Effects of Laser Shock Processing on the Mechanical Properties of 6061-T6 Aluminium Alloy Using Nanosecond and Picosecond Laser Pulses

Highlights

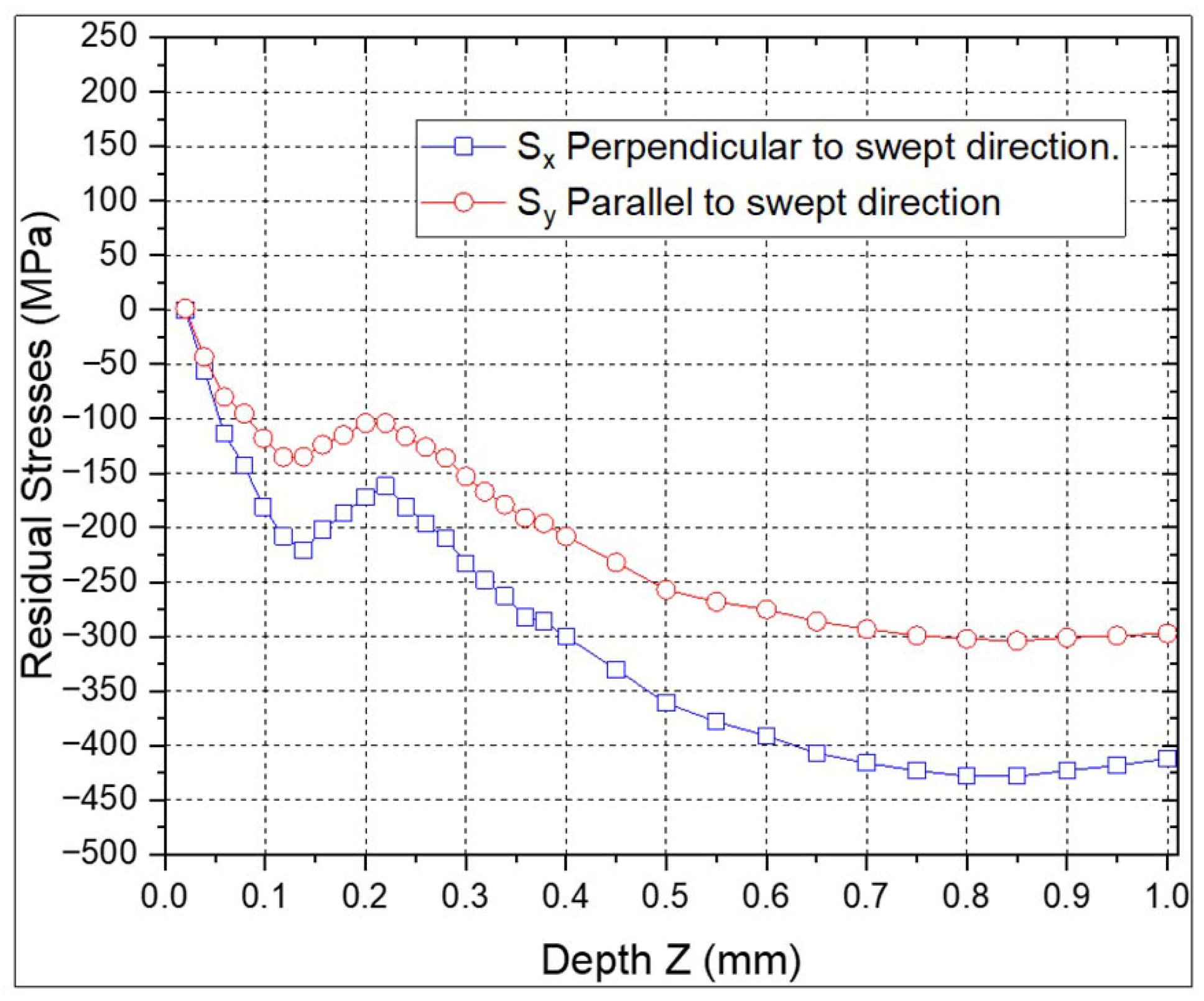

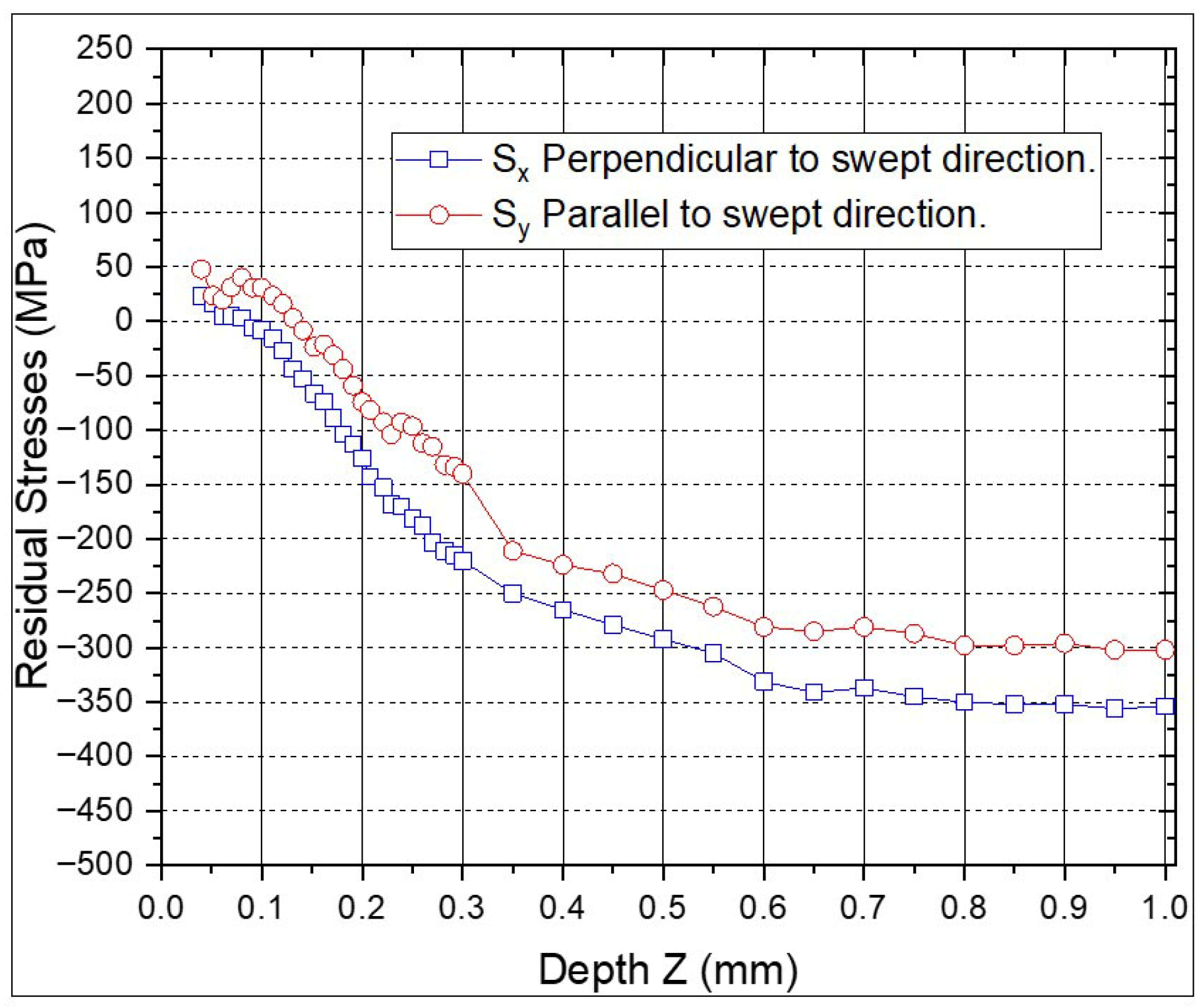

- All LSP treatments induced compressive stresses up to 1 mm depth. nsps-LSP treatment reached the highest (428 MPa at 0.85 mm).

- Combined treatments (nsps-LSP, psns-LSP) showed reduced separation between residual stress curves in parallel and perpendicular directions compared to traditional ns-LSP treatment.

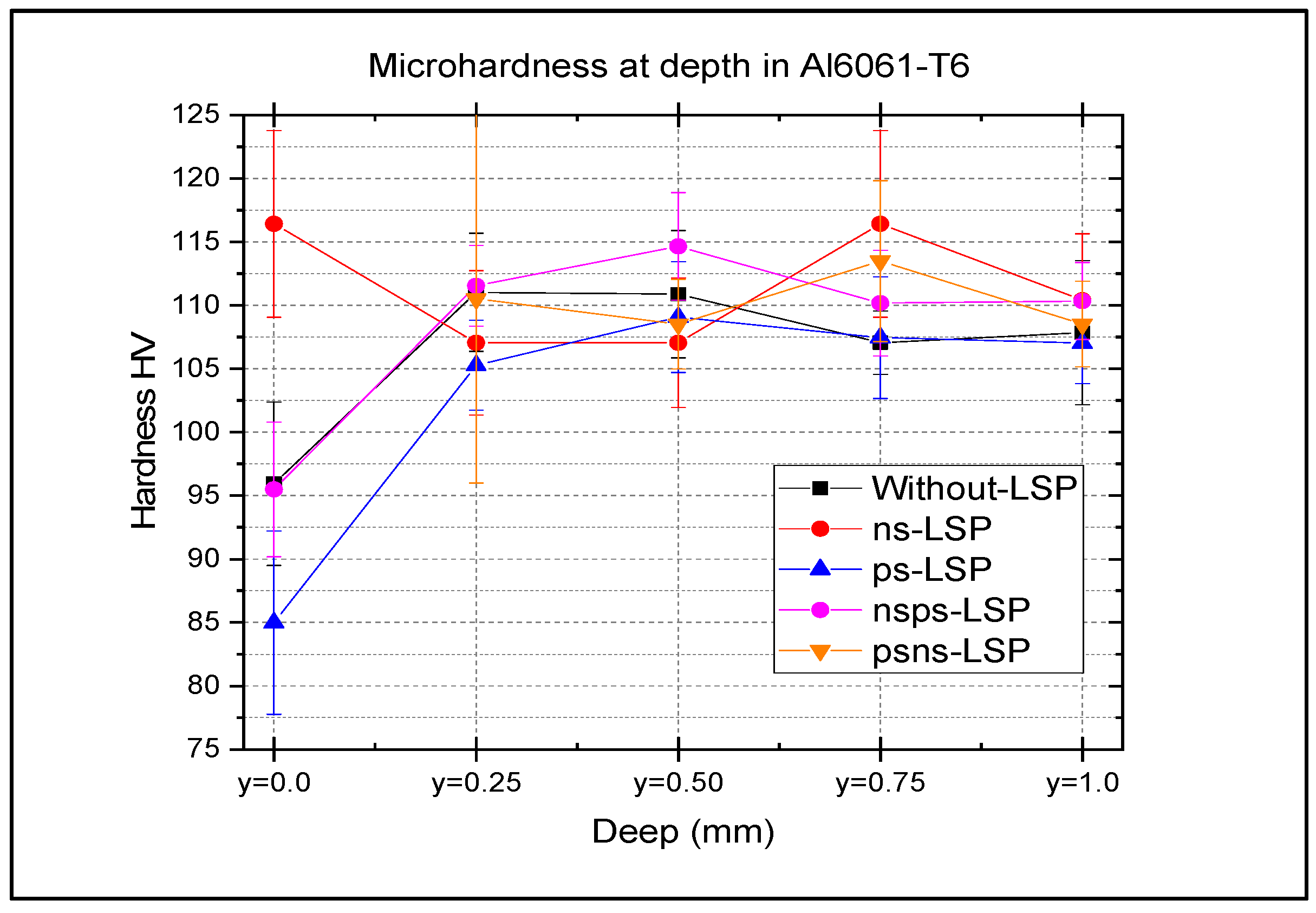

- The nsps-LSP treatment showed the highest microhardness at depths of 0.25, 0.5, and 1 mm.

- The lowest surface roughness (~6 μm) was observed in ps-LSP; while the highest (~12 μm) occurred in psns-LSP.

- The nsps-LSP treatment could be used to improve mechanical properties of metals.

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Samples Before Treatment

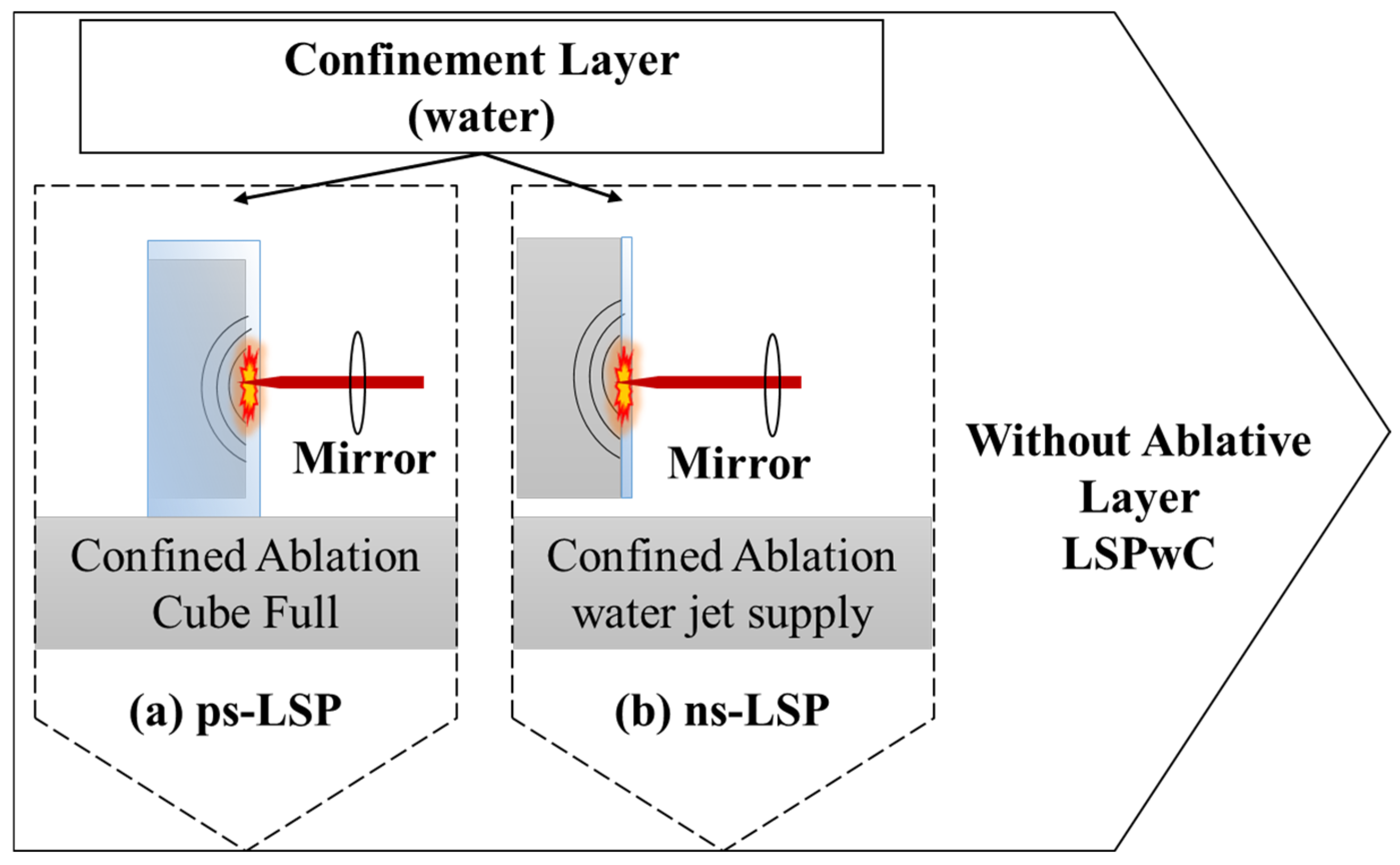

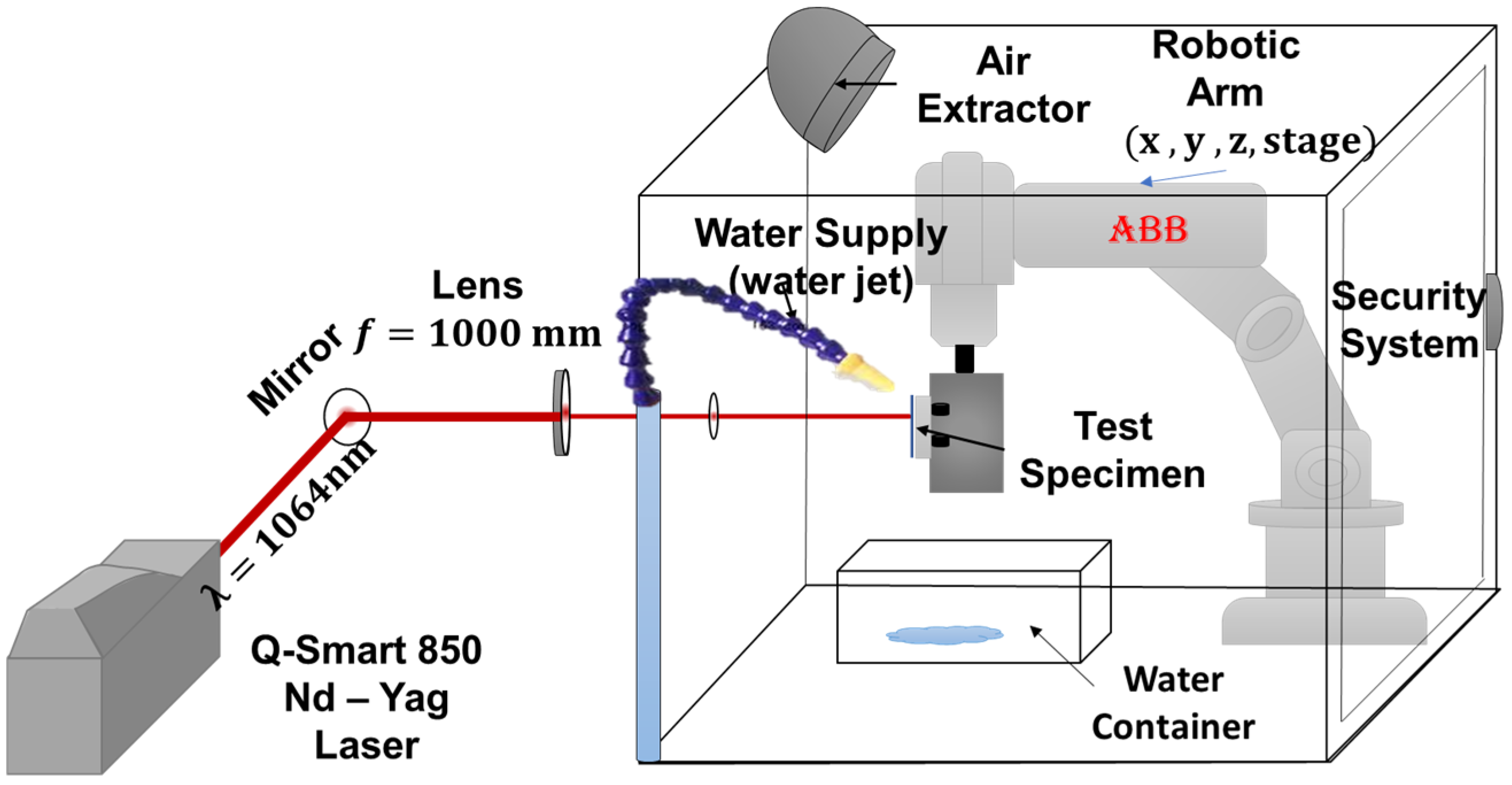

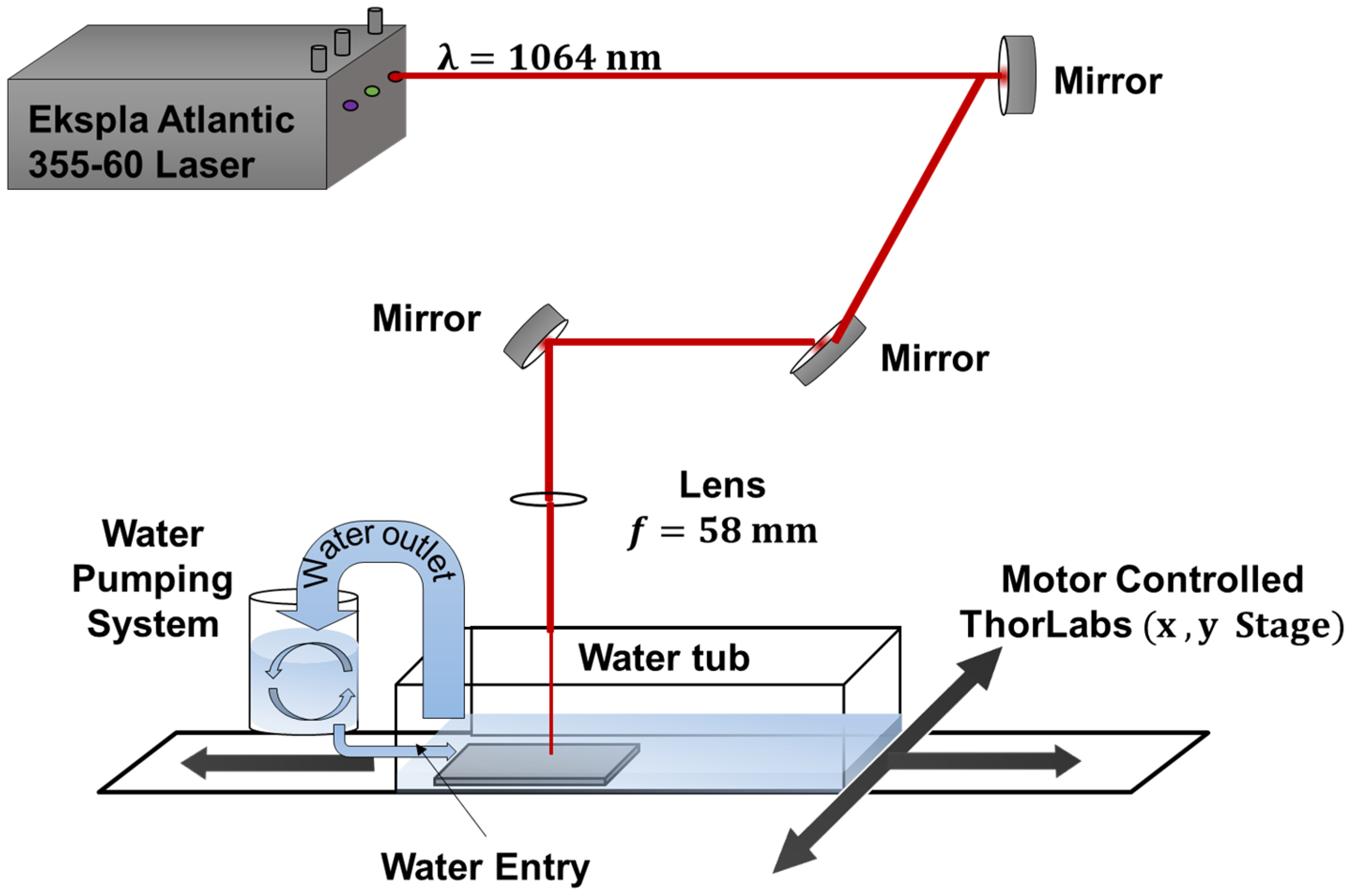

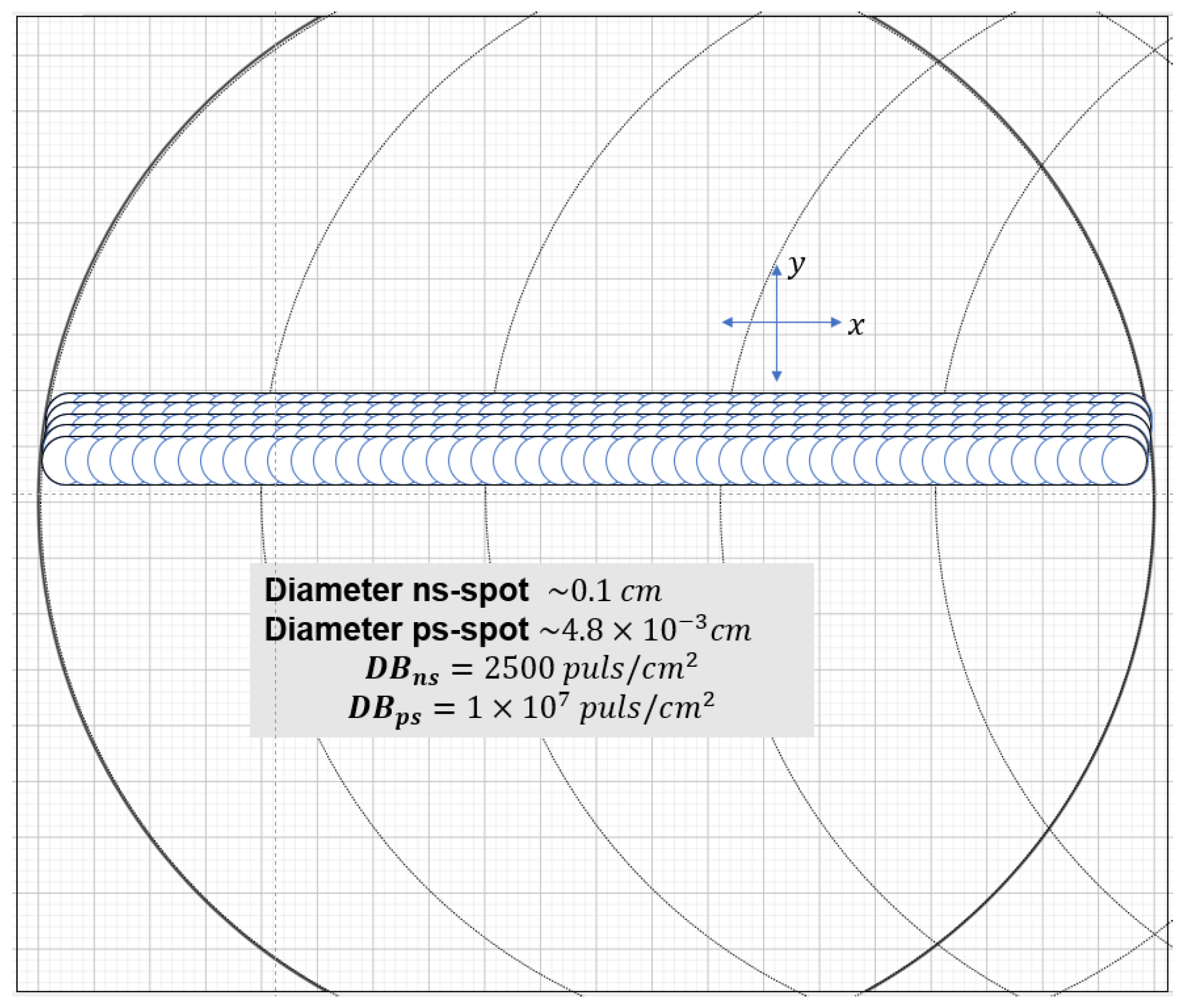

2.2. Experimental Setups and Mechanical Characterizations

3. Results

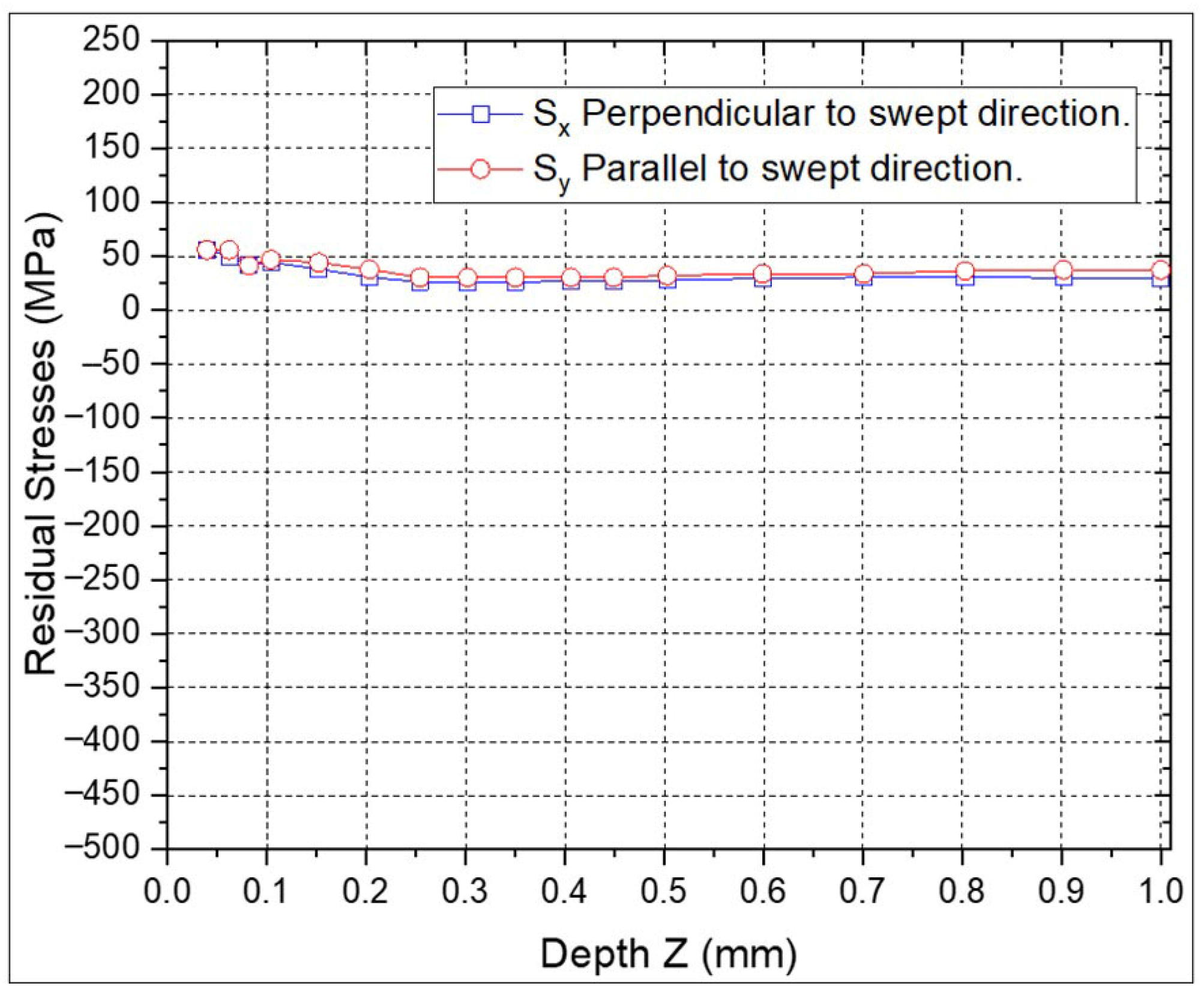

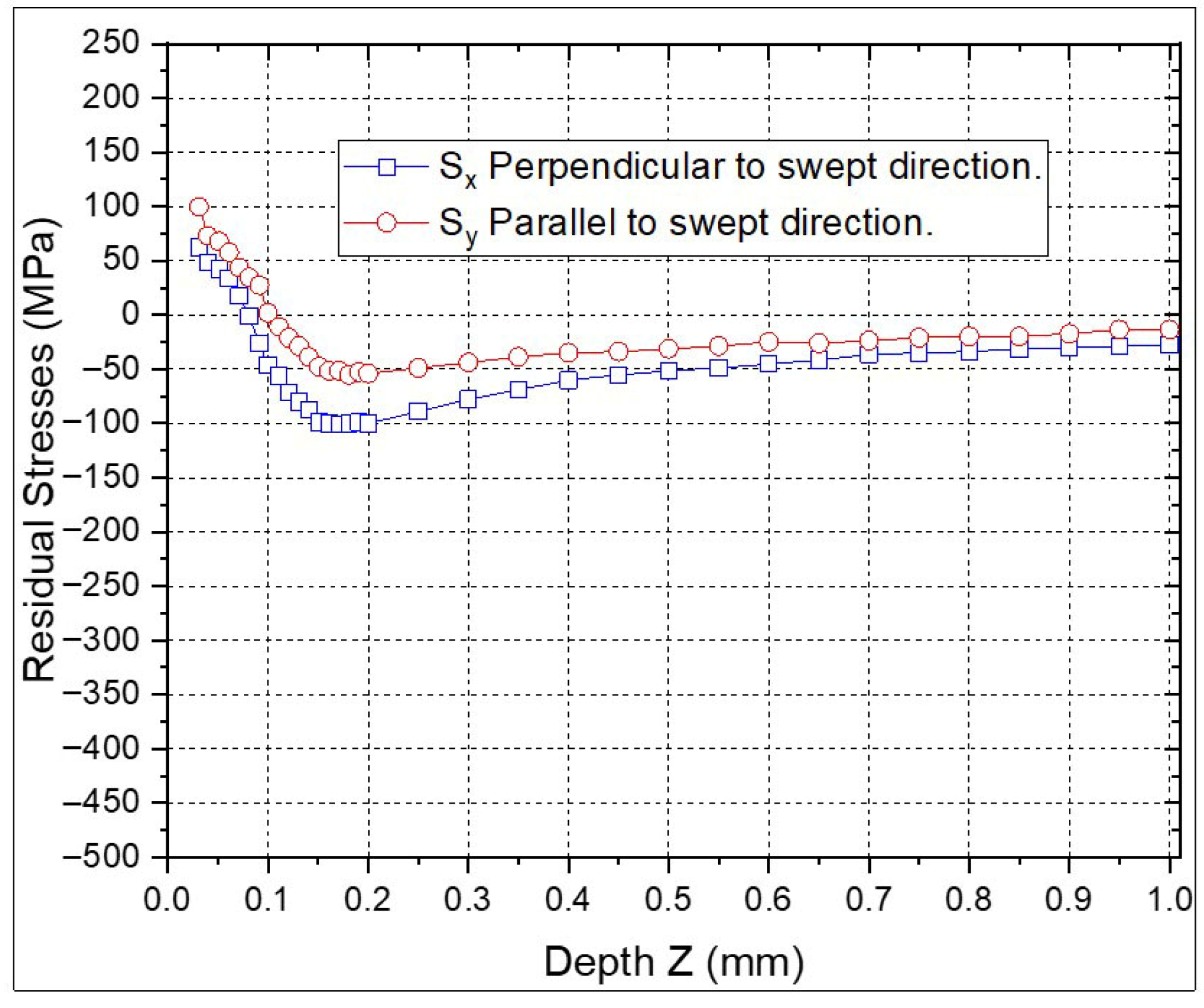

3.1. Residual Stresses (RS) Results

3.2. Microhardness Results

3.3. Roughness

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Uz, M.V.; Koçak, M.; Lemaitre, F.; Ehrström, J.C.; Kempa, S.; Bron, F. Improvement of damage tolerance of laser beam welded stiffened panels for airframes via local engineering. Int. J. Fatigue 2008, 31, 916–926. [Google Scholar] [CrossRef]

- Clauer, A.H. Laser shock peening, the path to production. Metals 2019, 9, 626. [Google Scholar] [CrossRef]

- Anderholm, N.C. Laser-generated stress waves. Appl. Phys. Lett. 1970, 16, 113–115. [Google Scholar] [CrossRef]

- Mallozzi, P.; Fairand, B. Altering Material Properties. U.S. Patent 3,850,698, 26 November 1974. [Google Scholar]

- Fox, J.A. Effect of water and paint coatings on laser-irradiated targets. Appl. Phys. Lett. 1974, 24, 461–464. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Pacchione, M.; Hombergsmeier, E. Hybrid metal laminates for low weight fuselage structures. In Engineering Against Fracture; Springer: Berlin/Heidelberg, Germany, 2009; pp. 41–57. [Google Scholar]

- Gómez-Rosas, G.; Rubio-González, C.; Ocaña, J.L.; Molpeceres, C.; Porro, J.A.; Morales, M.; Casillas, F.J. Laser shock processing of 6061-T6 Al alloy with 1064 nm and 532 nm wavelengths. Appl. Surf. Sci. 2010, 256, 5828–5831. [Google Scholar]

- He, Z.; Shen, Y.; Tao, J.; Chen, H.; Zeng, X.; Huang, X.; Abd El-Aty, A. Laser shock peening regulating aluminum alloy surface residual stresses for enhancing the mechanical properties: Roles of shock number and energy. Surf. Coat. Technol. 2021, 421, 127481. [Google Scholar] [CrossRef]

- Petronic, S.; Sibalija, T.; Burzic, M.; Polic, S.; Colic, K.; Milovanovic, D. Picosecond laser shock peening of Nimonic 263 at 1064 nm and 532 nm wavelength. Metals 2016, 6, 41. [Google Scholar] [CrossRef]

- Keshavarz, M.; Tan, B.; Venkatakrishnan, K. Functionalized stress component onto bio-template as a pathway of cytocompatibility. Sci. Rep. 2016, 6, 35425. [Google Scholar] [CrossRef]

- Sun, R.; He, G.; Bai, H.; Yan, J.; Guo, W. Laser shock peening of Ti6Al4V alloy with combined nanosecond and femtosecond laser pulses. Metals 2021, 12, 26. [Google Scholar] [CrossRef]

- Loja, J.L.L.; Zulca, P.A.M.; Morales, J.E.T. Características del proceso de conformado en láminas de aluminio de la serie 6000. Polo Conoc. 2020, 5, 3–21. [Google Scholar]

- Lopez, J.M.; Munoz-Martín, D.; Moreno-Labella, J.J.; Panizo-Laiz, M.; Gomez-Rosas, G.; Molpeceres, C.; Morales, M. Picose-cond laser shock micro-forming of stainless steel: Influence of high-repetition pulses on thermal effects. Materials 2022, 15, 4226. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Zhang, Z.; Lu, W.; Li, J.; Pan, H.; Liu, L. Corrosion behavior of laser powder bed fusion TA2-Cu-Q345 composite plate subjected to picosecond laser shock peening. Opt. Laser Technol. 2025, 189, 113120. [Google Scholar] [CrossRef]

- Morales, M.; Ocaña, J.L.; Molpeceres, C.; Porro, J.A.; Garcia-Beltran, A. Model-based optimization criteria for the generation of deep compressive residual stress fields in high elastic limit metallic alloys by ns-laser shock processing. Surf. Coat. Technol. 2008, 202, 2257–2262. [Google Scholar] [CrossRef]

- Correa, C.; Peral, D.; Porro, J.A.; Diaz, M.; De Lara, L.R.; Garcia-Beltran, A.; Ocaña, J.L. Random-type scanning patterns in laser shock peening without absorbing coating in 2024-T351 Al alloy: A solution to reduce residual stress anisotropy. Opt. Laser Technol. 2015, 73, 179–187. [Google Scholar] [CrossRef]

- Sano, Y. Quarter century development of laser peening without coating. Metals 2020, 10, 152. [Google Scholar] [CrossRef]

- Rubio-Gonzalez, C.; Ocaña, J.L.; Gomez-Rosas, G.; Molpeceres, C.; Paredes, M.; Banderas, A. Effect of laser shock processing on fatigue crack growth and fracture toughness of 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2004, 386, 291–295. [Google Scholar] [CrossRef]

- Flaman, M.T.; Manning, B.H. Determination of residual-stress variation with depth by the hole-drilling method. Exp. Mech. 1985, 25, 205–207. [Google Scholar] [CrossRef]

- Wang, J.Y. Measurement of residual stress by the hole-drilling method: General stress-strain relationship and its solution. Exp. Mech. 1988, 28, 355–358. [Google Scholar] [CrossRef]

- Cheng, J.; Perrie, W.; Edwardson, S.P.; Fearon, E.; Dearden, G.; Watkins, K.G. Effects of laser operating parameters on metals micromachining with ultrafast lasers. Appl. Surf. Sci. 2009, 256, 1514–1520. [Google Scholar] [CrossRef]

- Kukreja, L.M.; Hoppius, J.S.; Elango, K.; Macias Barrientos, M.; Pohl, F.; Walther, F.; Ostendorf, A. Optimization of processing parameters of ultrashort (100 fs-2 ps) pulsed laser shock peening of stainless steel. J. Laser App. 2021, 33, 042048. [Google Scholar] [CrossRef]

| Chemical Composition | |||||||||

| Element | Si | Mg | Fe | Cu | Mn | Cr | Zn | Ti | Others |

| % | 0.4–0.8 | 0.8–1.2 | 0.7 | 0.15–0.40 | 0.8–1.2 | 0.04–0.35 | 0.25 | 0.15 | 0.15 |

| Mechanical Properties | |||||||||

| Heat Treatment | Density | Poisson Coefficient | Tensile Strength | Yield Strength | Elongation (%) | Young Module | Vickers Hardness | ||

| T6 | g/cm3 | 1/16 Thickness | 1/2 Diameter | ||||||

| 2.70 | ~0.33 | ~310 | ~276 | ~12 | ~17 | 68.9 | 107 | ||

| Make and Model | Pulse Energy | Pulse Width | Pulse Frequency | Beam Diameter on Sample | Power Density | Pulse Density |

|---|---|---|---|---|---|---|

| mJ | s | Hz | ||||

|

Quantel Q-Smart 850 Nd-YAG | ||||||

|

Ekspla Atlantic 355-60 |

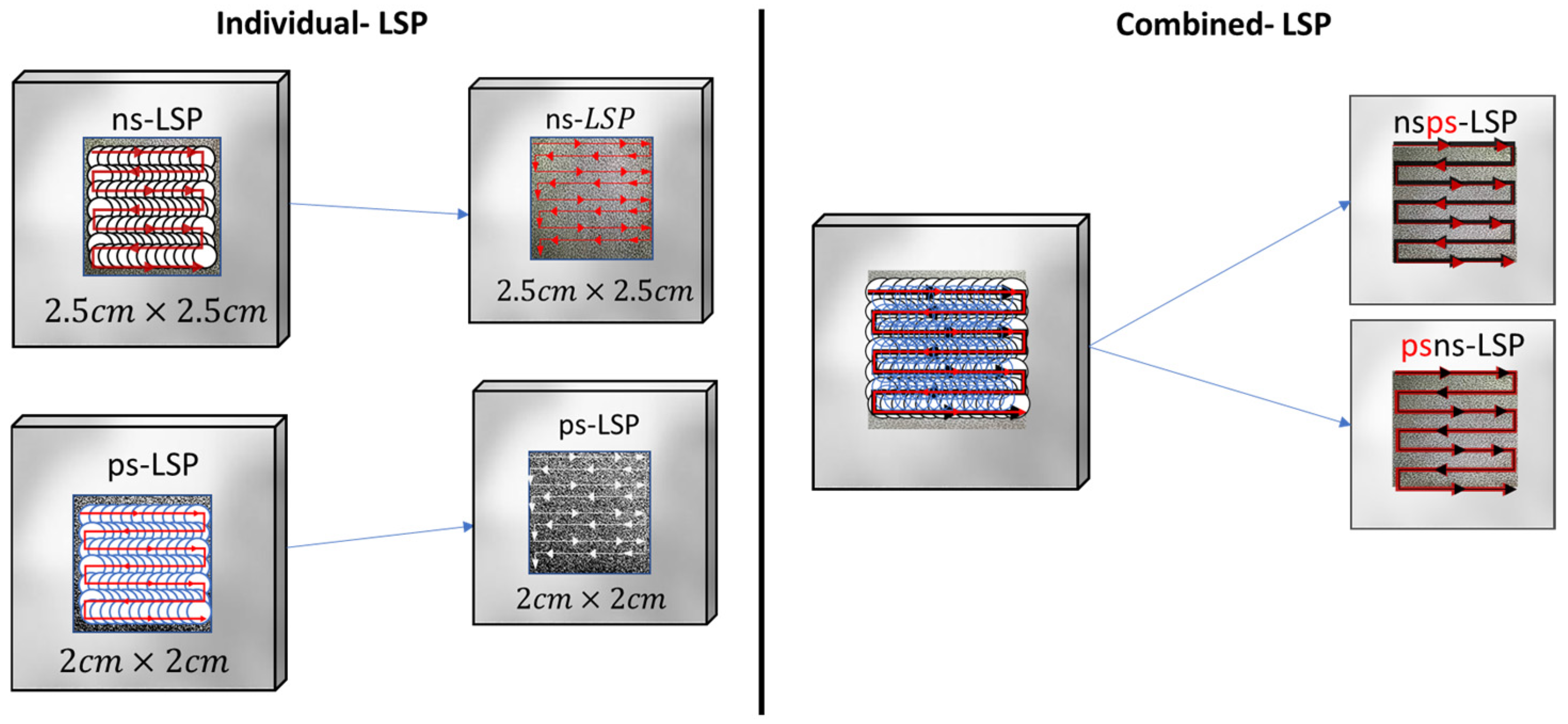

| Nomenclature | Meaning | Pulse Density (Pulses/cm2) | Power Density |

|---|---|---|---|

| Without-LSP | Targets without LSP treatment | ||

| ns-LSP | Targets treated with ns | ||

| ps-LSP | Targets treated with ps | ||

| nsps-LSP | Targets treated with ns and post ps | ||

| psns-LSP | Targets treated with ps and post ns |

| LSP Treatments | Compressive Residual Stresses Perpendicular (Sx) (MPa) | Depth (mm) |

|---|---|---|

| ns-LSP | −383 | 1.0 |

| ps-LSP | −100 | 0.2 |

| nsps-LSP | −428 | 0.85 |

| psns-LSP | −356 | 0.95 |

| Target | Roughness (Ra) (μm) | |

|---|---|---|

| without | 0.334 | ±0.129 |

| ns-LSP | 7.276 | ±0.585 |

| ps-LSP | 6.389 | ±0.455 |

| nsps-LSP | 7.167 | ±0.539 |

| psns-LSP | 12.109 | ±0.504 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arredondo Bravo, M.G.; Gomez-Rosas, G.; Morales, M.; Munoz-Martin, D.; Moreno-Labella, J.J.; Lopez Lopez, J.M.; Quiñones Galvan, J.G.; Rubio-Gonzalez, C.; Casillas Rodriguez, F.J.; Molpeceres, C. Effects of Laser Shock Processing on the Mechanical Properties of 6061-T6 Aluminium Alloy Using Nanosecond and Picosecond Laser Pulses. Materials 2025, 18, 4649. https://doi.org/10.3390/ma18204649

Arredondo Bravo MG, Gomez-Rosas G, Morales M, Munoz-Martin D, Moreno-Labella JJ, Lopez Lopez JM, Quiñones Galvan JG, Rubio-Gonzalez C, Casillas Rodriguez FJ, Molpeceres C. Effects of Laser Shock Processing on the Mechanical Properties of 6061-T6 Aluminium Alloy Using Nanosecond and Picosecond Laser Pulses. Materials. 2025; 18(20):4649. https://doi.org/10.3390/ma18204649

Chicago/Turabian StyleArredondo Bravo, Martha Guadalupe, Gilberto Gomez-Rosas, Miguel Morales, David Munoz-Martin, Juan Jose Moreno-Labella, Jose Manuel Lopez Lopez, Jose Guadalupe Quiñones Galvan, Carlos Rubio-Gonzalez, Francisco Javier Casillas Rodriguez, and Carlos Molpeceres. 2025. "Effects of Laser Shock Processing on the Mechanical Properties of 6061-T6 Aluminium Alloy Using Nanosecond and Picosecond Laser Pulses" Materials 18, no. 20: 4649. https://doi.org/10.3390/ma18204649

APA StyleArredondo Bravo, M. G., Gomez-Rosas, G., Morales, M., Munoz-Martin, D., Moreno-Labella, J. J., Lopez Lopez, J. M., Quiñones Galvan, J. G., Rubio-Gonzalez, C., Casillas Rodriguez, F. J., & Molpeceres, C. (2025). Effects of Laser Shock Processing on the Mechanical Properties of 6061-T6 Aluminium Alloy Using Nanosecond and Picosecond Laser Pulses. Materials, 18(20), 4649. https://doi.org/10.3390/ma18204649