1. Introduction

Due to their exceptional electrical, thermal, and mechanical properties, carbon nanotubes are utilized as reinforcement agents in metal matrix composites to improve their performance [

1]. They have found extensive applications in various sectors including electronic components, aerospace, and national defense.

Carbon nanotube-doped metal matrix composites, including aluminum, magnesium, copper, titanium, silver, nickel–aluminum, nickel–iron, iron–cobalt, and iron, are of significant interest for high-strength and lightweight structural applications. Research in this area has primarily concentrated on process challenges, mechanical characteristics, and reinforcement mechanisms, leading to notable advancements [

1,

2,

3,

4]. For instance, incorporating CNTs into Al through high-energy ball milling and adding 15 vol% carbon nanotubes to a copper matrix enhances yield strength [

5]. For the Cu-Ti alloy, it achieves a tensile yield strength of 515 MPa, tensile strength of 542 MPa, elastic modulus of 95.6 GPa, and elongation of 10.4%. In the iron–cobalt alloy, 0.5 vol% carbon nanotubes boost hardness by 18% (1 vol% graphene nanoplatelets) and achieve a maximum magnetic induction of 2.39 T [

6]. Notably, research on carbon nanotube-reinforced iron-based composites is limited, primarily focusing on mechanical properties like hardness and strength [

1,

7,

8,

9,

10,

11], with minimal exploration of their magnetic characteristics [

12,

13,

14,

15,

16]. Consequently, further investigations into the structure and magnetic properties of carbon nanotube-reinforced iron-based composites are warranted.

Numerous studies have demonstrated the crucial role of interfacial bonding quality between carbon nanotubes and metal matrices in determining composite properties [

17,

18,

19]. High-energy ball milling is a widely recognized method for achieving homogeneous dispersion of carbon nanotubes within metal matrices, albeit at the expense of causing structural damage to the nanotubes, such as shortening and amorphization [

20,

21]. This structural damage triggers various interfacial reactions, including the formation of solid solutions or carbides, which significantly impact interfacial bonding strength. Notably, in the case of transition metals, there is potential for 3d-2p hybridization between their vacant 3d orbitals and the graphite structure of carbon nanotubes [

22], facilitating favorable interfacial bonding [

18,

19]. The extent of structural damage and interfacial reactions during high-energy ball milling is intricately linked to the carbon nanotube content. Therefore, investigating the influence of carbon nanotube content on the structure and magnetic properties of iron-based carbon nanotube composites holds substantial importance.

In this study, Fe-CNT composites were synthesized via high-energy ball milling, followed by a comprehensive analysis of the impact of carbon nanotube concentration on the phase composition, morphology, and magnetic characteristics of the composites.

2. Materials and Methods

Water-atomized iron powder (particle size ≤ 150 μm, purity ≥ 99.5%, Tianjiu Metal Material Co., Ltd., Changsha, China) and carbon nanotubes (average outer diameter: 1–2 nm, length: 1–3 μm, purity ≥ 95%, Shanghai Aladdin Biochemical Technology Co., Ltd., Shanghai, China) were utilized as raw materials. The experimental procedure for fabricating Fe-CNT composites involved initially pre-mixing the iron powder and carbon nanotubes (at CNT contents of 1 wt%, 2 wt%, and 3 wt%, respectively) in a V-shaped powder mixer for 15 min. Subsequently, the mixture underwent dry-milling in a planetary ball mill (1-SL, Qingdao Union Machinery Co., Ltd., Qingdao, China) for 2 h. This milling process employed 304 stainless steel ball-milling jars and 304 stainless steel grinding balls, with a ball-to-powder ratio of 50:1, a rotation speed of 200 rpm, and the introduction of an argon protective atmosphere to prevent oxidation. The resulting ball-milled powder was then annealed at 600 °C for 2 h to relieve internal stress, with continuous maintenance of an argon protective atmosphere. Additionally, to assess the impact of carbon nanotubes on magnetic properties, pure iron powder without doping was prepared under identical conditions.

The soft magnetic powders were subjected to analysis of crystal structure and phase composition using an X-ray diffractometer (XRD) with Cu-Kα radiation, operating at 30 kV and 30 mA (DX-2007, Dandong fangyuan Co., Ltd., Dandong, China). Internal structural features of carbon nanotubes were characterized using a Raman spectrometer (Lab RAM HR-Evolution, HORIBA Scientific, Paris, France) with a laser wavelength of 532 nm, a spectral range of 200–210 nm, and a test range of 800–200 cm−1. The microstructure morphology of composite powders doped with carbon nanostructures was observed using a scanning electron microscope (SEM) (Nova NanoSEM 450, FEI, Portland, OR, USA). The hysteresis loops of the soft magnetic powders were measured using a vibrating sample magnetometer (VSM) (Model 7407, Lakeshore, Westerville, OH, USA) to analyze static magnetic properties including saturation magnetization, coercivity, and remanence.

3. Results

3.1. Phase Composition of the Fe-CNT Composites

Figure 1a illustrates X-ray diffraction (XRD) patterns of Fe–carbon nanotube (CNT) composites with varying CNT contents (1 wt%, 2 wt%, 3 wt%). All samples display three prominent peaks at approximately 44.67° (110), 65.02° (200), and 82.33° (211), indicative of a typical body-centered cubic crystal structure in Fe-CNT primarily comprising the α-Fe phase. Relative to pure iron, the diffraction peaks of Fe-1 wt% CNTs exhibit a slight shift towards lower angles with reduced intensities, implying the formation of a solid solution identified as ferrite α-(Fe, C). With increasing CNT content, iron carbide phases emerge in the Fe-CNT composites, predominantly identified as Fe

3C cementite. Comparison of the diffraction patterns reveals that, in contrast to Fe-1 wt% CNTs, the diffraction peaks of Fe-2 wt% CNTs and Fe-3 wt% CNTs shift towards higher angles, with the degree of shift escalating with rising carbon content, as depicted in the magnified XRD pattern excerpt in

Figure 1b. Consequently, excessive CNT incorporation results in the precipitation of iron carbide phases like cementite at the iron–CNT interface, compromising the magnetic properties.

The lattice parameters of Fe-CNT composites exhibited an increase in comparison to pure iron, as detailed in

Table 1. This phenomenon primarily arises from the creation of a solid solution through the incorporation of carbon atoms into the iron matrix during the ball milling process [

23]. Nevertheless, a decline in lattice parameters was observed once the CNT content surpassed 1 wt%. This trend suggests that with higher CNT concentrations, carbon saturation within the iron matrix occurs, leading to the precipitation of iron–carbon compounds [

12].

The grain size of the Fe-CNT composites was determined using the Scherrer formula applied to the XRD pattern [

24]. Scherrer’s formula is as follows:

where

D is the grain size,

k is the Scherrer’s constant,

β is the FWHM and 2θ is the Bragg angle.

Table 1 illustrates that the grain size of the composite increased progressively with higher carbon nanotube content. Under deformation, fracture, and rewelding processes, the iron powder particles exhibited growth in a flattened orientation along the vertical axis. This behavior aligns with previous findings indicating a consistent upward trend in grain size [

25,

26].

The lattice strain in Fe-CNT composites is lower compared to pure iron powder. This reduction can be attributed to the formation of numerous small pores within the iron powder particles due to carbon nanotube aggregation, which can absorb some of the residual strain. Additionally, the nano-scale cavities in carbon nanotubes facilitate stress relaxation. However, an increase in CNT content leads to higher lattice strain, possibly due to localized agglomeration and uneven distribution of CNTs within the iron powder particles.

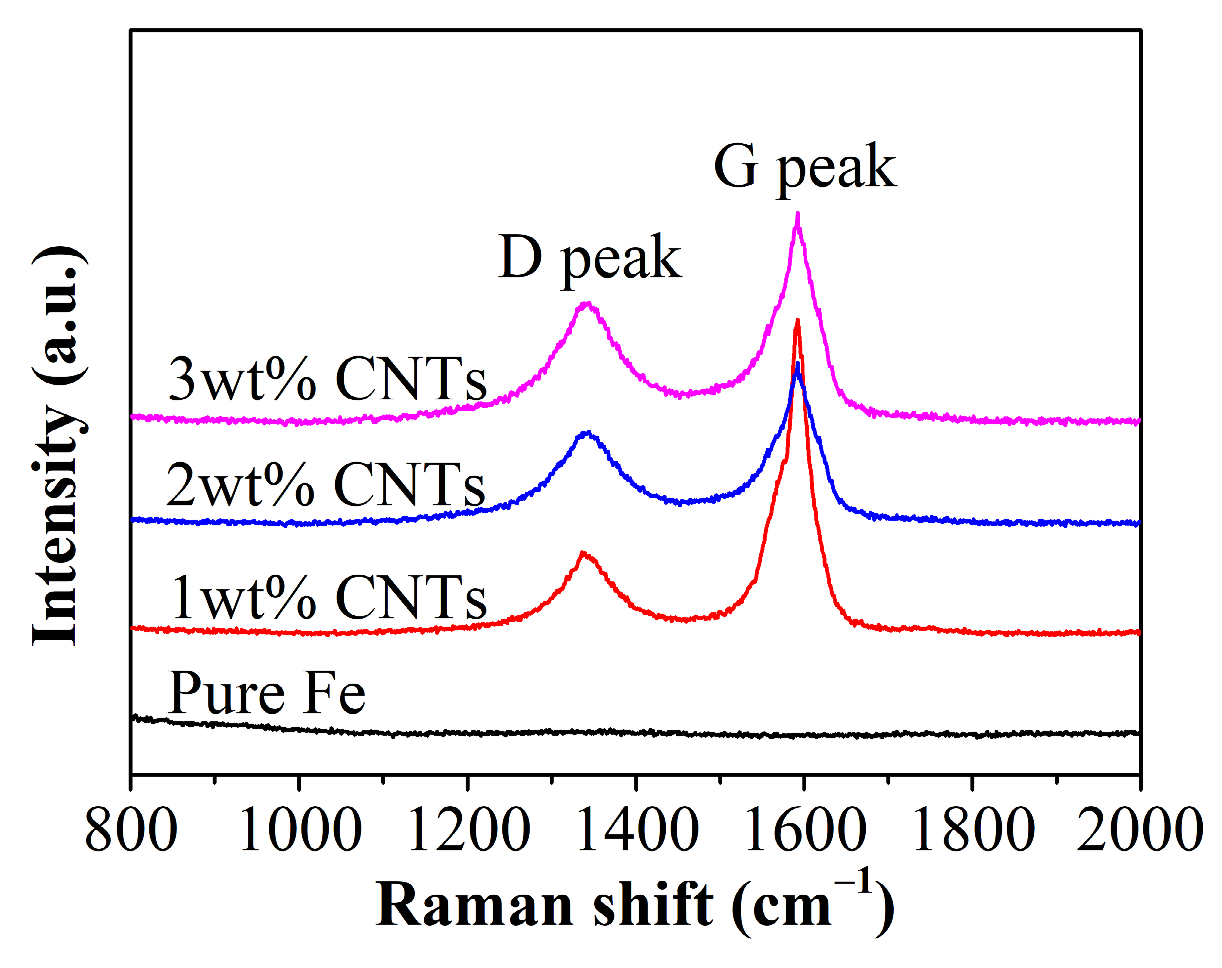

3.2. Structural Stability of CNTs

Raman spectroscopy was utilized to assess the structural stability of carbon nanotubes (CNTs) by conducting tests and analyses on a composite powder of Fe-CNT, as depicted in

Figure 2. The results reveal that all samples demonstrate two distinctive peak positions characteristic of CNTs: the D band at approximately 1344 cm

−1 and the G band at around 1598 cm

−1. Specifically, the G band is attributed to the graphite structure of sp

2 hybridized carbon bonds, whereas the D band is associated with defects within the graphite structure.

Comparison of the Raman spectra of Fe-CNT composites reveals that with increasing carbon nanotube content, the G peak shifts to higher wavenumbers, exhibiting a shorter and broader profile. In contrast, the D peak experiences a slight shift to lower wavenumbers. These observations suggest that the ball-milling process induces damage to the graphite structure, leading to an increase in defect density [

27,

28].

The ratio of the intensity of the D peak to that of the G peak, denoted as (I

D/I

G), serves as a quantitative measure of defect density [

10,

27], as detailed in

Table 2. In Fe-CNT composites, the (I

D/I

G) values are consistently low, indicating a higher defect density compared to pure CNTs while suggesting the preservation of the graphite structure [

13]. With an increase in the carbon nanotube concentration, the (I

D/I

G) ratio gradually rises, likely attributed to the heightened presence of (sp

2) hybridized carbon rings in high CNT content composites. Additionally, the elevated ratio may result from the cleavage of (sp

2) carbon bonds, leading to the formation of minor quantities of amorphous carbon, solid solutions, and iron–carbon compounds [

25,

26,

29].

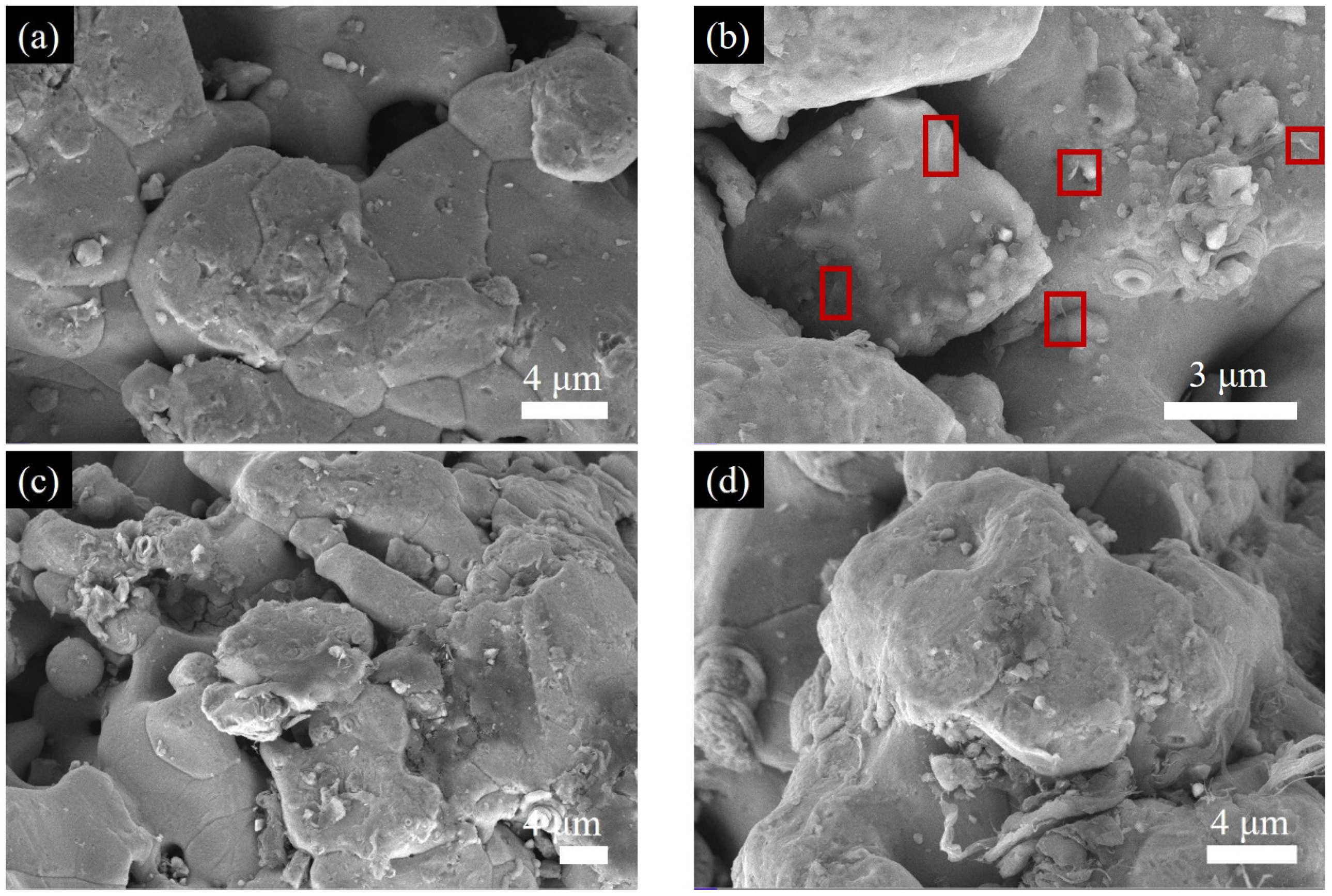

3.3. Microstructure of the Fe-CNT Composites

The surface morphology of pure iron powder post-ball milling, devoid of attached CNTs, is depicted in

Figure 3a.

Figure 3b–d illustrate the morphological characteristics of Fe-CNT composites with varying carbon nanotube concentrations. A notable observation is the considerable reduction in CNT size across all samples compared to the pristine materials, with the majority measuring less than 1 μm. This reduction signifies that the high-energy ball milling process induces damage to the CNT length, leading to size diminution [

30]. Despite the size reduction, the CNTs largely preserve their one-dimensional structure, as evidenced by Raman spectroscopy results.

Figure 3b–d illustrates that the majority of carbon nanotubes (CNTs) are integrated within the iron matrix metal particles, indicating potential robust interfacial bonding. Conversely, a minority of CNTs exhibit partial embedding or remain unembedded on the iron powder particles surface, consistent with prior literature [

13]. This phenomenon primarily arises from the dispersion, fragmentation, refinement, cold welding, and alloying of powder particles occurring throughout the ball milling process [

31].

Upon comparing and analyzing the dispersion of carbon nanotubes (CNTs) within Fe-CNT composites, it is evident that at a lower CNT concentration (1 wt%), CNTs exhibit a relatively homogeneous distribution within the iron matrix, as depicted in

Figure 3a. As the CNT concentration increases to 2 wt%, agglomeration of CNTs initiates, as illustrated in

Figure 3b. Subsequently, at 3 wt% CNT concentration, agglomeration becomes more pronounced, as demonstrated in

Figure 3d. This localized agglomeration significantly undermines interfacial bonding, consequently impeding the overall performance of Fe-CNT composites.

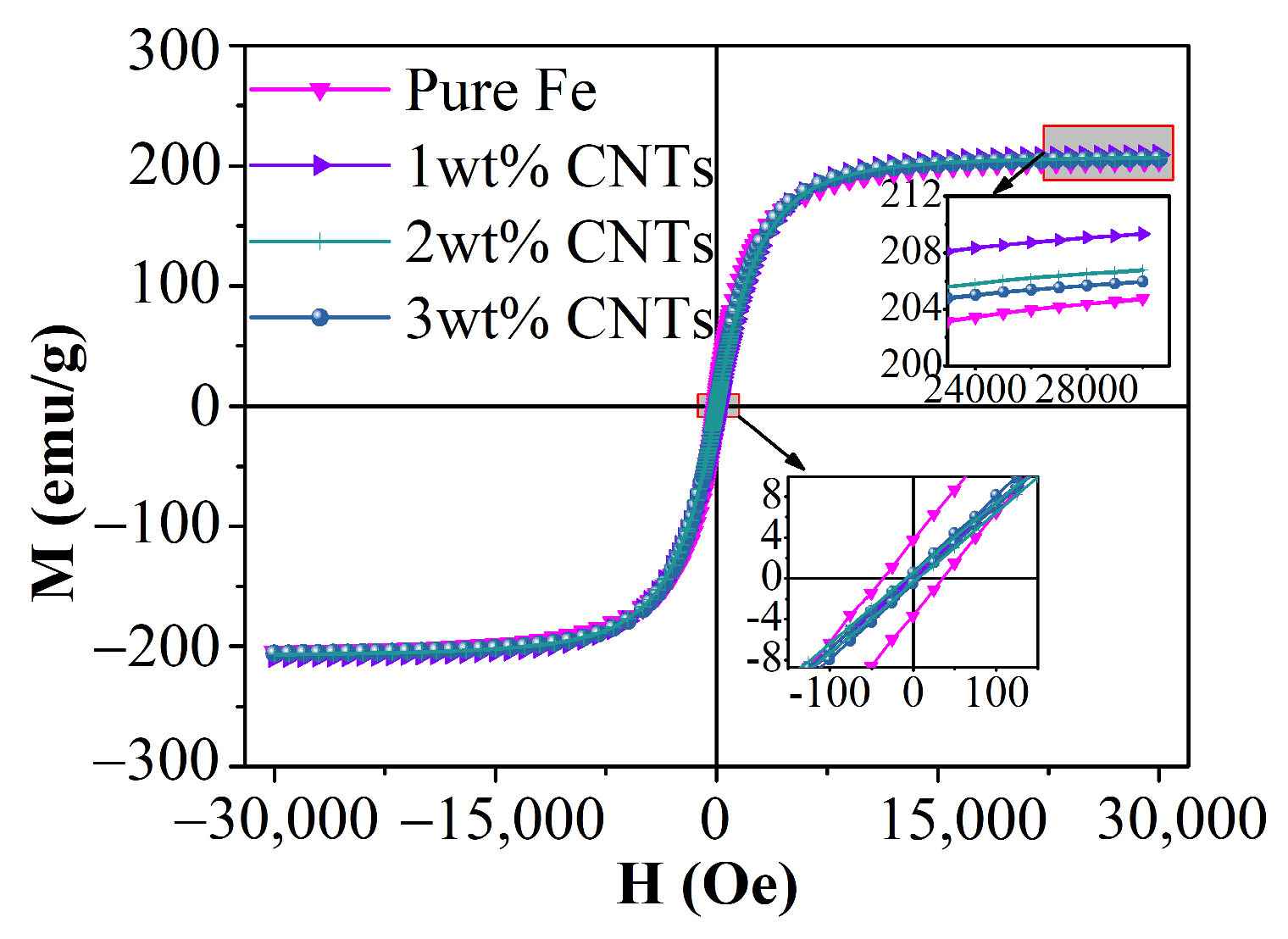

3.4. Magnetic Properties of the Fe-CNT Composites

Figure 4 illustrates the hysteresis loops of the Fe-CNT composites, demonstrating consistent ferromagnetic characteristics across all samples. The findings reveal an enhanced saturation magnetization (M

s) and a reduced coercivity (H

c) in the Fe-CNT composites compared to pure iron powder, as evidenced by the detailed analysis provided in the figure.

As cited in References [

32,

33], ball milling typically induces strain accumulation within pure iron powder particles, leading to a decline in magnetic properties characterized by reduced saturation magnetization and increased coercivity. However, post-ball milling, the magnetization of Fe-CNT composites can increase by 2.25%, while coercivity can decrease by 91.74%, indicating a positive impact of carbon nanotubes on the magnetic properties of iron powder, as shown in

Table 3. Carbon nanotubes exhibit ferromagnetic properties due to their preparation with iron as a catalyst [

34]. This effect is primarily attributed to the interfacial interaction between carbon nanotubes and iron powder. Following ball milling treatment, carbon nanotubes can be effectively integrated into the iron powder matrix, establishing a robust interfacial bonding structure with high cohesion, ensuring strong bonding strength [

12]. Then, the refinement effect of ball milling on composite powder particles plays a crucial role. Studies [

12,

13] have shown that when the particle size of the composite powder post-ball milling falls within the 35–40 nm range, the material typically adopts a single magnetic domain structure and interfaces coherently with carbon nanotubes. Under an external magnetic field, the magnetic domains of the composite material align neatly along the applied magnetic field, resulting in a notably high saturation magnetization. Furthermore, partial damage to carbon bonds in carbon nanotubes due to ball milling facilitates the precipitation of available carbon atoms at dislocations of adjacent iron crystals, promoting a 3d-2p hybridization reaction and forming a smooth CNTs-Fe matrix interface, positively influencing remanence. This enhanced remanence contributes to an overall improvement in saturation magnetization [

12]. The coercivity of the composite powder is primarily influenced by factors such as grain size, dislocation defects, and stress. X-ray diffraction (XRD) analysis reveals that the powder with this doping level exhibits minimal internal stress, resulting in the least hindrance to magnetic domain movement and consequently lower coercivity.

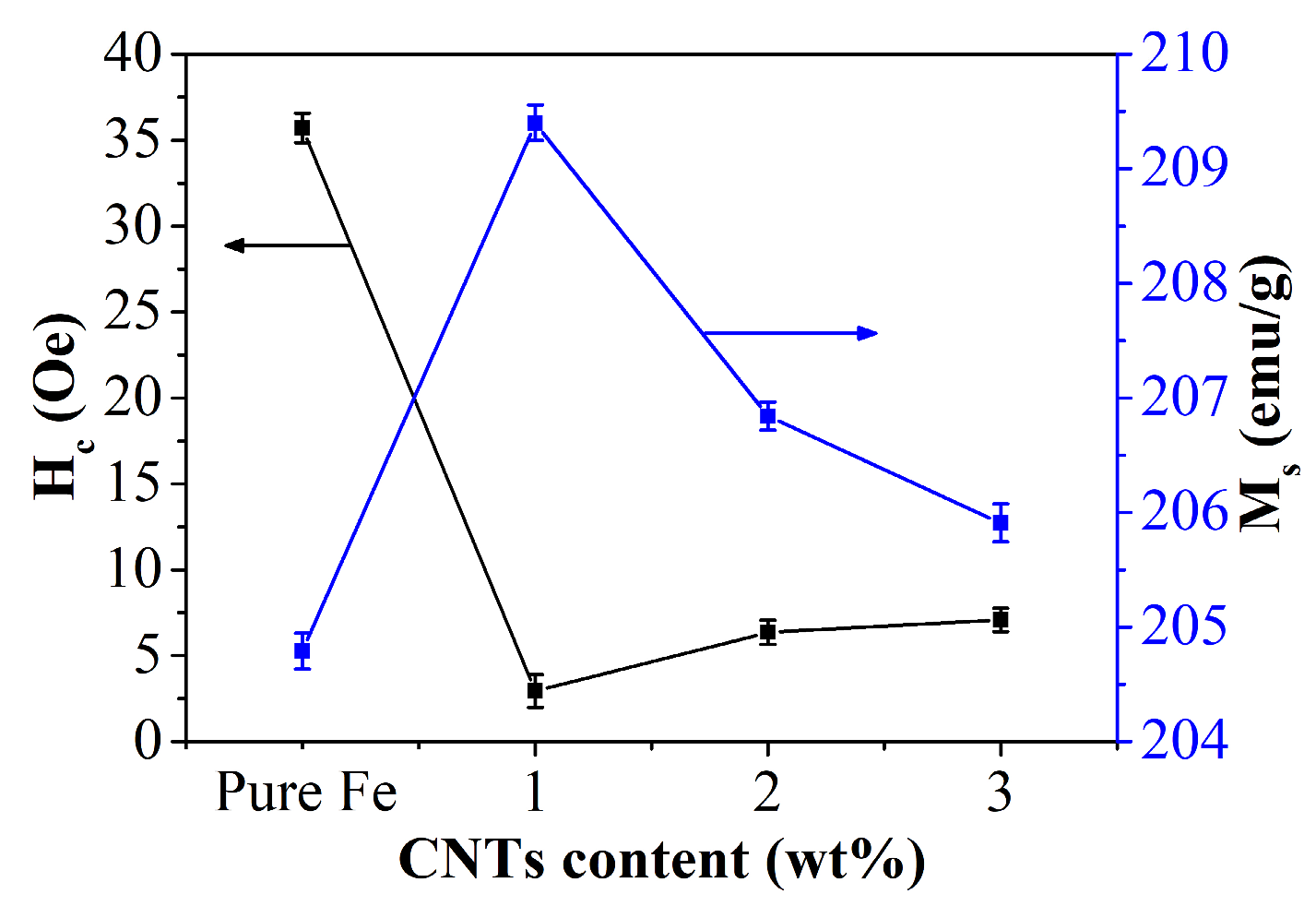

Figure 5 illustrates the saturation magnetization (M

s) and coercivity (H

c) of Fe-CNT composites with varying amounts of carbon nanotube additions. The data reveals a non-linear relationship where M

s initially rises and then declines with increasing carbon nanotube content, while H

c exhibits the opposite trend. Specifically, at a carbon nanotube addition of 1 wt%, the composite demonstrates peak saturation magnetization and minimal coercivity. This behavior is predominantly attributed to the even dispersion of carbon nanotubes, as elucidated in the preceding SEM analysis.

4. Conclusions

The Fe-CNT composites were fabricated via mechanical ball milling, preserving the one-dimensional nanostructure of carbon nanotubes and ensuring their uniform dispersion within the iron matrix. With increasing CNT content, local agglomeration gradually emerges, causing some structural damage to the CNTs and leading to the formation of solid solutions and iron–carbon compounds within the iron matrix. The Fe-CNT composites exhibit enhanced Ms and reduced Hc compared to pure iron. This enhancement in Ms is primarily attributed to the strong interfacial interaction achieved through effective interfacial bonding and high cohesion between CNTs and iron powder post-ball milling. The composite powder displays reduced particle size, a single magnetic domain structure, and a coherent interface with CNTs, facilitating the alignment of magnetic domains along an external magnetic field and resulting in high Ms. The partial damage to carbon bonds in CNTs during ball milling prompts the precipitation of available carbon atoms at dislocations of neighboring iron crystals, facilitating 3d-2p hybridization reactions and promoting a smooth CNTs-Fe matrix interface, thereby enhancing remanence and overall saturation magnetization. Additionally, CNTs synthesized using iron as a catalyst exhibit inherent ferromagnetism. The Hc is directly influenced by grain size, lattice strain, and material density. Among the samples, the Fe-1 wt% CNT composite demonstrates optimal CNT dispersion, exhibiting the highest Ms and the lowest Hc.

Author Contributions

Conceptualization, C.Z. and B.Y.; methodology, C.Z.; software, B.Y.; validation, C.Z. and L.Y.; formal analysis, C.Z., Z.H., Y.C. and X.X.; investigation, C.Z. and B.Y.; resources, B.Y.; data curation, C.Z.; writing—original draft preparation, C.Z.; writing—review and editing, C.Z., Z.H., Y.C. and X.X.; visualization, C.Z. and L.Y.; supervision, C.Z. and L.Y.; project administration, C.Z.; funding acquisition, B.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Meher, B.S.; Saha, R.; Sahoo, B.K.; Chaira, D. Effect of Wet Milling and Reinforcement Content on Iron-Multi-Walled Carbon Nanotube Metal Matrix Composite Fabricated by Conventional Powder Metallurgy. J. Mater. Eng. Perform. 2023, 32, 3755–3771. [Google Scholar] [CrossRef]

- Ahmadian, H.; Sallakhniknezhad, R.; Zhou, T.; Kiahosseini, S.R. Mechanical Properties of Al-Mg/MWCNT Nanocomposite Powder Produced under Different Parameters of Ball Milling Process. Diam. Relat. Mater. 2022, 121, 108755. [Google Scholar] [CrossRef]

- Srinivasan, V.; Kunjiappan, S.; Palanisamy, P. A Brief Review of Carbon Nanotube Reinforced Metal Matrix Composites for Aerospace and Defense Applications. Int. Nano Lett. 2021, 11, 321–345. [Google Scholar] [CrossRef]

- Chabri, S. Morphology and Magnetic Characteristics of Cu-Co/CNT Nano-Composite Synthesized by Mechanical Alloying. J. Mater. Eng. Perform. 2024, 33, 8255–8261. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent Advances in the Development of Aerospace Materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Albaaji, A.J.; Castle, E.G.; Reece, M.J.; Hall, J.P.; Evans, S.L. Synthesis and Properties of Graphene and Graphene/Carbon Nanotube-Reinforced Soft Magnetic FeCo Alloy Composites by Spark Plasma Sintering. J. Mater. Sci. 2016, 51, 7624–7635. [Google Scholar] [CrossRef]

- Polat, G.; Canbolat, I.E.; Uzunoğlu, A.; Kotan, H. Effect of Milling Time, MWCNT Content, and Annealing Temperature on Microstructure and Hardness of Fe/MWCNT Nanocomposites Synthesized by High-Energy Ball Milling. Adv. Powder Technol. 2021, 32, 3107–3116. [Google Scholar] [CrossRef]

- Meher, B.S.; Chaira, D. Effect of MWCNTs Content and Sintering Atmosphere on Microstructure and Various Properties of Iron-MWCNTs MMC Fabricated by Conventional Powder Metallurgy. Diam. Relat. Mater. 2025, 153, 112086. [Google Scholar] [CrossRef]

- Meher, B.S.; Saha, R.; Chaira, D. Fabrication of MWCNTs Reinforced Iron Metal Matrix Composite by Powder Metallurgy: Effects of Wet and Dry Milling. J. Alloys Compd. 2021, 872, 159688. [Google Scholar] [CrossRef]

- Suh, J.Y.; Bae, D.H. Mechanical Properties of Fe-Based Composites Reinforced with Multi-Walled Carbon Nanotubes. Mater. Sci. Eng. A 2013, 582, 321–325. [Google Scholar] [CrossRef]

- Sharma, P.; Kumar, A.; Banerjee, M.K. Structural Evolution in Mechanically Alloyed and Spark Plasma Sintered Iron–0.15 Wt.% MWCNT Composite. J. Mater. Eng. Perform. 2018, 27, 4740–4748. [Google Scholar] [CrossRef]

- Kumar, A.; Banerjee, M.K.; Pandel, U. Development of a Novel MWCNT Reinforced Iron Matrix Nanocomposite through Powder Metallurgy Route. Powder Technol. 2018, 331, 41–51. [Google Scholar] [CrossRef]

- Kumar, A.; Banerjee, U.; Chowrasia, M.K.; Shekhar, H.; Banerjee, M.K. Effect of MWCNT Content on the Structure and Properties of Spark Plasma-Sintered Iron-MWCNT Composites Synthesized by High-Energy Ball Milling. J. Mater. Eng. Perform. 2019, 28, 2983–3000. [Google Scholar] [CrossRef]

- Kumar, A.; Chowrasia, M.K.; Banerjee, U.; Banerjee, M.K. Enhancing Structural Stability and Physical Properties of Silver Added Iron-MWCNT Composite Prepared by High Energy Ball Milling and Spark Plasma Sintering. Diam. Relat. Mater. 2021, 111, 108228. [Google Scholar] [CrossRef]

- Boshko, O.; Nakonechna, O.; Dashevskyi, M.; Ivanenko, K.; Belyavina, N.; Revo, S. Effect of the Carbon Nanotubes on Structure and Magnetic Properties of the Fe–Cu (4:1) Composites. Adv. Powder Technol. 2016, 27, 1101–1108. [Google Scholar] [CrossRef]

- Kumar, P.; Pathak, S.; Singh, A.; Verma, R.; Khanduri, H.; Jain, K.; Tawale, J.; Wang, L.; Pant, R.P. Augmented Magnetic Nanoparticle Assimilation in rGO Sheets for Tailored Static and Dynamic Magnetic Properties in Surface Functionalized Co0.8 Zn0.2 Fe2 O4 Nanoferrite–rGO Hybrid Structures. J. Mater. Chem. C 2024, 12, 18036–18047. [Google Scholar] [CrossRef]

- Zhou, W.; Yamaguchi, T.; Kikuchi, K.; Nomura, N.; Kawasaki, A. Effectively Enhanced Load Transfer by Interfacial Reactions in Multi-Walled Carbon Nanotube Reinforced Al Matrix Composites. Acta Mater. 2017, 125, 369–376. [Google Scholar] [CrossRef]

- Zhou, W.; Bang, S.; Kurita, H.; Miyazaki, T.; Fan, Y.; Kawasaki, A. Interface and Interfacial Reactions in Multi-Walled Carbon Nanotube-Reinforced Aluminum Matrix Composites. Carbon 2016, 96, 919–928. [Google Scholar] [CrossRef]

- Housaer, F.; Beclin, F.; Touzin, M.; Tingaud, D.; Legris, A.; Addad, A. Interfacial Characterization in Carbon Nanotube Reinforced Aluminum Matrix Composites. Mater. Charact. 2015, 110, 94–101. [Google Scholar] [CrossRef]

- Peng, T.; Chang, I. Mechanical Alloying of Multi-Walled Carbon Nanotubes Reinforced Aluminum Composite Powder. Powder Technol. 2014, 266, 7–15. [Google Scholar] [CrossRef]

- Tucho, W.M.; Mauroy, H.; Walmsley, J.C.; Deledda, S.; Holmestad, R.; Hauback, B.C. The Effects of Ball Milling Intensity on Morphology of Multiwall Carbon Nanotubes. Scr. Mater. 2010, 63, 637–640. [Google Scholar] [CrossRef]

- Hudziak, S.; Darfeuille, A.; Zhang, R.; Peijs, T.; Mountjoy, G.; Bertoni, G.; Baxendale, M. Magnetoresistive Phenomena in an Fe-Filled Carbon Nanotube/Elastomer Composite. Nanotechnology 2010, 21, 125505. [Google Scholar] [CrossRef] [PubMed]

- Boshko, O.; Nakonechna, O.; Belyavina, N.; Dashevskyi, M.; Revo, S. Nanocrystalline Fe–C Composites Obtained by Mechanical Alloying of Iron and Carbon Nanotubes. Adv. Powder Technol. 2017, 28, 964–972. [Google Scholar] [CrossRef]

- Zhou, C.; Li, T.; Wei, X.; Yan, B. Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films. Metals 2020, 10, 896. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xu, S.J.; Xiao, B.L.; Xue, P.; Wang, W.G.; Ma, Z.Y. Effect of Ball-Milling Time on Mechanical Properties of Carbon Nanotubes Reinforced Aluminum Matrix Composites. Compos. Part Appl. Sci. Manuf. 2012, 43, 2161–2168. [Google Scholar] [CrossRef]

- Hassan, M.T.Z.; Esawi, A.M.K.; Metwalli, S. Effect of Carbon Nanotube Damage on the Mechanical Properties of Aluminium–Carbon Nanotube Composites. J. Alloys Compd. 2014, 607, 215–222. [Google Scholar] [CrossRef]

- Delhaes, P.; Couzi, M.; Trinquecoste, M.; Dentzer, J.; Hamidou, H.; Vix-Guterl, C. A Comparison between Raman Spectroscopy and Surface Characterizations of Multiwall Carbon Nanotubes. Carbon 2006, 44, 3005–3013. [Google Scholar] [CrossRef]

- Jeyasimman, D.; Sivaprasad, K.; Sivasankaran, S.; Narayanasamy, R. Fabrication and Consolidation Behavior of Al 6061 Nanocomposite Powders Reinforced by Multi-Walled Carbon Nanotubes. Powder Technol. 2014, 258, 189–197. [Google Scholar] [CrossRef]

- Munir, K.S.; Qian, M.; Li, Y.; Oldfield, D.T.; Kingshott, P.; Zhu, D.M.; Wen, C. Quantitative Analyses of MWCNT-Ti Powder Mixtures Using Raman Spectroscopy: The Influence of Milling Parameters on Nanostructural Evolution. Adv. Eng. Mater. 2015, 17, 1660–1669. [Google Scholar] [CrossRef]

- Bi, S.; Xiao, B.L.; Ji, Z.H.; Liu, B.S.; Liu, Z.Y.; Ma, Z.Y. Dispersion and Damage of Carbon Nanotubes in Carbon Nanotube/7055Al Composites During High-Energy Ball Milling Process. Acta Metall. Sin. Engl. Lett. 2021, 34, 196–204. [Google Scholar] [CrossRef]

- Barzegar Vishlaghi, M.; Ataie, A. Investigation on Solid Solubility and Physical Properties of Cu–Fe/CNT Nano-Composite Prepared via Mechanical Alloying Route. Powder Technol. 2014, 268, 102–109. [Google Scholar] [CrossRef]

- Bui, T.T.; Le, X.Q.; To, D.P.; Nguyen, V.T. Investigation of Typical Properties of Nanocrystalline Iron Powders Prepared by Ball Milling Techniques. Adv. Nat. Sci. Nanosci. Nanotechnol. 2013, 4, 045003. [Google Scholar] [CrossRef]

- Shokrollahi, H. The Magnetic and Structural Properties of the Most Important Alloys of Iron Produced by Mechanical Alloying. Mater. Des. 2009, 30, 3374–3387. [Google Scholar] [CrossRef]

- Dillon, F.C.; Bajpai, A.; Koós, A.; Downes, S.; Aslam, Z.; Grobert, N. Tuning the Magnetic Properties of Iron-Filled Carbon Nanotubes. Carbon 2012, 50, 3674–3681. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).