Towards a New Plastination Technique for Moisture Management of Western Red Cedar Without Loss of Strength and with Enhanced Stability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

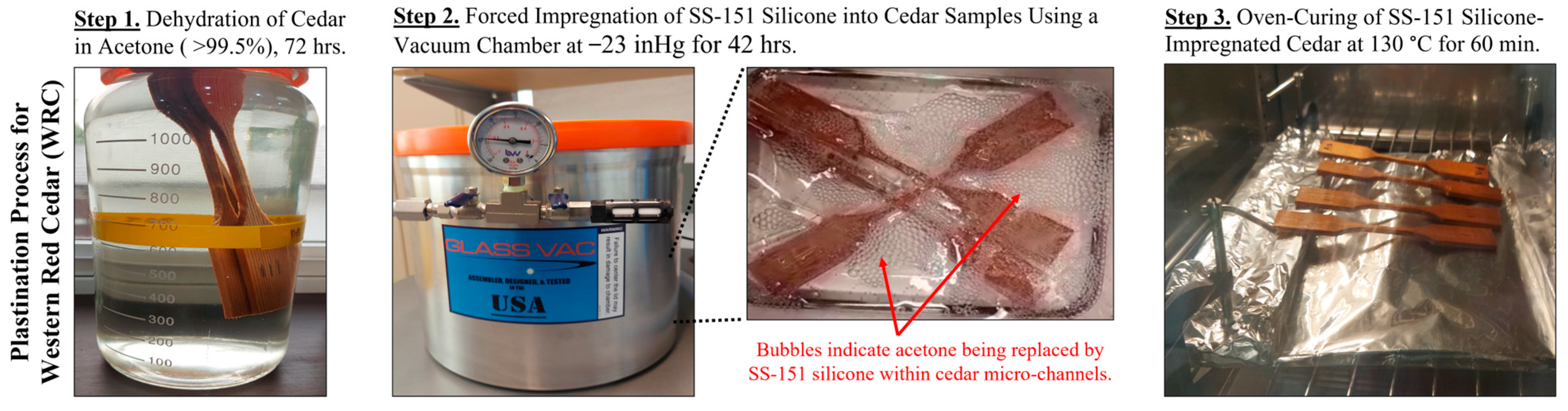

2.2. WRC Plastination Steps

- Dehydration should occur to replace moisture from WRC with a highly volatile substance, in this case acetone. WRC specimens were fully submerged in acetone for 72 hrs at room temperature (20 ± 2 °C) and stirred every 24 hrs.

- After the completion of dehydration, forced impregnation can be initiated. The dehydrated WRC samples were submersed in SS-151 silicone and placed in a 5-gallon vacuum chamber purchased from McMaster-Carr (Robbinsville, NJ, United States) at a pressure of −23 inHg (−77.9 kPa) for 42 h using a TRIVAC AR4-8 vacuum pump supplied by Leybold GmbH (Cologne, NW, Germany). Under these conditions, acetone vaporizes at room temperature [31], creating a pressure differential that draws silicone into the vacated cellular spaces, allowing it to occupy the voids left behind by the evaporating acetone [23,24]. After vacuum treatment, atmospheric pressure was restored and maintained for an additional 6 hrs to complete the impregnation process.

- Upon forced impregnation, WRC specimens were placed in a 130 °C oven for 60 min to cure SS-151 silicone. Once cured and cooled, the excess silicone was scraped off.

2.3. Characterization

3. Results and Discussion

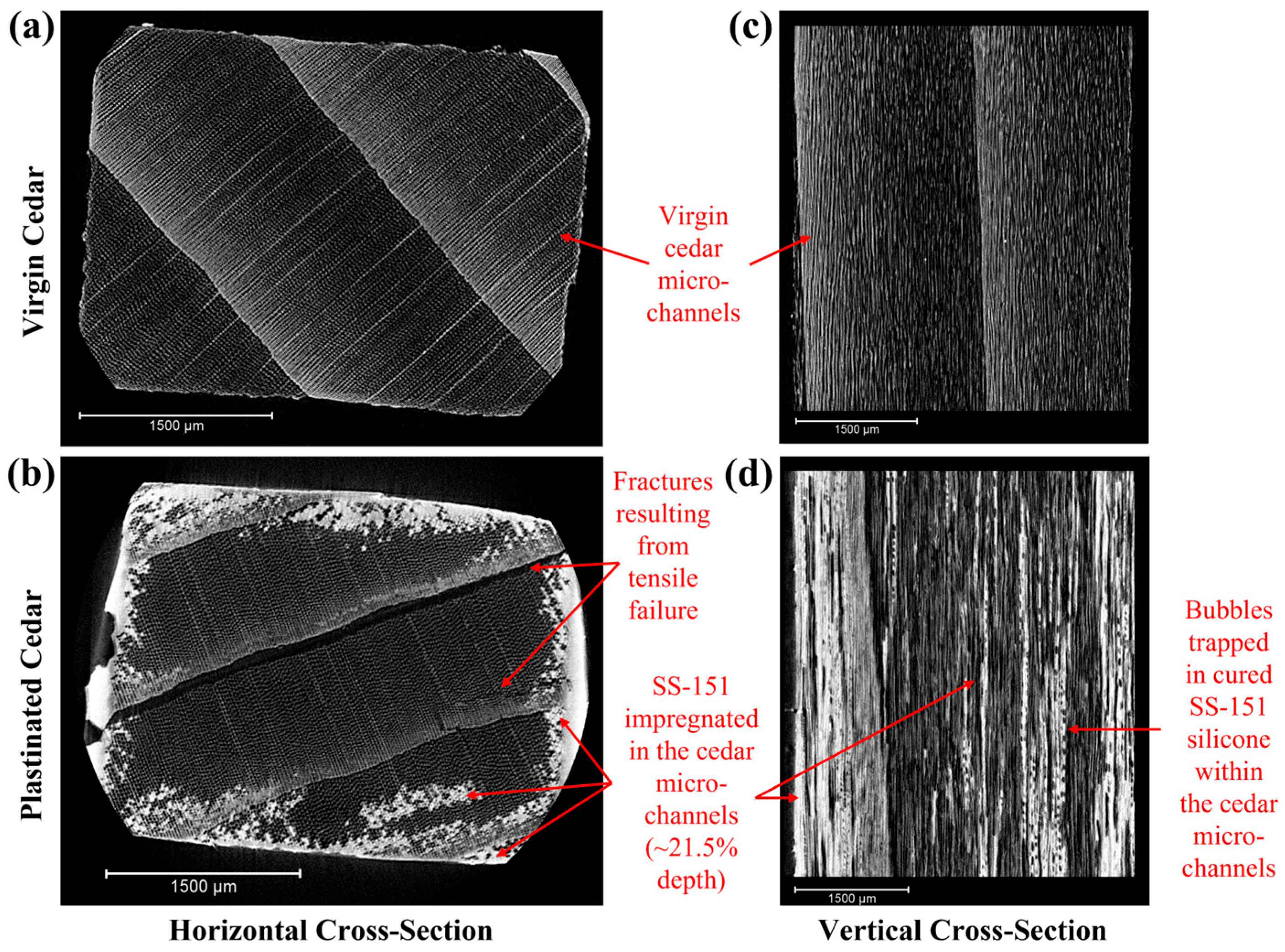

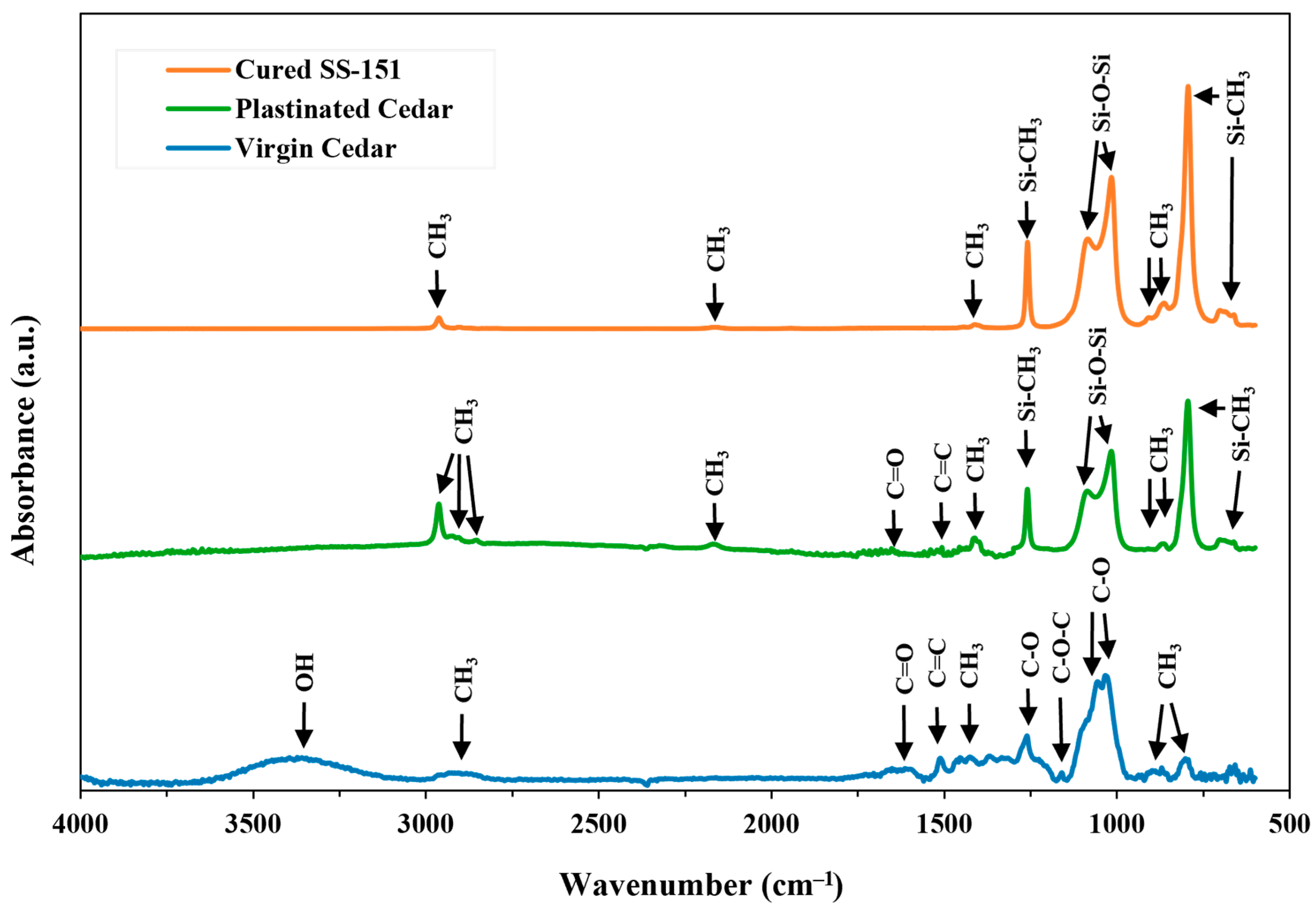

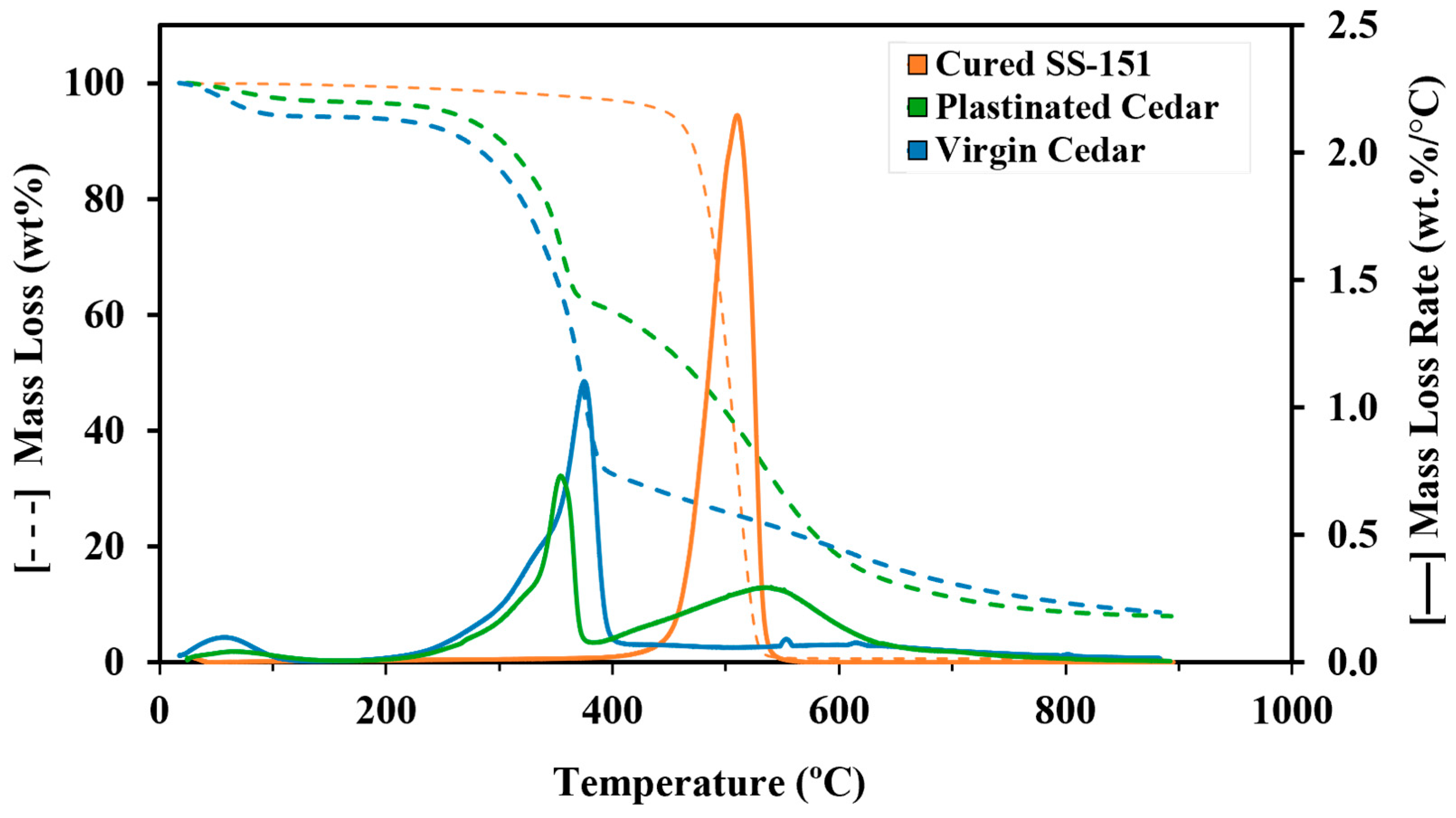

3.1. Characterization

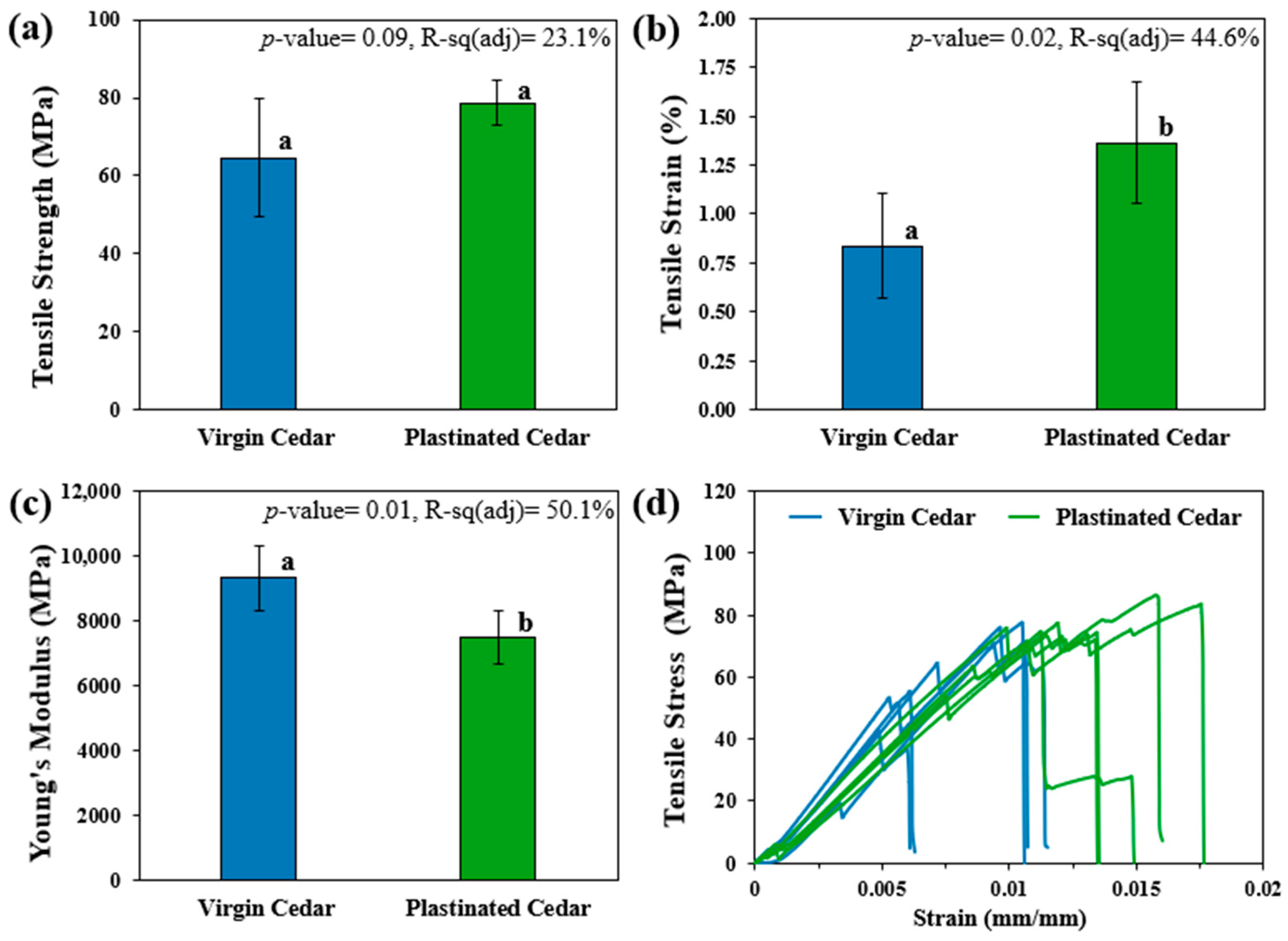

3.2. Effect of Plastination on Mechanical Properties

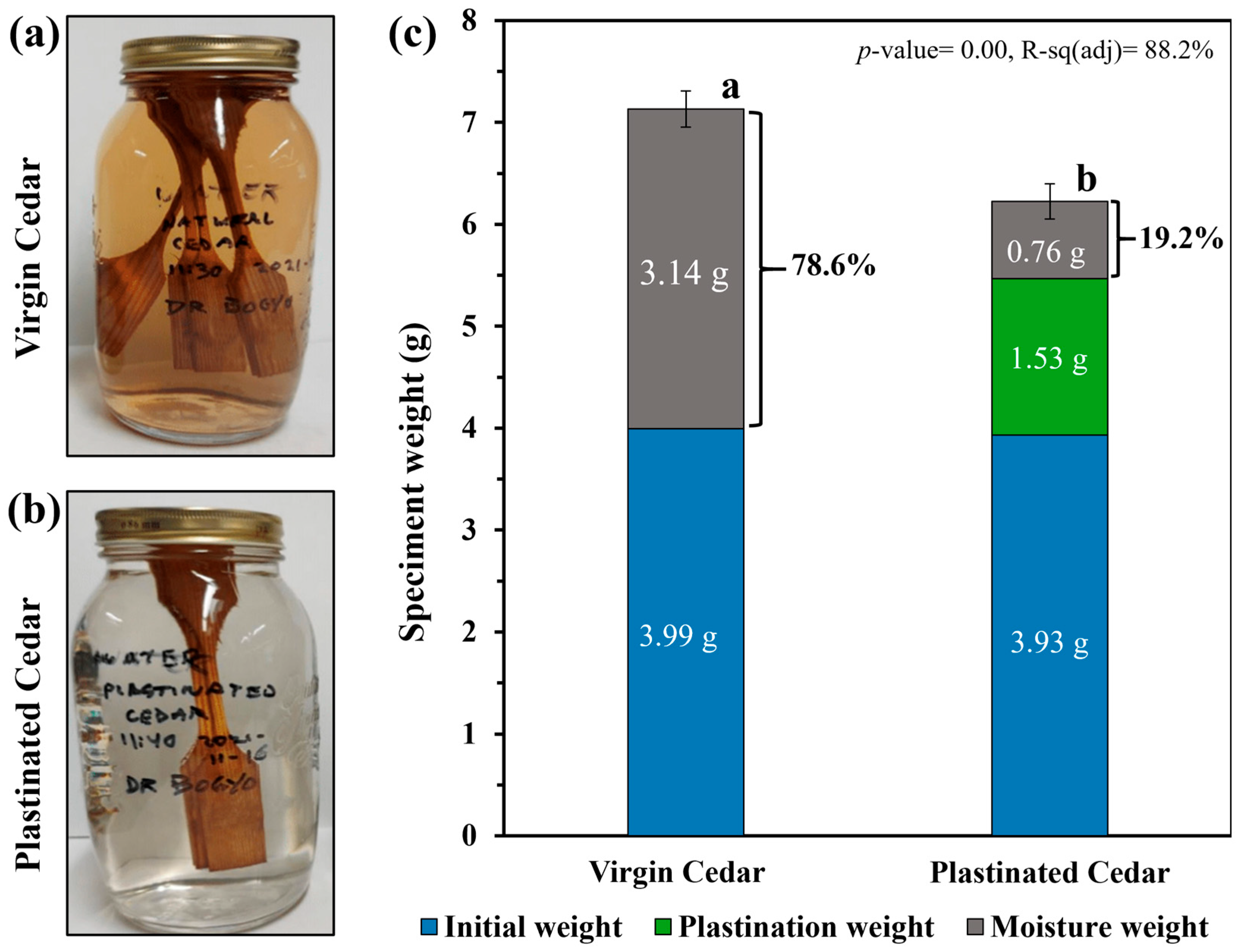

3.3. Effect of Plastination on Environmental Durability

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WRC | Western Red Cedar |

| μCT | Micro X-ray Computed Tomography |

| FTIR | Fourier Transform Infrared Spectroscopy |

| TGA | Thermogravimetry Analysis |

| CCA | Copper Chrome Arsenate |

| QAC | Quaternary Ammonium Compounds |

| PLA | Polylactic Acid |

| DTG | Derivative Thermogravimetry |

References

- Gregory, C.; Mcbeath, A.; Filipescu, C. An Economic Assessment of the Western Redcedar Industry in British Columbia; Canadian Forest Service: Victoria, BC, Canada, 2018.

- Peng, Y.; Nair, S.S.; Chen, H.; Farnood, R.; Yan, N.; Cao, J. Application of Different Bark Fractions in Polypropylene Composites: UV and Thermal Stability. Polym. Compos. 2020, 41, 2198–2209. [Google Scholar] [CrossRef]

- Hundhausen, U.; Mai, C.; Slabohm, M.; Gschweidl, F.; Schwarzenbrunner, R. The Staining Effect of Iron (II) Sulfate on Nine Different Wooden Substrates. Forests 2020, 11, 658. [Google Scholar] [CrossRef]

- Shilova, O.A.; Tsvetkova, I.N.; Vlasov, D.Y.; Ryabusheva, Y.V.; Sokolov, G.S.; Kychkin, A.K.; Văn Nguyên, C.; Khoroshavina, Y.V. Microbiologically Induced Deterioration and Environmentally Friendly Protection of Wood Products. In Biodegradation and Biodeterioration at the Nanoscale; Elsevier: Amsterdam, The Netherlands, 2021; pp. 283–321. ISBN 9780128239704. [Google Scholar]

- Morrell, J.J. Protection of Wood: A Global Perspective on the Future. Sigma J. Eng. Nat. Sci. 2019, 10, 81–94. [Google Scholar]

- Sargent, R. Evaluating Dimensional Stability in Modified Wood: An Experimental Comparison of Test Methods. Forests 2022, 13, 613. [Google Scholar] [CrossRef]

- Woźniak, M. Antifungal Agents in Wood Protection—A Review. Molecules 2022, 27, 6392. [Google Scholar] [CrossRef]

- Shukla, S.R.; Kamdem, D.P. Effect of Micronized Copper Treatments on Retention, Strength Properties, Copper Leaching and Decay Resistance of Plantation Grown Melia Dubia Cav. Wood. Eur. J. Wood Wood Prod. 2023, 81, 513–528. [Google Scholar] [CrossRef]

- Jirouš-Rajković, V.; Miklečić, J. Enhancing Weathering Resistance of Wood—A Review. Polymers 2021, 13, 1980. [Google Scholar] [CrossRef] [PubMed]

- Sahu, P.; Gupta, M.K. Water Absorption Behavior of Cellulosic Fibres Polymer Composites: A Review on Its Effects and Remedies. J. Ind. Text. 2022, 51, 7480S–7512S. [Google Scholar] [CrossRef]

- Rowell, R.M. Understanding Wood Surface Chemistry and Approaches to Modification: A Review. Polymers 2021, 13, 2558. [Google Scholar] [CrossRef]

- Gao, H.; Li, Y.; Xie, Y.; Liang, D.; Li, J.; Wang, Y.; Xiao, Z.; Wang, H.; Gan, W.; Pattelli, L.; et al. Optical Wood with Switchable Solar Transmittance for All-Round Thermal Management. Compos. Part B Eng. 2024, 275, 111287. [Google Scholar] [CrossRef]

- Augustina, S.; Dwianto, W.; Wahyudi, I.; Syafii, W.; Gérardin, P.; Marbun, S.D. Wood Impregnation in Relation to Its Mechanisms and Properties Enhancement. Bioresources 2023, 18, 4332–4372. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of Wood Modification and Wood Functionalization Technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- Zeng, Q.; Yu, X.; Wei, N.; Wu, Z.; Liu, Q.; Chen, N.; Zhao, W. Effect of Impregnation with Natural Shellac Polymer on the Mechanical Properties of Fast-Growing Chinese Fir. Polymers 2022, 14, 3871. [Google Scholar] [CrossRef]

- Stolf, D.O.; Antonio, F.; Lahr, R. Wood-Polymer Composite: Physical and Mechanical Properties of Some Wood Species Impregnated with Styrene and Methyl Methacrylate. Mater. Res. 2004, 7, 611–617. [Google Scholar] [CrossRef]

- Lemaire-Paul, M.; Beuthe, C.A.; Riahinezhad, M.; Reza Foruzanmehr, M. The Impact of Vacuum Pressure on the Effectiveness of SiO2 Impregnation of Spruce Wood. Wood Sci. Technol. 2023, 57, 147–171. [Google Scholar] [CrossRef]

- Teacă, C.A.; Tanasa, F. Wood Surface Modification-Classic and Modern Approaches in Wood Chemical Treatment by Esterification Reactions. Coatings 2020, 10, 629. [Google Scholar] [CrossRef]

- Lin, Q.; Wu, J.; Yu, Y.; Huang, Y.; Yu, W. Immobilization of Ferric Tannate on Wood Fibers to Functionalize Wood Fibers/Diphenylmethane Di-Isocyanate Composites. Ind. Crops Prod. 2020, 154, 112753. [Google Scholar] [CrossRef]

- Elamin, M.A.M.; Li, S.X.; Osman, Z.A.; Otitoju, T.A. Preparation and Characterization of Wood-Plastic Composite by Utilizing a Hybrid Compatibilizer System. Ind. Crops Prod. 2020, 154, 112659. [Google Scholar] [CrossRef]

- Csizmadia, R.; Faludi, G.; Renner, K.; Móczó, J.; Pukánszky, B. PLA/Wood Biocomposites: Improving Composite Strength by Chemical Treatment of the Fibers. Compos. Part A Appl. Sci. Manuf. 2013, 53, 46–53. [Google Scholar] [CrossRef]

- Kamperidou, V.; Ratajczak, I.; Perdoch, W.; Mazela, B. Impact of Thermal Modification Combined with Silicon Compounds Treatment on Wood Structure. Wood Res. 2022, 67, 773–784. [Google Scholar] [CrossRef]

- Dhir, D.K.; Rashidi, A.; Bogyo, G.; Ryde, R.; Pakpour, S.; Milani, A.S. Environmental Durability Enhancement of Natural Fibres Using Plastination: A Feasibility Investigation on Bamboo. Molecules 2020, 25, 474. [Google Scholar] [CrossRef]

- Osmond, R.; Margoto, O.H.; Basar, I.A.; Olfatbakhsh, T.; Eskicioglu, C.; Golovin, K.; Milani, A.S. An Improved Plastination Method for Strengthening Bamboo Culms, without Compromising Biodegradability. Sci. Rep. 2023, 13, 5640. [Google Scholar] [CrossRef]

- Laleicke, P.F.; Hubbe, M.A. Outdoor Wood Finishing: A Review on Making Wood Resistant to Moisture, Ultraviolet Light, and Degradation. Bioresources 2025, 20, 7903–7982. [Google Scholar] [CrossRef]

- von Horst, C.; von Hagens, R.; Sora, C.M.; Henry, R.W. History and Development of Plastination Techniques. Anat. Histol. Embryol. 2019, 48, 512–517. [Google Scholar] [CrossRef]

- Awotwe-Mensah, M.; Appiah-Kubi, E.; Mitchual, S.J. Assessment of Density and Anatomical Features of Young and Old Bambusa Vulgaris (Schrad. Ex J.C. Wendl.) Culm Heights as Sustainable Structural Material in Ghana. Int. J. For. Res. 2024, 2024, 1–14. [Google Scholar] [CrossRef]

- Esteban, L.G.; de Palacios, P.; Heinz, I.; Gasson, P.; García-Iruela, A.; García-Fernández, F. Softwood Anatomy: A Review. Forests 2023, 14, 323. [Google Scholar] [CrossRef]

- ASTM D4442; Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. ASTM: West Conshohocken, PA, USA, 2020.

- Silicone Solutions SS-151 Silicone Conformal Coating Safety Data Sheet (SDS). 2025. Available online: https://siliconesolutions.com/media/pdf/SS-151SDS.pdf (accessed on 15 September 2025).

- Ambrose, D.; Sprake, C.H.S.; Townsend, R. Thermodynamic Properties of Organic Oxygen Compounds XXXIII. The Vapour Pressure of Acetone. J. Chem. Thermodyn. 1974, 6, 693–700. [Google Scholar] [CrossRef]

- ASTM International D4761; Standard Test Methods for Mechanical Properties of Lumber and Wood-Based Structural Materials. ASTM: West Conshohocken, PA, USA, 2019.

- ASTM International D5229-20; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2020.

- Osmond, R. Towards Improving and Developing a Plastination Technique for Bamboo Culms and Flax Fibres. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2021. [Google Scholar]

- Khazaei, J. Water Absorption Characteristics of Three Wood Varieties. Cercet. Agron. Mold. 2008, 41, 134. [Google Scholar]

- Pemberger, N.; Huck, C.W.; Bittner, L.K.H. Using Near-Infrared Spectroscopy to Monitor the Curing Reaction of Silicone Adhesives. Spectrosc. Suppl. 2015, 30, 8–19. [Google Scholar]

- Chen, H.; Yan, N. Application of Western Red Cedar (Thuja plicata) Tree Bark as a Functional Filler in PMDI Wood Adhesives. Ind. Crops Prod. 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Sharma, V.; Yadav, J.; Kumar, R.; Tesarova, D.; Ekielski, A.; Mishra, P.K. On the Rapid and Non-Destructive Approach for Wood Identification Using ATR-FTIR Spectroscopy and Chemometric Methods. Vib. Spectrosc. 2020, 110, 103097. [Google Scholar] [CrossRef]

- Longo, S.; Corsaro, C.; Granata, F.; Fazio, E. Clinical CT Densitometry for Wooden Cultural Heritage Analysis Validated by FTIR and Raman Spectroscopies. Radiat. Phys. Chem. 2022, 199, 110376. [Google Scholar] [CrossRef]

- Célino, A.; Gonçalves, O.; Jacquemin, F.; Fréour, S. Qualitative and Quantitative Assessment of Water Sorption in Natural Fibres Using ATR-FTIR Spectroscopy. Carbohydr. Polym. 2014, 101, 163–170. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Ufodike, C.O.; Eze, V.O.; Ahmed, M.F.; Oluwalowo, A.; Park, J.G.; Liang, Z.; Wang, H. Investigation of Molecular and Supramolecular Assemblies of Cellulose and Lignin of Lignocellulosic Materials by Spectroscopy and Thermal Analysis. Int. J. Biol. Macromol. 2020, 146, 916–921. [Google Scholar] [CrossRef]

- Senalik, C.A.; Farber, B. Mechanical Properties of Wood. In Wood Handbook: Wood as an Engineering Material; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; Volume FPL-GTR-282, pp. 1–46. [Google Scholar]

- Mohammed, M.; Rasidi, M.S.M.; Mohammed, A.M.; Rahman, R.; Osman, A.F.; Adam, T.; Betar, B.O.; Dahham, O.S. Interfacial Bonding Mechanisms of Natural Fibre-Matrix Composites: An Overview. Bioresources 2022, 17, 7031–7090. [Google Scholar] [CrossRef]

- Torres, J.P.; Vandi, L.J.; Veidt, M.; Heitzmann, M.T. The Mechanical Properties of Natural Fibre Composite Laminates: A Statistical Study. Compos. Part A Appl. Sci. Manuf. 2017, 98, 99–104. [Google Scholar] [CrossRef]

- Acda, M.N.; Morrell, J.J.; Levien, K.L. Supercritical Fluid Impregnation of Selected Wood Species with Tebuconazole. Wood Sci. Technol. 2021, 35, 127–136. [Google Scholar] [CrossRef]

- Lemaire-Paul, M.; Foruzanmehr, M.R. The Study of Physico-Mechanical Properties of SiO2-Impregnated Wood under Dry and Saturated Conditions. Wood Sci. Technol. 2023, 57, 1039–1059. [Google Scholar] [CrossRef]

- Ferdinánd, M.; Jerabek, M.; Várdai, R.; Lummerstorfer, T.; Pretschuh, C.; Gahleitner, M.; Faludi, G.; Móczó, J.; Pukánszky, B. Impact Modification of Wood Flour Reinforced PP Composites: Problems, Analysis, Solution. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107445. [Google Scholar] [CrossRef]

- Zhao, D.; Chen, B.; Sun, J. Enhancing Performance of Engineering Structures under Dynamic Disasters with ECC–FRP Composites: A Review at Material and Member Levels. Buildings 2023, 13, 2099. [Google Scholar] [CrossRef]

- Hui, B.; Li, Y.; Huang, Q.; Li, G.; Li, J.; Cai, L.; Yu, H. Fabrication of Smart Coatings Based on Wood Substrates with Photoresponsive Behavior and Hydrophobic Performance. Mater. Des. 2015, 84, 277–284. [Google Scholar] [CrossRef]

- Amin, M.; Akbar, M.; Amin, S. Hydrophobicity of Silicone Rubber Used for Outdoor Insulation (An Overview). Rev. Adv. Mater. Sci. 2007, 16, 10–26. [Google Scholar]

- Hassan, M.S.; Attia, M.K.; Attia, R.M. Improving of Thermal Stability and Water Repellency of Cotton Fabrics via Coating with Silicone Rubber under the Effect of Electron Beam Irradiation. J. Ind. Text. 2022, 51, 4899S–4912S. [Google Scholar] [CrossRef]

- Mastouri, A.; Efhamisisi, D.; Shirmohammadli, Y.; Oladi, R. Physicochemical Properties of Thermally Treated Poplar Wood in Silicone and Rapeseed Oils: A Comparative Study. J. Build. Eng. 2021, 43, 102511. [Google Scholar] [CrossRef]

- Ding, Z.; Lin, W.; Yang, W.; Chen, H.; Zhang, X. A Silicone Resin Coating with Water-Repellency and Anti-Fouling Properties for Wood Protection. Polymers 2022, 14, 3062. [Google Scholar] [CrossRef]

- Mohd Aref, Y.; Othaman, R.; Anuar, F.H.; Ku Ahmad, K.Z.; Baharum, A. Superhydrophobic Modification of Sansevieria Trifasciata Natural Fibres: A Promising Reinforcement for Wood Plastic Composites. Polymers 2023, 15, 594. [Google Scholar] [CrossRef] [PubMed]

- Pandey, K.K.; Vinoth Kumar, S.; Srinivas, K. Inhibition of Leaching of Water Soluble Extractives of Pterocarpus Marsupium by Heat Treatment. Eur. J. Wood Wood Prod. 2016, 74, 223–229. [Google Scholar] [CrossRef]

- Bajpai, P. 7. Properties of Wood. In Biermann’s Handbook of Pulp and Paper: Raw Material and Pulp Making; Elsevier: Amsterdam, The Netherlands, 2018; Volume 1, pp. 215–232. [Google Scholar]

- Fu, Z.; Chen, Y.; Xie, Y. Review on Wood Deformation and Cracking during Moisture Loss. Polymers 2023, 15, 3295. [Google Scholar] [CrossRef]

- Báder, M.; Németh, R. Moisture-dependent mechanical prop erties of longitudinally compressed wood. Eur. J. Wood Wood Prod. 2019, 77, 1009–1019. [Google Scholar] [CrossRef]

- Yamamoto, H.; Kojima, Y. Properties of cell wall constituents in relation to longitudinal elasticity of wood: Part 1. Formulation of the longitudinal elasticity of an isolated wood fiber. Wood Sci. Technol. 2002, 36, 55–74. [Google Scholar] [CrossRef]

- Ozyhar, T.; Hering, Y.; Niemz, P. Moisture-dependent elastic and strength anisotropy of European beech wood in tension. J. Mater. Sci. 2012, 47, 6141–6150. [Google Scholar] [CrossRef]

- Meng, Y.; Xia, Y.; Young, T.M.; Cai, Z.; Wang, S. Viscoelasticity of wood cell walls with different moisture content as measured by nanoindentation. RSC Adv. 2015, 47538–47547. [Google Scholar] [CrossRef]

- Jiang, J.; Bachtiar, E.V.; Lu, J.; Niemz, P. Moisture-Dependent Orthotropic Elasticity and Strength Properties of Chinese Fir Wood. Eur. J. Wood Wood Prod. 2017, 75, 927–938. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood Modification by Heat Treatment: A Review. Bioresources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Van Acker, J.; Tjeerdsma, B.F.; Kegel, E.V. Strength Properties of Thermally Modified Softwoods and Its Relation to Polymeric Structural Wood Constituents. Ann. For. Sci. 2007, 64, 679–690. [Google Scholar] [CrossRef]

- Haghi Kashani, M.; Hosseini, A.; Sassani, F.; Ko, K.K.; Milani, A.S. Understanding Different Types of Coupling in Mechanical Behavior of Woven Fabric Reinforcements: A Critical Review and Analysis. Compos. Struct. 2017, 179, 558–567. [Google Scholar] [CrossRef]

| Sample | Onset T5% (°C) | Tdmax1 (°C) | Tdmax2 (°C) | Tdmax3 (°C) | Residual at 800 °C (%) |

|---|---|---|---|---|---|

| Cured SS-151 | 447.3 | - | - | 510.0 | 0.6 |

| Virgin cedar | 86.2 | 57.6 | 375.0 | - | 10.3 |

| Plastinated cedar | 254.7 | 66.2 | 354.4 | 553.5 | 8.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Margoto, O.H.; Szypula, M.M.; Bogyo, G.R.; Yang, V.; Milani, A.S. Towards a New Plastination Technique for Moisture Management of Western Red Cedar Without Loss of Strength and with Enhanced Stability. Materials 2025, 18, 4353. https://doi.org/10.3390/ma18184353

Margoto OH, Szypula MM, Bogyo GR, Yang V, Milani AS. Towards a New Plastination Technique for Moisture Management of Western Red Cedar Without Loss of Strength and with Enhanced Stability. Materials. 2025; 18(18):4353. https://doi.org/10.3390/ma18184353

Chicago/Turabian StyleMargoto, Olivia H., Madisyn M. Szypula, Grant R. Bogyo, Victor Yang, and Abbas S. Milani. 2025. "Towards a New Plastination Technique for Moisture Management of Western Red Cedar Without Loss of Strength and with Enhanced Stability" Materials 18, no. 18: 4353. https://doi.org/10.3390/ma18184353

APA StyleMargoto, O. H., Szypula, M. M., Bogyo, G. R., Yang, V., & Milani, A. S. (2025). Towards a New Plastination Technique for Moisture Management of Western Red Cedar Without Loss of Strength and with Enhanced Stability. Materials, 18(18), 4353. https://doi.org/10.3390/ma18184353