homogenisation of shear-flexible beam elements: A Direct FE2 approach. Comput. Mech. 2022, 70, 891–910. [Google Scholar] [CrossRef]

- Zhi, J.; Raju, K.; Tay, T.E.; Tan, V.B.C. Multiscale analysis of thermal problems in heterogeneous materials with Direct FE2 method. Int. J. Numer. Methods Eng. 2021, 122, 7482–7503. [Google Scholar] [CrossRef]

- Zhao, H.; Yeoh, K.M.; Zhi, J.; Tan, V.B.C. Direct FE2 multiscale modeling of hydrogen-induced cracking in reactor pressure vessels. Int. J. Mech. Sci. 2024, 274, 109285. [Google Scholar] [CrossRef]

- Zhi, J.; Yang, B.; Li, Y.; Tay, T.-E.; Tan, V.B.C. Multiscale thermo-mechanical analysis of cure-induced deformation in composite laminates using Direct FE2. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107704. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, H.; Liu, Z.; Shu, X.; Li, P. A direct FE2 method for concurrent multilevel modeling of a coupled thermoelectric problem–Joule heating effect–in multiscale materials and structures. Thin-Walled Struct. 2024, 203, 112166. [Google Scholar] [CrossRef]

- Zhao, A.; Li, P.; Cui, Y.; Hu, Z.; Tan, V.B.C. Multiscale topology optimization with Direct FE2. Comput. Methods Appl. Mech. Eng. 2024, 419, 116662. [Google Scholar] [CrossRef]

- Zhao, A.; Tan, V.B.C.; Li, P.; Liu, K.; Hu, Z. A Reconstruction Approach for Concurrent Multiscale Topology Optimization Based on Direct FE2 Method. Mathematics 2023, 11, 2779. [Google Scholar] [CrossRef]

- Zhao, A.; Li, P.; Liu, K.; Cui, Y. Topology optimization design of frame structures based on the Direct FE2 method. Mater. Des. 2025, 254, 114091. [Google Scholar] [CrossRef]

- Liu, K.; Yeoh, K.M.; Cui, Y.; Zhao, A.; Luo, Y.; Zhong, Z. Integrated multiscale topology optimization of frame structures for minimizing compliance. Eng. Struct. 2025, 339, 120561. [Google Scholar] [CrossRef]

- EN 1993–1-2: 2005; Eurocode 3: Design of Steel Structures—Part 1-2: General Rules—Structural Fire Design. European Committee for Standardization: Brussels, Belgium, 2005.

- Özdemir, I.; Brekelmans, W.A.M.; Geers, M.G.D. FE2 computational homogenization for the thermo-mechanical analysis of heterogeneous solids. Comput. Methods Appl. Mech. Eng. 2008, 198, 602–613. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, A.; Liu, Z.; Meng, L.; Zhang, L.; Li, P. Evaluating the elastic wave speed in heterogeneous materials and structures: A concurrent multiscale modeling approach. Compos. Struct. 2025, 365, 119193. [Google Scholar] [CrossRef]

- Chen, L.L.; Lian, H.; Liu, Z.; Chen, H.B.; Atroshchenko, E.; Bordas, S.P. A Structural shape optimization of three-dimensional acoustic problems with isogeometric boundary element methods. Comput. Methods Appl. Mech. Eng. 2019, 355, 926–951. [Google Scholar] [CrossRef]

- Chen, L.; Lu, C.; Lian, H.; Liu, Z.; Zhao, W.; Li, S.; Chen, H.; Bordas, S.P.A. Acoustic topology optimization of sound absorbing materials directly from subdivision surfaces with isogeometric boundary element methods. Comput. Methods Appl. Mech. Eng. 2020, 362, 112806. [Google Scholar] [CrossRef]

| Parameters | Units | Value |

|---|---|---|

| 7850 | ||

| 210 | ||

| 0.3 | ||

| 45 | ||

| Yield Stress () | Plastic Strain |

|---|---|

| 362 | 0.00000 |

| 373 | 0.04702 |

| 383 | 0.07514 |

| 394 | 0.10248 |

| 401 | 0.12031 |

| 408 | 0.13782 |

| Parameters | Units | Boron Fiber | Aluminum Matrix |

|---|---|---|---|

| 2600 | 2700 | ||

| 385 | 75 | ||

| 0.2 | 0.33 | ||

| 38 | 247 | ||

| Parameters | Units | Value | Temperature |

|---|---|---|---|

| 7850 | |||

| 210 | 20 °C | ||

| 210 | 100 °C | ||

| 189 | 200 °C | ||

| 0.3 | |||

| 45 | 20 °C | ||

| 53 | 200 °C | ||

| 1.2 × 10−5 | 20 °C | ||

| 1.264 × 10−5 | 100 °C | ||

| 1.344 × 10−5 | 200 °C | ||

| ) | 440 | 20 °C | |

| 690 | 200 °C |

| Numerical Case | Number of Elements | Degrees of Freedom | Total Computational Time (s) | |||

|---|---|---|---|---|---|---|

| Direct FE2 | DNS | Direct FE2 | DNS | Direct FE2 | DNS | |

| Case 1 | 40,000 | 1,000,000 | 120,000 | 3,630,000 | 85 | 530 |

| Case 2 | 37,632 | 940,800 | 133,632 | 3,340,800 | 333 | 21,419 |

| Case 3 | 409,600 | 5,760,000 | 1,329,600 | 18,697,500 | 706 | 3015 |

| Case 4 | 37,632 | 940,800 | 133,632 | 3,340,800 | 296 | 10,700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Yang, S.; Li, Y.; Huang, L.; Xu, Y.; Zhang, H.; Li, P. Concurrent Multiscale Modelling of Thermomechanical Responses of Heterogeneous Partition Walls. Materials 2025, 18, 4744. https://doi.org/10.3390/ma18204744

Wang S, Yang S, Li Y, Huang L, Xu Y, Zhang H, Li P. Concurrent Multiscale Modelling of Thermomechanical Responses of Heterogeneous Partition Walls. Materials. 2025; 18(20):4744. https://doi.org/10.3390/ma18204744

Chicago/Turabian StyleWang, Shige, Sen Yang, Yang Li, Lian Huang, Yanming Xu, Heng Zhang, and Pei Li. 2025. "Concurrent Multiscale Modelling of Thermomechanical Responses of Heterogeneous Partition Walls" Materials 18, no. 20: 4744. https://doi.org/10.3390/ma18204744

APA StyleWang, S., Yang, S., Li, Y., Huang, L., Xu, Y., Zhang, H., & Li, P. (2025). Concurrent Multiscale Modelling of Thermomechanical Responses of Heterogeneous Partition Walls. Materials, 18(20), 4744. https://doi.org/10.3390/ma18204744