Effect of GGBFS Content and Curing Temperature on Early-Age Strength and Maturity-Based Modeling of Concrete

Abstract

1. Introduction

2. Materials and Methods

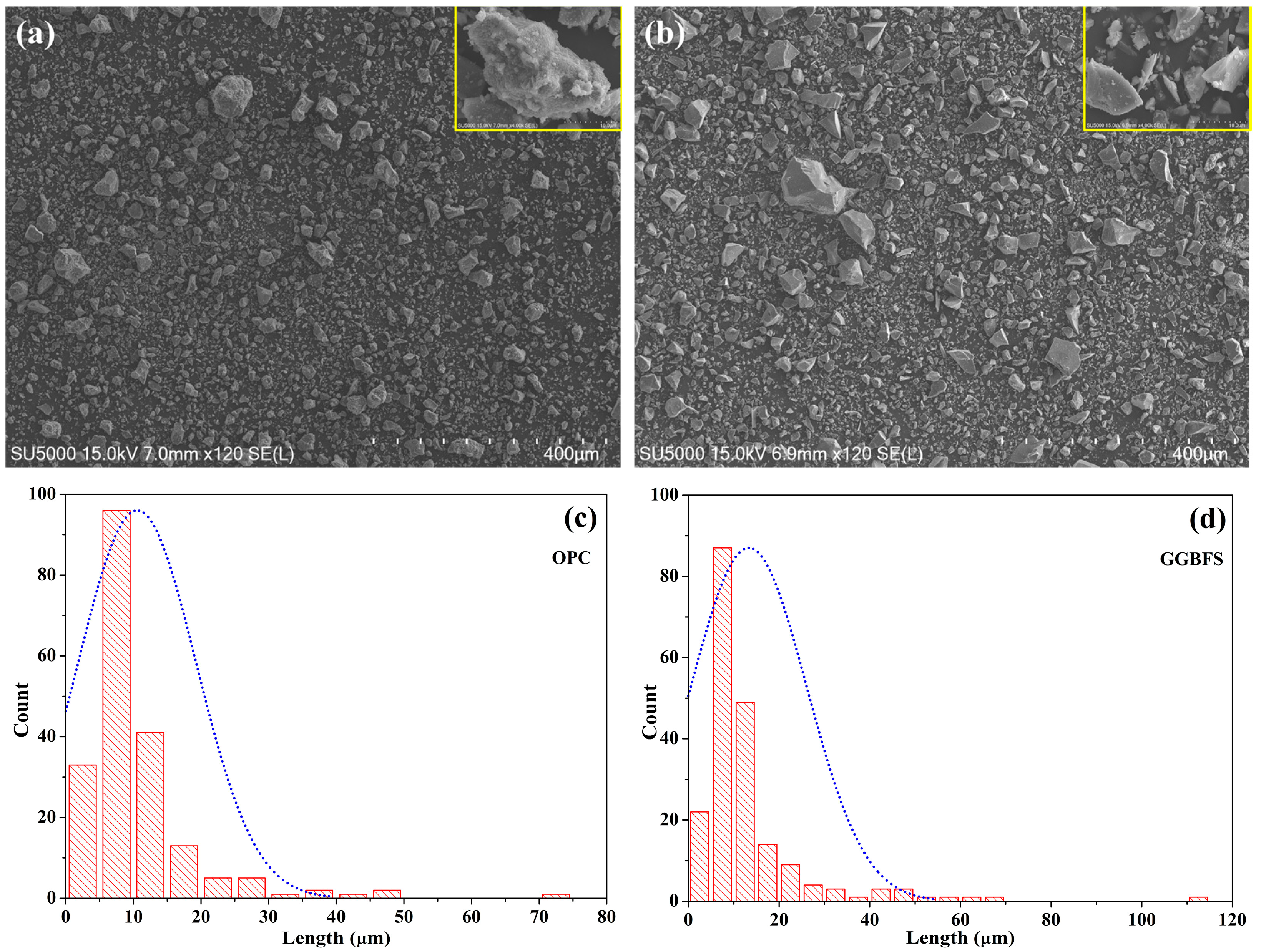

2.1. Materials

2.2. Experimental Variables

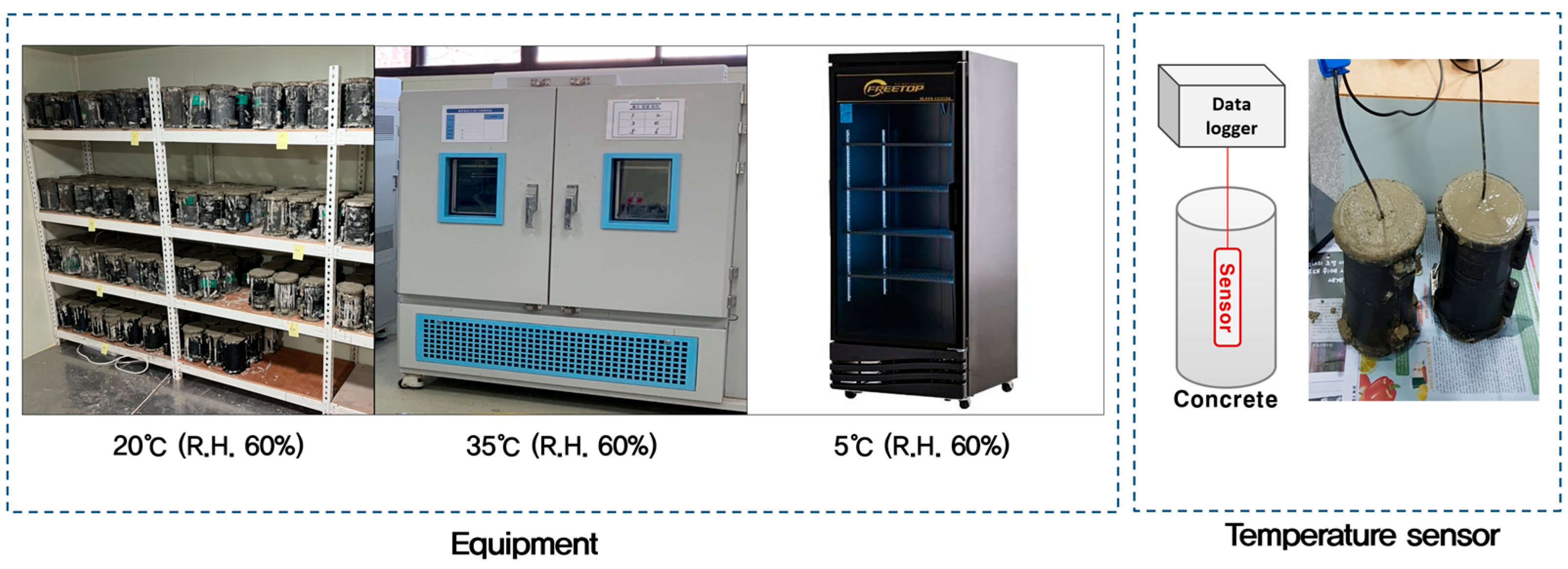

2.3. Experimental Method

2.3.1. Methodology for Datum Temperature (T0) Estimation

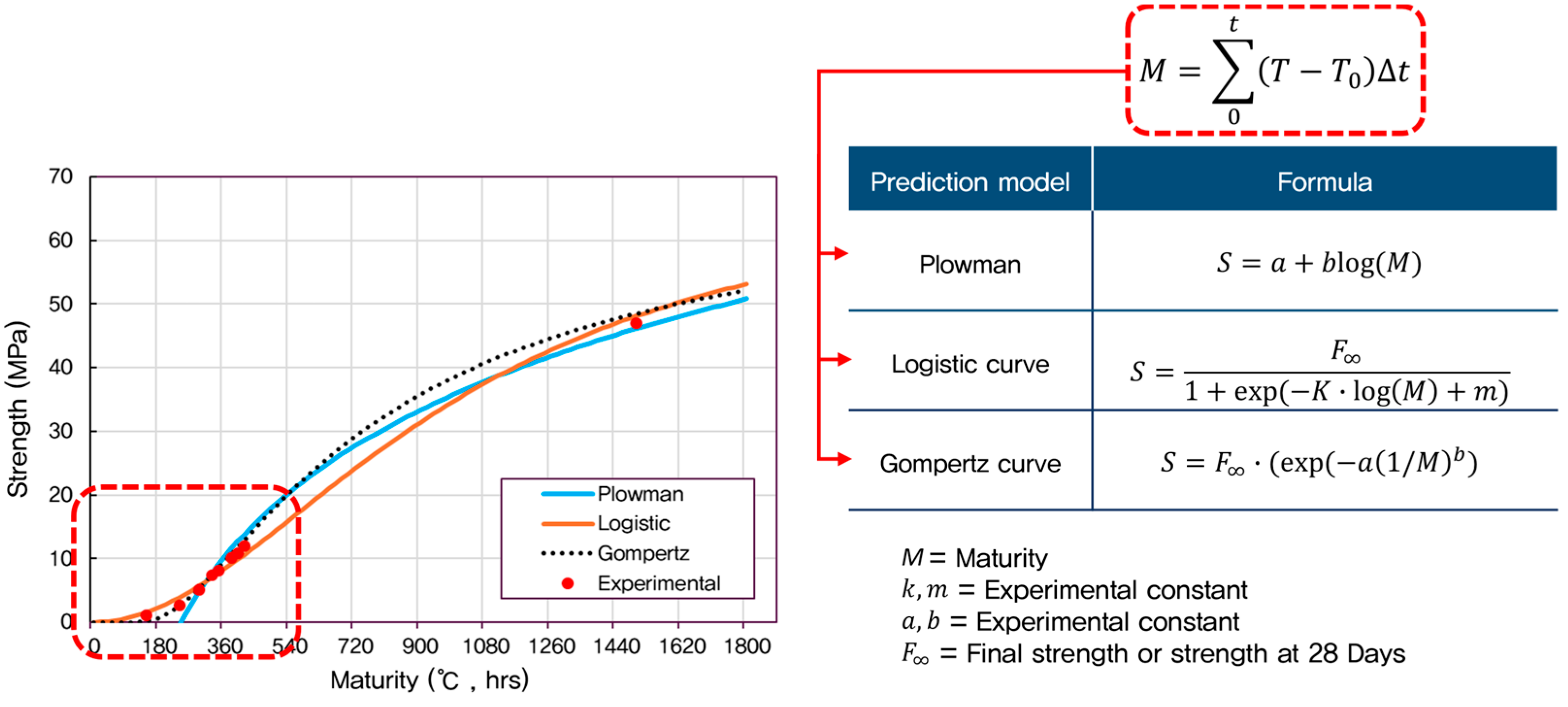

2.3.2. Compressive Strength Prediction Models

3. Results and Discussion

3.1. Fresh Properties of Concrete

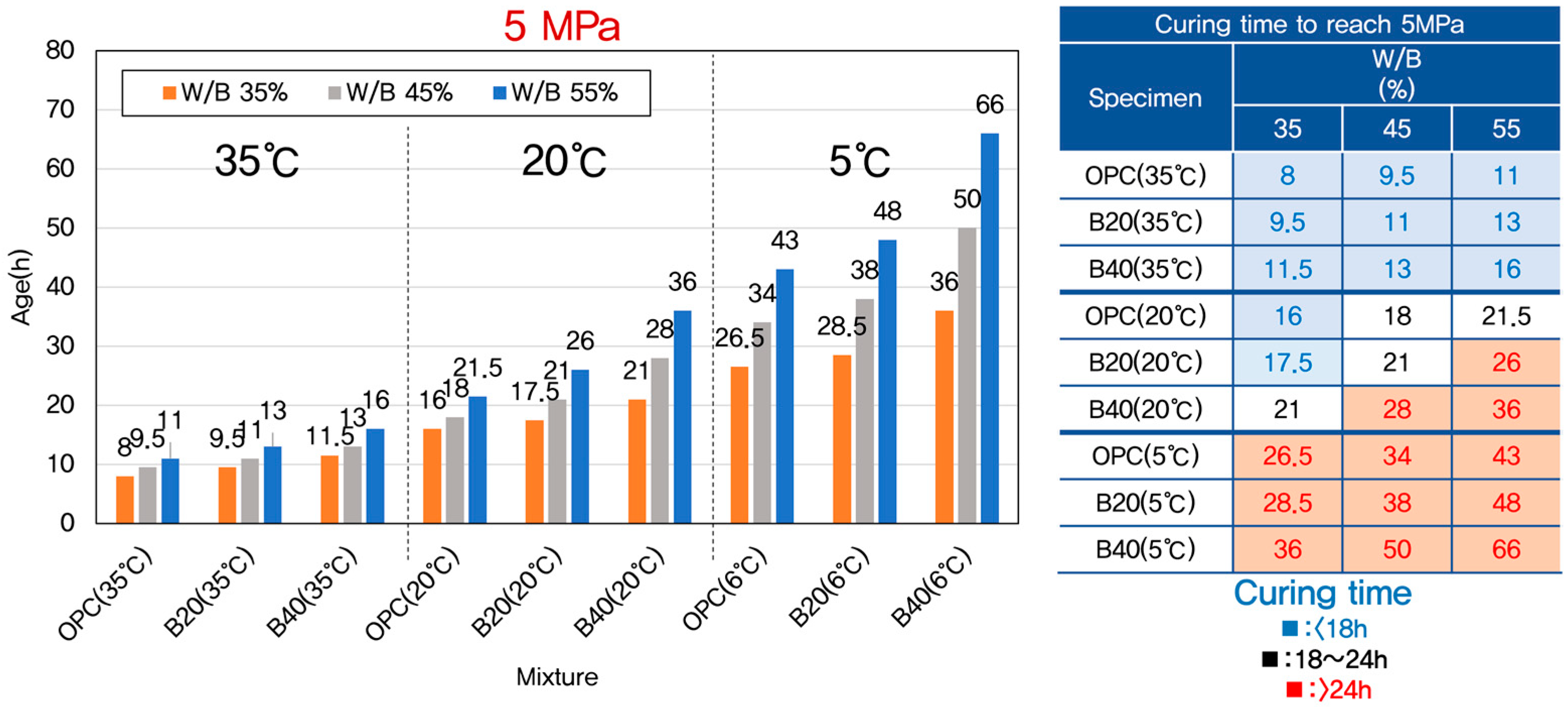

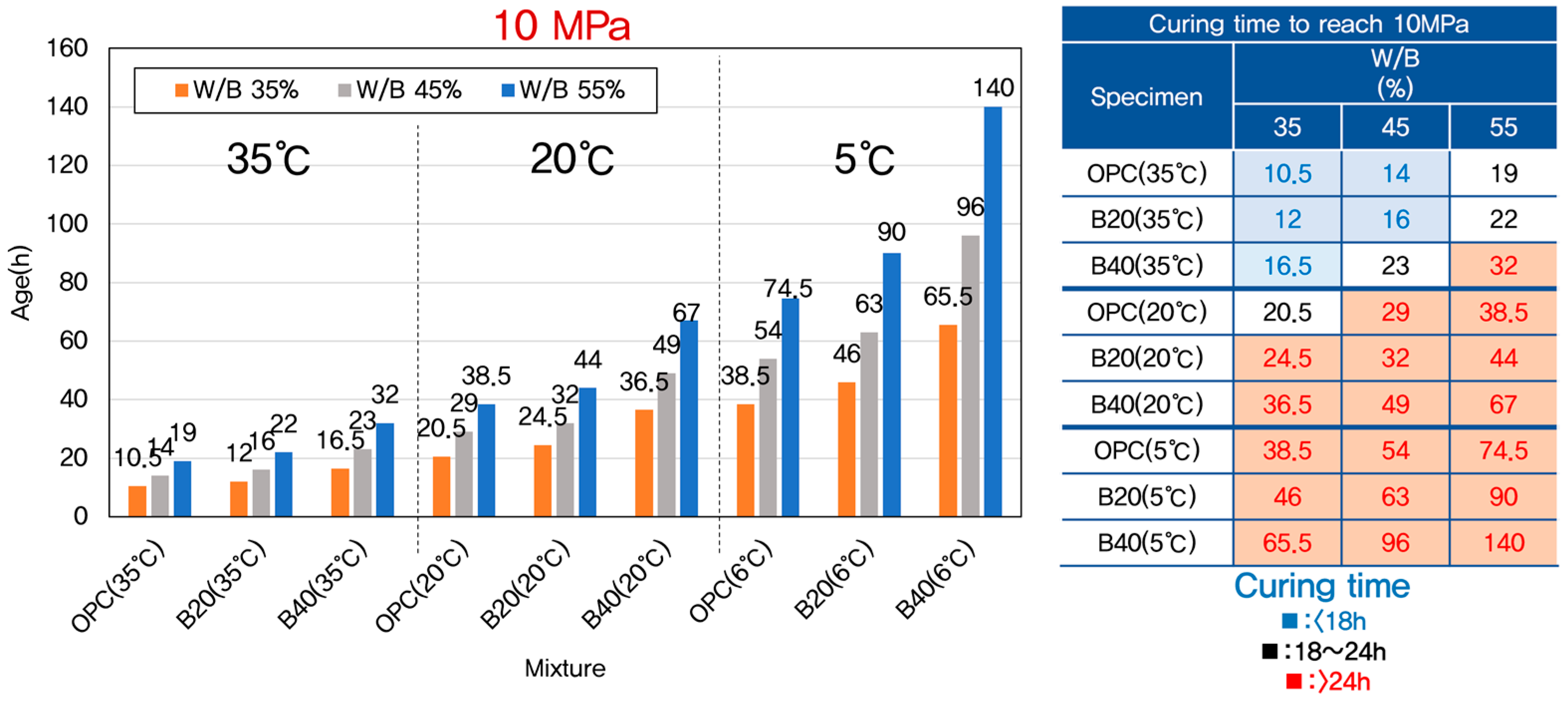

3.2. Early-Age Compressive Strength Development

3.3. Determination of Datum Temperature (T0)

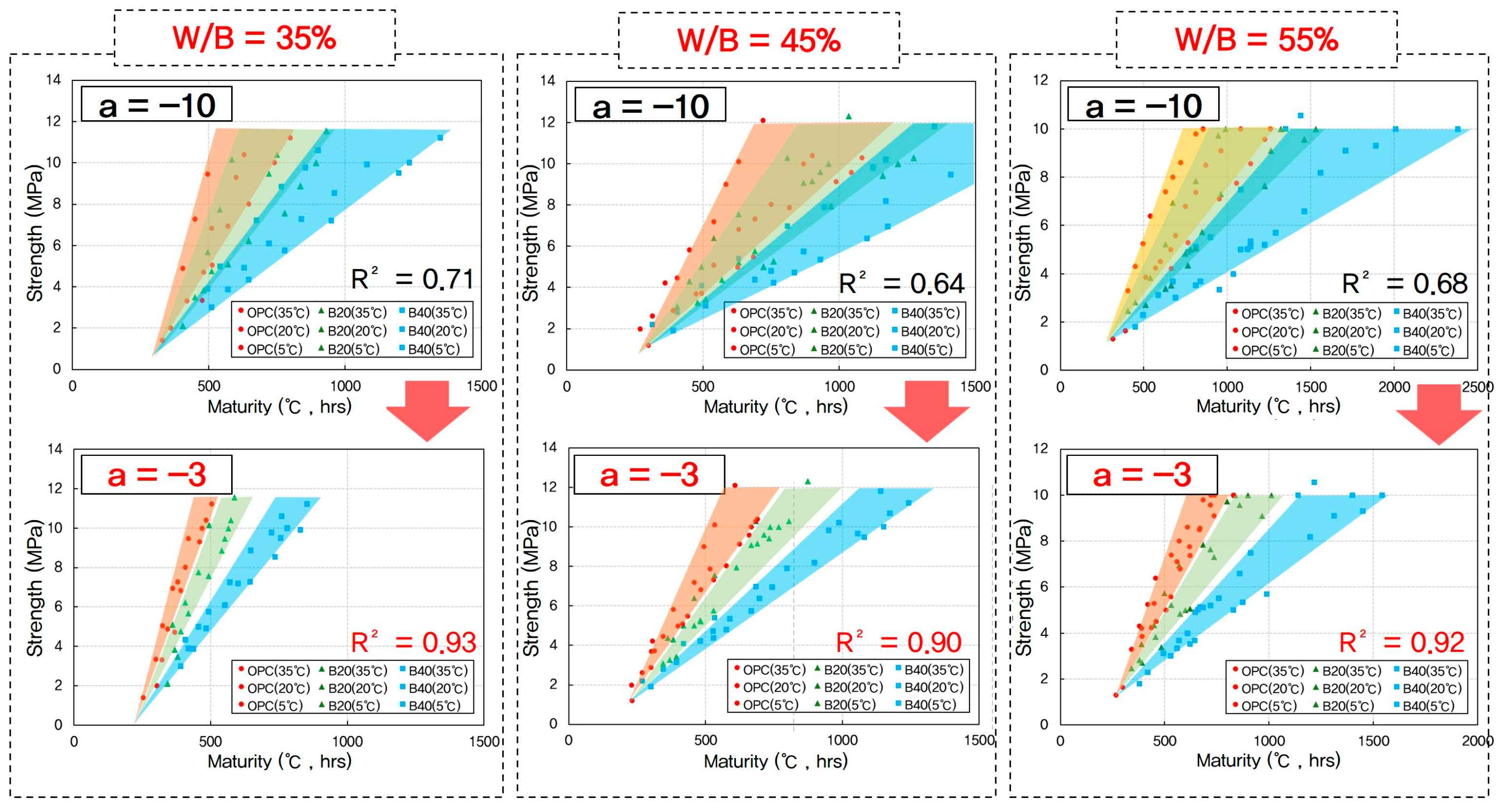

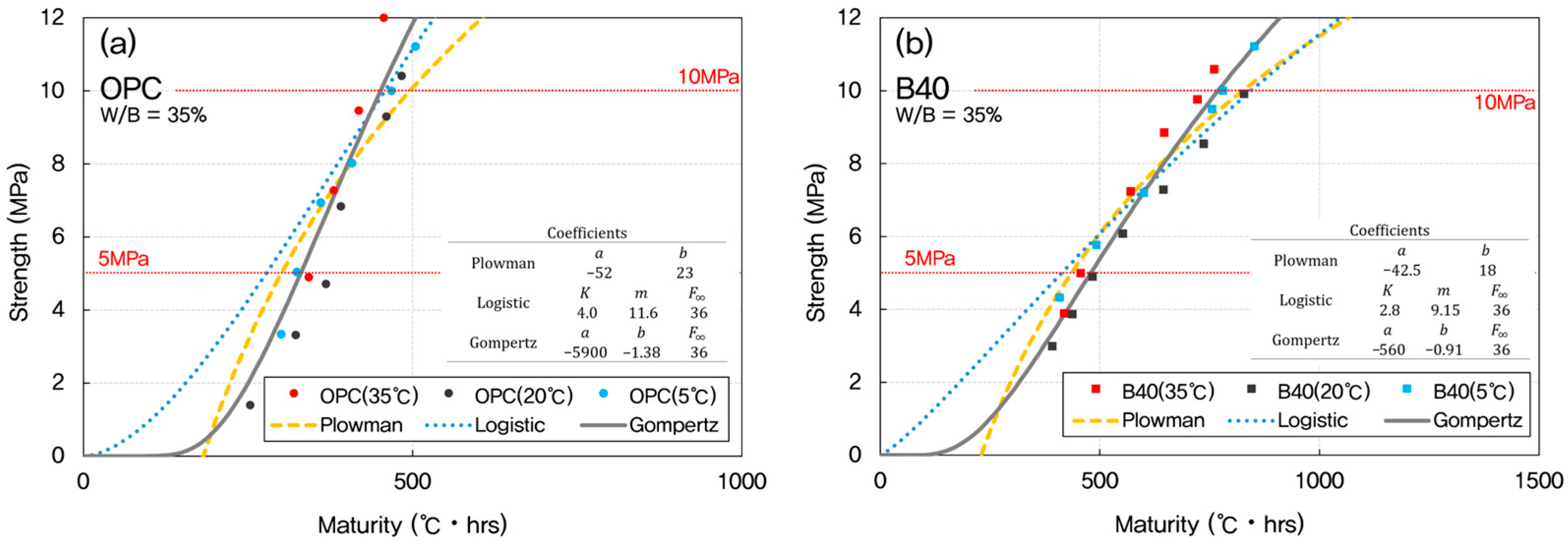

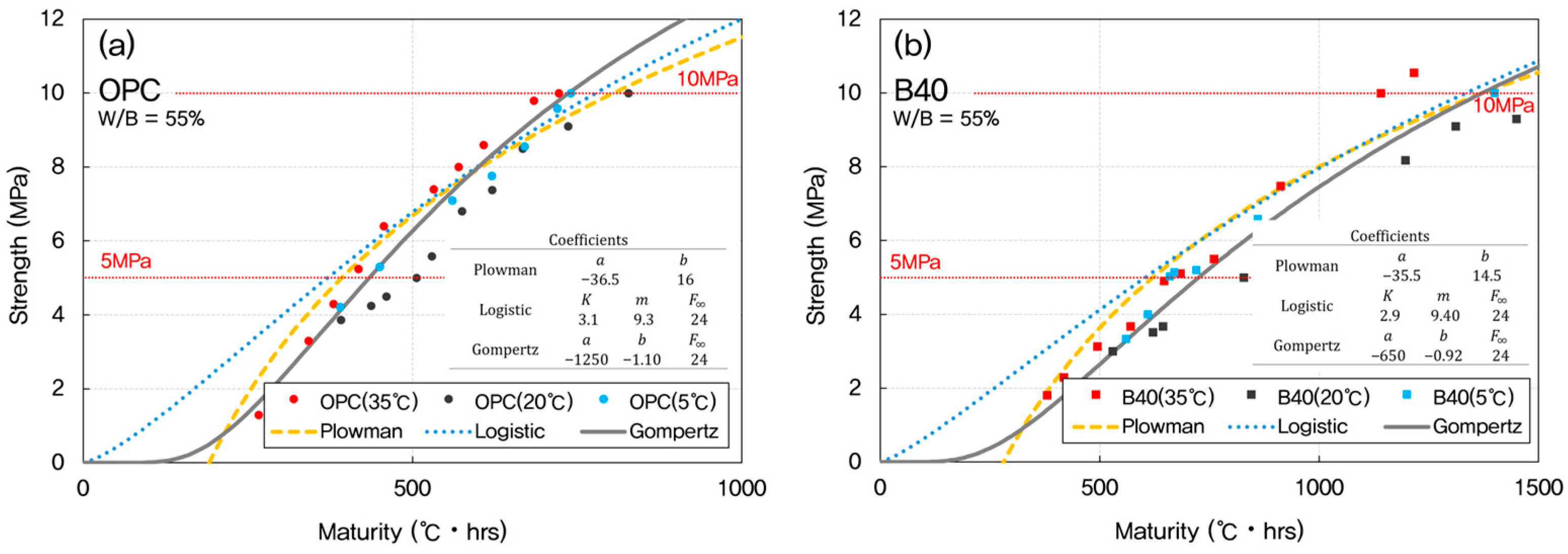

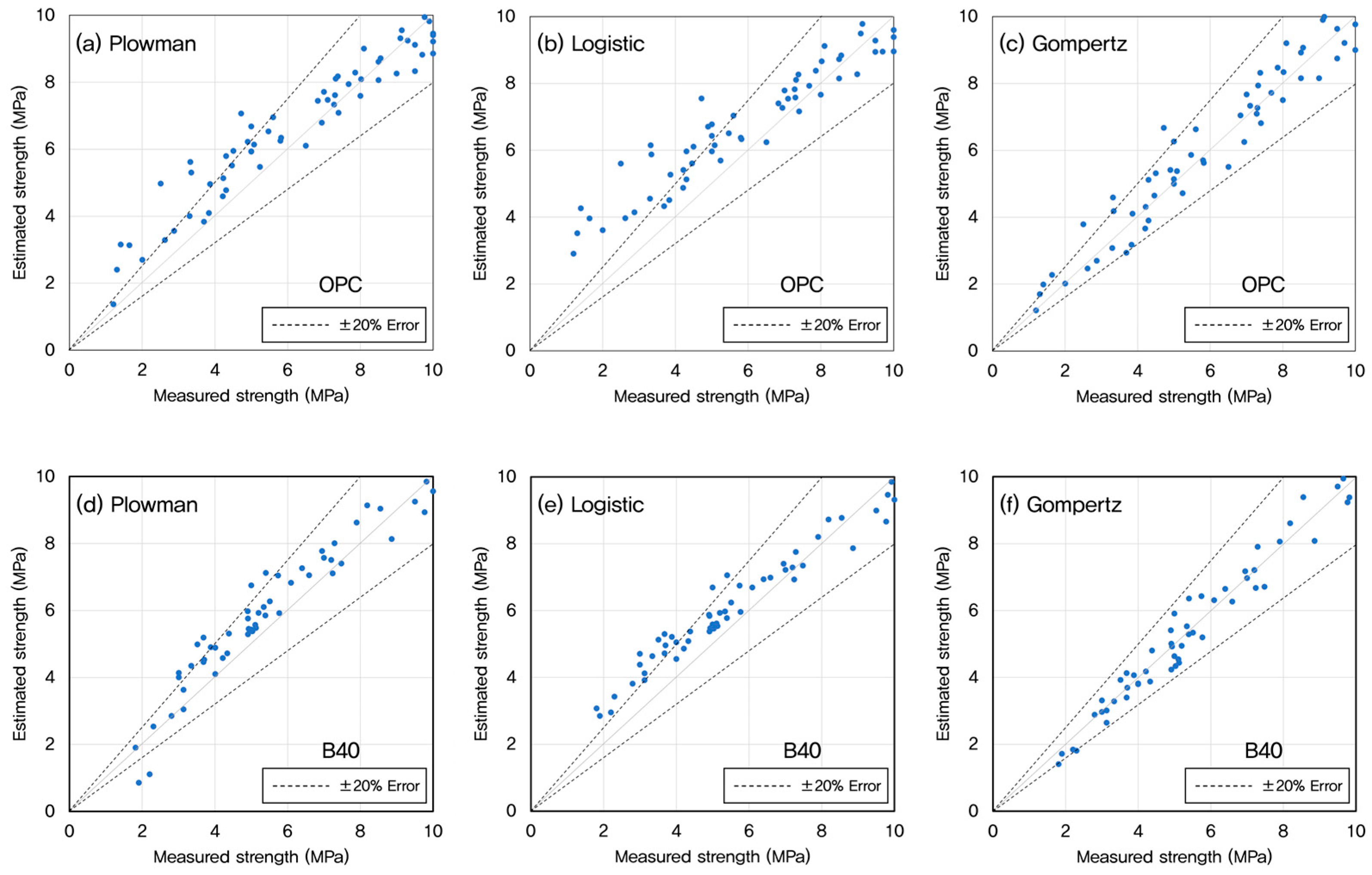

3.4. Prediction of Early-Age Strength Using Maturity Models

4. Conclusions

- (i)

- At a constant target slump of 180 mm, a decrease in W/B ratio resulted in an increased demand for the high-performance air-entraining water-reducing admixture (AEWR). For mixtures with the same W/B ratio, an increase in GGBFS content led to reduced admixture demand due to the smoother texture and lower water demand of GGBFS particles.

- (ii)

- All mixtures satisfied the target air content of 4.5 ± 1.5%, indicating that air entrainment was stable and unaffected by either the W/B ratio or GGBFS replacement level.

- (iii)

- Increasing the GGBFS replacement ratio from 0% to 40% delayed early-age compressive strength development. This delay was more prominent at lower curing temperatures, reflecting the slower pozzolanic reactivity of GGBFS during the initial hydration period.

- (iv)

- Higher curing temperatures accelerated strength development. For example, at 35 °C, both 5 MPa and 10 MPa strength levels were reached significantly faster compared to those at 5 °C, across all mixtures.

- (v)

- The traditionally used datum temperature of −10 °C was found unsuitable for maturity-based strength prediction of GGBFS concretes at early age. A datum temperature of −3 °C produced the highest coefficients of determination across both OPC and GGBFS mixtures.

- (vi)

- Among the models tested, the Gompertz model provided the most accurate prediction of early-age strength. It captured the sigmoidal trend of strength gain more effectively than the Plowman and Logistic models, particularly in low W/B and slag-containing mixtures.

- (vii)

- For GGBFS-blended concrete, both the Plowman and Gompertz models showed reliable predictive performance in the early-age range of 5 to 10 MPa, although the Gompertz model generally offered higher accuracy.

- (viii)

- A single datum temperature of −3 °C is recommended for maturity-based strength prediction of both OPC and GGBFS concretes, making it suitable for practical field applications regardless of binder composition.

- (ix)

- This study supports sustainable concrete practices by enabling reliable early-age strength prediction for GGBFS mixtures and promoting their broader use in structural applications under time or temperature constraints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, D.B. Field Application of High Strength Concrete by Cement Types Using Maturity. J. Soc. Disaster Inf. 2020, 16, 472–478. [Google Scholar]

- Wang, L.; Zhou, H.; Zhang, J.; Wang, Z.; Zhang, L.; Nehdi, M.L. Prediction of concrete strength considering thermal damage using a modified strength-maturity model. Constr. Build. Mater. 2023, 400, 132779. [Google Scholar] [CrossRef]

- Benaicha, M.; Jalbaud, O.; Alaoui, A.H.; Burtschell, Y. Porosity effects on rheological and mechanical behavior of self-compacting concrete. J. Build. Eng. 2022, 48, 103964. [Google Scholar] [CrossRef]

- el Asri, Y.; Benaicha, M.; Zaher, M.; Hafidi Alaoui, A. Prediction of the compressive strength of self-compacting concrete using artificial neural networks based on rheological parameters. Struct. Concr. 2022, 23, 3864–3876. [Google Scholar] [CrossRef]

- Moohan, K. An Experimental Study on Strength Control of High Fluidity Concrete by Maturity Method; KCI: Seoul, Republic of Korea, 2000. [Google Scholar]

- Soutsos, M.; Hatzitheodorou, A.; Kanavaris, F.; Kwasny, J. Compressive strength estimates of adiabatically cured concretes using maturity methods. J. Mater. Civ. Eng. 2019, 31, 04019122. [Google Scholar] [CrossRef]

- Shin, S.; Goh, G.; Lee, C. Predictions of compressive strength of GPC blended with GGBFS developed at varying temperatures. Constr. Build. Mater. 2019, 206, 1–9. [Google Scholar] [CrossRef]

- Varghese, L.; Rao, V.V.L.K.; Parameswaran, L. Nanosilica-added concrete: Strength and its correlation with time-dependent properties. Proc. Inst. Civ. Eng. Constr. Mater. 2019, 172, 85–94. [Google Scholar] [CrossRef]

- Choi, H.; Hama, Y.; Taniguchi, M. Maturity and Strength Development of Mortar with Antifreezing Admixture at Temperatures Lower than 0 °C. Materials 2019, 12, 3172. [Google Scholar] [CrossRef]

- Nielsen, C.V.; Kaasgaard, M. Activation energy for the concrete maturity model—Part 1: Compressive strength tests at different curing temperatures. Nord. Concr. Res. 2020, 62, 87–106. [Google Scholar] [CrossRef]

- Benaicha, M.; Burtschell, Y.; Alaoui, A.H. Prediction of compressive strength at early age of concrete—Application of maturity. J. Build. Eng. 2016, 6, 119–125. [Google Scholar] [CrossRef]

- ASTM C1074; Standard Practice for Estimating Concrete Strength by the Maturity Method. ASTM International: West Conshohocken, PA, USA, 1998.

- Soutsos, M.; Hatzitheodorou, A.; Kanavaris, F.; Kwasny, J. Effect of temperature on the strength development of mortar mixes with GGBS and fly ash. Mag. Concr. Res. 2017, 69, 787–801. [Google Scholar] [CrossRef]

- Viviani, M.; Glisic, B.; Smith, I.F. Three-day prediction of concrete compressive strength evolution. ACI Mater. J. 2005, 102, 231. [Google Scholar] [CrossRef]

- Han, S.-H.; Kim, J.-K.; Park, Y.-D. Prediction of compressive strength of fly ash concrete by new apparent activation energy function. Cem. Concr. Res. 2003, 33, 965–971. [Google Scholar] [CrossRef]

- Van, V.T.A.; Rössler, C.; Bui, D.D.; Ludwig, H.M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Comp. 2014, 53, 270–278. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder—Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Sim, S.; Rhee, J.H.; Oh, J.-E.; Kim, G. Enhancing the durability performance of thermally damaged concrete with ground-granulated blast furnace slag and fly ash. Constr. Build. Mater. 2023, 407, 133538. [Google Scholar] [CrossRef]

- Siddique, R.; Kaur, D. Properties of concrete containing ground granulated blast furnace slag (GGBFS) at elevated temperatures. J. Adv. Res. 2012, 3, 45–51. [Google Scholar] [CrossRef]

- Vessalas, K.; Thomas, P.S.; Ray, A.S.; Guerbois, J.P.; Joyce, P.; Haggman, J. Pozzolanic reactivity of the supplementary cementitious material pitchstone fines by thermogravimetric analysis. J. Therm. Anal. Calorim. 2009, 97, 71–76. [Google Scholar] [CrossRef]

- Zhang, T.S.; Yu, Q.J.; Wei, J.X.; Zhang, P.P. Efficient utilization of cementitious materials to produce sustainable blended cement. Cem. Concr. Comp. 2012, 34, 692–699. [Google Scholar] [CrossRef]

- Xu, G.; Tian, Q.; Miao, J.; Liu, J. Early-age hydration and mechanical properties of high volume slag and fly ash concrete at different curing temperatures. Constr. Build. Mater. 2017, 149, 367–377. [Google Scholar] [CrossRef]

- Langan, B.; Weng, K.; Ward, M. Effect of silica fume and fly ash on heat of hydration of Portland cement. Cem. Concr. Res. 2002, 32, 1045–1051. [Google Scholar] [CrossRef]

- De Schutter, G. Hydration and temperature development of concrete made with blast-furnace slag cement. Cem. Concr. Res. 1999, 29, 143–149. [Google Scholar] [CrossRef]

- Chen, W.; Brouwers, H. The hydration of slag, part 1: Reaction models for alkali-activated slag. J. Mater. Sci. 2007, 42, 428–443. [Google Scholar] [CrossRef]

- Juenger, M.C.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Suraneni, P.; Weiss, J. Examining the pozzolanicity of supplementary cementitious materials using isothermal calorimetry and thermogravimetric analysis. Cem. Concr. Compos. 2017, 83, 273–278. [Google Scholar] [CrossRef]

- Pittrich, T.; Weise, F.; Stelzner, L. The impact of blended cements on the spalling behavior of concrete at elevated temperatures: A review. Mater. Struct. 2025, 58, 186. [Google Scholar] [CrossRef]

- Escalante-Garcıa, J.; Sharp, J. The microstructure and mechanical properties of blended cements hydrated at various temperatures. Cem. Concr. Res. 2001, 31, 695–702. [Google Scholar] [CrossRef]

- Escalante, J.; Gomez, L.; Johal, K.; Mendoza, G.; Mancha, H.; Mendez, J. Reactivity of blast-furnace slag in Portland cement blends hydrated under different conditions. Cem. Concr. Res. 2001, 31, 1403–1409. [Google Scholar] [CrossRef]

- Roy, D. Hydration, Structure, and properties of blast furnace slag cements, mortars, and concrete. J. Proc. 1982, 79, 444–457. [Google Scholar]

- Zhang, J.; Huang, Y.; Wang, Y.; Ma, G. Multi-objective optimization of concrete mixture proportions using machine learning and metaheuristic algorithms. Constr. Build. Mater. 2020, 253, 119208. [Google Scholar] [CrossRef]

- Boháč, M.; Palou, M.; Novotný, R.; Másilko, J.; Všianský, D.; Staněk, T. Investigation on early hydration of ternary Portland cement-blast-furnace slag–metakaolin blends. Constr. Build. Mater. 2014, 64, 333–341. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM C989; Standard Specification for Slag Cement for Use in Concrete and Mortars. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM C617; Standard Practice for Capping Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- Saul, A. Principles underlying the steam curing of concrete at atmospheric pressure. Mag. Concr. Res. 1951, 2, 127–140. [Google Scholar] [CrossRef]

- ACI 306R-16; Guide to Cold Weather Concreting. Korea Concrete Institute: Seoul, Republic of Korea, 2017.

- Al-Naghi, A.A.A.; Ahmad, A.; Amin, M.N.; Algassem, O.; Alnawmasi, N. Sustainable Optimisation of GGBS-Based Concrete: De-Risking Mix Design through Predictive Machine Learning Models. Case Stud. Constr. Mater. 2025, 23, e04900. [Google Scholar] [CrossRef]

- Omer, B.; Saeed, N.M.; Dheyaaldin, M.H.; Jamal, A.S.; Kurda, R. Evaluating the long-term strength of GGBFS-blended cement across various water-to-binder and superplasticizer ratios under heating/cooling cycles. PLoS ONE 2025, 20, e0319923. [Google Scholar] [CrossRef] [PubMed]

- Pantiru, A.; Luca, B.I.; Barbuta, M. Experimental study of mixture proportions and fresh properties of concrete with fly ash and silica fume as a replacement for cement for 3D printing. Environ. Eng. Manag. J. 2023, 22, 1647–1653. [Google Scholar] [CrossRef]

- Bedada, K.; Nyabuto, A.; Kınotı, I.; Marangu, J. Review on advances in bio-based admixtures for concrete. J. Sustain. Constr. Mater. Technol. 2023, 8, 344–367. [Google Scholar] [CrossRef]

- Altun, M.G.; Özen, S.; Mardani-Aghabaglou, A. Effect of side chain length change of polycarboxylate-ether based high range water reducing admixture on properties of self-compacting concrete. Constr. Build. Mater. 2020, 246, 118427. [Google Scholar] [CrossRef]

- Cavusoglu, I. Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills. Minerals 2024, 14, 1242. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Klemczak, B.; Gołaszewski, J.; Smolana, A.; Gołaszewska, M.; Cygan, G. Shrinkage behaviour of self-compacting concrete with a high volume of fly ash and slag experimental tests and analytical assessment. Constr. Build. Mater. 2023, 400, 132608. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Arulraj, G.P.; Anand, N.; Kanagaraj, B.; Lubloy, E. Eco-friendly alkali-activated nano concrete: Impact of nano-GGBFS on mechanical and microstructural properties. Case Stud. Chem. Environ. Eng. 2025, 11, 101131. [Google Scholar]

- Alsharari, F. Utilization of Industrial, Agricultural, and Construction Waste in Cementitious Composites: A Comprehensive Review of their Impact on Concrete Properties and Sustainable Construction Practices. Mater. Today Sustain. 2025, 29, 101080. [Google Scholar] [CrossRef]

- ASTM C231/C231M; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. ASTM International: West Conshohocken, PA, USA, 2010.

- Plank, J.; Sakai, E.; Miao, C.; Yu, C.; Hong, J. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Saedi, A.; Jamshidi-Zanjani, A.; Darban, A.K. A review of additives used in the cemented paste tailings: Environmental aspects and application. J. Environ. Manag. 2021, 289, 112501. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A.; Majeed, S.S.; Aisheh, Y.I.A.; Salih, M.N.A. Fresh, hardened, durability and microstructure properties of seawater concrete: A systematic review. J. CO2 Util. 2024, 83, 102815. [Google Scholar] [CrossRef]

- Yang, H.-M.; Kwon, S.-J.; Myung, N.V.; Singh, J.K.; Lee, H.-S.; Mandal, S. Evaluation of strength development in concrete with ground granulated blast furnace slag using apparent activation energy. Materials 2020, 13, 442. [Google Scholar] [CrossRef]

- Wang, K.; Moon, J.; Du, H.; Xia, X.; Zhu, D.; Zhang, P.; Guo, J. Early-age shrinkage and hydration of concrete incorporating a mutually reinforcing systems of super absorbent polymers and MgO expansive agent under low humidity conditions. Constr. Build. Mater. 2024, 417, 135350. [Google Scholar] [CrossRef]

- Soutsos, M.; Kanavaris, F.; Hatzitheodorou, A. Critical analysis of strength estimates from maturity functions. Case Stud. Constr. Mater. 2018, 9, e00183. [Google Scholar] [CrossRef]

- Kim, W.; Kim, J.; Kim, Y.; Lee, T.; Park, S. Experimental studies for evaluation of the removal time of form on concrete using ultrasonic pulse velocity methods. Case Stud. Constr. Mater. 2024, 21, e03837. [Google Scholar] [CrossRef]

- Jackson, P.J. Portland cement: Classification and manufacture. In Lea’s Chemistry of Cement and Concrete; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Alzaza, A.; Ohenoja, K.; Illikainen, M. Improved strength development and frost resistance of Portland cement ground-granulated blast furnace slag binary binder cured at 0 C with the addition of calcium silicate hydrate seeds. J. Build. Eng. 2022, 48, 103904. [Google Scholar] [CrossRef]

- Abdel-Jawad, Y.A. The maturity method: Modifications to improve estimation of concrete strength at later ages. Constr. Build. Mater. 2006, 20, 893–900. [Google Scholar] [CrossRef]

- Han, M.-C.; Han, C.-G. Use of maturity methods to estimate the setting time of concrete containing super retarding agents. Cem. Concr. Compos. 2010, 32, 164–172. [Google Scholar] [CrossRef]

- Lee, C.H.; Hover, K.C. Influence of datum temperature and activation energy on maturity strength predictions. ACI Mater. J. 2015, 112, 781. [Google Scholar] [CrossRef]

- Ogirigbo, O.R.; Black, L. Influence of slag composition and temperature on the hydration and microstructure of slag blended cements. Constr. Build. Mater. 2016, 126, 496–507. [Google Scholar] [CrossRef]

- Chi, M.C.; Chi, J.H.; Wu, C.H. Effect of GGBFS on compressive strength and durability of concrete. Adv. Mater. Res. 2018, 1145, 22–26. [Google Scholar] [CrossRef]

- Ryu, G.-S.; An, G.-H.; Yoon, Y.-S.; Kim, J.-Y.; Choi, S. Evaluation of Concrete Compressive Strength Prediction Using the Maturity Method Incorporating Various Curing Temperatures and Binder Compositions. Materials 2024, 17, 5794. [Google Scholar] [CrossRef]

- Nandhini, K.; Karthikeyan, J. The early-age prediction of concrete strength using maturity models: A review. J. Build. Pathol. Rehabil. 2021, 6, 7. [Google Scholar] [CrossRef]

- Taniguchi, M.; Katsura, O.; Sagawa, T.; Hama, Y. Effects of the Mineral Composition of Cement on the Temperature Dependency of Strength Development. J. Adv. Concr. Technol. 2022, 20, 117–126. [Google Scholar] [CrossRef]

| Prediction Model | Formula |

|---|---|

| Plowman curve | |

| Logistic curve | |

| Gompertz curve |

| Parameter | Phases | OPC | GGBFS |

|---|---|---|---|

| Chemical composition (%) | SiO2 | 21.2 | 34.0 |

| Al2O3 | 5.03 | 16.4 | |

| Fe2O3 | 3.31 | 0.50 | |

| CaO | 63.18 | 37.2 | |

| MgO | 2.8 | 6.29 | |

| SO3 | 2.1 | 2.71 | |

| Na2O | 0.1 | 1.33 | |

| K2O | 0.9 | - | |

| Physical properties | Density (g/cm3) | 3.15 | 2.89 |

| Fineness (cm2/g) | 3450 | 4330 |

| Category | Experimental Level | Unit |

|---|---|---|

| W/B | 35, 45, 55 | % |

| Temperature | 5, 20, 35 | °C |

| GGBFS | 0, 20, 40 | replacement ratio (% of B) |

| Measurement period | 28 | days |

| No. | Name | GGBFS (%of B) | W/B (%) | W (kg) | S/a (%) | S (kg) | G (kg) | Binder | Ad (kg) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | GGBFS | |||||||||

| 1 | OPC-35 | 0 | 35 | 133 | 51 | 890 | 870 | 380 | 0 | 4.3 |

| 2 | B20-35 | 20 | 890 | 870 | 304 | 76 | 2.0 | |||

| 3 | B40-35 | 40 | 890 | 870 | 228 | 152 | 1.9 | |||

| 4 | OPC-45 | 0 | 45 | 171 | 51 | 890 | 870 | 380 | 0 | 4.0 |

| 5 | B20-45 | 20 | 890 | 870 | 304 | 76 | 1.7 | |||

| 6 | B40-45 | 40 | 890 | 870 | 228 | 152 | 1.6 | |||

| 7 | OPC-55 | 0 | 55 | 181.5 | 51 | 890 | 870 | 330 | 0 | 3.2 |

| 8 | B20-55 | 20 | 890 | 870 | 264 | 66 | 1.4 | |||

| 9 | B40-55 | 40 | 890 | 870 | 198 | 132 | 1.2 | |||

| No. | Name | GGBFS (% of B) | W/B (%) | Ad (kg/m3) | Slump (mm) | Air Content (%) |

|---|---|---|---|---|---|---|

| 1 | OPC-35 | 0 | 35 | 4.3 | 180 | 4.5 |

| 2 | B20-35 | 20 | 2.0 | 4.0 | ||

| 3 | B40-35 | 40 | 1.9 | 3.8 | ||

| 4 | OPC-45 | 0 | 45 | 4.0 | 180 | 4.4 |

| 5 | B20-45 | 20 | 1.7 | 4.3 | ||

| 6 | B40-45 | 40 | 1.6 | 4.5 | ||

| 7 | OPC-55 | 0 | 55 | 3.2 | 180 | 4.2 |

| 8 | B20-55 | 20 | 1.4 | 4.4 | ||

| 9 | B40-55 | 40 | 1.2 | 4.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-S.; Lee, H.-S. Effect of GGBFS Content and Curing Temperature on Early-Age Strength and Maturity-Based Modeling of Concrete. Materials 2025, 18, 4525. https://doi.org/10.3390/ma18194525

Kim H-S, Lee H-S. Effect of GGBFS Content and Curing Temperature on Early-Age Strength and Maturity-Based Modeling of Concrete. Materials. 2025; 18(19):4525. https://doi.org/10.3390/ma18194525

Chicago/Turabian StyleKim, Han-Sol, and Han-Seung Lee. 2025. "Effect of GGBFS Content and Curing Temperature on Early-Age Strength and Maturity-Based Modeling of Concrete" Materials 18, no. 19: 4525. https://doi.org/10.3390/ma18194525

APA StyleKim, H.-S., & Lee, H.-S. (2025). Effect of GGBFS Content and Curing Temperature on Early-Age Strength and Maturity-Based Modeling of Concrete. Materials, 18(19), 4525. https://doi.org/10.3390/ma18194525