Optimisation of Using Low-Grade Kaolinitic Clays in Limestone Calcined Clay Cement Production (LC3)

Abstract

1. Introduction

2. Experimental Procedures

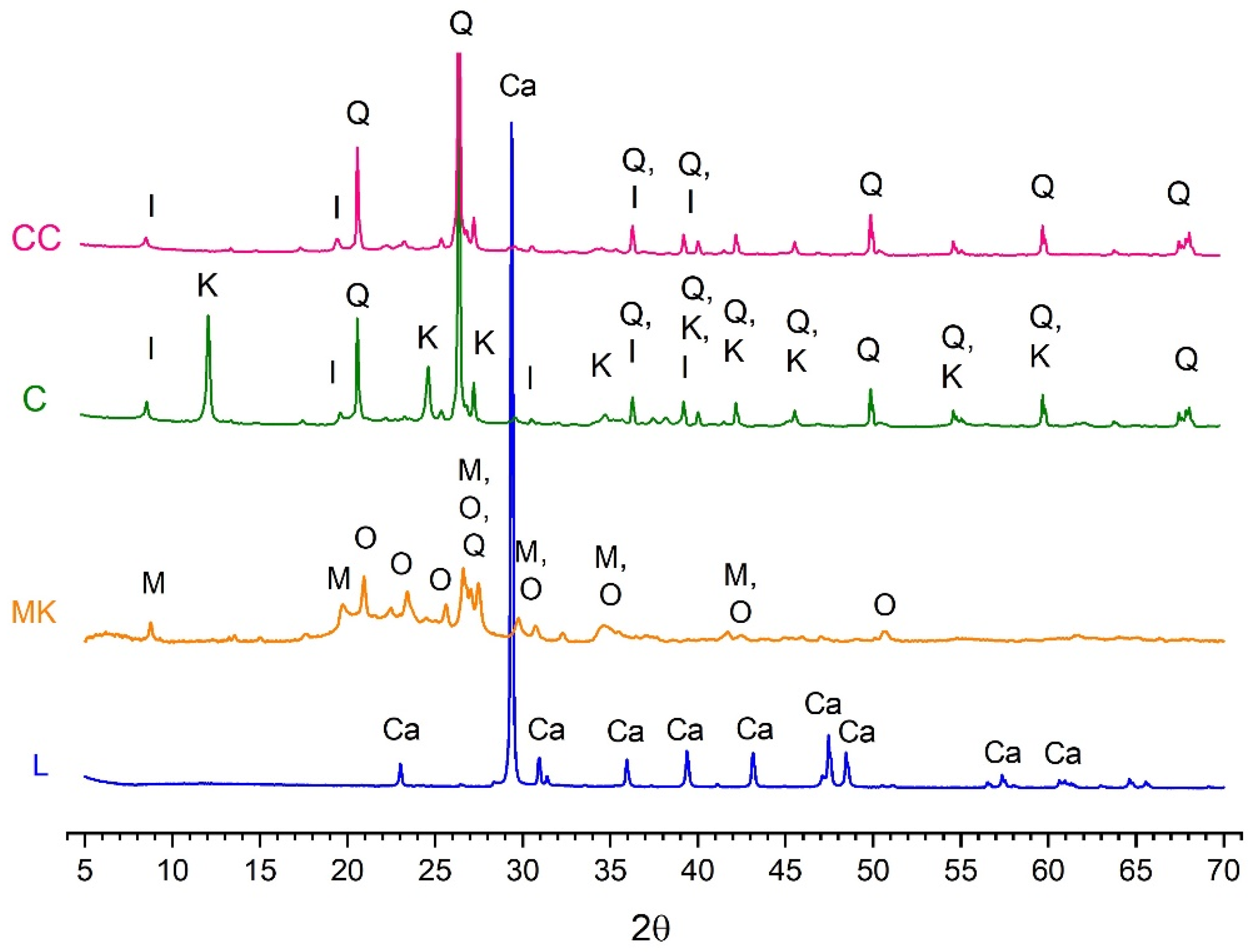

2.1. Materials

2.2. Mixture Dose

2.3. Test Methods

3. Results

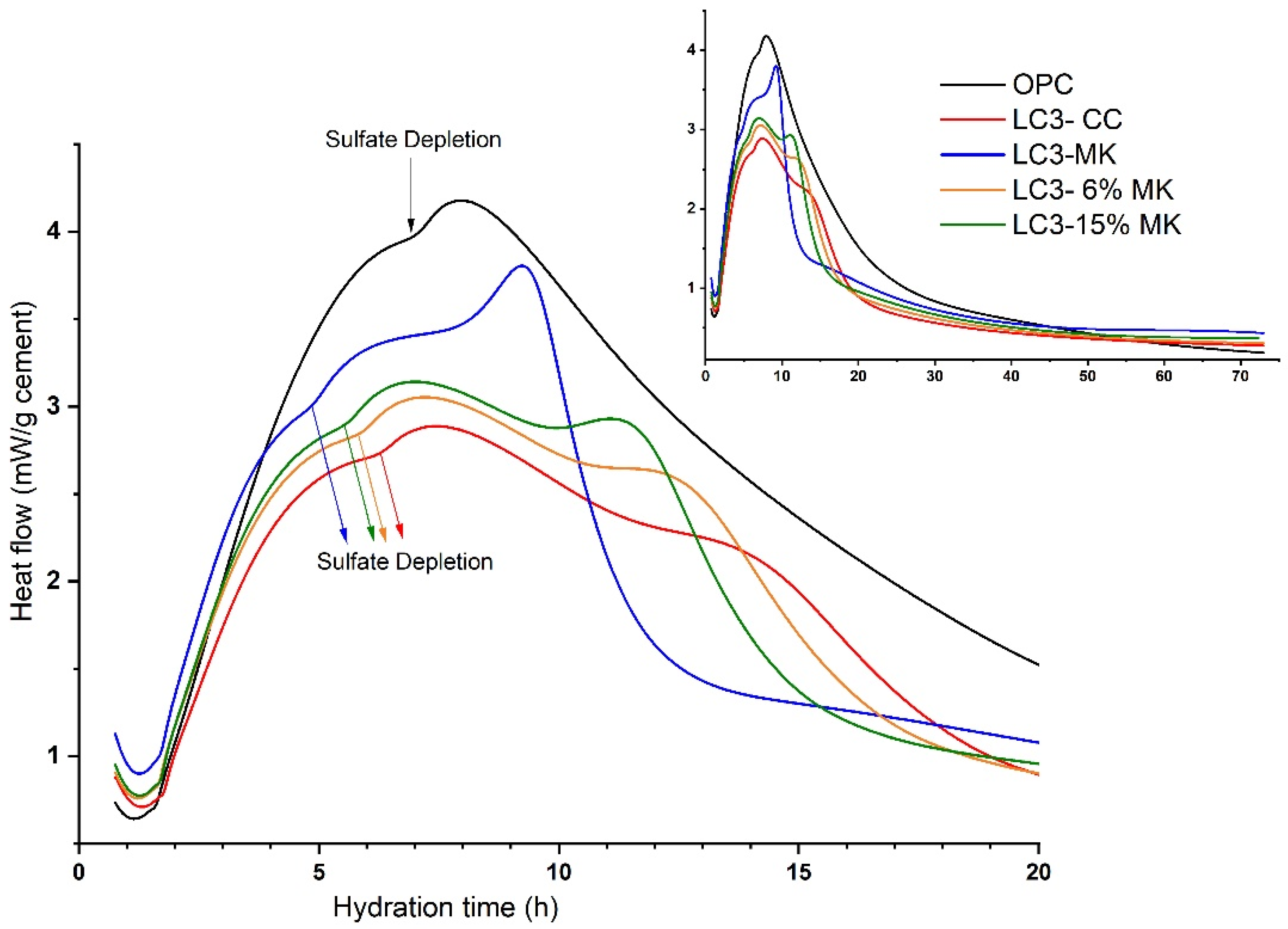

3.1. Hydration Kinetics by Isothermal Calorimetry

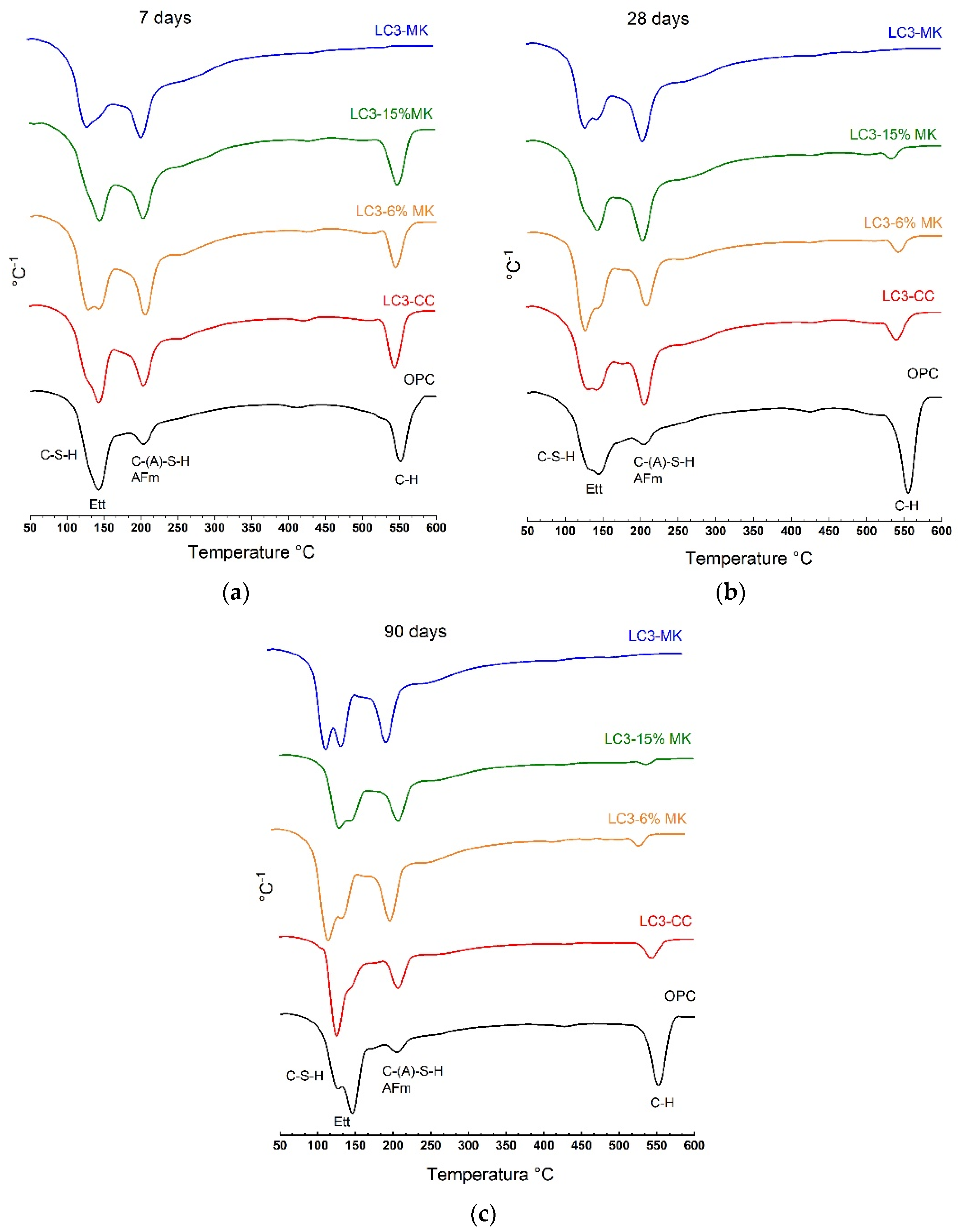

3.2. Thermogravimetry Analysis

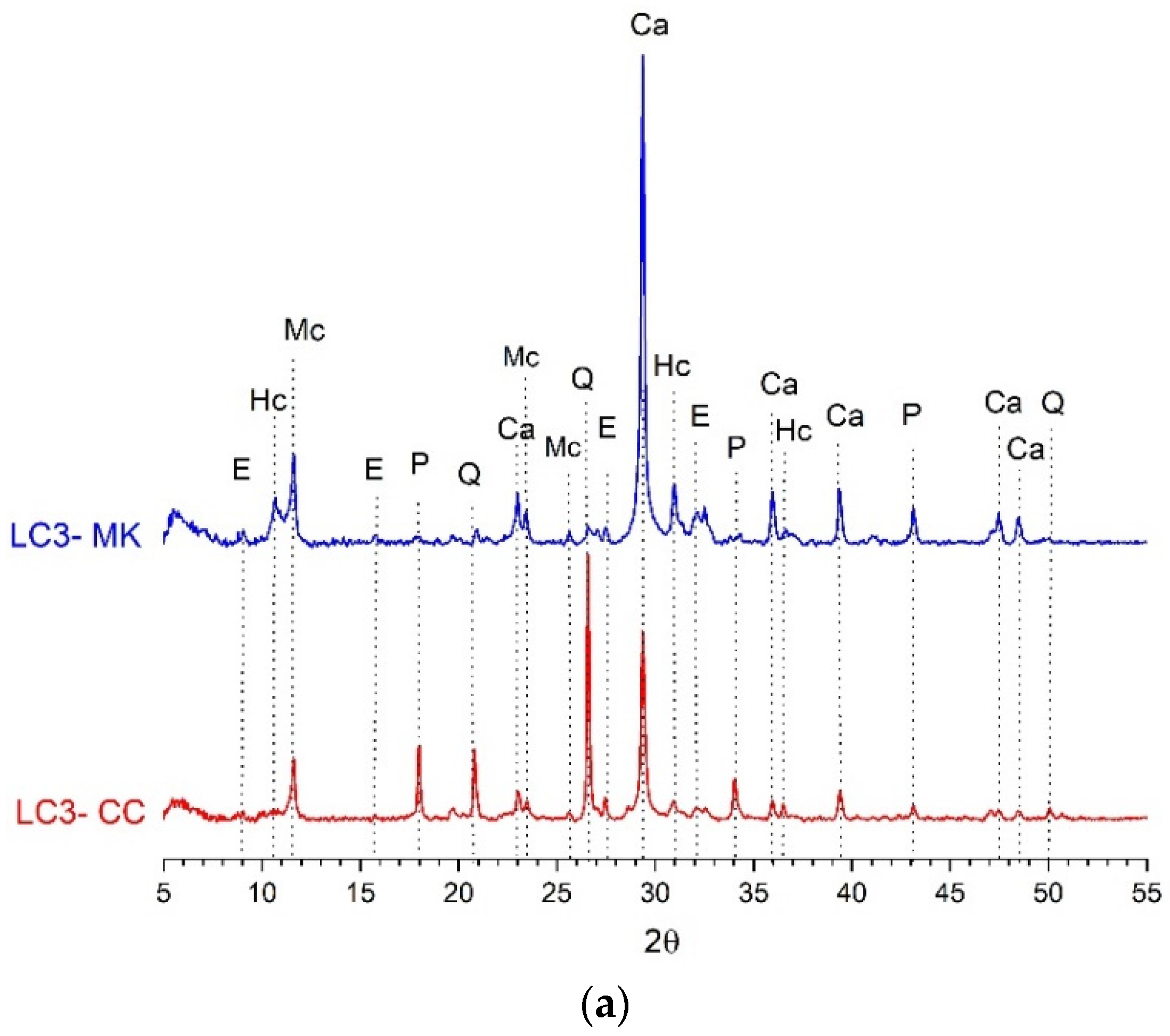

3.3. Hydrated Phases by Powder X-Ray Diffraction

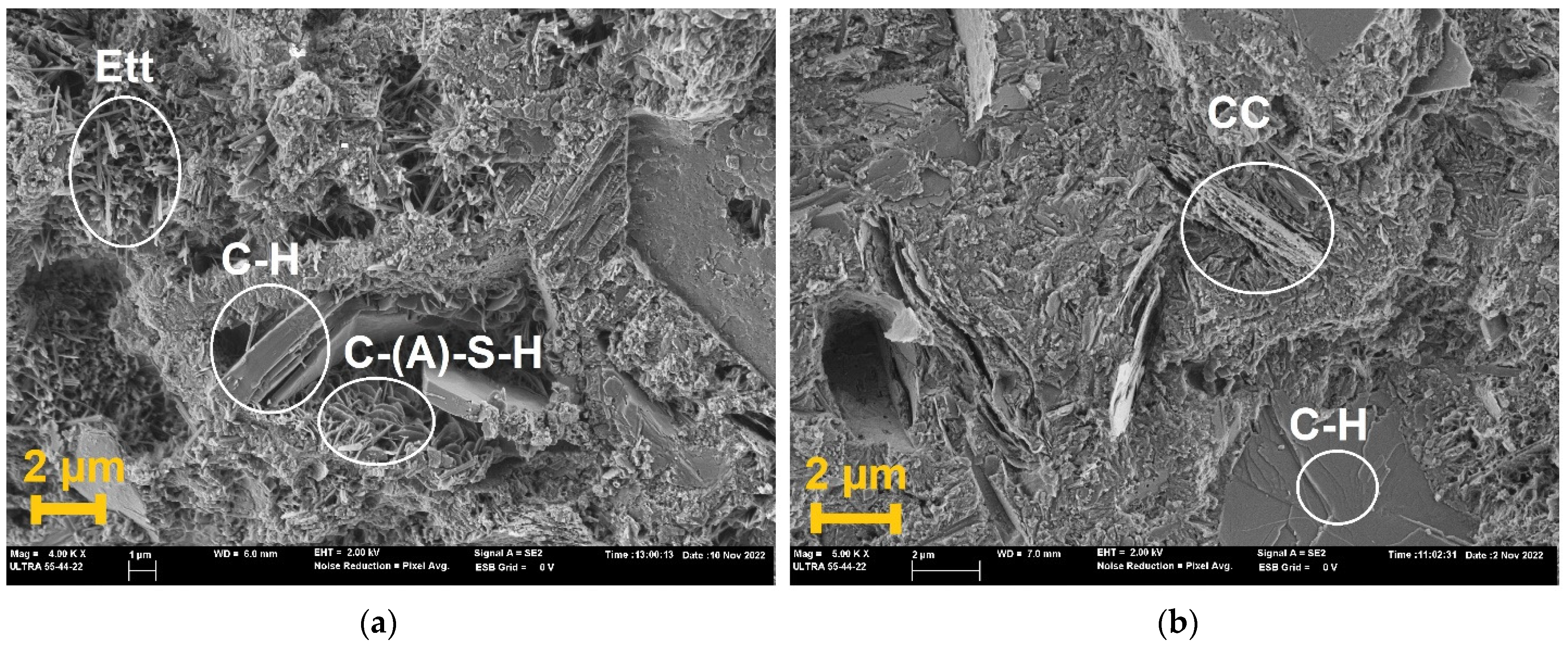

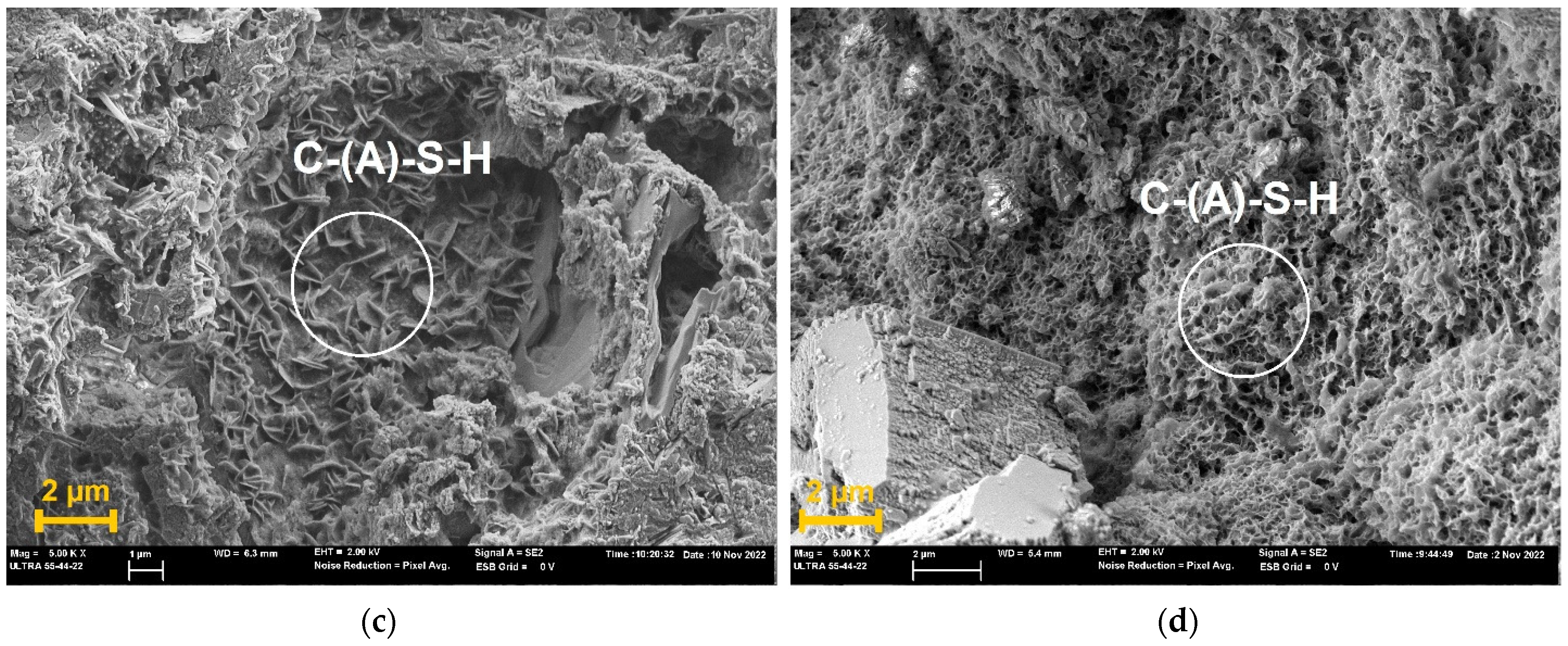

3.4. Microstructural Analysis of the Hydrated Phases by SEM

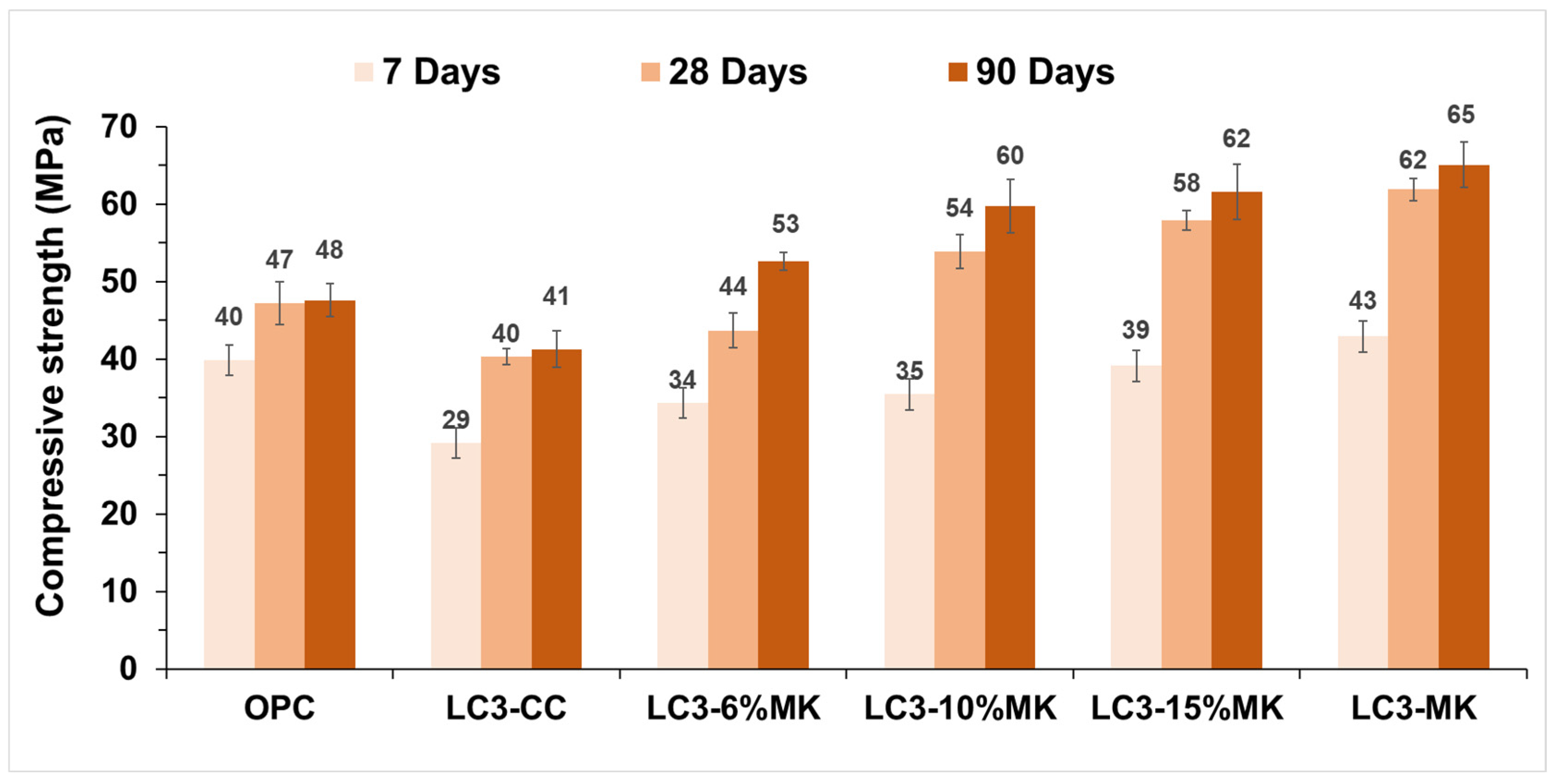

3.5. Compressive Strength in Mortars

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbhuiyaa, S.; Nepala, J.; Das, B.B. Properties, compatibility, environmental benefits and future directions of limestone calcined clay cement (LC3) concrete: A review. J. Build. Eng. 2023, 79, 107794. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. Reactivity and performance of limestone calcined-clay cement (LC3) Cured at Low Temperature. In Calcined Clays for Sustainable Concrete; RILEM Bookseries; Springer Nature: Berlin/Heidelberg, Germany, 2016; Volume 16, pp. 514–520. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Kosmidi, D.; Panagiotopoulou, C.; Angelopoulos, P.; Taxiarchou, M. Thermal Activation of Kaolin: Effect of Kaolin Mineralogy on the Activation Process. Mater. Proc. 2021, 5, 18. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Yanguatin, H.; Tobón, J.; Ramírez, J. Pozzolanic reactivity of kaolin clays, a review. Rev. Ing. Constr. 2017, 32, 3–24. [Google Scholar] [CrossRef]

- Gettu, R.; Patel, A.; Rathi, V.; Prakasan, S.; Basavaraj, A.S.; Palaniappan, S.; Maity, S. Influence of supplementary cementitious materials on the sustainability parameters of cements and concretes in the Indian context. Mater. Struct. 2019, 52, 10. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Emmanuel, A.C.; Haldar, P.; Maity, S.; Bishnoi, S. Second pilot production of limestone calcined clay cement in India: The experience. Indian Concr. J. 2016, 90, 57–63. [Google Scholar]

- Bishnoi, S.; Maity, S.; Mallik, A.; Joseph, S.; Krishnan, S. Pilot scale manufacture of limestone calcined clay cement: The Indian experience. Indian Concr. J. 2014, 88, 22–28. [Google Scholar]

- Perilli, P.; Global Cement. Calcined Clay Projects in Africa. 2022. Available online: https://www.globalcement.com/news/item/13938-calcined-clay-projects-in-africa (accessed on 5 January 2025).

- Rodriguez, H.C.P. Evaluación de la Interacción en el uso Conjunto de un Material Arcilloso Activado Térmicamente, Caliza y Sulfato Sobre la Cinética de Hidratación y Desempeño Mecánico del Cemento. Universidad Nacional de Colombia. 2019. Available online: https://repositorio.unal.edu.co/bitstream/handle/unal/77233/1128387371.2019.pdf?sequence=1 (accessed on 5 January 2025).

- Malacarne, C.S.; Longhi, M.A.; Silva, M.R.C.; Gonçalves, J.P.; Rodríguez, E.D.; Kirchheim, A.P. Influence of low-grade materials as clinker substitute on the rheological behavior, hydration and mechanical performance of ternary cements. Case Stud. Constr. Mater. 2021, 15, e00776. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Yanguatin, H.; Ramírez, J.H.; Tironi, A.; Tobón, J.I. Effect of thermal treatment on pozzolanic activity of excavated waste clays. Constr. Build. Mater. 2019, 211, 814–823. [Google Scholar] [CrossRef]

- Almenares, R.R. Potencialidades de Arcillas Caoliníticas Cubanas para la Obtención de Materiales Cementicios Suplementarios. Ph.D. Thesis, Universidad Central Marta Abreu de las Villas, Santa Clara, Cuba, 2017. [Google Scholar]

- Fernandez, A.; Leung, Y. Technology Roadmap: Low-Carbon Transition in the Cement Industry; International Energy Agency: Paris, France, 2018; p. 66. Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 5 January 2025).

- Almenares, R.R.; Fernando, J.; Hernández, M.; Rodríguez, C.A.L.; Rodríguez, S.B.; Carratalá, F.A. Identificación y evaluación de arcillas caoliníticas para la producción de cemento ternario LC3 y adiciones minerales activas LC2. An. Acad. Cienc. Cuba 2021, 11, 1–9. [Google Scholar]

- Díaz, A.A.; Reyes, R.A.; Carratalá, F.A.; García, L.A.P.; Rodríguez, C.A.L.; Hernández, J.F.M. The Experience of Cuba TRC on the Survey of Kaolinitic Clay Deposits as Source of SCMs—Main Outcomes and Learned Lessons. In Calcined Clays for Sustainable Concrete; Springer: Singapore, 2020; Volume 25, pp. 1–8. [Google Scholar] [CrossRef]

- Monfil, E.Q. La arcilla: Un recurso mineral estratégico. Energía Minas 2020, 16, 6–17. [Google Scholar]

- Instituto Geológico y Minero de España. IGME, Panorama Minero; Instituto Geológico y Minero de España: Madrid, Spain, 2016; pp. 255–298. [Google Scholar]

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Zolfagharnasab, A.; Ramezanianpour, A.A.; Bahman-Zadeh, F. Investigating the potential of low-grade calcined clays to produce durable LC3 binders against chloride ions attack. Constr. Build. Mater. 2021, 303, 124541. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Reig, L.; Alvero, V.; Hernández-Figueirido, D.; Melchor-Eixea, A.; Pitarch, Á.M.; Piquer, A. Utilisation of Ceramic Stoneware Tile Waste as Recycled Aggregate in Concrete. Buildings 2023, 13, 1968. [Google Scholar] [CrossRef]

- Meseguer, S.; Jordán, M.M.; Pardo, F.; Sanfeliu, T. Geology and Application of Clays Used in Castellon Ceramic Cluster (NE, Spain). J. Geogr. Geol. 2011, 3, 132–140. [Google Scholar] [CrossRef]

- Garcia-Valles, M.; Alfonso, P.; Martínez, S.; Roca, N. Mineralogical and thermal characterization of kaolinitic clays from terra alta (Catalonia, Spain). Minerals 2020, 10, 142. [Google Scholar] [CrossRef]

- Zunino, F.; Scrivener, K. Increasing the kaolinite content of raw clays using particle classification techniques for use as supplementary cementitious materials. Constr. Build. Mater. 2020, 244, 118335. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Alujas Diaz, A.; Ben Haha, M.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Thermal analysis to assess pozzolanic activity of calcined kaolinitic clays. J. Therm. Anal. Calorim. 2014, 117, 547–556. [Google Scholar] [CrossRef]

- Hidalgo, S.; Soriano, L.; Monzó, J.; Payá, J.; Font, A.; Borrachero, M.V. Evaluation of rice straw ash as a pozzolanic addition in cementitious mixtures. Appl. Sci. 2021, 11, 773. [Google Scholar] [CrossRef]

- Velázquez, S. Aplicaciones del Catalizador de Craqueo Catalítico Usado (FCC) en la Preparación de Conglomerantes Hidráulicos. Estudio de sus Propiedades Puzolánicas. Universitat Politècnica de València. 2002. Available online: https://dialnet.unirioja.es/servlet/tesis?codigo=243002 (accessed on 5 January 2025).

- UNE 80103; Test Methods of Cements. Physical Analysis. Actual Density Determination. AENOR (Asociacíon Española de Normalización y Certificación): Madrid, Spain, 2013.

- Soriano, L.; Tashima, M.M.; Bonilla, M.; Payá, J.; Monzó, J.; Borrachero, M.V. Use of high-resolution thermogravimetric analysis (HRTG) technique in spent FCC catalyst/Portland cement pastes. J. Therm. Anal. Calorim. 2015, 120, 1511–1517. [Google Scholar] [CrossRef]

- UNE EN 196-1; Methods of Testing Cement. Part 1: Determination of Strength. AENOR (Asociacíon Española de Normalización y Certificación): Madrid, Spain, 2018.

- Krishnan, S.; Emmanuel, A.C.; Bishnoi, S. Hydration and phase assemblage of ternary cements with calcined clay and limestone. Constr. Build. Mater. 2019, 222, 64–72. [Google Scholar] [CrossRef]

- Py, L.G.; Andrade Neto, J.S.; Longhi, M.A.; Kirchheim, A.P. Evaluation of ultrafine calcined clays on LC3 cements on the sulfate requirement, water demand and strength development. Mater. Struct. 2024, 57, 13. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- Silva, M.R.C.; Neto, J.S.A.; Walkley, B.; Kirchheim, A.P. Exploring sulfate optimization techniques in Limestone Calcined Clay Cements (LC3): Limitations and insights. Cem. Concr. Res. 2024, 175, 107375. [Google Scholar] [CrossRef]

- Canbek, O.; Szeto, C.; Washburn, N.R.; Kurtis, K.E. A quantitative approach to determining sulfate balance for LC3. Cement 2023, 12, 100063. [Google Scholar] [CrossRef]

- Andrade Neto, J.d.S.; De la Torre, A.G.; Kirchheim, A.P. Effects of sulfates on the hydration of Portland cement—A review. Constr. Build. Mater. 2021, 279, 122428. [Google Scholar] [CrossRef]

- Soriano, L.; Monzó, J.; Bonilla, M.; Tashima, M.M.; Payá, J.; Borrachero, M.V. Effect of pozzolans on the hydration process of Portland cement cured at low temperatures. Cem. Concr. Compos. 2013, 42, 1–48. [Google Scholar] [CrossRef]

- Cardinaud, G.; Rozière, E.; Martinage, O.; Loukili, A.; Barnes-Davin, L.; Paris, M.; Deneele, D. Calcined clay—Limestone cements: Hydration processes with high and low-grade kaolinite clays. Constr. Build. Mater. 2021, 277, 122271. [Google Scholar] [CrossRef]

- Scrivener, K.; Avet, F.; Maraghechi, H.; Zunino, F.; Ston, J.; Hanpongpun, W.; Favier, A. Impacting factors and properties of limestone calcined clay cements (LC3). Green. Mater. 2018, 7, 3–14. [Google Scholar] [CrossRef]

| Oxide Composition [%] | OPC | C | L | MK |

|---|---|---|---|---|

| SiO2 | 15.66 | 63.97 | - | 52.54 |

| Al2O3 | 3.65 | 21.81 | 0.29 | 41.35 |

| Fe2O3 | 2.49 | 2.50 | - | 4.36 |

| CaO | 62.25 | 2.36 | 54.71 | 0.07 |

| MgO | 1.92 | 0.48 | 1.51 | 0.19 |

| Na2O | 0.12 | 0.17 | - | 0.26 |

| K2O | 1.03 | 3.19 | 0.07 | 0.64 |

| SO3 | 3.30 | - | 0.38 | - |

| TiO2 | 0.00 | - | 0.01 | - |

| P2O5 | 0.14 | 0.03 | 0.01 | - |

| MnO | 0.02 | - | - | - |

| LOI | 9.41 | 5.48 | 43.01 | 0.60 |

| Key | Mineral Phase | Chemical Formula | Code Xpert |

|---|---|---|---|

| Ca | Calcite | CaCO3 | 00-005-0586 |

| l | Illite | (K,H3O)Al2Si3 AlO10 (OH)2 | 00-026-0911 |

| K | Kaolinite | Al2Si2O5(OH)4 | 01-080-0886 |

| M | Muscovite | KAl2Si3AlO10(OH)2 | 00-007-0025 |

| O | Orthoclase | KAlSi3O8 | 01-075-1592 |

| Hc | Hemicarboaluminate | Ca4Al2O6(CO3)0.5(OH)·11.5H2O | 00-041-0221 |

| Mc | Monocarboaluminate | Ca4Al2O6(CO3)·11H2O | 00-041-0219 |

| P | Portlandite | Ca(OH)2 | 00-044-1481 |

| E | Ettringite | Ca6Al2(SO4)3(OH)12·26H2O | 00-041-1451 |

| Q | Quartz | SiO2 | 01-085-0796 |

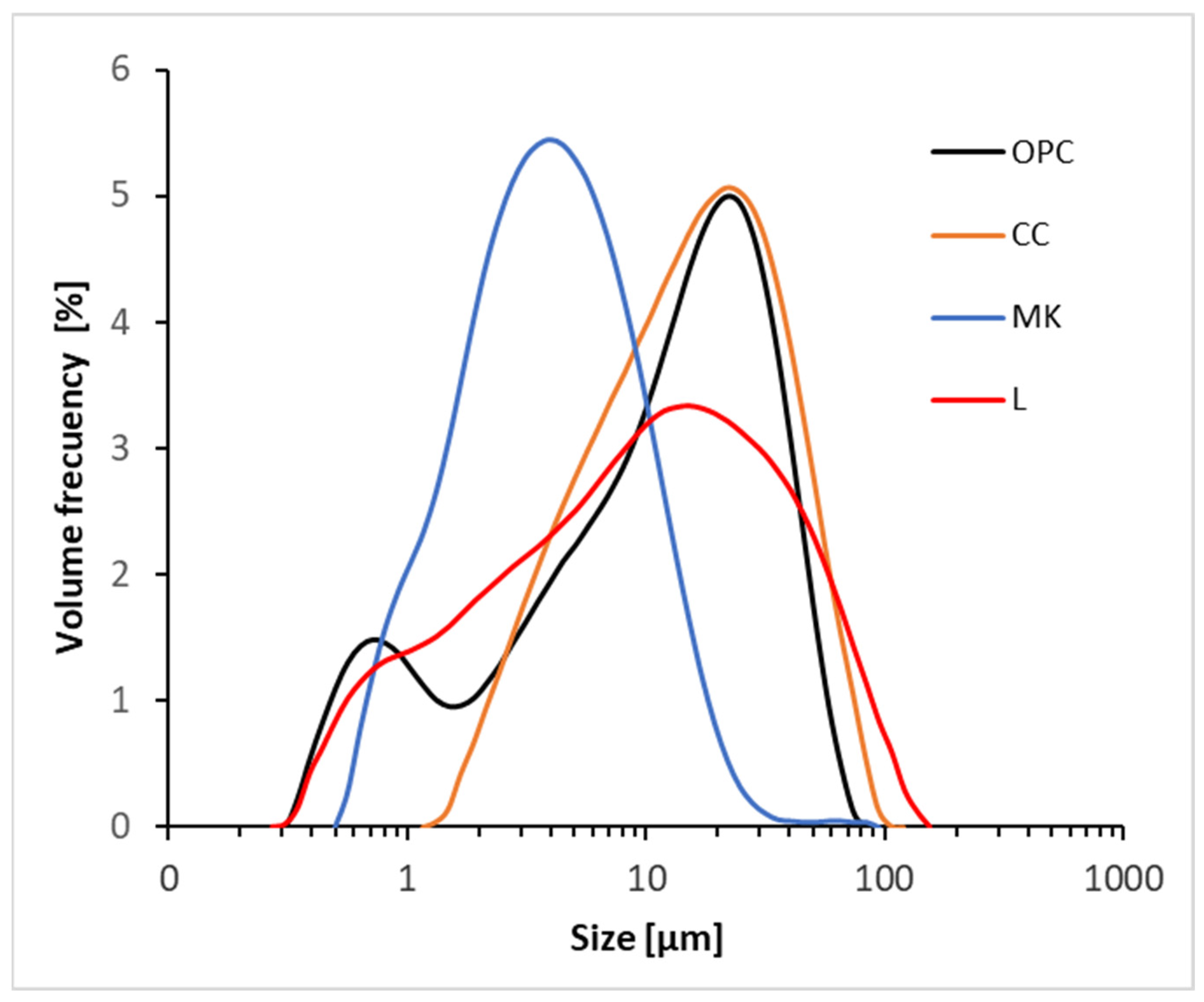

| Materials | Acronym | Particle Size Average (μm) | D10 (µm) | D50 (µm) | D90 (µm) | Specific Gravity |

|---|---|---|---|---|---|---|

| CEM II/A-L 42.5 R | OPC | 14.89 | 0.93 | 11.63 | 33.83 | 3.15 |

| Calcined Clay | CC | 19.50 | 3.76 | 14.80 | 42.31 | 2.64 |

| Limestone | L | 19.78 | 1.21 | 9.60 | 52.31 | 2.71 |

| Metakaolin | MK | 5.72 | 1.31 | 4.08 | 11.83 | 2.47 |

| Acronym Blend | OPC [wt%] | CC [wt%] | MK [wt%] | L [wt%] |

|---|---|---|---|---|

| OPC | 100 | - | - | - |

| LC3 -CC | 67.4 | 30 | - | 2.6 |

| LC3 -MK | 67.4 | 0 | 30 | 2.6 |

| LC3-6% MK | 67.4 | 24 | 6 | 2.6 |

| LC3-10% MK | 67.4 | 20 | 10 | 2.6 |

| LC3-15% MK | 67.4 | 15 | 15 | 2.6 |

| Sample | Fixed Lime [%] | Bound Water [%] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 90 Days | 7 Days | 28 Days | 90 Days | 7 Days | 28 Days | 90 Days | |

| 100–150 °C | 150–300 °C | ||||||||

| OPC | 4.0 | 3.5 | 5.8 | 4.3 | 4.1 | 4.5 | |||

| LC3-MK | 98.9 | 97.0 | 98.0 | 4.3 | 4.7 | 6.3 | 6.4 | 7.1 | 7.7 |

| LC3-15% MK | 37.1 | 84.7 | 92.1 | 3.2 | 4.1 | 5.0 | 5.3 | 6.6 | 7.1 |

| LC3-6% MK | 19.4 | 67.0 | 78.8 | 3.8 | 5.9 | 5.4 | 4.9 | 6.3 | 6.9 |

| LC3-CC | 12.0 | 46.2 | 61.1 | 3.3 | 3.4 | 5.9 | 4.7 | 5.7 | 6.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas, P.; Borrachero, M.V.; Payá, J.; Macián, A.; Tobón, J.I.; Martirena, F.; Soriano, L. Optimisation of Using Low-Grade Kaolinitic Clays in Limestone Calcined Clay Cement Production (LC3). Materials 2025, 18, 285. https://doi.org/10.3390/ma18020285

Vargas P, Borrachero MV, Payá J, Macián A, Tobón JI, Martirena F, Soriano L. Optimisation of Using Low-Grade Kaolinitic Clays in Limestone Calcined Clay Cement Production (LC3). Materials. 2025; 18(2):285. https://doi.org/10.3390/ma18020285

Chicago/Turabian StyleVargas, Paola, María Victoria Borrachero, Jordi Payá, Ana Macián, Jorge Iván Tobón, Fernando Martirena, and Lourdes Soriano. 2025. "Optimisation of Using Low-Grade Kaolinitic Clays in Limestone Calcined Clay Cement Production (LC3)" Materials 18, no. 2: 285. https://doi.org/10.3390/ma18020285

APA StyleVargas, P., Borrachero, M. V., Payá, J., Macián, A., Tobón, J. I., Martirena, F., & Soriano, L. (2025). Optimisation of Using Low-Grade Kaolinitic Clays in Limestone Calcined Clay Cement Production (LC3). Materials, 18(2), 285. https://doi.org/10.3390/ma18020285