Research on the Aging Characteristics of Simulated Asphalt Within Pavement Structures in Natural Environments

Abstract

1. Introduction

2. Materials and Methods

2.1. Asphalt Materials

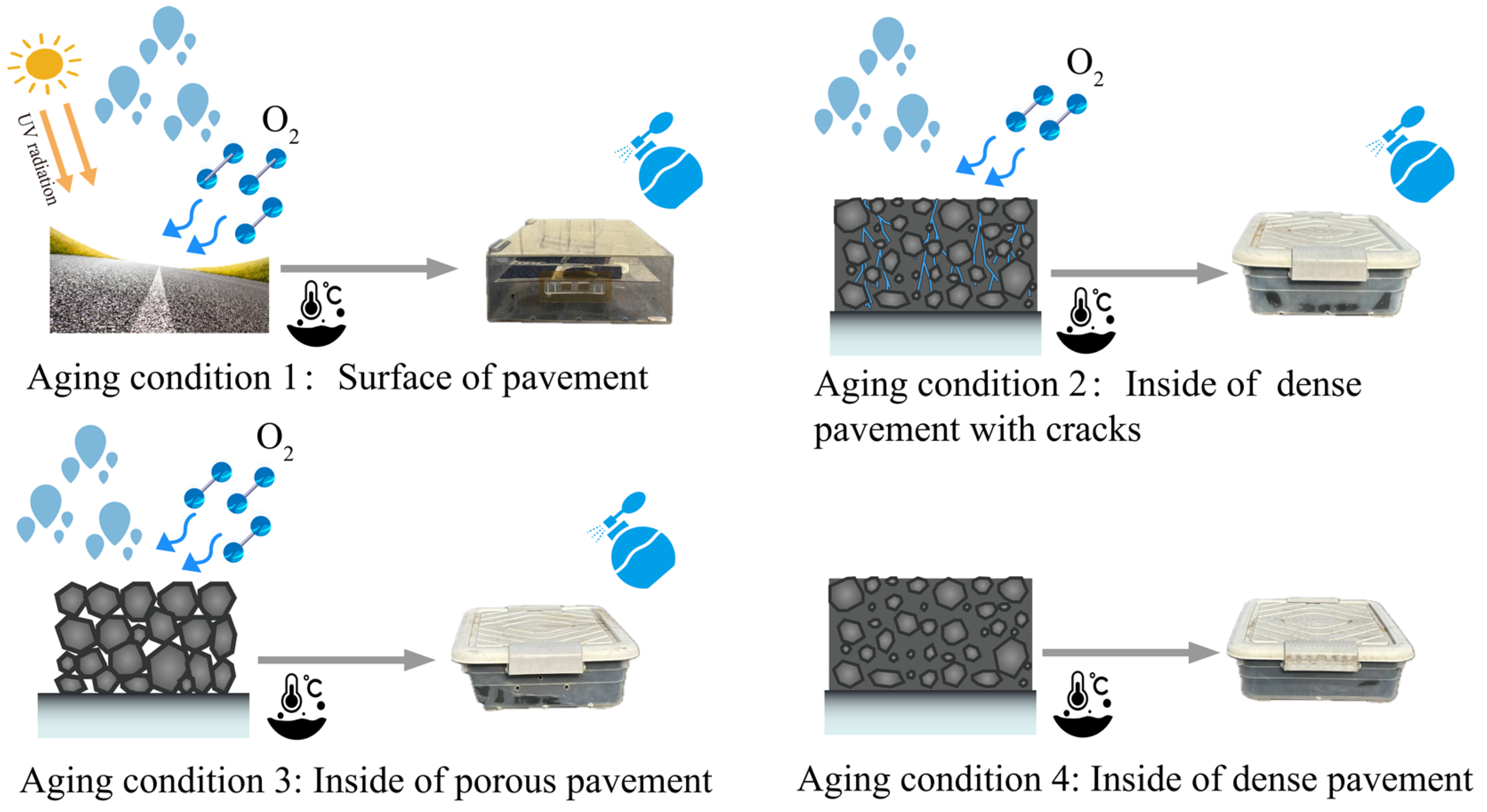

2.2. Preparation of Asphalt Samples Under Different Aging Conditions

2.3. Selection of Testing Frequency

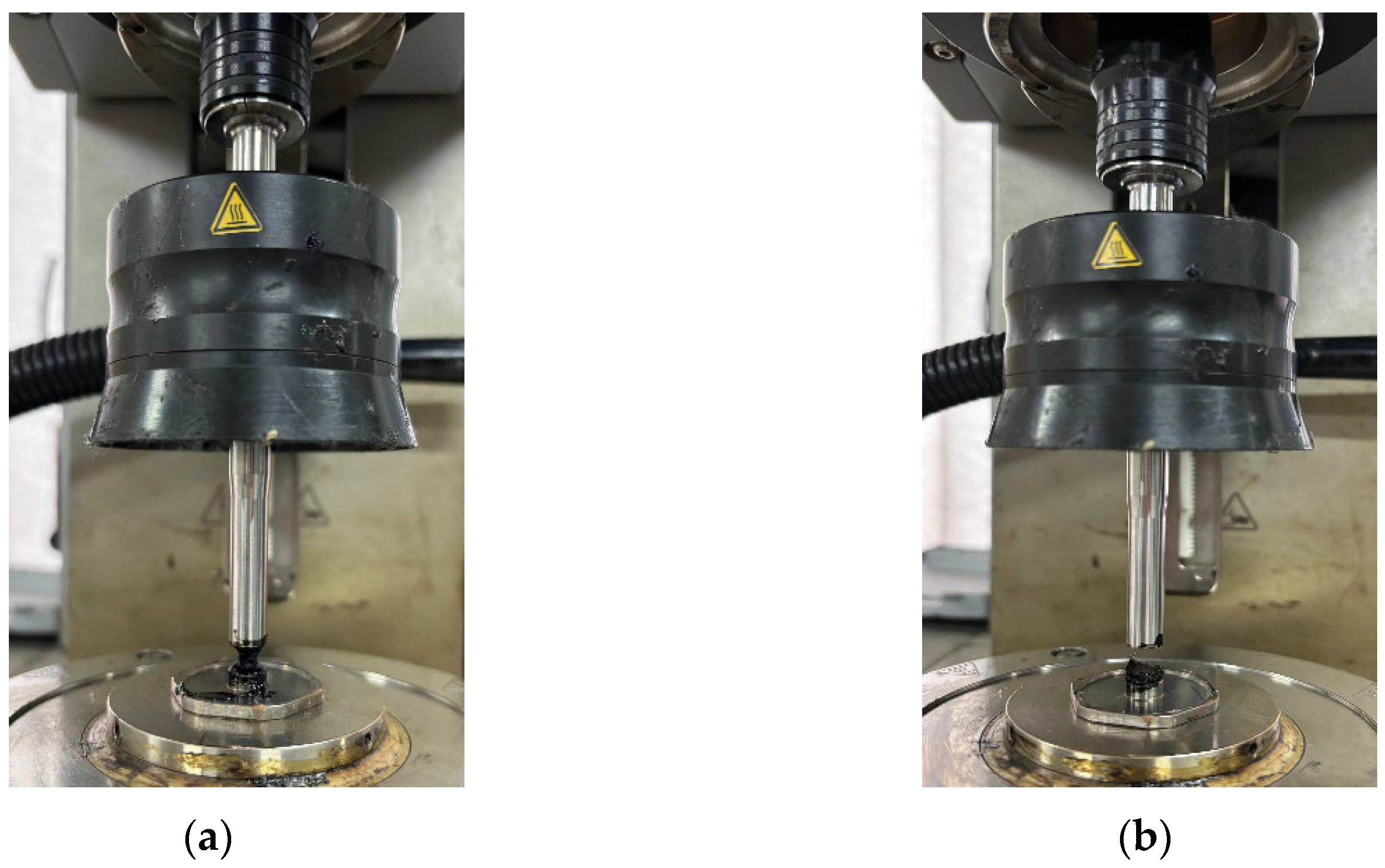

2.4. Test Methods

2.4.1. Fourier Transform Infrared Spectroscopy Test

2.4.2. Atomic Force Microscopy Test

2.4.3. Linear Amplitude Sweep Test

3. Results

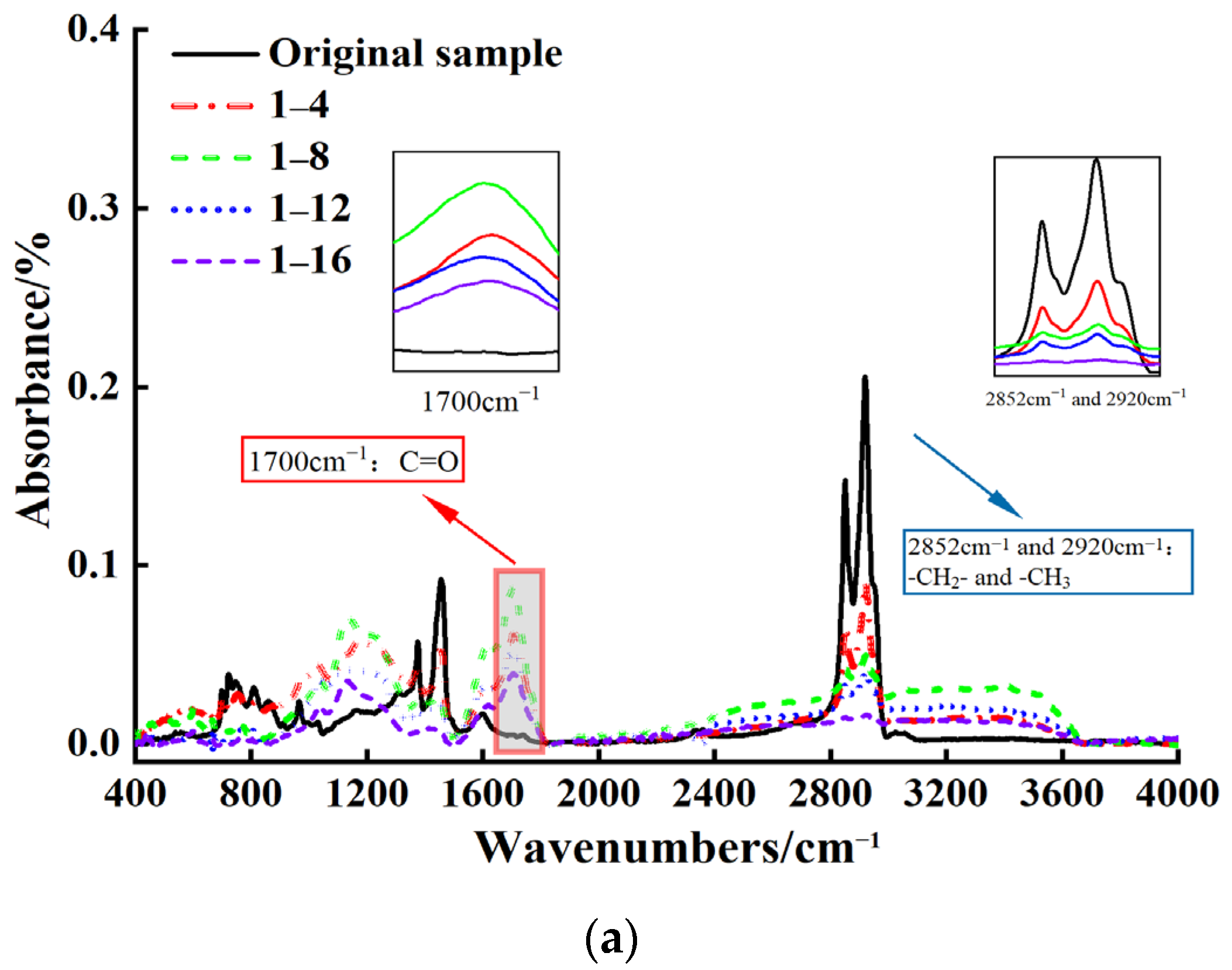

3.1. Chemical Composition

3.2. Microstructure

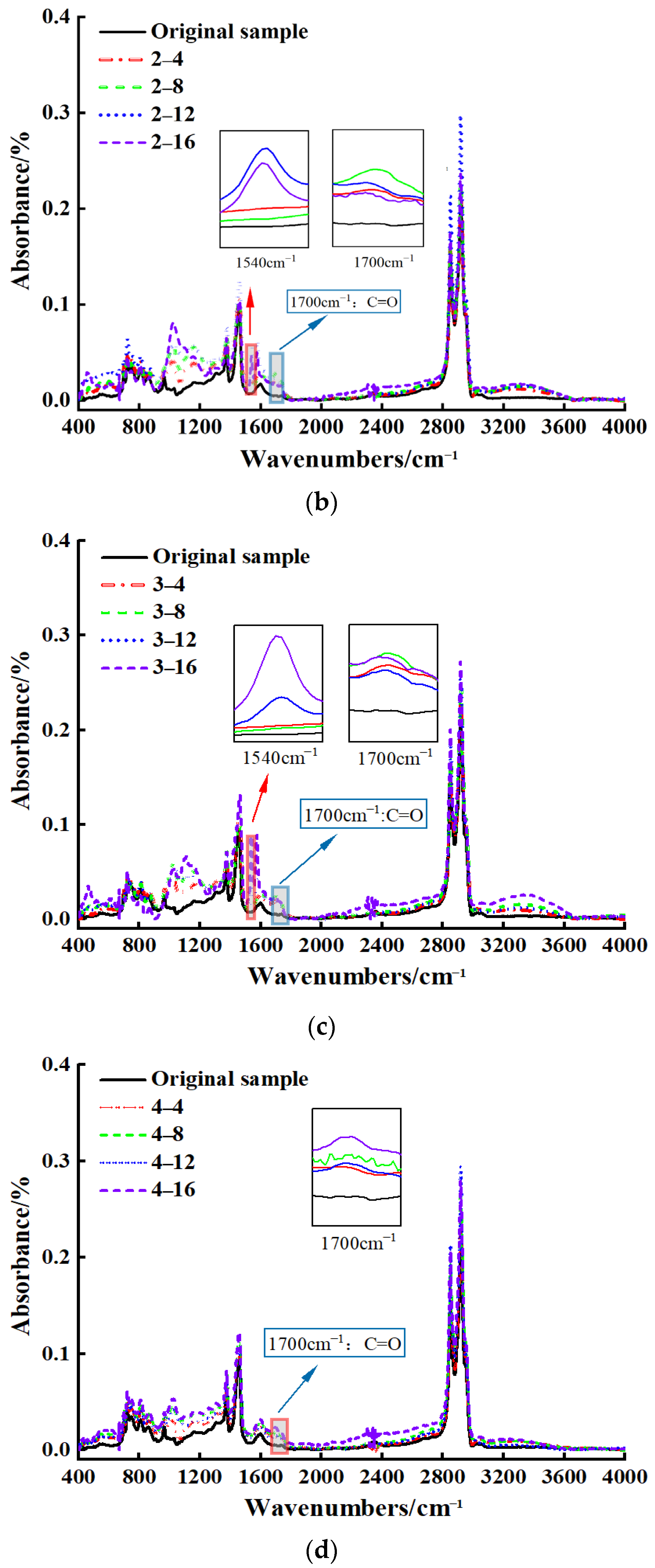

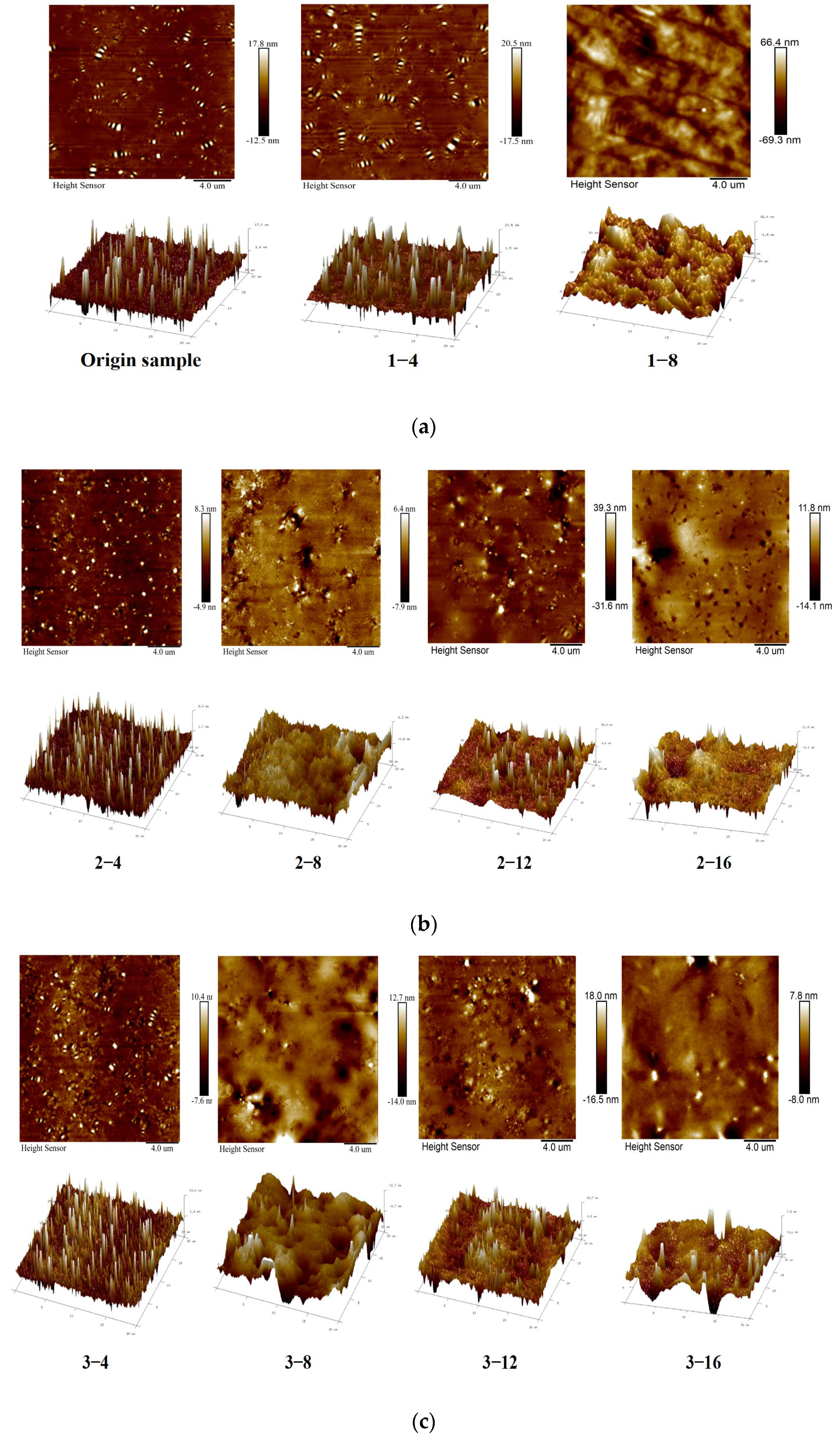

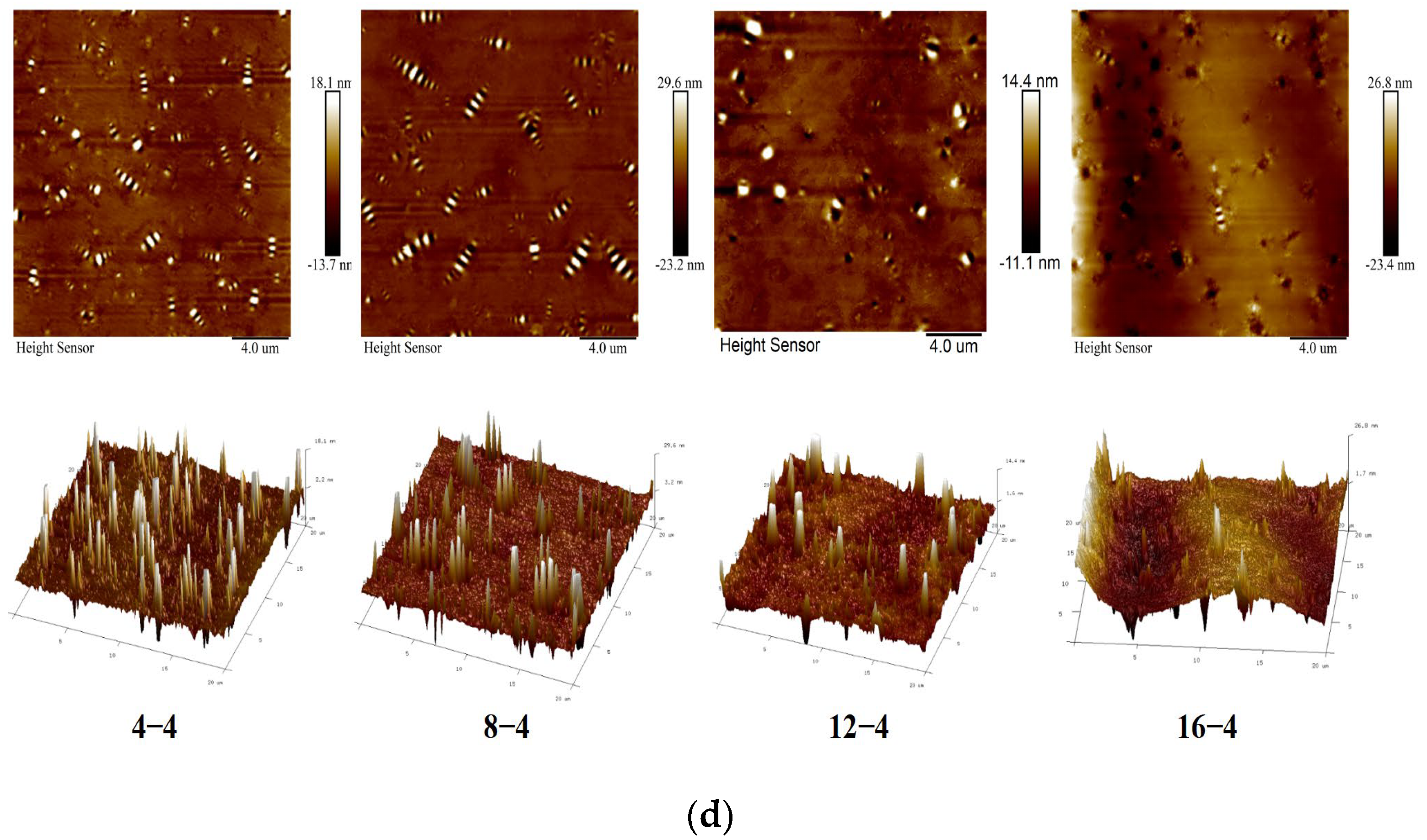

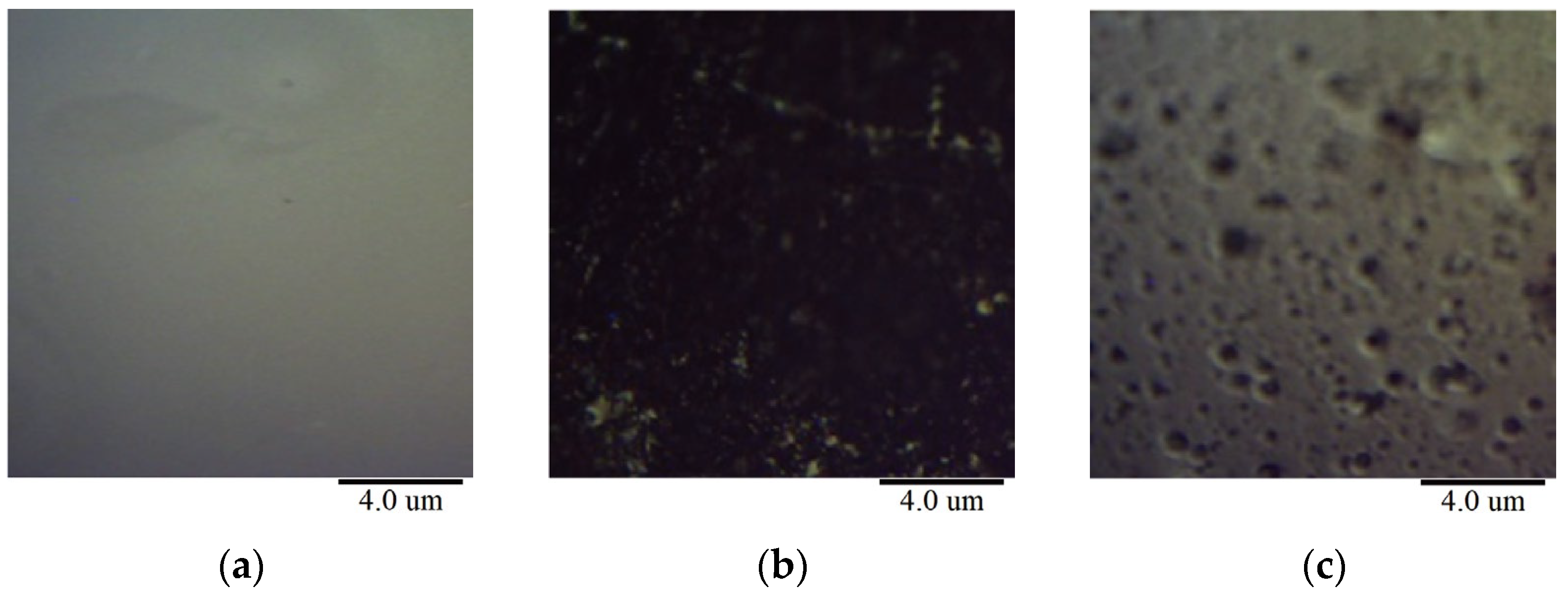

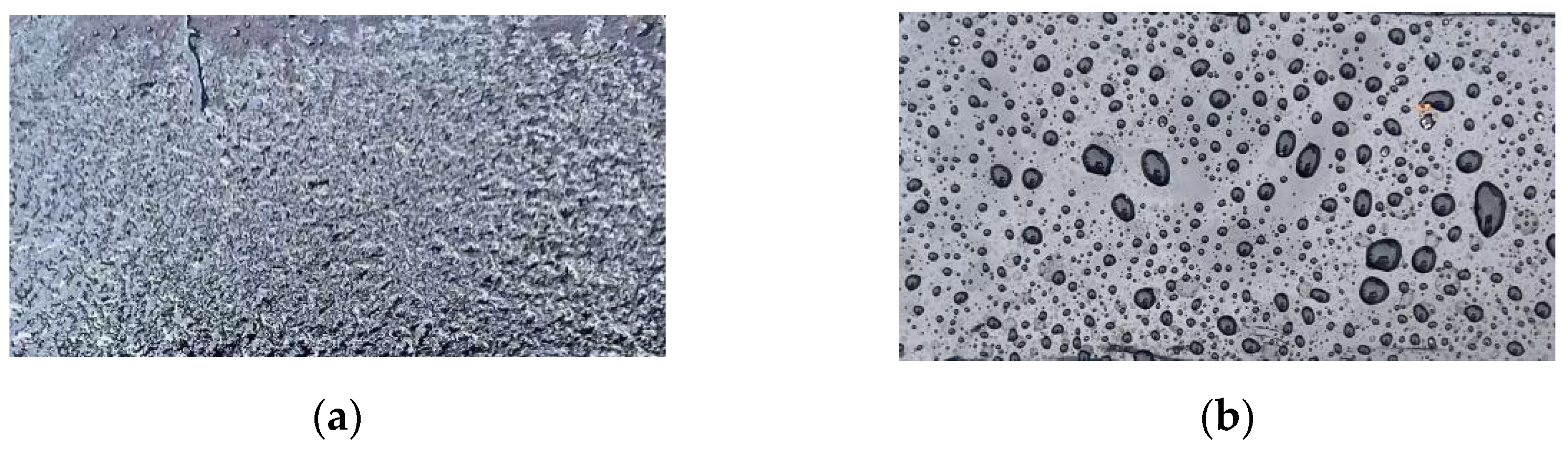

3.2.1. Surface Microtopography Map

3.2.2. Surface Roughness

3.3. Fatigue Behavior

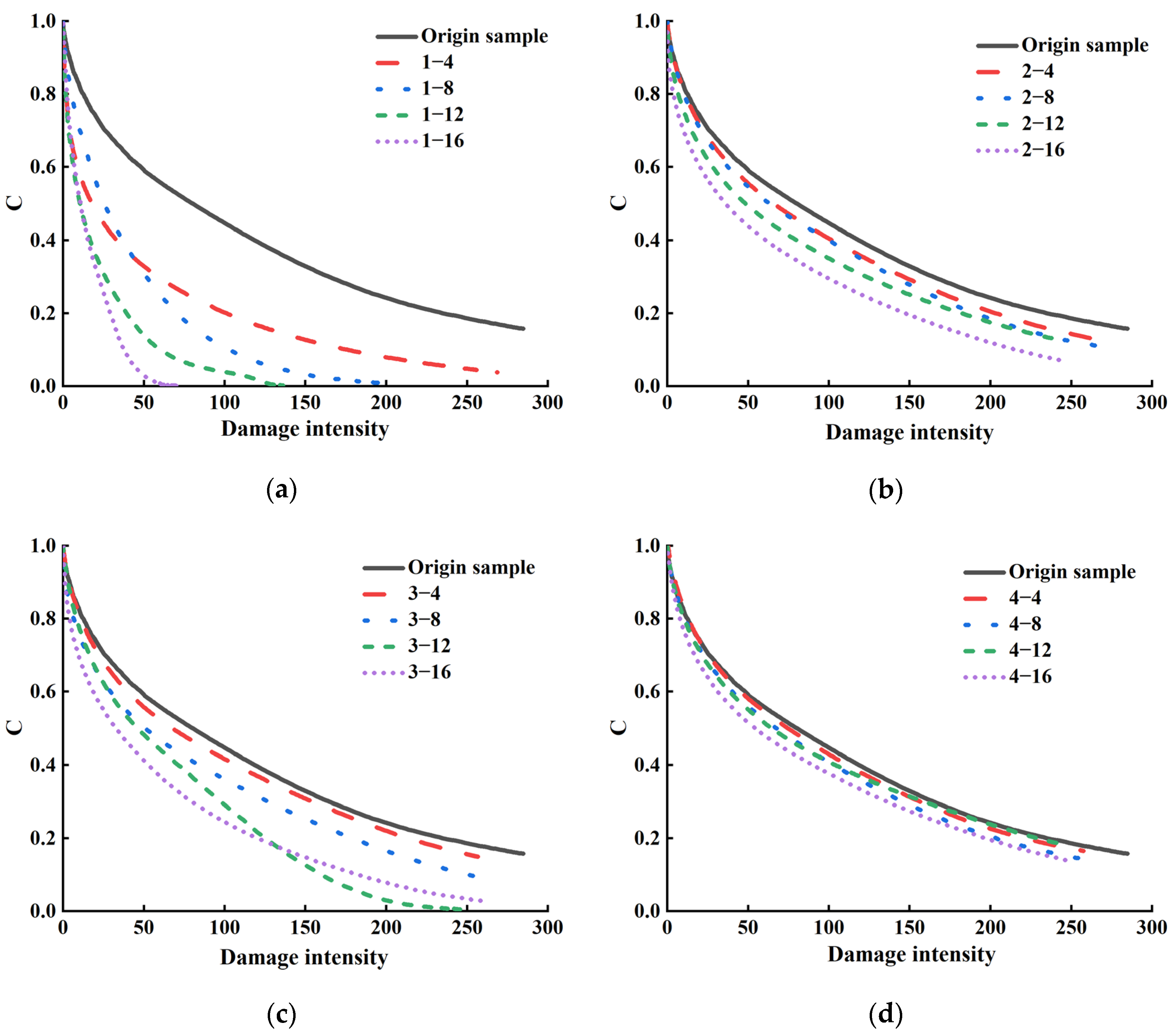

3.3.1. Loss Characteristic Curves

3.3.2. Shear Stress–Strain Curve

3.3.3. Fatigue Life Prediction

4. Conclusions

- (1)

- The aging degree of the asphalt binder on the pavement’s surface is the worst, as the carbon–hydrogen bonds in the CH2 and CH3 groups of asphalt break or oxidize under the influence of natural factors, weakening the intermolecular bonding strength of the asphalt. As the aging duration increases, the surface roughness of the SBS-modified asphalt binder gradually increases, leading to severe oxidation of the asphalt binder surface, making it extremely hard and brittle.

- (2)

- The asphalt in dense pavements with cracks will absorb moisture from the environment. These water molecules interact with the functional groups in the asphalt binder, resulting in new absorption peaks in the infrared spectrum. A honeycomb-like structure aggregation phenomenon appears on the surface, and the area of the honeycomb structure gradually decreases. The asphalt binders’ ability to resist fatigue damage is further weakened.

- (3)

- In high-temperature environments during summer, although the asphalt binder inside the porous pavement dissipates moisture more quickly, it comes into complete contact with the air in the natural environment, resulting in a greater decline in fatigue life compared to the asphalt binder in dense pavements with cracks. The breaking and cross-linking of asphalt molecular chains cause the surface structure to become irregular and fragile, resulting in more severe damage to the microscopic morphology.

- (4)

- For dense pavements, the variation in various aging parameters is minimal under various working conditions. Increasing the density of asphalt concrete and reducing the contact between the asphalt binder and external environments can significantly decrease the aging degree of asphalt binder.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Symbols

| PG | Performance Grade |

| JTG | China’s transportation industry standards of the People’s Republic of China |

| UV | Ultraviolet |

| PF-QNM | Peak Force Quantitative Nanomechanical Mode |

| α | Material constants in the undamaged state |

| m | Estimation of parameters for the primary curve’s slope |

| δ | Phase angle |

| γ0 | Shear strain at the beginning of the cycle |

References

- Ke, S.; Fu, Z.; Ma, F.; Liu, J.; Song, R.M.; Li, J.R.; Dai, J.S.; Li, C.; Wen, Y.L. Development on the rheological properties and micromorphology of active reagent-rejuvenated SBS-modified asphalt. ACS Sustain. Chem. Eng. 2022, 10, 16734–16751. [Google Scholar]

- Ma, X.; Wang, D.J.; Liu, S.; Jiang, J.W.; Kan, J.Q.; Tu, M.Y. Analysis of asphalt microscopic and force curves under water-temperature coupling with AFM. Case Stud. Constr. Mater. 2024, 20, e03071. [Google Scholar] [CrossRef]

- Liu, X.M.; Li, T.Y.; Zhang, H.L. Short-term aging resistance investigations of polymers and polyphosphoric acid modified asphalt binders under RTFOT aging process. Constr. Build. Mater. 2018, 191, 787–794. [Google Scholar] [CrossRef]

- Zhen, T.; Kang, X.X.; Liu, J.Y.; Zhang, B.W.; Si, W.; Ling, T.Q. Multiscale evaluation of asphalt aging behaviour: A review. Sustainability 2023, 15, 2953. [Google Scholar] [CrossRef]

- Nan, Y.; Li, Y.S.; Ma, R.G. An efficient method for detecting asphalt pavement cracks and sealed cracks based on a deep data-driven model. Appl. Sci. 2022, 12, 10089. [Google Scholar] [CrossRef]

- Xu, J.Q.; Fan, Z.P.; Lin, J.; Liu, P.F.; Wang, D.W.; Oeser, M. Study on the effects of reversible aging on the low temperature performance of asphalt binders. Constr. Build. Mater. 2021, 295, 123604. [Google Scholar] [CrossRef]

- Hajj, R.; Bhasin, A. The search for a measure of fatigue cracking in asphalt binders-a review of different approaches. Int. J. Pavement Eng. 2018, 19, 205–219. [Google Scholar] [CrossRef]

- Zeiada, W.; Liu, H.; Alani, M.W.; Ezzat, H.; Al-Khateeb, G.G. An efficient and robust method for evaluating the low-temperature performance of asphalt binder based on DSR testing. Constr. Build. Mater. 2024, 448, 138196. [Google Scholar] [CrossRef]

- Nian, T.F.; Li, P.; Wei, X.Y.; Wang, P.H.; Li, H.S.; Guo, R. The effect of freeze-thaw cycles on durability properties of SBS-modified bitumen. Constr. Build. Mater. 2018, 187, 77–88. [Google Scholar] [CrossRef]

- Song, S.J.; Li, Q.; Wang, J.Q.; Wang, N.; Shang, J.L.; Zhang, S. Utilization of thermoplastic resin as foamed asphalt modifier in cold recycled mixtures. J. Clean. Prod. 2024, 478, 143973. [Google Scholar] [CrossRef]

- Yuan, J.; Li, H.Y.; Li, T.H.; Huang, J.; Sun, W.W. Evolution of asphalt performance under the coupled aging of ultraviolet, high temperature and water. Case Stud. Constr. Mater. 2024, 20, e03220. [Google Scholar] [CrossRef]

- Xia, W.J.; Wang, S.W.; Wang, H.; Xu, T. Thermal characteristics, kinetic models, and volatile constituents during the energy conversion of bituminous SARA Fractions in air. ACS Omega 2020, 5, 20831–20841. [Google Scholar] [CrossRef] [PubMed]

- Javadi, N.H.S.; Hajimohammadi, A.; Heydari, S.; Ng, J.J.K.C.; Kypreos, J.E.; Khalili, N. Investigating the applicability of storage stability test for waste plastic modified bitumen: Morphological analyses. Constr. Build. Mater. 2024, 441, 137451. [Google Scholar] [CrossRef]

- Hong, H.K.; Zhang, H.L.; Zhang, S. Effect of multi-dimensional nanomaterials on the aging behavior of asphalt by atomic force microscope. Constr. Build. Mater. 2020, 260, 120389. [Google Scholar] [CrossRef]

- Yu, T.J.; Wang, J.J.; Zhang, H.T.; Sun, J.Z. Microanalysis of behavior characteristics for asphalt binders on different mineral surfaces based on MD and SEM. Constr. Build. Mater. 2024, 438, 137292. [Google Scholar] [CrossRef]

- Zhang, W.X.; Li, Q.; Wang, J.Q.; Zhao, Z.L.; Jin, D.Z. Physical and chemical evaluation of adhesion recovery property of aged high-viscosity asphalt based on specialized composite rejuvenators. J. Clean. Prod. 2023, 414, 137758. [Google Scholar] [CrossRef]

- Magazzù, A.; Marcuello, C. Investigation of Soft Matter Nanomechanics by Atomic Force Microscopy and Optical Tweezers: A Comprehensive Review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef]

- Hirato, T.; Himeno, K.; Murayama, M.; Takahashi, S. Effect of long-term aging on rheological properties of asphalt. J. Jpn. Pet. Inst. 2016, 59, 97–103. [Google Scholar] [CrossRef]

- Li, Q.; Zeng, X.H.; Wang, J.Q.; Luo, S.; Meng, Y.P.; Gao, L.; Wang, X.W. Aging performance of high viscosity modified asphalt under complex heat-light-water coupled conditions. Constr. Build. Mater. 2022, 325, 126314. [Google Scholar] [CrossRef]

- Song, S.L.; Liang, M.C.; Wang, L.B.; Li, D.N.; Guo, M.; Yan, L.C.; Zhang, X.J.; Ding, W.X. Effects of different natural factors on rheological properties of sbs modified asphalt. Materials 2022, 15, 5628. [Google Scholar] [CrossRef]

- Wu, S.P.; Zhao, Z.J.; Xiao, Y.; Yi, M.W.; Chen, Z.W.; Li, M.L. Evaluation of mechanical properties and aging index of 10-year field aged asphalt materials. Constr. Build. Mater. 2017, 155, 1158–1167. [Google Scholar] [CrossRef]

- Yao, H.; Dai, Q.L.; You, Z.P. Fourier Transform Infrared Spectroscopy characterization of aging-related properties of original and nano-modified asphalt binders. Constr. Build. Mater. 2015, 101, 1078–1087. [Google Scholar] [CrossRef]

- Wang, H.T.; Du, Z.M.; Liu, G.Y.; Luo, X.F.; Yang, C.L. Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene-Butadiene-Styrene-Modified Bio-Blend Bitumen. Polymers 2023, 15, 2911. [Google Scholar] [CrossRef] [PubMed]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communication Press: Beijing, China, 2011.

- AASHTO Designation:TP101-14; Standard Test Method for Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- Schapery, R.A. Deformation and fracture characterization of inelastic composite materials using potentials. Polym. Eng. Sci. 1987, 27, 63–76. [Google Scholar] [CrossRef]

- Wei, H.; Bai, X.P.; Qian, G.P.; Wang, F.Y.; Li, Z.F.; Jin, J.; Zhang, Y.H. Aging mechanism and properties of SBS modified bitumen under complex environmental conditions. Materials 2019, 12, 1189. [Google Scholar] [CrossRef] [PubMed]

- Xia, Q.Q.; Shi, L.S.; Ma, D.; Xu, T. Biodegradation mechanism of asphalt by microbial consortia in asphalt pavement of forest area road. Int. Biodeterior. Biodegrad. 2025, 196, 105930. [Google Scholar] [CrossRef]

- Cong, P.L.; Chen, Z.H.; Ge, W.S. Influence of moisture on the migration of asphalt components and the adhesion between asphalt binder and aggregate. Constr. Build. Mater. 2023, 385, 131513. [Google Scholar] [CrossRef]

- Luo, L.; Yang, S.H.; Markus, O.; Liu, P.F. Moisture damage mechanism of asphalt mixtures containing reclaimed asphalt pavement binder: A novel molecular dynamics study. J. Clean. Prod. 2024, 475, 143711. [Google Scholar] [CrossRef]

- Xu, H.Y.; Xu, T.; Liu, S.; Gan, X.L.; Yang, C.H.; Liu, H.H. Investigation into diffusion behaviours of moisture in asphalt film using Fourier transform infrared spectroscopy. Int. J. Pavement Eng. 2024, 25, 2400549. [Google Scholar] [CrossRef]

- Liu, F.; Wang, Q.; Zhang, X.; Zhou, Z.D.; Guo, C.Y. Effect of oxidation kinetic aging on the adhesion behaviour of asphalt-aggregate interfaces from molecular view. Int. J. Pavement Eng. 2024, 25, 2313499. [Google Scholar] [CrossRef]

- Dourado, E.R.; Simao, R.A.; Leite, L.F.M. Mechanical properties of asphalt binders evaluated by atomic force microscopy. J. Microsc. 2012, 245, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Hung, A.M.; Goodwin, A.; Fini, E.H. Effects of water exposure on bitumen surface microstructure. Constr. Build. Mater. 2017, 135, 682–688. [Google Scholar] [CrossRef]

- Sun, E.Y.; Zhao, Y.Q.; Wang, G.Z. Analysis of nanoscale evolution features of microstructure of asphalt based on atomic force microscopy. Constr. Build. Mater. 2023, 409, 133958. [Google Scholar] [CrossRef]

- Hu, M.J.; Sun, D.Q.; Zhang, Y.; Yu, F.; Lu, T.; Sun, G.Q.; Ma, J.M. Evaluation of weathering aging on resistance of high viscosity modified asphalt to permanent deformation and fatigue damage. Constr. Build. Mater. 2020, 264, 120683. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Xu, G.; Chen, X.H.; Wang, R.; Shen, K. Effect of long-term laboratory aging on rheological properties and cracking resistance of polymer-modified asphalt binders at intermediate and low temperature range. Constr. Build. Mater. 2019, 226, 767–777. [Google Scholar] [CrossRef]

- Hintz, C.; Bahia, H. Understanding mechanisms leading to asphalt binder fatigue in the dynamic shear rheometer. Road Mater. Pavement Des. 2013, 14, 231–251. [Google Scholar] [CrossRef]

- Yi, M.W.; Delehei, D.; Wang, J.C.; Feng, X.D. Effect of ultraviolet light aging on fatigue properties of asphalt. Key Eng. Mater. 2014, 599, 125–129. [Google Scholar] [CrossRef]

| Technical Index | Test Result | Technical Requirement | |

|---|---|---|---|

| Penetration (25 °C, g, 5 s) (0.1 mm) | 55.5 | 40~60 | |

| Ductility (5 °C, 5 cm/min) (cm) | 37.4 | ≥20 | |

| Softening point (°C) | 78.5 | ≥60 | |

| After thin film oven test (TFOT) | Weight loss (%) | −0.15 | ±0.6 |

| Penetration comparison (%) | 73.2 | ≥65 | |

| Ductility (cm) | 25 | ≥20 | |

| Performance grade | PG76-22 | ||

| Aging Stage | Accumulative Aging Time | Four Months | Eight Months | Twelve Months | Sixteen Months |

|---|---|---|---|---|---|

| Increased Aging Period | 24 October 2022–24 February 2023 | 24 February 2023–24 June 2023 | 24 June 2023–24 October 2023 | 24 October 2023–24 February 2024 | |

| Temperature (°C) | Average value | 7.6 | 18.5 | 25.5 | 7.1 |

| Maximum value | 25.0 | 35.8 | 38.5 | 29.4 | |

| Humidity (%) | Average value | 71.6 | 68.6 | 81.7 | 72.7 |

| Maximum value | 100 | 100 | 100 | 100 | |

| Radiation (W/m2) | Accumulative value | 334,780 | 5,663,308 | 493,785 | 356,724 |

| Average value | 112.49 | 196.63 | 168.64 | 119.28 | |

| Maximum value | 765.9 | 993.4 | 953.1 | 757.0 |

| Sample Number | Ra | Rq | Rq − Ra |

|---|---|---|---|

| Original sample | 1.515 | 3.270 | 1.755 |

| 4-S-1 | 3.380 | 4.710 | 1.330 |

| 8-S-1 | 3.750 | 4.850 | 1.100 |

| 4-S-2 | 0.921 | 1.550 | 0.629 |

| 8-S-2 | 1.357 | 2.060 | 0.703 |

| 12-S-2 | 2.470 | 3.177 | 0.707 |

| 16-S-2 | 2.760 | 3.760 | 1.000 |

| 4-S-3 | 1.383 | 2.487 | 1.104 |

| 8-S-3 | 1.798 | 2.598 | 0.800 |

| 12-S-3 | 2.543 | 3.590 | 1.047 |

| 16-S-3 | 3.177 | 4.410 | 1.233 |

| 4-S-4 | 1.735 | 3.405 | 1.670 |

| 8-S-4 | 2.095 | 3.815 | 1.720 |

| 12-S-4 | 2.087 | 3.117 | 1.030 |

| 16-S-4 | 1.773 | 2.710 | 0.937 |

| Fatigue Life | ||||||||

|---|---|---|---|---|---|---|---|---|

| Aging condition | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 |

| Original sample | 31,577 | 4128 | ||||||

| Four months | 15,986 | 22,862 | 21,989 | 32,807 | 2593 | 3690 | 3553 | 5292 |

| Eight months | 2687 | 19,625 | 18,437 | 22,575 | 435 | 3165 | 2959 | 3640 |

| Twelve months | 1759 | 8352 | 5956 | 20,378 | 282 | 1341 | 950 | 3025 |

| Sixteen months | 434 | 4254 | 2326 | 17,161 | 70 | 682 | 376 | 2771 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Diao, W.; Xu, J.; Wang, D.; Hou, Y. Research on the Aging Characteristics of Simulated Asphalt Within Pavement Structures in Natural Environments. Materials 2025, 18, 434. https://doi.org/10.3390/ma18020434

Ma X, Diao W, Xu J, Wang D, Hou Y. Research on the Aging Characteristics of Simulated Asphalt Within Pavement Structures in Natural Environments. Materials. 2025; 18(2):434. https://doi.org/10.3390/ma18020434

Chicago/Turabian StyleMa, Xiang, Weiyi Diao, Jiachen Xu, Dongjia Wang, and Yanming Hou. 2025. "Research on the Aging Characteristics of Simulated Asphalt Within Pavement Structures in Natural Environments" Materials 18, no. 2: 434. https://doi.org/10.3390/ma18020434

APA StyleMa, X., Diao, W., Xu, J., Wang, D., & Hou, Y. (2025). Research on the Aging Characteristics of Simulated Asphalt Within Pavement Structures in Natural Environments. Materials, 18(2), 434. https://doi.org/10.3390/ma18020434