Composting Poultry Feathers with Keratinolytic Bacillus subtilis: Effects on Degradation Efficiency and Compost Maturity

Abstract

1. Introduction

2. Materials and Methods

2.1. The Keratinous Substrate

2.2. Keratinolytic Bacteria

2.3. Feather Degradation in Submerged Cultures

2.4. Feather Degradation in Solid State Cultures and Compost

2.5. Determination of Proteolytic and Keratinolytic Activity

2.6. Characterization of Proteases and Keratinases

- % Inhibition = 100%−(I/C) 100%

- % Activation = (A/C) 100%−100%, where

- I—proteolytic activity in the presence of an inhibitor

- A—proteolytic activity in the presence of an activator

- C—proteolytic activity in the control sample

2.7. Measurement of Keratin Degradation Products

2.8. Determination of Protease and Dehydrogenase Activity in Solid-State Cultures

2.9. Chemical Analysis of Compost

- Cw—water-soluble carbon in water with a sample to water mass ratio of 1:20,

- Ck—carbon soluble in sulfuric acid (VI) (proteins, hemicellulose, fulvic acids) extracted with 5% sulfuric acid at 80 °C,

- Cbit—compounds from the bitumen group extracted with a mixture of ethyl alcohol:benzene (1:2).

2.10. Statistical Analysis

3. Results and Discussion

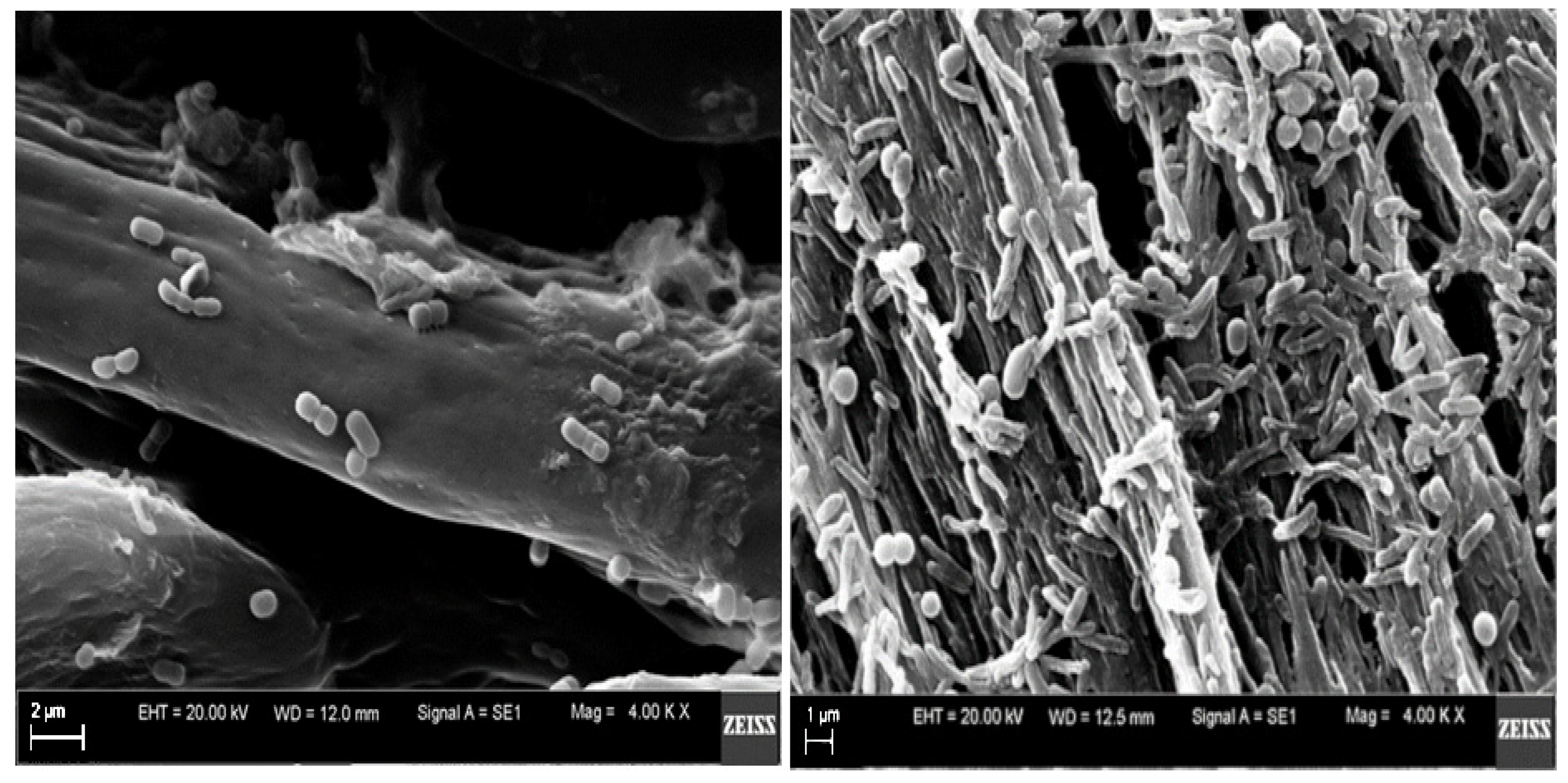

3.1. Degradation of Feather Keratin in Submerged Culture

3.2. Characterization of Proteases and Keratinases of B. subtilis P22

3.3. Degradation of Feather Keratin in Solid-State Culture

3.4. Composting of Feathers on Semi-Technical Scale

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PMSF | Phenyl methyl sulfonic acid fluoride |

| NEM | N-Ethyl maleimide |

| EDTA | Ethylene diamine tetraacetic acid disodium salt |

References

- Patil, S.; Patil, R.; Wagh, C.; Kavathekar, B.; Raorane, C.; Aruna, K. Microbial degradation of poultry feather biomass in a constructed bioreactor and evaluation of degraded product as a biofertilizer. Int. J. Res. Eng. Appl. Manag. 2023, 9, 76–83. [Google Scholar] [CrossRef]

- Możejko, M.; Bohacz, J. Optimization of Conditions for Feather Waste Biodegradation by Geophilic Trichophyton ajelloi Fungal Strains towards Further Agricultural Use. Int. J. Environ. Res. Public Health 2022, 19, 10858. [Google Scholar] [CrossRef]

- Samira Alahyaribeik, S.; Zubair, M.; Ullah, A. Eco-friendly innovations for enhancing value from farm to function using poultry feathers. Process Biochem. 2024, 147, 402–417. [Google Scholar] [CrossRef]

- Choińska-Pulit, A.; Łaba, W.; Rodziewicz, A. Enhancement of pig bristles waste bioconversion by inoculum of keratinolytic bacteria during composting. Waste Manag. 2019, 84, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Pereira, J.Q.; Lopes, F.C.; Petry, M.V.; da Medina, L.F.C.; Brandelli, A. Isolation of three novel Antarctic psychrotolerant feather-degrading bacteria and partial purification of keratinolytic enzyme from Lysobacter sp. A03. Int. Biodeterior. Biodegrad. 2014, 88, 1–7. [Google Scholar] [CrossRef]

- Tamilkani, P.; Karnan, M.; Kanimozhi, K.; Panneerselvam, A. Screening of keratinolytic bacteria from keratin waste dumped soil in Thanjavur (Dt), Tamil Nadu, India. Int. J. Pharm. Pharma. Res. 2017, 8, 25–32. [Google Scholar]

- Chaisemsaeng, P.; Sabu, A.; Ansanan, S.; Sirisan, S. Feather degradation and keratinase production by Bacillus sp. and Lactobacillus sp. Int. J. Bio-Tech. Res. 2017, 7, 29–36. [Google Scholar] [CrossRef]

- Prajapati, S.; Koirala, S.; Anal, A.K. Bioutilization of chicken feather waste by newly isolated keratinolytic bacteria and conversion into protein hydrolysates with improved functionalities. Appl. Biochem. Biotechnol. 2021, 193, 2497–2515. [Google Scholar] [CrossRef]

- Brandelli, A.; Sala, L.; Kalil, S.J. Microbial enzymes for bioconversion of poultry waste into added–value products. Food Res. Int. 2015, 73, 3–12. [Google Scholar] [CrossRef]

- Samuel, P.; Maheswari, M.; Vijayakumar, J.; Selvarathinam, T.; Amirtharaj, K.; Deenathayalan, R. Bio-prospecting of marine-derived fungi with special reference to production of ecovaluable enzyme keratinase-a need-based optimization study. J. Appl. Biol. Biotech. 2018, 6, 35–41. [Google Scholar] [CrossRef]

- Haq, I.; Akram, F.; Jabbar, Z. Keratinolytic enzyme-mediated biodegradation of recalcitrant poultry feathers waste by newly isolated Bacillus sp. NKSP-7 under submerged fermentation. Folia Microbiol. 2020, 65, 823–834. [Google Scholar] [CrossRef]

- Li, Z.W.; Liang, S.; Ke, Y.; Deng, J.J.; Zhang, M.S.; Lu, D.L.; Li, J.Z.; Luo, X.C. The feather degradation mechanisms of a new Streptomyces sp. isolate SCUT-3. Commun. Biol. 2020, 3, 191. [Google Scholar] [CrossRef]

- Al-Bedak, O.A.-H.M.; Moharram, A.M.; Hussein, N.A.-G.; Taha, D.M.; Stephenson, S.L.; Ameen, F. Microbial Exploitation of Feather Wastes for Sustainable Production of Keratinase and Collagenase Enzymes by Didymella keratinophila AUMC 15399 in Submerged Fermentation. Fermentation 2023, 9, 507. [Google Scholar] [CrossRef]

- Tamreihao, K.; Mukherjee, S.; Khunjamayum, R.; Devi, L.J.; Asem, R.S.; Ningthoujam, D.S. Feather degradation by keratinolytic bacteria and biofertilizing potential for sustainable agricultural production. J. Basic Microbiol. 2019, 59, 4–13. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, B.; Khatri, M.; Singh, G.; Arya, S.K. Microbial keratinases: An overview of biochemical characterization and its eco-friendly approach for industrial applications. J. Clean. Prod. 2020, 252, 119847. [Google Scholar] [CrossRef]

- Riaz, A.; Muzzamal, H.; Maqsood, B.; Naz, S.; Latif, F.; Saleem, M. Characterization of a Bacterial Keratinolytic Protease for Effective Degradation of Chicken Feather Waste into Feather Protein Hydrolysates. Front. Biosci. 2024, 16, 22. [Google Scholar] [CrossRef]

- Suharti, S.; Riesmi, M.T.; Hidayati, A.; Zuhriyah, U.F.; Wonorahardjo, S.; Susanti, E. Enzymatic dehairing of goat skin using keratinase from Bacillus sp. MD24, a newly isolated soil bacterium. Pertanika J. Trop. Agric. Sci. 2018, 41, 1449–1461. [Google Scholar]

- Łaba, W.; Rodziewicz, A. Biodegradation of keratinous wastes from poultry industry involving bacteria of genera Bacillus and Sarcina. Acta Sci. Pol. Biotechnol. 2004, 3, 109–120. [Google Scholar]

- Bohacz, J. Lignocellulose–degrading enzymes, free–radical transformations during composting of lignocellulosic waste andbiothermal phases in small–scale reactors. Sci. Total Environ. 2017, 580, 744–754. [Google Scholar] [CrossRef]

- Joardar, J.C.; Rahman, M.M. Poultry feather waste management and effects on plant growth. Int. J. Recycl. Org. Waste Agric. 2018, 7, 183–188. [Google Scholar] [CrossRef]

- Vargas-García, M.C.; Suarez-Estrella, F.; Lopez, M.J.; Moreno, J. Microbial population dynamics and enzyme activities in composting processes with different starting materials. Waste Manag. 2010, 30, 771–778. [Google Scholar] [CrossRef]

- Liu, D.Y.; Zhang, R.F.; Wu, H.S.; Xu, D.; Tang, Z.; Yu, G.H.; Xu, Z.H.; Shen, Q.R. Changes in biochemical and microbiological parameters during the period of rapid composting of dairy manure with rice chaff. Bioresour. Technol. 2011, 102, 9040–9049. [Google Scholar] [CrossRef] [PubMed]

- Tesfaye, T.; Sithole, B.; Ramjugernath, D. Valorisation of chicken feathers: A review on recycling and recovery route-current status and future prospects. Clean Technol. Environ. Policy 2017, 19, 2363–2378. [Google Scholar] [CrossRef]

- Pylak, M.; Oszust, K.; Frąc, M. Review report on the role of bioproducts, biopreparations, biostimulants and microbial inoculants in organic production of fruit. Rev. Environ. Sci. Biol. 2019, 18, 597–616. [Google Scholar] [CrossRef]

- Timpanaro, G.; Foti, V.T.; Cascone, G.; Trovato, M.; Grasso, A.; Vindigni, G. Living Lab for the Diffusion of Enabling Technologies in Agriculture: The Case of Sicily in the Mediterranean Context. Agriculture 2024, 14, 2347. [Google Scholar] [CrossRef]

- Łaba, W.; Piegza, M.; Kawa-Rygielska, J. Evaluation of brewer’s spent grain as a substrate for production of hydrolytic enzymes by keratinolytic bacteria. J. Chem. Technol. Biotechnol. 2017, 92, 1389–1396. [Google Scholar] [CrossRef]

- Rodziewicz, A.; Łaba, W. Biodegradation of feather keratin by Bacillus cereus in pure culture and compost. Electron. J. Pol. Agric. Univ. 2008, 11, 2. [Google Scholar]

- Ostrowska, A.; Gawliński, S.; Szczubiałka, Z. Metody Analizy i Oceny Właściwości Gleb i Roślin; Dział Wydawnictw Instytutu Ochrony środowiska: Warsaw, Poland, 1991. [Google Scholar]

- Łaba, W.; Choińska-Pulit, A.; Rodziewicz, A.; Piegza, M. Keratinolytic abilities of Micrococcus luteus from poultry waste. Braz. J. Microbiol. 2015, 46, 691–700. [Google Scholar] [CrossRef]

- Riener, C.K.; Kada, G.; Gruber, H.J. Quick measurement of protein sulfhydrylswith Ellman’s reagent and with 4,4’-dithiodipyridine. Anal. Bioanalitycal Chem. 2002, 373, 266–276. [Google Scholar] [CrossRef]

- Ladd, J.N.; Butler, J.H.A. Short-term assays of soil proteolytic activities using proteins and dipeptide derivatives as substrates. Soil Biol. Biochem. 1972, 4, 19–33. [Google Scholar] [CrossRef]

- Stevenson, F.J. Humus Chemistry: Genesis, Compositions, Reactions; John Wiley and Sons: New York, NY, USA, 1994. [Google Scholar]

- Kim, J.M.; Lim, W.J.; Suh, H.J. Feather-degrading Bacillus species from poultry waste. Process Biochem. 2001, 37, 287–291. [Google Scholar] [CrossRef]

- Korniłłowicz–Kowalska, T. Studies on the decomposition of keratin wastes by saprotrophic microfungi. I. Criteria for evaluating keratinolytic activity. Acta Mycol. 1997, 32, 51–79. [Google Scholar] [CrossRef]

- Gurav, R.G.; Tang, J.; Jadhav, J.P. Sulfitolytic and keratinolytic potential of Chryseobacterium sp. RBT revealed hydrolysis of melanin containing feathers. 3Biotech 2016, 6, 145. [Google Scholar] [CrossRef]

- Gerlicz, W.; Sypka, M.; Jodłowska, I.; Białkowska, A.M. Isolation, Selection, and Identification of Keratinolytic Bacteria for Green Management of Keratin Waste. Molecules 2024, 29, 3380. [Google Scholar] [CrossRef]

- Aktayeva, S.; Khassenov, B. High keratinase and other types of hydrolase activity of the new strain of Bacillus paralicheniformis. PLoS ONE 2024, 19, e0312679. [Google Scholar] [CrossRef] [PubMed]

- Brandelli, A. Bacterial Keratinases: Useful Enzymes for Bioprocessing Agroindustrial Wastes and Beyond. Food Bioprocess Technol. 2008, 1, 105–116. [Google Scholar] [CrossRef]

- Contesini, F.J.; Melo, R.R.; Sato, H.H. An overview of Bacillus proteases: From production to application. Crit. Rev. Biotechnol. 2018, 38, 321–334. [Google Scholar] [CrossRef] [PubMed]

- Mehraban, S.; Bahreini, M.; Assodeh, A.; Sharifmoghadam, M.R. Enhancing keratinase production by a native Bacillus paralicheniformis FUM-2 through random mutagenesis using chemical agent and ultraviolet. Microbiol. Metab. Biotechnol. 2023, 6, 63–72. [Google Scholar] [CrossRef]

- Nagarajan, S.; Eswaran, P.; Masilamani, R.; Natarajan, H. Chicken Feather Compost to Promote the Plant Growth Activity by Using Keratinolytic Bacteria. Waste Biomass Valor. 2018, 9, 531–538. [Google Scholar] [CrossRef]

- Łaba, W.; Żarowska, B.; Chorążyk, D.; Pudło, A.; Piegza, M.; Kancelista, A.; Kopeć, W.; Łaba, W. New keratinolytic bacteria in valorization of chicken feather waste. AMB Express 2018, 8, 9. [Google Scholar] [CrossRef]

- Harwood, C.R.; Kikuchi, Y. The ins and outs of Bacillus proteases: Activities, functions and commercial significance. FEMS Microbiol. Rev. 2022, 46, fuab046. [Google Scholar] [CrossRef]

- Mazotto, A.M.; Cedrola, S.M.L.; de Souza, E.P.; Couri, S.; Alane, B.; Vermelho, A.B. Enhanced keratinase production by Bacillus subtilis amr using experimental optimization tools to obtain feather protein lysate for industrial applications. 3Biotech 2022, 12, 90. [Google Scholar] [CrossRef]

- Park, G.T.; Son, H.J. Keratinolytic activity of Bacillus megaterium F7-1, a feather-degrading mesophilic bacterium. Microbiol. Res. 2009, 164, 478–485. [Google Scholar] [CrossRef]

- Moussa, Z.; Darwish, D.B.; Alrdahe, S.S.; Saber, W.I.A. Innovative Artificial-Intelligence- Based Approach for the Biodegradation of Feather Keratin by Bacillus paramycoides, and Cytotoxicity of the Resulting Amino Acids. Front. Microbiol. 2021, 22, 731262. [Google Scholar] [CrossRef]

- Gupta, R.; Ramnani, P. Microbial keratinases and their prospective applications: An overview. Appl. Microbiol. Biotechnol. 2006, 70, 21–33. [Google Scholar] [CrossRef]

- Suh, J.H.; Lee, H.K. Characterization of a Keratinolytic Serine Protease from Bacillus subtilis KS-1. J. Protein Chem. 2001, 20, 165–169. [Google Scholar] [CrossRef]

- Mazotto, A.M.; de Melo, A.C.N.; Macrae, A.; Rosado, A.S.; Peixoto, R.S.; Cedrola, S.M.L.; Couri, S.; Zingali, R.B.; Villa, A.L.V.; Rabinovitch, L.; et al. Biodegradation of Feather Waste by Extracellular Keratinases and Gelatinases from Bacillus spp. World J. Microbiol. Biotechnol. 2011, 27, 1355–1365. [Google Scholar] [CrossRef]

- Nnolim, N.E.; Okoh, A.I.; Nwodo, U.U. Proteolytic Bacteria Isolated from Agro-Waste Dumpsites Produced Keratinolytic Enzymes. Biotechnol. Rep. 2020, 27, e00483. [Google Scholar] [CrossRef] [PubMed]

- Bohacz, J.; Korniłłowicz-Kowalska, T. Changes in enzymatic activity in composts containing chicken feathers. Bioresour. Technol. 2009, 100, 3604–3612. [Google Scholar] [CrossRef]

- Vuorinen, A.H. Efect of the bulking agent on acid and alkaline phosphomonoesterase and b-D-glucosidase activities during manure composting. Bioresour. Technol. 2000, 75, 133–138. [Google Scholar] [CrossRef]

- Albrecht, R.; Le Petit, J.; Calvert, V.; Terrom, G.; Périssol, C. Changes in the level of alkaline and acid phosphatase activities during green wastes and sewage sludge cocomposting. Bioresour. Technol. 2010, 101, 228–233. [Google Scholar] [CrossRef] [PubMed]

- Mondini, C.; Fornasier, F.; Sinicco, T. Enzymatic activity as a parameter for the characterization of the composting process. Soil Biol. Biochem. 2004, 36, 1587–1594. [Google Scholar] [CrossRef]

- Sarkar, S.; Banerjee, R.; Chanda, S.; Das, P.; Ganguly, S.; Pal, S. Effectiveness of Inoculation with isolated Geobacillus strains in the thermophilic stage of vegetable waste composting. Biores. Technol. 2010, 101, 2892–2895. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 Laying Down Rules on the Making Available on the Market of EU Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 2003/2003. Off. J. Eur. Union, 2019; 170, L170/1.

- Wu, J.Z.; Yue, Q.; Haishi, Z.; Xinyu, Y.; Tianxu, D.; Yingqiu, Z.; Hui, W.; Zimin, W. Identifying the key factors that affect the formation of humic substance during different materials composting. Bioresour. Technol. 2017, 244, 1193–1196. [Google Scholar] [CrossRef]

- Bohacz, J. Changes in mineral forms of nitrogen and sulfur and enzymatic activities during composting of lignocellulosic waste and chicken feathers. Environ. Sci. Pollut. Res. Int. 2019, 26, 10333–10342. [Google Scholar] [CrossRef]

- Chand, S.; Sunita, D.; Diksha, D.; Priyanka, A.; Kumari, M.; Kritika, K.; Megha, S.; Rohit, B.; Manica, T. Microbial and Physico-Chemical Dynamics Associated with Chicken Feather Compost Preparation Vis-à-Vis Its Impact on the Growth Performance of Tomato Crop. Biocat. Agric. Biotechnol. 2023, 54, 102885. [Google Scholar] [CrossRef]

- Alvarenga, P.; Mourinha, C.; Farto, M.; Santos, T.; Palma, P.; Sengo, J.; Morais, M.C.; Cunha-Queda, C. Sewage sludge, compost and other representative organic wastes as agricultural soil amendments: Benefits versus limiting factors. Waste Manag. 2015, 40, 44–52. [Google Scholar] [CrossRef] [PubMed]

- Geisseler, D.; Smith, R.; Cahn, M.; Muramoto, J. Nitrogen mineralization from organic fertilizers and composts: Literature survey and model fitting. J. Environ. 2021, 50, 1325–1338. [Google Scholar] [CrossRef] [PubMed]

- Adebayo, T.S.; Alola, A.; Ullah, S. Probing the carbon neutrality drive of environmental-related technologies and energy transition in France and Germany: A novel time–frequency technique. Clean Technol. Environ. Policy 2024, 26, 4325–4343. [Google Scholar] [CrossRef]

- Pedroza, R.H.P.; David, C.; Barriada, J.L.; Rey-Castro, C.; Lodeiro, P. The role of photooxidation and organic matter in Cr(III) and Cr(VI) interactions with poly(lactic acid) microplastics in aqueous solution. Sci. Total Environ. 2025, 963, 178431. [Google Scholar] [CrossRef] [PubMed]

- Rowbotham, A.L.; Levy, L.S.; Shuker, L. Chromium in the environment: An evaluation of exposure of the UK general population and possible adverse health effects. J. Toxicol. Environ. Health 2020, 3, 145–178. [Google Scholar] [CrossRef]

- Liang, J.; Huang, X.; Yan, J.; Li, Y.; Zhao, Z.; Liu, Y.; Ye, J.; Wei, Y. A Review of the Formation of Cr(VI) via Cr(III) Oxidation in Soils and Groundwater. Sci. Total Environ. 2021, 774, 145762. [Google Scholar] [CrossRef]

- Mason, I.G.; Milke, M.W. Physical modelling of the composting environment: A review. Part 1: Reactor system. Waste Manag. 2005, 25, 481–500. [Google Scholar] [CrossRef]

- Lashermes, G.; Barriuso, E.; Le Villio-Poitrenaud, M.; Houot, S. Composting in small laboratory pilots: Performance and reproducibility. Waste Manag. 2012, 32, 271–277. [Google Scholar] [CrossRef] [PubMed]

| Compost | Corg | Cbit | Cw | Ck | St | Nt | N-NH4 | N-NO3 | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|---|---|

| g/kg | ||||||||||

| Control | 237.0 | 10.2 | 2.6 | 2.0 | 5.2 | 19.4 | 1.15 | 1.50 | 1.13 | 1.83 |

| Inoclulated | 229.9 | 9.0 | 2.1 | 2.7 | 6.1 | 22.6 | 0.88 | 2.45 | 2.27 | 2.06 |

| Desired trend * | >7.5% * | ↓ | ↑ | ↑ | ↑ | ↑ | ↓ | ↑ | ↑ | ↑ |

| Compost | C/N | N-NH4/N-NO3 | Cw/Corg |

|---|---|---|---|

| - | - | [%] | |

| Control | 12.2 | 0.8 | 1.1 |

| Inoculated | 10.2 | 0.4 | 0.9 |

| Desired trend | ↓ <12 | ↓ <1 | ↓ <1% |

| Compost | Ca | Mg | Fe | Mn | Na | Ni | Cr | Cd | Hg | Pb | Zn | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| g/kg | mg/kg | |||||||||||

| Control | 6.0 | 0.7 | 8.7 | 0.1 | 0.8 | 5.4 | 4.6 | nd * | nd * | 16.1 | 62.3 | 7.4 |

| Inoculated | 6.7 | 0.8 | 9.8 | 0.1 | 1.2 | 6.8 | 5.1 | nd * | nd * | 19.6 | 65.8 | 8.9 |

| Desired trend *** | ↑ | ↑ | ↑ | ↑ | ↑ | <50 | <2 ** | <2 | <1 | <120 | <800 | <300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobolczyk-Bednarek, J.; Choińska-Pulit, A.; Łaba, W. Composting Poultry Feathers with Keratinolytic Bacillus subtilis: Effects on Degradation Efficiency and Compost Maturity. Materials 2025, 18, 4667. https://doi.org/10.3390/ma18204667

Sobolczyk-Bednarek J, Choińska-Pulit A, Łaba W. Composting Poultry Feathers with Keratinolytic Bacillus subtilis: Effects on Degradation Efficiency and Compost Maturity. Materials. 2025; 18(20):4667. https://doi.org/10.3390/ma18204667

Chicago/Turabian StyleSobolczyk-Bednarek, Justyna, Anna Choińska-Pulit, and Wojciech Łaba. 2025. "Composting Poultry Feathers with Keratinolytic Bacillus subtilis: Effects on Degradation Efficiency and Compost Maturity" Materials 18, no. 20: 4667. https://doi.org/10.3390/ma18204667

APA StyleSobolczyk-Bednarek, J., Choińska-Pulit, A., & Łaba, W. (2025). Composting Poultry Feathers with Keratinolytic Bacillus subtilis: Effects on Degradation Efficiency and Compost Maturity. Materials, 18(20), 4667. https://doi.org/10.3390/ma18204667