Utilization of Hazel (Corylus avellana L.) Wood Particles in the Production of Three-Layer Particleboards for Furniture and Interior Applications

Abstract

1. Introduction

2. Materials and Methods

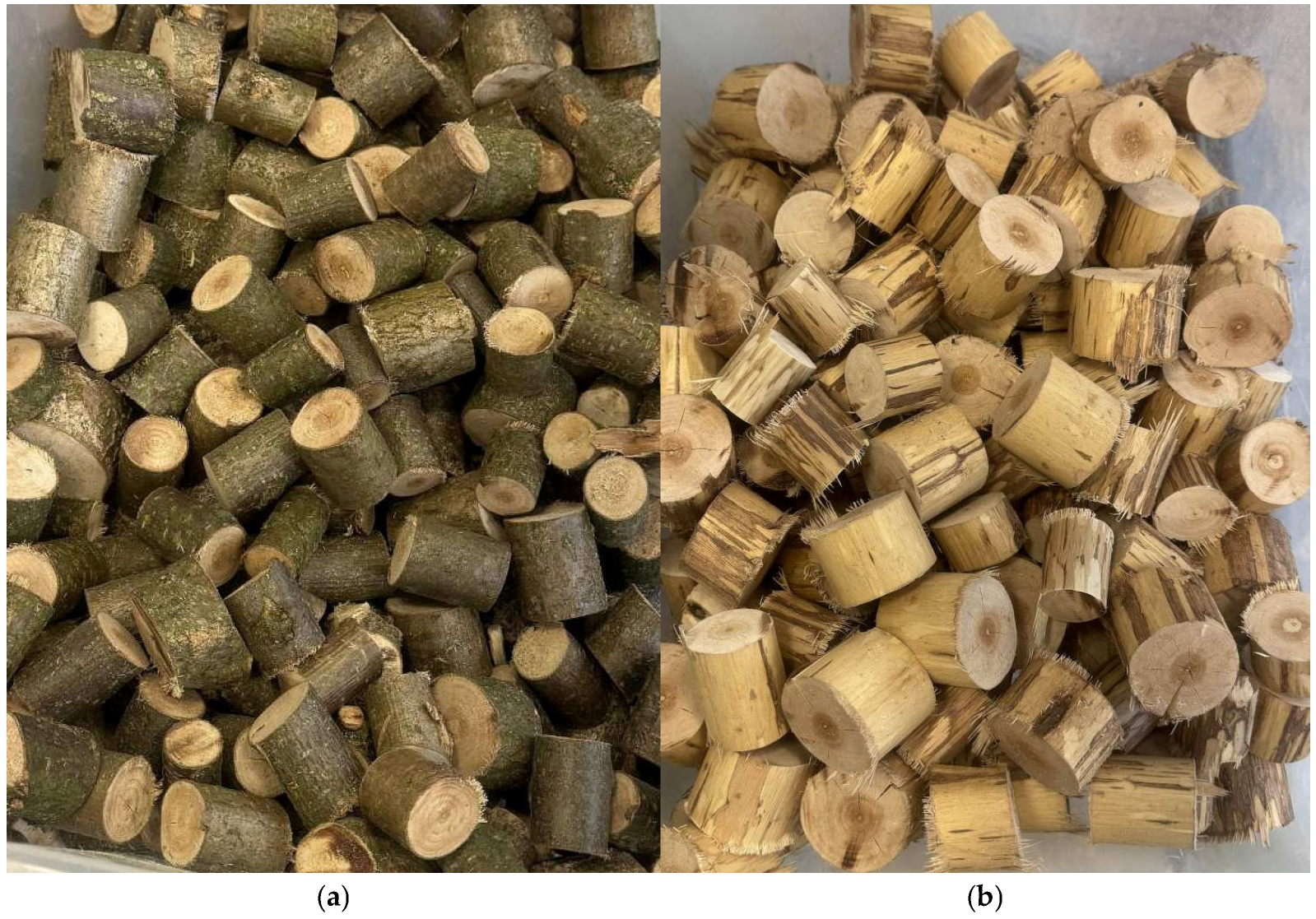

2.1. Materials

2.2. Sample Preparation

2.3. Characterization of the Manufactured Panels

2.4. Statistical Analysis

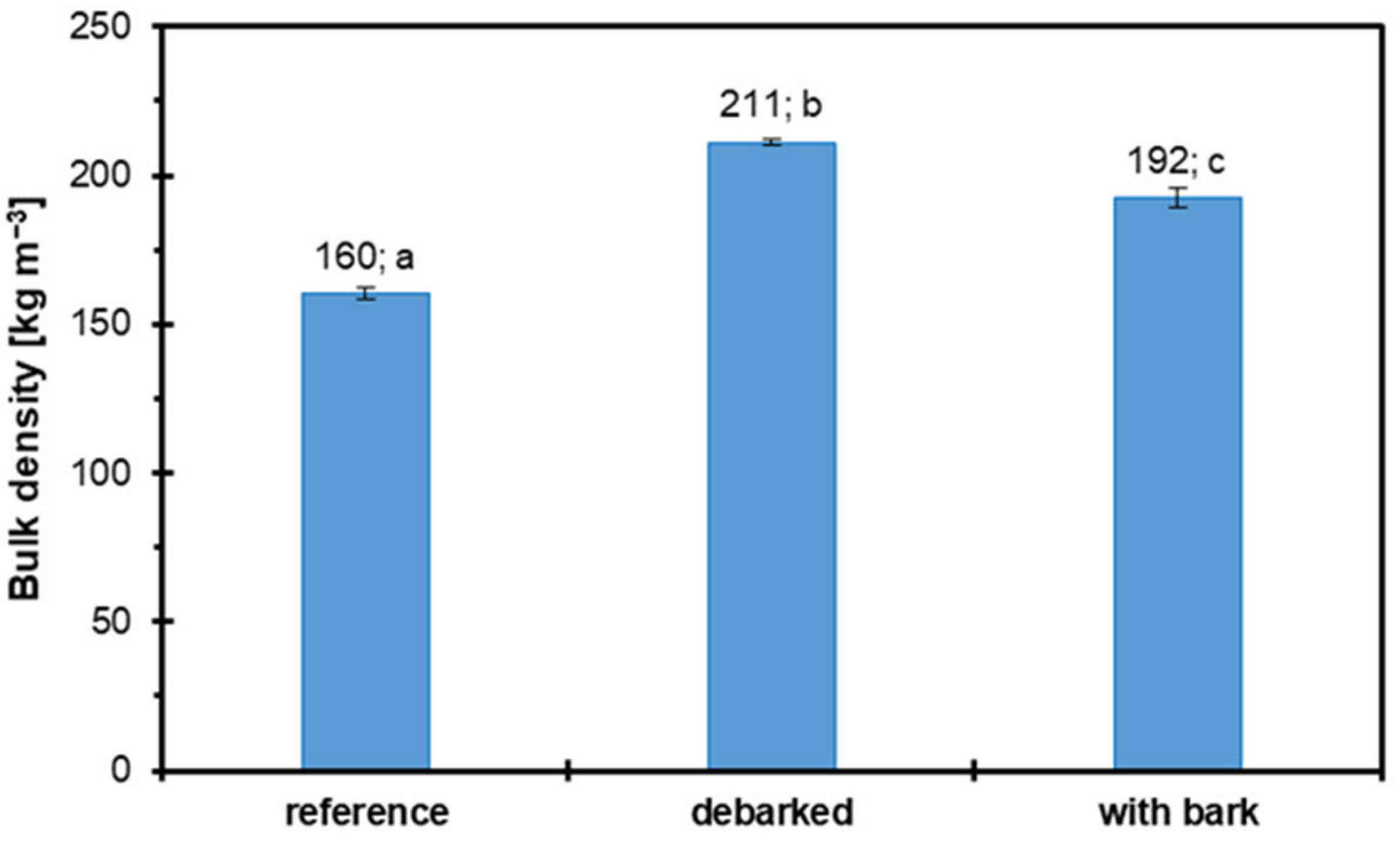

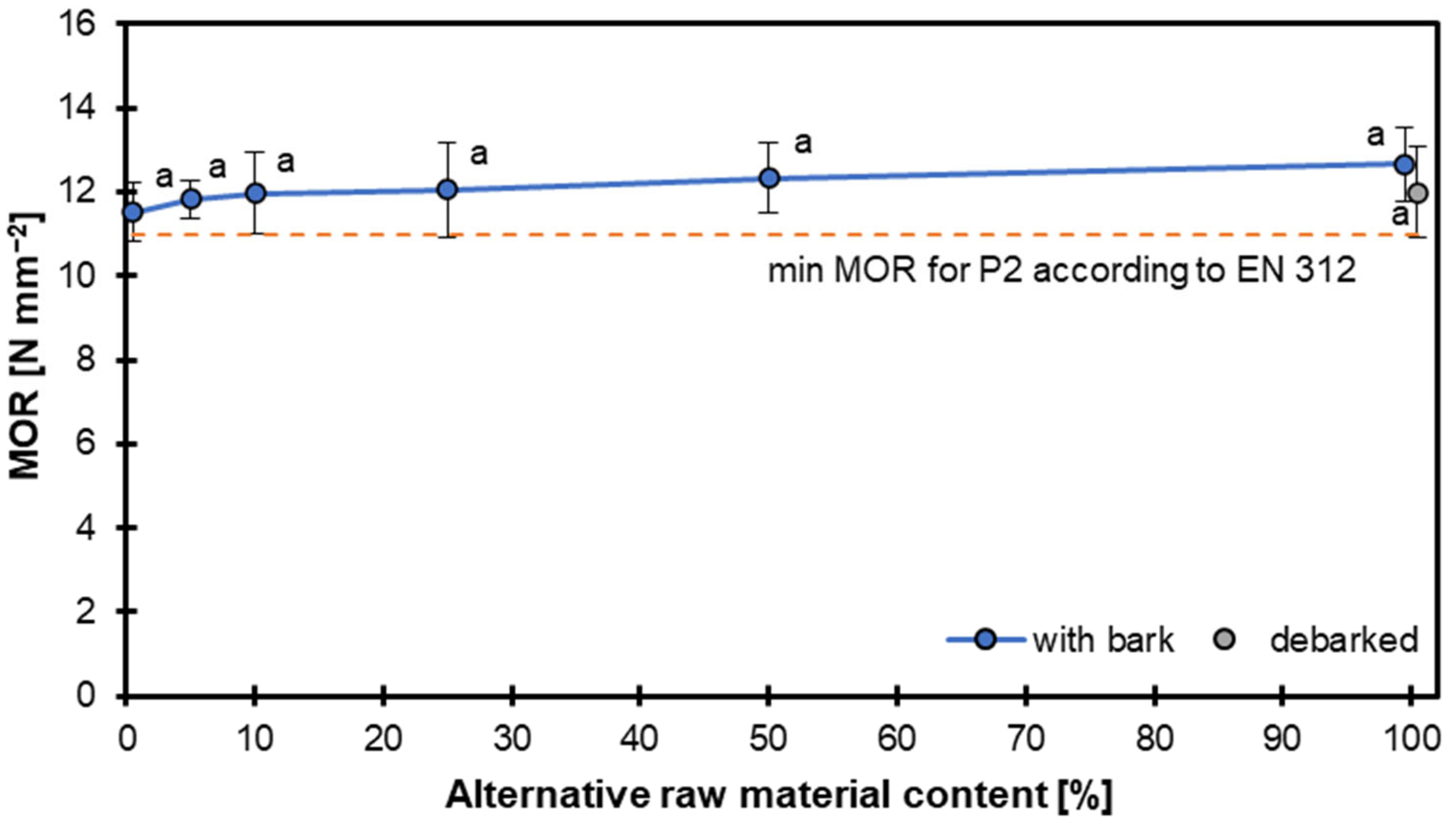

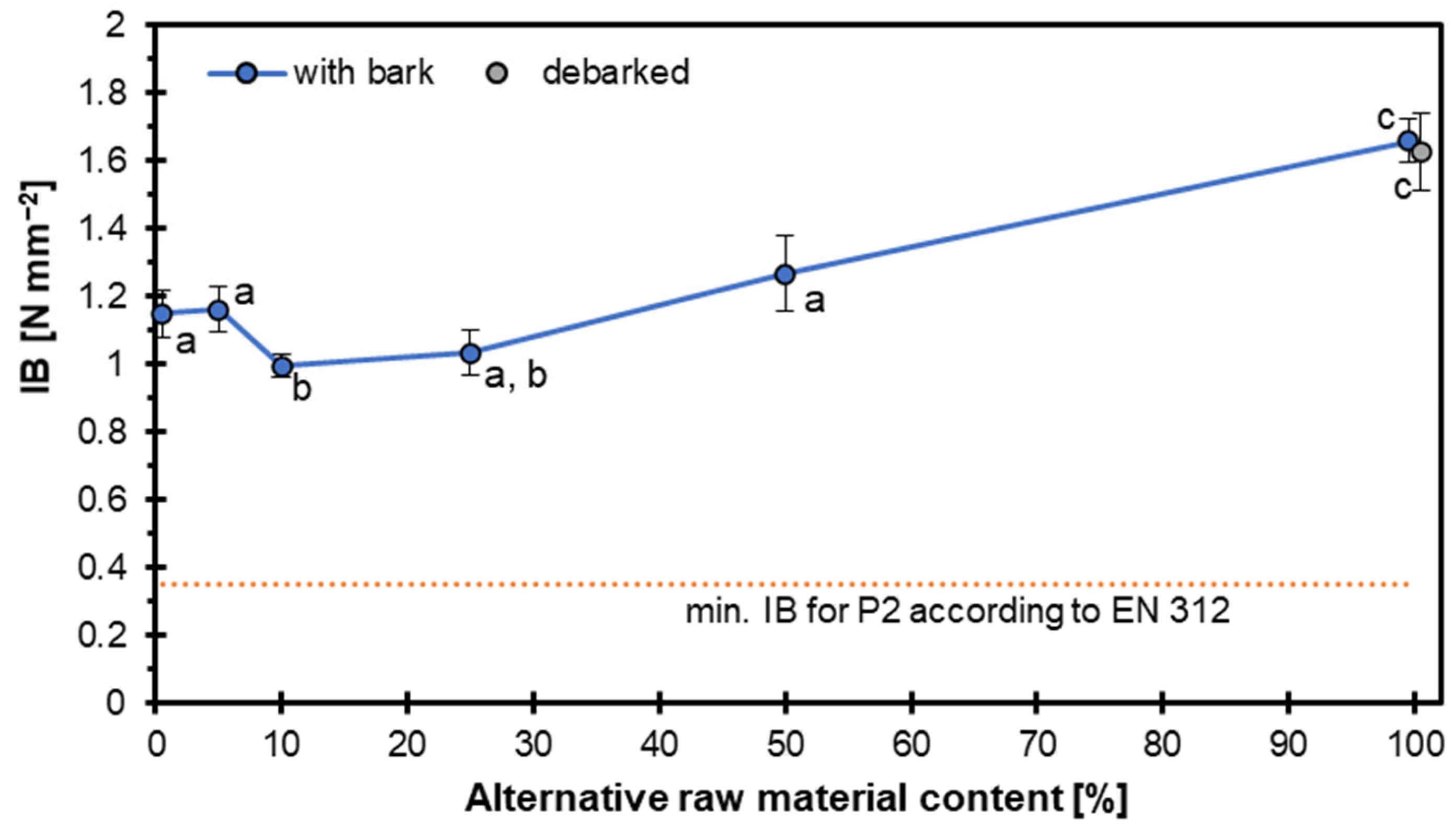

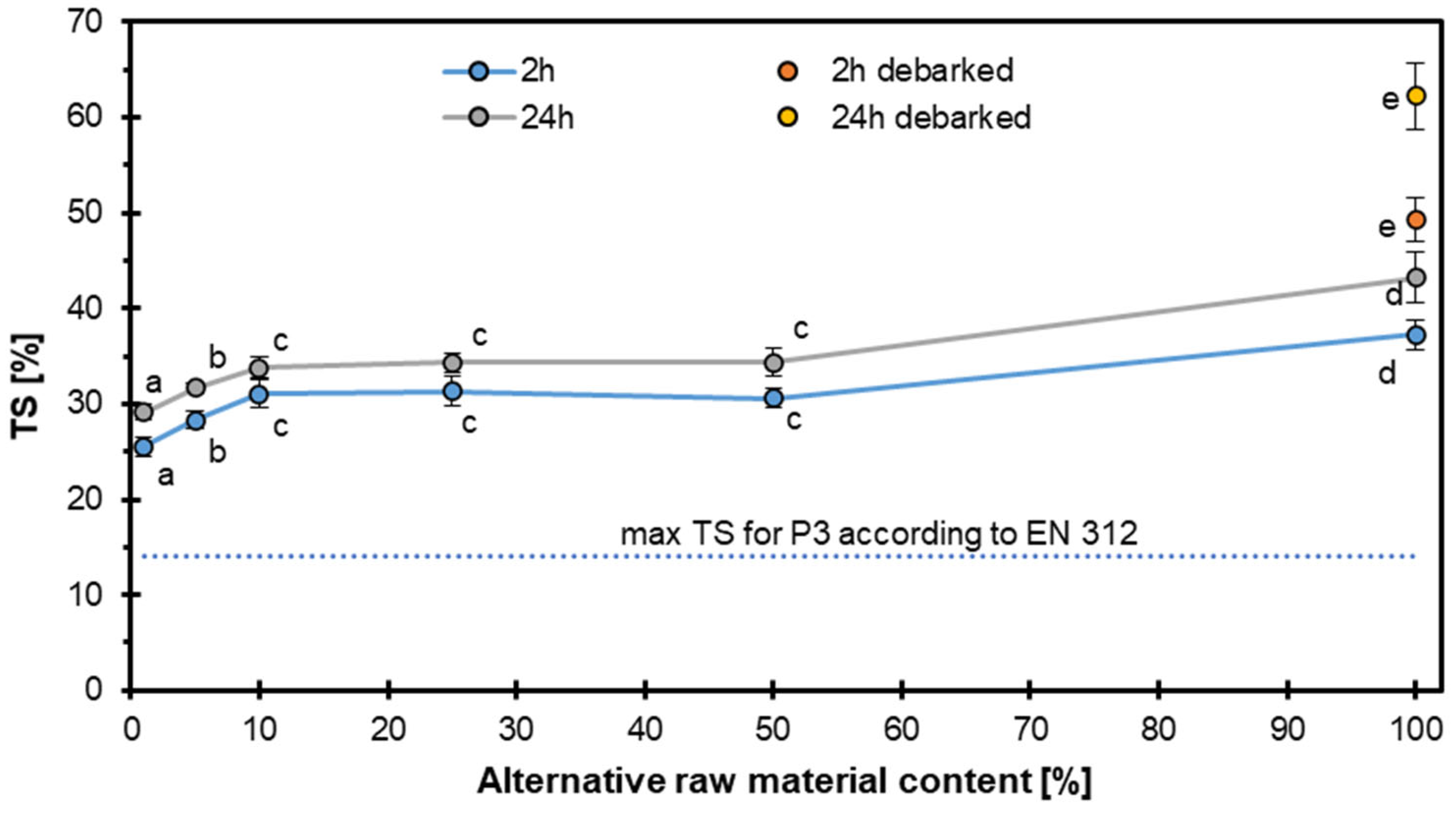

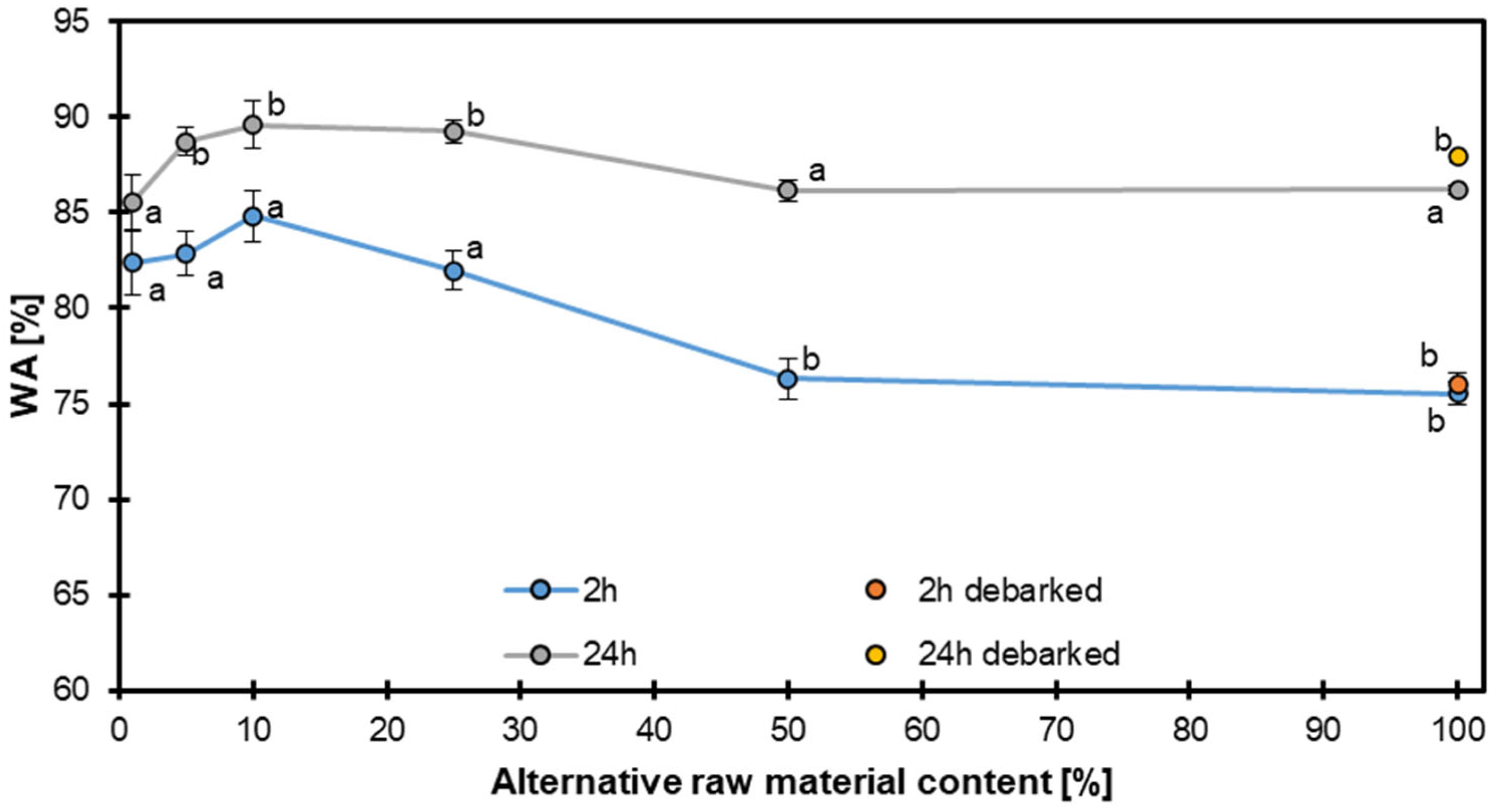

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaputa, V. Rynek Materiałów Drzewnych w Polsce. Intercathedra 2004, 20, 74–78. [Google Scholar] [CrossRef]

- Ratajczak, E. Sustainable Management of Wood Resources in Poland. An Introduction. (Zrównoważona Gospodarka Zasobami Surowca Drzewnego w Polsce. Wprowadzenie). Konsumpcja Rozw. 2014, 7, 15–27. [Google Scholar]

- Yorur, H.; Birinci, E.; Gunay, M.N.; Tor, O. Effects of Factors on Direct Screw Withdrawal Resistance in Medium Density Fiberboard and Particleboard. Maderas Cienc. Tecnol. 2020, 22, 375–384. [Google Scholar] [CrossRef]

- Nemli, G.; Aydin, I.; Zekoviç, E. Evaluation of Some of the Properties of Particleboard as Function of Manufacturing Parameters. Mater. Des. 2007, 28, 1169–1176. [Google Scholar] [CrossRef]

- Dukarska, D.; Kawalerczyk, J.; Sedliačik, J.; Antov, P.; Unisa, M. Alternative Wood Raw Material Sources in Particleboard and OSB Production—Challenges and Perspectives. Polymers 2025, 17, 1760. [Google Scholar] [CrossRef]

- Sydor, M. Drewno w Budowie Maszyn: Historia Najważniejszego Tworzywa; Wydawnictwo Uniwersytetu Przyrodniczego w Poznaniu: Poznań, Poland, 2011; ISBN 9788371606298. [Google Scholar]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative Lignocellulosic Raw Materials in Particleboard Production: A Review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- García-Ortuño, T.; Andréu-Rodríguez, J.; Ferrández-García, M.T.; Ferrández-Villena, M.; Ferrández-García, C.E. Evaluation of the Physical and Mechanical Properties of Particleboard Made from Giant Reed (Arundo donax L.). BioResources 2011, 6, 477–486. [Google Scholar] [CrossRef]

- Mantanis, G.; Nakos, P.; Rigal, L. Turning Agricultural Straw Residues into Value-Added Composite Products: A New Environmentally Friendly Technology. In Proceedings of the 5th International Conference on Environmental Pollution, Thessaloniki, Greece, 28 August–1 September 2000; pp. 840–848. [Google Scholar]

- Valarelli, I.D.; Battistelle, R.A.G.; Branco, L.A.M.N.; Chahud, E.; Christoforo, A.L.; Rocco Lahr, F.A.; Bezerra, B.S. Evaluation of Bamboo Particleboards Produced with Urea-Formaldheyde Resin. Adv. Mater. Res. 2014, 1025–1026, 432–435. [Google Scholar] [CrossRef]

- Grigorov, R.; Savov, V. Mechanical Properties of Three-Layered Particleboards with Face Layers of Beech and Oak Particles and a Core Layer of Conifer and Sunflower Stalks Particles. In Innovation in Woodworking Industry and Engineering Design; Trichkov, N., Angelova, D., Minkovski, N., Savov, V., Vitchev, P., Eds.; University of Forestry—Faculty of Forest Industry: Sofia, Bulgaria, 2023; Volume 2, pp. 60–69. [Google Scholar]

- Güler, C.; Bektas, I.; Kalaycioglu, H. The Experimental Particleboard Manufacture from Sunflower Stalks. Forest 2006, 56, 56–60. [Google Scholar]

- Neitzel, N.; Hosseinpourpia, R.; Adamopoulos, S. Effect of Press Temperature on Oat Husk Particleboards Bound with a Dialdehyde Starch Adhesive. Res. Sq. 2023, 3–8. [Google Scholar] [CrossRef]

- Frąckowiak, I.; Fuczek, D.; Kowaluk, G. Impact of Different Lignocelluosic Materials Used in Core of Particleboard on Modulus of Elasticity and Bending Strength. Drewno. Pr. Naukowe. Doniesienia. Komun. 2008, 51, 5–14. [Google Scholar]

- Reh, R.; Kristak, L.; Kral, P.; Pipiska, T.; Jopek, M. Perspectives on Using Alder, Larch, and Birch Wood Species to Maintain the Increasing Particleboard Production Flow. Polymers 2024, 16, 1532. [Google Scholar] [CrossRef] [PubMed]

- Çöpür, Y.; Güler, C.; Akgül, M.; Taşçioǧlu, C. Some Chemical Properties of Hazelnut Husk and Its Suitability for Particleboard Production. Build. Environ. 2007, 42, 2568–2572. [Google Scholar] [CrossRef]

- Rolnik, A.; Olas, B. Orzechy Leszczyny Pospolitej (Corylus avellana) i Jej Inne Organy Jako Bogate Źródło Związków o Właściwościach Prozdrowotnych. Kosmos 2018, 67, 643–646. [Google Scholar] [CrossRef]

- Matuszkiewicz, W.; Szwed, W.; Sikorski, P.; Wierzba, M. Zbiorowiska Roślinne Polski. Lasy i Zarośla; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2012. [Google Scholar]

- Zanne, A.E.; Lopez-Gonzalez, G.; Coomes, D.A.; Ilic, J.; Jansen, S.; Lewis, S.L.; Miller, R.B.; Swenson, N.G.; Wiemann, M.C.; Chave, J. Global Wood Density Database. Dryad Identifier 2009. [Google Scholar] [CrossRef]

- Krzysik, F. Nauka o Drewnie; Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1975. [Google Scholar]

- Çöpür, Y.; Güler, C.; Taşçioǧlu, C.; Tozluoǧlu, A. Incorporation of Hazelnut Shell and Husk in MDF Production. Bioresour. Technol. 2008, 99, 7402–7406. [Google Scholar] [CrossRef]

- Güler, C.; Çöpür, Y.; Buyuksari, U. Producing Particleboards from Hazelnut (Corylus avellana L.) Husk and European Black Pine (Pinus nigra Arnold). Wood Res. 2009, 54, 125–132. [Google Scholar]

- Karahan, S.; Guler, C. Some Physical and Mechanical Properties of Particle Boards Produced with Hazelnut Husk and Astragalus (Astragalus membranaceus) Plant. Maderas Cienc. Tecnol. 2025, 27, e0225. [Google Scholar] [CrossRef]

- Bilgin, U.; Colakoglu, G. Effect of Using Urea Formaldehyde Modified with Extracts in Plywood on Formaldehyde Emission. Drv. Ind. 2021, 72, 237–244. [Google Scholar] [CrossRef]

- EN 312; Particleboards—Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

- EN 827; Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 310; Wood-Based Panels; Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards; Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 320; Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screws. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 317; Particleboards and Fiberboards—Determination of Swelling in Thickness After Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- Kowaluk, G.; Wronka, A. Selected Physical and Mechanical Properties of Particleboards Produced from Lignocellulosic Particles of Black Chokeberry (Aronia melanocarpa (Michx.) Elliott). Ann. WULS For. Wood Technol. 2020, 112, 60–70. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Influence of Density on Selected Properties of Furniture Particleboards Made of Raspberry Rubus idaeus L. Lignocellulosic Particles. Ann. WULS For. Wood Technol. 2019, 105, 113–124. [Google Scholar] [CrossRef]

- Zeidler, A. Variation of Wood Density in Turkish Hazel (Corylus colurna L.) Grown in the Czech Republic. J. For. Sci. 2012, 58, 145–151. [Google Scholar] [CrossRef]

- Jeżo, A.; Wronka, A.; Dębiński, A.; Kristak, L.; Reh, R.; Rizhikovs, J.; Kowaluk, G. Influence of Upcycled Post-Treatment Bark Biomass Addition to the Binder on Produced Plywood Properties. Forests 2023, 14, 110. [Google Scholar] [CrossRef]

- Nelis, P.A.; Mai, C. The Influence of Low-Density (Paulownia spp.) and High-Density (Fagus sylvatica L.) Wood Species on Various Characteristics of Light and Medium-Density Three-Layered Particleboards. Wood Mater. Sci. Eng. 2021, 16, 21–26. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. Upcycling Different Particle Sizes and Contents of Pine Branches into Particleboard. Polymers 2022, 14, 4559. [Google Scholar] [CrossRef]

- Laemlaksakul, V. Physical and Mechanical Properties of Particleboard from Bamboo Waste. Int. J. Mater. Metall. Eng. 2010, 4, 276–280. [Google Scholar] [CrossRef]

- Pirayesh, H.; Moradpour, P.; Sepahvand, S. Particleboard from Wood Particles and Sycamore Leaves: Physico-Mechanical Properties. Eng. Agric. Environ. Food 2015, 8, 38–43. [Google Scholar] [CrossRef]

- Barbu, M.C.; Sepperer, T.; Tudor, E.M.; Petutschnigg, A. Walnut and Hazelnut Shells: Untapped Industrial Resources and Their Suitability in Lignocellulosic Composites. Appl. Sci. 2020, 10, 6340. [Google Scholar] [CrossRef]

- Warmbier, K.; Wilczyński, A.; Danecki, L. Properties of One-Layer Experimental Particleboards from Willow (Salix viminalis) and Industrial Wood Particles. Eur. J. Wood Wood Prod. 2013, 71, 25–28. [Google Scholar] [CrossRef][Green Version]

- Thoemen, H.; Irle, M.; Sernek, M. Wood-Based Panels—An Introduction for Specialists; Brunel University Press: Uxbridge, UK, 2010; ISBN 9781902316826. [Google Scholar]

- Sellers, T.J. Wood Adhesive Innovations and Applications in North America. For. Prod. J. 2001, 51, 12–22. [Google Scholar][Green Version]

- Şahin, H.İ. The Potential of Using Forest Waste as a Raw Material in Particleboard Manufacturing. BioResources 2020, 15, 7780–7795. [Google Scholar] [CrossRef]

- Pędzik, M.; Tomczak, K.; Janiszewska-Latterini, D.; Tomczak, A.; Rogoziński, T. Management of Forest Residues as a Raw Material for the Production of Particleboards. Forests 2022, 13, 1933. [Google Scholar] [CrossRef]

- Czarnecki, R.; Dukarska, D.; Kawalerczyk, J.; Filipski, A. Utilization of Pine and Birch Juvenile Wood for Low-Density Particleboard Production. Materials 2025, 18, 1140. [Google Scholar] [CrossRef] [PubMed]

- Camlibel, O. Influence of the Multiday and Continuous Hot Press on the Physical, Mechanical and Formaldehyde Emission Properties of the Particleboard. Maderas Cienc. Tecnol. 2023, 25, e0723. [Google Scholar] [CrossRef]

- Lykidis, C.; Grigoriou, A.; Barboutis, I. Utilisation of Wood Biomass Residues from Fruit Tree Branches, Evergreen Hardwood Shrubs and Greek Fir Wood as Raw Materials for Particleboard Production. Part A. Mechanical Properties. Wood Mater. Sci. Eng. 2014, 9, 202–208. [Google Scholar] [CrossRef]

- Pereira, A.A.C.; d’Almeida, J.R.M. Mechanical and Physical Screw Withdrawal Properties Behavior of Agglomerated Panels Reinforced with Coir and Pejibaye Fibers. Wood Mater. Sci. Eng. 2018, 13, 286–295. [Google Scholar] [CrossRef]

- Hristodorova, D.; Mihailov, V.; Savov, V. Influence of Density on the Withdrawal Staple Strength from Hemp Shive Panels. Bull. Transilv. Univ. Brasov Ser. II For. Wood Ind. Agric. Food Eng. 2023, 16, 117–126. [Google Scholar] [CrossRef]

- Wronka, A.; Kowaluk, G. The Influence of Multiple Mechanical Recycling of Particleboards on Their Selected Mechanical and Physical Properties. Materials 2022, 15, 8487. [Google Scholar] [CrossRef]

- Rammou, E.; Mitani, A.; Ntalos, G.; Koutsianitis, D.; Taghiyari, H.R.; Papadopoulos, A.N. The Potential Use of Seaweed (Posidonia oceanica) as an Alternative Lignocellulosic Raw Material for Wood Composites Manufacture. Coatings 2021, 11, 69. [Google Scholar] [CrossRef]

- Nemli, G.; Aydin, A. Evaluation of the Physical and Mechanical Properties of Particleboard Made from the Needle Litter of Pinus Pinaster Ait. Ind. Crops Prod. 2007, 26, 252–258. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Performance Properties of Microcrystalline Cellulose as a Reinforcing Agent in Wood Plastic Composites. Compos. Part B Eng. 2010, 41, 578–581. [Google Scholar] [CrossRef]

- Kord, B.; Hemmasi, A.H.; Ghasemi, I. Properties of PP/Wood Flour/Organomodified Montmorillonite Nanocomposites. Wood Sci. Technol. 2011, 45, 111–119. [Google Scholar] [CrossRef]

- Najafi, S.K.; Hamidinia, E.; Tajvidi, M. Mechanical Properties of Composites from Sawdust and Recycled Plastics. J. Appl. Polym. Sci. 2006, 100, 3641–3645. [Google Scholar] [CrossRef]

- Kowaluk, G.; Szymanowski, K.; Kozłowski, P.; Kukuła, W.; Sala, C.; Robles, E.; Czarniak, P. Functional Assessment of Particleboards Made of Apple and Plum Orchard Pruning. Waste Biomass Valorization 2020, 11, 2877–2886. [Google Scholar] [CrossRef]

| Panel Name (Variant) | Hazel Wood Particle Content [% by Weight] | Industrial Particle Content [% by Weight] | ||

|---|---|---|---|---|

| Face Layer | Core Layer | Face Layer | Core Layer | |

| 0 | 0 | 0 | 100 | 100 |

| 5 | 5 | 5 | 95 | 95 |

| 10 | 10 | 10 | 90 | 90 |

| 25 | 25 | 25 | 75 | 75 |

| 50 | 50 | 50 | 50 | 50 |

| 100 | 100 | 100 | 0 | 0 |

| 100 DB * | 100 * | 100 * | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rukat, P.; Kowaluk, G. Utilization of Hazel (Corylus avellana L.) Wood Particles in the Production of Three-Layer Particleboards for Furniture and Interior Applications. Materials 2025, 18, 4261. https://doi.org/10.3390/ma18184261

Rukat P, Kowaluk G. Utilization of Hazel (Corylus avellana L.) Wood Particles in the Production of Three-Layer Particleboards for Furniture and Interior Applications. Materials. 2025; 18(18):4261. https://doi.org/10.3390/ma18184261

Chicago/Turabian StyleRukat, Paulina, and Grzegorz Kowaluk. 2025. "Utilization of Hazel (Corylus avellana L.) Wood Particles in the Production of Three-Layer Particleboards for Furniture and Interior Applications" Materials 18, no. 18: 4261. https://doi.org/10.3390/ma18184261

APA StyleRukat, P., & Kowaluk, G. (2025). Utilization of Hazel (Corylus avellana L.) Wood Particles in the Production of Three-Layer Particleboards for Furniture and Interior Applications. Materials, 18(18), 4261. https://doi.org/10.3390/ma18184261