Positron Annihilation Studies of Hydrostatically Extruded AA1050 Aluminum

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. X-Ray Diffraction

3.2. The Positron Annihilation Studies

3.2.1. Extruded Material

3.2.2. Isochronal Annealing of the Extrusion Products

4. Conclusions

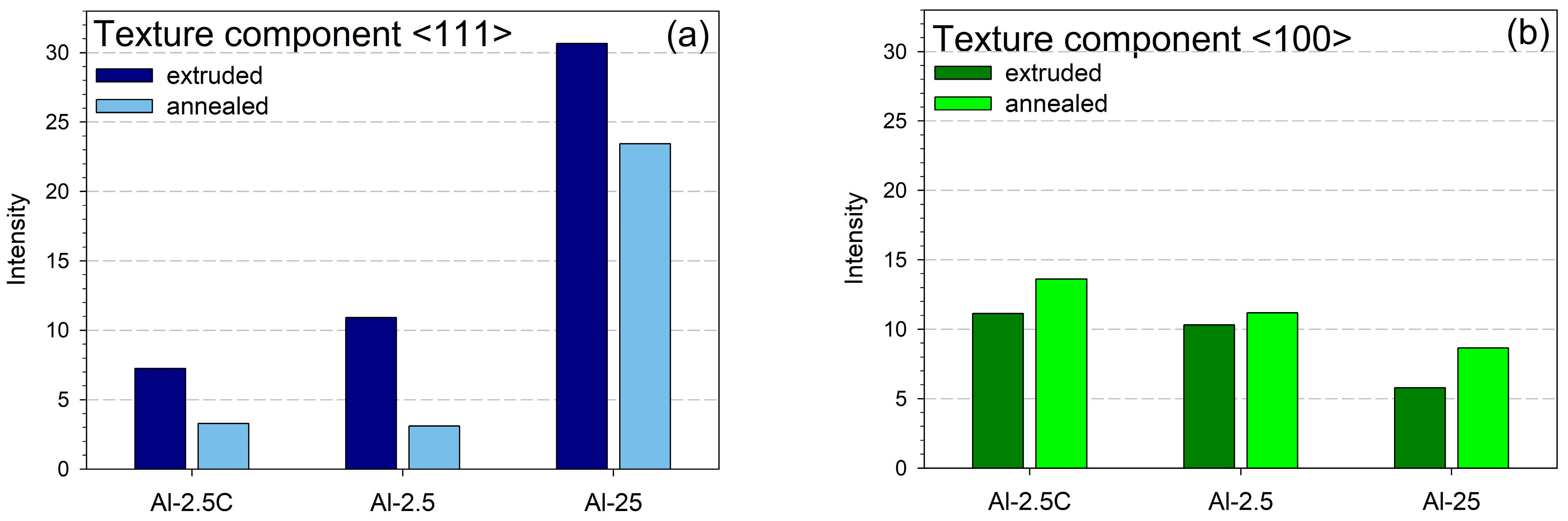

- Distinct axial textures were found both for the hydrostatically extruded and post-deformation annealed samples of aluminum grade AA1050. The relative contributions of the main components of the axial texture, i.e., <111> and <100>, depend on the HE conditions. An increase in the contribution of the <100> texture component for the cryo-cooled material can be related to the effect of the low temperature and high stress rate of deformation. Recrystallization causes an increase in the intensity of the <100> texture component, combined with a decrease in the intensity of the <111> one.

- Shortening in the positron diffusion path, more significant for the cryo-cooled material at the true strain of 0.9 and that extruded at RT at the strain of 3.2, resulted from increased density of the lattice defects. This was also reflected in the bulk values of the S parameter and the mean positron lifetime.

- Vacancies associated with dislocations are the main positron-trapping defects revealed by PALS. However, the contribution of monovacancies or even divacancies cannot be excluded.

- The cryo-cooled material extruded at a true strain of 0.9, as well as the one extruded at RT at a true strain of 3.2, exhibited significantly higher mean lattice defect concentrations and considerably lower recrystallization temperatures compared to the sample extruded at RT at a true strain of 0.9, which had a less defective crystal structure.

- The activation energy for grain boundary migration during the recrystallization of hydrostatically extruded AA1050 aluminum, as determined from the positron diffusion trapping model, is approximately 1.5 eV and showed only a slight dependence on the extrusion temperature and true strain.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PALS | Positron Annihilation Lifetime Spectroscopy |

| DB | Doppler Broadening |

| CAGR | Compound Annual Growth Rate |

| HE | Hydrostatic Extrusion |

| TEM | Transmission Electron Microscopy |

| RT | Room Temperature |

| XRD | X-ray Diffraction |

| TREOR | Trial and Error |

| ODF | Orientation Distribution Function |

| ADC | Arbitrarily Defined Cell |

| VEP | Variable Energy Positron |

| YS | Yield Strength |

| UTS | Ultimate Tensile Strength |

| ET | Extrusion Temperature |

| EP | Extrusion Pressure |

| R | Cross-Section Area Reduction Ratio |

| TS | True Strain |

| MES | Mean Extrusion Speed |

| fcc | Face Centered Cubic |

| SFE | Stacking Fault Energy |

| ECAP | Equal-Channel Angular Pressing |

References

- Aluminum Extrusion Market (2025–2030). Grant View Research Report ID: GVR-3-68038-700-1. Available online: https://www.grandviewresearch.com/industry-analysis/aluminum-extrusion-market (accessed on 15 September 2025).

- Sheppard, T. Extrusion of Aluminium Alloys, 1st ed.; Springer: New York, NY, USA, 1999. [Google Scholar]

- Dančenko, V.N.; Milenin, A.A.; Golovko, A.N. Proizvodstvo Profilej iz Aljuminievyh Splavov, 1st ed.; Sistemnye Tehnologii: Dnepropetrovsk, Ukraine, 2002. [Google Scholar]

- Meyer, G.E.; Simonen, F.A.; Gerdeen, J.C.; Fiorentino, R.J.; Sabroff, A.M. Design of a Production hydrostatic Extrusion Press; Technical Report AFML-TR-68-52; Battelle Columbus Memorial Institute Laboratories: Columbus, OH, USA, 1968; Available online: https://apps.dtic.mil/sti/tr/pdf/AD0855302.pdf (accessed on 1 July 2024).

- Pugh, H.L.; Ashcroft, K. The Hydrostatic or Ramless Extrusion of Metals by Fluid Pressure; NEL Report No. 32; National Engineering Laboratory: Glasgow, Scotland, 1962. [Google Scholar]

- Sachs, G.; Eisbein, W.; Kuntze, W.; Linicus, W. Kraftbedarf und Fließvorgänge beim Stangenpressen. In Spanlose Formung der Metalle. Mitteilungen der Deutschen Materialprüfugsanstalten; Springer: Berlin/Heidelberg, Germany, 1931; Volume 16, pp. 67–96. [Google Scholar] [CrossRef]

- Robertson, J. Improvements in or Appertaining to the Manufacture of Compressing, Shaping, and Drawing of Metal Tubes, Tubular, Hollow, and Solid Articles, and in Means and Apparatus Therefor. British Patent No. 11436, 6 July 1891. [Google Scholar]

- Robertson, J. Method of an Apparatus for Forming Metal Articles. British Patent No. 19356, 14 October 1893. [Google Scholar]

- Robertson, J. Shaping Metal Tubes. US481060, 16 August 1892. [Google Scholar]

- Robertson, J. Method of and Apparatus for Shaping and Drawing Metal Tubes. US493946, 21 March 1893. [Google Scholar]

- Robertson, J. Method of and Apparatus for Forming Metal Articles. US524504, 14 August 1894. [Google Scholar]

- Robertson, J. Apparatus for Forming Metal Articles. US524505, 14 August 1894. [Google Scholar]

- Robertson, J. Apparatus for the Manufacture of Metal Tubes, Rods &c. US524506, 14 August 1894. [Google Scholar]

- Robertson, J. Method of Forming Metal Articles. US524508, 14 August 1894. [Google Scholar]

- Robertson, J. Apparatus for Shaping, Drawing, Solidifying and Squirting Metals. US629610, 25 July 1899. [Google Scholar]

- Kronberger, H. Review Lecture. Hydrostatic Extrusion. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1969, 311, 331–347. Available online: http://www.jstor.org/stable/2416236 (accessed on 1 July 2024).

- Bridgman, P.J. Method and Apparatus for Cold Drawing. US2558035, 26 June 1951. [Google Scholar]

- Inoue, N. Introduction. In Hydrostatic Extrusion, Theory and Application; Inoue, N., Nishihara, M., Eds.; Springer: Dordrecht, The Netherlands, 1985. [Google Scholar] [CrossRef]

- Vladislav, I.E.; Livenko, N.D. Method and Means for Shaping Parts by Hydraulic Extrusion. US4011744A, 15 March 1977. [Google Scholar]

- Cerovsky, F. Hydraulic Extrusion Tool with Integrated Induction Device. US11141766B2, 12 October 2021. [Google Scholar]

- Poggenpohl, K. Hydraulic Extrusion Press and Method for Operating a Hydraulic Extrusion Press. WO 2013/167111A1, 2 April 2015. [Google Scholar]

- Poggenpohl, K. Presse à Filer Hydraulique et Procédé de Fonctionnement d’Une Presse à Filer Hydraulique. US11407192B2, 9 August 2022. [Google Scholar]

- Alexander, J.M. Hydrostatic extrusion, the state of the art. In Proceedings of the Fourteenth International Machine Tool Design and Research Conference, Manchester, UK, 12–14 September 1973; Koenigsberger, F., Tobias, S.A., Eds.; Palgrave: London, UK, 1974. [Google Scholar] [CrossRef]

- Moodij, E. Friction Phenomena in Hydrostatic Extrusion of Magnesium. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2014. [Google Scholar][Green Version]

- Hettwer, P.F.; Uy, J.C.; McCann, D.R. Aluminum wire by cold hydrostatic extrusion. J. Basic Eng. 1969, 91, 822–829. [Google Scholar] [CrossRef]

- Herø, H.; Mikkelsen, J.A. Some mechanical and structural properties of hydrostatically extruded aluminum and aluminum alloys. J. Inst. Metals 1969, 97, 18–22. [Google Scholar]

- Lee, E.H.; Mallett, R.L.; McMeeking, R.M.; Sherby, O.J.; Shyne, J.C.; Whalen, R.T. Hydrostatic Extrusion; Final Rep.; Department of Materials Science and Engineering of Stanford University: Stanford, CA, USA, 1978; Available online: https://apps.dtic.mil/sti/tr/pdf/ADA052056.pdf (accessed on 1 July 2024).

- Kalish, D.; LeFevre, B.G. Subgrain strengthening of aluminum conductor wires. Metall. Trans. A 1975, 6, 1319–1324. [Google Scholar] [CrossRef]

- Pachla, W.; Kulczyk, M.; Smalc-Koziorowska, J.; Wróblewska, M.; Skiba, J.; Przybysz, S.; Przybysz, M. Mechanical properties and microstructure of ultrafine grained commercial purity aluminium prepared by cryo-hydrostatic extrusion. Mater. Sci. Eng. A 2017, 695, 178–192. [Google Scholar] [CrossRef]

- Richert, M.W.; Leszczyńska-Madej, B.; Pachla, W.; Skiba, J. The microstructure and properties of hydrostatically extruded polycrystalline aluminium Al99.5. Arch. Metal. Mater. 2012, 57, 911–917. [Google Scholar] [CrossRef]

- Pachla, W.; Kulczyk, M.; Świderska-Środa, A.; Lewandowska, M.; Garbacz, H.; Mazur, A.; Kurzydłowski, K.J. Nanostructuring of metals by hydrostatic extrusion. In Proceedings of 9th International Conference on Metal Forming ESAFORM 2006, Glasgow, UK, 26–28 April 2006; Juster, N., Rosochowski, A., Eds.; Publ. House Akapi: Kraków, Poland, 2006; pp. 535–538. [Google Scholar]

- Kulczyk, M.; Skiba, J.; Pachla, W. Microstructure and mechanical properties of AA5483 treated by a combination of ECAP and hydrostatic extrusion. Arch. Metal. Mater. 2014, 59, 163–166. [Google Scholar] [CrossRef]

- Towarek, A.; Jurczak, W.; Zdunek, J.; Kulczyk, M.; Mizera, J. Influence of Hydrostatic Extrusion on the Mechanical Properties of the Model Al-Mg Alloys. J. Mater. Eng. Perform. 2021, 30, 3502–3509. [Google Scholar] [CrossRef]

- Brynk, T.; Pakieła, Z.; Kulczyk, M.; Kurzydłowski, K.J. Fatigue crack growth rate in ultrafine-grained Al 5483 and 7475 alloys processed by hydro-extrusion. Mech. Mater. 2013, 67, 46–52. [Google Scholar] [CrossRef]

- Orłowska, M.; Ura-Bińczyk, E.; Śnieżek, L.; Skudniewski, P.; Kulczyk, M.; Adamczyk-Cieślak, B.; Mizera, J. Increasing the Mechanical Strength and Corrosion Resistance of Aluminum Alloy 7075 via Hydrostatic Extrusion and Aging. Materials 2022, 15, 4577. [Google Scholar] [CrossRef]

- Skiba, J.; Kossakowska, J.; Kulczyk, M.; Pachla, W.; Przybysz, S.; Smalc-Koziorowska, J.; Przybysz, M. The impact of severe plastic deformations obtained by hydrostatic extrusion on the machinability of ultrafine-grained AA5083 alloy. J. Manuf. Process. 2020, 58, 1232–1240. [Google Scholar] [CrossRef]

- Kulczyk, M.; Skiba, J.; Pachla, W.; Smalc-Koziorowska, J.; Przybysz, S.; Przybysz, M. The effect of high-pressure plastic forming on the structure and strength of AA5083 and AA5754 alloys intended for fasteners. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 903–911. [Google Scholar] [CrossRef]

- Selim, F.A. Positron Annihilation Spectroscopy Applied to Materials Science and Engineering. Solid State Phenom. 2025, 372, 99–114. [Google Scholar] [CrossRef]

- Čížek, J. Characterization of lattice defects in metallic materials by positron annihilation spectroscopy: A review. J. Mater. Sci. Technol. 2018, 34, 577–598. [Google Scholar] [CrossRef]

- ISO-6892-1:2019; Metallic Materials—Tensile Testing. Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- ISO 6507-1:2023; Metallic Materials-Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2023.

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- Werner, P.E.; Eriksson, L.; Westdahl, M. TREOR, a semi-exhaustive trial-and-error powder indexing program for all symmetries. J. Appl. Cryst. 1985, 18, 367–370. [Google Scholar] [CrossRef]

- Boultif, A.; Louër, D. Powder pattern indexing with the dichotomy method. J. Appl. Cryst. 2004, 37, 724–731. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Met. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Dryzek, J.; Wróbel, M.; Dryzek, E. Recrystallization in severely deformed Ag, Au, and Fe studied by positron-annihilation and XRD methods. Phys. Status Solidi B 2016, 253, 2031–2042. [Google Scholar] [CrossRef]

- Dryzek, J.; Wróbel, M. Observation of the recrystallization process in pure Nb and Zr using positron lifetime spectroscopy and XRD techniques. Phys. Status Solidi B 2018, 255, 1800051. [Google Scholar] [CrossRef]

- Dryzek, J.; Wróbel, M. Recovery and recrystallization in molybdenum studied by positron annihilation and X-ray methods. Int. J. Refract. Met. Hard Mater. 2021, 97, 105514. [Google Scholar] [CrossRef]

- Dryzek, J.; Wróbel, M.; Czeppe, T. Recovery and recrystallization in vanadium foil studied by positron annihilation and X-ray methods. Int. J. Refract. Met. Hard Mater. 2022, 103, 105759. [Google Scholar] [CrossRef]

- Schulz, L.G. A direct method of determining preferred orientation of a flat reflection sample using a Geiger counter X-ray spectrometer. J. Appl. Phys. 1949, 20, 1030–1033. [Google Scholar] [CrossRef]

- Pawlik, K. Determination of the orientation distribution function from pole figures in arbitrarily defined cells. Phys. Status Solidi B 1986, 134, 477–483. [Google Scholar] [CrossRef]

- LaboTex, the Texture Analysis Software for Windows. Available online: http://www.labosoft.com.pl/ (accessed on 16 September 2024).

- Caleyo, F.; Baudin, T.; Mathon, M.H.; Penelle, R. Comparison of several methods for the reproduction of the orientation distribution function from pole figures in medium to strong textured materials. Eur. Phys. J. Appl. Phys. 2001, 15, 85–96. [Google Scholar] [CrossRef]

- Horodek, P.; Kobets, A.G.; Meshkov, I.N.; Sidorin, A.A.; Orlov, O.S. Slow positron beam at the JINR, Dubna. Nukleonika 2015, 60, 725–728. [Google Scholar] [CrossRef]

- Kansy, J. Microcomputer program for analysis of positron annihilation lifetime spectra. Nucl. Instrum. Methods Phys. Res. A 1996, 374, 235–244. [Google Scholar] [CrossRef]

- Aluminium: Specifications, Properties, Classifications and Classes. Available online: https://www.azom.com/article.aspx?ArticleID=2863 (accessed on 10 January 2024).

- Sun, P.L.; Cerreta, E.K.; Gray III, G.T.; Bingert, J.F. The effect of grain size, strain rate, and temperature on the mechanical behavior of commercial purity aluminum. Metall. Mater. Trans. A 2006, 37, 2984–2994. [Google Scholar] [CrossRef]

- Takata, N.; Okitsu, Y.; Tsuji, N. Dynamic deformation behavior of ultrafine grained aluminum produced by ARB and subsequent annealing. J. Mater. Sci. 2008, 43, 7385–7390. [Google Scholar] [CrossRef]

- English, A.T.; Chin, G.Y. On the variation of wire texture with stacking fault energy in f.c.c. metals and alloys. Acta Metall. 1965, 13, 1013–1016. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J. Theory of Dislocations; John Wiley & Sons, Inc.: Malabar, FL, USA, 1982. [Google Scholar]

- Curtze, S.; Kuokkala, V.T.; Oikari, A.; Talonen, J.; Hänninen, H. Thermodynamic modeling of the stacking fault energy of austenitic steels. Acta Mater. 2011, 59, 1068–1076. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Kurosu, S.; Matsumoto, H.; Chiba, A. Ultrafine grain refinement of biomedical Co–29Cr–6Mo alloy during conventional hot-compression. Metall. Mater. Trans. A 2009, 40, 1980–1994. [Google Scholar] [CrossRef]

- Lee, B.S.; Koizumi, Y.; Matsumoto, H.; Chiba, A. Collective behavior of strain-induced martensitic transformation (SIMT) in biomedical Co–Cr–Mo–N alloy polycrystal: An ex-situ electron backscattering diffraction study. Mater. Sci. Eng. A 2014, 611, 263–273. [Google Scholar] [CrossRef]

- Rémy, L.; Pineau, A. Temperature dependence of stacking fault energy in close-packed metals and alloys. Mater. Sci. Eng. 1978, 36, 47–63. [Google Scholar] [CrossRef]

- Ericsson, T. The temperature and concentration dependence of the stacking fault energy in the Co-Ni system. Acta Metall. 1966, 14, 853–865. [Google Scholar] [CrossRef]

- Dryzek, E.; Wróbel, M.; Rogal, Ł.; Sarnek, M. Effect of rolling temperature on martensitic transformation and strain hardening of Fe–21.2Mn–0.68C Steel. Metall. Mater. Trans. A 2024, 55, 839–853. [Google Scholar] [CrossRef]

- Bhogra, M.; Ramamurty, U.; Waghmare, U.V. Temperature-dependent stability of stacking faults in Al, Cu, and Ni: First-principles analysis. J. Phys. Condens. Matter 2014, 26, 385402. [Google Scholar] [CrossRef]

- Liu, L.H.; Chen, J.H.; Fan, T.W.; Liu, Z.R.; Zhang, Y.; Yuan, D.W. The possibilities to lower the stacking fault energies of aluminum materials investigated by first-principles energy calculations. Comput. Mater. Sci. 2015, 108, 136–146. [Google Scholar] [CrossRef]

- Zhang, X.; Grabowski, B.; Körmann, F.; Ruban, A.V.; Gong, Y.; Reed, R.C.; Hickel, T.; Neugebauer, J. Temperature dependence of the stacking-fault Gibbs energy for Al, Cu, and Ni. Phys. Rev. B 2018, 98, 224106. [Google Scholar] [CrossRef]

- Liu, L.L.; Wang, R.; Wu, X.Z.; Gan, L.Y.; Wei, Q.Y. Temperature effects on the generalized planar fault energies and twinnabilities of Al, Ni, and Cu: First principles calculations. Comput. Mater. Sci. 2014, 88, 124–130. [Google Scholar] [CrossRef]

- Tisone, T.C. The concentration and temperature dependence of the stacking fault energy in face-centered cubic Co-Fe alloys. Acta Metall. 1973, 21, 229–236. [Google Scholar] [CrossRef]

- Walter, M.; Mujica Roncery, L.; Weber, S.; Leich, L.; Theisen, W. XRD measurement of stacking fault energy of Cr–Ni austenitic steels: Influence of temperature and alloying elements. J. Mater. Sci. 2020, 55, 13424–13437. [Google Scholar] [CrossRef]

- Pontini, A.E.; Hermida, J.D. X-ray diffraction measurement of the stacking fault energy reduction induced by hydrogen in an AISI 304 steel. Scr. Mater. 1997, 37, 1831–1837. [Google Scholar] [CrossRef]

- Fu, W.; Zheng, W.; Huang, Y.; Guo, F.; Jiang, S.; Xue, P.; Ren, Y.; Fan, H.; Ning, Z.; Sun, J. Cryogenic mechanical behaviors of CrMnFeCoNi high-entropy alloy. Mater. Sci. Eng. A 2020, 789, 139579. [Google Scholar] [CrossRef]

- Hu, H. Textures of materials. Texture Stress Microstruct. 1979, 1, 233–258. [Google Scholar] [CrossRef]

- Zhao, F.; Zhu, Y.; Xie, J. Deformation twinning in pure aluminum under ultrahigh strain rate: Dependence of strain rate and crystallographic orientation. Mater. Lett. 2021, 285, 129181. [Google Scholar] [CrossRef]

- Chen, M.; Ma, E.; Hemker, K.J.; Shehg, H.; Wang, Y.; Cheng, X. Deformation Twinning in Nanocrystalline Aluminum. Science 2003, 300, 1275–1277. [Google Scholar] [CrossRef]

- Krause-Rehberg, R.; Bondarenko, V.; Thiele, E.; Klemm, R.; Schell, N. Determination of absolute defect concentrations for saturated positron trapping-deformed polycrystalline Ni as a case study. Nucl. Instr. Meth. Phys. Res. B 2005, 240, 719–725. [Google Scholar] [CrossRef]

- Hansen, H.E.; Ingerslev-Jensen, U. Penetration of fast electrons and positrons. J. Phys. D Appl. Phys. 1983, 16, 1353–1370. [Google Scholar] [CrossRef]

- Valkealahti, S.; Nieminen, R.M. Monte-Carlo calculations of keV electron and positron slowing down in solids. Appl. Phys. A 1983, 32, 95–106. [Google Scholar] [CrossRef]

- Van Veen, A.; Schut, H.; Clement, M.; De Nijs, J.M.M.; Kruseman, A.; Ijpma, M.R. VEPFIT applied to depth profiling problems. Appl. Surf. Sci. 1995, 85, 216–224. [Google Scholar] [CrossRef]

- Hebert, K.R.; Gessmann, T.; Lynn, K.G.; Asoka-Kumar, P. Positron annihilation spectroscopy study of interfacial defects formed by anodic oxidation of aluminum. J. Electrochem. Soc. 2004, 151, B22. [Google Scholar] [CrossRef][Green Version]

- Wu, Y.C.; Zhai, T.; Coleman, P.G. A positron annihilation study of corrosion of aluminum and aluminum alloy by NaOH. Metall. Mater. Trans. A 2012, 43, 2823–2831. [Google Scholar] [CrossRef]

- Dryzek, J.; Horodek, P. GEANT4 simulation of slow positron beam implantation profiles. Nucl. Instr. Methods Phys. Res. B 2008, 266, 4000–4009. [Google Scholar] [CrossRef]

- Bergersen, B.; Stott, M.J. The effect of vacancy formation on the temperature dependence of the positron lifetime. Solid State Commun. 1969, 7, 1203–1205. [Google Scholar] [CrossRef]

- Su, L.H.; Lu, C.; He, L.Z.; Zhang, L.C.; Guagliardo, P.; Tieu, A.K.; Samarin, S.N.; Williams, J.F.; Li, H.J. Study of vacancy-type defects by positron annihilation in ultrafine-grained aluminum severely deformed at room and cryogenic temperatures. Acta Mater. 2012, 60, 4218–4228. [Google Scholar] [CrossRef][Green Version]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2004. [Google Scholar][Green Version]

- Styczyński, L.; Pachla, W.; Wojciechowski, S. Thermal-softening processes in polycrystalline aluminium during hydrostatic extrusion. Met. Sci. 1982, 16, 525–528. [Google Scholar] [CrossRef]

- Fluss, M.J.; Smedskjaer, L.C.; Chason, M.K.; Legnini, D.G.; Siegel, R.W. Measurements of the vacancy formation enthalpy in aluminum using positron annihilation spectroscopy. Phys. Rev. B 1978, 17, 3444. [Google Scholar] [CrossRef]

- Häkkinen, H.; Mäkinen, S.; Manninen, M. Edge dislocations in fcc metals: Microscopic calculations of core structure and positron states in Al and Cu. Phys. Rev. B 1990, 41, 12441. [Google Scholar] [CrossRef]

- Puska, M.J.; Nieminen, R.M. Defect spectroscopy with positrons: A general calculational method. J. Phys. F Met. Phys. 1983, 13, 333–346. [Google Scholar] [CrossRef]

- Petersen, K.; Repin, I.A.; Trumpy, G. Positron lifetime analysis of dislocations arising from tensile strain. J. Phys. Condens. Matter. 1996, 8, 2815. [Google Scholar] [CrossRef]

- Hidalgo, C.; González-Doncel, G.; Linderoth, S.; San Juan, J. Structure of dislocations in Al and Fe as studied by positron-annihilation spectroscopy. Phys. Rev. B 1992, 45, 7017. [Google Scholar] [CrossRef]

- Čížek, J.; Procházka, I.; Kmječ, T.; Vostrý, P. Using of modified trapping model in positron lifetime study of cold-worked aluminium. Phys. Status Solidi A 2000, 180, 439–458. [Google Scholar] [CrossRef]

- Cao, Y.; He, L.; Cao, X.; Zhang, P.; Wang, B.; Zhou, Y.; Wang, P.; Cui, J. The relationship of dislocation and vacancy cluster with yield strength in magnetic annealed UFG 1050 aluminum alloy. Mater. Sci. Eng. A 2017, 679, 417–421. [Google Scholar] [CrossRef]

- Dangwal, S.; Edalati, K.; Valiev, R.Z.; Langdon, T.G. Breaks in the Hall–Petch Relationship after Severe Plastic Deformation of Magnesium, Aluminum, Copper, and Iron. Crystals 2023, 13, 413. [Google Scholar] [CrossRef]

- Dryzek, J. Positron annihilation studies of recrystallization in the subsurface zone induced by friction in magnesium-effect of the inhomogeneity on measured positron annihilation characteristics. Appl. Phys. A 2014, 114, 465–475. [Google Scholar] [CrossRef][Green Version]

- Dryzek, J.; Siemek, K.; Ziewiec, K.; Schut, H. Positron annihilation and tribological studies of nano-embedded Al alloys. Bull. Mater. Sci. 2015, 38, 1141–1148. [Google Scholar] [CrossRef]

| Sample | ET | EP [MPa] | R = A0/Af | TS lnR | MES [1/s] | Hardness HV0.2 | UTS Rm [MPa] | YS R0.2 [MPa] | Elongation at Break ε [%] |

|---|---|---|---|---|---|---|---|---|---|

| initial | - | - | - | - | - | 29 | 76 | 51 | 36 |

| Al-2.5 | room | 217 | 2.49 | 0.91 | 1.37 | 46 | 125 | 118 | 15.7 |

| Al-2.5C | cryo-cooled | 175 | 2.51 | 0.92 | 2.02 | 47 | 138 | 132 | 14.6 |

| Al-25 | room | 180 | 25.3 | 3.23 | 5.55 | 49 | 129 | 121 | 16.4 |

| Sample | Al-2.5C | Al-2.5 | Al-25 | |||

|---|---|---|---|---|---|---|

| Extruded | Annealed | Extruded | Annealed | Extruded | Annealed | |

| Lattice parameter [Å] | 4.0504(2) | 4.0499(4) | 4.0504(2) | 4.0502(2) | 4.0510(3) | 4.0503(2) |

| Crystallite size [Å] | 371(36) | 479(118) | 382(28) | 381(51) | 381(61) | 332(21) |

| Lattice strain [%] | −0.04(2) | −0.06(4) | −0.04(1) | −0.06(2) | −0.06(3) | −0.08(1) |

| Sample | L+ [nm] | Sbulk |

|---|---|---|

| reference | 97(8) | 0.4964(3) |

| Al-2.5 | 78(10) | 0.5010(3) |

| Al-2.5C | 16(5) | 0.5124(2) |

| Al-25 | 22(2) | 0.5092(2) |

| Sample | [ps] | [ps] | [%] | [ps] |

|---|---|---|---|---|

| Al-2.5 | 125 ± 2 | 247 ± 2 | 53 ± 1 | 190 |

| Al-2.5C | 131 ± 3 | 251 ± 3 | 60 ± 2 | 203 |

| Al-25 | 133 ± 2 | 249 ± 2 | 58 ± 1 | 200 |

| Sample | Q [eV] |

|---|---|

| Al-2.5 | 1.51 ± 0.21 |

| Al-2.5C | 1.45 ± 0.36 |

| Al-25 | 1.50 ± 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dryzek, E.; Wróbel, M.; Sarnek, M.; Skiba, J. Positron Annihilation Studies of Hydrostatically Extruded AA1050 Aluminum. Materials 2025, 18, 4428. https://doi.org/10.3390/ma18184428

Dryzek E, Wróbel M, Sarnek M, Skiba J. Positron Annihilation Studies of Hydrostatically Extruded AA1050 Aluminum. Materials. 2025; 18(18):4428. https://doi.org/10.3390/ma18184428

Chicago/Turabian StyleDryzek, Ewa, Mirosław Wróbel, Maciej Sarnek, and Jacek Skiba. 2025. "Positron Annihilation Studies of Hydrostatically Extruded AA1050 Aluminum" Materials 18, no. 18: 4428. https://doi.org/10.3390/ma18184428

APA StyleDryzek, E., Wróbel, M., Sarnek, M., & Skiba, J. (2025). Positron Annihilation Studies of Hydrostatically Extruded AA1050 Aluminum. Materials, 18(18), 4428. https://doi.org/10.3390/ma18184428