Exploitation of Perennial Plant Biomass for Particleboards Designed for Insulation Applications

Abstract

1. Introduction

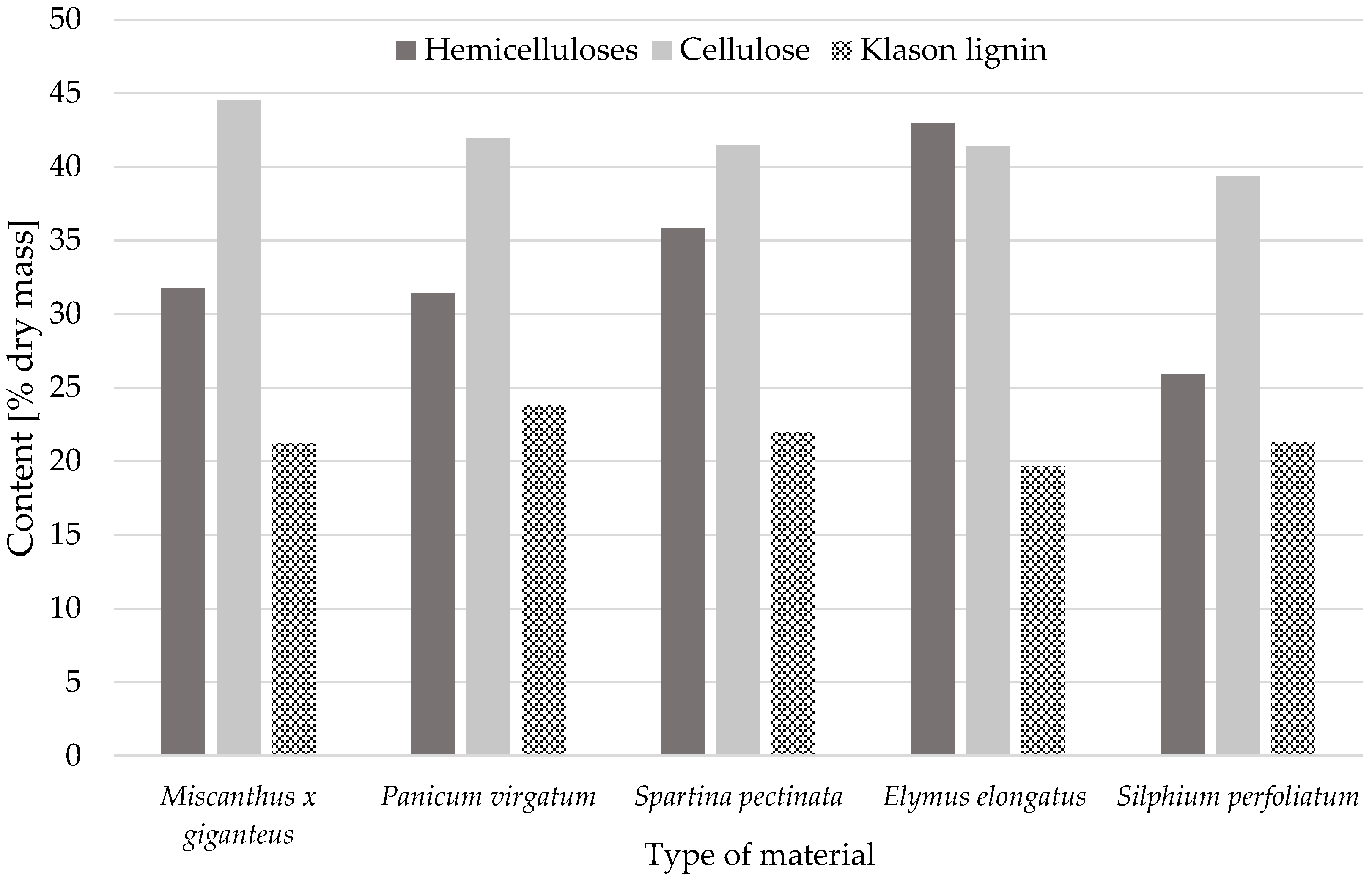

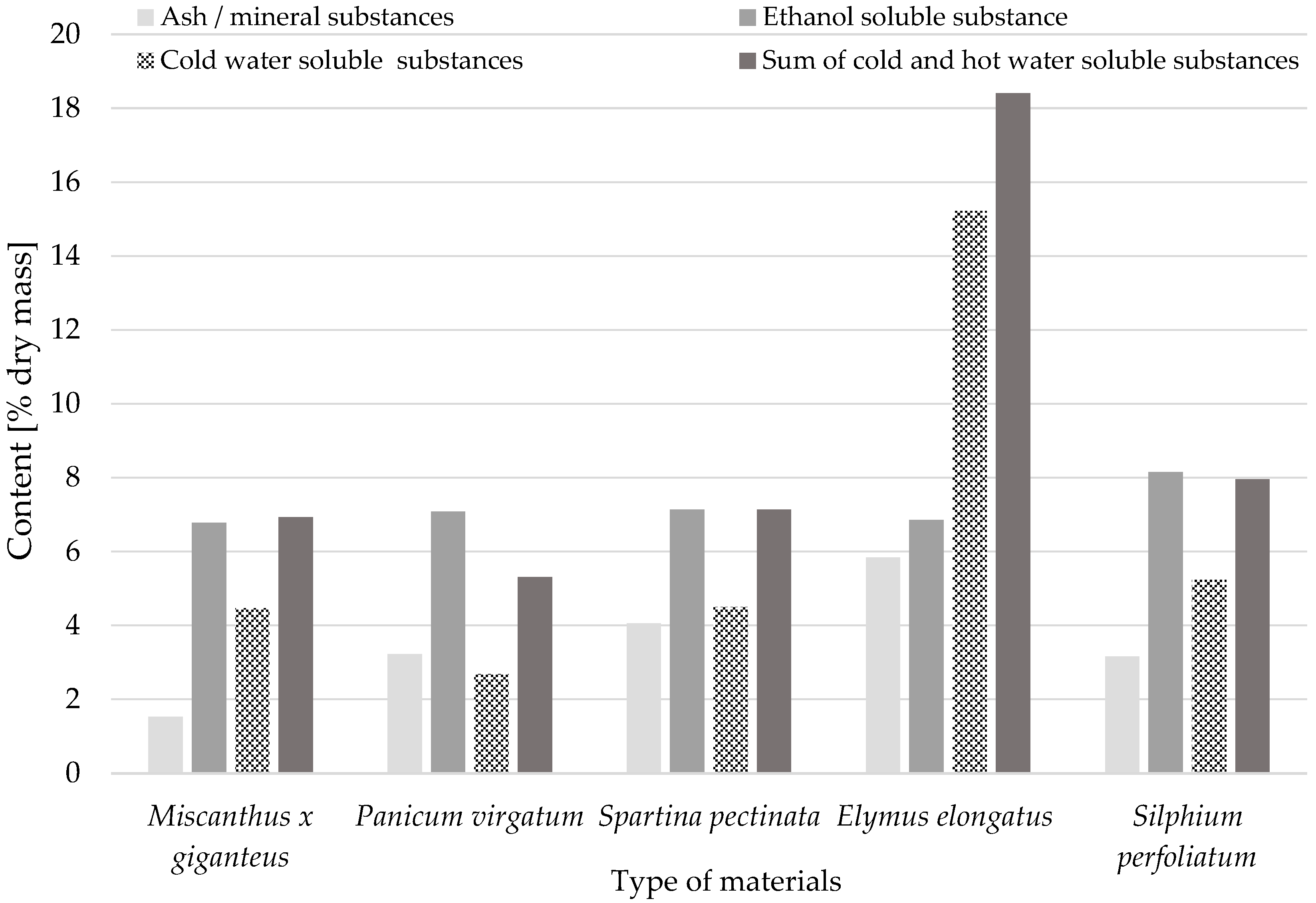

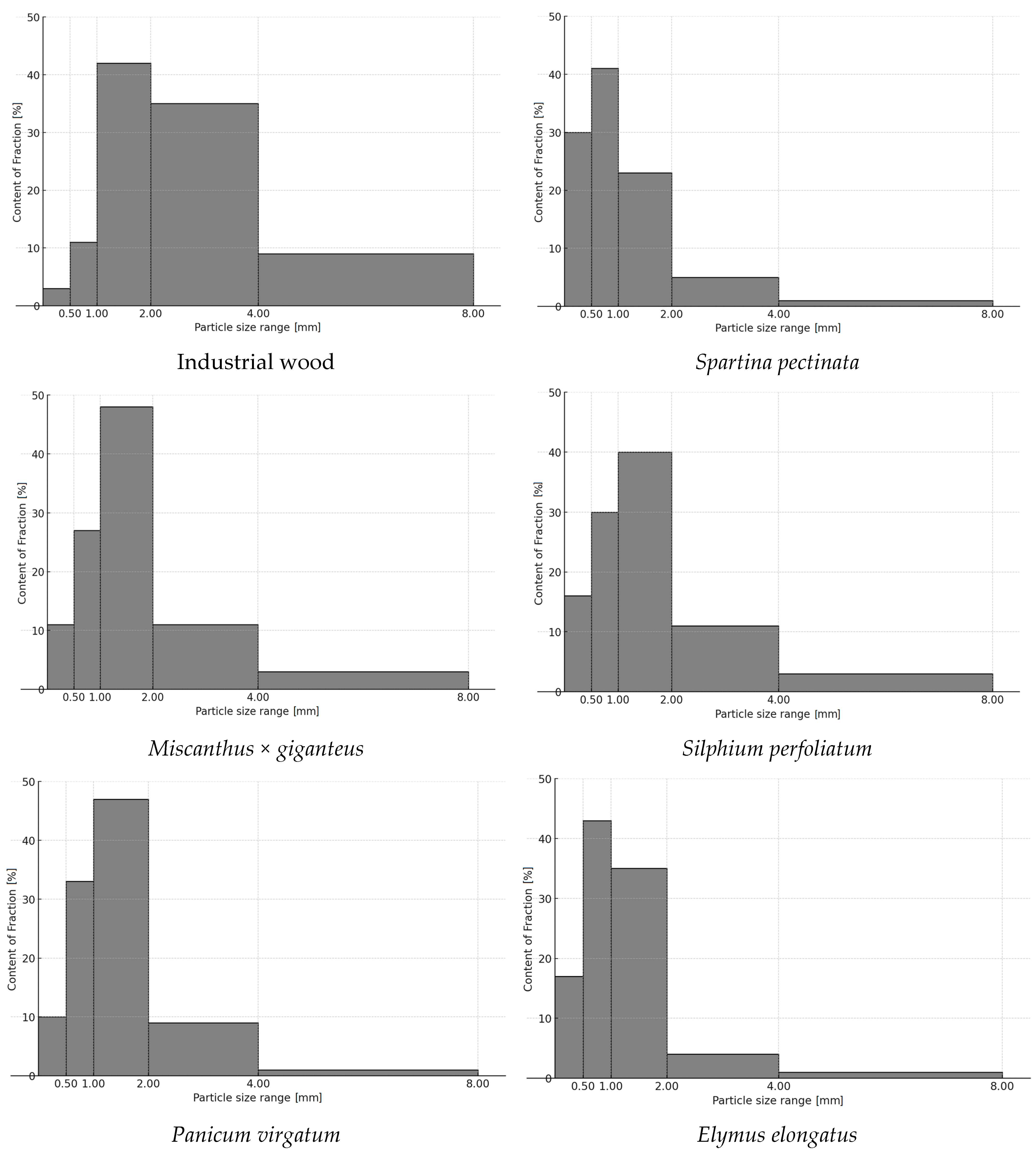

2. Materials and Methods

2.1. Collection of Perennial Grass Biomass and Preparation of Materials

2.2. Production of Particleboard

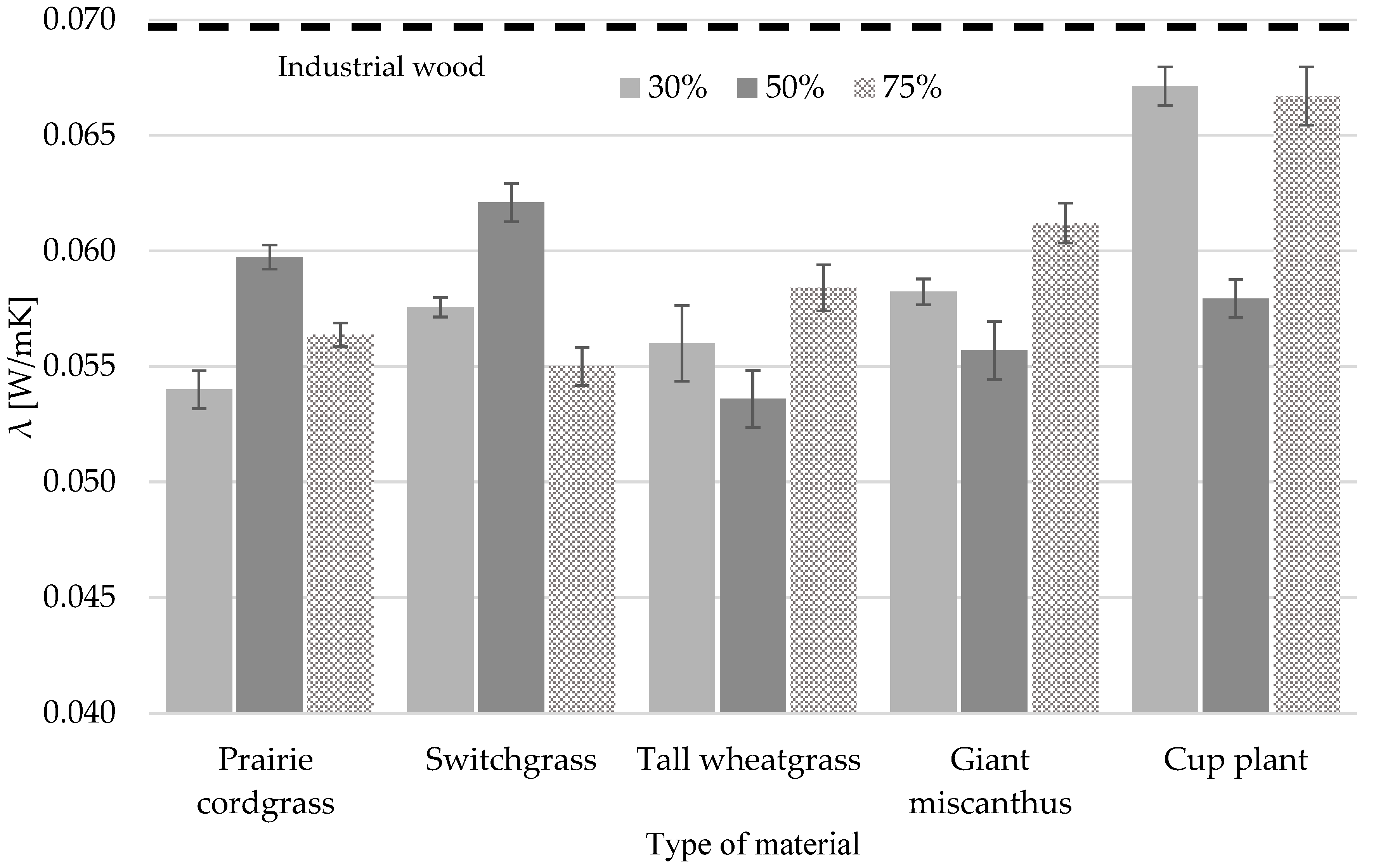

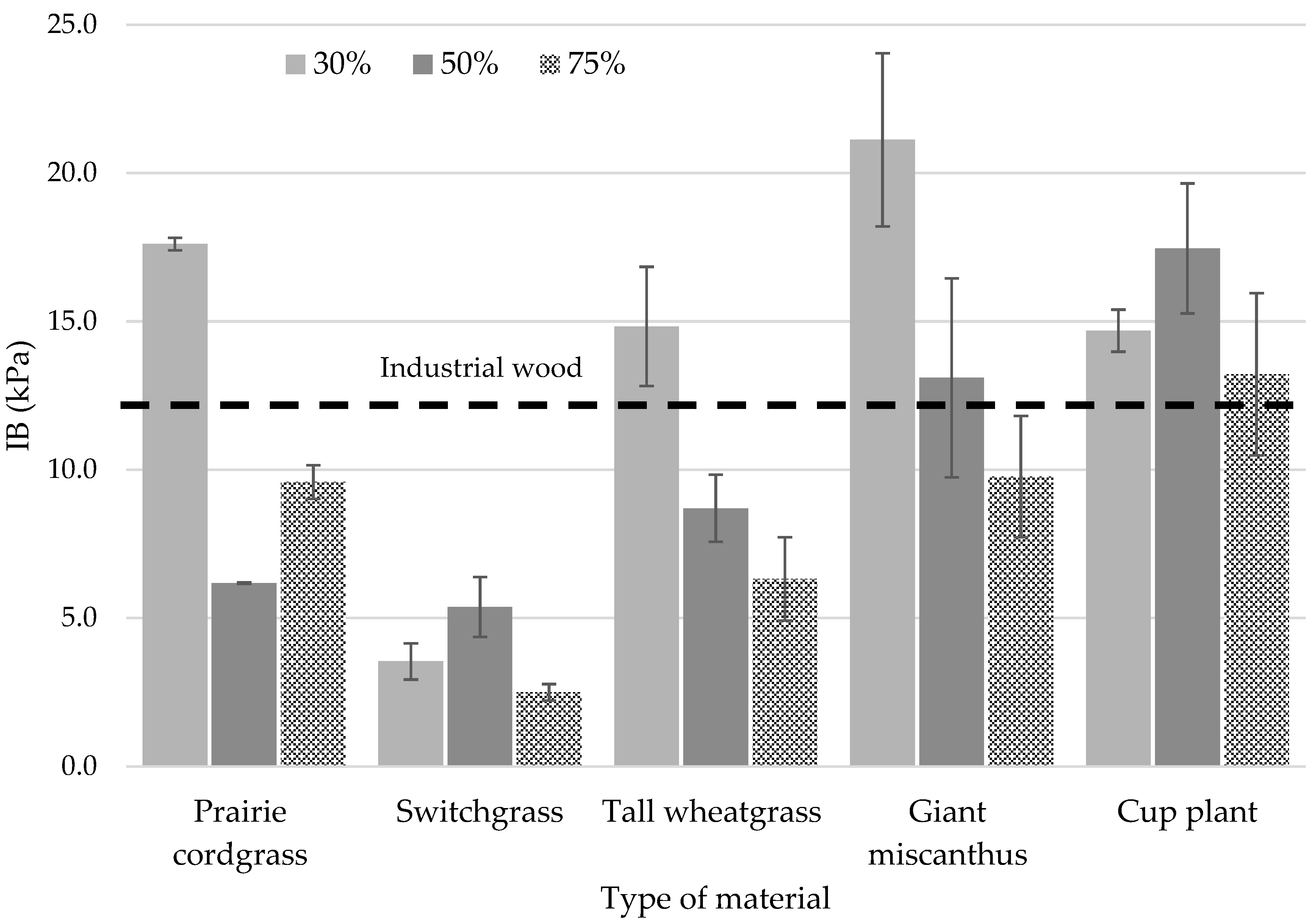

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. Global Forest Resources Assessment 2020; FAO: Rome, Italy, 2020. [Google Scholar]

- Köhl, M.; Linser, S.; Prins, K.; Talarczyk, A. The EU Climate Package “Fit for 55”—A Double-Edged Sword for Europeans and Their Forests and Timber Industry. For. Policy Econ. 2021, 132, 102596. [Google Scholar] [CrossRef]

- De Lombaerde, E.; Vangansbeke, P.; Lenoir, J.; Van Meerbeek, K.; Lembrechts, J.; Rodríguez-Sánchez, F.; Luoto, M.; Scheffers, B.; Haesen, S.; Aalto, J.; et al. Maintaining Forest Cover to Enhance Temperature Buffering under Future Climate Change. Sci. Total Environ. 2022, 810, 151338. [Google Scholar] [CrossRef] [PubMed]

- Reyer, C.; Guericke, M.; Ibisch, P.L. Climate Change Mitigation via Afforestation, Reforestation and Deforestation Avoidance: And What about Adaptation to Environmental Change? New For. 2009, 38, 15–34. [Google Scholar] [CrossRef]

- Green, M.; Taggart, J. Tall Wood Buildings: Design, Construction and Performance; Birkhäuser: Basel, Switzerland, 2020; ISBN 9783035604764. [Google Scholar]

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Wood as a Building Material in the Light of Environmental Assessment of Full Life Cycle of Four Buildings. Constr. Build. Mater. 2014, 52, 428–436. [Google Scholar] [CrossRef]

- Michalec, K.; Wąsik, R.; Gach, M. Impact of the Presence of Foreign Bodies on Quality and Value of Oak Timber. Drewno. Pr. Nauk. Doniesienia Komun. Wood. Res. Pap. Rep. Announc. 2023, 66, 00005. [Google Scholar] [CrossRef]

- Łukawski, D.; Hochmańska-Kaniewska, P.; Janiszewska-Latterini, D.; Lekawa-Raus, A. Functional Materials Based on Wood, Carbon Nanotubes, and Graphene: Manufacturing, Applications, and Green Perspectives. Wood Sci. Technol. 2023, 57, 989–1037. [Google Scholar] [CrossRef]

- Ahmed, M.Z.; Sikora, K.S. Mechanical Properties of Cross Laminated Panels Made From Date Palm Fibres. Drewno. Pr. Nauk. Doniesienia Komun. Wood. Res. Pap. Rep. Announc. 2024, 67, 213. [Google Scholar] [CrossRef]

- Tomczak, K.; Mania, P.; Cukor, J.; Vacek, Z.; Tomczak, A. Wood Quality of Pendulate Oak on Post-Agricultural Land: A Case Study Based on Physico-Mechanical and Anatomical Properties. Forests 2024, 15, 1394. [Google Scholar] [CrossRef]

- Zeidler, A.; Borůvka, V.; Tomczak, K.; Vacek, Z.; Cukor, J.; Vacek, S.; Tomczak, A. The Potential of Non-Native Pines for Timber Production—A Case Study from Afforested Post-Mining Sites. Forests 2024, 15, 1388. [Google Scholar] [CrossRef]

- Pędzik, M.; Tomczak, K.; Janiszewska-Latterini, D.; Tomczak, A.; Rogoziński, T. Management of Forest Residues as a Raw Material for the Production of Particleboards. Forests 2022, 13, 1933. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Pędzik, M.; Júda, M.; Kminiak, R.; Czerniejewska-Wolska, H.; Rogoziński, T. The Effect of Average Chip Thickness on the Potentially Respirable Dust from CNC Finish Milling of Wood-Based Materials. Drewno. Pr. Nauk. Doniesienia Komun. Wood. Res. Pap. Rep. Announc. 2024, 67, 213. [Google Scholar] [CrossRef]

- Rathour, R.K.; Behl, M.; Dhashmana, K.; Sakhuja, D.; Ghai, H.; Sharma, N.; Meena, K.R.; Bhatt, A.K.; Bhatia, R.K. Non-Food Crops Derived Lignocellulose Biorefinery for Sustainable Production of Biomaterials, Biochemicals and Bioenergy: A Review on Trends and Techniques. Ind. Crops Prod. 2023, 204, 117220. [Google Scholar] [CrossRef]

- Janiszewska, D.; Żurek, G.; Martyniak, D.; Bałęczny, W. Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture. Materials 2022, 15, 6384. [Google Scholar] [CrossRef] [PubMed]

- Klímek, P.; Wimmer, R.; Meinlschmidt, P.; Kúdela, J. Utilizing Miscanthus Stalks as Raw Material for Particleboards. Ind. Crops Prod. 2018, 111, 270–276. [Google Scholar] [CrossRef]

- Nassi o di Nasso, N.; Roncucci, N.; Triana Jimeno, F.; Tozzini, C.; Bonari, E. Productivity of Giant Reed (Arundo Donax L.) and Miscanthus (Miscanthus × Giganteus Greef et Deuter) as Energy Crops: Growth Analysis. Ital. J. Agron. 2011, 6, e22. [Google Scholar] [CrossRef]

- Scordia, D.; Cosentino, S. Perennial Energy Grasses: Resilient Crops in a Changing European Agriculture. Agriculture 2019, 9, 169. [Google Scholar] [CrossRef]

- Trischler, J.; Sandberg, D. Monocotyledons in Particleboard Production: Adhesives, Additives, and Surface Modification of Reed Canary Grass. Bioresources 2014, 9, 3919–3938. [Google Scholar] [CrossRef][Green Version]

- Klímek, P.; Meinlschmidt, P.; Wimmer, R.; Plinke, B.; Schirp, A. Using Sunflower (Helianthus Annuus L.), Topinambour (Helianthus tuberosus L.) and Cup-Plant (Silphium perfoliatum L.) Stalks as Alternative Raw Materials for Particleboards. Ind. Crops Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- Cumplido-Marin, L.; Graves, A.R.; Burgess, P.J.; Morhart, C.; Paris, P.; Jablonowski, N.D.; Facciotto, G.; Bury, M.; Martens, R.; Nahm, M. Two Novel Energy Crops: Sida hermaphrodita (L.) Rusby and Silphium perfoliatum L.—State of Knowledge. Agronomy 2020, 10, 928. [Google Scholar] [CrossRef]

- Peni, D.; Stolarski, M.J.; Dębowski, M. Green Biomass Quality of Perennial Herbaceous Crops Depending on the Species, Type and Level of Fertilization. Ind. Crops Prod. 2022, 184, 115026. [Google Scholar] [CrossRef]

- Shadhin, M.; Rahman, M.; Jayaraman, R.; Chen, Y.; Mann, D.; Zhong, W. Natural Biomass & Waste Biomass Fibers—Structures, Environmental Footprints, Sustainability, Degumming Methods, & Surface Modifications. Ind. Crops Prod. 2023, 204, 117252. [Google Scholar] [CrossRef]

- Kowalska, G.; Baj, T.; Kowalski, R.; Hanif, M.A. Characteristics of Selected Silphium Species as Alternative Plants for Cultivation and Industry with Particular Emphasis on Research Conducted in Poland: A Review. Sustainability 2022, 14, 5092. [Google Scholar] [CrossRef]

- Bozsaky, D. Nature-Based Thermal Insulation Materials From Renewable Resources—A State-Of-The-Art Review. Slovak. J. Civ. Eng. 2019, 27, 52–59. [Google Scholar] [CrossRef]

- Ljungberg, L.Y. Materials Selection and Design for Development of Sustainable Products. Mater. Des. 2007, 28, 466–479. [Google Scholar] [CrossRef]

- Fu, H.; Ding, Y.; Li, M.; Li, H.; Huang, X.; Wang, Z. Research on Thermal Performance and Hygrothermal Behavior of Timber-Framed Walls with Different External Insulation Layer: Insulation Cork Board and Anti-Corrosion Pine Plate. J. Build. Eng. 2020, 28, 101069. [Google Scholar] [CrossRef]

- Latif, E.; Ciupala, M.A.; Tucker, S.; Wijeyesekera, D.C.; Newport, D.J. Hygrothermal Performance of Wood-Hemp Insulation in Timber Frame Wall Panels with and without a Vapour Barrier. Build. Environ. 2015, 92, 122–134. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas, R.J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Berge, A.; Johansson, P. Literature Review of High Performance Thermal Insulation; Chalmers University of Technology: Gothenburg, Sweden, 2012. [Google Scholar]

- Panyakaew, S.; Fotios, S. New Thermal Insulation Boards Made from Coconut Husk and Bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Philip, S.; Rakendu, R. Thermal Insulation Materials Based on Water Hyacinth for Application in Sustainable Buildings. Mater. Today Proc. 2020, 33, 3803–3809. [Google Scholar] [CrossRef]

- Salas-Ruiz, A.; del Mar Barbero-Barrera, M.; Ruiz-Téllez, T. Microstructural and Thermo-Physical Characterization of a Water Hyacinth Petiole for Thermal Insulation Particle Board Manufacture. Materials 2019, 12, 560. [Google Scholar] [CrossRef] [PubMed]

- Charai, M.; Sghiouri, H.; Mezrhab, A.; Karkri, M. Thermal Insulation Potential of Non-Industrial Hemp (Moroccan Cannabis Sativa L.) Fibers for Green Plaster-Based Building Materials. J. Clean. Prod. 2021, 292, 126064. [Google Scholar] [CrossRef]

- Krenn, S.; Huber, H.; Barbu, M.C.; Petutschnigg, A.; Schnabel, T. Insulation Boards Made of Annual and Perennial Plants Bonded with Tannins and Other Adhesives. Pro Ligno 2017, 13, 227–235. [Google Scholar]

- Nagl, L.; Barbu, M.C.; Schnabel, T.; Petutschnigg, A.; Jäger, A.; Huber, H. Use of Annual and Perennial Plants for Dimensionally Stable Insulation Panels. Pro Ligno 2015, 11, 181–186. [Google Scholar]

- Gaspar, F.; Bakatovich, A.; Davydenko, N.; Joshi, A. Building Insulation Materials Based on Agricultural Wastes. In Bio-Based Materials and Biotechnologies for Eco-Efficient Construction; Elsevier: Amsterdam, The Netherlands, 2020; pp. 149–170. [Google Scholar]

- Moll, L.; Höller, M.; Hubert, C.; Korte, C.A.C.; Völkering, G.; Wever, C.; Pude, R. Cup Plant (Silphium perfoliatum L.) Biomass as Substitute for Expanded Polystyrene in Bonded Leveling Compounds. Agronomy 2022, 12, 178. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative Life Cycle Assessment of Bio-based Insulation Materials: Environmental and Economic Performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Eschenhagen, A.; Raj, M.; Rodrigo, N.; Zamora, A.; Labonne, L.; Evon, P.; Welemane, H. Investigation of Miscanthus and Sunflower Stalk Fiber-Reinforced Composites for Insulation Applications. Adv. Civ. Eng. 2019, 2019, 9328087. [Google Scholar] [CrossRef]

- EN 312; Particleboards–Specifications. CEN: Brussels, Belgium, 2010.

- EN 322; Wood-Based Panels–Determination of Moisture Content. CEN: Brussels, Belgium, 1993.

- TAPPI. Test Methods (1996–1997); TAPPI: Atlanta, GA, USA, 1996. [Google Scholar]

- TAPPI. T 204 cm-97 Solvent Extractives of Wood and Pulp; TAPPI: Atlanta, GA, USA, 2007. [Google Scholar]

- TAPPI. T 207 CM Water Solubility of Wood and Pulp; TAPPI: Atlanta, GA, USA, 2008. [Google Scholar]

- TAPPI. T 222 om-02 Acid-Insoluble Lignin in Wood and Pulp; TAPPI: Atlanta, GA, USA, 2006. [Google Scholar]

- TAPPI. T 212 OM-12 1% Sodium Hydroxide Solubility of Wood and Pulp; TAPPI: Atlanta, GA, USA, 2012. [Google Scholar]

- Kulak, P.; Komorowicz, M.; Lachowicz, H. Fibre Morphological Characteristics, Chemical Composition and Fuel Properties of Paulownia COTEVISA-2 Wood. Eur. J. Wood Wood Prod. 2024, 82, 1605–1614. [Google Scholar] [CrossRef]

- EN 323; Wood-Based Panels—Determination of Density. European Committee for Standardization. CEN: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. CEN: Brussels, Belgium, 1993.

- ASTM D6007-14; Standard Test Method for Determining Formaldehyde Concentrations in Air from Wood Products Using a Small-Scale Chamber. ASTM International: West Conshohocken, PA, USA, 2014.

- EN 12667; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. CEN: Brussels, Belgium, 2001.

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A Review on Natural Fibers for Development of Eco-Friendly Bio-Composite: Characteristics, and Utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Naimi, L.J.; Hoque, M.; Mani, S.; Womac, A.R.; Narayan, S.; Ye, X.P. Bulk Density of Wet and Dry Wheat Straw and Switchgrass Particles. Appl. Eng. Agric. 2008, 24, 351–358. [Google Scholar] [CrossRef]

- Dukarska, D.; Pędzik, M.; Rogozińska, W.; Rogoziński, T.; Czarnecki, R. Characteristics of Straw Particles of Selected Grain Species Purposed for the Production of Lignocellulose Particleboards. Part. Sci. Technol. 2021, 39, 213–222. [Google Scholar] [CrossRef]

- Neitzel, N.; Eder, M.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Chemical Composition, Particle Geometry, and Micro-Mechanical Strength of Barley Husks, Oat Husks, and Wheat Bran as Alternative Raw Materials for Particleboards. Mater. Today Commun. 2023, 36, 106602. [Google Scholar] [CrossRef]

- Andre, N.; Young, T.M.; Rials, T.G. On-Line Monitoring of the Buffer Capacity of Particleboard Furnish by Near-Infrared Spectroscopy. Appl. Spectrosc. 2006, 60, 1204–1209. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Mi, Y.; Kan, Y.; Bai, Y.; Li, J.; Gao, Z. Evaluation of the Interactions of Typical Wood Extracts on the Bonding Performance of Soybean-Based Adhesives. Polym. Test. 2023, 118, 107908. [Google Scholar] [CrossRef]

- Wan, H.; Wang, X.-M.; Jun, S. Recycling Wood Composite Panels: Characterizing Recycled Materials. Bioresources 2014, 9, 7554–7565. [Google Scholar] [CrossRef]

- Król, P.; Toczyłowska-Mamińska, R.; Mamiński, M. A Critical Role for the Presence of Lignocellulosic Material in the Determination of Wood Buffering Capacity. J. Wood Chem. Technol. 2017, 37, 478–484. [Google Scholar] [CrossRef]

- Xing, C.; Zhang, S.Y.; Deng, J.; Wang, S. Urea–Formaldehyde-resin Gel Time as Affected by the PH Value, Solid Content, and Catalyst. J. Appl. Polym. Sci. 2007, 103, 1566–1569. [Google Scholar] [CrossRef]

- Gusyachkin, A.M.; Sabitov, L.S.; Khakimova, A.M.; Hayrullin, A.R. Effects of Moisture Content on Thermal Conductivity of Thermal Insulation Materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 570, 012029. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Lacoste, C.; El Hage, R.; Bergeret, A.; Corn, S.; Lacroix, P. Sodium Alginate Adhesives as Binders in Wood Fibers/Textile Waste Fibers Biocomposites for Building Insulation. Carbohydr. Polym. 2018, 184, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Rahim, M.; Douzane, O.; Tran Le, A.D.; Langlet, T. Effect of Moisture and Temperature on Thermal Properties of Three Bio-Based Materials. Constr. Build. Mater. 2016, 111, 119–127. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Development and Characterization of Thermal Insulation Materials from Renewable Resources. Constr. Build. Mater. 2019, 214, 685–697. [Google Scholar] [CrossRef]

- Latif, E.; Tucker, S.; Ciupala, M.A.; Wijeyesekera, D.C.; Newport, D. Hygric Properties of Hemp Bio-Insulations with Differing Compositions. Constr. Build. Mater. 2014, 66, 702–711. [Google Scholar] [CrossRef]

- Ducoulombier, L.; Lafhaj, Z. Comparative Study of Hygrothermal Properties of Five Thermal Insulation Materials. Case Stud. Therm. Eng. 2017, 10, 628–640. [Google Scholar] [CrossRef]

- Zhou, Y.; Trabelsi, A.; El Mankibi, M. Hygrothermal Properties of Insulation Materials from Rice Straw and Natural Binders for Buildings. Constr. Build. Mater. 2023, 372, 130770. [Google Scholar] [CrossRef]

- Uitterhaegen, E.; Labonne, L.; Ballas, S.; Véronèse, T.; Evon, P. The Coriander Straw, an Original Agricultural by-Product for the Production of Building Insulation Materials. In Proceedings of the 3rd International Conference on Bio-Based Building Materials (ICBBM), Belfast, UK, 26–28 June 2019. [Google Scholar]

- EN 13986:2004+A1; Wood-Based Panels for Use in Construction. Characteristics, Evaluation of Conformity and Marking. CEN: Brussels, Belgium, 2015.

| Type of Raw Material | Share [%] | Board Desnity [kg/m3] |

|---|---|---|

| Industrial wood | 100 | 239 ± 1 |

| Prairie cordgrass | 30 | 220 ± 2 |

| 50 | 226 ± 3 | |

| 75 | 221 ± 3 | |

| Switchgrass | 30 | 239 ± 3 |

| 50 | 229 ± 3 | |

| 75 | 236 ± 2 | |

| Tall wheatgrass | 30 | 233 ± 1 |

| 50 | 227 ± 2 | |

| 75 | 220 ± 2 | |

| Giant miscanthus | 30 | 239 ± 3 |

| 50 | 238 ± 5 | |

| 75 | 229 ± 1 | |

| Cup plant | 30 | 237 ± 1 |

| 50 | 234 ± 1 | |

| 75 | 242 ± 2 |

| Property | Type of Raw Material | |||||

|---|---|---|---|---|---|---|

| Industrial Wood | Switchgrass | Prairie Cordgrass | Tall Wheatgrass | Giant Miscanthus | Cup Plant | |

| pH | 4.5 ± 0.1 | 4.9 ± 0.1 | 6.0 ± 0.2 | 5.0 ± 0.1 | 4.7 ± 0.1 | 5.0 ± 0.0 |

| Acid buffer capacity [mmol NaOH/100 g] | 2.53 ± 0.04 | 2.38 ± 0.07 | 1.97 ± 0.10 | 5.61 ± 0.06 | 2.93 ± 0.03 | 4.8 ± 0.06 |

| Alkaline buffer capacity [mmol H2SO4/100 g] | 5.63 ± 0.06 | 1.85 ± 0.10 | 4.23 ± 0.03 | 3.72 ± 0.01 | 1.89 ± 0.04 | 4.83 ± 0.07 |

| Type of Raw Material | Share [%] | FE [ppm] |

|---|---|---|

| Industrial wood | 100 | 0.100 |

| Prairie cordgrass | 30 | 0.050 |

| 50 | 0.052 | |

| 75 | 0.079 | |

| Switchgrass | 30 | 0.052 |

| 50 | 0.048 | |

| 75 | 0.053 | |

| Tall wheatgrass | 30 | 0.052 |

| 50 | 0.058 | |

| 75 | 0.059 | |

| Giant miscanthus | 30 | 0.054 |

| 50 | 0.042 | |

| 75 | 0.045 | |

| Cup plant | 30 | 0.054 |

| 50 | 0.070 | |

| 75 | 0.080 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martyniak, D.; Pędzik, M.; Żurek, G.; Tomczak, K.; Gąsiorowski, R.; Komorowicz, M.; Janiszewska-Latterini, D. Exploitation of Perennial Plant Biomass for Particleboards Designed for Insulation Applications. Materials 2025, 18, 352. https://doi.org/10.3390/ma18020352

Martyniak D, Pędzik M, Żurek G, Tomczak K, Gąsiorowski R, Komorowicz M, Janiszewska-Latterini D. Exploitation of Perennial Plant Biomass for Particleboards Designed for Insulation Applications. Materials. 2025; 18(2):352. https://doi.org/10.3390/ma18020352

Chicago/Turabian StyleMartyniak, Danuta, Marta Pędzik, Grzegorz Żurek, Karol Tomczak, Ryszard Gąsiorowski, Magdalena Komorowicz, and Dominika Janiszewska-Latterini. 2025. "Exploitation of Perennial Plant Biomass for Particleboards Designed for Insulation Applications" Materials 18, no. 2: 352. https://doi.org/10.3390/ma18020352

APA StyleMartyniak, D., Pędzik, M., Żurek, G., Tomczak, K., Gąsiorowski, R., Komorowicz, M., & Janiszewska-Latterini, D. (2025). Exploitation of Perennial Plant Biomass for Particleboards Designed for Insulation Applications. Materials, 18(2), 352. https://doi.org/10.3390/ma18020352