Reuse of Coarse Aggregates Recovered from Demolished Concrete Through the Jigging Concentration Process in New Concrete Formulations

Abstract

1. Introduction

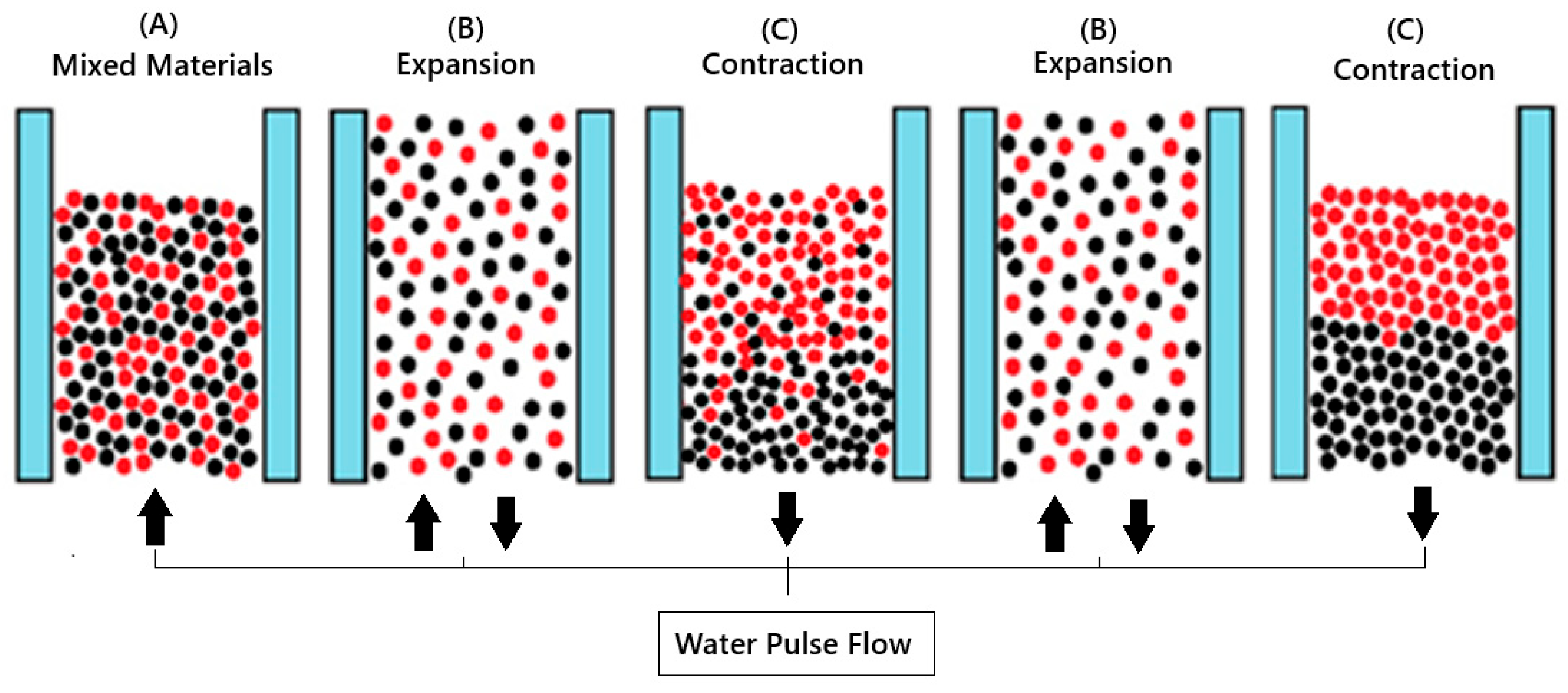

Jigging Process

2. Materials and Methods

2.1. Material Preparation

2.2. Jig Concentration Process

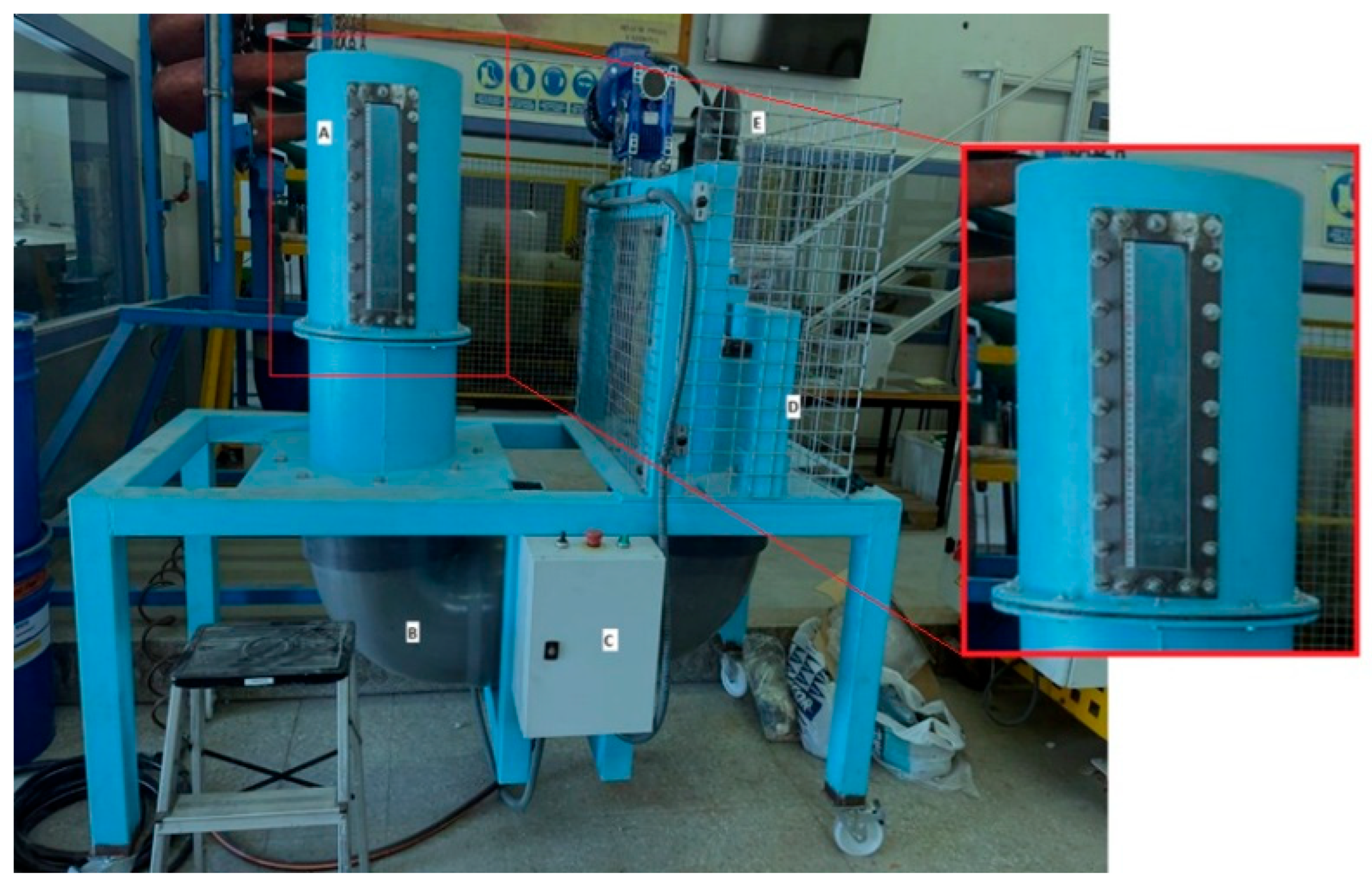

2.2.1. Jig Equipment

2.2.2. Jigging Process

2.3. Characterization Analysis

2.3.1. Densimetric Distribution Test and Analysis of the Concrete Substrate Constitution

2.3.2. Specific Density (OD), Saturated Specific Density (SSD), Bulk Density, and Water Absorption

2.3.3. Form Factor

2.4. Concrete Production and Compressive Strength Test Parameters

3. Results and Discussion

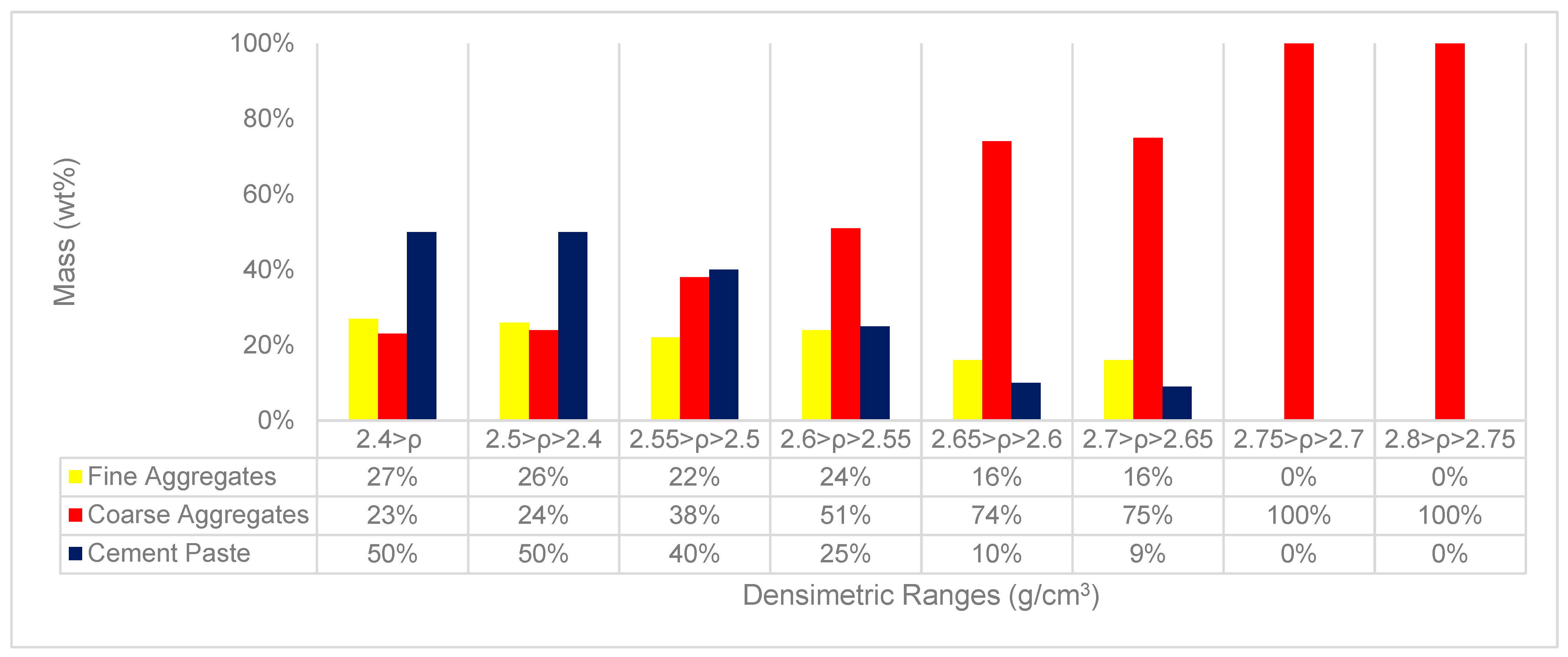

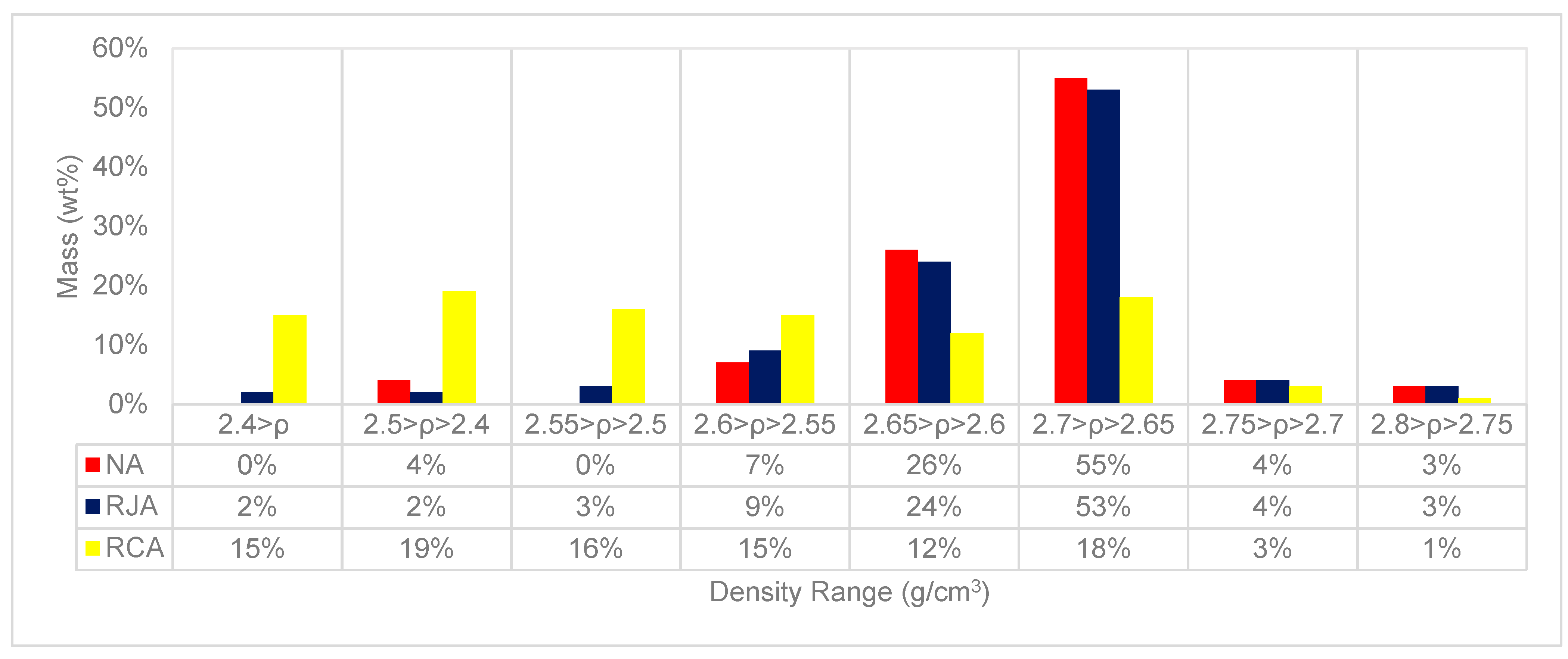

3.1. Concrete Substrate Analysis and Densimetric Distribution of the Recycled Concrete Aggregate (RCA)

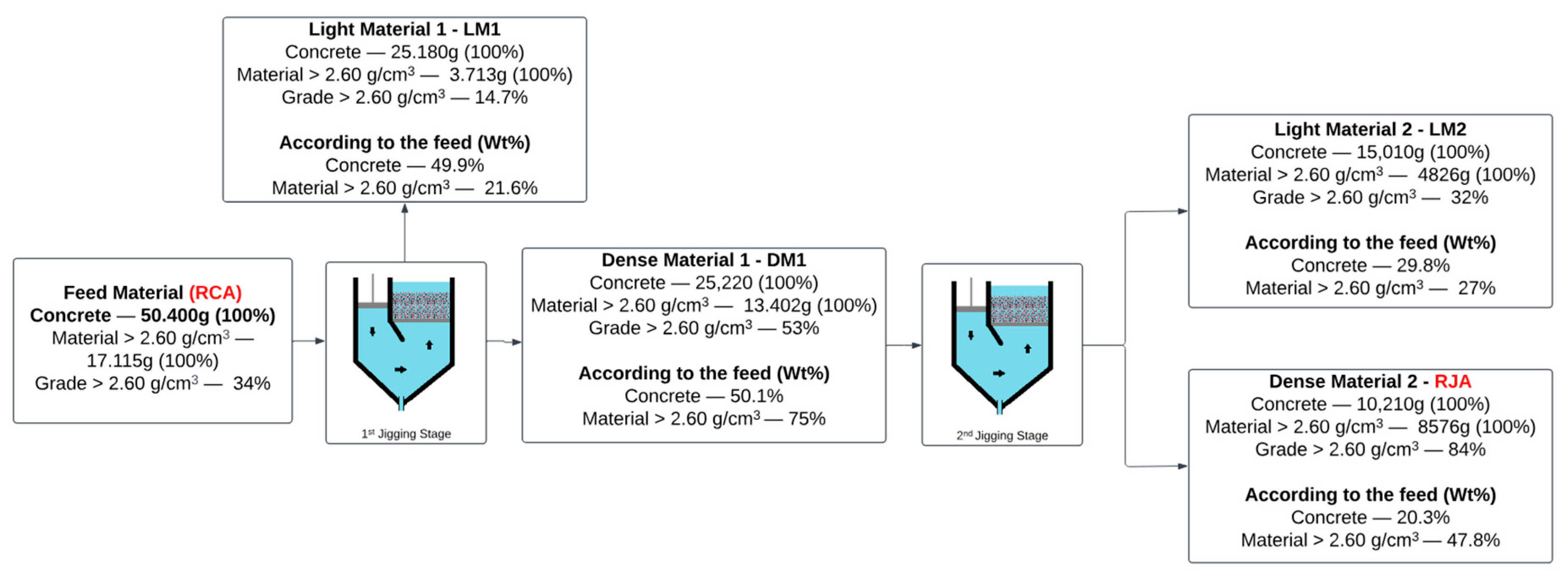

3.2. RCA Processing, RJA Generation—Jig Concentration Process

3.3. Physical Properties Analysis

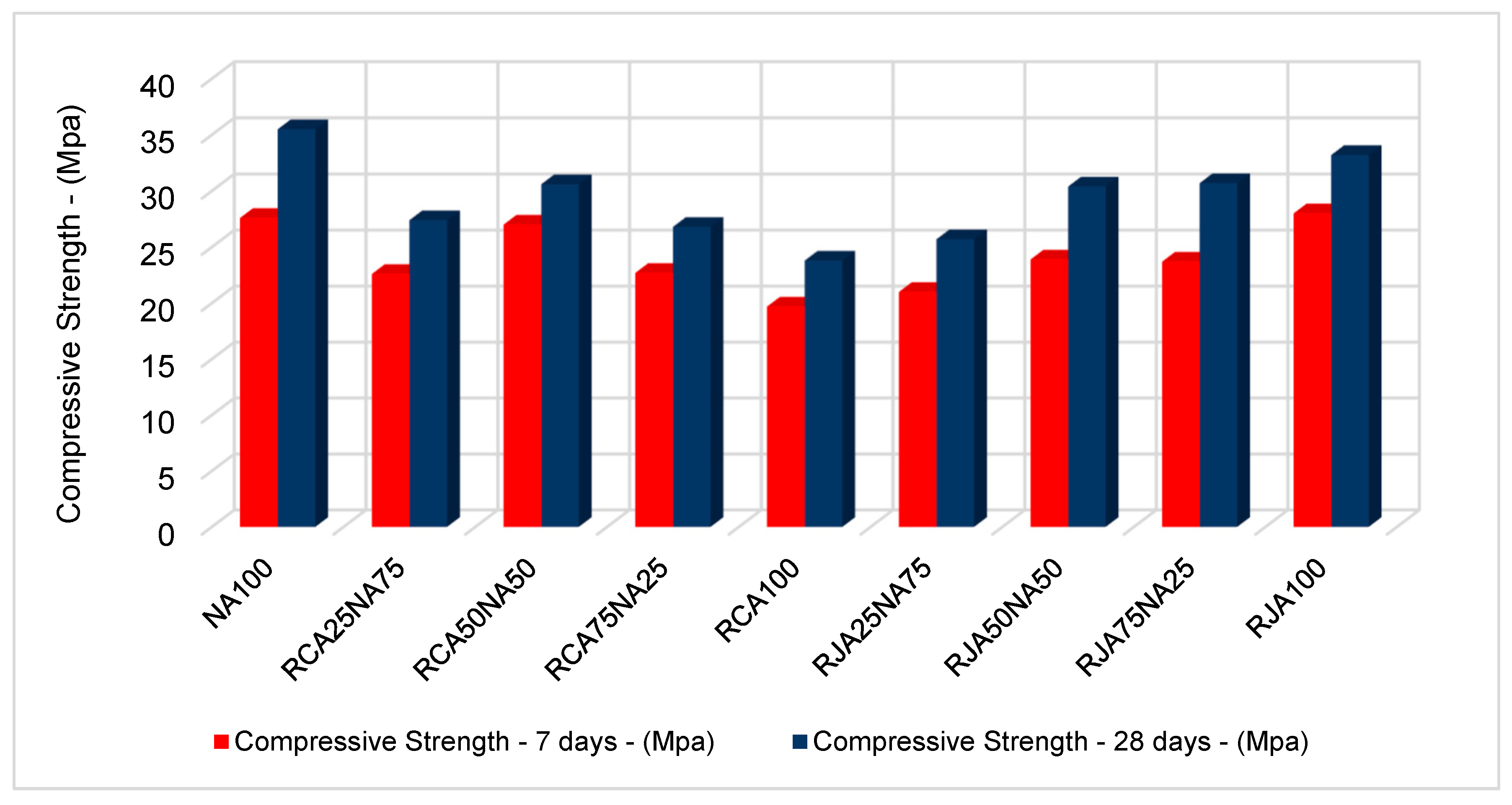

3.4. Compressive Strength Tests

4. Conclusions

- (I)

- The results observed in recycled aggregates, in a granulometric range of 5 to 20 mm, originating from C16/20 concrete, have a large densimetric variability, with a high cement paste content and a negative variation in physical characteristics.

- (II)

- The proposed jigging process efficiently removes less dense particles and can improve RCA’s physical characteristics. The densimetric stratification of the material and concentration of the coarse aggregates present, enabling the generation of a recycled aggregate (RJA) with characteristics similar to those found in natural aggregates.

- (III)

- The reduction in the cement paste content of the material is directly linked to the water absorption of the recycled aggregates when compared to the physical properties of the materials. The cement paste content also negatively influences the behavior of concrete when analyzing the values measured in the compression strength tests.

- (IV)

- A reduction of up to 30% in strength values is observed when the replacement of NA by RCA is analyzed. This presents a considerable variation in values due to the increase in the replacement rate of NA by RCA. The material cannot be used as a substitute for NA in C30/40 concrete formulations.

- (V)

- A 13% and 6% reduction in strength is observed when natural aggregates are replaced by the material obtained after the jigging process (RJA), at 50 and 100%, respectively, after jigging tests.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. 2011. Available online: http://ec.europa.eu/environment/waste/pdf/2011_CDW_Report.pdf (accessed on 15 November 2024).

- EUROSTAT. Generation of Waste by Waste Category, Hazardousness and NACE Rev, 2 Activity; EUROSTAT: Luxembourg, 2017. [Google Scholar]

- Eurostat. Waste Statistics in Europe. Available online: http://epp.eurostat.ec.europa.eu/ (accessed on 15 November 2024).

- Cristóbal García, J.; Caro, D.; Foster, G.; Pristerà, G.; Gallo, F.; Tonini, D. Techno-Economic and Environmental Assessment of Construction and Demolition Waste Management in the European Union; JRC135470; Publications Office of the European Union: Luxembourg, 2024. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Environmental analysis of a construction and demolition waste recycling plant in Portugal—Part I: Energy consumption and CO2 emissions. Waste Manag. 2013, 33, 1258–1267. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Economic viability analysis of a construction and demolition waste recycling plant in Portugal—Part I: Location, materials, technology, and economic analysis. J. Clean. Prod. 2013, 39, 338–352. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Environmental analysis of a construction and demolition waste recycling plant in Portugal—Part II: Environmental sensitivity analysis. Waste Manag. 2013, 33, 147–161. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Economic viability analysis of a construction and demolition waste recycling plant in Portugal—Part II: Economic sensitivity analysis. J. Clean. Prod. 2013, 39, 329–337. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Dinis Silvestre, J.; Brito, J.; Duarte Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.W.; Shen, L.; Liu, G. Quantifying construction and demolition waste: An analytical review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef] [PubMed]

- Reis, G.S.; Quattrone, M.; Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Agrela, F.; Cabrera, M.; Galvín, A.P.; Barbudo, A.; Ramirez, A. Influence of the sulfate content of recycled aggregates on the properties of cement-treated granular materials using Sulphate-Resistant Portland Cement. Constr. Build. Mater. 2014, 68, 127–134. [Google Scholar] [CrossRef]

- Brito, J.; Saikia, N. Recycled Aggregate in Concrete—Use of Industrial, Construction, and Demolition Waste; Springer: London, UK, 2013; Chapter 3; p. 81. [Google Scholar]

- Zou, Q.; Wang, W.; Wang, X.; Liu, Y. Pore structure characteristics of cement stone modified by nano-MgO with different mass fractions. Powder Technol. 2025, 453, 120670. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical behavior of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Hua, K.; Chen, Y.; Naz, F.; Zeng, C.; Cao, S. Separation studies of concrete and brick from construction and demolition waste. Waste Manag. 2019, 85, 396–404. [Google Scholar] [CrossRef]

- Tam, V.; Tam, C.; Le, K. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Teixeira, A.B.; Sampaio, C.H.; Moncunill, J.O.; Cortina Palas, J.L.; Lima, M.M.D.; La Rosa, G.T.H. Analysis of Physical Properties of Coarse Aggregates Recovered from Demolished Concrete with a Two-Stage Water Jigs Process for Reuse as Aggregates in Concrete. Buildings 2024, 14, 2226. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C & D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Shima, H.; Tateyashiki, H.; Matsuhashi, R.; Yoshida, Y. An Advanced Concrete Recycling Technology and its Applicability Assessment through Input-Output Analysis. J. Adv. Concr. Technol. 2005, 3, 53–67. [Google Scholar] [CrossRef]

- Cho, S.; Kim, G.; Kim, K.; Seon, S.; Park, J. A Study on AggregateWaste Separation Efficiency Using Adsorption System with Rotating Separation Net. J. Korean Recycl. Constr. Resour. Inst. 2021, 9, 85–91. [Google Scholar]

- Hu, K.; Chen, Y.; Yu, C.; Xu, D.; Cao, S.; Pang, R. Upgrading the Quality of Recycled Aggregates from Construction and Demolition Waste by Using a Novel Brick Separation and Surface Treatment Method. Materials 2020, 13, 2893. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G. Separation Processes to Improve the Quality of Recycled Concrete Aggregates (RCA). In Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing Limited: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Galan, B.; Viguri, J.R.; Cifrian, E.; Dosal, E.; Andres, A. Influence of input streams on the construction and demolition waste (CDW) recycling performance of basic and advanced treatment plants. J. Clean. Prod. 2019, 236, 117523. [Google Scholar] [CrossRef]

- Salgado, F.D.; Silva, F.D. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Etxeberria, M.; V’azquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Ignjatović, I.S.; Marinković, S.B.; Mišković, Z.M.; Savić, A.R. Flexural behavior of reinforced recycled aggregate concrete beams under short-term loading. Mater. Struct. 2013, 46, 1045–1059. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, Y.; Zeng, W.; Lu, Z.; Shah, S.P. Using microbial carbonate precipitation to improve the properties of recycled fine aggregate and mortar. Constr. Build. Mater. 2020, 230, 116949. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Tavares, L.M.M. Beneficiamento Gravimétrico: Uma Introdução Aos Processos de Concentração Mineral e Reciclagem de Materiais Por Densidade; Editora UFRGS: Porto Alegre, Brazil, 2005. [Google Scholar]

- Sampaio, C.H.; Ambrós, W.M.; Cazacliu, B.G.; Oliva Moncunill, J.; Veras, M.M.; Miltzarek, G.L.; Silva, L.F.O.; Kuerten, A.S.; Liendo, M.A. Construction and Demolition Waste Recycling through Conventional Jig, Air Jig, and Sensor-Based Sorting: A Comparison. Minerals 2021, 11, 904. [Google Scholar] [CrossRef]

- Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Wall effects on particle separation in air jigs. Powder Technol. 2016, 301, 369–378. [Google Scholar] [CrossRef]

- Paranhos, R.S.; Cazacliu, B.G.; Sampaio, C.H.; Petter, C.O.; Neto, R.O.; Huchet, F. A sorting method to value recycled concrete. J. Clean. Prod. 2016, 112 Pt 4, 2249–2258. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Cazacliu, B.G.; Miltzarek, G.L.; Huchet, F.; le Guen, L.; Petter, C.O.; Paranhos, R.; Ambrós, W.M.; Oliveira, M.L.S. Stratification in air jigs of concrete/brick/gypsum particles. Constr. Build. Mater. 2016, 109, 63–72. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Lyman, G.J. Review of jigging principles and control. Coal Prep. 1992, 11, 145–165. [Google Scholar] [CrossRef]

- Mayer, F. A new theory concerning the mechanism of settling with its consequences for the rational shape of the diagram of the washing stroke and development of the corresponding regulator of a non-plunger jig. In Proceedings of the 1st First International Coal Preparation Conference, Paris, France, June 1950; pp. 316–322. [Google Scholar]

- Mayer, F. Fundamentals of a potential theory of the jigging process. In Proceedings of the 7th International Mineral Processing Congress, New York, NY, USA, 20–24 September 1964; pp. 75–86. [Google Scholar]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T. Acid Treatment Technique for Determining the Mortar Content of Recycled Concrete Aggregates. J. Test. Eval. 2013, 41, 441–450. [Google Scholar] [CrossRef]

- ASTM C127-07; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 2009.

- EN 933-4:2008; Tests for Geometrical Properties of Aggregates. Part 4: Determination of Particle Shape—Shape Index. British Standards Institution: London, UK, 2009.

- EHE-08, Royal Decrete 1247/2008; Structural Concrete Instruction. Available online: https://www.mitma.gob.es/recursos_mfom/1820100.pdf (accessed on 17 November 2024).

- EN 12390-3:2009+AC1:2011; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Spanish Normative: Madrid, España, 2011.

- Sampaio, C.H.; Cazacliu, B.G.; Ambrós, W.M.; Kronbauer, M.A.; Tubino, R.M.C.; Dal Molin, D.C.C.; Oliva Moncunill, J.; Miltzarek, G.L.; Waskow, R.P.; dos Santos, V.L.G.; et al. Characterization of Demolished Concretes with Three Different Strengths for Recycling as Coarse Aggregate. Minerals 2021, 11, 803. [Google Scholar] [CrossRef]

- Salgado, F.A.; Silva, F.A. Properties of recycled aggregates from different composition and its influence on concrete strength. Rev. IBRACON Estrut. Mater. 2021, 14, e14605. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Ferreira, L.; Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- De Juan, M.S. Study on the Use of Recycled Aggregates in Structural Concrete Production. Ph.D. Thesis, Polytechnic University of Madrid, Madrid, Spain, 2004. [Google Scholar]

- Santos, J.; Branco, F.A.; de Brito, J. Reinforced concrete beams with recycled aggregates from demolished concrete of a stadium. In Proceedings of the SB05—3rd International Conference on Sustainable Building, Tokyo, Japan, 23–29 September 2005; pp. 2011–2018. [Google Scholar]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- de Brito, J.; Ferreira, J.; Pacheco, J.; Soares, D.; Guerreiro, M. Structural, material, mechanical and durability properties and behavior of recycled aggregates concrete. J. Build. Eng. 2016, 6, 1–16. [Google Scholar] [CrossRef]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.B.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Construct. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of recycled aggregate treatment techniques on the durability of concrete: A comparative evaluation. Construct. Build. Mater. 2020, 264, 120284. [Google Scholar] [CrossRef]

- Bairagi, N.K.; Ravande, K.; Pareek, V.K. Behaviour of concrete with different proportions of natural and recycled aggregates. Resour. Conserv. Recycl. 1993, 9, 109–126. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. The use of recycled aggregate in concrete in Hong Kong. Resour. Conserv. Recycl. 2007, 50, 293–305. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Petter, C.O.; de Freitas Sampaio, L.; Moncunill, J.O.; Ambrós, W.M.; Teixeira, A.B. Concentration Plants of Construction and Demolition Waste for Coarse Aggregate Recycling. Minerals 2024, 14, 619. [Google Scholar] [CrossRef]

| Materials | Description |

|---|---|

| NA | Natural Aggregates—Aggregates are usually used in the civil industry to manufacture concrete. |

| RCA | Recycled Concrete Aggregates—Material generated after the comminution and screening (Figure 2), typically generated in CDW concentration plants. |

| RJA | Recycled Jigging Aggregates—Material generated after the two stages of the jigging process proposed in this work. |

| Material | Mix (kg/m3) | Proportion (%) |

|---|---|---|

| Cement | 150 | 15 |

| Water | 75 | 7.5 |

| Coarse Aggregates | 525 | 52.5 |

| Fine Aggregates | 250 | 25 |

| Additives | 0 | 0 |

| Sample Name | Coarse Material Replacement Ratio | ||

|---|---|---|---|

| Natural Aggregates (NA) (%) | Recycled Concrete Aggregates (RCA) (%) | Recycled Jigging Aggregates (RJA) (%) | |

| NA100 | 100 | 0 | 0 |

| RCA25NA75 | 75 | 25 | 0 |

| RCA50NA50 | 50 | 50 | 0 |

| RCA75NA25 | 25 | 75 | 0 |

| RCA100 | 0 | 100 | 0 |

| RJA25NA75 | 75 | 0 | 25 |

| RJA50NA50 | 50 | 0 | 50 |

| RJA75NA25 | 25 | 0 | 75 |

| RJA100 | 0 | 0 | 100 |

| Analysis | Densimetric Ranges (g/cm3) | |||||||

|---|---|---|---|---|---|---|---|---|

| 2.4 > ρ | 2.4 < ρ < 2.5 | 2.5 < ρ < 2.55 | 2.55 < ρ < 2.6 | 2.6 < ρ < 2.65 | 2.65 < ρ < 2.7 | 2.7 < ρ < 2.75 | 2.75 < ρ < 2.8 | |

| Retained Material | 15% | 19% | 16% | 15% | 12% | 18% | 3% | 1% |

| Proprieties | Present Work | Salgado [46] | |||

|---|---|---|---|---|---|

| NA | RJA | RCA | NA | RCA | |

| Specific Density (OD) (g/cm3) | 2.67 | 2.66 | 2.59 | 2.57 | 2.25 |

| Specific Density (SSD) (g/cm3) | 2.65 | 2.60 | 2.47 | 2.60 | 2.39 |

| Bulk Density (g/cm3) | 1.38 | 1.38 | 1.37 | 1.42 | 1.31 |

| Water Absorption (%) | 0.72 | 1.20 | 4.73 | 1.20 | 6.40 |

| Form Factor | 2.09 | 2.07 | 2.19 | 1.87 | 1.97 |

| Cement Paste Content (%) | 0.00 | 15.10 | 46.20 | - | - |

| Concrete Samples | Compressive Strength—7 Days—(MPa) | Compressive Strength—28 Days—(MPa) |

|---|---|---|

| NA100 | 27.6 | 35.5 |

| RCA25NA75 | 22.6 | 27.4 |

| RCA50NA50 | 27 | 30.6 |

| RCA75NA25 | 22.7 | 26.8 |

| RCA100 | 19.7 | 23.8 |

| RJA25NA75 | 21 | 25.7 |

| RJA50NA50 | 23.9 | 30.4 |

| RJA75NA25 | 23.7 | 30.7 |

| RJA100 | 28 | 33.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, A.B.; Sampaio, C.H.; Moncunill, J.O.; Lima, M.M.D.; Herrera La Rosa, G.T.; Veras, M.M.; Ambrós, W.M.; Cazacliu, B.G.; Solsona, A. Reuse of Coarse Aggregates Recovered from Demolished Concrete Through the Jigging Concentration Process in New Concrete Formulations. Materials 2025, 18, 4310. https://doi.org/10.3390/ma18184310

Teixeira AB, Sampaio CH, Moncunill JO, Lima MMD, Herrera La Rosa GT, Veras MM, Ambrós WM, Cazacliu BG, Solsona A. Reuse of Coarse Aggregates Recovered from Demolished Concrete Through the Jigging Concentration Process in New Concrete Formulations. Materials. 2025; 18(18):4310. https://doi.org/10.3390/ma18184310

Chicago/Turabian StyleTeixeira, Artur Bressanelli, Carlos Hoffmann Sampaio, Josep Oliva Moncunill, Monica Mariana Davila Lima, Grethel Tamara Herrera La Rosa, Moacir Medeiros Veras, Weslei Monteiro Ambrós, Bogdan Grigore Cazacliu, and Albert Solsona. 2025. "Reuse of Coarse Aggregates Recovered from Demolished Concrete Through the Jigging Concentration Process in New Concrete Formulations" Materials 18, no. 18: 4310. https://doi.org/10.3390/ma18184310

APA StyleTeixeira, A. B., Sampaio, C. H., Moncunill, J. O., Lima, M. M. D., Herrera La Rosa, G. T., Veras, M. M., Ambrós, W. M., Cazacliu, B. G., & Solsona, A. (2025). Reuse of Coarse Aggregates Recovered from Demolished Concrete Through the Jigging Concentration Process in New Concrete Formulations. Materials, 18(18), 4310. https://doi.org/10.3390/ma18184310