Recycling of Agricultural Film Wastes for Use as a Binder in Building Composites

Abstract

1. Introduction

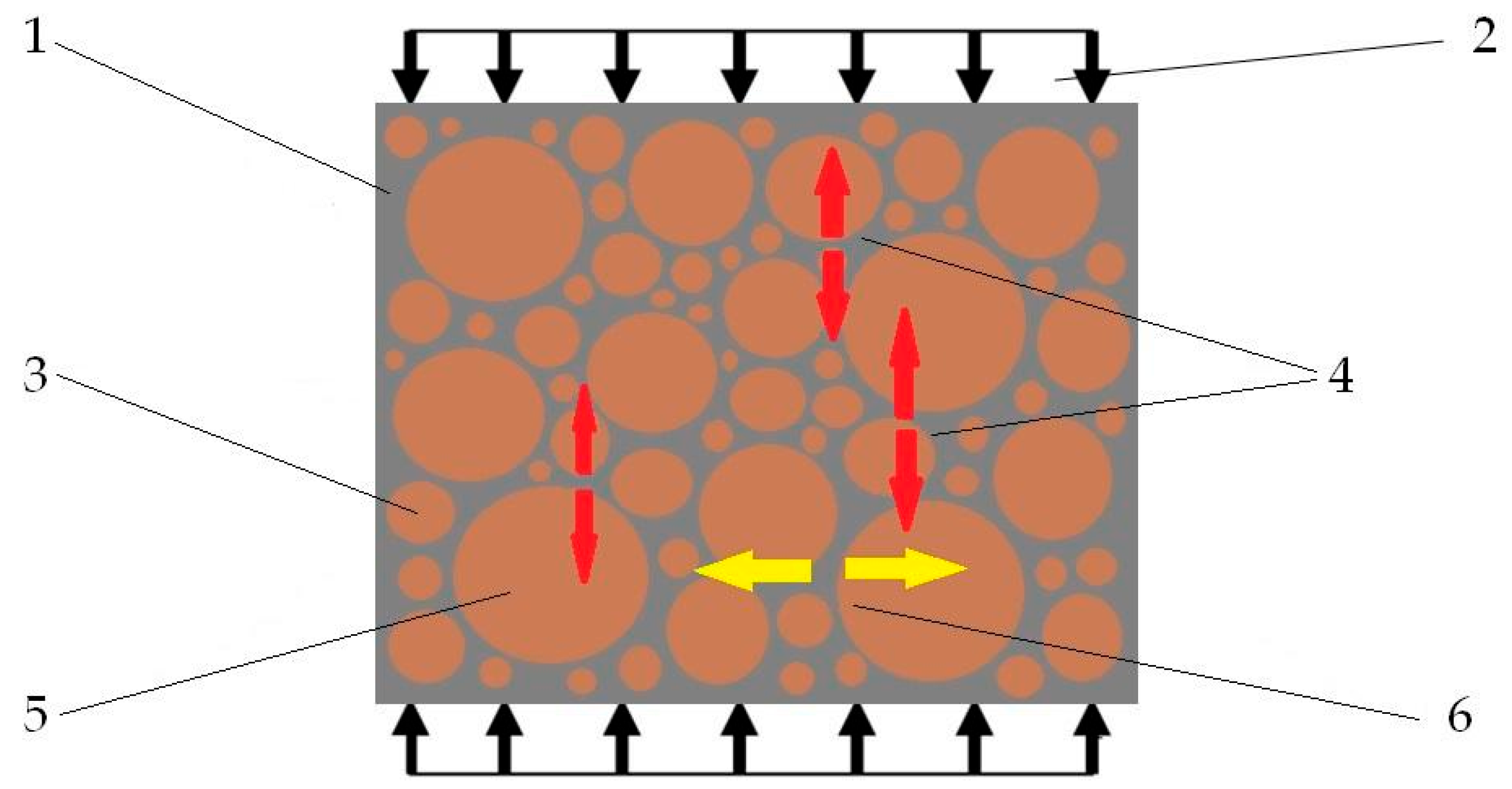

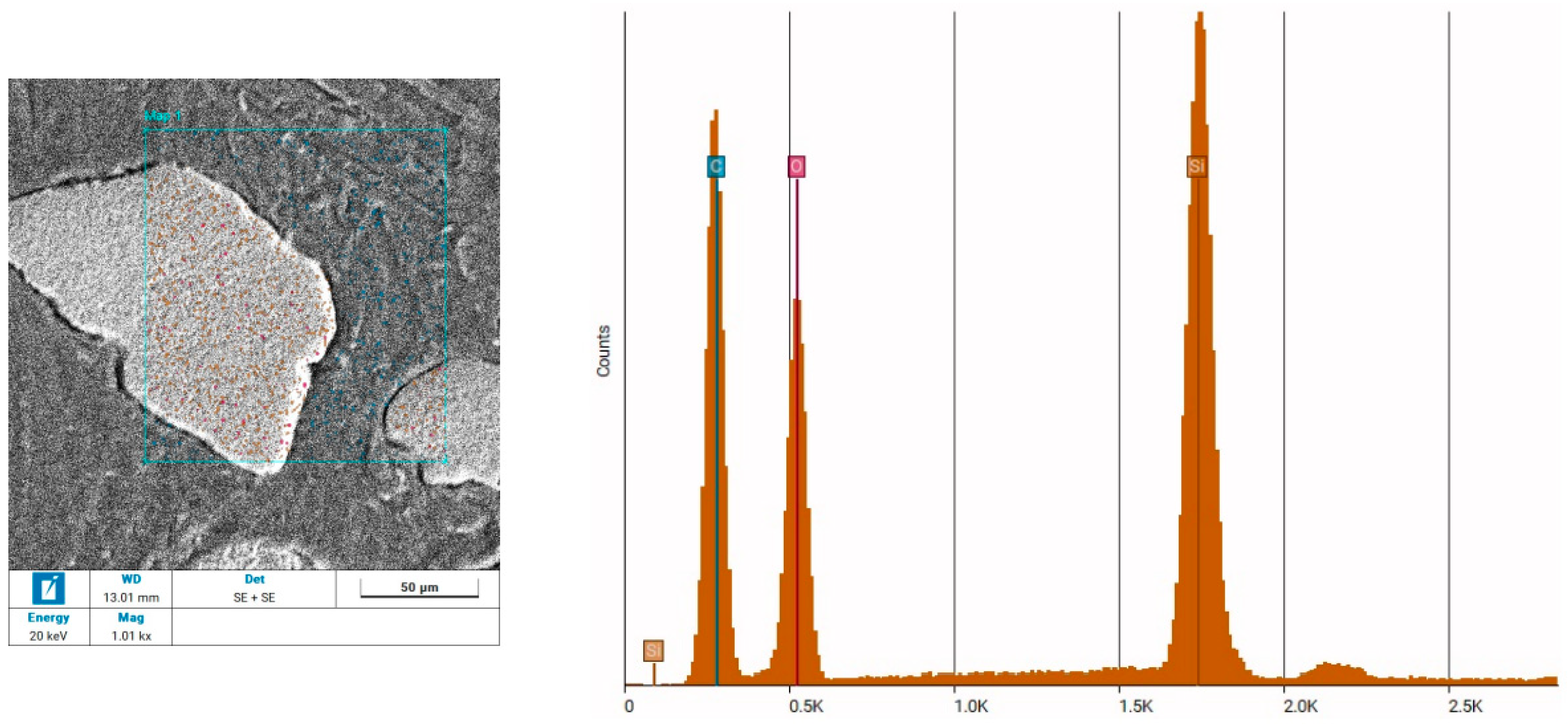

2. Materials and Methods

2.1. Materials

- (1)

- Determination of the melting point of the recyclate.

- (2)

- Evaluation of the maximum aggregate saturation of the melted recyclate.

- (3)

- Preparation of a weighting recipe for the composite with maximum aggregate saturation of the recyclate.

- (4)

- Preparation of further weight prescriptions for the other composites with gradually decreasing aggregate saturation.

2.2. Testing Procedures

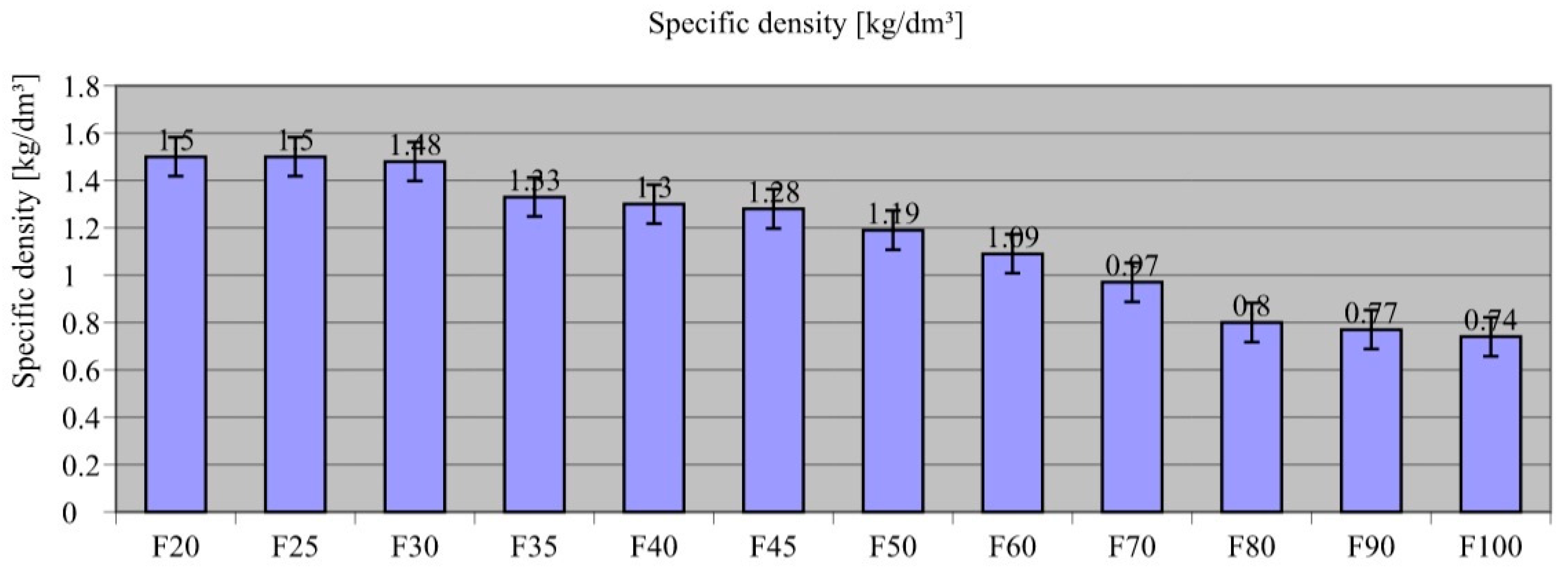

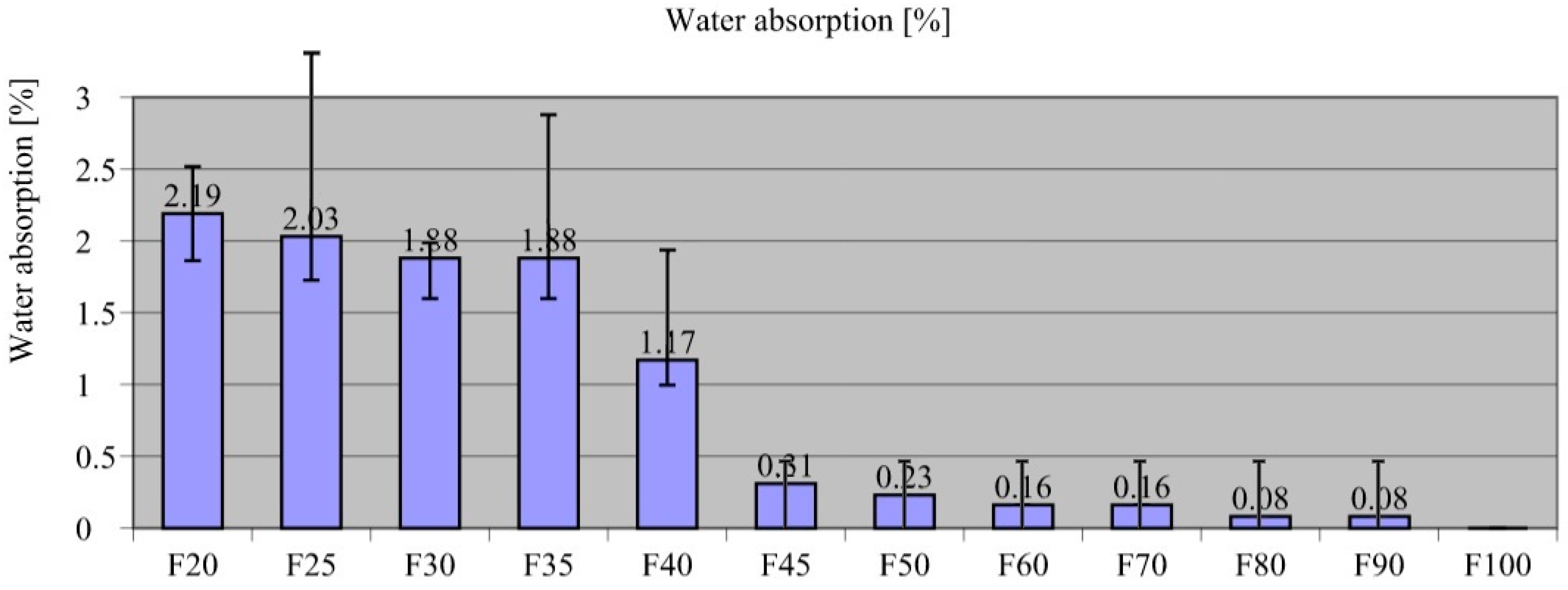

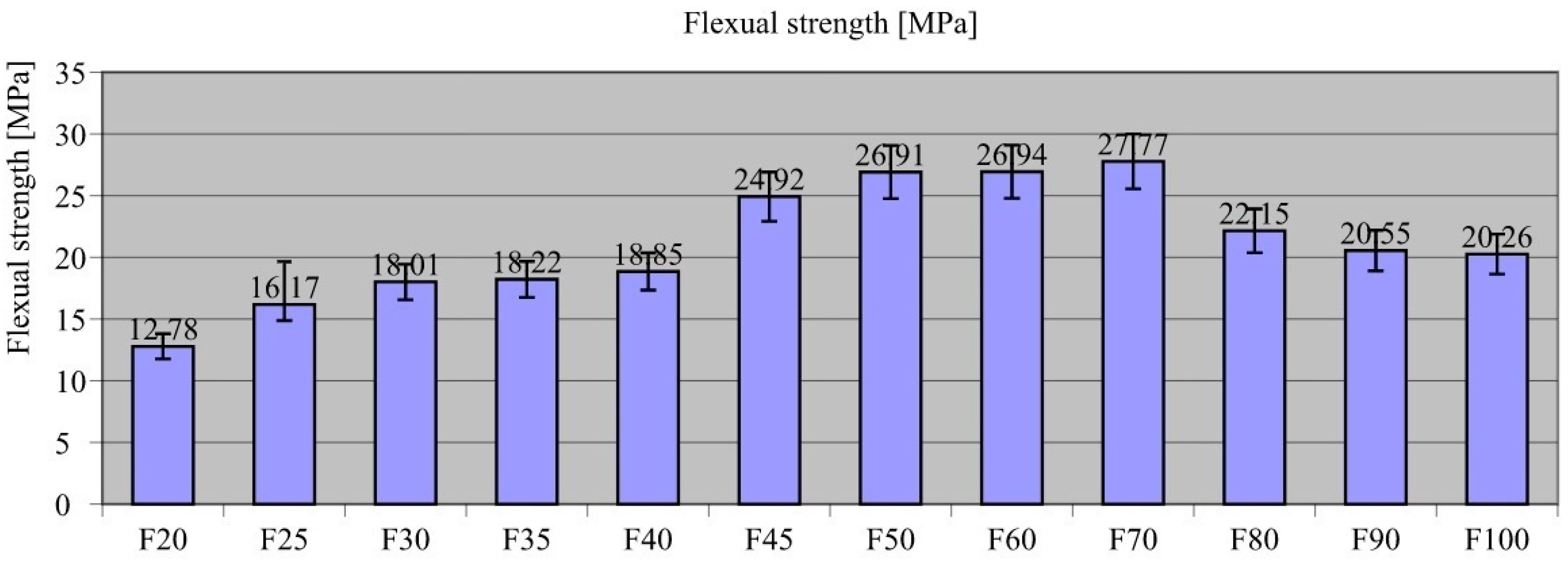

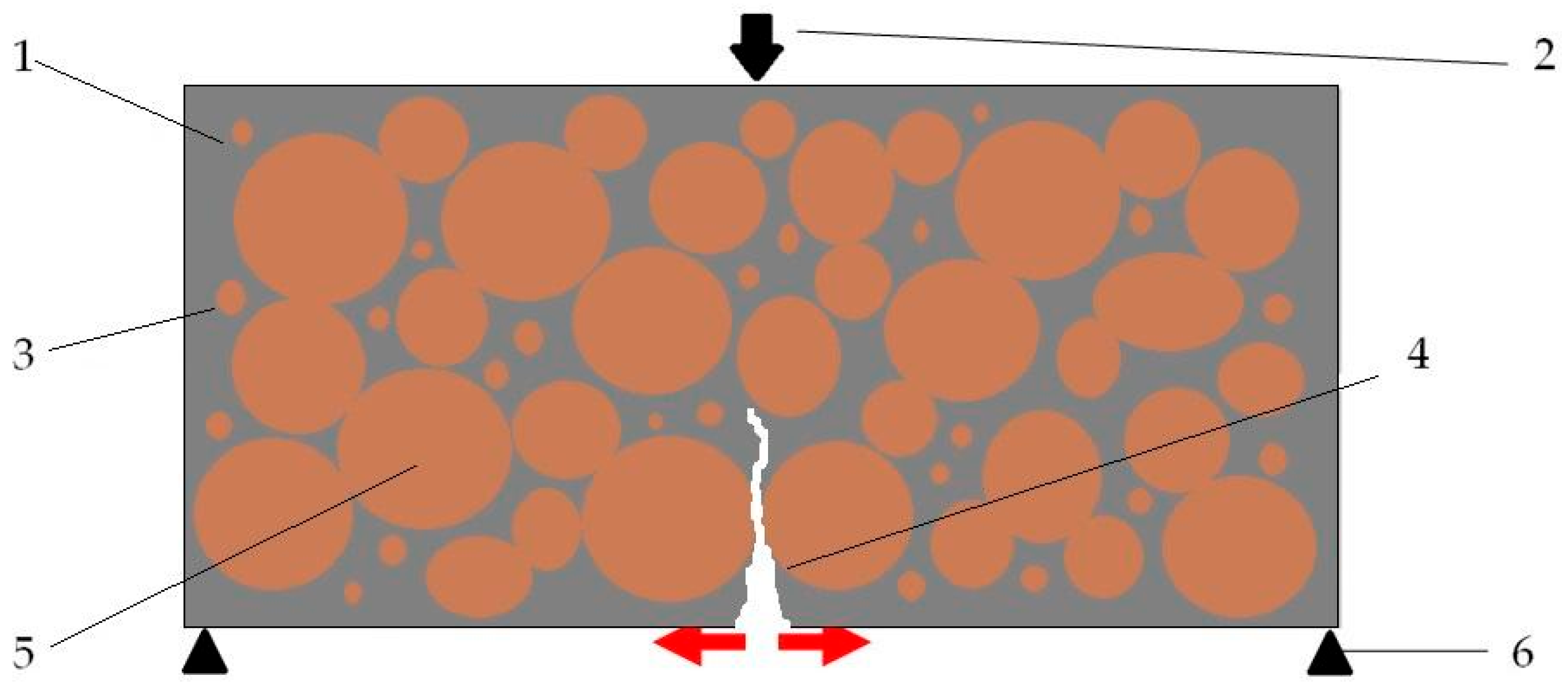

3. Research Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elvers, B. Ullmann’s Encyclopedia of Industrial Chemistry; Verlag Chemie: Hoboken, NJ, USA, 1991. [Google Scholar]

- Mark, J.E. Polymer Data Handbook; Oxford University Press: New York, NY, USA, 1999. [Google Scholar]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Janssens, V. Plastics Facts—2022; PlasticsEurope AISBL: Brussels, Belgium, 2023. [Google Scholar]

- Guo, J.; Kim, Y.; Chong, Z.K.; Alassali, A.; Chacon, J.P.; Gottschalk, D.; Kitzberger, M.; Kuchta, K. Quality Changes of Low-Density Polyethylene (LDPE) Recyclates from the Pretreatment Process with a Cationic Surfactant and a Nonionic Surfactant as Cleaning Agents Upstream of Extrusion. Processes 2022, 10, 2174. [Google Scholar] [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2017, 3, 1. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular economy: The concept and its limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Keijer, T.; Bakker, V.; Slootweg, J.C. Circular chemistry to enable a circular economy. Nat. Chem. 2019, 11, 190–195. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy-A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Arbolino, R.; Carlucci, F.; De Simone, L.; Ioppolo, G.; Yigitcanlar, T. The policy diffusion of environmental performance in the European Countries. Ecol. Indic. 2018, 89, 130–138. [Google Scholar] [CrossRef]

- Carraher, C.E. Polymer Chemistry; McGraw-Hill Book Company, Marcel Dekker Inc.: New York, NY, USA, 2000. [Google Scholar]

- Helms, B.A.; Russell, T.P. Reaction: Polymer chemistries enabling cradle-tocradle life cycles for plastics. Chem 2016, 1, 816–818. [Google Scholar] [CrossRef]

- Welle, F. Twenty years of PET bottle to bottle recycling-An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Acker, K.; Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Hysa, E.; Kruja, A.; Rehman, N.U.; Laurenti, R. Circular economy innovation and environmental sustainability impact on economic growth: An integrated model for sustainable development. Sustainability 2020, 12, 4831. [Google Scholar] [CrossRef]

- Al-Salem, S.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Neale, C.; Hilyard, N.; Barber, P. Observations on the economics of recycling industrial scrap plastic in new products. Conserv. Recycl. 1983, 6, 91–105. [Google Scholar] [CrossRef]

- Al-Salem, S. Establishing an integrated databank for plastic manufacturers and converters in Kuwait. Waste Manag. 2009, 29, 479–484. [Google Scholar] [CrossRef]

- Jensen, J.; Holman, J.; Stephenson, J. Recycling and disposal of waste plastics. In Plastics Waste Management: Disposal, Recycling, and Reuse; Ann Arbor Science Publishing: Ann Arbor, MI, USA, 1974; pp. 219–249. [Google Scholar]

- Frounchi, M. Studies on degradation of PET in mechanical recycling. In Macromolecular Symposia; Wiley-VCH: Weinheim, Germany, 1999; pp. 465–469. [Google Scholar]

- Al-Salem, S.; Lettieri, P.; Baeyens, J. The valorization of plastic solid waste (PSW) by primary to quaternary routes: From re-use to energy and chemicals. Prog. Energy Combust. Sci. 2010, 36, 103–129. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, X.; Tang, S.; Lu, X.; Zhang, X.; Zhang, S. Urea as an efficient and reusable catalyst for the glycolysis of poly (ethylene terephthalate) wastes and the role of hydrogen bond in this process. Green Chem. 2012, 14, 2559–2566. [Google Scholar] [CrossRef]

- Zhu, M.; Li, S.; Li, Z.; Lu, X.; Zhang, S. Investigation of solid catalysts for glycolysis of polyethylene terephthalate. Chem. Eng. J. 2012, 185, 168–177. [Google Scholar] [CrossRef]

- Zhou, X.; Lu, X.; Wang, Q.; Zhu, M.; Li, Z. Effective catalysis of poly (ethylene terephthalate)(PET) degradation by metallic acetate ionic liquids. Pure Appl. Chem. 2012, 84, 789–801. [Google Scholar] [CrossRef]

- López-Fonseca, R.; González-Marcos, M.; González-Velasco, J.; Gutiérrez-Ortiz, J. A kinetic study of the depolymerisation of poly (ethylene terephthalate) by phase transfer catalysed alkaline hydrolysis. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2009, 84, 92–99. [Google Scholar] [CrossRef]

- Dimov, K.; Terlemezyan, E. Catalytic action of calcium acetate and the manganese acetate-sodium acetate mixture in the pre-esterification of dimethyl terephthalate with ethylene glycol. J. Polym. Sci. Part A-1 Polym. Chem. 1972, 10, 3133–3141. [Google Scholar] [CrossRef]

- Baliga, S.; Wong, W.T. Depolymerization of poly (ethylene terephthalate) recycled from post-consumer soft-drink bottles. J. Polym. Sci. Part A Polym. Chem. 1989, 27, 2071–2082. [Google Scholar] [CrossRef]

- Wi, R.; Imran, M.; Lee, K.G.; Yoon, S.H.; Cho, B.G.; Kim, D.H. Effect of support size on the catalytic activity of metal-oxide-doped silica particles in the glycolysis of polyethylene terephthalate. J. Nanosci. Nanotechnol. 2011, 11, 6544–6549. [Google Scholar] [CrossRef]

- Imran, M.; Lee, K.G.; Imtiaz, Q.; Kim, B.-K.; Han, M.; Cho, B.G.; Kim, D.H. Metal-oxide-doped silica nanoparticles for the catalytic glycolysis of polyethylene terephthalate. J. Nanosci. Nanotechnol. 2011, 11, 824–828. [Google Scholar] [CrossRef]

- Singh, A.K.; Fernando, S.D. Reaction kinetics of soybean oil transesterification using heterogeneous metal oxide catalysts. Chem. Eng. Technol. Ind. Chem.-Plant Equip.-Process Eng.-Biotechnol. 2007, 30, 1716–1720. [Google Scholar] [CrossRef]

- Heiz, U.; Landman, U. Nanocatalysis; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Das, S.K.; Eshkalak, S.K.; Chinnappan, A.; Ghosh, R.; Jayathilaka, W.; Baskar, C.; Ramakrishna, S. Plastic recycling of polyethylene terephthalate (PET) and polyhydroxybutyrate (PHB)-A comprehensive review. Mater. Circ. Econ. 2021, 3, 9. [Google Scholar] [CrossRef]

- Mastellone, M.; Perugini, F.; Ponte, M.; Arena, U. Fluidized bed pyrolysis of a recycled polyethylene. Polym. Degrad. Stab. 2002, 76, 479–487. [Google Scholar] [CrossRef]

- Cornell, D. Depolymerization of PET for food packaging. In Proceedings of the Society of Plastics Engineers RETEC Conference, Bethel, CT, USA, 22–23 September 1993. [Google Scholar]

- Kurokawa, H.; Ohshima, M.-A.; Sugiyama, K.; Miura, H. Methanolysis of polyethylene terephthalate (PET) in the presence of aluminium thiisopropoxide catalyst to form dimethyl terephthalate and ethylene glycol. Polym. Degrad. Stab. 2003, 79, 529–533. [Google Scholar] [CrossRef]

- Michel, R. Recovery of methyl esters of aromatic acids and glycols from thermoplastic polyester scrap using methanol vapour. Eur. Pat. 1992, 484, 963. [Google Scholar]

- Campanelli, J.; Kamal, M.; Cooper, D. Kinetics of glycolysis of poly (ethylene terephthalate) melts. J. Appl. Polym. Sci. 1994, 54, 1731–1740. [Google Scholar] [CrossRef]

- Imran, M.; Kim, B.-K.; Han, M.; Cho, B.G. Sub-and supercritical glycolysis of polyethylene terephthalate (PET) into the monomer bis (2-hydroxyethyl) terephthalate (BHET). Polym. Degrad. Stab. 2010, 95, 1686–1693. [Google Scholar] [CrossRef]

- Alnaqbi, M.A.; Mohsin, M.A.; Busheer, R.M.; Haik, Y. Microwave assisted glycolysis of poly (ethylene terephthalate) catalyzed by 1-butyl-3-methylimidazolium bromide ionic liquid. J. Appl. Polym. Sci. 2015, 132, 12. [Google Scholar] [CrossRef]

- Brown, G.E., Jr.; O’brien, R.C. Method for Recovering Terephthalic Acid and Ethylene Glycol from Polyester Materials. U.S. Patent No. 3952053, 20 April 1976. [Google Scholar]

- Pusztaszeri, S.F. Method for Recovery of Terephthalic Acid from Polyester Scrap. U.S. Patent No. 4,355,175, 19 October 1982. [Google Scholar]

- Collins, M.J.; Zeronian, S.H.; Marshall, M.L. Analysis of the molecular weight distributions of aminolyzed poly (ethylene terephthalate) by using gel permeation chromatography. J. Macromol. Sci. Chem. 1991, 28, 775–792. [Google Scholar] [CrossRef]

- Overton, J.; Haynes, S. Determination of the crystalline fold period in poly (ethylene terephthalate). J. Polym. Sci. Polym. Symp. 1973, 43, 9–17. [Google Scholar] [CrossRef]

- Bernasowski, M.; Łędzki, A.; Stachura, R.; Wcisło, Z.; Klimczyk, A.; Migas, P. The blast furnace as a utiliser of plastic waste. Metall. Metall. News 2010, 77, 296–300. [Google Scholar]

- Kim, D.; Shin, S.; Sohn, S.; Choi, J.; Ban, B. Waste plastics as supplemental fuel in the blast furnace process: Improving combustion efficiencies. J. Hazard. Mater. 2002, 94, 213–222. [Google Scholar] [CrossRef]

- Ziębik, A.; Stanek, W. Forecasting of the energy effects of injecting plastic wastes into the blast furnace in comparison with other auxiliary fuels. Energy 2001, 26, 1159–1173. [Google Scholar] [CrossRef]

- Gołek-Schild, J. Thermal processing installations for municipal waste in Poland—A source of energy of environmental importance. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią PAN 2018, 105, 147–156. [Google Scholar]

- O’Rourke, K.; Wurzer, C.; Murray, J.; Doyle, A.; Doyle, K.; Griffin, C.; Christensen, B.; Brádaigh, C.M.Ó.; Ray, D. Diverted from Landfill: Reuse of Single-Use Plastic Packaging Waste. Polymers 2022, 14, 5485. [Google Scholar] [CrossRef]

- The New Plastics Economy: Rethinking the Future of Plastics & Catalysing Action; Ellen MacArthur Foundation: Cowes, UK, 2016.

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Bascetin, A.; Adiguzel, D.; Eker, H.; Odabas, E. Effects of puzzolanic materials in surface paste disposal by pilot-scale tests: Observation of physical changes. Int. J. Environ. Sci. Technol. 2021, 18, 949–964. [Google Scholar] [CrossRef]

- Eker, H.; Bascetin, A. The study of strength behaviour of zeolite in cemented paste backfill. Geomech. Eng. 2022, 29, 421–434. [Google Scholar]

- Jin, R.; Chen, Q. Investigation of concrete recycling in the U.S. construction industry. Procedia Eng. 2015, 118, 894–901. [Google Scholar] [CrossRef]

- Pangsy-Kania, S. Development management system in Poland and the role of strategic documents in it. Stud. Public Policy 2015, 7, 120–137. [Google Scholar]

- Małaszkiewicz, D.; Pawluczuk, E. Influence of recycled aggregate on selected technical properties of concrete, Prace Naukowe Instytutu Budownictwa Politechniki Wrocławskiej. Stud. Mater. 2006, 87, 405–410. [Google Scholar]

- Hare, B.; Golebiowska, I. The future of concrete with recycled concrete aggregate. Inż. Ap. Chem. 2014, 53, 390–392. [Google Scholar]

- Anink, D.; Boonstra, C.; Mak, J. Handbook of Sustainable Building, an Environmental Preference Method for Selection of Materials for Use in Construction and Refurbishment; Chapman Publication: London, UK, 1996. [Google Scholar]

- Ajdukiewicz, A.; Kliszczewicz, A. Ad hoc and rheological properties of structural concretes on recycled aggregates. Zesz. Nauk. Politech. Rzeszowskiej. Constr. Environ. Eng. 2012, 3, 173–180. [Google Scholar]

- Ahn, T.H.; Kishi, T. Crack self-healing behaviour of cementitious composites incorporating various mineral admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef]

- Jevtić, D.; Zakić, D.; Savić, A. Achieving sustainability of concrete by recycling of solid waste materials. Mech. Test. Diagn. 2012, 2, 22–39. [Google Scholar]

- Hansen, T.C.; Narud, H. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int.-Des. Constr. 2003, 5, 35–48. [Google Scholar]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Res. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Collective work Best Practice Guide for the Use of Recycled Aggregates in New Concrete; CCANZ Technical Report; Cement and Concrete Association: Wellington, New Zealand, 2014.

- Senthamarai, R.M.; Devadas, A.; Manoharan, P.; Gobinath, D. Concrete made from ceramic industry waste: Durability propertis. Constr. Build. Mater. 2011, 25, 2413–2419. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, J.R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Reusing ceramic wastes in concrete. Constr. Build. Mater. 2010, 24, 832–838. [Google Scholar] [CrossRef]

- Debieb, A.; Farid, K.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Devenny, A.; Khalaf, F.M. Use of crushed brick as coarse aggregate in concrete. Mason. Int. 1999, 12, 81–84. [Google Scholar]

- Khalaf, F.M.; DeVenny, A.S. Recycling of demolished masonry rubble as coarse aggregate in concrete: Review. J. Mater. Civ. Eng. 2004, 16, 331–340. [Google Scholar] [CrossRef]

- Khalloo, A.R. Properties of concrete using crushed clinker brick as coarse aggregate. ACI Mater. J. 1994, 91, 401–407. [Google Scholar]

- Khatie, M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Guerra, I. Eco-efficient concrete: The effects of using recycled ceramic material from sanitary installations on the mechanical properties of concrete. Waste Manag. 2009, 29, 643–646. [Google Scholar] [CrossRef]

- Medina, C.; Frias, M.; De Rojas, M.I. Microstructure and properties of recycled concretes using ceramic sanitary ware industry waste as coarse aggregate. Constr. Build. Mater. 2012, 31, 112–118. [Google Scholar] [CrossRef]

- Halicka, A.; Ogrodnik, P.; Zegardło, B. Using ceramic sanitary ware waste as concrete aggregate. Constr. Build. Mater. 2014, 48, 295–305. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P. Ultra-high strength concrete made with recycled aggregate from sanitary ceramic wastes-The method of production and the interfacial transition zone. Constr. Build. Mater. 2016, 122, 736–742. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P. Concrete resistant to spalling made with recycled aggregate from sanitary ceramic wastes-effect of moisture and porosity on destructive processes occurring in fire conditions. Constr. Build. Mater. 2018, 173, 58–68. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Zegardło, B.; Radzikowska, M. Use of post-production sanitary ceramic waste as a filler for cementitious composites with high chemical resistance. Chem. Ind. 2017, 96, 1100–1104. [Google Scholar]

- Ogrodnik, P.; Zegardło, B.; Szeląg, M. The use of heat-resistant concrete made with ceramic sanitary ware waste for a thermal energy storage. Appl. Sci. 2017, 7, 1303. [Google Scholar] [CrossRef]

- Zegardło, B.; Brzyski, P.; Rymuza, K.; Bombik, A. Analysis of the Effects of Aggressive Environments Simulating Municipal Sewage on Recycled Concretes Based on Selected Ceramic Waste. Materials 2018, 11, 2565. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Majdi, A.; Alqurashi, M.; Deifalla, A.F. Overview of Concrete Performance Made with Waste Rubber Tires. A Step toward Sustainable Concrete. Materials 2022, 15, 5518. [Google Scholar] [CrossRef]

- Fashandi, H.; Pakravan, H.R.; Latifi, M. Application of modified carpet waste cuttings for production of eco-efficient lightweight concrete. Constr. Build. Mater. 2019, 198, 629–637. [Google Scholar] [CrossRef]

- Şahin, D.; Çullu, M.; Eker, H. The effect of different fineness values of Afşin Elbistan fly ash on permeability in concrete. Challenge 2020, 6, 73–83. [Google Scholar]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574–129577. [Google Scholar] [CrossRef]

- Zegardło, B.; Maraveas, C.; Kaleszko, S.; Bombik, A. Composites Containing Felt Wastes from the Automotive Industry. Appl. Sci. 2023, 13, 2375. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.; Levett, P. Evaluation of concrete performance with different types of recycled plastic waste for kerb application. Constr. Build. Mater. 2021, 293, 123477. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Feugeas, F.; Faqiri, A. Fresh and hardened properties of concrete containing different forms of plastic waste—A review. Waste Manag. 2020, 113, 157–175. [Google Scholar] [CrossRef]

- Thosar, C.P.; Husain, D.M. Reuse of plastic waste as replacement of sand in concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 789–794. [Google Scholar]

- Askar, M.K.; Askar, L.K.; Al-Kamaki, Y.S.S.; Ferhadi, R. Effects of chopped CFRP fiber on mechanical properties of concrete. Heliyon 2023, 9, e13832. [Google Scholar] [CrossRef]

- Marthong, C.; Marthong, S. An experimental study on the effect of PET fibers on the behavior of exterior RC beam-column connection subjected to reversed cyclic loading. Structures 2016, 5, 175–185. [Google Scholar] [CrossRef]

- Al-Hadithi, A.I.; Abbas, M.A. The effects of adding waste plastic fibers on the mechanical properties and shear strength of reinforced concrete beams. Iraqi J. Civ. Eng. 2018, 12, 110–124. [Google Scholar] [CrossRef]

- Khatab, H.R.; Mohammed, S.J.; Hameed, L.A. Mechanical Properties of Concrete Contain Waste Fibers of Plastic Straps. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Pešić, N.; Živanović, S.; Garcia, R.; Papastergiou, P. Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Constr. Build. Mater. 2016, 115, 362–370. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Fresh and strength properties of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 2017, 146, 455–463. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M.; Samadi, M. Waste metalized film food packaging as low cost and ecofriendly fibrous materials in the production of sustainable and green concrete composites. J. Clean. Prod. 2020, 258, 120726. [Google Scholar] [CrossRef]

- Dawood, A.O.; Al-Khazraji, H.; Falih, R.S. Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Skominas, R.; Zvinakevičius, L.; Gurskis, V.; Šadzevičius, R. Evaluation of suitability to use plastic waste in concrete production. In Proceedings of the International Scientific Conference Rural Development, Akademija, Lithuania, 23–24 November 2017; Aleksandras Stulginskis University: Akademija, Lithuania, 2017; pp. 428–432. [Google Scholar]

- Hama, S.M.; Hilal, N.N. 5-Fresh properties of concrete containing plastic aggregate. In Use of Recycled Plastics in Eco-Efficient Concrete; Pacheco-Torgal, F., Khatib, J., Colangelo, F., Tuladhar, R., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 85–114. [Google Scholar]

- Rai, B.; Rushad, S.T.; Kr, B.; Duggal, S. Study of waste plastic mix concrete with plasticizer. Int. Sch. Res. Not. 2012, 2012, 469272. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Saikia, N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Kumar, K.S.; Baskar, K. Recycling of E-plastic waste as a construction material in developing countries. J. Mater. Cycles Waste Manag. 2015, 17, 718–724. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Meena, A.; Surendranath, A.; Ramana, P.V. Assessment of mechanical properties and workability for polyethylene terephthalate fiber reinforced concrete. Mater. Today Proc. 2021, 50, 2307–2314. [Google Scholar] [CrossRef]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T.A. Durability performance of a novel ultra-high-performance PET green concrete (UHPPGC). Constr. Build. Mater. 2019, 209, 395–405. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pacheco-Torgal, F.; Lopes, A. Advantages and shortcomings of the utilization of recycled wastes as aggregates in structural concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Pereira, E.L.; de Oliveira Junior, A.L.; Fineza, A.G. Optimization of mechanical properties in concrete reinforced with fibers from solid urban wastes (PET bottles) for the production of ecological concrete. Constr. Build. Mater. 2017, 149, 837–848. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutierrez, A. Influence of content and particle size of waste pet bottles on concrete behaviour at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef]

- Azhdarpour, A.M.; Nikoudel, M.R.; Taheri, M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; a laboratory evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Askar, M.K.; Hassan, A.F.; Al-Kamaki, Y.S.S. Flexural and shear strengthening of reinforced concrete beams using FRP composites: A state of the art. Case Stud. Constr. Mater. 2022, 17, e01189. [Google Scholar] [CrossRef]

- Marcuello, C.; Chabbert, B.; Berzin, F.; Bercu, N.B.; Molinari, M.; Aguié-Béghin, V. Influence of Surface Chemistry of Fiber and Lignocellulosic Materials on Adhesion Properties with Polybutylene Succinate at Nanoscale. Materials 2023, 16, 2440. [Google Scholar] [CrossRef]

- Reixach, R.; Claramunt, J.; Chamorro, M.À.; Llorens, J.; Pareta, M.M.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M. On the Path to a New Generation of Cement-Based Composites through the Use of Lignocellulosic Micro/Nanofibers. Materials 2019, 12, 1584. [Google Scholar] [CrossRef]

- EN 12350-2:2011; Testing Fresh Concrete. Slump-Test. Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN 12390-7:2011; Testing Hardened Concrete. Density of Hardened Concrete. Polish Committee Standardisation: Warsaw, Poland, 2011.

- PN-EN 13755:2008; Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure. Polish Committee for Standardization: Warsaw, Poland, 2008.

- PN-EN 12390-5:2009; Testing Hardened Concrete. Flexural Strength of Test Specimens. Polish Committee Standardisation: Warsaw, Poland, 2009.

- PN-EN 12390-3:2011; Testing Hardened Concrete. Compressive Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2011.

| Feature | Value |

|---|---|

| Chemical composition | (CH2-CH2)n |

| Volumetric density | 0.915–0.920 g/cm3 |

| Thermal conductivity | 0.32–0.35 W/m-K |

| Tensile strength | 24.7 MPa |

| Relative elongation at yield stress | >9.1% |

| Temperature resistance | Below +80 °C |

| Technical Parameter | Unit | Value/Standard Deviation |

|---|---|---|

| Specific density | kg/dm3 | 2.65/±0.1 |

| Volumetric density | kg/dm3 | 1.78/±0.1 |

| Compressive strength | MPa | 22/±2 |

| Modulus of elasticity | 102 MPa | 200/±10% |

| Absorption | % | 2.8/±0.3 |

| Degree of shattering | % | 16.0/±2% |

| Component | Amount of Substrate in [g] in the Test Mixture | Substrate Density [g/mL]. | Volume in [mL] | Conversion Factor of Ingredient Quantity per 1 m3 Concrete Mixture | Amount of Substrate [kg/m3] of Concrete Mix | Substrate Density [kg/m3] | Component Volume in [m3] |

|---|---|---|---|---|---|---|---|

| LDPE recyclate | 77.000 | 0.92 | 83.70 | 3895.14 | 299.93 | 920.00 | 0.3260 |

| Sand and gravel aggregate 0–2 mm | 308.000 | 1.78 | 173.03 | 3895.14 | 1199.70 | 1780.00 | 0.6740 |

| SUMA | 385.000 | 256.73 | 3895.14 | 1499.63 | 1.0000 |

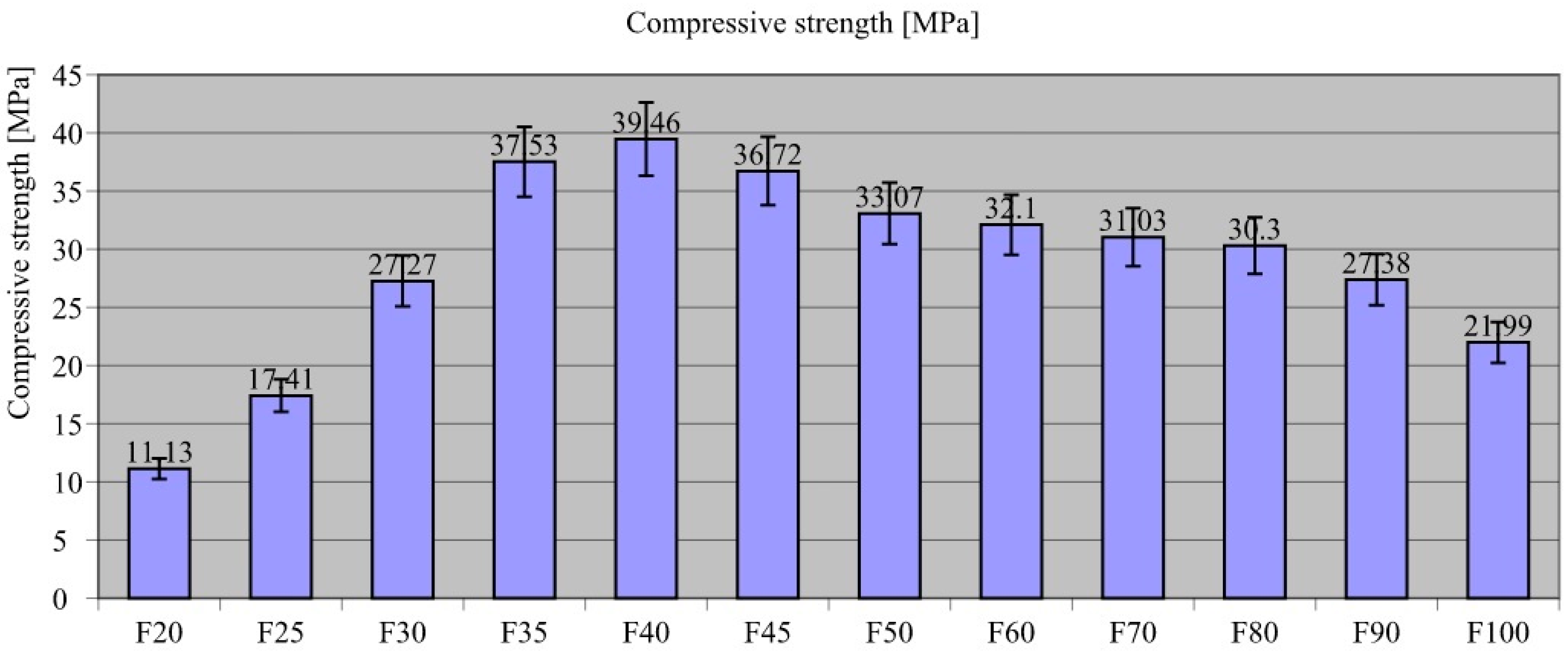

| Component/Quantity in kg/m3 | F20 | F25 | F30 | F35 | F40 | F45 | F50 | F60 | F70 | F80 | F90 | F100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LDPE recyclate | 299.93 | 373.93 | 451.84 | 506.37 | 564.80 | 576.48 | 611.54 | 693.34 | 759.55 | 817.98 | 876.41 | 927.04 |

| Sand and gravel aggregate 0–2 mm | 1199.70 | 1121.80 | 1054.29 | 940.40 | 847.19 | 704.59 | 611.54 | 462.22 | 325.52 | 204.49 | 97.38 | 0.00 |

| SUMA | 1499.63 | 1495.73 | 1506.13 | 1446.77 | 1411.99 | 1281.07 | 1223.08 | 1155.56 | 1085.07 | 1022.47 | 973.79 | 927.04 |

| Density of LDPE recyclate [kg/m3] | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 | 920.00 |

| Aggregate density [kg/m3] | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 | 1780.00 |

| Mixture volume [m3] | 1.00 | 1.04 | 1.08 | 1.08 | 1.09 | 1.02 | 1.01 | 1.01 | 1.01 | 1.00 | 1.01 | 1.01 |

| Percentage content of aggregate | 20.00 | 25.00 | 30.00 | 35.00 | 40.00 | 45.00 | 50.00 | 60.00 | 70.00 | 80.00 | 90.00 | 100.00 |

| Percentage of LDPE recyclate | 80.00 | 75.00 | 70.00 | 65.00 | 60.00 | 55.00 | 50.00 | 40.00 | 30.00 | 20.00 | 10.00 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zegardło, B.; Maraveas, C.; Rastawicki, K.; Woliński, P.; Bombik, A. Recycling of Agricultural Film Wastes for Use as a Binder in Building Composites. Materials 2025, 18, 251. https://doi.org/10.3390/ma18020251

Zegardło B, Maraveas C, Rastawicki K, Woliński P, Bombik A. Recycling of Agricultural Film Wastes for Use as a Binder in Building Composites. Materials. 2025; 18(2):251. https://doi.org/10.3390/ma18020251

Chicago/Turabian StyleZegardło, Bartosz, Chrysanthos Maraveas, Kacper Rastawicki, Paweł Woliński, and Antoni Bombik. 2025. "Recycling of Agricultural Film Wastes for Use as a Binder in Building Composites" Materials 18, no. 2: 251. https://doi.org/10.3390/ma18020251

APA StyleZegardło, B., Maraveas, C., Rastawicki, K., Woliński, P., & Bombik, A. (2025). Recycling of Agricultural Film Wastes for Use as a Binder in Building Composites. Materials, 18(2), 251. https://doi.org/10.3390/ma18020251