Effect of Laser Pulse Width on Cutting Quality and Efficiency in CFRP: Mechanism and Optimization

Abstract

1. Introduction

2. Experiment

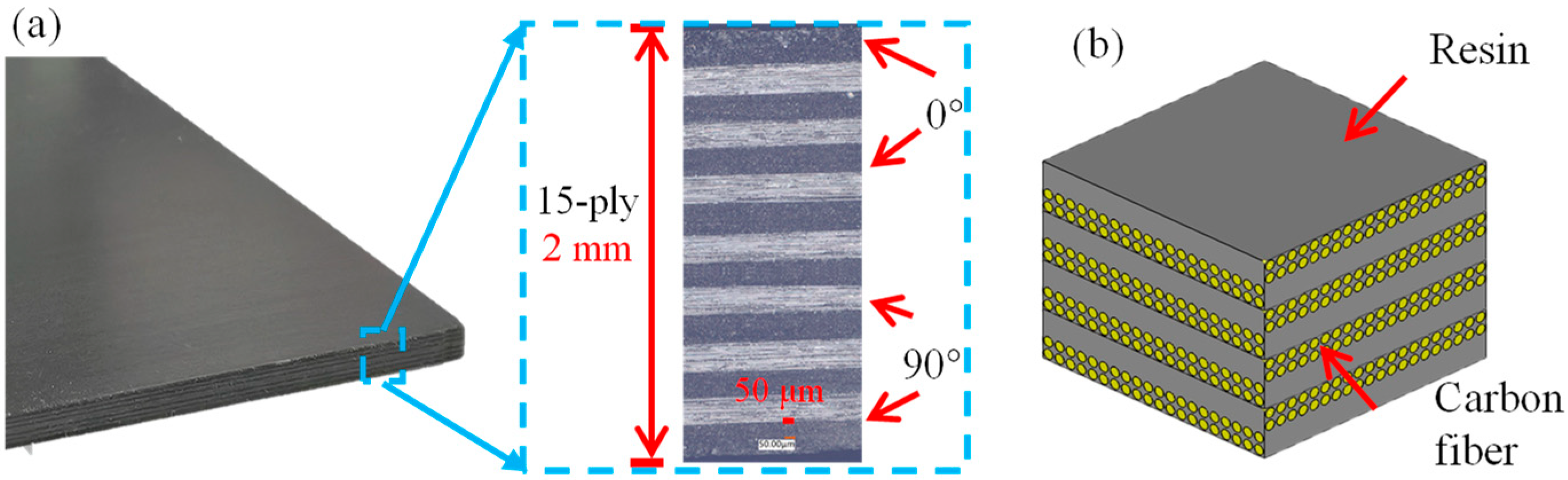

2.1. Materials

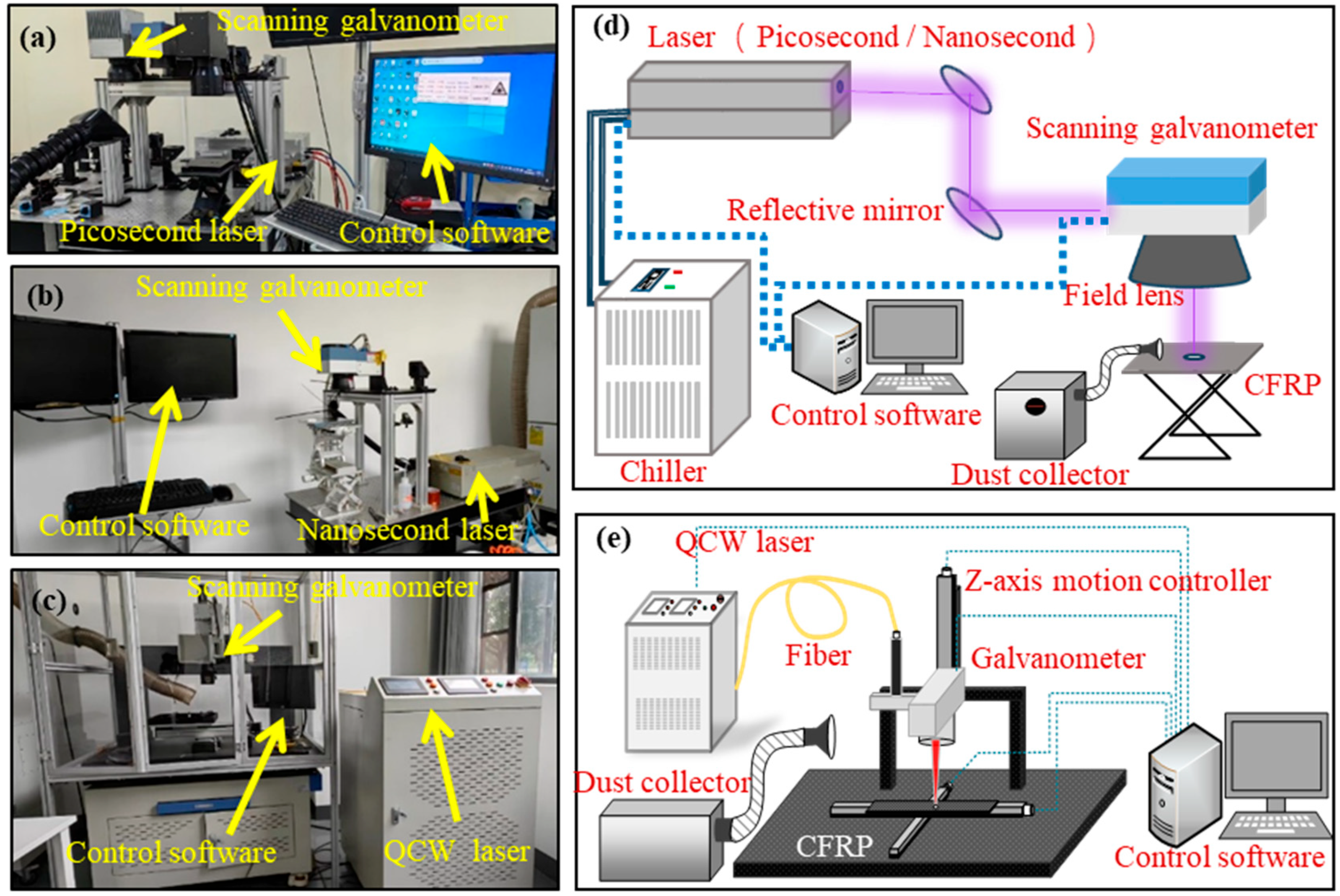

2.2. Equipment

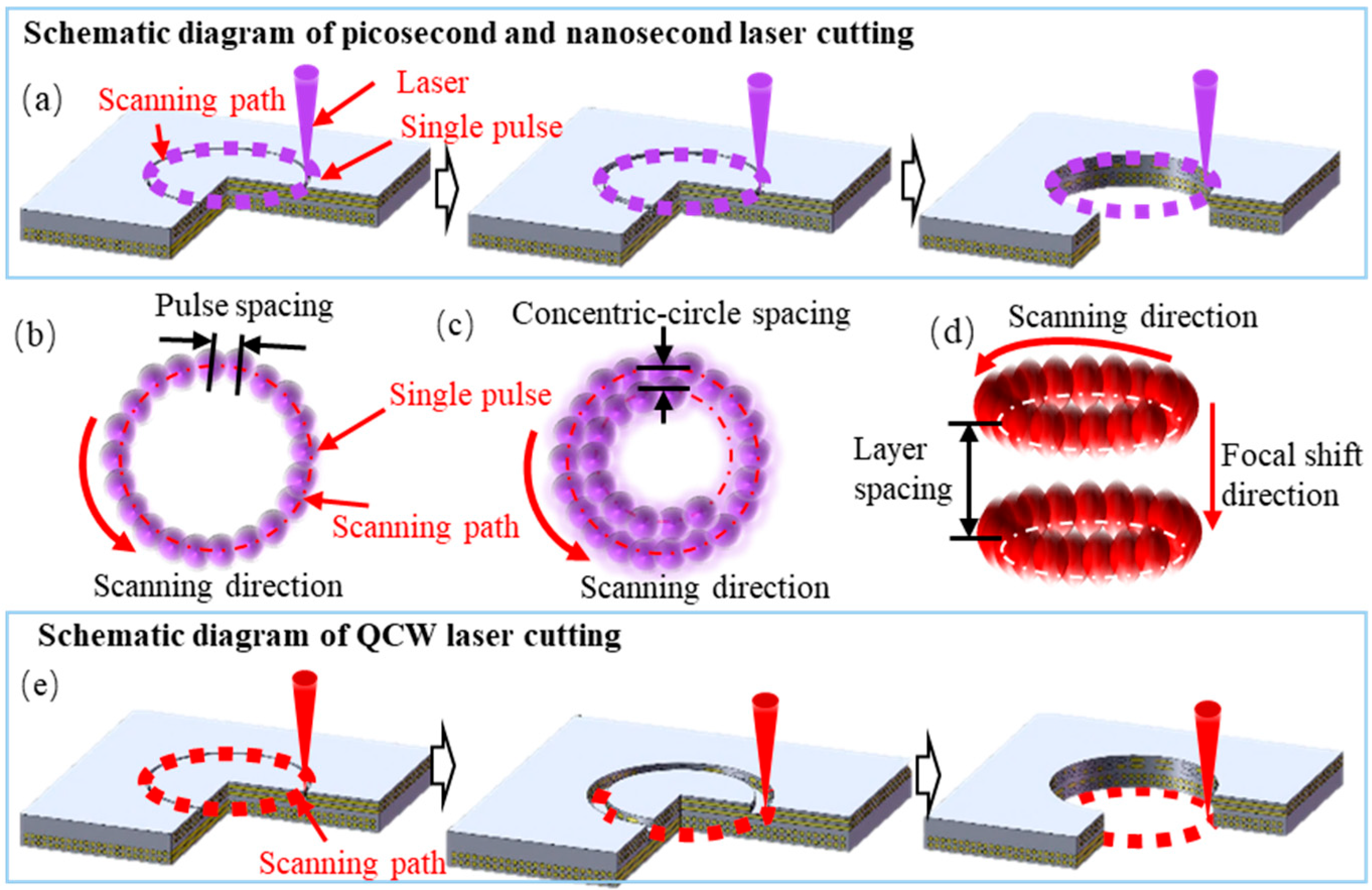

2.3. Method

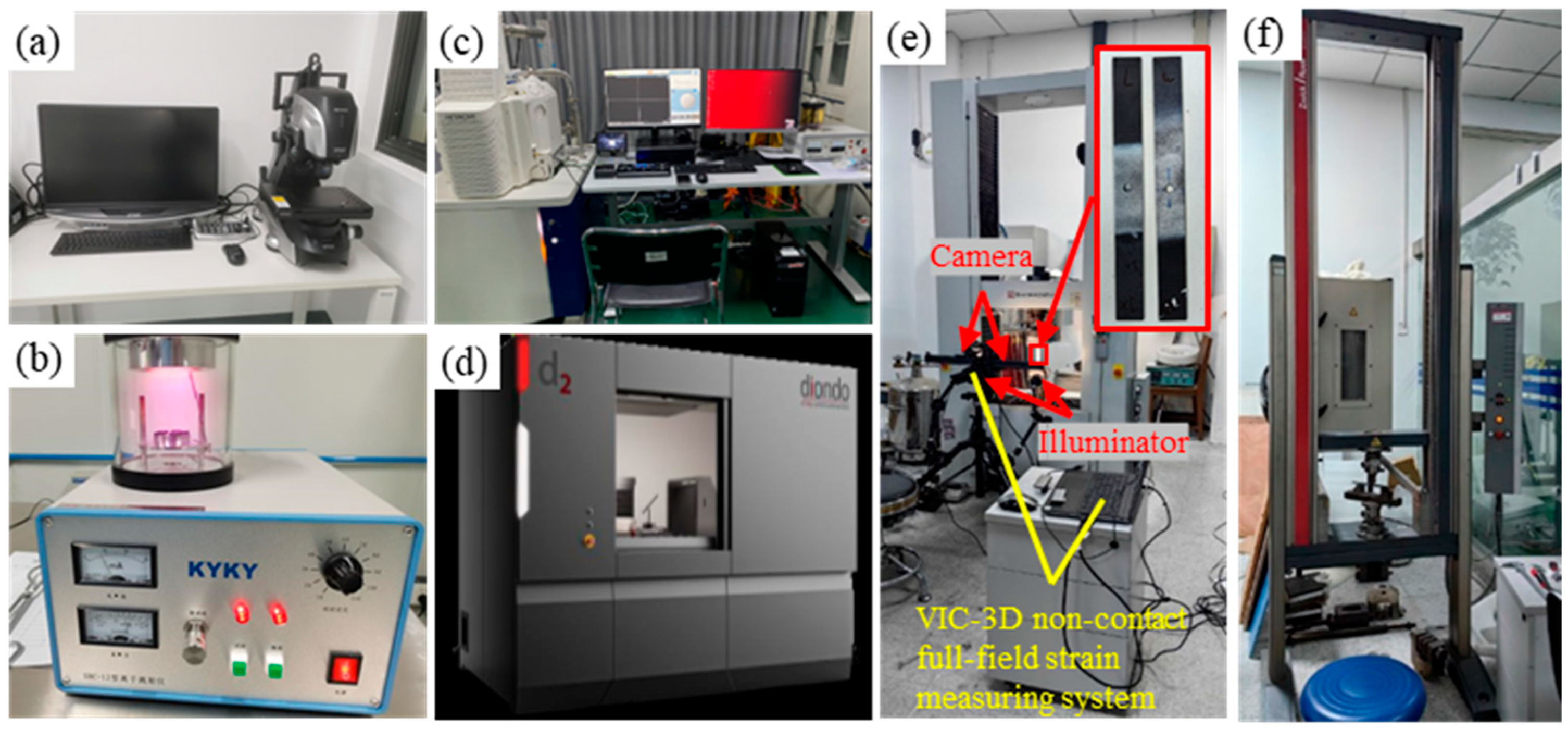

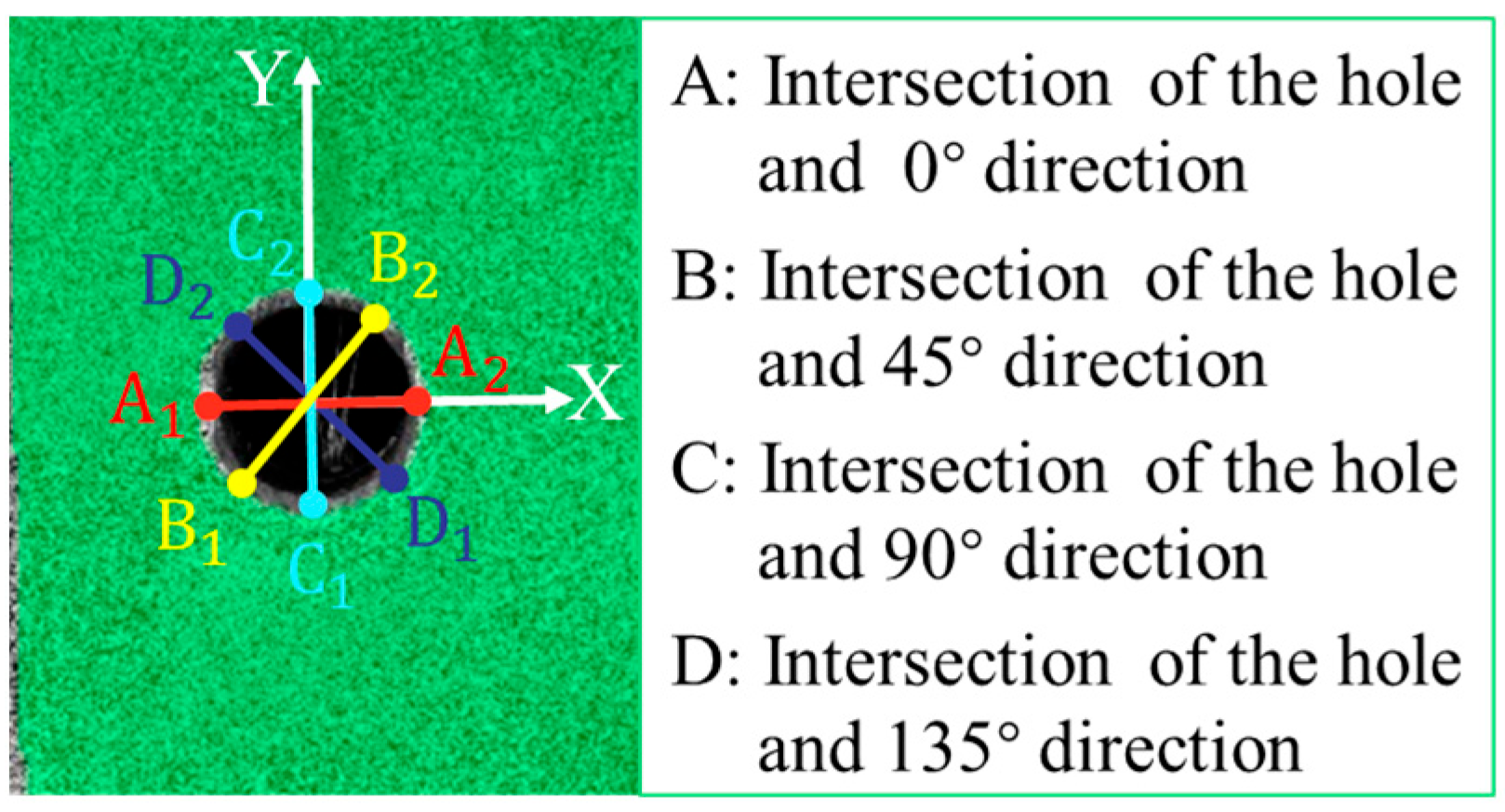

2.4. Measurement

3. Results and Discussion

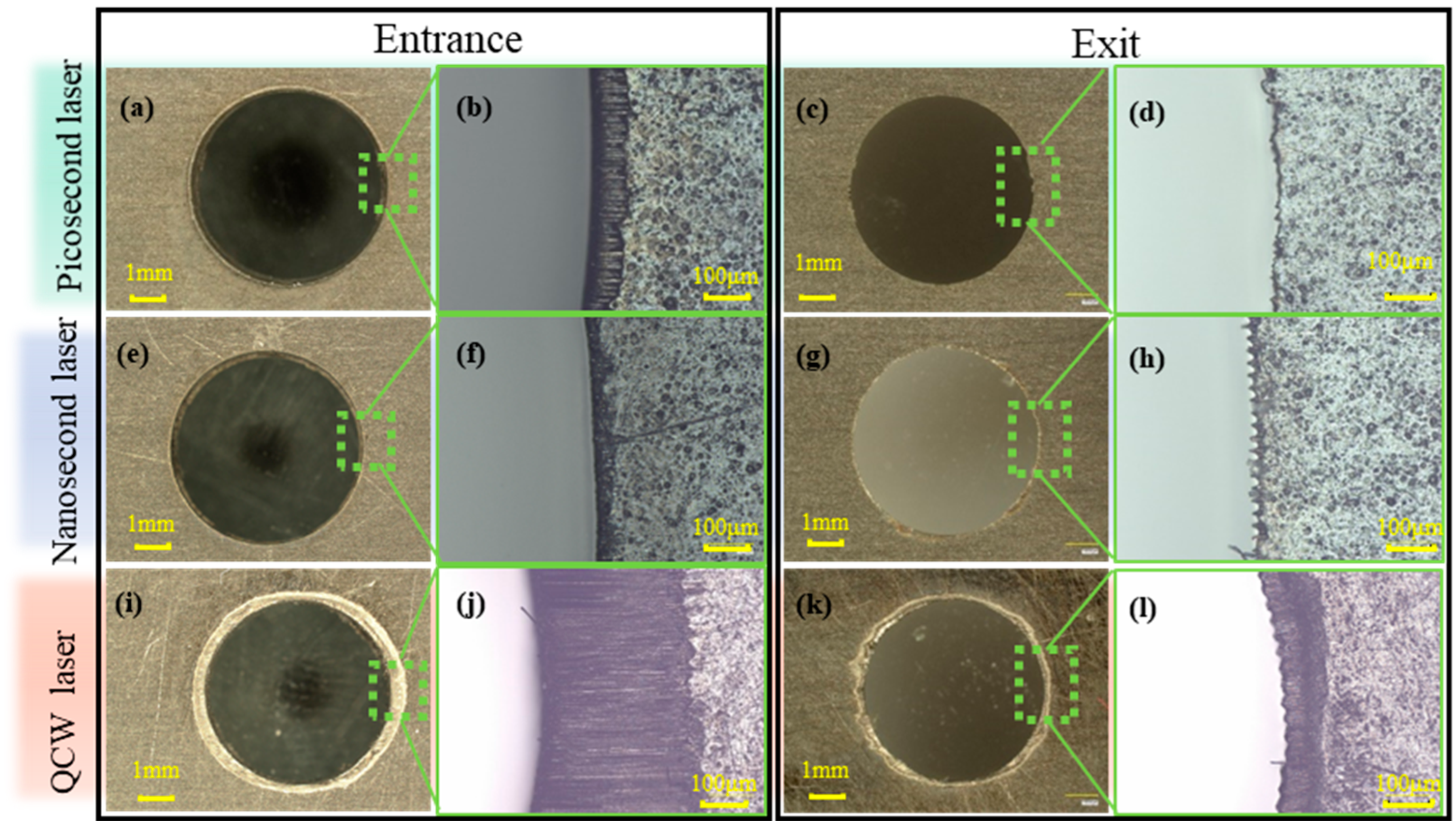

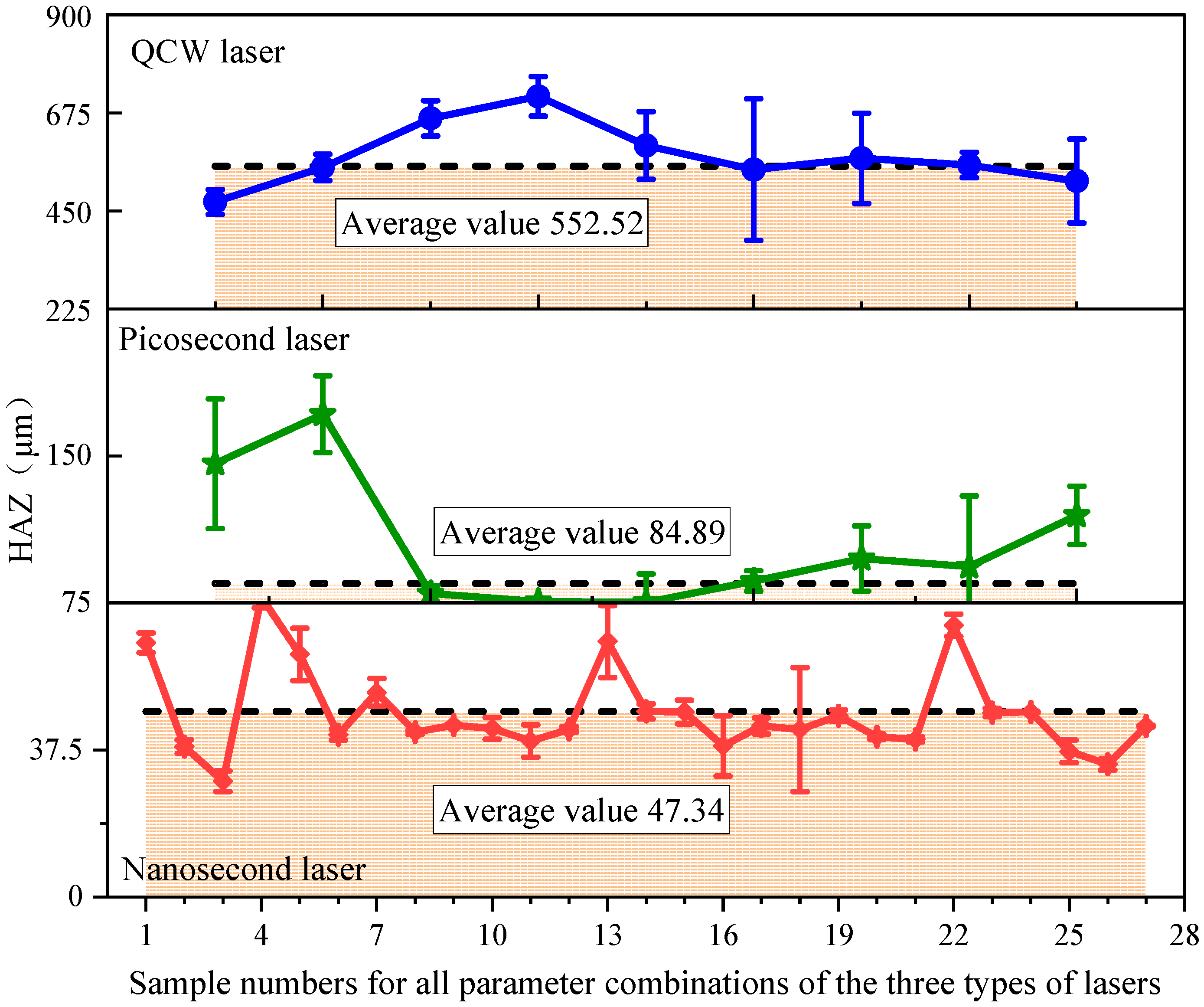

3.1. Influence of Three Distinct Pulse-Width Lasers on HAZ

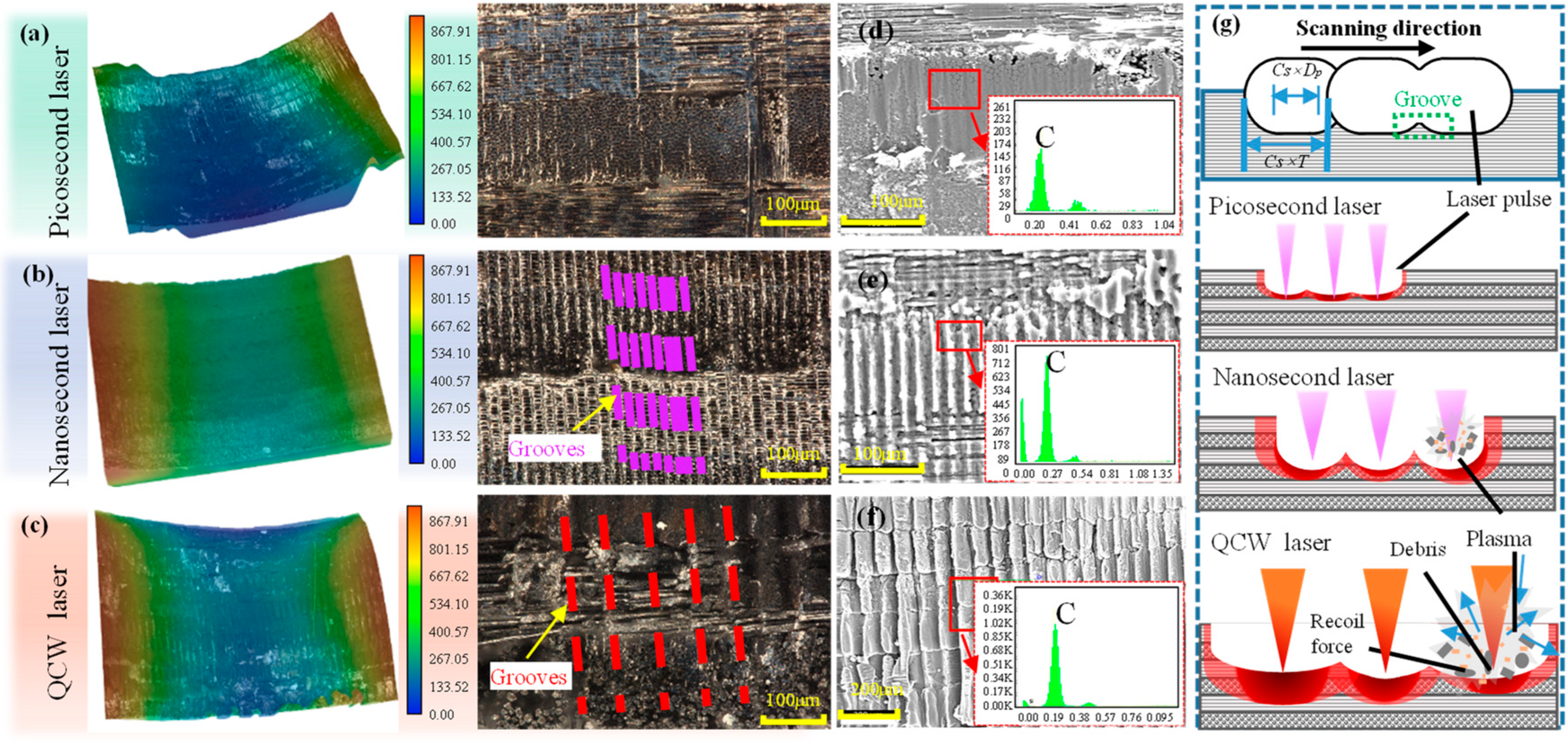

3.2. Influence of Three Distinct Pulse-Width Lasers on Sidewall Structure

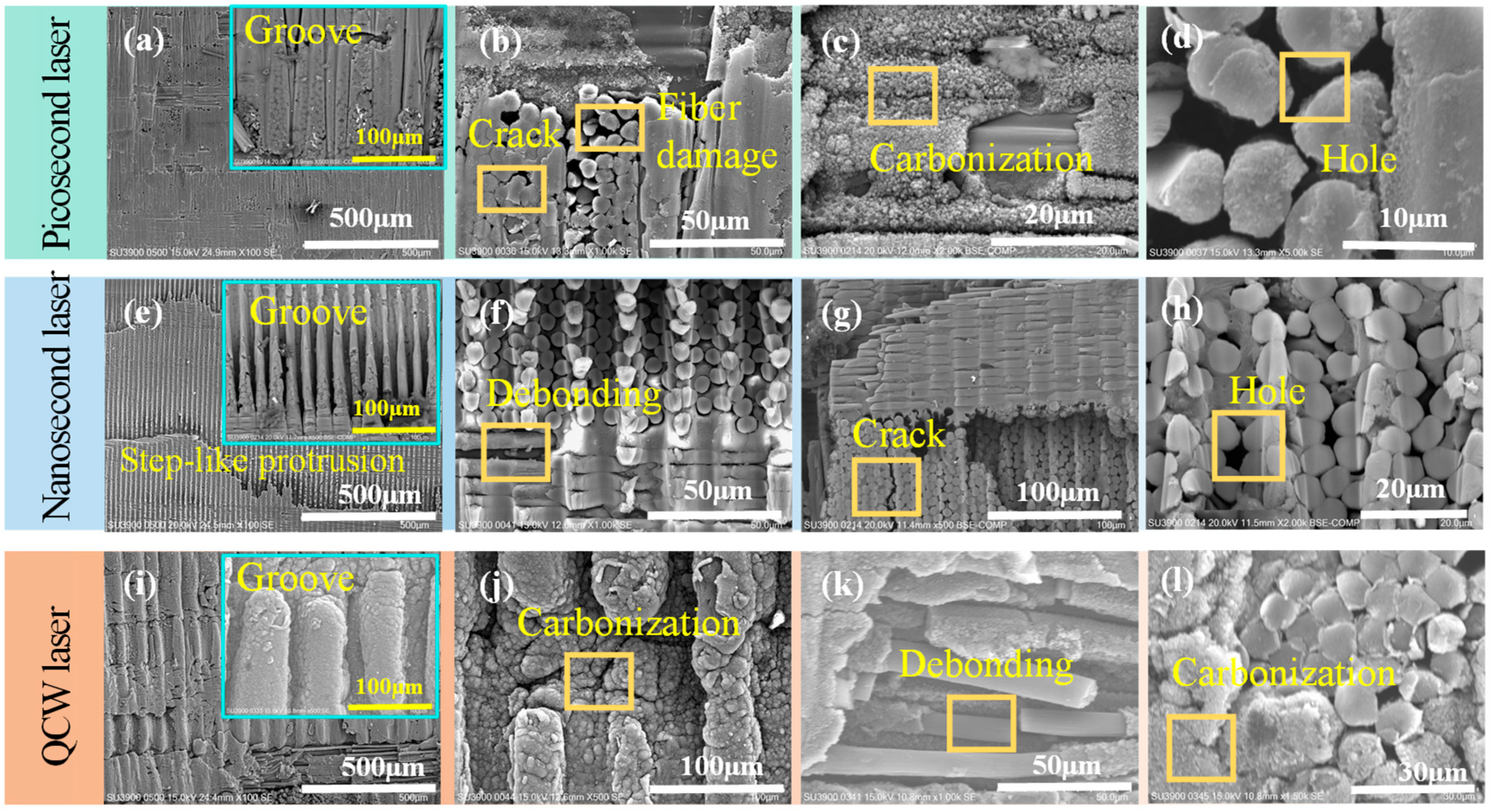

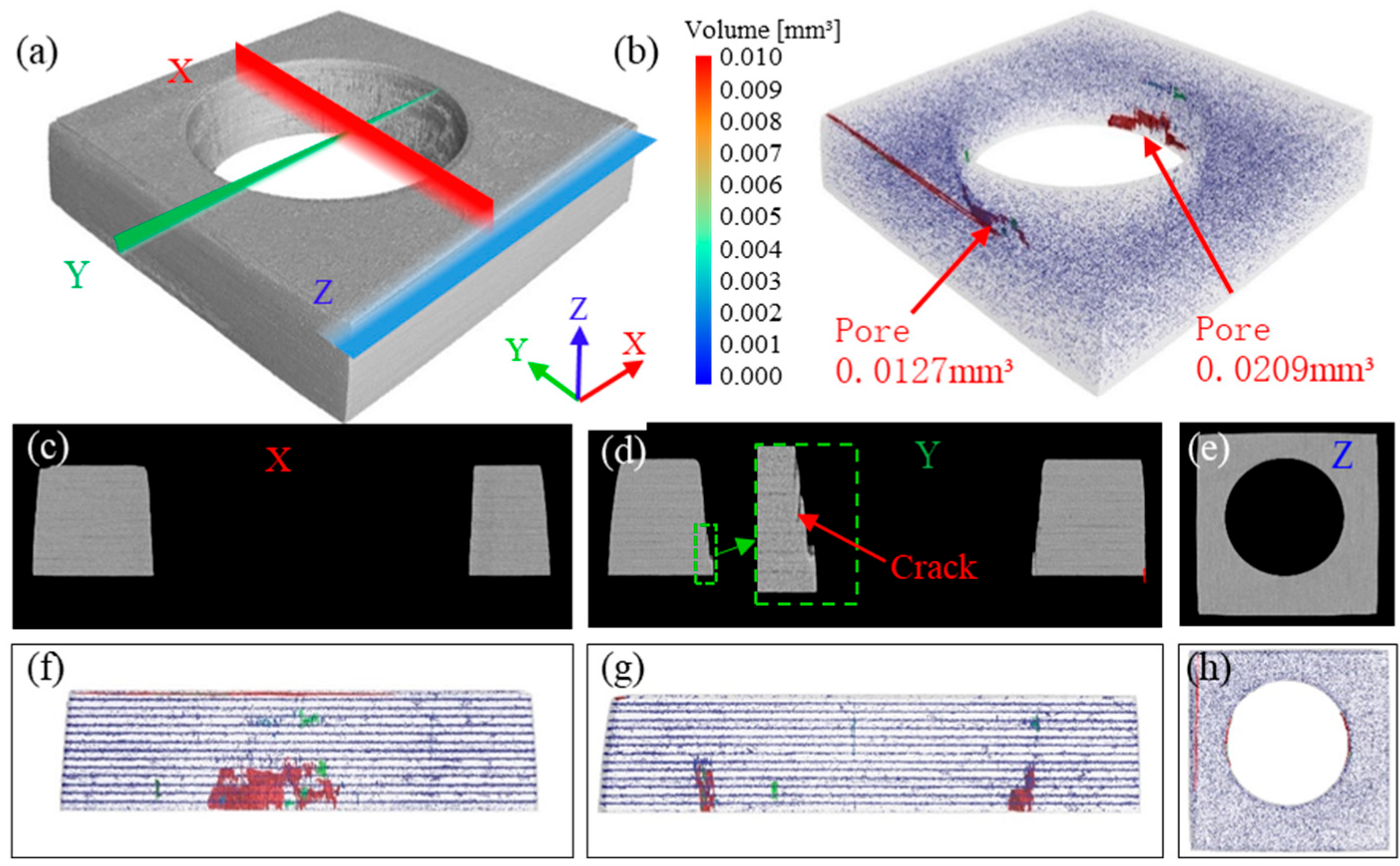

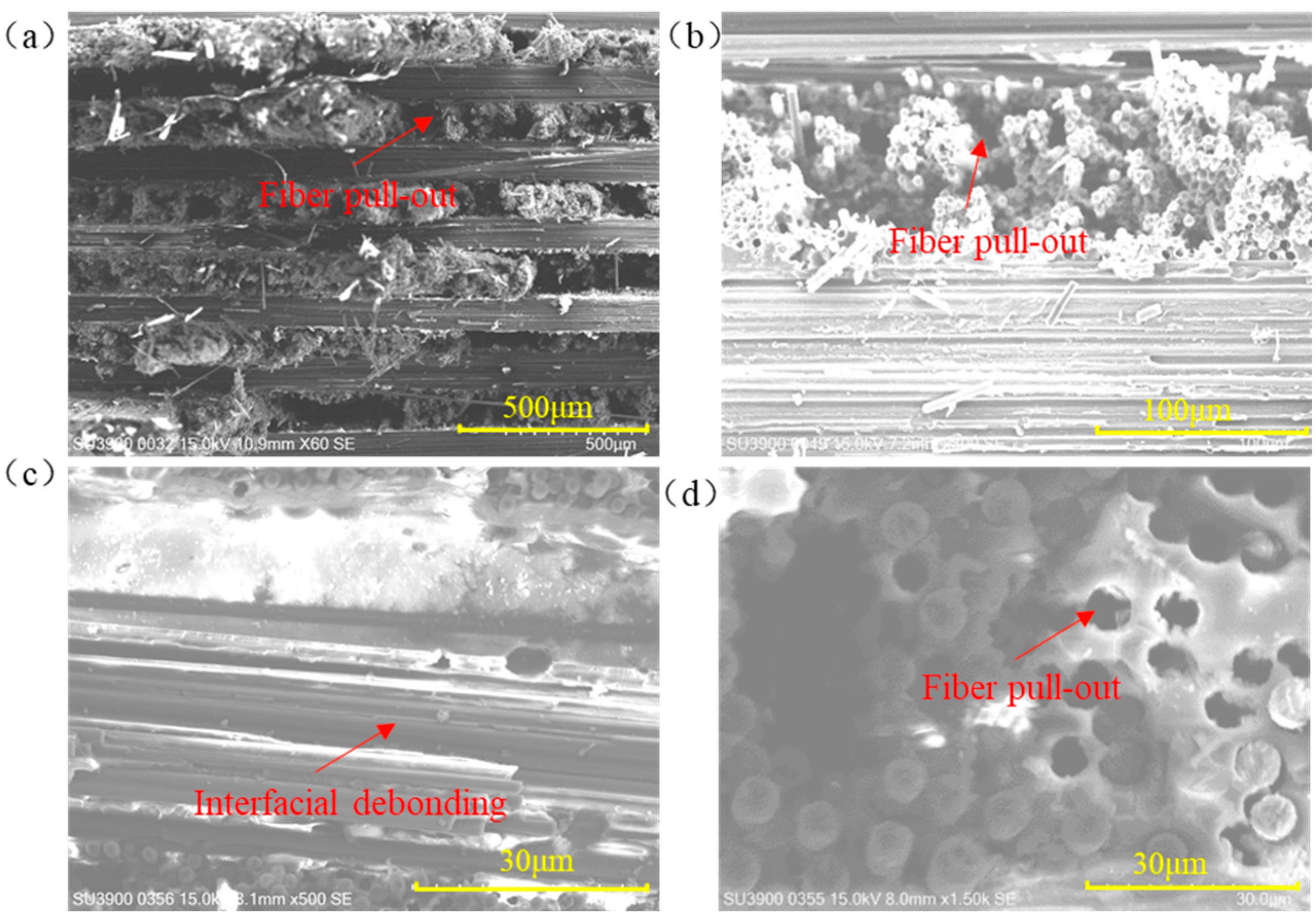

3.3. Influence of Three Distinct Pulse-Width Lasers on Internal Damage

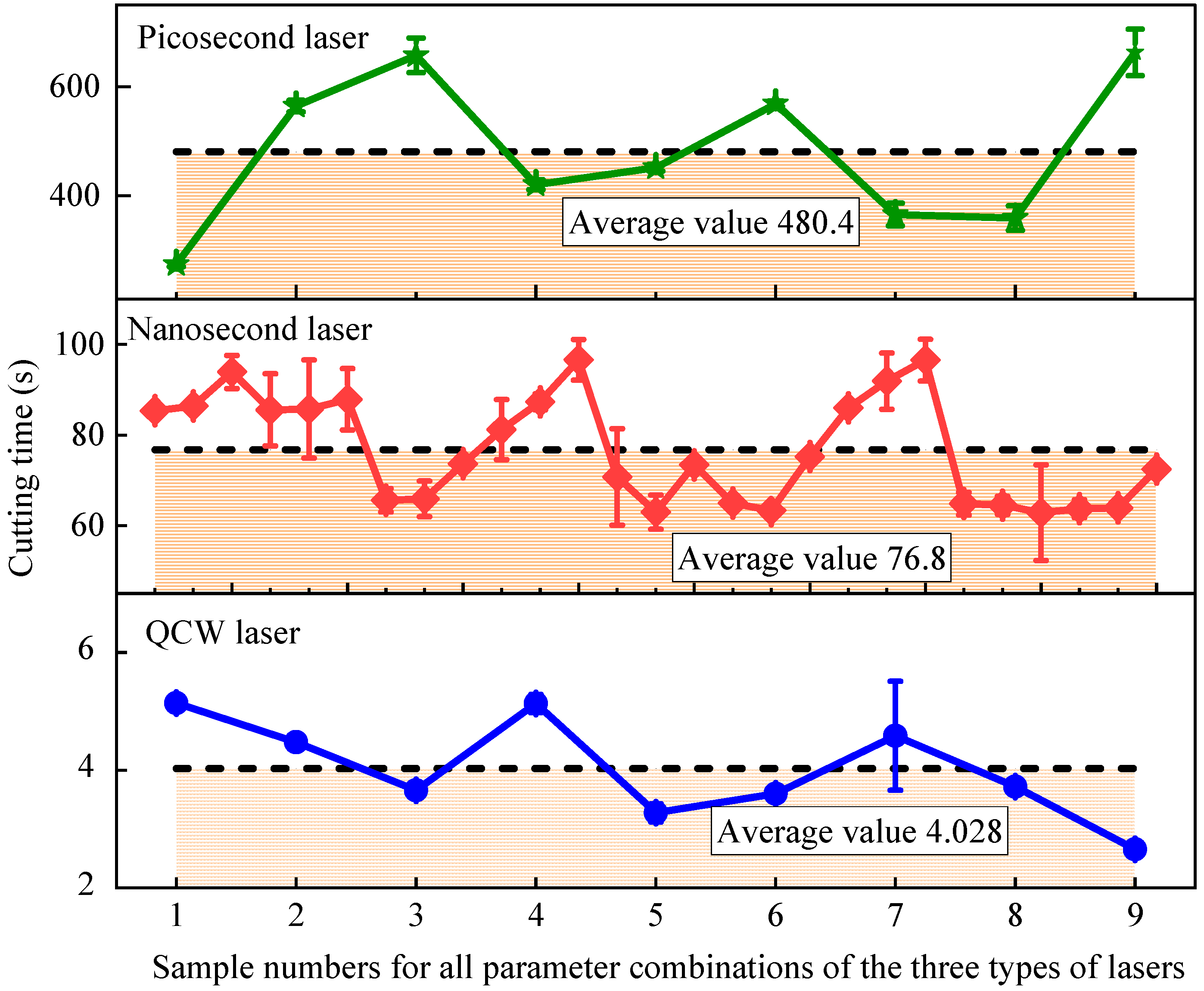

3.4. Influence of Three Distinct Pulse-Width Lasers on Efficiency

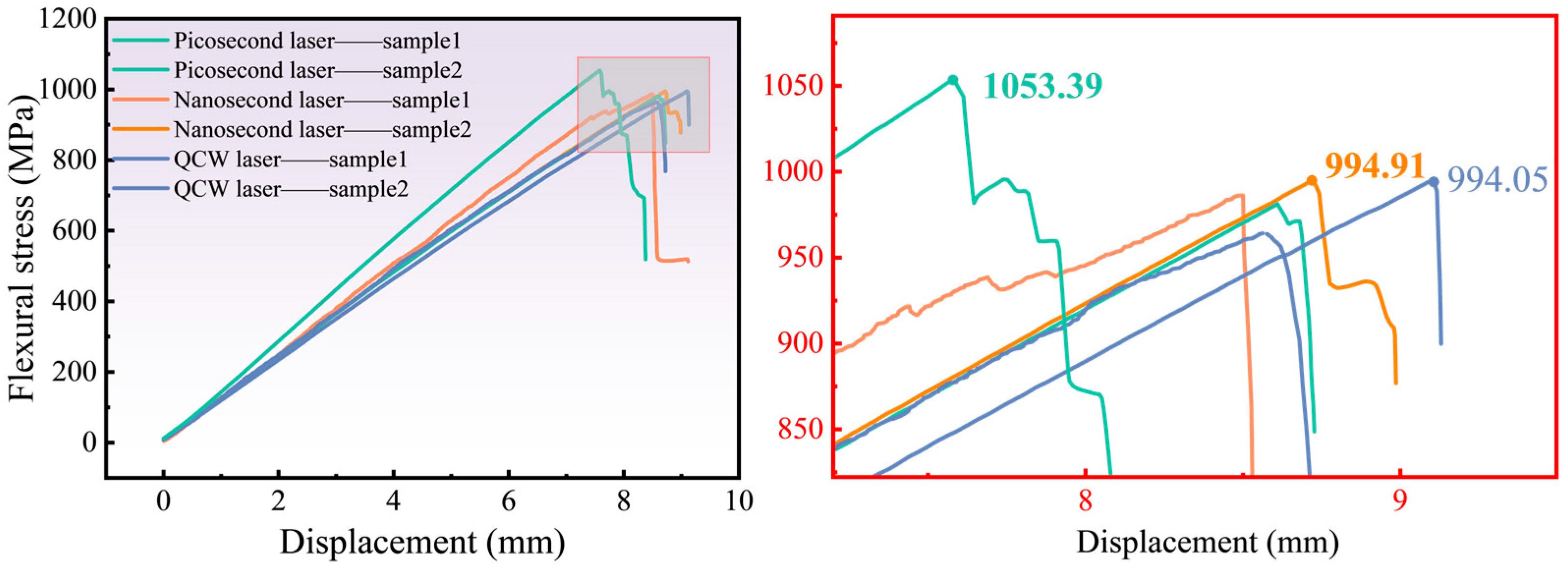

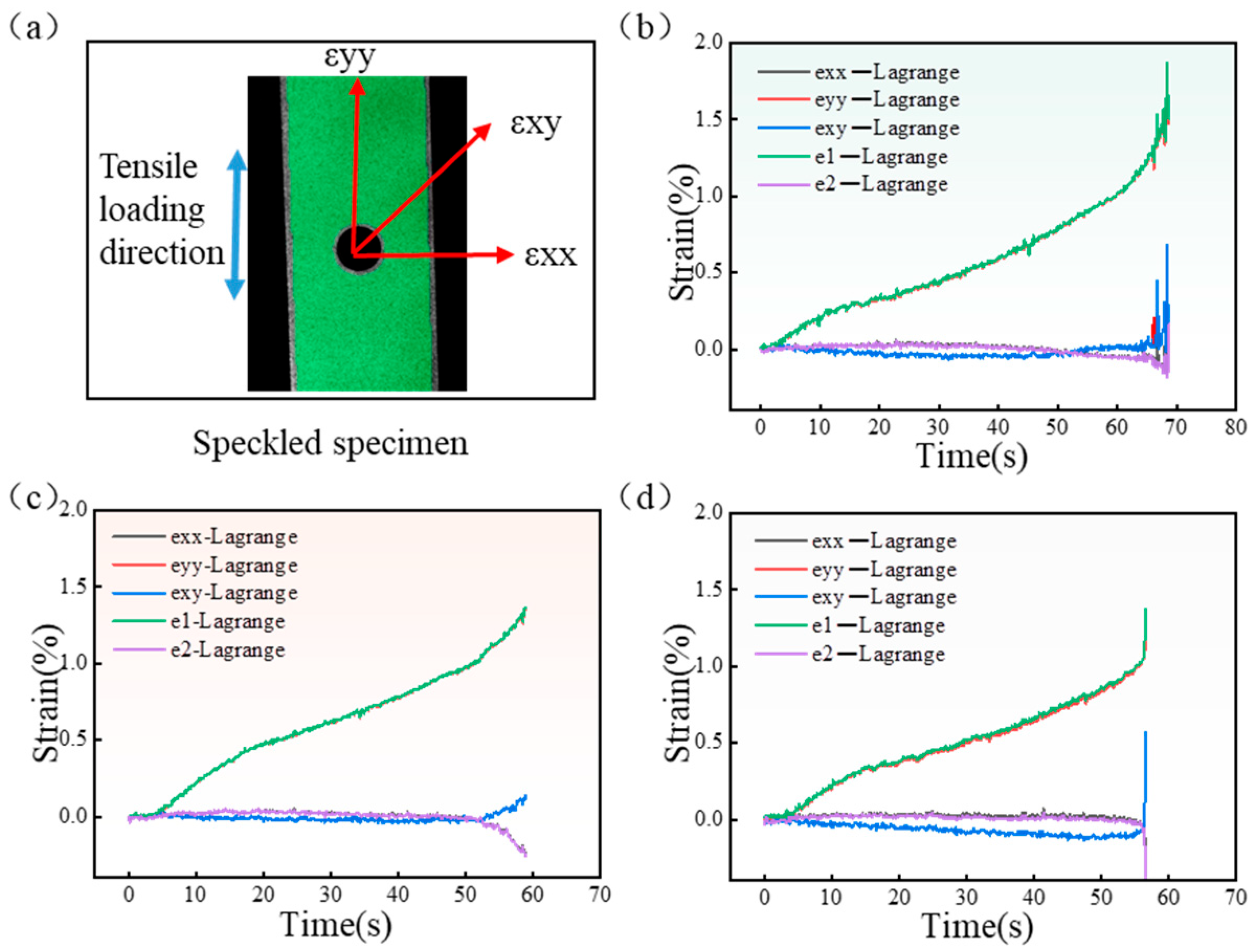

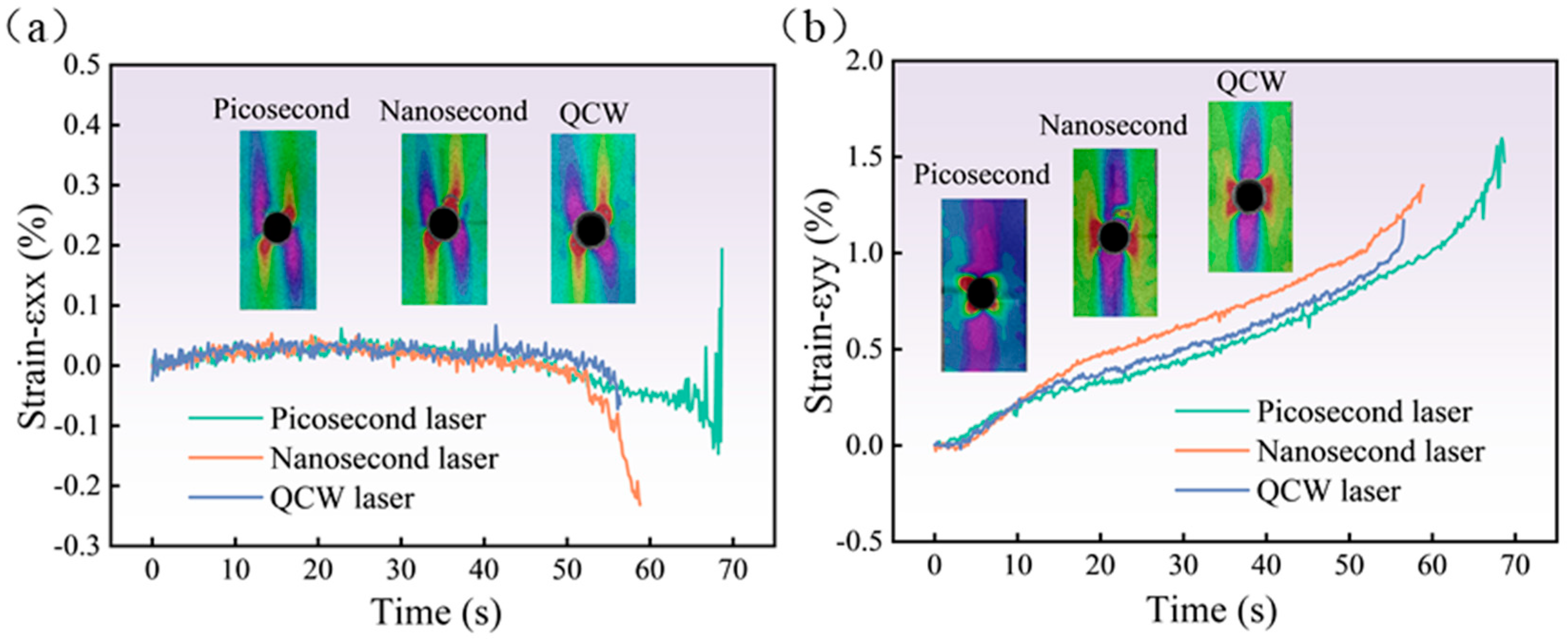

3.5. Influence of Three Distinct Pulse-Width Lasers on Mechanical Properties

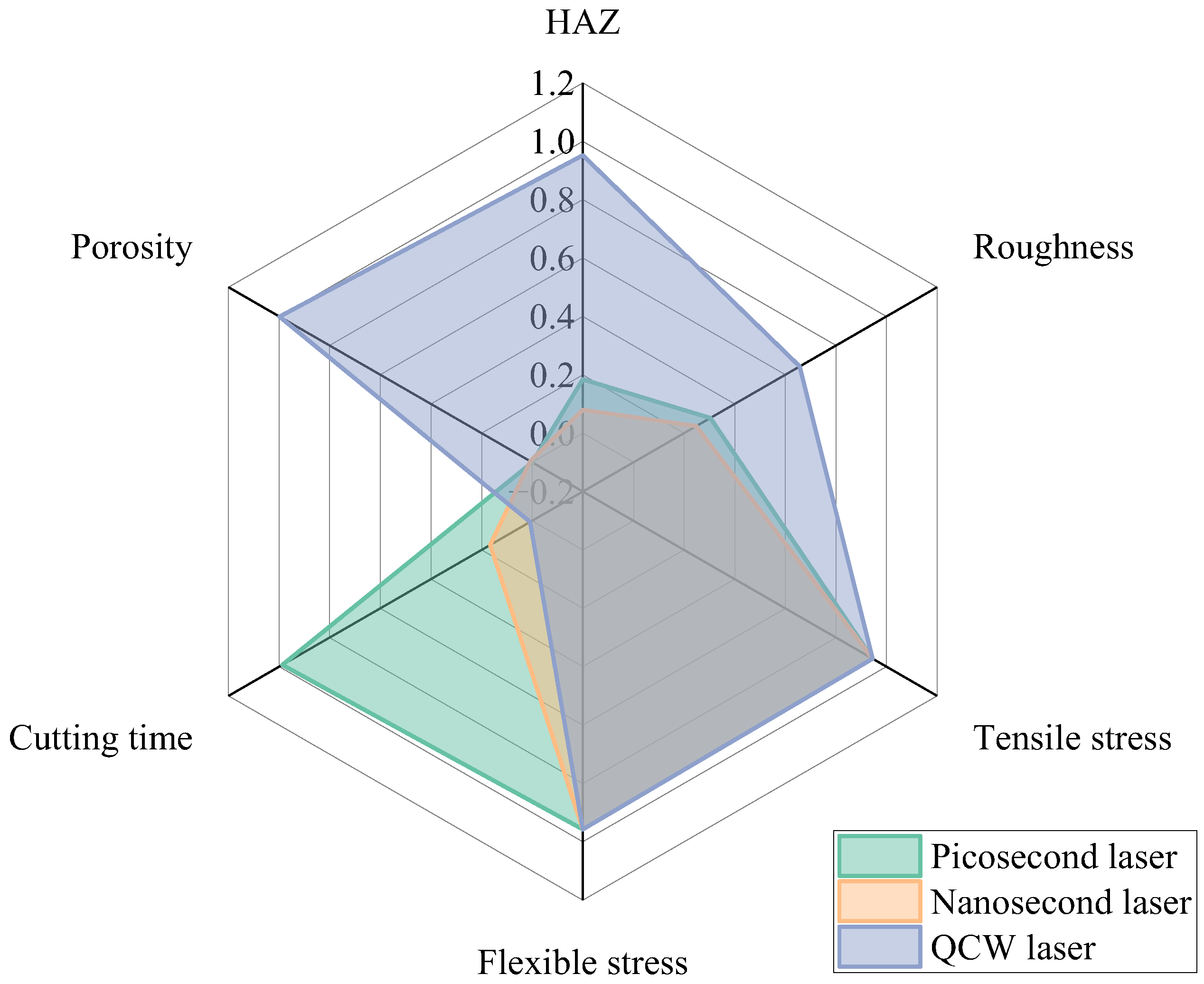

3.6. Application Analysis of Three Distinct Pulse-Width Lasers

4. Conclusions

- (1)

- The laser pulse duration decisively governs the material removal mechanism. Nanosecond pulses, with their moderate energy and duration, deliver the smallest HAZ among the three regimes; picosecond pulses, although ultrashort, suffer from limited average power and residual heat accumulation; and the QCW laser, dominated by sustained heat conduction, generates the largest HAZ (more than 11.6 times that of nanosecond pulses) and pronounced porosity.

- (2)

- Cutting efficiency exhibits an inverse scaling with pulse width. Owing to the six-order-of-magnitude span (10 ps–0.1 ms), single-hole processing time decreases from 480.4 s (picosecond-laser cutting) to 76.8 s (nanosecond-laser cutting) and 4.028 s (QCW-laser cutting), reflecting a transition from thermally driven ablation to mechanical spallation.

- (3)

- A multi-parameter optimization model identifies the following recommended process windows: a nanosecond laser at 200 W and 20 kHz best balances efficiency and quality (HAZ < 50 µm, cutting time < 80 s); a QCW laser is suited for coarse, rate-critical operations; and a picosecond laser remains advantageous for ultraprecision tasks.

- (4)

- CFRP anisotropy and laser-induced damage jointly dictate failure behavior. While all laser regimes yield <5% variation in tensile and flexural strength, they markedly alter damage morphology: longitudinal plies fail by fiber pull-out, producing brush-like fracture surfaces, whereas transverse plies fail via interfacial debonding. In situ DIC and CT imaging reveal that QCW-laser-cut specimens exhibit more uniform strain fields and higher damage tolerance owing to their widened HAZ.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ge, J.; Catalanotti, G.; Falzon, B.G.; Higgins, C.; McClory, C.; Thiebot, J.; Zhang, L.; He, M.; Jin, Y.; Sun, D. Process characteristics, damage mechanisms and challenges in machining of fibre reinforced thermoplastic polymer (FRTP) composites: A review. Compos. Part B Eng. 2024, 273, 111247. [Google Scholar] [CrossRef]

- Li, J.; Jia, B.; Li, B.; Xu, Q.; Huang, H. Effect of seawater and stress coupling on the durability of carbon fibre-reinforced polymer. J. Compos. Mater. 2022, 56, 3925–3937. [Google Scholar] [CrossRef]

- Qi, Z.; Liang, G.; Dai, Y.; Qiu, J.; Hao, H. The effects of countersink depth on fatigue performance of CFRP joint. Int. J. Adv. Manuf. Technol. 2023, 128, 4397–4412. [Google Scholar] [CrossRef]

- Seo, J.; Kim, D.C.; Park, H.; Kang, Y.S.; Park, H.W. Advancements and challenges in the carbon fiber-reinforced polymer (CFRP) trimming process. Int. J. Precis. Eng. Manuf.-Green Technol. 2024, 11, 1341–1360. [Google Scholar] [CrossRef]

- Liang, H.; Zhao, S.; Yu, H.; Jiang, L.; Zhang, Z.; Lin, X. Study on HAZ extension characteristics during laser ablation of CFRP based on dimensional analysis. Compos. Part B Eng. 2024, 275, 111295. [Google Scholar] [CrossRef]

- Wang, T.; Liu, S.; Meng, Z.; Hu, K.; Luo, B.; Zhang, K. Investigation on Hole Quality and Tool Wear of CFRP Drilling With Cryogenic-Minimal Quantity Lubrication. Polym. Compos. 2025, early view.. [CrossRef]

- Zuo, P.; Liu, T.; Li, F.; Wang, G.; Zhang, K.; Li, X.; Han, W.; Tian, H.; Zhu, D. Research progress on laser processing of carbon fiber composite materials. Polym. Compos. 2025, 46, 4992–5017. [Google Scholar] [CrossRef]

- El-Hofy, M.H.; El-Hofy, H. Laser beam machining of carbon fiber reinforced composites: A review. Int. J. Adv. Manuf. Technol. 2019, 101, 2965–2975. [Google Scholar] [CrossRef]

- Jia, Z.; Fu, R.; Wang, F. Research Advance Review of Machining Technology for Carbon Fiber Reinforced Polymer Composite Components. J. Mech. Eng. 2023, 59, 348–374. [Google Scholar]

- Yadav, M.; Tewari, A.; Divse, V.; Yelve, N.P. Exploring the Impact of Drilling Parameters on Damage Morphology and Strength of Carbon Fiber-Reinforced Plastic Laminates. J. Mater. Eng. Perform. 2024, 34, 7371–7385. [Google Scholar] [CrossRef]

- Barik, T.; Parida, S.; Pal, K. Optimizing Process Parameters in Drilling of CFRP Laminates: A Combined MOORA–TOPSIS–VIKOR Approach. Fibers Polym. 2024, 25, 1859–1876. [Google Scholar] [CrossRef]

- Liu, W.; Qin, X.; Li, S.; Wang, X. Experimental research on the matrix cracks and delamination distribution and their monitoring methods during drilling UD-CFRP. Int. J. Adv. Manuf. Technol. 2024, 130, 1595–1615. [Google Scholar] [CrossRef]

- Qu, M.; Song, Y.; Wen, J.; He, W.; Zhu, H.; Liu, K. Effect of nanosecond laser pulse width and energy on damage characteristics in carbon fibre reinforced plastic (CFRP) laminates. Polym. Compos. 2024, 45, 9741–9752. [Google Scholar] [CrossRef]

- Freitag, C.; Kononenko, T.V.; Weber, R.; Konov, V.I.; Graf, T. Influence of pulse repetition rate and pulse energy on the heat accumulation between subsequent laser pulses during laser processing of CFRP with ps pulses. Appl. Phys. A Mater. 2018, 124, 479. [Google Scholar] [CrossRef]

- Li, M.; Li, S.; Yang, X.; Zhang, Y.; Liang, Z. Effect of lay-up configuration and processing parameters on surface quality during fiber laser cutting of CFRP laminates. Int. J. Adv. Manuf. Technol. 2019, 100, 623–635. [Google Scholar] [CrossRef]

- Li, M.; Gan, G.; Zhang, Y.; Yang, X. Thermal damage of CFRP laminate in fiber laser cutting process and its impact on the mechanical behavior and strain distribution. Arch. Civ. Mech. Eng. 2019, 19, 1511–1522. [Google Scholar] [CrossRef]

- Xu, J.; Jing, C.; Jiao, J.; Sun, S.; Sheng, L.; Zhang, Y.; Xia, H.; Zeng, K. Experimental study on carbon fiber-reinforced composites cutting with nanosecond laser. Materials 2022, 15, 6686. [Google Scholar] [CrossRef]

- Chen, X.; Li, W.; Rong, Y.; Zhang, G.; Chen, L.; Huang, Y. Dimethicone-assisted laser cutting of CFRP hole. Arch. Civ. Mech. Eng. 2022, 22, 182. [Google Scholar] [CrossRef]

- Li, W.; Rong, Y.; Huang, Y.; Chen, X.; Chen, L.; Zhang, G. Dimethicone-assisted interlaced scanning compound cutting for regulating thermal damage in CFRP laser cutting by synergistic suppression of coupled heat effect. Compos. Part B Eng. 2023, 266, 110969. [Google Scholar] [CrossRef]

- Heiderscheit, T.; Shen, N.; Wang, Q.; Samanta, A.; Wu, B.; Ding, H. Keyhole cutting of carbon fiber reinforced polymer using a long-duration nanosecond pulse laser. Opt. Lasers Eng. 2019, 120, 101–109. [Google Scholar] [CrossRef]

- Qiao, Y.; Yang, H.; Ding, Y.; Chen, T.; Duan, J.; Xiong, W.; Deng, L. Large scanning field laser concurrent drilling system with a five-axis independent control for special-shaped holes. Opt. Express 2022, 31, 572–584. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ding, Y.; Ge, C.; Sun, X.; Yang, L.; Wang, Y.; Zhang, W.; Lu, Y. Investigations on 355 nm picosecond laser machining of carbon fiber reinforced polymer composites. J. Manuf. Process. 2023, 101, 854–866. [Google Scholar] [CrossRef]

- Ouyang, W.; Jiao, J.; Xu, Z.; Xia, H.; Ye, Y.; Zou QTian, R.; Sheng, L. Experimental study on CFRP drilling with the picosecond laser “double rotation” cutting technique. Opt. Laser Technol. 2021, 142, 107238. [Google Scholar] [CrossRef]

- Leone, C.; Mingione, E.; Genna, S. Laser cutting of CFRP by Quasi-Continuous Wave (QCW) fibre laser: Effect of process parameters and analysis of the HAZ index. Compos. Part B Eng. 2021, 224, 109146. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, J.; Huang, P.; Zhang, G.; Lin, Z.; Zhao, Z.; Huang, Y.; Jiao, H.; Long, Y. Study on the mechanism of quasi-continuous wave (QCW) fiber laser low-damage processing of carbon fiber-reinforced plastics. Int. J. Adv. Manuf. Technol. 2023, 124, 429–447. [Google Scholar] [CrossRef]

- Qin, T.; Zhong, Z.; Jiao, H.; Zhou, L.; Huang, Y.; Long, Y. Experimental study on gas-assisted laser cutting carbon fiber reinforced plastics. Int. J. Adv. Manuf. Technol. 2022, 119, 6361–6370. [Google Scholar] [CrossRef]

- Ye, Y.; Du, T.; Li, H.; Ren, X.; Kong, H.; Ren, N. Factors influencing the tensile strength of carbon fiber reinforced plastic laminates for laser machining method and the underlined mechanisms. J. Laser Appl. 2020, 32, 042011. [Google Scholar] [CrossRef]

- ASTM D5766; Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2018.

- Zhang, J.; Bi, R.; Jiang, S.; Wen, Z.; Luo, C.; Yao, J.; Liu, G.; Chen, C.; Wang, M. Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites. Polymers 2022, 14, 2676. [Google Scholar] [CrossRef]

| Property | Units | Carbon Fiber | Epoxy Resin |

|---|---|---|---|

| Density | kg/m3 | 1800 | 1250 |

| Thermal conductivity | W/(m·K) | 50 (axial) 5 (radial) | 0.2 |

| Specific heat capacity | J/(kg·K) | 710 | 1200 |

| Vaporization temperature | K | 3900 | 400 |

| Volume fraction | % | 67 | 33 |

| System Parameters | Ultrashort-Pulse Laser | Short-Pulse Laser | Long-Pulse Laser |

|---|---|---|---|

| Pulse Width (τ) | 10 ps | <15 ns@60 kHz | 0.05~50 ms |

| Wavelength (λ) | 355 | 355 nm | 1070 |

| Beam Quality (M2) | ≤1.2 | ≤1.2 | 5 mm × mrad |

| Spot Diameter (d0) | 6.8 μm | 37 μm | 74 μm |

| Repetition Rate (F) | ~1 MHz | 10~200 kHz | 0~50 kHz |

| Average Power (Pa) | 35 W | >15 W@60 kHz | 450 W |

| Peak Power (Pp) | - | - | 4500 W |

| Cutting Methods | Parameter 1 | Parameter 2 | Parameter 3 | |||

|---|---|---|---|---|---|---|

| Picosecond | Frequency (kHz) | 400, 500, 600 | Speed (m/s) | 0.3, 0.5, 0.7 | ||

| Nanosecond | Frequency (kHz) | 60, 70, 80 | Speed (mm/s) | 0.3, 0.5, 0.7 | Power (%) | 70, 80, 90 |

| QCW | Frequency (Hz) | 600, 800, 1000 | Power (%) | 70, 80, 90 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Chen, L.; Zhang, G.; Huang, Y.; Ma, H.; Rong, Y. Effect of Laser Pulse Width on Cutting Quality and Efficiency in CFRP: Mechanism and Optimization. Materials 2025, 18, 4707. https://doi.org/10.3390/ma18204707

Chen C, Chen L, Zhang G, Huang Y, Ma H, Rong Y. Effect of Laser Pulse Width on Cutting Quality and Efficiency in CFRP: Mechanism and Optimization. Materials. 2025; 18(20):4707. https://doi.org/10.3390/ma18204707

Chicago/Turabian StyleChen, Chunmeng, Long Chen, Guojun Zhang, Yu Huang, Huijuan Ma, and Youmin Rong. 2025. "Effect of Laser Pulse Width on Cutting Quality and Efficiency in CFRP: Mechanism and Optimization" Materials 18, no. 20: 4707. https://doi.org/10.3390/ma18204707

APA StyleChen, C., Chen, L., Zhang, G., Huang, Y., Ma, H., & Rong, Y. (2025). Effect of Laser Pulse Width on Cutting Quality and Efficiency in CFRP: Mechanism and Optimization. Materials, 18(20), 4707. https://doi.org/10.3390/ma18204707