A Review of Hybrid Manufacturing: Integrating Subtractive and Additive Manufacturing

Abstract

1. Introduction—Origins of Hybrid Manufacturing

1.1. Additive Manufacturing (AM)

1.2. Subtractive Manufacturing (SM)

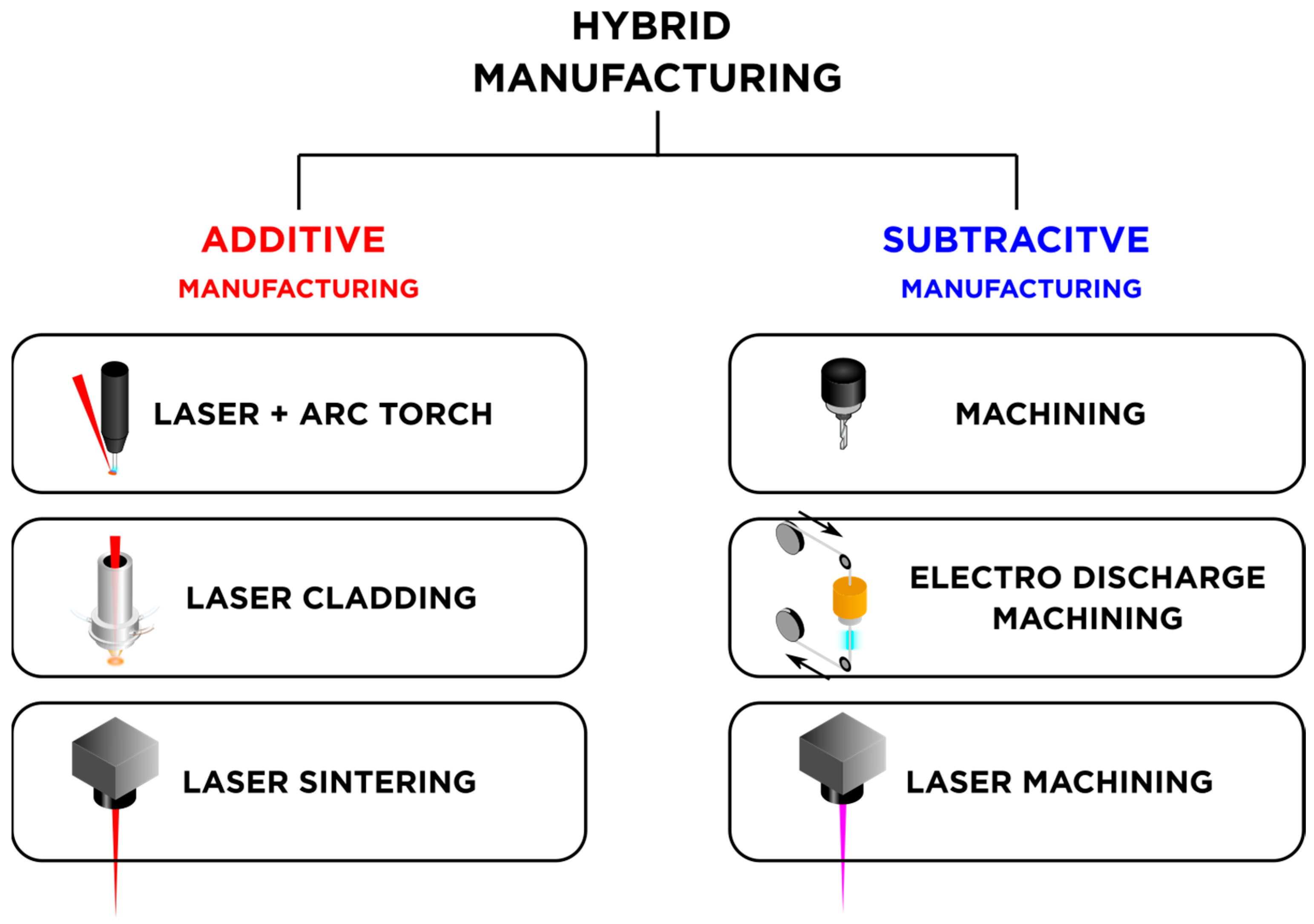

1.3. Hybrid Manufacturing (HM)

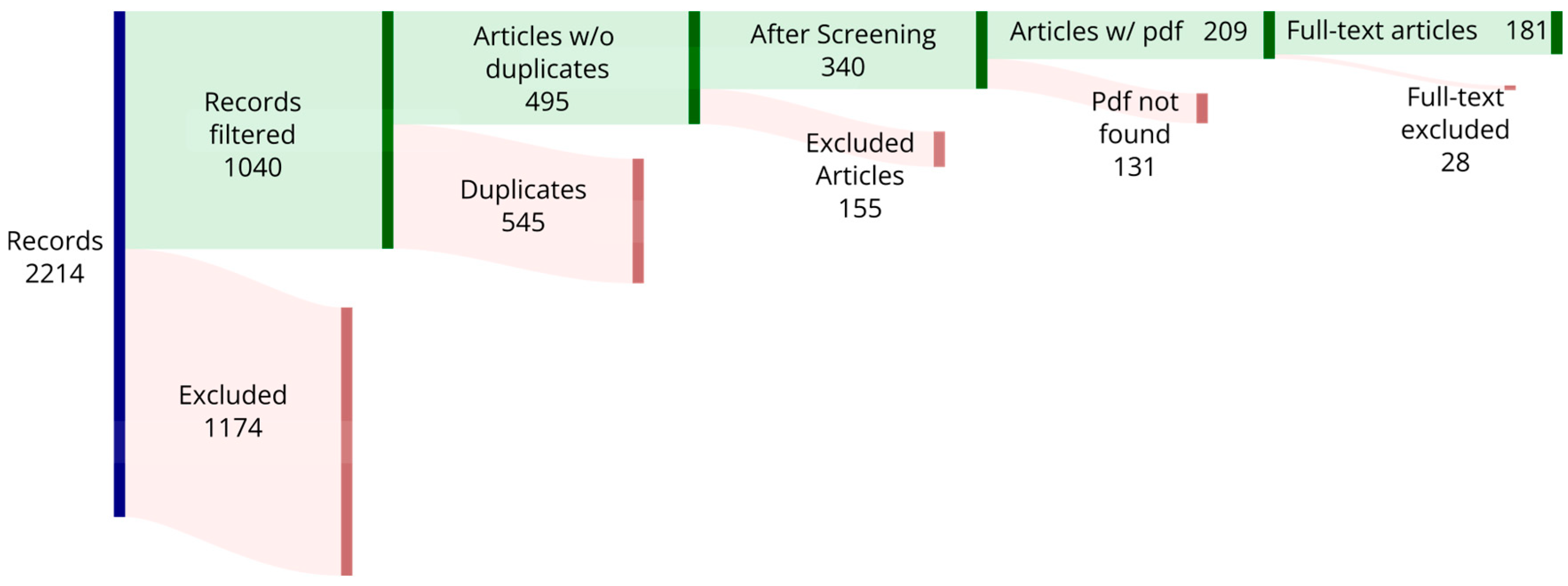

2. Methodology—Literature Search

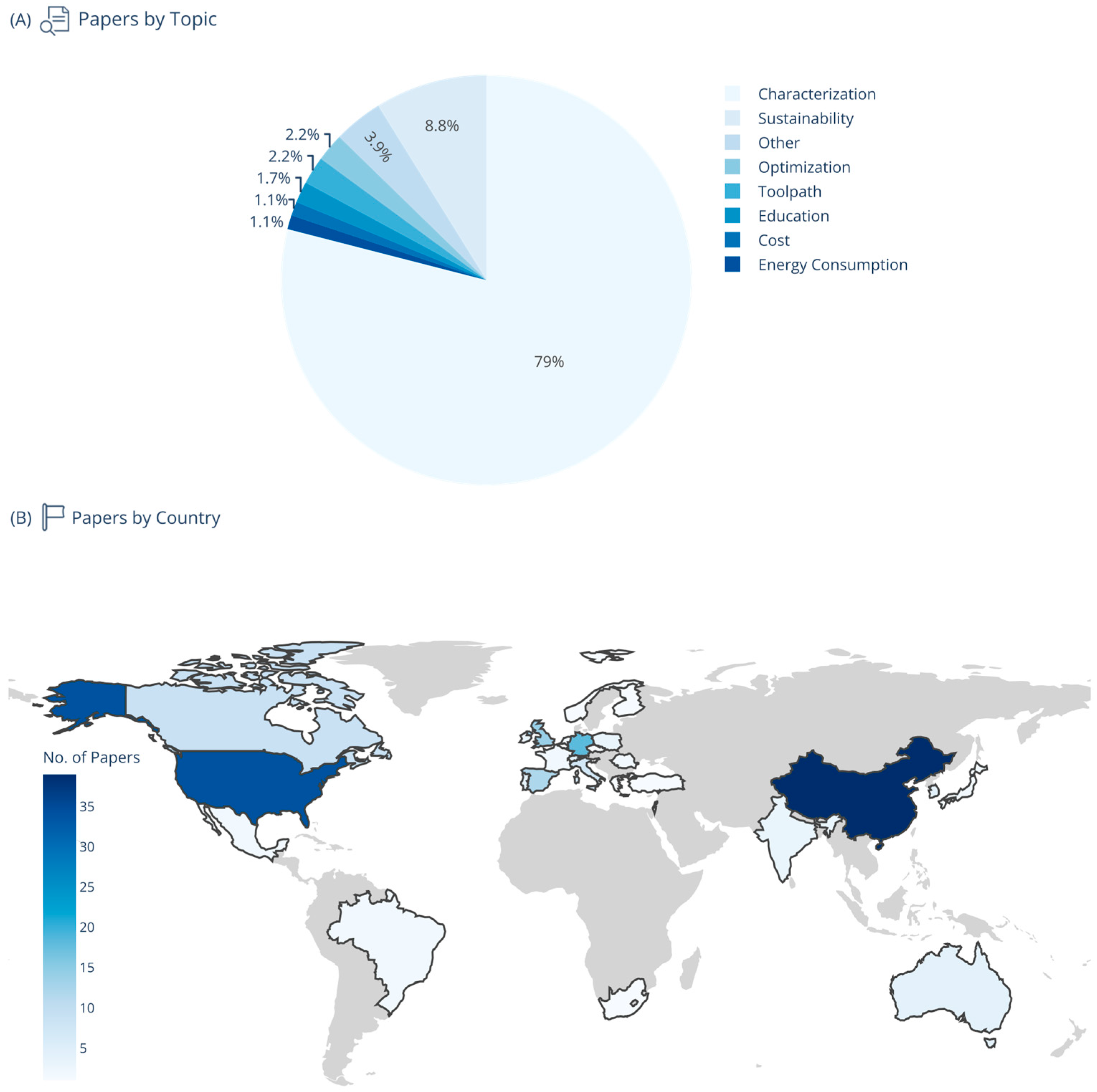

3. Results from Literature Overview

4. Hybrid Manufacturing Machines

4.1. Types of Hybrid Machines

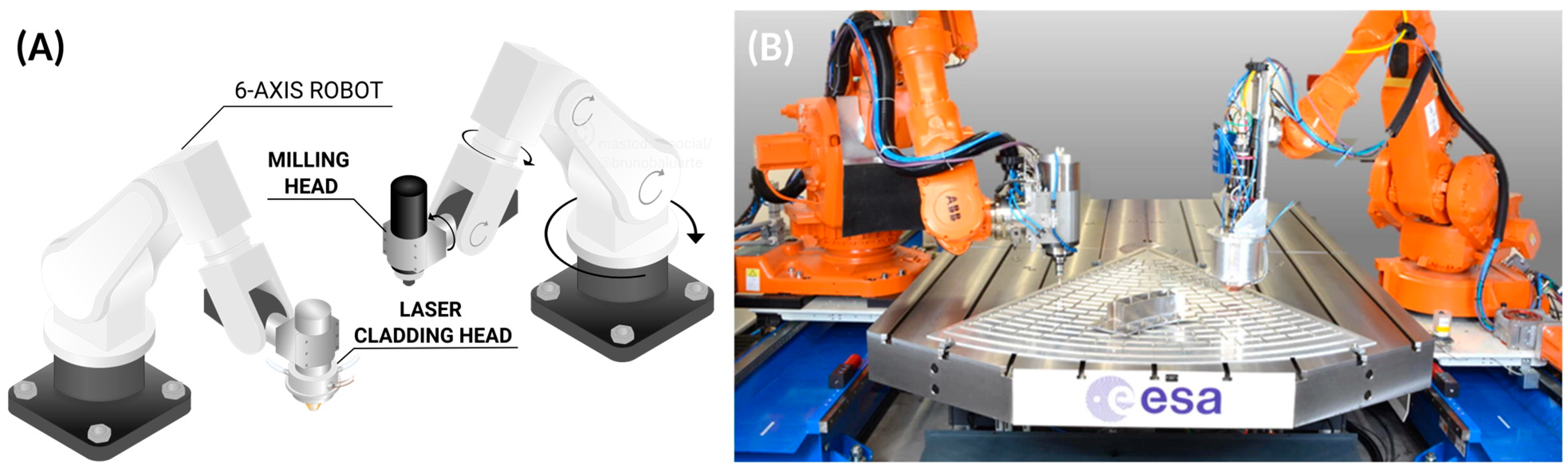

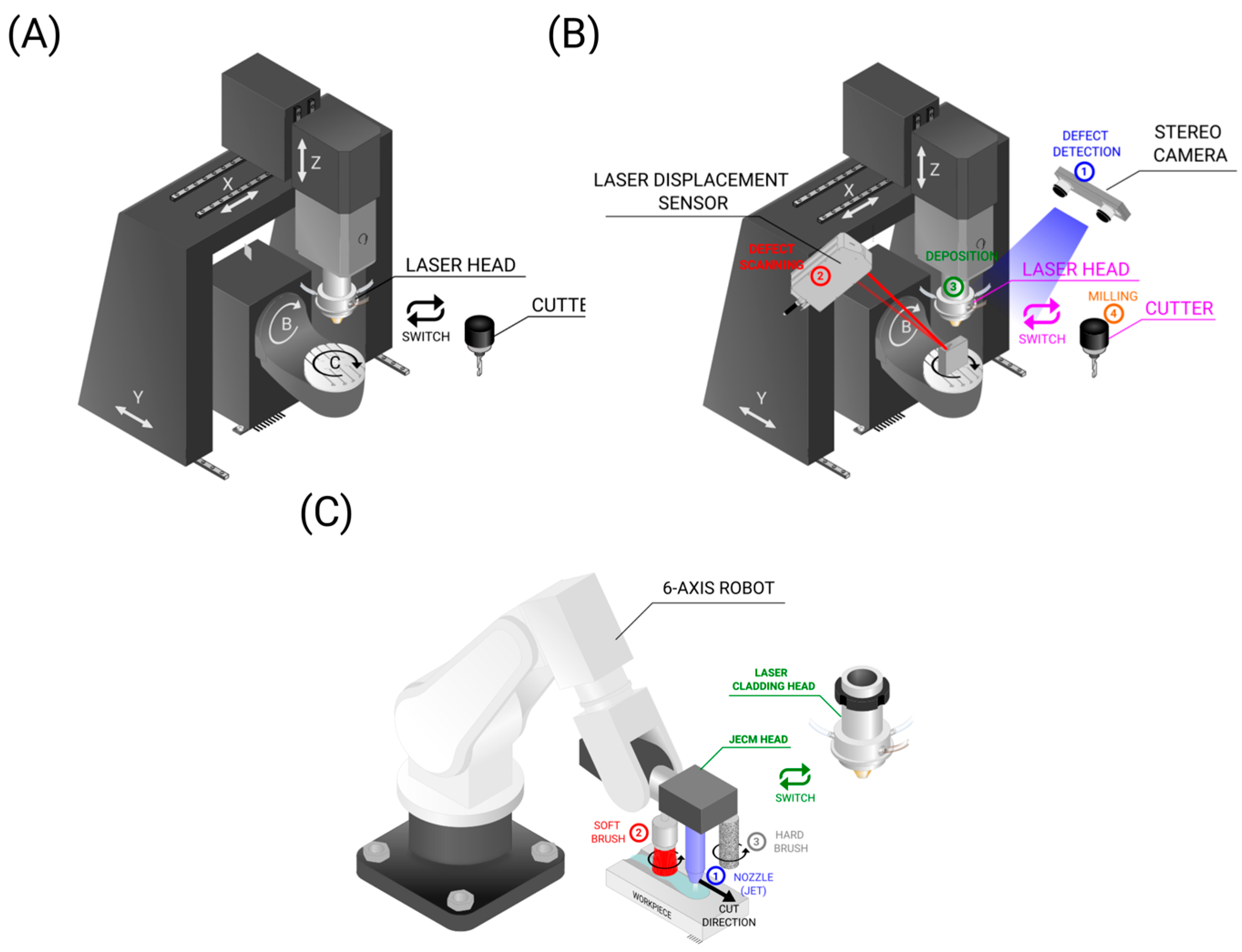

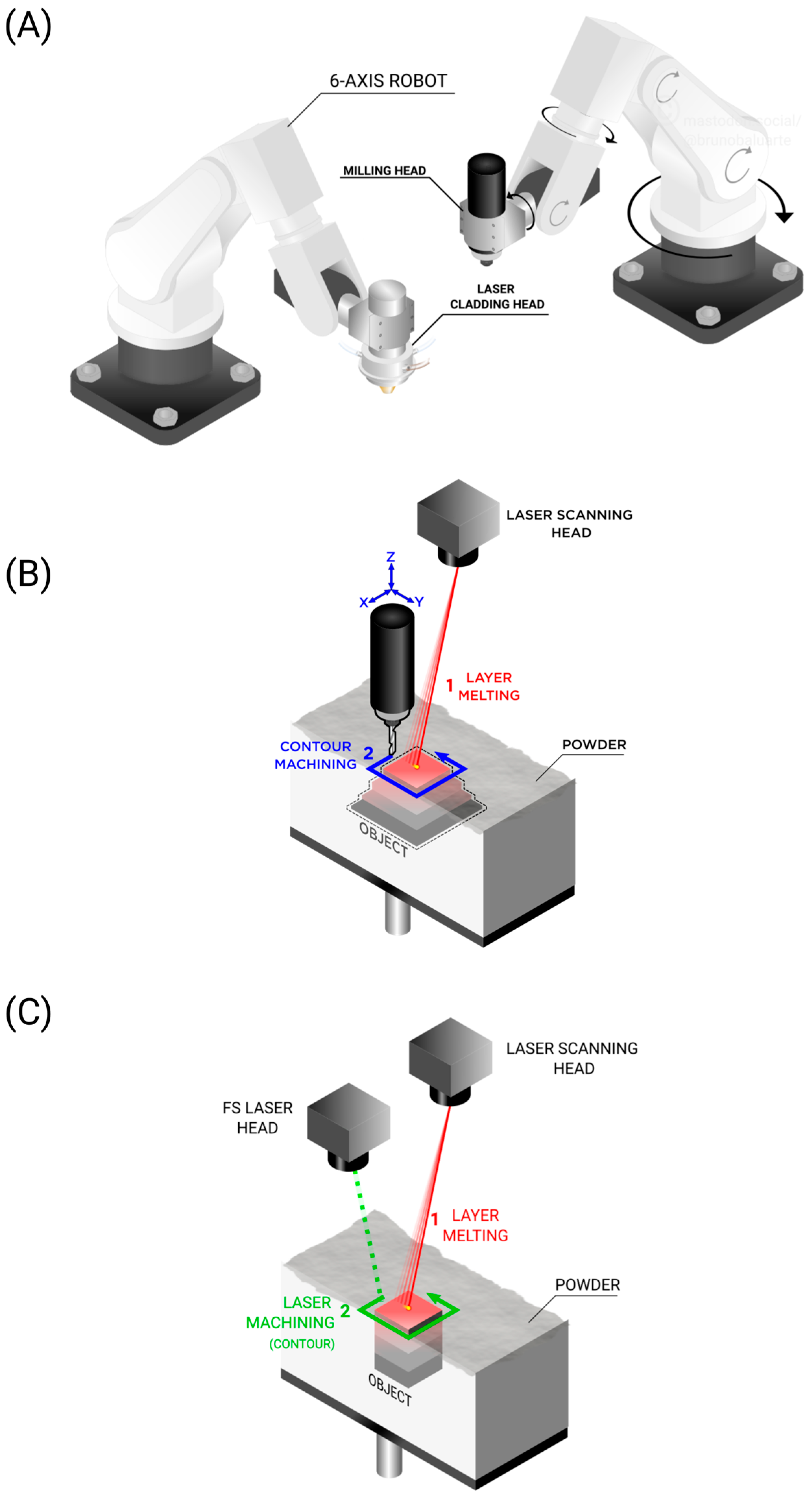

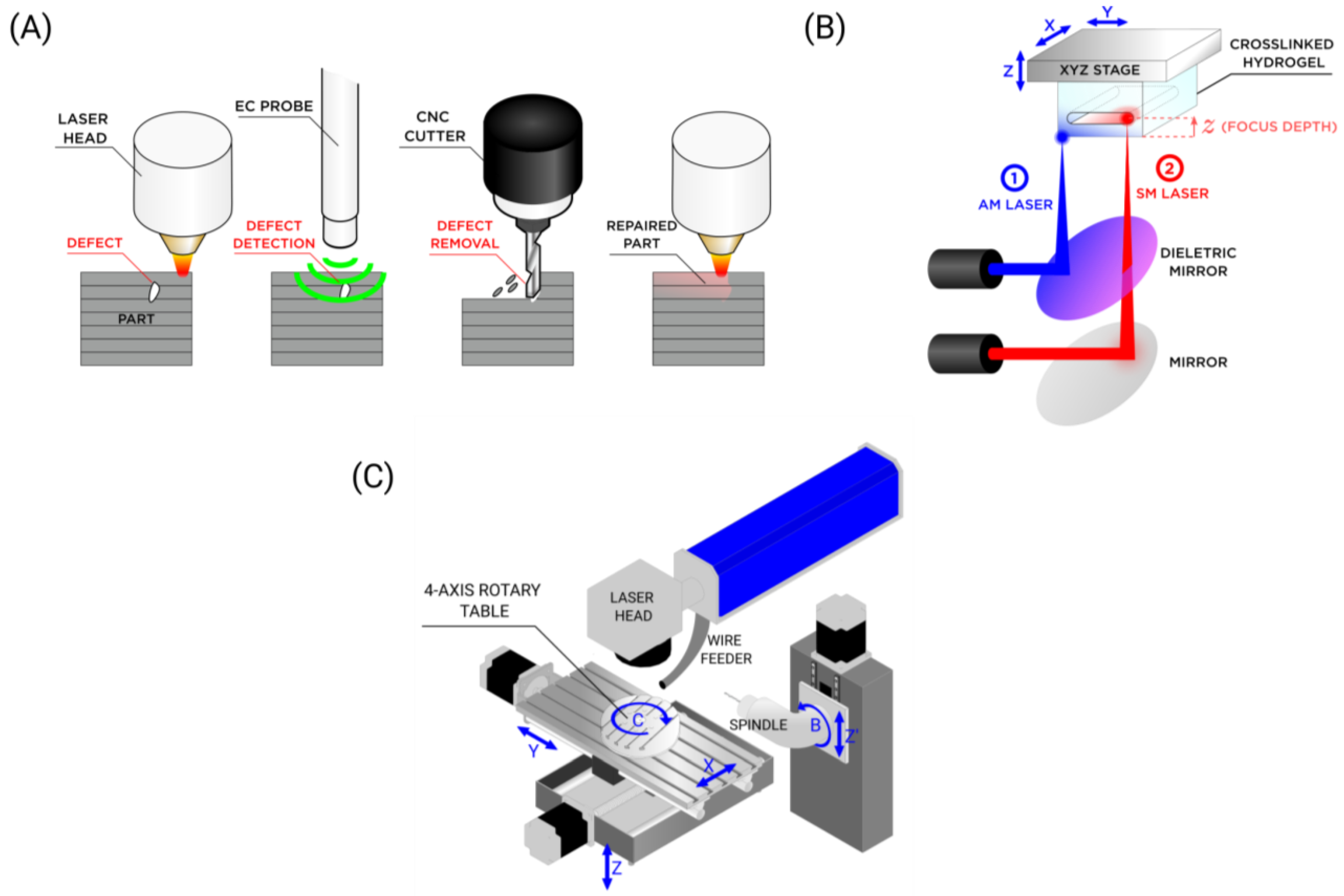

- Separate machines: This involves two separate machines, one for AM and another for SM, that are operated independently. This does not resemble a hybrid machine (Figure 11A).

- Single hybrid machine: This refers to a hybrid machine with changeable heads that work in shifts: one head for AM and another for SM. These can either be changed automatically or manually (Figure 11B).

- Continuous hybrid machine: This refers to a hybrid machine that can perform AM and SM synergistically. The AM and SM systems can work in shifts or simultaneously. The worktable can either be fixed or movable, functioning as an additional CNC machine for positioning of the part with respect to the laser head or milling tool. Instead of a milling tool, another laser can be used, and instead of a worktable, a powder bed may be used (Figure 11C).

4.2. Hybrid Machine Modes of Operation

5. Hybrid Manufacturing Categories

6. Manufacturing Processes

7. Raw Materials and Manufactured Parts

8. Recent Advances in Hybrid Manufacturing

9. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Christiansen, T.; Cotte, M.; de Nolf, W.; Mouro, E.; Reyes-Herrera, J.; de Meyer, S.; Vanmeert, F.; Salvadó, N.; Gonzalez, V.; Lindelof, P.E.; et al. Insights into the Composition of Ancient Egyptian Red and Black Inks on Papyri Achieved by Synchrotron-Based Microanalyses. Proc. Natl. Acad. Sci. USA 2020, 117, 27825–27835. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive Manufacturing—A Review of 4D Printing and Future Applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Wu, H.; Fahy, W.P.; Kim, S.; Kim, H.; Zhao, N.; Pilato, L.; Kafi, A.; Bateman, S.; Koo, J.H. Recent Developments in Polymers/Polymer Nanocomposites for Additive Manufacturing. Prog. Mater. Sci. 2020, 111, 100638. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015; Additive Manufacturing—General Principles—Terminology. International Organization for Standardization: Geneva, Switzerland, 2015.

- Singh, D.D.; Mahender, T.; Reddy, A.R. Powder Bed Fusion Process: A Brief Review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- Creative Tools. 3D Printshow 2014 London—Formlabs Form 1 SLA 3D Printer v01. Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:3D_Printshow_2014_London_-_Formlabs_Form_1_SLA_3D_printer_v01_(15150505392).jpg (accessed on 9 February 2024).

- Signage.Professional. Large Format Printing of Black Numbers on a Brushed Aluminum Sheet. Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:Large_Format_Printing_of_Black_Numbers_on_a_Brushed_Aluminum_Sheet.jpg (accessed on 14 February 2024).

- Marco Verch. 3D Printer. Flickr. Available online: https://foto.wuestenigel.com/3d-printer-printing/ (accessed on 4 February 2024).

- Windell Oskay. Scrap Acrylic. Flickr. Available online: https://www.flickr.com/photos/oskay/4439774665 (accessed on 26 January 2024).

- Oak Ridge National Laboratory. ExOne Binder Jet Machine. Flickr. Available online: https://www.flickr.com/photos/37940997@N05/16673206983 (accessed on 2 March 2024).

- Prokešová, L. Demonstration of Laser Welding in Practice. Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:Ukázka_laserového_navařování_v_praxi.png (accessed on 7 February 2024).

- Brigt Roar Skeie. Selective Laser Melting (SLM). NDLA. Available online: https://ndla.no/subject:1:59f2f355-ebf6-4a8c-a0a8-ccd229d2e901/topic:1:6387a82a-d239-4fcd-9bfc-39f86f21ca91/resource:36813874-cb0a-4003-ad5b-b1e1e32396be (accessed on 20 May 2023).

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- McNally, D. Titanium Parts Printed from Powder. Department of Defense Manufacturing Technology Program. Available online: https://www.dodmantech.mil/Media/Images/igphoto/2002808861/ (accessed on 10 March 2024).

- LaserTherm. Detail of Laser Cladding. Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:Detail_of_laser_cladding.png (accessed on 12 March 2024).

- Sureban, R.; Kulkarni, V.N.; Gaitonde, V.N. Modern Optimization Techniques for Advanced Machining Processes—A Review. Mater. Today Proc. 2019, 18, 3034–3042. [Google Scholar] [CrossRef]

- Iliescu, F.-C.; Deaconu, I.-D.; Fartinescu, C.G.; Deaconu, A.-S.; Chirilă, A.-I. Computer Numerically Controlled Device. In Proceedings of the 2015 9th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 7–9 May 2015; pp. 162–165. [Google Scholar]

- Koren, Y. Control of Machine Tools. J. Manuf. Sci. Eng. 1997, 119, 749–755. [Google Scholar] [CrossRef][Green Version]

- Zombieite. CNC Machining Aluminum Billet with Tormach. Flickr. Available online: https://www.flickr.com/photos/78593866@N00/10339203625 (accessed on 15 January 2024).

- Robbie Sproule. What Is it? Easy to Guess. Flickr. Available online: https://www.flickr.com/photos/85278812@N00/2496329104/ (accessed on 18 January 2024).

- WARDJet. WARDJet 5-Axis Cutting Head. Flickr. Available online: https://www.flickr.com/photos/37196272@N08/31550152491 (accessed on 22 January 2024).

- Opt Lasers. Close-Up Shot of CNC Lasers. Pexels. Available online: https://www.pexels.com/photo/close-up-shot-of-cnc-lasers-7254428/ (accessed on 30 January 2024).

- Dezaki, M.L.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Moradi, M.; Ariffin, M.K.A.; Bodaghi, M. A Review on Additive/Subtractive Hybrid Manufacturing of Directed Energy Deposition (DED) Process. Adv. Powder Mater. 2022, 1, 100054. [Google Scholar] [CrossRef]

- Moritz, J.; Seidel, A.; Kopper, M.; Bretschneider, J.; Gumpinger, J.; Finaske, T.; Riede, M.; Schneeweiss, M.; Lopez, E.; Bruckner, F.; et al. Hybrid Manufacturing of Titanium Ti-6Al-4V Combining Laser Metal Deposition and Cryogenic Milling. Int. J. Adv. Manuf. Technol. 2020, 107, 2995–3009. [Google Scholar] [CrossRef]

- Zhu, Z.; Dhokia, V.G.; Nassehi, A.; Newman, S.T. A Review of Hybrid Manufacturing Processes—State of the Art and Future Perspectives. Int. J. Comput. Integr. Manuf. 2013, 26, 596–615. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, J.; Zhang, H.; Kent, N.J.; Diamond, D.; Gilchrist, M.D. 3D Printing of Metallic Microstructured Mould Using Selective Laser Melting for Injection Moulding of Plastic Microfluidic Devices. Micromachines 2019, 10, 595. [Google Scholar] [CrossRef] [PubMed]

- Ostra, T.; Alonso, U.; Veiga, F.; Ortiz, M.; Ramiro, P.; Alberdi, A. Analysis of the Machining Process of Inconel 718 Parts Manufactured by Laser Metal Deposition. Materials 2019, 12, 2159. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Bai, Q.; Wang, Y.; Zhang, B. Eddy Current Detection of Subsurface Defects for Additive/Subtractive Hybrid Manufacturing. Int. J. Adv. Manuf. Technol. 2018, 95, 3185–3195. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Nedic, C. Stereo Vision-Based Repair of Metallic Components. Rapid Prototyp. J. 2017, 23, 65–73. [Google Scholar] [CrossRef]

- Li, S.; Zhang, B.; Bai, Q. Effect of Temperature Buildup on Milling Forces in Additive/Subtractive Hybrid Manufacturing of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2020, 107, 4191–4200. [Google Scholar] [CrossRef]

- Woo, W.-S.; Kim, E.-J.; Jeong, H.-I.; Lee, C.-M. Laser-Assisted Machining of Ti-6Al-4V Fabricated by DED Additive Manufacturing. Int. J. Precis. Eng. Manuf. -Green Technol. 2020, 7, 559–572. [Google Scholar] [CrossRef]

- Abbès, B.; Abbes, F.; Abdessalam, H.; Upganlawar, A. Finite Element Cooling Simulations of Conformal Cooling Hybrid Injection Molding Tools Manufactured by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2019, 103, 2515–2522. [Google Scholar] [CrossRef]

- Bose, S.; Nandi, T. Statistical and Experimental Investigation Using a Novel Multi-Objective Optimization Algorithm on a Novel Titanium Hybrid Composite Developed by Lens Process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 2911–2933. [Google Scholar] [CrossRef]

- Carvalho, O.; Sousa, F.; Madeira, S.; Silva, F.S.; Miranda, G. HAp-functionalized Zirconia Surfaces via Hybrid Laser Process for Dental Applications. Opt. Laser Technol. 2018, 106, 157–167. [Google Scholar] [CrossRef]

- Faria, D.; Henriques, B.; Souza, A.C.; Silva, F.S.; Carvalho, O. Laser-Assisted Production of HAp-coated Zirconia Structured Surfaces for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2020, 112, 104049. [Google Scholar] [CrossRef]

- Bouet, G.; Cabanettes, F.; Bidron, G.; Guignandon, A.; Peyroche, S.; Bertrand, P.; Vico, L.; Dumas, V. Laser-Based Hybrid Manufacturing of Endosseous Implants: Optimized Titanium Surfaces for Enhancing Osteogenic Differentiation of Human Mesenchymal Stem Cells. ACS Biomater. Sci. Eng. 2019, 5, 4376–4385. [Google Scholar] [CrossRef]

- Tapoglou, N.; Clulow, J. Investigation of Hybrid Manufacturing of Stainless Steel 316L Components Using Direct Energy Deposition. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1633–1643. [Google Scholar] [CrossRef]

- Feldhausen, T.; Raghavan, N.; Saleeby, K.; Love, L.; Kurfess, T. Mechanical Properties and Microstructure of 316L Stainless Steel Produced by Hybrid Manufacturing. J. Mater. Process. Technol. 2021, 290, 116970. [Google Scholar] [CrossRef]

- Kunwar, P.; Xiong, Z.; Mcloughlin, S.T.; Soman, P. Oxygen-Permeable Films for Continuous Additive, Subtractive, and Hybrid Additive/Subtractive Manufacturing. 3D Print. Addit. Manuf. 2020, 7, 216–221. [Google Scholar] [CrossRef] [PubMed]

- Junzhi, L.; Gao, C.; Shen, L.; Cheng, H.; Gao, X.; Han, X. Microstructure and Surface Morphology of Inconel 625 Alloy Prepared by Laser Melting Deposition Using Abrasive-Assisted Jet Electrochemical Machining. Int. J. Electrochem. Sci. 2018, 13, 10654–10668. [Google Scholar] [CrossRef]

- Kolsch, N.; Seidel, A.; Finaske, T.; Brueckner, F.; Gumpinger, J.; Bavdaz, M.; Rohr, T.; Ghidini, T.; Leyens, C. Novel Local Shielding Approach for the Laser Welding Based Additive Manufacturing of Large Structural Space Components from Titanium. J. Laser Appl. 2020, 32, 022075. [Google Scholar] [CrossRef]

- Air, A.; Shamsuddoha, M.; Oromiehie, E.; Prusty, B. Development of an Automated Fibre Placement-Based Hybrid Composite Wheel for a Solar-Powered Car. Int. J. Adv. Manuf. Technol. 2023, 125, 4083–4097. [Google Scholar] [CrossRef]

- Al-Lami, J.; Hoang, P.; Davies, C.; Pirzada, T.; Pham, M. Plastic Inhomogeneity and Crack Initiation in Hybrid Wrought—Additively Manufactured Inconel 718. Mater. Charact. 2023, 199, 112815. [Google Scholar] [CrossRef]

- Ambrogio, G.; Gagliardi, F.; Muzzupappa, M.; Filice, L. Additive-Incremental Forming Hybrid Manufacturing Technique to Improve Customised Part Performance. J. Manuf. Process. 2019, 37, 386–391. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Gronikowski, M.; Aniśko, J. A Novel Manufacturing Concept of LCP Fiber-Reinforced GPET-Based Sandwich Structures with an FDM 3D-Printed Core. Materials 2022, 15, 5405. [Google Scholar] [CrossRef]

- Babu, S.; Panigrahi, S.; Ram, G.; Venkitakrishnan, P.; Kumar, R. Cold Metal Transfer Welding of Aluminium Alloy AA 2219 to Austenitic Stainless Steel AISI 321. J. Mater. Process. Technol. 2019, 266, 155–164. [Google Scholar] [CrossRef]

- Bai, Q.; Wu, B.; Qiu, X.; Zhang, B.; Chen, J. Experimental Study on Additive/Subtractive Hybrid Manufacturing of 6511 Steel: Process Optimization and Machining Characteristics. Int. J. Adv. Manuf. Technol. 2020, 108, 1389–1398. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Sydow, B.; Hemes, S.; Meiners, F. Hybrid Manufacturing of Components from Ti-6Al-4V by Metal Forming and Wire-Arc Additive Manufacturing. J. Mater. Process. Technol. 2020, 282, 116689. [Google Scholar] [CrossRef]

- Bambach, M.; Unsal, I.; Sviridov, A.; Hama-Saleh, R.; Weisheit, A. Hybrid Manufacturing of Sheet Metals and Functionalizing for Joining Applications via Hole Flanging. Prod. Eng. Res. Dev. 2021, 15, 223–233. [Google Scholar] [CrossRef]

- Basinger, K.; Keough, C.; Webster, C.; Wysk, R.; Martin, T.; Harrysson, O. Development of a Modular Computer-Aided Process Planning (CAPP) System for Additive-Subtractive Hybrid Manufacturing of Pockets, Holes, and Flat Surfaces. Int. J. Adv. Manuf. Technol. 2018, 96, 2407–2420. [Google Scholar] [CrossRef]

- Bernardino, R.d.M.; Valentino, S.; Franchin, G.; Günster, J.; Zocca, A. Manufacturing of Ceramic Components with Internal Channels by a Novel Additive/Subtractive Hybridization Process. Open Ceram. 2020, 2, 100010. [Google Scholar] [CrossRef]

- Beziuk, G.; Baum, T.; Ghorbani, K.; Nicholson, K. RF Signal Multiplexer Embedded Into Multifunctional Composite Structure. IEEE Trans. Microw. Theory Tech. 2019, 67, 4935–4943. [Google Scholar] [CrossRef]

- Blindheim, J.; Welo, T.; Steinert, M. Investigating the Mechanics of Hybrid Metal Extrusion and Bonding Additive Manufacturing by FEA. Metals 2019, 9, 811. [Google Scholar] [CrossRef]

- Böhm, C.; Werz, M.; Weihe, S. Dilution Ratio and the Resulting Composition Profile in Dissimilar Laser Powder Bed Fusion of AlSi10Mg and Al99.8. Metals 2020, 10, 1222. [Google Scholar] [CrossRef]

- Bordinassi, E.; Mhurchadha, S.; Seriacopi, V.; Delijaicov, S.; Lebrao, S.; Thomas, K.; Batalha, G.; Raghavendra, R. Effect of Hybrid Manufacturing (Am-Machining) on the Residual Stress and Pitting Corrosion Resistance of 316L Stainless Steel. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 491. [Google Scholar] [CrossRef]

- Botcha, B.; Iquebal, A.; Bukkapatnam, S. Smart Manufacturing Multiplex. Manuf. Lett. 2020, 25, 102–106. [Google Scholar] [CrossRef]

- Bournias-Varotsis, A.; Friel, R.; Harris, R.; Engstrom, D. Ultrasonic Additive Manufacturing as a Form-Then-Bond Process for Embedding Electronic Circuitry into a Metal Matrix. J. Manuf. Process. 2018, 32, 664–675. [Google Scholar] [CrossRef]

- Brown, D.; Li, C.; Liu, Z.; Fang, X.; Guo, Y. Surface Integrity of Inconel 718 by Hybrid Selective Laser Melting and Milling. VIRTUAL Phys. Prototyp. 2018, 13, 26–31. [Google Scholar] [CrossRef]

- Bruzzo, F.; Catalano, G.; Demir, A.; Previtali, B. Surface Finishing by Laser Re-Melting Applied to Robotized Laser Metal Deposition. Opt. Lasers Eng. 2021, 137, 106391. [Google Scholar] [CrossRef]

- Butt, J.; Hewavidana, Y.; Mohaghegh, V.; Sadeghi-Esfahlani, S.; Shirvani, H. Hybrid Manufacturing and Experimental Testing of Glass Fiber Enhanced Thermoplastic Composites. J. Manuf. Mater. Process. 2019, 3, 96. [Google Scholar] [CrossRef]

- Calleja, A.; Urbikain, G.; Gonzalez, H.; Cerrillo, I.; Polvorosa, R.; Lamikiz, A. InconelA (R) 718 Superalloy Machinability Evaluation After Laser Cladding Additive Manufacturing Process. Int. J. Adv. Manuf. Technol. 2018, 97, 2873–2885. [Google Scholar] [CrossRef]

- Campatelli, G.; Venturini, G.; Grossi, N.; Baffa, F.; Scippa, A.; Yamazaki, K. Design and Testing of a WAAM Retrofit Kit for Repairing Operations on a Milling Machine. Machines 2021, 9, 322. [Google Scholar] [CrossRef]

- Castro, P.; Edesa, M.; Gurrutxaga, A.; Mentxaka, A. Optimization of the Efficiency of the Laser Metal Deposition Process Applied to High Hardness Coatings by the Analysis of Different Types of Coaxial Nozzles. DYNA 2018, 93, 613–619. [Google Scholar] [CrossRef]

- Chen, N.; Barnawal, P.; Frank, M. Automated Post Machining Process Planning for a New Hybrid Manufacturing Method of Additive Manufacturing and Rapid Machining. Rapid Prototyp. J. 2018, 24, 1077–1090. [Google Scholar] [CrossRef]

- Chierici, M.; Demir, A.; Kanyilmaz, A.; Berto, F.; Castiglioni, C.; Previtali, B. Hybrid Manufacturing of Steel Construction Parts via Arc Welding of LPBF-produced and Hot-Rolled Stainless Steels. Prog. Addit. Manuf. 2023, 9, 471–492. [Google Scholar] [CrossRef]

- Cicek, U.I.; Southee, D.J.; Johnson, A.A. 2D Characterisation and Evaluation of Multi-Material Structures Towards 3D Hybrid Printing. Virtual Phys. Prototyp. 2023, 18, e2181193. [Google Scholar] [CrossRef]

- Cornelius, A.; Jacobs, L.; Lamsey, M.; McNeil, L.; Hamel, W.; Schmitz, T. Hybrid Manufacturing of Invar Mold for Carbon Fiber Layup Using Structured Light Scanning. Manuf. Lett. 2022, 33, 133–142. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.; Ukar, E.; Lamikiz, A. Analysis of the Influence of the Use of Cutting Fluid in Hybrid Processes of Machining and Laser Metal Deposition (LMD). Coatings 2018, 8, 61. [Google Scholar] [CrossRef]

- Cristino, V.A.M.; Pragana, J.P.M.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid Manufacturing of Stiffening Grooves in Additive Deposited Thin Parts. J. Manuf. Mater. Process. 2021, 5, 140. [Google Scholar] [CrossRef]

- Cui, D.; Zhang, Y.; He, F.; Ma, J.; Zhang, K.; Yang, Z.; Li, J.; Wang, Z.; Kai, J.; Wang, J.; et al. Heterogeneous Microstructure of the Bonding Zone and Its Dependence on Preheating in Hybrid Manufactured Ti-6Al-4V. Mater. Res. Lett. 2021, 9, 422–428. [Google Scholar] [CrossRef]

- de Assis, C.L.F.; Mecelis, G.R.; Coelho, R.T. An Investigation of Stainless Steel 316L Parts Produced by Powder Bed Fusion Submitted to Micro-Endmilling Operations. Int. J. Adv. Manuf. Technol. 2020, 109, 1867–1880. [Google Scholar] [CrossRef]

- Deb, S.; Panigrahi, S.; Weiss, M. Development of Bulk Ultrafine Grained Al-SiC Nano Composite Sheets by a SPD Based Hybrid Process: Experimental and Theoretical Studies. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 738, 323–334. [Google Scholar] [CrossRef]

- Dehaeck, S.; Cavaiani, M.; Chafai, A.; Tourtit, Y.; Vitry, Y.; Lambert, P. Hybrid Two-Scale Fabrication of Sub-Millimetric Capillary Grippers. Micromachines 2019, 10, 224. [Google Scholar] [CrossRef]

- Deng, F.; Nguyen, Q.; Zhang, P. Multifunctional Liquid Metal Lattice Materials Through Hybrid Design and Manufacturing. Addit. Manuf. 2020, 33, 101117. [Google Scholar] [CrossRef]

- Dhandapani, A.; Krishnasamy, S.; Nagarajan, R.; Selvaraj, A.D.A.; Thiagamani, S.M.K.; Muthukumar, C.; Mohammad, F.; Al-Lohedan, H.A.; Ismail, S.O. Investigation of Wear Behavior in Self-Lubricating ABS Polymer Composites Reinforced with Glass Fiber/ABS and Glass Fiber/Carbon Fiber/ABS Hybrid. Lubricants 2023, 11, 131. [Google Scholar] [CrossRef]

- Dolev, O.; Osovski, S.; Shirizly, A. Ti-6Al-4V Hybrid Structure Mechanical Properties-Wrought and Additive Manufactured Powder-Bed Material. Addit. Manuf. 2021, 37, 101657. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. Machining Characteristics of 18Ni-300 Steel in Additive/Subtractive Hybrid Manufacturing. Int. J. Adv. Manuf. Technol. 2018, 95, 2509–2519. [Google Scholar] [CrossRef]

- Duan, X.; Cui, R.; Yang, H.; Yang, X. Hybrid Additive and Subtractive Manufacturing Method Using Pulsed Arc Plasma. Materials 2023, 16, 4561. [Google Scholar] [CrossRef] [PubMed]

- Dugar, J.; Ikram, A.; Klobčar, D.; Pušavec, F. Sustainable Hybrid Manufacturing of AlSi5 Alloy Turbine Blade Prototype by Robotic Direct Energy Layered Deposition and Subsequent Milling: An Alternative to Selective Laser Melting? Materials 2022, 15, 8631. [Google Scholar] [CrossRef] [PubMed]

- Dvorak, J.; Gilmer, D.; Zameroski, R.; Cornelius, A.; Schmitz, T. Freeform Hybrid Manufacturing: Binderjet, Structured Light Scanning, Confocal Microscopy, and CNC Machining. J. Manuf. Mater. Process. 2023, 7, 79. [Google Scholar] [CrossRef]

- Emdadi, A.; Bolz, S.; Weiß, S. Hot Working of an Fe-25Al-1.5Ta Alloy Produced by Laser Powder Bed Fusion. Crystals 2023, 13, 1335. [Google Scholar] [CrossRef]

- Erasmus, J.; Grefen, P.; Vanderfeesten, I.; Traganos, K. Smart Hybrid Manufacturing Control Using Cloud Computing and the Internet-of-Things. Machines 2018, 6, 62. [Google Scholar] [CrossRef]

- Feldhausen, T.; Kannan, R.; Raghavan, N.; Saleeby, K.; Kurfess, T.; Nandwana, P. Investigation of Interfacial Structures for Hybrid Manufacturing. Mater. Lett. 2022, 307, 131040. [Google Scholar] [CrossRef]

- Feldhausen, T.; Paramanathan, M.; Heineman, J.; Hassen, A.; Heinrich, L.; Kurfess, R.; Fillingim, K.; Saleeby, K.; Post, B. Hybrid Manufacturing of Conformal Cooling Channels for Tooling. J. Manuf. Mater. Process. 2023, 7, 74. [Google Scholar] [CrossRef]

- Ferreira, I.; Madureira, R.; Villa, S.; de Jesus, A.; Machado, M.; Alves, J. Machinability of PA12 and Short Fibre-Reinforced PA12 Materials Produced by Fused Filament Fabrication. Int. J. Adv. Manuf. Technol. 2020, 107, 885–903. [Google Scholar] [CrossRef]

- Fitzgerald, K.; Bindra, R.; Canning, S.; Tansley, G.; Lloyd, D.G.; Zheng, M.; Quinn, A.; Maharaj, J.; Perevoshchikova, N.; Saxby, D.J. A Human-Centred Design Approach to Hybrid Manufacturing of a Scapholunate Interosseous Ligament Medical Practice Rig. Ann. 3D Print. Med. 2023, 9, 100084. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.; Renteria-Rodriguez, A. Effect of Nanoparticles on the Mechanical Properties of Kenaf Fiber-Reinforced Bio-Based Epoxy Resin. Text. Res. J. 2021, 91, 1313–1325. [Google Scholar] [CrossRef]

- Gao, S.; Liu, R.; Huang, R.; Song, X.; Seita, M. A Hybrid Directed Energy Deposition Process to Manipulate Microstructure and Properties of Austenitic Stainless Steel. Mater. Des. 2022, 213, 110360. [Google Scholar] [CrossRef]

- Ghafoori, E.; Dahaghin, H.; Diao, C.; Pichler, N.; Li, L.; Mohri, M.; Ding, J.; Ganguly, S.; Williams, S. Fatigue Strengthening of Damaged Steel Members Using Wire Arc Additive Manufacturing. Eng. Struct. 2023, 284, 115911. [Google Scholar] [CrossRef]

- Gomez, M.; Honeycutt, A.; Schmitz, T. Hybrid Manufactured Dynamometer for Cutting Force Measurement. Manuf. Lett. 2021, 29, 65–69. [Google Scholar] [CrossRef]

- Gong, Y.; Yang, Y.; Qu, S.; Li, P.; Liang, C.; Zhang, H. Laser Energy Density Dependence of Performance in Additive/Subtractive Hybrid Manufacturing of 316L Stainless Steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1585–1596. [Google Scholar] [CrossRef]

- Gong, K.; Liu, H.; Huang, C.; Cao, Z.; Fuenmayor, E.; Major, I. Hybrid Manufacturing of Acrylonitrile Butadiene Styrene (ABS) via the Combination of Material Extrusion Additive Manufacturing and Injection Molding. Polymers 2022, 14, 5093. [Google Scholar] [CrossRef]

- Gong, K.; Liu, H.; Huang, C.; Jiang, Q.; Xu, H.; Cao, Z.; Fuenmayor, E.; Major, I. Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process. Polymers 2022, 14, 5413. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Barrio, H.; Calleja-Ochoa, A.; de Lacalle, L.; Lamikiz, A. Hybrid Manufacturing of Complex Components: Full Methodology Including Laser Metal Deposition (LMD) Module Development, Cladding Geometry Estimation and Case Study Validation. Mech. Syst. Signal Process. 2022, 179, 109337. [Google Scholar] [CrossRef]

- Granse, T.; Pfeffer, S.; Springer, P.; Refle, O.; Leitl, S.; Neff, M.; Duffner, E.; Dorneich, A.; Fritton, M. Manufacturing of Individualized Sensors: Integration of Conductive Elements in Additively Manufactured PBT Parts and Qualification of Functional Sensors. Prog. Addit. Manuf. 2023, 9, 273–283. [Google Scholar] [CrossRef]

- Greco, S.; Schmidt, M.; Klauer, K.; Kirsch, B.; Aurich, J. Hybrid Manufacturing: Influence of Material Properties During Micro Milling of Different Additively Manufactured AISI 316L. Prod. Eng. Res. Dev. 2022, 16, 797–809. [Google Scholar] [CrossRef]

- Guo, S.; Ren, G.; Zhang, B. Subsurface Defect Evaluation of Selective-Laser-Melted Inconel 738LC Alloy Using Eddy Current Testing for Additive/Subtractive Hybrid Manufacturing. Chin. J. Mech. Eng. 2021, 34, 111. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, Y.; Lin, J. Effect of Additive and Subtractive Hybrid Manufacturing Process on the Surface Quality of 18Ni300 Maraging Steel. Mater. Res. Express 2023, 10, 056501. [Google Scholar] [CrossRef]

- Hadidi, H.; Feng, R.; Sealy, M. Low Velocity Impact of Hybrid Stacked Steel Plates. Int. J. Impact Eng. 2020, 140, 103556. [Google Scholar] [CrossRef]

- Hamann, I.; Gebhardt, F.; Eisenhut, M.; Koch, P.; Thielsch, J.; Rotsch, C.; Drossel, W.-G.; Heyde, C.-E.; Leimert, M. Investigation into the Hybrid Production of a Superelastic Shape Memory Alloy with Additively Manufactured Structures for Medical Implants. Materials 2021, 14, 3098. [Google Scholar] [CrossRef]

- He, Y.; Wei, J.; Liu, J.; Wang, X.; Wang, Y.; He, L. Experimental Study on the Fabrication Profile and Mechanical Properties by Substrate-Inclined Angle Using Laser Melting Deposition (LMD) Integrating with the Substrate of Stainless Steel. Opt. Laser Technol. 2020, 125, 106038. [Google Scholar] [CrossRef]

- Helfesrieder, N.; Neubauer, M.; Lechler, A.; Verl, A. Hybrid Manufacturing of Topology Optimized Machine Tool Parts Through a Layer Laminated Manufacturing Method: Practical Validation Using the Example of a Bearing Block. Prod. Eng. Res. Dev. 2022, 16, 493–502. [Google Scholar] [CrossRef]

- Hemes, S.; Meiners, F.; Sizova, I.; Hama-Saleh, R.; Röhrens, D.; Weisheit, A.; Häfner, C.L.; Bambach, M. Microstructures and Mechanical Properties of Hybrid, Additively Manufactured Ti6Al4V After Thermomechanical Processing. Materials 2021, 14, 1039. [Google Scholar] [CrossRef]

- Herrault, F.; Wong, J.; Regan, D.; Brown, D.; Fung, H.; Tang, Y.; Sharifi, H. Metal-Embedded Chiplet Assembly for Microwave Integrated Circuits. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1579–1582. [Google Scholar] [CrossRef]

- Honeycutt, A.; Mhatre, P.; Gibson, B.; Smith, S.; Richardson, B. Iterative Hybrid Manufacture of a Titanium Alloy Component. Manuf. Lett. 2021, 29, 90–93. [Google Scholar] [CrossRef]

- Jang, K.; Yoon, H.; Lee, H.; Kim, E.; Ahn, S. 50 Nm Scale Alignment Method for Hybrid Manufacturing Processes for Full 3D Structuring. Int. J. Precis. Eng. Manuf. 2020, 21, 2407–2417. [Google Scholar] [CrossRef]

- Lee, P.; Kim, J.; Lee, S.; Shao, C.; Chung, H. Experimental Investigation on a Hybrid Manufacturing Process of Micro-Scale Mold for Biomimetic Intestinal Villi’s Scaffold. J. Mech. Sci. Technol. 2018, 32, 4283–4289. [Google Scholar] [CrossRef]

- Lee, U.; Kim, B.; Kim, S.; Oh, C. Rapid Manufacturing of Large Diameter Cu Micropillars by Micro-Electrical Discharge Machining and Focused Ion Beam. Int. J. Adv. Manuf. Technol. 2021, 113, 1153–1162. [Google Scholar] [CrossRef]

- Lee, J.; Song, J.; Lee, Y.C.; Kim, J.T. Development of a Huge Hybrid 3D-printer Based on Fused Deposition Modeling (FDM) Incorporated with Computer Numerical Control (CNC) Machining for Industrial Applications. High Temp. Mater. Process. 2022, 41, 123–131. [Google Scholar] [CrossRef]

- Kaiser, N.; Goossens, N.; Jimenez, A.; Laraudogoitia, I.; Psarras, S.; Tsantzalis, S. Advanced Manufacturing Concept of a Bio-Inspired Reaction Wheel Rotor for Small- and Medium-Sized Constellation Satellites. CEAS Space J. 2023, 16, 73–86. [Google Scholar] [CrossRef]

- Kang, D.; Zou, P.; Wu, H.; Wang, W.; Xu, J. Theoretical and Experimental Study of Ultrasonic Vibration-Assisted Laser Polishing 304 Stainless Steel. IEEE Access 2020, 8, 206146–206163. [Google Scholar] [CrossRef]

- Kannan, R.; Nandwana, P.; Feldhausen, T. Comparing the Deformation Mechanism in 316 L Stainless Steel Fabricated by Hybrid and Additive Manufacturing. Mater. Lett. 2021, 288, 129369. [Google Scholar] [CrossRef]

- Katahira, K.; Ogawa, Y.; Morita, S.; Yamazaki, K. Experimental Investigation for Optimizing the Fabrication of a Sapphire Capillary Using Femtosecond Laser Machining and Diamond Tool Micromilling. CIRP Ann. Manuf. Technol. 2020, 69, 229–232. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. Porosity, Surface Quality, Microhardness and Microstructure of Selective Laser Melted 316L Stainless Steel Resulting from Finish Machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef]

- Komorowski, P.; Sokołowska, P.; Siatkowska, M.; Elgalal, M.; Rosowski, M.; Makowski, K.; Lipińska, L.; Leszczewicz, M.; Styczyński, A.; Fogel, K.; et al. Designing Laser-Modified Surface Structures on Titanium Alloy Custom Medical Implants Using a Hybrid Manufacturing Technology. J. Biomed. Mater. Res. Part B Appl. Biomater. 2020, 108, 1790–1800. [Google Scholar] [CrossRef]

- Kretzschmar, N.; Lipponen, S.; Klar, V.; Pearce, J.; Ranger, T.; Seppala, J.; Partanen, J. Mechanical Properties of Ultraviolet-Assisted Paste Extrusion and Postextrusion Ultraviolet-Curing of Three-Dimensional Printed Biocomposites. 3D Print. Addit. Manuf. 2019, 6, 127–137. [Google Scholar] [CrossRef]

- Li, P.; Gong, Y.; Wen, X.; Xin, B.; Liu, Y.; Qu, S. Surface Residual Stresses in Additive/Subtractive Manufacturing and Electrochemical Corrosion. Int. J. Adv. Manuf. Technol. 2018, 98, 687–697. [Google Scholar] [CrossRef]

- Li, Y. Rapid Prototyping of Sheet Metal Workpieces Using Bending-Machining Hybrid Process. Int. J. Adv. Manuf. Technol. 2018, 99, 287–300. [Google Scholar] [CrossRef]

- Li, P.; Gong, Y.; Liang, C.; Yang, Y.; Cai, M. Effect of Post-Heat Treatment on Residual Stress and Tensile Strength of Hybrid Additive and Subtractive Manufacturing. Int. J. Adv. Manuf. Technol. 2019, 103, 2579–2592. [Google Scholar] [CrossRef]

- Li, P.; Gong, Y.; Xu, Y.; Qi, Y.; Sun, Y.; Zhang, H. Inconel-Steel Functionally Bimetal Materials by Hybrid Directed Energy Deposition and Thermal Milling: Microstructure and Mechanical Properties. Arch. Civ. Mech. Eng. 2019, 19, 820–831. [Google Scholar] [CrossRef]

- Li, Y.; Han, Q.; Horvath, I.; Zhang, G. Repairing Surface Defects of Metal Parts by Groove Machining and Wire Plus Arc Based Filling. J. Mater. Process. Technol. 2019, 274, 116268. [Google Scholar] [CrossRef]

- Li, Y.; Reents, T. Capability Study of 2D Heat-Assisted Mill-Bend Process. Int. J. Interact. Des. Manuf. (IJIDeM) 2020, 14, 759–772. [Google Scholar] [CrossRef]

- Li, G.; Odum, K.; Yau, C.; Soshi, M.; Yamazaki, K. High Productivity Fluence Based Control of Directed Energy Deposition (DED) Part Geometry. J. Manuf. Process. 2021, 65, 407–417. [Google Scholar] [CrossRef]

- Li, P.; Zhou, J.; Li, L.; Zhang, T.; Gou, Y.; Meng, X.; Lyu, J. Tensile Fracture Behavior of 316L Stainless Steel Components Fabricated with Hybrid Directed Energy Deposition and Thermal Milling Manufacturing. Appl. Phys. A Mater. Sci. Process. 2021, 127, 212. [Google Scholar] [CrossRef]

- Li, J.; Yang, Y.; Zhu, G.; Sun, C.; Chen, Y.; Wang, K.; Shi, S. The Anisotropic Electrochemical Machinability of Laser Cladding Deposited Ti6Al4V Alloy in NaCl Solution. Materials 2022, 15, 3642. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Zhang, J.; Deng, T.; Ren, F. Convertible Thermal Meta-Structures via Hybrid Manufacturing of Stereolithography Apparatus 3D Printing and Surface Metallization for Thermal Flow Manipulation. Polymers 2022, 15, 174. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.; Motlag, M.; Saei, M.; Jin, S.; Rahimi, R.; Bahr, D.; Cheng, G. Shock Engineering the Additive Manufactured Graphene-Metal Nanocomposite with High Density Nanotwins and Dislocations for Ultra-Stable Mechanical Properties. ACTA Mater. 2018, 150, 360–372. [Google Scholar] [CrossRef]

- Liravi, F.; Vlasea, M. Powder Bed Binder Jetting Additive Manufacturing of Silicone Structures. Addit. Manuf. 2018, 21, 112–124. [Google Scholar] [CrossRef]

- Liravi, F.; Toyserkani, E. A Hybrid Additive Manufacturing Method for the Fabrication of Silicone Bio-Structures: 3D Printing Optimization and Surface Characterization. Mater. Des. 2018, 138, 46–61. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Zhao, K.; Wang, K. Machining of Microchannel at SS316 Surface Using Abrasive-Assisted Electrochemical Jet Machining. Int. J. Adv. Manuf. Technol. 2018, 95, 1143–1152. [Google Scholar] [CrossRef]

- Liu, B.; Shen, H.; Deng, R.; Li, S.; Tang, S.; Fu, J.; Wang, Y. Research on a Planning Method for Switching Moments in Hybrid Manufacturing Processes. J. Manuf. Process. 2020, 56, 786–795. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Li, Y.; Yuan, H.; Li, F. The Effect of Thermal Spraying on the Forming Performance of Incremental Sheet Forming. J. Mater. Res. Technol.—JMRT 2021, 12, 776–787. [Google Scholar] [CrossRef]

- Liu, W.; Deng, K.; Wei, H.; Zhao, P.; Li, J.; Zhang, Y. A Decision-Making Model for Comparing the Energy Demand of Additive-Subtractive Hybrid Manufacturing and Conventional Subtractive Manufacturing Based on Life Cycle Method. J. Clean. Prod. 2021, 311, 127795. [Google Scholar] [CrossRef]

- Liu, J.-F.; Zhou, Y.-G.; Chen, S.-J.; Ren, S.-Q.; Zou, J. Effects of Friction Stir Welding on the Mechanical Behaviors of Extrusion-Based Additive Manufactured Polymer Parts. Polymers 2023, 15, 3288. [Google Scholar] [CrossRef]

- Liverani, A.; Bacciaglia, A.; Nisini, E.; Ceruti, A. Conformal 3D Material Extrusion Additive Manufacturing for Large Moulds. Appl. Sci. 2023, 13, 1892. [Google Scholar] [CrossRef]

- Loyda, A.; Arizmendi, M.; de Galarreta, S.; Rodriguez-Florez, N.; Jimenez, A. Meeting High Precision Requirements of Additively Manufactured Components Through Hybrid Manufacturing. CIRP J. Manuf. Sci. Technol. 2023, 40, 199–212. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Y.; Li, J.; Cui, D.; Wang, Z.; Wang, J. Microstructure and Mechanical Properties of Forging-Additive Hybrid Manufactured Ti?6Al?4V Alloys. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2021, 811, 140984. [Google Scholar] [CrossRef]

- Marin, F.; de Souza, A.F.; Ahrens, C.H.; de Lacalle, L.N.L. A New Hybrid Process Combining Machining and Selective Laser Melting to Manufacture an Advanced Concept of Conformal Cooling Channels for Plastic Injection Molds. Int. J. Adv. Manuf. Technol. 2021, 113, 1561–1576. [Google Scholar] [CrossRef]

- Marin, F.; De Souza, A.; Mikowski, A.; Fontanella, L.; Soares, P.; De Lacalle, L. Energy Density Effect on the Interface Zone in Parts Manufactured by Laser Powder Bed Fusion on Machined Bases. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 905–923. [Google Scholar] [CrossRef]

- Masek, P.; Fornusek, T.; Zeman, P.; Bucko, M.; Smolik, J.; Heinrich, P. MACHINABILITY THE AISI 316 STAINLESS STEEL AFTER PROCESSING BY VARIOUS METHODS OF 3D PRINTING. MM Sci. J. 2019, 2019, 3338–3346. [Google Scholar] [CrossRef]

- Mehmeti, A.; Penchev, P.; Lynch, D.; Vincent, D.; Maillol, N.; Maurath, J.; Bajolet, J.; Wimpenny, D.; Essa, K.; Dimov, S. Mechanical Behaviour and Interface Evaluation of Hybrid MIM/PBF Stainless Steel Components. Rapid Prototyp. J. 2020, 26, 1809–1825. [Google Scholar] [CrossRef]

- Mehmeti, A.; Lynch, D.; Penchev, P.; Ramos, R.M.; Vincent, D.; Maurath, J.; Wimpenny, D.I.; Essa, K.; Dimov, S. The Effect of Hot Isostatic Pressing on Surface Integrity, Microstructure and Strength of Hybrid Metal Injection Moulding, and Laser-Based Powder Bed Fusion Stainless-Steel Components. Appl. Sci. 2021, 11, 7490. [Google Scholar] [CrossRef]

- Mehmeti, A.; Bidare, P.; Imbrogno, S.; Wimpenny, D.; Essa, K.; Dimov, S. Surface Integrity of Hybrid CM247LC/Inconel 718 Components Produced by Laser-Directed Energy Deposition. Int. J. Adv. Manuf. Technol. 2022, 121, 4961–4980. [Google Scholar] [CrossRef]

- Meng, Z.; Mu, X.; He, J.; Zhang, J.; Ling, R.; Li, D. Embedding Aligned Nanofibrous Architectures Within 3D-printed Polycaprolactone Scaffolds for Directed Cellular Infiltration and Tissue Regeneration. Int. J. Extrem. Manuf. 2023, 5, 025001. [Google Scholar] [CrossRef]

- Meyer, T.; Tanikella, N.; Reich, M.; Pearce, J. Potential of Distributed Recycling from Hybrid Manufacturing of 3-D Printing and Injection Molding of Stamp Sand and Acrylonitrile Styrene Acrylate Waste Composite. Sustain. Mater. Technol. 2020, 25, e00169. [Google Scholar] [CrossRef]

- Mishurova, T.; Sydow, B.; Thiede, T.; Sizova, I.; Ulbricht, A.; Bambach, M.; Bruno, G. Residual Stress and Microstructure of a Ti-6Al-4V Wire Arc Additive Manufacturing Hybrid Demonstrator. Metals 2020, 10, 701. [Google Scholar] [CrossRef]

- Moetazedian, A.; Allum, J.; Gleadall, A.; Mele, E.; Silberschmidt, V. MaTrEx AM: A New Hybrid Additive Manufacturing Process to Selectively Control Mechanical Properties. Addit. Manuf. 2021, 47, 102337. [Google Scholar] [CrossRef]

- Mohring, H.; Becker, D.; Eisseler, R.; Stehle, T.; Reeber, T. Influence of the Manufacturing Parameters of an AlMg5 Wire-Based Hybrid Production Process on Quality and Mechanical Properties. Int. J. Adv. Manuf. Technol. 2022, 119, 2445–2460. [Google Scholar] [CrossRef]

- Muvunzi, R.; Hagedorn-Hansen, D.; Matope, S.; Madyibi, X.; Swart, C.; Nagel, M. Industry Case Study: Process Chain for Manufacturing of a Large Hybrid Hot Stamping Tool with Conformal Cooling Channels. Int. J. Adv. Manuf. Technol. 2020, 110, 1723–1730. [Google Scholar] [CrossRef]

- Osman, M.; Sarafan, S.; Wanjara, P.; Bernier, F.; Atabay, S.E.; Gholipour, J.; Molavi-Zarandi, M.; Soost, J.; Brochu, M. Effect of Heat Treatment on the Microstructure and Mechanical Properties of 18Ni-300 Maraging Steel Produced by Additive-Subtractive Hybrid Manufacturing. Materials 2023, 16, 4749. [Google Scholar] [CrossRef]

- Parenti, P.; Cataldo, S.; Annoni, M. Shape Deposition Manufacturing of 316L Parts via Feedstock Extrusion and Green-State Milling. Manuf. Lett. 2018, 18, 6–11. [Google Scholar] [CrossRef]

- Pascu, S.; Balc, N. Process Parameter Optimization for Hybrid Manufacturing of PLA Components with Improved Surface Quality. Polymers 2023, 15, 3610. [Google Scholar] [CrossRef]

- Pashneh-Tala, S.; Moorehead, R.; Claeyssens, F. Hybrid Manufacturing Strategies for Tissue Engineering Scaffolds Using Methacrylate Functionalised Poly(glycerol Sebacate). J. Biomater. Appl. 2020, 34, 1114–1130. [Google Scholar] [CrossRef]

- Paz, R.; Santamarta, J.; Monzón, M.D.; García, J.; Pei, E. An Analysis of Key Process Parameters for Hybrid Manufacturing by Material Extrusion and CNC Machining. Bio-Des. Manuf. 2018, 1, 237–244. [Google Scholar] [CrossRef]

- Perez-Ruiz, J.; de Lacalle, L.; Urbikain, G.; Pereira, O.; Martinez, S.; Bris, J. On the Relationship Between Cutting Forces and Anisotropy Features in the Milling of LPBF Inconel 718 for Near Net Shape Parts. Int. J. Mach. Tools Manuf. 2021, 170, 103801. [Google Scholar] [CrossRef]

- Platt, T.; Meijer, A.; Biermann, D. Conduction-Based Thermally Assisted Micromilling Process for Cutting Difficult-to-Machine Materials. J. Manuf. Mater. Process. 2020, 4, 34. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Tarba, C.; Laptoiu, D. Fast Production of Customized Three-Dimensional-Printed Hand Splints. Rapid Prototyp. J. 2020, 26, 134–144. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Rosenthal, S.; Bragança, I.M.F.; Silva, C.M.A.; Tekkaya, A.E.; Martins, P.A.F. Hybrid Additive Manufacturing of Collector Coins. J. Manuf. Mater. Process. 2020, 4, 115. [Google Scholar] [CrossRef]

- Qin, L.; Men, J.; Zhang, L.; Zhao, S.; Li, C.; Yang, G.; Wang, W. Microstructure Homogenizations of Ti-6Al-4V Alloy Manufactured by Hybrid Selective Laser Melting and Laser Deposition Manufacturing. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 759, 404–414. [Google Scholar] [CrossRef]

- Rauch, M.; Hascoet, J.Y. Opening New Opportunities for Aeronautic, Naval and Train Large Components Realization with Hybrid and Twin Manufacturing. J. Mach. Eng. 2022, 22, 5–20. [Google Scholar] [CrossRef]

- Ren, G.; Guo, S.; Zhang, B. Surface Integrity of Inconel 738LC Parts Manufactured by Selective Laser Melting Followed by High-speed Milling. Chin. J. Mech. Eng. 2023, 36, 5. [Google Scholar] [CrossRef]

- Rittinghaus, S.-K.; Schmelzer, J.; Rackel, M.W.; Hemes, S.; Vogelpoth, A.; Hecht, U.; Weisheit, A. Direct Energy Deposition of TiAl for Hybrid Manufacturing and Repair of Turbine Blades. Materials 2020, 13, 4392. [Google Scholar] [CrossRef]

- Robles, U.; Kudzal, A.; Rumpf, R. Automated Hybrid 3-D Printing of 3-D Meandering Interconnects. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1184–1189. [Google Scholar] [CrossRef]

- Ruiz, A.J.; Wu, M.; LaRochelle, E.P.M.; Gorpas, D.; Ntziachristos, V.; Pfefer, T.J.; Pogue, B.W. Indocyanine Green Matching Phantom for Fluorescence-Guided Surgery Imaging System Characterization and Performance Assessment. J. Biomed. Opt. 2020, 25, 1–15. [Google Scholar] [CrossRef]

- Sadrfaridpour, B.; Wang, Y. Collaborative Assembly in Hybrid Manufacturing Cells: An Integrated Framework for Human-Robot Interaction. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1178–1192. [Google Scholar] [CrossRef]

- Salahshoor, M.; Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Surface Integrity and Corrosion Performance of Biomedical Magnesium-Calcium Alloy Processed by Hybrid Dry Cutting-Finish Burnishing. J. Mech. Behav. Biomed. Mater. 2018, 78, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Molavi-Zarandi, M.; Soost, J.; Brochu, M. Evaluation of Maraging Steel Produced Using Hybrid Additive/Subtractive Manufacturing. J. Manuf. Mater. Process. 2021, 5, 107. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Soost, J.; Amos, R.; Patnaik, P.; Brochu, M. Benchmarking of 316L Stainless Steel Manufactured by a Hybrid Additive/Subtractive Technology. J. Manuf. Mater. Process. 2022, 6, 30. [Google Scholar] [CrossRef]

- Sealy, M.; Karunakaran, R.; Ortgies, S.; Madireddy, G.; Malshe, A.; Rajurkar, K. Reducing Corrosion of Additive Manufactured Magnesium Alloys by Interlayer Ultrasonic Peening. CIRP Ann. Manuf. Technol. 2021, 70, 179–182. [Google Scholar] [CrossRef]

- Shen, H.; Jin, J.; Liu, B.; Zhou, Z. Measurement and Evaluation of Laser-Scanned 3D Profiles in Wire Arc Hybrid Manufacturing Processes. Meas. J. Int. Meas. Confed. 2021, 176, 109089. [Google Scholar] [CrossRef]

- Shi, B.; Wang, L.; Zhan, X.; Lyu, F.; Gao, Z.; Shi, H. Weld Morphology, Microstructure Evolution, and Mechanical Properties of Laser Beam Welding of Wire Arc Additive Manufactured Al-Cu Substrate. Int. J. Adv. Manuf. Technol. 2023, 127, 1935–1949. [Google Scholar] [CrossRef]

- Silva, E.C.; Candiango, J.A.; Rodrigues, S.J.; Sampaio, Á.M.; Pontes, A.J. Hybrid Manufacturing of Aluminium Parts Combining Additive and Conventional Technologies—Mechanical and Thermal Properties. J. Manuf. Mater. Process. 2022, 6, 40. [Google Scholar] [CrossRef]

- Soffel, F.; Eisenbarth, D.; Hosseini, E.; Wegener, K. Interface Strength and Mechanical Properties of Inconel 718 Processed Sequentially by Casting, Milling, and Direct Metal Deposition. J. Mater. Process. Technol. 2021, 291, 117021. [Google Scholar] [CrossRef]

- Sommer, D.; Götzendorfer, B.; Esen, C.; Hellmann, R. Design Rules for Hybrid Additive Manufacturing Combining Selective Laser Melting and Micromilling. Materials 2021, 14, 5753. [Google Scholar] [CrossRef]

- Song, J.-H.; Kim, H.-J.; Kim, M.-S.; Min, S.-H.; Wang, Y.; Ahn, S.-H. Direct Printing of Performance Tunable Strain Sensor via Nanoparticle Laser Patterning Process. Virtual Phys. Prototyp. 2020, 15, 265–277. [Google Scholar] [CrossRef]

- Sorocki, J.; Piekarz, I. Low-Cost Microwave Components’ Fabrication in Hybrid Technology of Laminates and Additive Manufacturing on an Example of Miniaturized Suspended Directional Coupler. IEEE Access 2020, 8, 128766–128775. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Bikas, H.; Avram, O.; Valente, A.; Chryssolouris, G. Hybrid Subtractive-Additive Manufacturing Processes for High Value-Added Metal Components. Int. J. Adv. Manuf. Technol. 2020, 111, 645–655. [Google Scholar] [CrossRef]

- Sun, J.; Su, A.; Wang, T.; Chen, W.; Guo, W. Effect of Laser Shock Processing with Post-Machining and Deep Cryogenic Treatment on Fatigue Life of GH4169 Super Alloy. Int. J. Fatigue 2019, 119, 261–267. [Google Scholar] [CrossRef]

- Sunny, S.; Mathews, R.; Gleason, G.; Malik, A.; Halley, J. Effect of Metal Additive Manufacturing Residual Stress on Post-Process Machining-Induced Stress and Distortion. Int. J. Mech. Sci. 2021, 202–203, 106534. [Google Scholar] [CrossRef]

- Sydow, B.; Jhanji, A.; Hälsig, A.; Buhl, J.; Härtel, S. The Benefit of the Process Combination of Wire Arc Additive Manufacturing (WAAM) and Forming—A Numerical and Experimental Study. Metals 2022, 12, 988. [Google Scholar] [CrossRef]

- Tapoglou, N.; Clulow, J.; Curtis, D. Increased Shielding of a Direct Energy Deposition Process to Enable Deposition of Reactive Materials; an Investigation into Deposition of 15-5 PH Stainless Steel, Inconel 718 and Ti-6Al-4V. CIRP J. Manuf. Sci. Technol. 2022, 36, 227–235. [Google Scholar] [CrossRef]

- Tejo-Otero, A.; Fenollosa-Artés, F.; Uceda, R.; Castellví-Fernández, A.; Lustig-Gainza, P.; Valls-Esteve, A.; Ayats-Soler, M.; Munuera, J.; Buj-Corral, I.; Krauel, L. 3D Printed Prototype of a Complex Neuroblastoma for Preoperative Surgical Planning. Ann. 3D Print. Med. 2021, 2, 100014. [Google Scholar] [CrossRef]

- Thien, A.; Saldana, C.; Kurfess, T. Surface Qualification Toolpath Optimization for Hybrid Manufacturing. J. Manuf. Mater. Process. 2021, 5, 94. [Google Scholar] [CrossRef]

- Tian, H.; Lu, Z.; Chen, S. Predictive Modeling of Thermally Assisted Machining and Simulation Based on RSM After WAAM. Metals 2022, 12, 691. [Google Scholar] [CrossRef]

- Togwe, T.; Gokce, A.; Chen, Y.; German, R.; Atre, S. Metal Matrix Composites for Fabricating Tooling. Int. J. Refract. Met. Hard Mater. 2020, 87, 105169. [Google Scholar] [CrossRef]

- Tommasi, A.; Maillol, N.; Bertinetti, A.; Penchev, P.; Bajolet, J.; Gili, F.; Pullini, D.; Mataix, D.B. Influence of Surface Preparation and Heat Treatment on Mechanical Behavior of Hybrid Aluminum Parts Manufactured by a Combination of Laser Powder Bed Fusion and Conventional Manufacturing Processes. Metals 2021, 11, 522. [Google Scholar] [CrossRef]

- Torii, M.; Nakata, T.; Takahashi, K.; Kawamura, N.; Shimpo, H.; Ohkubo, C. Fitness and Retentive Force of Cobalt-Chromium Alloy Clasps Fabricated with Repeated Laser Sintering and Milling. J. Prosthodont. Res. 2018, 62, 342–346. [Google Scholar] [CrossRef]

- Traganos, K.; Grefen, P.; Vanderfeesten, I.; Erasmus, J.; Boultadakis, G.; Bouklis, P. The HORSE Framework: A Reference Architecture for Cyber-Physical Systems in Hybrid Smart Manufacturing. J. Manuf. Syst. 2021, 61, 461–494. [Google Scholar] [CrossRef]

- Urbanic, R.J.; Hedrick, R.W.; Saquib, S.; Nazemi, N. Material Bead Deposition with 2+2 A1/2 Multi-Axis Machining Process Planning Strategies with Virtual Verification for Extruded Geometry. Int. J. Adv. Manuf. Technol. 2018, 95, 3167–3184. [Google Scholar] [CrossRef]

- Urbanic, R.; Saqib, S. A Manufacturing Cost Analysis Framework to Evaluate Machining and Fused Filament Fabrication Additive Manufacturing Approaches. Int. J. Adv. Manuf. Technol. 2019, 102, 3091–3108. [Google Scholar] [CrossRef]

- Vaughan, D.; Saldana, C.; Kurfess, T.; Nycz, A. Implementation of Sacrificial Support Structures for Hybrid Manufacturing of Thin Walls. J. Manuf. Mater. Process. 2022, 6, 70. [Google Scholar] [CrossRef]

- Vazquez-Armendariz, J.; Tejeda-Alejandre, R.; Rodriguez-Garcia, A.; Vega-Cantu, Y.I.; Mendoza-Buenrostro, C.; Rodriguez, C.A. Influence of Controlled Cooling on Crystallinity of Poly (L-Lactic Acid) Scaffolds After Hydrolytic Degradation. Materials 2020, 13, 2943. [Google Scholar] [CrossRef]

- Veiga, F.; Val, A.G.D.; Suárez, A.; Alonso, U. Analysis of the Machining Process of Titanium Ti6Al-4V Parts Manufactured by Wire Arc Additive Manufacturing (WAAM). Materials 2020, 13, 766. [Google Scholar] [CrossRef]

- Wang, X.; Carter, L.N.; Adkins, N.J.E.; Essa, K.; Attallah, M.M. Novel Hybrid Manufacturing Process of CM247LC and Multi-Material Blisks. Micromachines 2020, 11, 492. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, H.; Wang, H.; Li, D.; Xuan, J.; Zhang, L. Hybrid Manufacturing of 3D Hierarchical Porous Carbons for Electrochemical Storage. Adv. Mater. Technol. 2020, 5, 1901030. [Google Scholar] [CrossRef]

- Wang, Z.; Parande, G.; Gupta, M. Effect of Varying Hot Extrusion Temperatures on the Properties of a Sinterless Turning Induced Deformation Processed Eco-Friendly Mg-Zn-Ca Alloy. Crystals 2022, 13, 3. [Google Scholar] [CrossRef]

- Wang, H.; Lin, X.; Kang, N.; Qin, Z.; Shi, S.; Li, J.; Huang, W. Interfacial Characteristics and Mechanical Behavior of Hybrid Manufactured AlSi10Mg-Al6061 Bimetal via Selective Laser Melting and Forging. Acta Metall. Sin. 2022, 35, 375–388. [Google Scholar] [CrossRef]

- Wasserfall, F.; Hendrich, N.; Ahlers, D.; Zhang, J. Topology-Aware Routing of 3D-printed Circuits. Addit. Manuf. 2020, 36, 101523. [Google Scholar] [CrossRef]

- Weatherall, A.D.; Rogerson, M.D.; Quayle, M.R.; Cooper, M.G.; McMenamin, P.G.; Adams, J.W. A Novel 3-Dimensional Printing Fabrication Approach for the Production of Pediatric Airway Models. Anesth. Analg. 2021, 133, 1251–1259. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, N.; Kay, R.; Harris, R. Electrohydrodynamic and Aerosol Jet Printing for the Copatterning of Polydimethylsiloxane and Graphene Platelet Inks. Adv. Mater. Technol. 2020, 5, 2000148. [Google Scholar] [CrossRef]

- Williams, A.; Nowak, J.F.; Dass, R.; Samuel, J.; Mills, K.L. Toward Morphologically Relevant Extracellular Matrix in Vitro Models: 3D Fiber Reinforced Hydrogels. Front. Physiol. 2018, 9, 966. [Google Scholar] [CrossRef] [PubMed]

- Wippermann, A.; Gutowski, T.; Denkena, B.; Dittrich, M.; Wessarges, Y. Electrical Energy and Material Efficiency Analysis of Machining, Additive and Hybrid Manufacturing. J. Clean. Prod. 2020, 251, 119731. [Google Scholar] [CrossRef]

- Wong, D.; Yim, C.; Park, S. Hybrid Manufacturing of Oxidation Resistant Cellulose Nanocrystals-Copper-Graphene Nanoplatelets Based Electrodes. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 375–389. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, W.; He, Y. Deformation Prediction and Experimental Study of 316L Stainless Steel Thin-Walled Parts Processed by Additive-Subtractive Hybrid Manufacturing. Materials 2021, 14, 5582. [Google Scholar] [CrossRef]

- Xie, S.; Erjawetz, J.; Schuster, C.; Schift, H. Hybrid Structures by Direct Write Lithography-Tuning the Contrast and Surface Topography of Grayscale Photoresist with Nanoimprint. J. Vac. Sci. Technol. B 2021, 39, 052603. [Google Scholar] [CrossRef]

- Xu, H.; Ebrahimi, F.; Gong, K.; Cao, Z.; Fuenmayor, E.; Major, I. Hybrid Manufacturing of Oral Solid Dosage Forms via Overprinting of Injection-Molded Tablet Substrates. Pharmaceutics 2023, 15, 507. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Cui, W.; Newkirk, J.; Liou, F.; Thomas, E.; Baker, A.; Castle, J. Build Strategy Investigation of Ti-6Al-4V Produced Via a Hybrid Manufacturing Process. JOM 2018, 70, 1706–1713. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Qu, S.; Rong, Y.; Sun, Y.; Cai, M. Densification, Surface Morphology, Microstructure and Mechanical Properties of 316L Fabricated by Hybrid Manufacturing. Int. J. Adv. Manuf. Technol. 2018, 97, 2687–2696. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Qu, S.; Yin, G.; Liang, C.; Li, P. Additive and Subtractive Hybrid Manufacturing (ASHM) of 316L Stainless Steel: Single-Track Specimens, Microstructure, and Mechanical Properties. JOM 2021, 73, 759–769. [Google Scholar] [CrossRef]

- Zeng, C.; Yang, C.; Chen, Z.; Dai, S. Robot Learning Human Stiffness Regulation for Hybrid Manufacture. Assem. Autom. 2018, 38, 539–547. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.; Gao, M.; Wang, F.; Li, Q.; Zeng, X. Effects of Milling Thickness on Wire Deposition Accuracy of Hybrid Additive/Subtractive Manufacturing. Sci. Technol. Weld. Join. 2019, 24, 375–381. [Google Scholar] [CrossRef]

- Zhang, X.; Cui, W.; Li, W.; Liou, F. A Hybrid Process Integrating Reverse Engineering, Pre-Repair Processing, Additive Manufacturing, and Material Testing for Component Remanufacturing. Materials 2019, 12, 1961. [Google Scholar] [CrossRef]

- Zhang, S.; Gong, M.; Zeng, X.; Gao, M. Residual Stress and Tensile Anisotropy of Hybrid Wire Arc Additive-Milling Subtractive Manufacturing. J. Mater. Process. Technol. 2021, 293, 117077. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, J.; Ahmad, R. A Cost-Driven Process Planning Method for Hybrid Additive-Subtractive Remanufacturing. J. Manuf. Syst. 2020, 55, 248–263. [Google Scholar] [CrossRef]

- Zong, X.; Ji, Z.; Zhao, Z.; Feng, X.; Ding, X.; Nan, H. Microstructure and Tensile Property of Hybrid Fabricated Ti-6Al-4V Alloy by Investment Casting and Laser Additive Manufacturing. Metals 2023, 13, 668. [Google Scholar] [CrossRef]

- Conradie, P.J.T.; Dimitrov, D.; Oosthuizen, G.A.; Hugo, P.; Saxer, M. Comparative Assessment of Process Combination for Ti6Al4V Components. Rapid Prototyp. J. 2017, 23, 624–632. [Google Scholar] [CrossRef]

- Bhaduri, D.; Penchev, P.; Essa, K.; Dimov, S.; Carter, L.; Pruncu, C.; Pullini, D. Evaluation of Surface/Interface Quality, Microstructure and Mechanical Properties of Hybrid Additive-Subtractive Aluminium Parts. CIRP Ann. Manuf. Technol. 2019, 68, 237–240. [Google Scholar] [CrossRef]

- Stournaras, A.; Stavropoulos, P.; Salonitis, K.; Chryssolouris, G. An Investigation of Quality in CO2 Laser Cutting of Aluminum. CIRP J. Manuf. Sci. Technol. 2009, 2, 61–69. [Google Scholar] [CrossRef]

- Didier, P.; Coz, G.L.; Robin, G.; Lohmuller, P.; Piotrowski, B.; Moufki, A.; Laheurte, P. Consideration of Additive Manufacturing Supports for Post-Processing by End Milling: A Hybrid Analytical-Numerical Model and Experimental Validation. Prog. Addit. Manuf. 2022, 7, 15–27. [Google Scholar] [CrossRef]

- Cen, L.; Melkote, S.N.; Castle, J.; Appelman, H. A Wireless Force-Sensing and Model-Based Approach for Enhancement of Machining Accuracy in Robotic Milling. IEEE/ASME Trans. Mechatron. 2016, 21, 2227–2235. [Google Scholar] [CrossRef]

- Chen, Z.C.; Dong, Z.; Vickers, G.W. Automated Surface Subdivision and Tool Path Generation for 31212-Axis CNC Machining of Sculptured Parts. Comput. Ind. 2003, 50, 319–331. [Google Scholar] [CrossRef]

- Perini, M.; Bosetti, P.; Balc, N. Additive Manufacturing for Repairing: From Damage Identification and Modeling to DLD. Rapid Prototyp. J. 2020, 26, 929–940. [Google Scholar] [CrossRef]

- Zhang, W.; Soshi, M.; Yamazaki, K. Development of an Additive and Subtractive Hybrid Manufacturing Process Planning Strategy of Planar Surface for Productivity and Geometric Accuracy. Int. J. Adv. Manuf. Technol. 2020, 109, 1479–1491. [Google Scholar] [CrossRef]

- Fontes, J.; Santos, J.; Silva, M. Torque Optimization of Parallel Manipulators by The Application of Kinematic Redundancy. In Proceeding of the 8th National Congress of Mechanical Engineering, Taiyuan, China, 10–14 August 2014. [Google Scholar]

- Liou, F.; Slattery, K.; Kinsella, M.; Newkirk, J.; Chou, H.-N.; Landers, R. Applications of a Hybrid Manufacturing Process for Fabrication of Metallic Structures. Rapid Prototyp. J. 2007, 13, 236–244. [Google Scholar] [CrossRef]

- Li, L.; Haghighi, A.; Yang, Y. A Novel 6-Axis Hybrid Additive-Subtractive Manufacturing Process: Design and Case Studies. J. Manuf. Process. 2018, 33, 150–160. [Google Scholar] [CrossRef]

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Juhasz, M.; Tiedemann, R.; Dumstorff, G.; Walker, J.; Plessis, A.D.; Conner, B.; Lang, W.; MacDonald, E. Hybrid Directed Energy Deposition for Fabricating Metal Structures with Embedded Sensors. Addit. Manuf. 2020, 35, 101397. [Google Scholar] [CrossRef]

- Furumoto, T.; Abe, S.; Yamaguchi, M.; Hosokawa, A. Improving Surface Quality Using Laser Scanning and Machining Strategy Combining Powder Bed Fusion and Machining Processes. Int. J. Adv. Manuf. Technol. 2021, 117, 3405–3413. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sampaio, R.F.V.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid Metal Additive Manufacturing: A State–of–the-Art Review. Adv. Ind. Manuf. Eng. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Y.; Yang, Y.; Xiao, D. Theoretical and Experimental Study on Surface Roughness of 316L Stainless Steel Metal Parts Obtained Through Selective Laser Melting. Rapid Prototyp. J. 2016, 22, 706–716. [Google Scholar] [CrossRef]

- Moheimani, S.K.; Iuliano, L.; Saboori, A. The Role of Substrate Preheating on the Microstructure, Roughness, and Mechanical Performance of AISI 316L Produced by Directed Energy Deposition Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2022, 119, 7159–7174. [Google Scholar] [CrossRef]

- Lefky, C.S.; Zucker, B.; Nassar, A.R.; Simpson, T.W.; Hildreth, O.J. Impact of Compositional Gradients on Selectivity of Dissolvable Support Structures for Directed Energy Deposited Metals. Acta Mater. 2018, 153, 1–7. [Google Scholar] [CrossRef]

- Lee, K.; Jee, H. Slicing Algorithms for Multi-Axis 3-D Metal Printing of Overhangs. J. Mech. Sci. Technol. 2015, 29, 5139–5144. [Google Scholar] [CrossRef]

- Rojas-Nastrucci, E.A.; Tsang, H.; Deffenbaugh, P.I.; Ramirez, R.A.; Hawatmeh, D.; Ross, A.; Church, K.; Weller, T.M. Characterization and Modeling of K-Band Coplanar Waveguides Digitally Manufactured Using Pulsed Picosecond Laser Machining of Thick-Film Conductive Paste. IEEE Trans. Microw. Theory Tech. 2017, 65, 3180–3187. [Google Scholar] [CrossRef]

- Mognol, P.; Rivette, M.; Jegou, L.; Lesprier, T. A First Approach to Choose Between HSM, EDM and DMLS Processes in Hybrid Rapid Tooling. Rapid Prototyp. J. 2007, 13, 7–16. [Google Scholar] [CrossRef]

- Ye, Z.; Zhang, Z.; Jin, X.; Xiao, M.-Z.; Su, J. Study of Hybrid Additive Manufacturing Based on Pulse Laser Wire Depositing and Milling. Int. J. Adv. Manuf. Technol. 2017, 88, 2237–2248. [Google Scholar] [CrossRef]

- Hassanin, H.; Modica, F.; El-Sayed, M.A.; Liu, J.; Essa, K. Manufacturing of Ti–6Al–4V Micro-Implantable Parts Using Hybrid Selective Laser Melting and Micro-Electrical Discharge Machining. Adv. Eng. Mater. 2016, 18, 1544–1549. [Google Scholar] [CrossRef]

- Riede, M.; Knoll, M.; Wilsnack, C.; Gruber, S.; Alegre Cubillo, A.; Melzer, C.; Brandão, A.; Pambaguian, L.; Seidel, A.; Lopez, E.; et al. Material Characterization of AISI 316L Flexure Pivot Bearings Fabricated by Additive Manufacturing. Materials 2019, 12, 2426. [Google Scholar] [CrossRef] [PubMed]

- Seltzman, A.H.; Wukitch, S.J. Surface Roughness and Finishing Techniques in Selective Laser Melted GRCop-84 Copper for an Additive Manufactured Lower Hybrid Current Drive Launcher. Fusion Eng. Des. 2020, 160, 111801. [Google Scholar] [CrossRef]

- Dewes, R.C.; Aspinwall, D.K. A Review of Ultra High Speed Milling of Hardened Steels. J. Mater. Process. Technol. 1997, 69, 1–17. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Yu, Z.; Chen, J.; Yang, J. A Processing Technology of Grooves by Picosecond Ultrashort Pulse Laser in Ni Alloy: Enhancing Efficiency and Quality. Opt. Laser Technol. 2019, 111, 214–221. [Google Scholar] [CrossRef]

- Näsström, J.; Brueckner, F.; Kaplan, A.F.H. Laser Enhancement of Wire Arc Additive Manufacturing. J. Laser Appl. 2019, 31, 022307. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Wang, Y. A Complete Study on Satellite Thruster Structure (STS) Manufactured by a Hybrid Manufacturing (HM) Process with Integration of Additive and Subtractive Manufacture. Int. J. Adv. Manuf. Technol. 2017, 92, 4367–4377. [Google Scholar] [CrossRef]

- Pajaziti, A.; Tafilaj, O.; Gjelaj, A.; Berisha, B. Optimization of Toolpath Planning and CNC Machine Performance in Time-Efficient Machining. Machines 2025, 13, 65. [Google Scholar] [CrossRef]

- Liao, J.; Huang, Z. Data Model-Based Toolpath Generation Techniques for CNC Milling Machines. Front. Mech. Eng. 2024, 10, 1358061. [Google Scholar] [CrossRef]

- Kukreja, A.; Pande, S.S. Optimal Toolpath Planning Strategy Prediction Using Machine Learning Technique. Eng. Appl. Artif. Intell. 2023, 123, 106464. [Google Scholar] [CrossRef]

- Hou, G. Computing Tool Accessibility of Polyhedral Models for Toolpath Planning in Multi-Axis Machining. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2019. [Google Scholar]

- Hamilton, J.D.; Glockner, W.W.; Weisbeck, P. Process Development of a Large-Scale Hybrid Manufacturing Platform for Advanced Toolpath and Parametric Control. In Proceeding of the 2024 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 11–14 August 2024. [Google Scholar]

- Chen, Y.; Zhang, T.; Huang, Y.; Liu, T.; Wang, C.C.L. Co-Optimization of Tool Orientations, Kinematic Redundancy, and Waypoint Timing for Robot-Assisted Manufacturing. arXiv 2024. [Google Scholar] [CrossRef]

- Török, J.; Dupláková, D. Integrated Practical Framework for Multidisciplinary Prototype Design and Manufacturing Process. Processes 2025, 13, 454. [Google Scholar] [CrossRef]

- Török, J.; Kočiško, M.; Pollák, M.; Vandžura, R. Manufacturing and testing of pliers to weld 3D printing filaments. J. Phys. Conf. Ser. 2024, 2805, 012006. [Google Scholar] [CrossRef]

- Swathi, B.; Polyakov, S.V.; Kandavalli, S.R.; Singh, D.K.; Murthy, M.Y.B.; Gopi, A. Enhancing Hybrid Manufacturing with AI-driven Real-Time Adaptive Process Control: Integrating Machine Learning Models and Robotic Systems. Int. J. Adv. Manuf. Technol. 2024, 1–9. [Google Scholar] [CrossRef]

- Anang, A.N.; Obidi, P.O.; Mesogboriwon, A.O.; Obidi, J.O.; Kuubata, M.; Ogunbiyi, D. THE Role of Artificial Intelligence in Industry 5.0: Enhancing Human-Machine Collaboration. World J. Adv. Res. Rev. 2024, 24, 380–400. [Google Scholar] [CrossRef]

- Xu, J.; Sun, Q.; Han, Q.-L.; Tang, Y. When Embodied AI Meets Industry 5.0: Human-Centered Smart Manufacturing. IEEE/CAA J. Autom. Sin. 2025, 12, 485–501. [Google Scholar] [CrossRef]

- Su, C.; Tang, X.; Jiang, Q.; Han, Y.; Wang, T.; Jiang, D. Digital Twin System for Manufacturing Processes Based on a Multi-Layer Knowledge Graph Model. Sci. Rep. 2025, 15, 12835. [Google Scholar] [CrossRef]

- Chen, Y.; He, D.; Hao, J.; Deng, X.; Zhang, W.; Fu, Z.; Wang, Y.; Chen, L.; Hu, P.; Tang, K. Five-Axis Hybrid Manufacturing with DED and Milling for Complex Multi-Branched Metallic Parts. Int. J. Comput. Integr. Manuf. 2025, 1–30. [Google Scholar] [CrossRef]

| Multi-Material | Material Type | Material | Other Process | SM Process | AM Process | Operation | Configuration | Type | Topic | Area | Country | Citation Key |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yes | Composite | Carbon Fiber, Epoxy | Hand Layup | - | Automated Fibre Placement (AFP) | Sequential | Separate | HAM | Characterization | Vehicle | Australia | (Air et al., 2023) [43] |

| No | Metal | Inconel 718 | Wrought | - | Directed Energy Deposition (DED) | Sequential | Separate | HAM | Characterization | Research | UK | (Al-Lami et al., 2023) [44] |

| No | Metal | Stainless Steel (SS) | Single Point Incremental Forming | - | Selective Laser Sintering (SLS) | Sequential | Separate | HAM | Characterization | Research | Italy | (Ambrogio et al., 2019) [45] |

| Yes | Polymer, Composite | GPET, LCP Fiber | Compression Molding | - | Fused Deposition Modeling (FDM) | Sequential | Separate | HAM | Characterization | Research | Poland | (Andrzejewski et al., 2022) [46] |

| Yes | Metal | AA 2219, AISI 321 | Friction Surfacing | - | Cold Metal Transfer (CMT) Welding | Sequential | Separate | HAM | Characterization | Research | India | (Babu et al., 2019) [47] |

| No | Metal | 6511 SS | Precision Machining (PM) | Selective Laser Melting (SLM) | Sequential | Separate | HM | Characterization | Research | China | (Bai et al., 2020) [48] | |

| No | Metal | Ti-6Al-4V | Metal Forming | - | Wire Arc Additive Manufacturing (WAAM) | Sequential | Separate | HAM | Characterization | Vehicle | Germany | (Bambach et al., 2020) [49] |

| No | Metal | AA 6016 | Hole-Flanging Forming | - | Directed Energy Deposition (DED) | Sequential | Separate | HAM | Characterization | Vehicle | Switzerland | (Bambach et al., 2021) [50] |

| No | Polymer | VisiJet® M2 RWT | Machining | MultiJet Printing (MJP) | Manual | Separate | HM | Characterization | Medicine | USA | (Basinger et al., 2018) [51] | |

| Yes | Ceramic | Porcelain, Graphite Ink | Direct Ink Writing (DIW) | Machining | Layerwise Slurry Deposition | Sequential | Single | HAM | Characterization | Electronics | Germany | (Bernardino et al., 2020) [52] |

| Yes | Metal, Composite | Structural Glass, Silver Ink | Laser Ablation (LA) | Inkjet Printing | Sequential | Separate | HM | Characterization | Electronics | Australia | (Beziuk et al., 2019) [53] | |

| No | Metal | AA6082 | Machining | Hybrid Additive Manufacturing (HYB-AM) | Sequential | Separate | HM | Characterization | Research | Norway | (Blindheim et al., 2019) [54] | |

| Yes | Metal | AlSi10Mg, Al99.8 | Forging | - | Laser Powder Bed Fusion (LPBF) | Manual | Separate | HAM | Characterization | Research | Germany | (Bohm et al., 2020) [55] |

| No | Metal | 316L SS | Machining | Directed Energy Deposition (DED) | Sequential | Separate | HM | Characterization | Research | Brazil | (Bordinassi et al., 2022) [56] | |

| No | Metal | 316L SS | Polishing, Grinding | Machining | Directed Energy Deposition (DED) | Sequential | Single | HM | Characterization | Research | USA | (Botcha et al., 2020) [57] |

| No | Metal | Ti-6Al-4V | Femtosecond Laser Ablation (FSLA) | Additive Manufacturing (Laser-Based) (AM-LB) | Cyclical | Separate | HM | Characterization | Medicine | France | (Bouet et al., 2019) [37] | |

| No | Metal | Aluminum (Al) | Machining | Ultrasonic Additive Manufacturing (UAM) | Cyclical | Separate | HM | Characterization | Electronics | UK | (Bournias-Varotsis et al., 2018) [58] | |

| No | Metal | Inconel 718 | Machining | Selective Laser Melting (SLM) | Sequential | Separate | HM | Characterization | Research | USA | (Brown et al., 2018) [59] | |

| No | Metal | 316L SS | Laser Re-melting | - | Directed Energy Deposition (DED) | Sequential | Separate | HAM | Characterization | Research | Italy | (Bruzzo et al., 2021) [60] |

| Yes | Polymer, Composite | Glass Fiber, PLA | vacuum forming | Machining | Fused Deposition Modeling (FDM) | Sequential | Separate | HM | Characterization | Research | UK | (Butt et al., 2019) [61] |

| No | Metal | Inconel 718 | Machining | Laser Cladding Deposition | Sequential | Separate | HM | Characterization | Research | Spain | (Calleja et al., 2018) [62] | |

| No | Metal | AISI H13 | Machining | Wire Arc Additive Manufacturing (WAAM) | Sequential | Separate | HM | Sustainability | Research | Italy | (Campatelli et al., 2021) [63] | |

| Yes | Metal | Eutroloy 16606A, 42CrMoS4 | Machining | Laser Metal Deposition (LMD) | Sequential | Separate | HM | Sustainability | Research | Spain | (Castro et al., 2018) [64] | |

| - | - | - | Machining | Electron Beam Melting (EBM) | Sequential | Separate | HM | Toolpath | Research | USA | (Chen et al., 2018) [65] | |

| No | Metal | 316L SS | Welding | - | Laser Powder Bed Fusion (LPBF) | Sequential | Separate | HM | Other | Civil | Italy | (Chierici et al., 2023) [66] |

| Yes | Metal, Polymer | PC, ABS, PLA, TPLA, Silver Paste | Material Extrusion (ME) | - | Direct Writing (DW) | Sequential | Separate | HAM | Characterization | Electronics | UK | (Cicek et al., 2023) [67] |

| - | - | - | Machining | Wire Arc Additive Manufacturing (WAAM) | Sequential | Separate | HM | Characterization | Research | USA | (Cornelius et al., 2022) [68] | |

| Yes | Metal | Inconel 718, MetcoClad 718 | Machining | Directed Energy Deposition (DED) | Sequential | Separate | HM | Characterization | Research | Spain | (Cortina et al., 2018) [69] | |

| No | Metal | 316L SS | single-point incremental forming, (SPIF) | - | Wire Arc Additive Manufacturing (WAAM) | Sequential | Separate | HAM | Characterization | Research | Portugal | (Cristino et al., 2021) [70] |

| No | Metal | Ti-6Al-4V | Forging | - | Laser Metal Deposition (LMD) | Sequential | Separate | HAM | Characterization | Research | China | (Cui et al., 2021) [71] |

| No | Metal | 316L SS | Micro-End Milling (MEM) | Powder Bed Fusion (PBF) | Sequential | Separate | HM | Characterization | Research | Brazil | (de Assis et al., 2020) [72] | |

| Yes | Composite | Al 1050, β-SiC | Cryorolling | - | Stir Casting | Sequential | Separate | HAM | Characterization | Research | India | (Deb et al., 2018) [73] |

| No | Polymer | Polydimethylsiloxane (PDMS) | Two-photon polymerization (TPP or 2PP) | - | Stereolithography (SLA) | Sequential | Separate | HAM | Characterization | Micromanufacturing | Belgium | (Dehaeck et al., 2019) [74] |

| Yes | Metal, Polymer | Liquid Metal, Elastomer | vacuum casting, coating | - | Digital Light Processing (DLP) | Sequential | Separate | HAM | Characterization | Research | USA | (Deng et al., 2020) [75] |

| Yes | Polymer, Composite | Glass Fiber, Carbon Fiber, ABS | Hot Press Molding | - | Fused Deposition Modeling (FDM) | Sequential | Separate | HAM | Characterization | Research | India | (Dhandapani et al., 2023) [76] |

| No | Metal | Ti-6Al-4V | Milling | Powder Bed Fusion (PBF) | Sequential | Separate | HM | Characterization | Research | Israel | (Dolev et al., 2021) [77] | |

| No | Metal | Ti-6Al-4V | Milling | Directed Laser Deposition (DLD) | Sequential | Separate | HM | Sustainability | Research | China | (Du et al., 2018) [29] | |

| No | Metal | 18Ni-300 Steel | Milling | Selective Laser Melting (SLM) | Sequential | Single | HM | Characterization | Research | China | (Du et al., 2018) [78] | |

| No | Metal | 316L SS | Dry EDM Milling (DEDM) | Plasma Arc Powder (PAP-WAAM) | Concurrent | Separate | HM | Characterization | Research | China | (Duan et al., 2023) [79] | |

| No | Metal | AlSi5 Aluminum | Milling | Wire Arc Additive Manufacturing (WAAM) | Sequential | Separate | HM | Sustainability | Research | Slovenia | (Dugar et al., 2022) [80] | |

| No | Ceramic | Silicon Carbide (SiC) | Structured Light Scanning | Machining | Binder Jetting (BJ) | Sequential | Separate | HM | Characterization | Research | USA | (Dvorak et al., 2023) [81] |

| No | Metal | Fe-25Al-1.5Ta | Hot Working (HW) | Laser Powder Bed Fusion (LPBF) | Sequential | Separate | HM | Characterization | Research | Germany | (Emdadi et al., 2023) [82] | |

| - | - | - | Collaborative Assembly | - | - | Concurrent | In-situ | HHRM | Other | Robotics | The Netherlands | (Erasmus et al., 2018) [83] |

| No | Metal | 316L SS | Machining | Directed Energy Deposition (DED) | Sequential | Single | HM | Characterization | Vehicle | USA | (Feldhausen et al., 2021) [39] | |

| No | Metal | 316L SS | Machining | Directed Energy Deposition (DED) | Sequential | Single | HM | Characterization | Research | USA | (Feldhausen et al., 2022) [84] | |

| Yes | Metal | 316L SS, 1060 | Machining | Directed Energy Deposition (DED) | Sequential | Single | HM | Characterization | Research | USA | (Feldhausen et al., 2023) [85] | |

| Yes | Polymer, Composite | PA12, Fiber-PA12 | Machining | Fused Filament Fabrication (FFF) | Sequential | Separate | HM | Characterization | Research | Portugal | (Ferreira et al., 2020) [86] | |

| Yes | Polymer | Resin, Medical Silicone GSM50 | Casting | - | Stereolithography (SLA) | Manual | Separate | HAM | Education | Medicine | Australia | (Fitzgerald et al., 2023) [87] |

| Yes | Polymer, Composite | Kenaf, EVO Resin | autoclave | - | Vacuum-Assisted Resin Infusion (VARI) | Manual | Separate | HAM | Sustainability | Medicine | Mexico | (Franco-Urquiza et al., 2021) [88] |

| No | Metal | 316L SS | single point incremental forming (SPIF) | - | Directed Energy Deposition (DED) | Sequential | Separate | HAM | Characterization | Research | Singapore | (Gao et al., 2022) [89] |

| No | Metal | S355J2 | CMT | Machining | Wire Arc Additive Manufacturing (WAAM) | Sequential | Separate | HAM | Sustainability | Civil | Switzerland | (Ghafoori et al., 2023) [90] |

| No | Metal | 316L SS | Wire-EDM (WEDM) | Powder Bed Fusion (PBF) | Sequential | Separate | HM | Characterization | Research | USA | (Gomez et al., 2021) [91] | |

| No | Metal | 316L SS | Machining | Directed Energy Deposition (DED) | Sequential | Single | HM | Characterization | Research | Ireland | (Gong et al., 2019) [92] | |

| No | Polymer | ABS | Injection Molding (IM) | - | Fused Deposition Modeling (FDM) | Sequential | Separate | HAM | Other | Research | Ireland | (Gong et al., 2022) [93] |

| No | Polymer | PLA | Injection Molding (IM) | - | Fused Deposition Modeling (FDM) | Sequential | Separate | HAM | Characterization | Research | China | (Gong et al., 2022) [94] |

| Yes | Metal | Hastelloy, Inconel 718 | Machining | Directed Energy Deposition (DED) | Sequential | Separate | HM | Sustainability | Research | Spain | (Gonzalez-Barrio et al., 2022) [95] | |

| Yes | Metal, Polymer | PBT, Silver Paste | - | ARBURG Plastic Freeforming (APF) | Sequential | Separate | HAM | Characterization | Electronics | Germany | (Granse et al., 2023) [96] | |

| No | Metal | 316L SS | High-speed laser directed energy deposition (HS L-DED) | Micro Milling | Laser Powder Bed Fusion (LPBF) | Sequential | Separate | HM | Characterization | Micromanufacturing | Germany | (Greco et al., 2022) [97] |

| No | Metal | Inconel 738LC | Machining | Selective Laser Melting (SLM) | Sequential | Separate | HM | Characterization | Research | China | (Guo et al., 2021) [98] | |

| No | Metal | 18Ni300 Maraging Steel | Milling | Selective Laser Melting (SLM) | Sequential | Separate | HM | Characterization | Research | China | (Guo et al., 2023) [99] | |

| No | Metal | 1070 Steel | Manual Stacking | - | Shot Peening (SP) | Manual | Separate | HAM | Characterization | Vehicle | USA | (Hadidi et al., 2020) [100] |

| Yes | Metal | Ti6Al4V, NiTi SMA | Purchased | - | Laser Powder Bed Fusion (LPBF) | Sequential | Separate | HAM | Characterization | Medicine | Germany | (Hamann et al., 2021) [101] |

| No | Metal | 316L SS | Machining | Laser Metal Deposition (LMD) | Sequential | Separate | HM | Sustainability | Research | China | (He et al., 2020) [102] | |

| No | Metal | Structural Steel | Layer laminated manufacturing (LLM) – LOM | - | LOM | Sequential | Separate | HM | Optimization | Research | Germany | (Helfesrieder et al., 2022) [103] |

| No | Metal | Ti-6Al-4V | Hot Forging | - | Laser Directed Energy Deposition (L-DED) | Sequential | Separate | HAM | Characterization | Research | Germany | (Hemes et al., 2021) [104] |

| Yes | Metal, Ceramic | Copper, SiC | Etching | Electroplating | Sequential | Separate | HM | Characterization | Electronics | USA | (Herrault et al., 2020) [105] | |

| No | Metal | Titanium Alloy (Ti Alloy) | Milling | Laser Hotwire Directed Energy Deposition (DED) | Sequential | Separate | HM | Characterization | Research | USA | (Honeycutt et al., 2021) [106] | |

| Yes | Metal, Ceramic, Polymer | PMMA, Silver Nanoparticles, TiO2 | Focused Ion Beam (FIB) Milling | Micro Milling | Aerodynamically Focused Nanoparticles Printing (AFN) | Sequential | Separate | HM | Characterization | Micromanufacturing | South Korea | (Jang et al., 2020) [107] |

| No | Polymer | PLA | Machining | Fused Deposition Modeling (FDM) | Sequential | Separate | HM | Characterization | Research | South Korea | (Lee et al., 2018) [108] | |

| Yes | Metal | Nano-AlSi10Mg + Al2O3 | Casting | Machining | Binder Jetting (BJ) | Sequential | Separate | HM | Characterization | Research | Germany | (Lee et al., 2021) [109] |

| No | Metal | 304 SS | Ultrasonic vibration-assisted laser polishing (UVLP) | - | - | Assisted | Separate | HSM | Characterization | Research | China | (Lee et al., 2022) [110] |

| No | Metal | 316L SS | Wire-EDM (WEDM) | Hot Wire Deposition (HWD) | Sequential | Separate | HM | Characterization | Research | USA | (Kaiser et al., 2023) [111] | |

| No | Ceramic | Sapphire | micromilling | Laser Machining (LM) | - | Sequential | Separate | HSM | Characterization | Micromanufacturing | Japan | (Kang et al., 2020) [112] |

| No | Metal | 316L SS | Machining | Selective Laser Melting (SLM) | Sequential | Separate | HM | Characterization | Medicine | Turkey | (Kannan et al., 2021) [113] | |

| No | Metal | Ti Alloy | milling | Laser Ablation (LA) | - | Manual | Separate | HSM | Characterization | Medicine | Poland | (Katahira et al., 2020) [114] |

| Yes | Composite | Acrylic Mixture | UV Curing | - | Paste Extrusion | Assisted | Separate | HM | Characterization | Medicine | Finland | (Kaynak et al., 2018) [115] |

| No | Polymer | PDMS | Laser-based machining | Micro-Drilling (MD) | - | Sequential | Separate | HSM | Characterization | Medicine | USA | (Komorowski et al., 2020) [116] |

| No | Metal | Copper (Cu) | Focused ion beam | Micro-Electrical Discharge Machining (MEDM) | - | Sequential | Separate | HSM | Characterization | Micromanufacturing | South Korea | (Kretzschmar et al., 2019) [117] |

| Yes | Metal | 316L, 40 Steel | Machining | Directed Energy Deposition (DED) | Sequential | Single | HM | Characterization | Research | China | (Li et al., 2018) [118] | |

| No | Metal | Al 6061 | Milling | Bending | Sequential | Separate | HM | Characterization | Research | USA | (Li et al., 2018) [119] | |

| No | Metal | 316L SS Powder, Inconel 718 Powder | Thermal Milling (TM) | Directed Laser Deposition (DLD) | Sequential | Separate | HM | Characterization | Research | China | (Li et al., 2019) [120] | |