An Inverse Analysis of Interfacial Parameter Values for Mode I Debonding Between Steel and Hot-Melt Adhesive

Abstract

1. Introduction

2. Experimental Section

2.1. Specimen Preparation

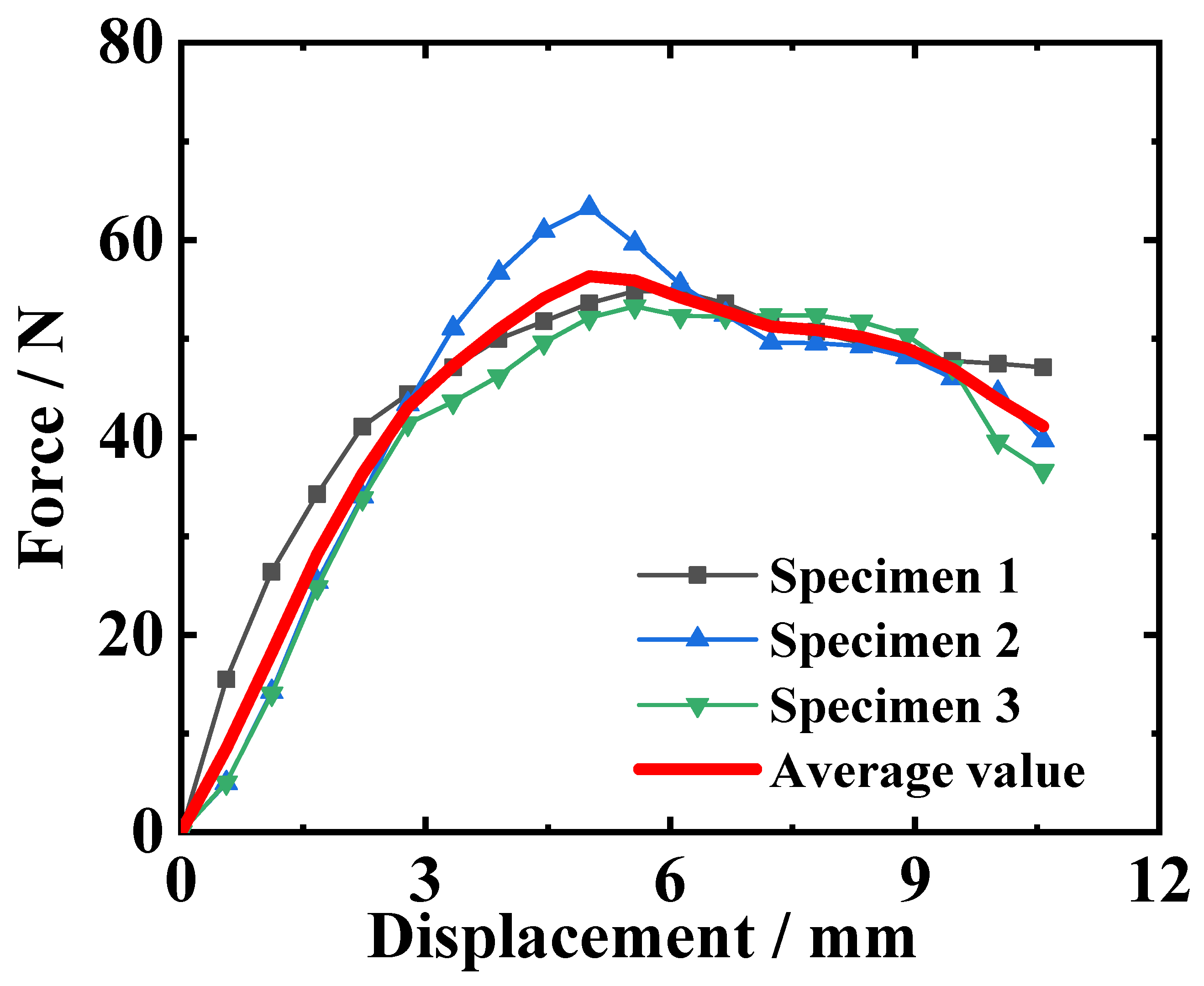

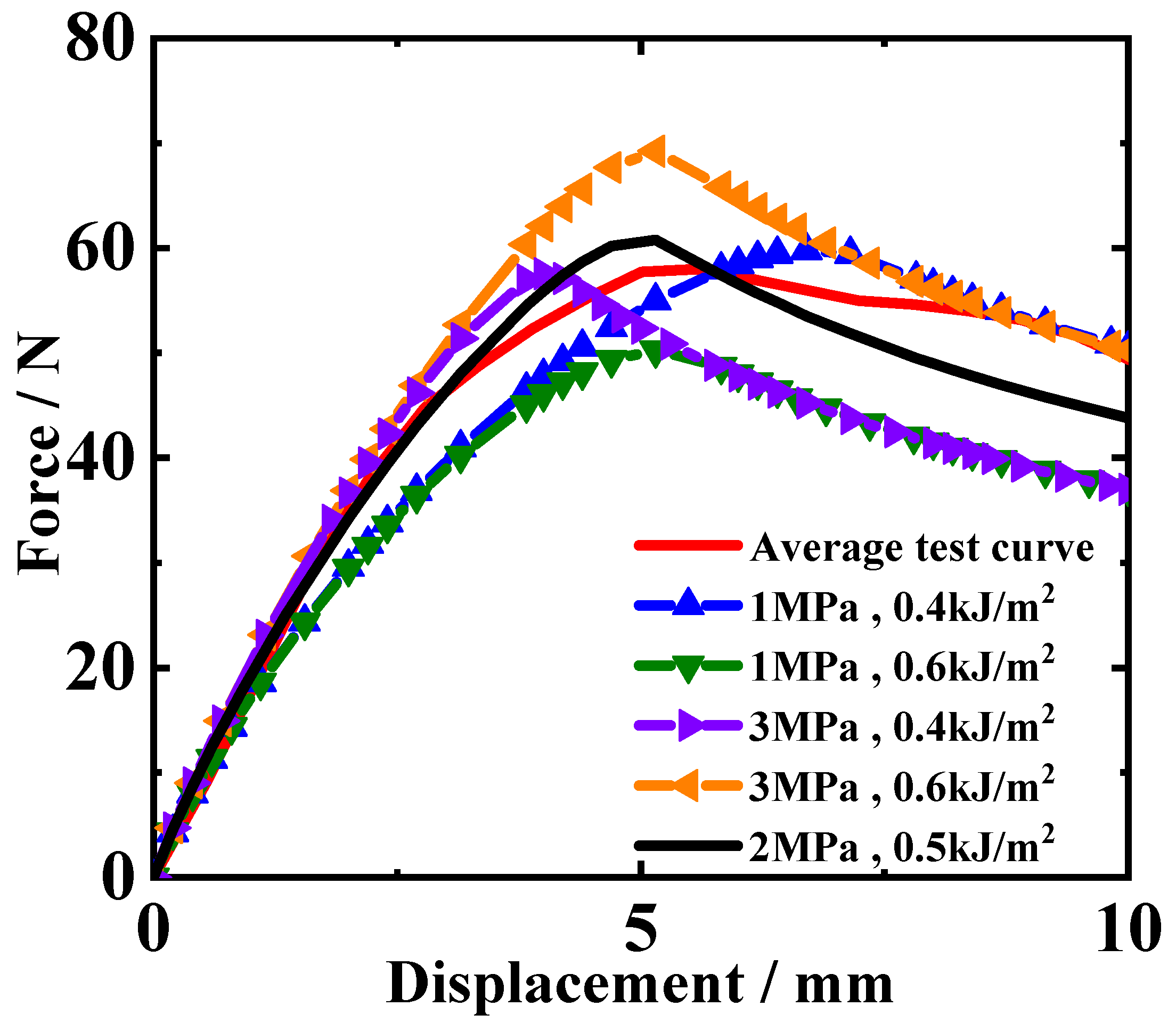

2.2. Test Results

3. Numerical Simulation

3.1. Cohesive Zone Model

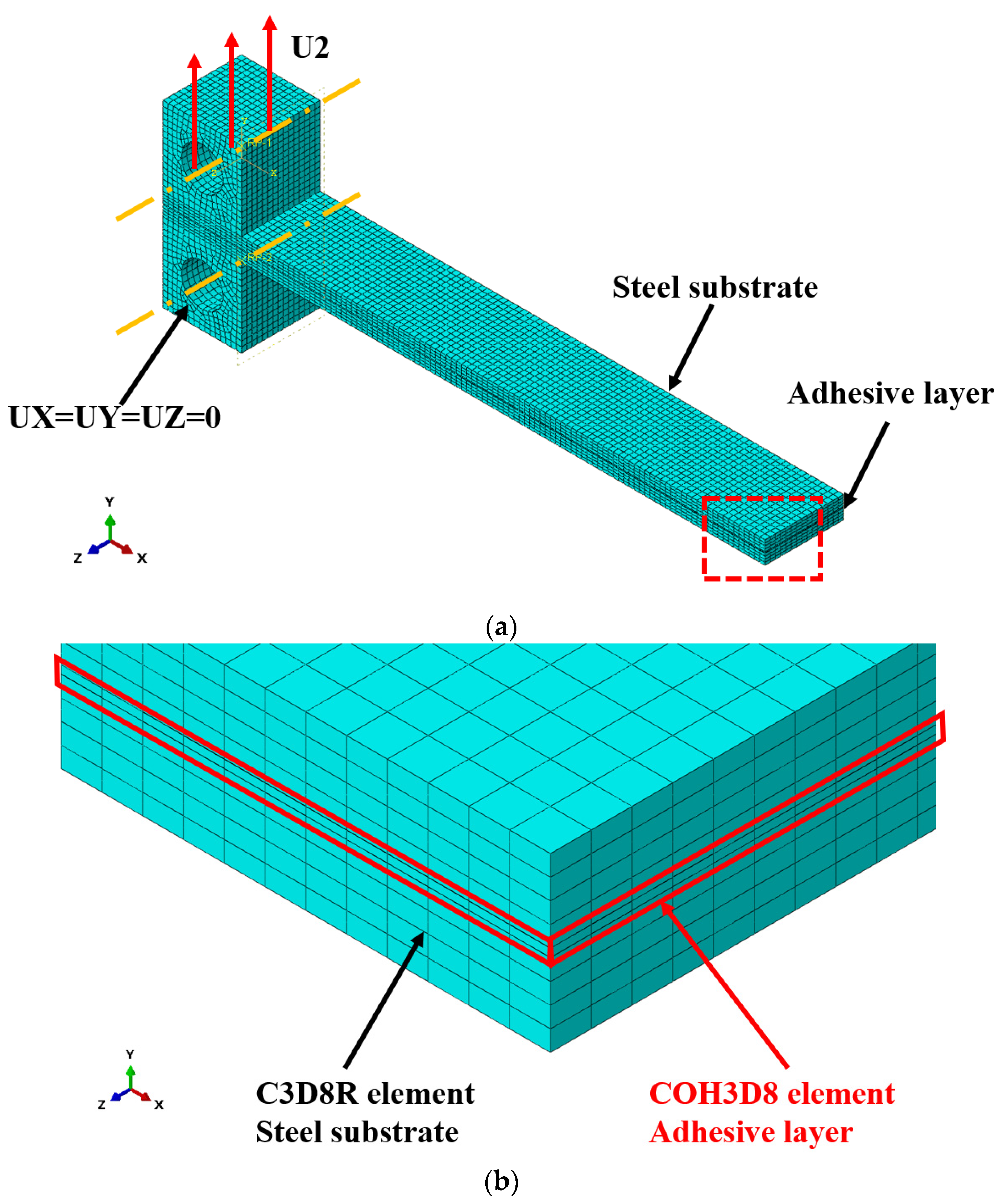

3.2. Finite Element Model

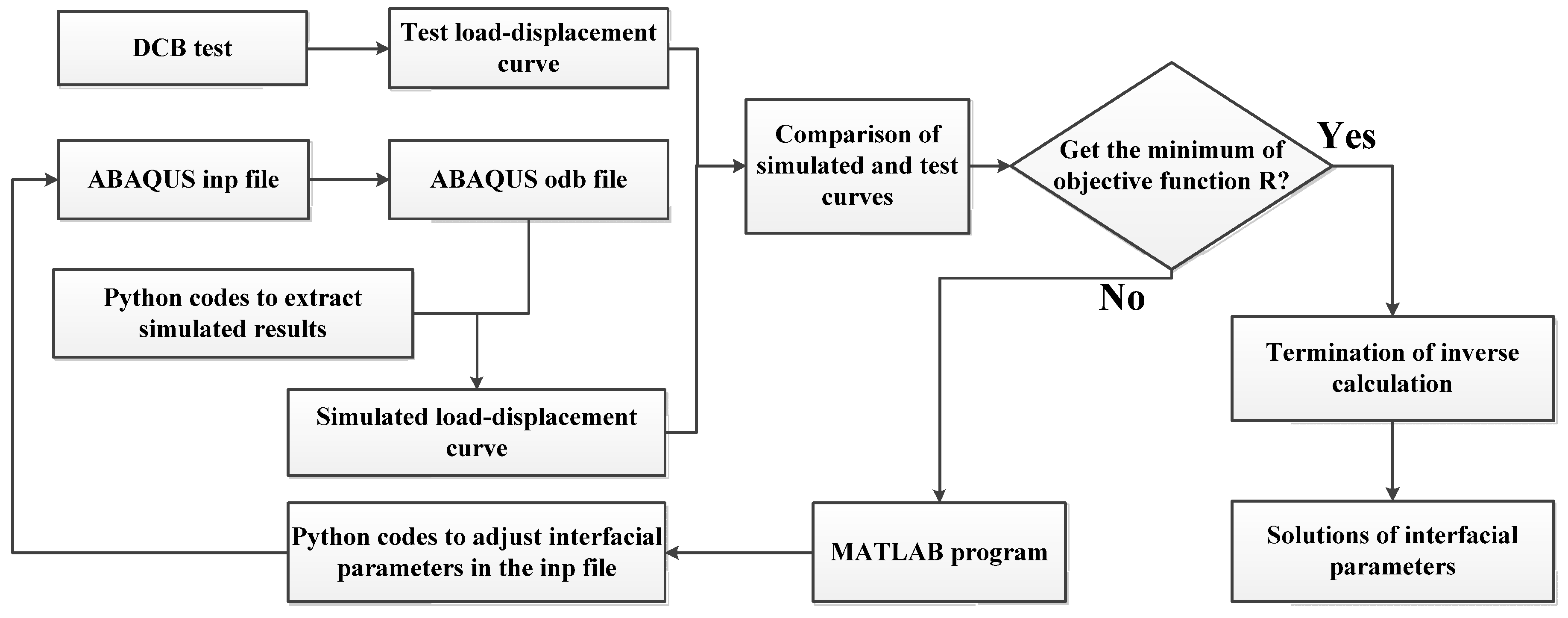

3.3. Inversion Method

4. Results and Discussion

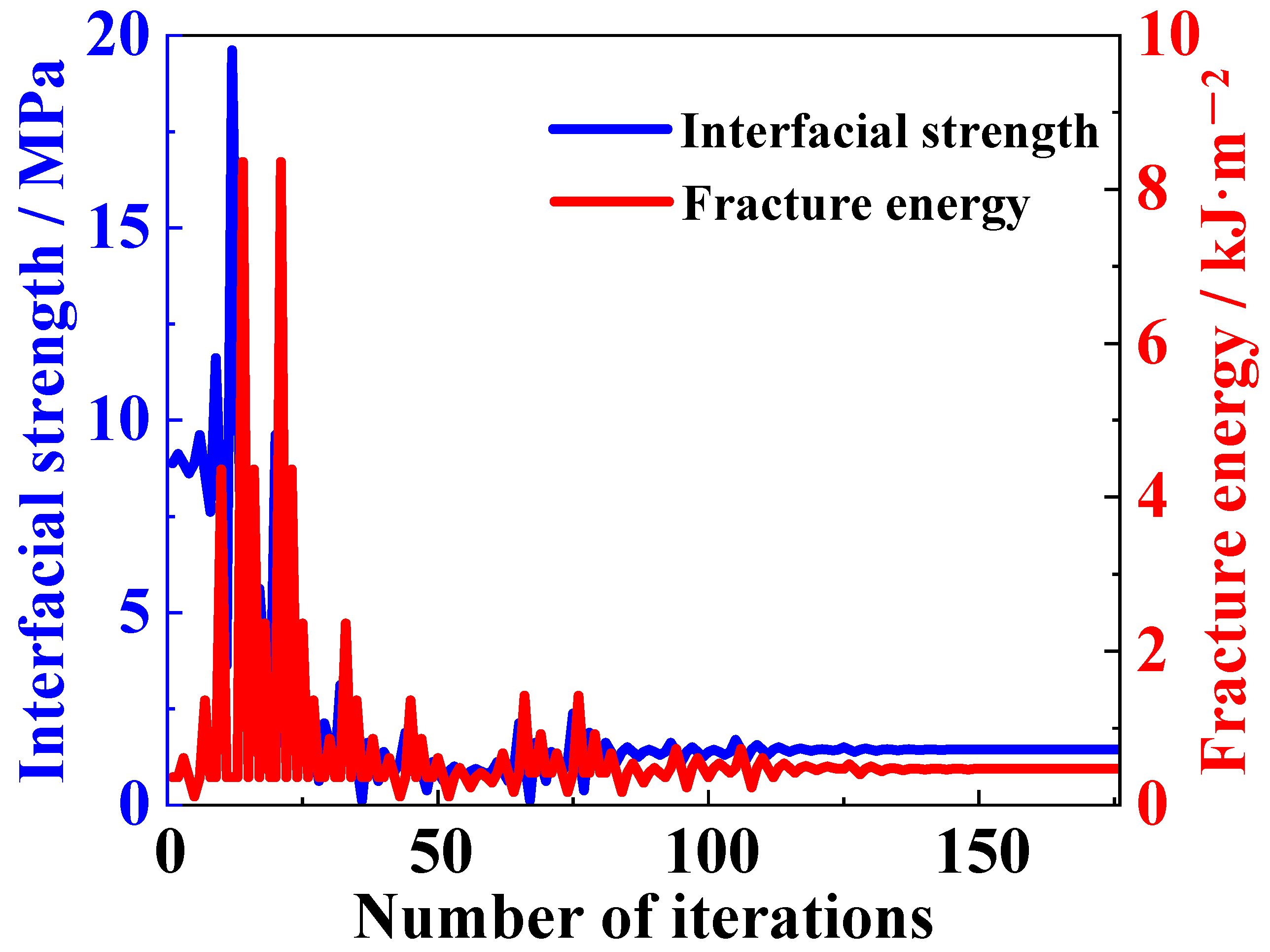

4.1. Inversion Results

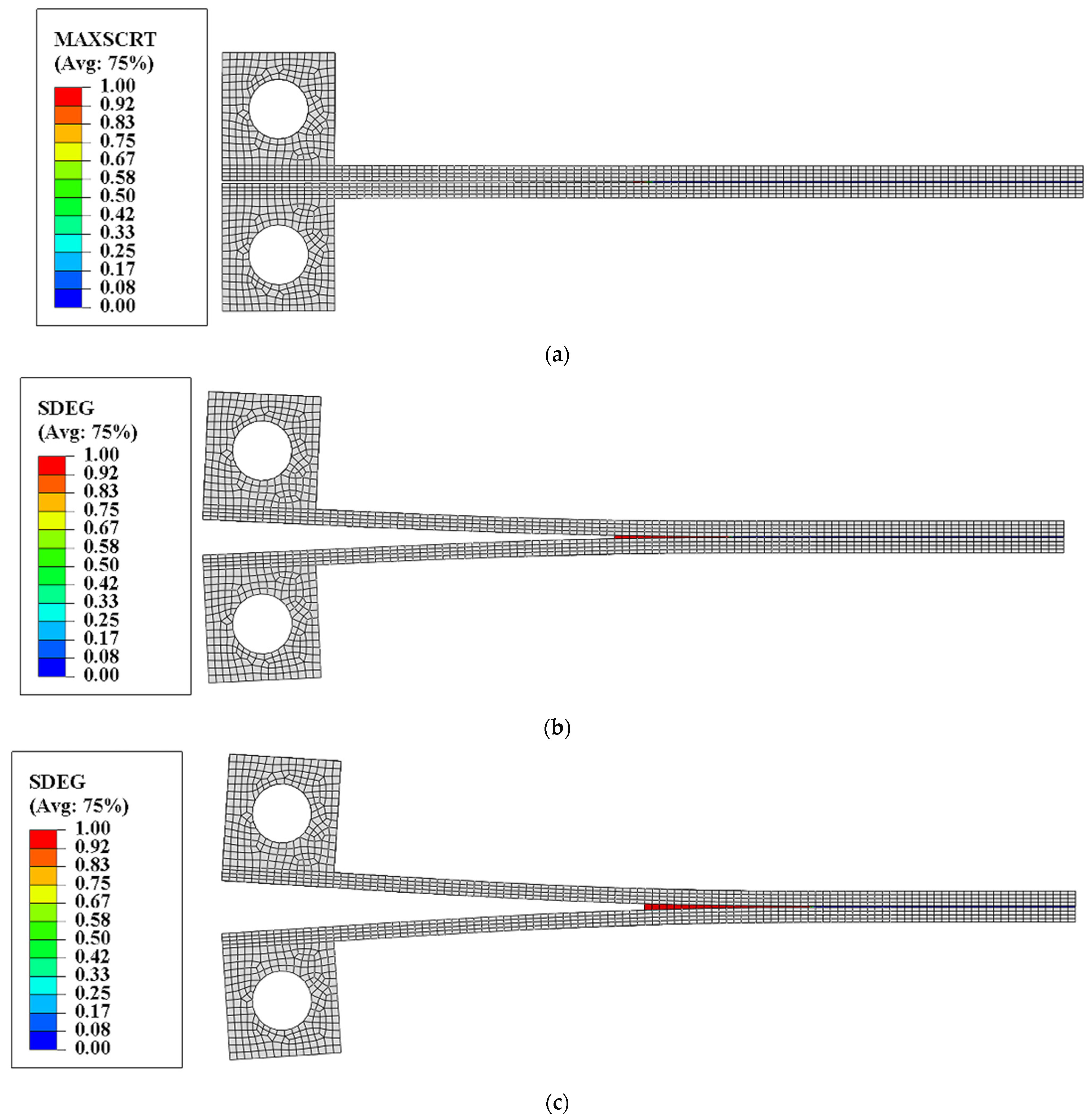

4.2. Interfacial Failure Process

4.3. Crack Verification

5. Conclusions

- (1)

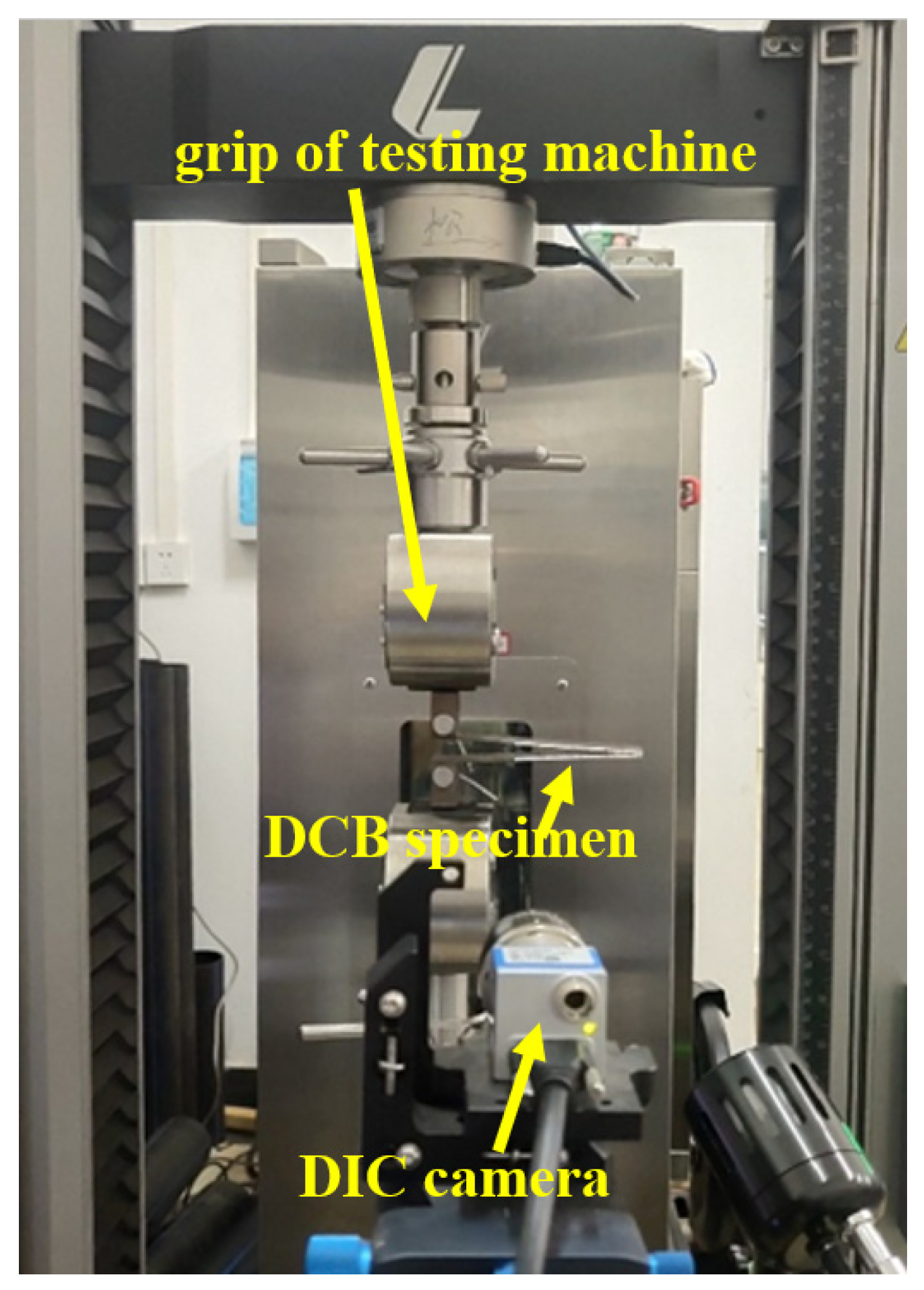

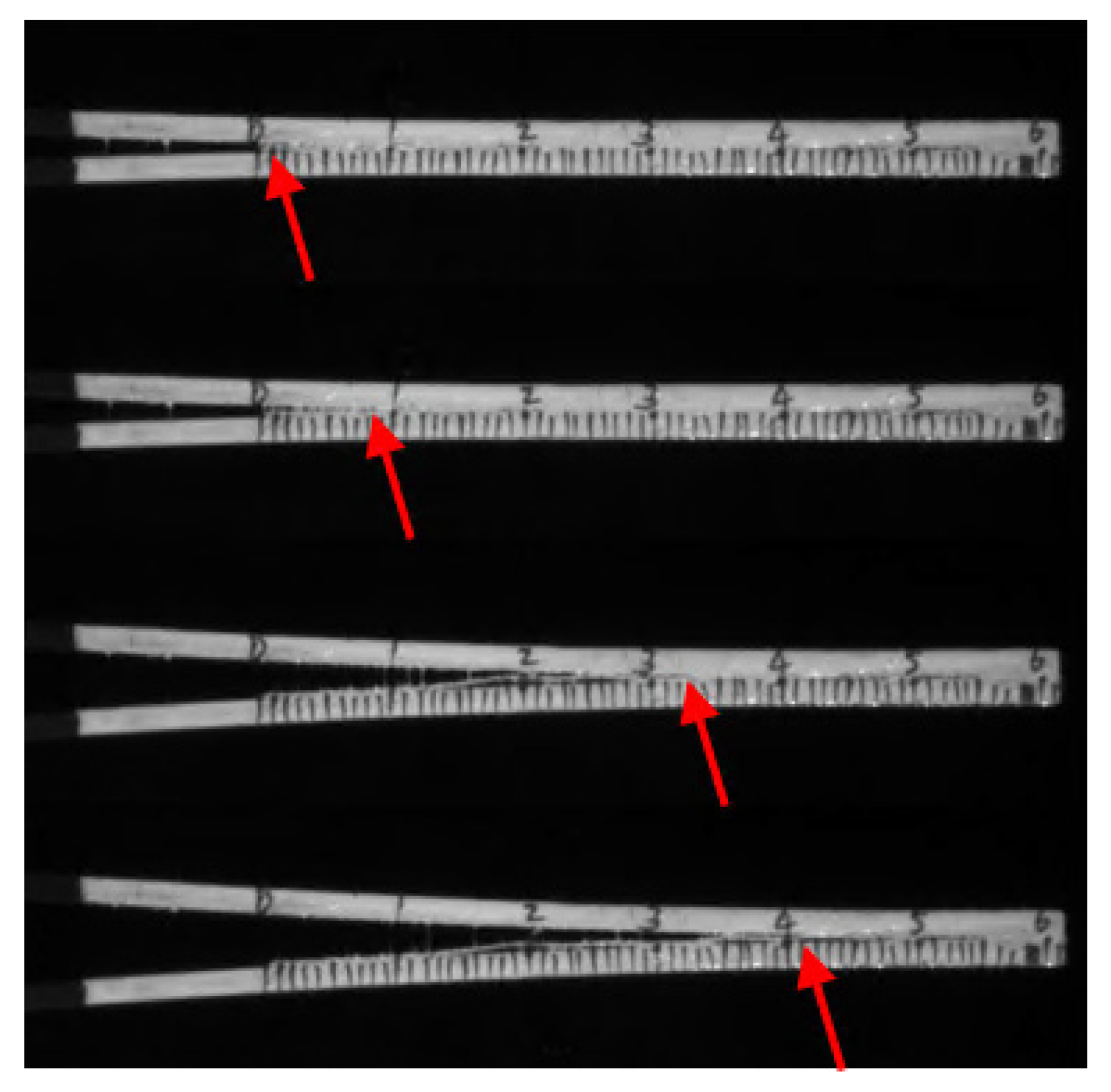

- Double cantilever beam (DCB) specimens were prepared using steel strips and hot-melt adhesive to investigate interfacial failure behavior. A Digital Image Correlation (DIC) system was set up to monitor crack tip propagation. After the tests, the loading curve of reaction force versus loading displacement could be obtained, as well as the curve of crack tip propagation versus loading displacement. The former is used for the inverse calculation of interfacial parameters, while the latter is used to verify the accuracy and reliability of the obtained interfacial parameters from a new dimension.

- (2)

- A finite element model was established to represent the DCB specimen under tensile loading. Cohesive elements were employed to characterize the steel/polymer interface. As the two key cohesive parameters, interface strength and fracture energy, could not be directly obtained, an inversion optimization calculation method was thus proposed to determine the interfacial parameters. An ABAQUS–Python–MATLAB interactive program was developed to employ the pattern search algorithm and adjust the key interfacial parameters during iterative calculations. As expected, in the iterative calculations round by round, the program successfully made the computed load–displacement curve increasingly close to the experimental curve. Finally, the program met the convergence criteria, and the interface parameters were solved.

- (3)

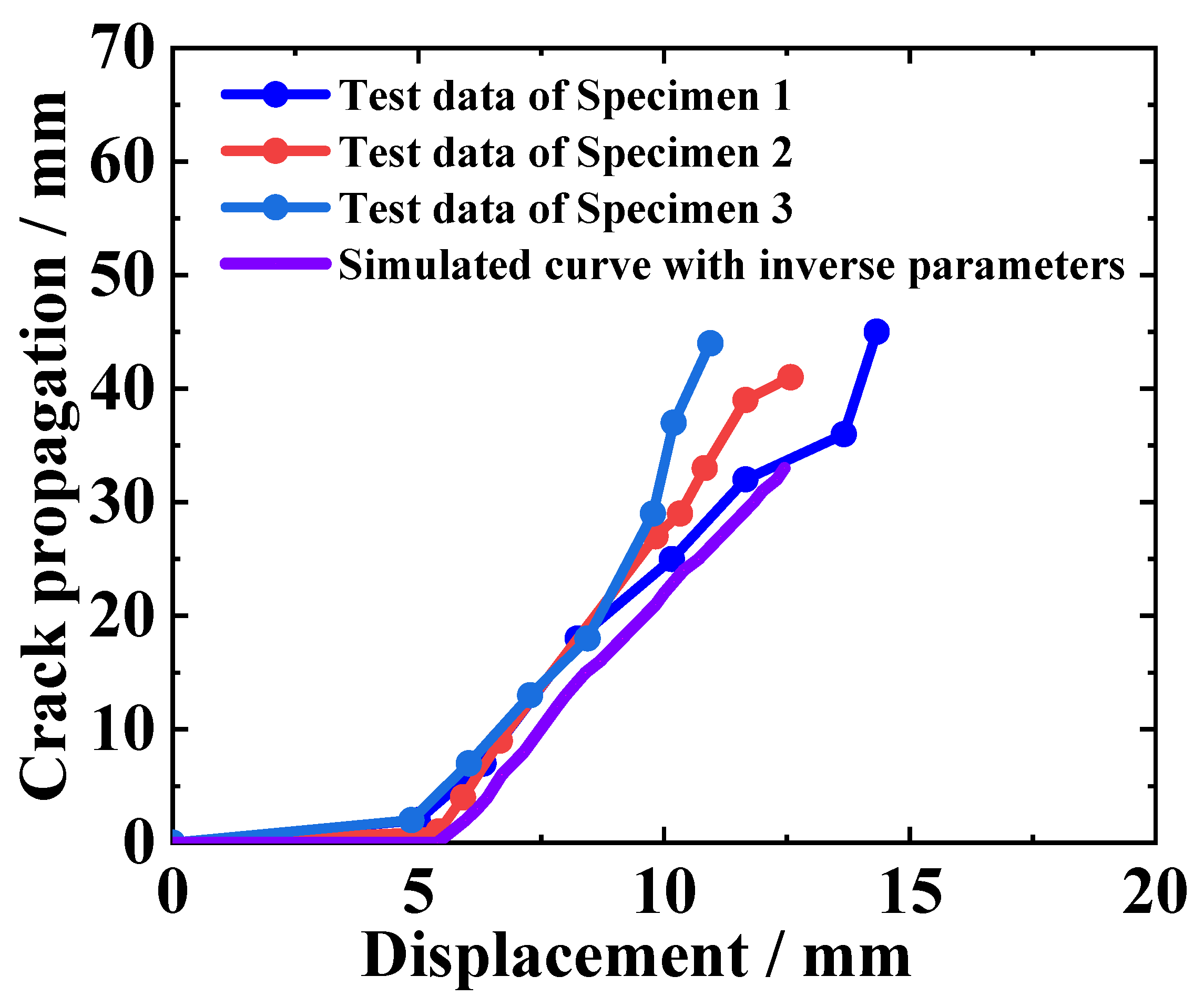

- Furthermore, crack tip propagation with loading displacement was employed to verify the validity of the inversion calculation method. By substituting the parameters obtained from inversion into the finite element model, the propagation process of the crack tip with loading displacement could be reproduced through the DCB finite element model. It showed that the curve of the finite element simulation results for the crack tip propagation process was basically consistent with the trend of the crack propagation curves of the three specimens. This proved the effectiveness of the inversion calculation method from another dimension, indicating that the simulation results of the DCB model were consistent with the experiment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. A comprehensive review on material selection for polymer matrix composites subjected to impact load. Def. Technol. 2020, 17, 257–277. [Google Scholar]

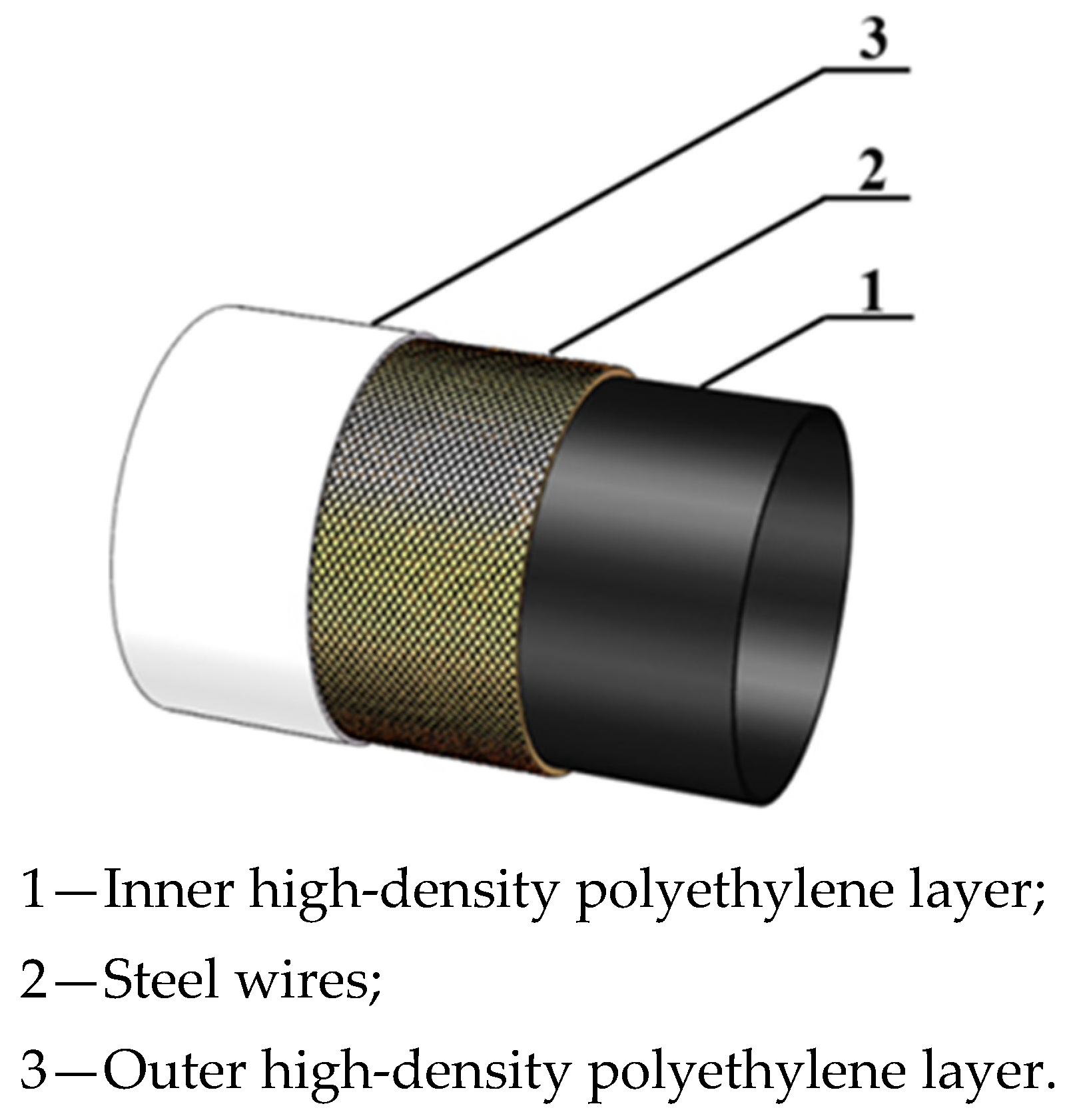

- Zheng, J.; Shi, J.; Shi, J.; Zhong, S.; Rao, J.; Li, G.; Li, X. Short-term burst pressure of polyethylene pipe reinforced by winding steel wires under various temperatures. Compos. Struct. 2015, 121, 163–171. [Google Scholar] [CrossRef]

- Shi, J.; Zhong, S.; Nie, X.; Shi, J.; Zheng, J. Study on steel wire reinforced thermoplastic pipes under combined internal pressure and bending moment at various temperatures. Thin-Walled Struct. 2021, 169, 108381. [Google Scholar] [CrossRef]

- Shi, J.; Feng, X.; Li, S.; Gong, C. Investigation on the Mechanical Behavior of Polyethylene Pipes Reinforced by Winding Steel Wires under Radial Compression. J. Pipeline Syst. Eng. Pract. 2025, 16, 04025044. [Google Scholar]

- Shi, J.; Rao, J.; Li, X.; Shen, S.; Shen, Y. A Review of Design, Manufacture, and Mechanical Properties of Steel Skeleton Reinforced Thermoplastic Pipes. J. Pipeline Syst. Eng. Pract. 2023, 14, 03123002. [Google Scholar] [CrossRef]

- Shi, J.; Hu, Z.; Zeng, L.; Lu, P.; Chen, H.; Yu, N.; Li, X. Study on mechanical failure behavior of steel-wire wound reinforced thermoplastic pipe under combined internal pressure and soil landslide conditions. Materials 2023, 16, 848. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Yu, N.; Zeng, L.; Chen, H.; Li, X. Study on buried polyethylene pipe reinforced by steel wires under internal pressure and foundation settlement. J. Thermoplast. Compos. Mater. 2024, 37, 1619–1647. [Google Scholar] [CrossRef]

- Shi, J. Research on Bulge Failure in the Joint of Polyethylene Pipe Reinforced by Winding Steel Wires Owing to Steel/Polymer Interfacial Debonding. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- Shi, J.; Zeng, L.; Wan, Y.; Shi, J.; Nie, X.; Chen, H.; Yu, Z.; Li, G. Modeling the Interfacial Debonding Behavior Between Steel Wire and Adhesive. J. Press. Vessel. Technol. 2020, 142, 061501. [Google Scholar] [CrossRef]

- Goda, I.; Padayodi, E.; Raoelison, R.N. Computational analysis of the interfacial debonding in polymer composites: Research progress and challenges. Adv. Compos. Hybrid Mater. 2024, 7, 231. [Google Scholar] [CrossRef]

- Xie, X.; Feng, Q.; Zhang, M.; Liao, N. Evaluating fracture properties and interfacial strengths of silicon oxycarbide thin-films: XFEM simulations and experimental validation. Eng. Fract. Mech. 2023, 292, 109648. [Google Scholar] [CrossRef]

- Nakrani, J.; Shrivastava, A.; Yan, W. Effect of a deposit-substrate interface on fatigue crack propagation in WAAM-deposited SS316L: XFEM modeling with orthotropic material properties. Int. J. Solids Struct. 2025, 322, 113616. [Google Scholar] [CrossRef]

- Zhong, Y.; Yu, H.; Wang, Q.; Chen, X.; Ke, X.; Huang, H.; Wu, H. Hydraulic fracturing in layered heterogeneous shale: The interaction between adjacent weak interfaces. Eng. Fract. Mech. 2024, 303, 110115. [Google Scholar] [CrossRef]

- Teimouri, F.; Heidari-Rarani, M.; Aboutalebi, F.H. An XFEM-VCCT coupled approach for modeling mode I fatigue delamination in composite laminates under high cycle loading. Eng. Fract. Mech. 2021, 249, 107760. [Google Scholar] [CrossRef]

- Karmakov, S.; Cepero-Mejías, F.; Curiel-Sosa, J. Numerical analysis of the delamination in CFRP laminates: VCCT and XFEM assessment. Compos. Part C Open Access 2020, 2, 100014. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Duan, Y.; Meng, L. Experimental and Numerical Study of the Interfacial Shear Strength in Carbon Fiber/Epoxy Resin Composite under Thermal Loads. Int. J. Polym. Sci. 2018, 2018, 3206817. [Google Scholar] [CrossRef]

- Nian, G.; Li, Q.; Xu, Q.; Qu, S. A cohesive zone model incorporating a Coulomb friction law for fiber-reinforced composites. Compos. Sci. Technol. 2018, 157, 195–201. [Google Scholar] [CrossRef]

- Li, D.; Yang, Q.-S.; Liu, X.; He, X.-Q. Experimental and cohesive finite element investigation of interfacial behavior of CNT fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2017, 101, 318–325. [Google Scholar] [CrossRef]

- Zou, Z.; Lee, H. A Cohesive Zone Model Taking Account of the Effect of Through-Thickness Compression. Compos. Part A Appl. Sci. Manuf. 2017, 98, 90–98. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Bo, W. The Cohesive Zone Model for Fatigue Crack Growth. Adv. Mech. Eng. 2013, 5, 737392. [Google Scholar] [CrossRef]

- Zhao, G.; Xu, J.; Feng, Y.; Tang, J.; Chen, Y.; Xin, S.; Jian, X.; Li, S.; Zhang, S.; Xu, J. A Rate-Dependent Cohesive Zone Model with the effects of Interfacial Viscoelasticity and Progressive Damage. Eng. Fract. Mech. 2021, 248, 107695. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Gonçalves, J.P.M.; Chousal, J.A.G.; Campilho, R.D.S.G. Cohesive and continuum mixed-mode damage models applied to the simulation of the mechanical behaviour of bonded joints. Int. J. Adhes. Adhes. 2008, 28, 419–426. [Google Scholar] [CrossRef]

- Zhandarov, S.; Pisanova, E.; Mäder, E. Is there any contradiction between the stress and energy failure criteria in micromechanical tests? Part III. Experimental observation of crack propagation in the microbond test. J. Adhes. Sci. Technol. 2005, 19, 679–704. [Google Scholar] [CrossRef]

- Sockalingam, S.; Dey, M.; Gillespie, J.W.; Keefe, M. Finite element analysis of the microdroplet test method using cohesive zone model of the fiber/matrix interface. Compos. Part A Appl. Sci. Manuf. 2014, 56, 239–247. [Google Scholar] [CrossRef]

- Xu, Y.; Li, X.; Wang, X.; Liang, L. Inverse parameter identification of cohesive zone model for simulating mixed-mode crack propagation. Int. J. Solids Struct. 2014, 51, 2400–2410. [Google Scholar] [CrossRef]

- Wang, J.; Kang, Y.L.; Qin, Q.H.; Fu, D.H.; Li, X.Q. Identification of time-dependent interfacial mechanical properties of adhesive by hybrid/inverse method. Comput. Mater. Sci. 2008, 43, 1160–1164. [Google Scholar]

- Pappas, G.; Canal, L.P.; Botsis, J. Characterization of intralaminar mode I fracture of AS4/PPS composite using inverse identification and micromechanics. Compos. Part A Appl. Sci. Manuf. 2016, 91, 117–126. [Google Scholar]

- Zhou, Q.C.; Chen, X.; Niu, R.M.; Zhou, C.S. Extraction of rate-dependent fracture properties of adhesive interface involving large-scale yielding. J. Adhes. Sci. Technol. 2015, 29, 1118–1135. [Google Scholar]

- Kang, Y.L.; Lin, X.H.; Qin, Q.H. Inverse/genetic method and its application in identification of mechanical parameters of interface in composite. Compos. Struct. 2004, 66, 449–458. [Google Scholar] [CrossRef]

- Zhou, Q.C.; Ju, Y.T.; Wei, Z.; Han, B.; Zhou, C.S. Cohesive Zone Modeling of Propellant and Insulation Interface Debonding. J. Adhes. 2014, 90, 230–251. [Google Scholar] [CrossRef]

- Oh, J.C.; Kim, H.G. Inverse estimation of cohesive zone laws from experimentally measured displacements for the quasi-static mode I fracture of PMMA. Eng. Fract. Mech. 2013, 99, 118–131. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Q.H.; Kang, Y.L.; Li, X.Q.; Rong, Q.Q. Viscoelastic adhesive interfacial model and experimental characterization for interfacial parameters. Mech. Mater. 2010, 42, 537–547. [Google Scholar] [CrossRef]

- Tariq, A.; Deliktaş, B. An Inverse Parameter Identification in Finite Element Problems Using Machine Learning-Aided Optimization Framework. Exp. Mech. 2025, 65, 325–349. [Google Scholar] [CrossRef]

- Papa, T.; Bocciarelli, M. Identification of the parameters contained in a cyclic cohesive zone model for fatigue crack propagation. Eng. Fract. Mech. 2023, 279, 109055. [Google Scholar] [CrossRef]

- Gaynutdinova, L.; Rokoš, O.; Havelka, J.; Pultarová, I.; Zeman, J. Bayesian approach to micromechanical parameter identification using Integrated Digital Image Correlation. Int. J. Solids Struct. 2023, 280, 112388. [Google Scholar] [CrossRef]

- ASTM D5528; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA.

| Material | Density (g/cm3) | Elastic Modulus (MPa) | Yield Strength | Poisson’s Ratio |

|---|---|---|---|---|

| 45# steel | 7.8 | 204,309 | 284 | 0.26 |

| Hot-melt adhesive | 0.95 | 625 | \ | 0.45 |

| Item | Maximum Load (N) | Corresponding Displacement (mm) |

|---|---|---|

| Specimen 1 | 54.84 | 5.56 |

| Specimen 2 | 63.30 | 5.01 |

| Specimen 3 | 53.28 | 5.57 |

| Mean value | 57.14 | 5.38 |

| Item | Fracture Energy (kJ/m2) |

|---|---|

| Specimen 1 | 0.44 |

| Specimen 2 | 0.45 |

| Specimen 3 | 0.42 |

| Average | 0.44 |

| Element Size (mm) | Element Number | Peak Reaction Force (N) | Normalized Value |

|---|---|---|---|

| 2 | 4952 | 56.64 | 0.978 |

| 1 | 20,910 | 56.72 | 0.979 |

| 0.5 | 106,260 | 56.79 | 0.981 |

| 0.3 | 506,100 | 57.91 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Zhang, J.; Hu, M.; Li, Y.; Deng, G.; Liu, W. An Inverse Analysis of Interfacial Parameter Values for Mode I Debonding Between Steel and Hot-Melt Adhesive. Materials 2025, 18, 4648. https://doi.org/10.3390/ma18204648

Shi J, Zhang J, Hu M, Li Y, Deng G, Liu W. An Inverse Analysis of Interfacial Parameter Values for Mode I Debonding Between Steel and Hot-Melt Adhesive. Materials. 2025; 18(20):4648. https://doi.org/10.3390/ma18204648

Chicago/Turabian StyleShi, Jun, Jian Zhang, Mingzhen Hu, Yingjie Li, Guide Deng, and Wenjun Liu. 2025. "An Inverse Analysis of Interfacial Parameter Values for Mode I Debonding Between Steel and Hot-Melt Adhesive" Materials 18, no. 20: 4648. https://doi.org/10.3390/ma18204648

APA StyleShi, J., Zhang, J., Hu, M., Li, Y., Deng, G., & Liu, W. (2025). An Inverse Analysis of Interfacial Parameter Values for Mode I Debonding Between Steel and Hot-Melt Adhesive. Materials, 18(20), 4648. https://doi.org/10.3390/ma18204648