Aspects of Design Thinking, Material and Usability Engineering in the Design of Suit for Police Officers Operating on Motorcycles—Part I: Design and Safety Aspects

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Cordura 1100 woven fabric originated from C.F.WEBER GmbH (Leutersdorf, Germany); codded in Table 1 as C1100 layer;

- Cordura 560 woven fabric originated from C.F.WEBER GmbH (Leutersdorf, Germany); codded in Table 1 as C560 layer;

- Oratlion originated from YORK (Radom/Poland); codded in Table 1 as O layer;

- Black knitting mesh originated from GEDEON (Lodz, Poland); codded in Table 1 as BK layer;

- Waterproof membrane originated from Green Side (Warsaw, Poland); codded in Table 1 as WM layer;

- Oultlast lining originated from Outlast Technologies GmbH (Heidenheim, Germany); codded in Table 1 as OL layer;

- Navy blue mesh originated from GEDEON (Lodz, Poland); codded in Table 1 as NBK layer;

- Kevlar knit originated from INVENTEX (Hof/Saale, Germany); codded in Table 1 as KK layer;

- Black woven lining originated from C.F.WEBER GmbH (Leutersdorf, Germany); codded in Table 1 as BL layer;

2.2. Methods

2.2.1. Design Thinking Methodology

2.2.2. Usability Engineering

2.2.3. Estimation of the Safety of the Designed Motorcycle Suits

2.2.4. Chemical Safety

3. Results and Discussion

3.1. Design Thinking

3.2. Usability Engineering

- every day, typical use;

- redundant use;

- use in extreme conditions (e.g., at temperatures above +50 °C or below −30 °C);

- inconsistent with the maintenance process indicated by the manufacturer;

- illegible or overly complicated instructions for use;

- illegible label;

- too long time between trainings;

- insufficient quality of training;

- improper primary/secondary packaging;

- incompatible storage/transport conditions of the textile motorcycle suits;

- lack of checking the skills of the direct user;

- accidental damage to the product during use and the procedure for reporting/replacing the textile motorcycle suits;

- use of the textile motorcycle suits after the defined period of use;

- incorrect drying process of the product after use in rain/snow;

- failure to provide the comfort required by the specificity of use, including thermal comfort and ergonomics;

- quick wear of the materials and protectors used;

- inappropriate size design;

- too high exposure to a collision;

- too high exposure to abrasion;

- exposure to carcinogenic, skin-irritating, and sensitizing substances (substance migration from the man-made fibers);

- loss of safety after maintenance processes.

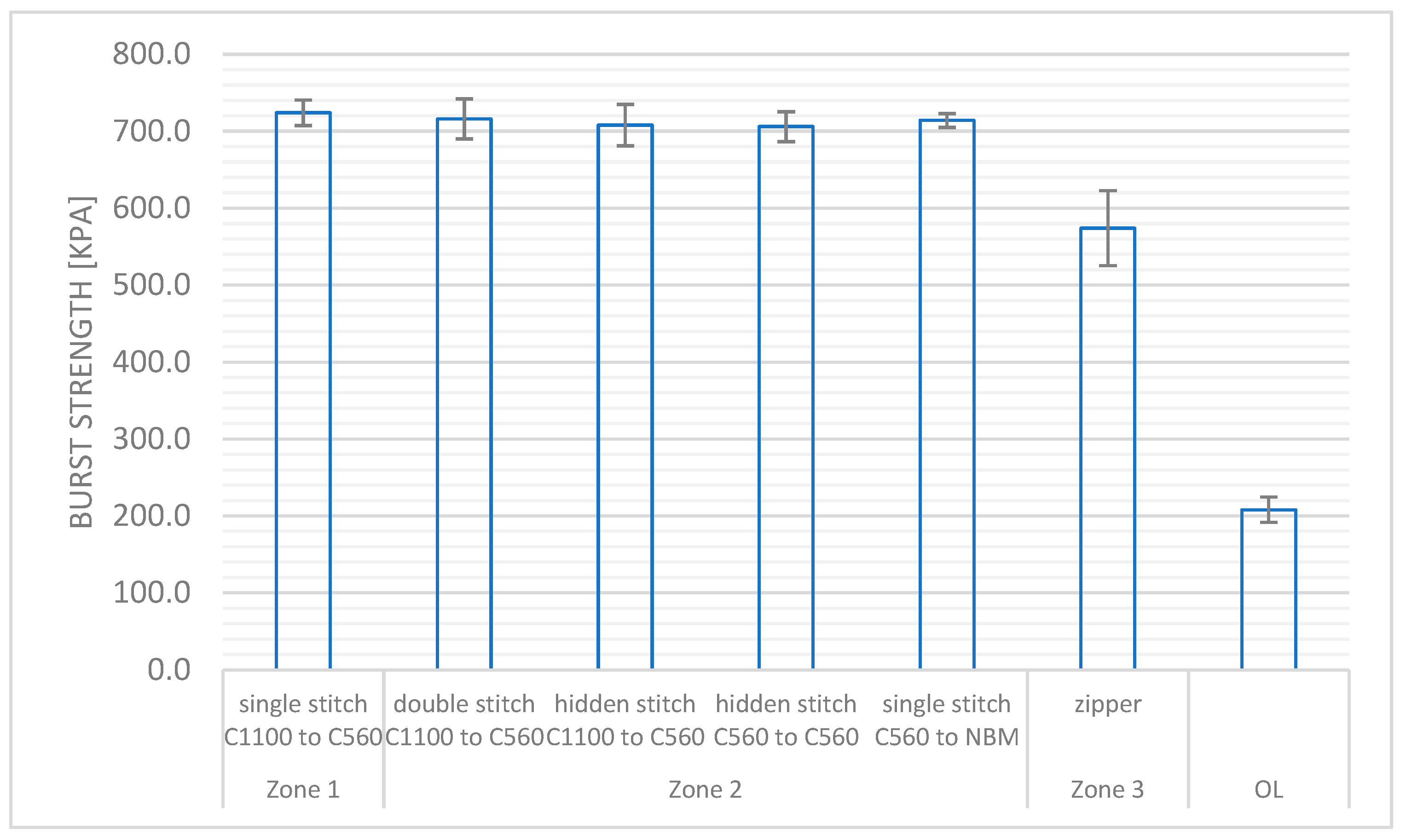

3.3. Safety Assessment

3.4. Chemical Safety Aspect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McCann, J.; Bryson, D. Smart Clothes and Wearable Technology; Woodhead Publishing Limited: Oxford, UK; Cambrigde, UK; CRC Press LLC: New Delhi, India, 2009; pp. 45–69, 95–107. [Google Scholar]

- Neves, E.P.; Brigattoa, A.C.; Paschoarellia, L.C. Fashion and Ergonomic Design: Aspects that influence the perception of clothing usability. Procedia Manuf. 2015, 3, 6133–6139. [Google Scholar] [CrossRef]

- Yao, M.; Li, I.L. Design Thinking Applied to Home Textiles Innovation: A Case Study in an Elderly Centre in Hong Kong. Designs 2022, 6, 49. [Google Scholar] [CrossRef]

- Lamb, J.M.; Kallal, M.J. A conceptual framework for apparel design. CTRJ 1992, 10, 42–47. [Google Scholar] [CrossRef]

- Gupta, D. Design and engineering of functional clothing. IJFTR 2011, 36, 327–335. [Google Scholar]

- Grabowska, G.; Struszczyk, M.H.; Błaszczyk, J.; Woźniakowska, M. Operational Qualification of the Individualisation of Protective Clothing Design Based on the 3D Scanning Technique. Fibres Text. East. Eur. 2020, 28, 89–97. [Google Scholar]

- Grabowska, G.; Struszczyk, M.H.; Błaszczyk, J.; Woźniakowska, M. Process Qualification of the Individualization of Protective Clothing Design Based on 3D Scanning Technique. Fibres Text. East. Eur. 2020, 28, 112–118. [Google Scholar]

- Heesun, K. Evaluating the Usability of Size Comparison UI for Online Clothing Shopping Malls. IJIBC 2020, 12, 61–70. [Google Scholar]

- Padez, A.J.; Pombo, N.G.C.C.; Santos, N.M.G.; Pereira, M.M.R. State of the Art-Ergonomics and Modeling of Functional Clothing Products with Biosignals Sensor Integration, International Congress on Engineering—Engineering for Evolution. KnE Eng. 2020, 2020, 155–168. [Google Scholar]

- Meredith, L.; Hurren, C.H.; Clarke, E.; Fitzharris, M.; Baldock, M.; De Rome, L.; Olivier, J.; Brown, J. Validation of the abrasion resistance test protocols and performance criteria of EN13595: The probability of soft tissue injury to motorcycle riders by abrasion resistance of their clothing. J. Saf. Res. 2017, 61, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Meredith, L.; Brown, J.; Clarke, E. Relationship between skin abrasion injuries and clothing material characteristics in motorcycle crashes. Biotribology 2015, 3, 20–26. [Google Scholar] [CrossRef]

- Wali, B.; Ahmad, N.; Khattak, A.J. Toward better measurement of traffic injuries—Comparison of anatomical injury measures in predicting the clinical outcomes in motorcycle crashes. J. Saf. Res. 2022, 80, 175–189. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 13595-1:2005; Protective Clothing for Professional Motorcycle Riders–Jackets, Trousers and One Piece or Divided Suits. Polish Committee for Standardization: Warsaw, Poland, 2005.

- Meredith, L.; Brown, J.; Ivers, R.; De Rome, L. Distribution and Type of Crash Damage to Motorcyclists’ Clothing: Validation of the Zone Approach in the European Standard for Motorcycle Protective Clothing, EN13595. Traffic Inj. Prev. 2014, 15, 501–507. [Google Scholar] [CrossRef] [PubMed]

- De Rome, L.; Ivers, R.; Fitzharri, M.; Du, W.; Haworth, N.; Heritier, S.; Richardson, D. Motorcycle protective clothing: Protection from injury or just the weather? Accid. Anal. Prev. 2011, 43, 1893–1900. [Google Scholar] [CrossRef] [PubMed]

- De Rome, L.; Meredith, L.; Ivers, R.; Brown, J. Validation of the principles of injury risk zones for motorcycle protective clothing. J. Saf. Res. 2014, 50, 83–87. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, G.; Rajan, P. Review on the performance characteristics and quality standards of motorcycle protective clothing. J. Ind. Text. 2022, 51, 7409S–7427S. [Google Scholar] [CrossRef]

- Hurren, C.H.; Varnsverry, P.; De Rome, L.A. A Guide to Designing and Manufacturing Motorcycle Protective Clothing. December 2022. Available online: https://www.motocap.com.au/sites/default/files/2023-02/A%20guide%20to%20designing%20and%20manufacturing%20motorcycle%20protective%20clothing_0.pdf (accessed on 15 July 2025).

- Baldock, M.R.J.; Thompson, J.P. Motorcycle Protective Clothing in the ACT. ISBN 978 1 925971 43 9. November 2022. Available online: https://www.cityservices.act.gov.au/__data/assets/pdf_file/0004/2168257/Report-Final-report-for-Motorcycle-Protective-Clothing-8_12_22.pdf (accessed on 15 August 2025).

- Zwolińska, M. Case Study of the Impact of Motorcycle Clothing on the Human Body and its Thermal Insulation. Fibres Text. East. Eur. 2013, 21, 124–130. [Google Scholar]

- Yousif, T.M.; Sadullah, A.F.M.; Abu Kassimb, K.A.A. A review of behavioural issues contribution to motorcycle safety. IATSS Res. 2020, 44, 142–154. [Google Scholar] [CrossRef]

- Varshney, G.; Singh, P.; Yadav, S.; Kaur, R. A review on unleashing the potential solution of thermal comfort: Exploring the cutting-edge progress of advanced engineering application of phase change materials integrated textiles. Sustain. Energy Technol. Assess. 2024, 72, 104089. [Google Scholar] [CrossRef]

- Das, A.; Apu, M.H.; Akter, A.; Reza, A.R.; Mia, R. An overview of phase change materials, their production, and applications in textiles. Results Eng. 2025, 25, 103603. [Google Scholar] [CrossRef]

- Shirvan, A.R.; Nouri, A.; Kordjazi, S. Allergies caused by textiles and their control. In The Textile Institute Book Series, Medical Textiles from Natural Resources; Woodhead Publishing: Cambridge, UK, 2022; pp. 551–579. [Google Scholar]

- EN 1621-1; Motorcyclists’ Protective Clothing Against Mechanical Impact—Part 1: Motorcyclists’ Limb Joint Impact Protector—Requirements aand Test Methods. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 1621-2; Motorcyclists’ Protective Clothing Against Mechanical Impact—Part 2: Motorcyclists’ Back Protectors—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2014.

- EN 1621-3; Motorcyclists’ Protective Clothing Against Mechanical Impact—Part 3: Motorcyclists’ Chest Protectors—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2018.

- EN 1621-4; Motorcyclists’ Protective Clothing Against Mechanical Impact—Part 4: Motorcyclists’ Inflatable Protectors—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2013.

- Suchocki, P.; Ratyński, W.; Jabłoński, P.; Kulesza, B.; Błesznowski, K.; Kot, P.; Błaszczyk, B.; Woźniakowska, M.; Grabowska, G.; Gutowska, A.; et al. UE Design: Motorcyclist’s Suit (Summer, Winter Jacket, Pants). EUIPO 015003909-0001 (Application Granted 21.11.2022); EUIPO 015003909-0002 (Application Granted 21.11.2022); EUIPO 015003909-0003 (Application Granted 21.11.2022), 21 November 2022. Available online: https://euipo.europa.eu/eSearch/#basic/1+1+1+1/100+100+100+100/015003909 (accessed on 26 August 2025).

- Suchocki, P.; Błaszczyk, J.; Grabowska, G.; Woźniakowska, M.; Gutowska, A.; Miedzianowski, T.; Kudlińska, M. Motorcycle Trousers. PL Utility Model Ru 72747, 25 July 2022. [Google Scholar]

- Suchocki, P.; Błaszczyk, J.; Grabowska, G.; Woźniakowska, M.; Gutowska, A.; Miedzianowski, T.; Kudlińska, M. Winter Motorcycle Jacket. PL Utility Model Ru 72748, 25 July 2022. [Google Scholar]

- Suchocki, P.; Błaszczyk, J.; Grabowska, G.; Woźniakowska, M.; Gutowska, A.; Miedzianowski, T.; Kudlińska, M. Summer Motorcycle Jacket. PL Utility Model Ru 72749, 25 July 2022. [Google Scholar]

- PN-EN 62366-1:2015-07/A1:2021-03; Medical Devices—Part 1: Application of Utility Engineering to Medical Devices. Polish Committee for Standardization: Warsaw, Poland, 2021.

- PN-EN ISO 4674-1:2017-02; Flat Textile Products Coated with Rubber or Plastics—Determination of Tear Resistance—Part 1: Constant Speed Tearing Methods. Polish Committee for Standardization: Warsaw, Poland, 2017.

- PN-EN 13595-2:2005; Protective Clothing for Professional Motorcycle Riders—Part 2: Test Method for Determination of Impact Abrasion Resistance. Polish Committee for Standardization: Warsaw, Poland, 2005.

- PN-EN 13595-4:2005; Protective Clothing for Professional Motorcycle Riders—Part 4: Test Method for Determination of Impact Cut Resistance. Polish Committee for Standardization: Warsaw, Poland, 2005.

- PN-EN 13595-3:2005; Protective Clothing for Professional Motorcycle Riders—Part 3: Test Method for Determination of the Burst Strength. Polish Committee for Standardization: Warsaw, Poland, 2005.

- ISO 6330:2012; Tekstylia—Metody Prania Domowego i Suszenia Stosowane do Badania PłAskiego Wyrobu Włókienniczego. International Organization for Standardization: Geneva, Switzerland, 2012.

- Mascall, G. Testing of Motorcycle Jacket Referenced as “Summer Jacket” in Accordance with EN 13595-1:2002; Satra Technology Center Ltd.: Kettering, UK, 2019. [Google Scholar]

- Mascall, G. Testing of Motorcycle Jacket Referenced as “Winter Jacket” in Accordance with EN 13595-1:2002; Satra Technology Center Ltd.: Kettering, UK, 2019. [Google Scholar]

- Mascall, G. Testing of Motorcycle Trousers in Accordance with EN 13595-1:2002; Satra Technology Center Ltd.: Kettering, UK, 2019. [Google Scholar]

- PN-EN 14362-1:2012; Textiles—Methods for the Determination of Certain Aromatic Amines Derived from Azo Dyes—Part 1: Detection of the Use of Certain Azo Dyes Available by Extraction and Without Fibre Extraction. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 14362-3:2012; Textiles—Methods for the Determination of Certain Aromatic Amines Derived from Azo Dyes—Part 3: Detection of the Use of Certain Azo Dyes Which May Release 4-Aminoazobenzene. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN ISO 14184-1:2011; Textiles—Determination of Formaldehyde—Part 1: Free and Hydrolyzed Formaldehyde (Aqueous Extraction Method). Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN ISO 3071:2007; Textiles—Determination of pH of Aqueous Extracts. Polish Committee for Standardization: Warsaw, Poland, 2007.

- PN-EN 16711-1:2016-01; Textiles—Determination of Metal Content—Part 1: Determination of Metals Using Microwave Digestion. Polish Committee for Standardization: Warsaw, Poland, 2016.

- PN-EN 16711-2:2016-01; Textiles—Determination of Metal Content—Part 2: Determination of Metals Extracted by Artificial Sour Sweat Solution. Polish Committee for Standardization: Warsaw, Poland, 2016.

- EN 12472:2005+A1:2009; Method for the Simulation of Accelerated Wear and Corrosion for the Detection of Nickel Release from Coated Items. European Committee for Standardization: Brussels, Belgium, 2009.

| Zone acc. PN-EN 13595-1:2005 Standard | Material Arrangement in Material System (Top Layer → … → Bottom Layer) |

|---|---|

| 1 | C1100 → O → O → OL → WM → BK |

| 2 | C560 → KK → OL → WM → BL |

| 3 1) | C560 → OL → WM → BK |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Struszczyk, M.H.; Kudlińska, M.; Miedzianowski, T.; Fejdyś, M.; Gutowska, A.; Kośla, K.; Suchocki, P. Aspects of Design Thinking, Material and Usability Engineering in the Design of Suit for Police Officers Operating on Motorcycles—Part I: Design and Safety Aspects. Materials 2025, 18, 4156. https://doi.org/10.3390/ma18174156

Struszczyk MH, Kudlińska M, Miedzianowski T, Fejdyś M, Gutowska A, Kośla K, Suchocki P. Aspects of Design Thinking, Material and Usability Engineering in the Design of Suit for Police Officers Operating on Motorcycles—Part I: Design and Safety Aspects. Materials. 2025; 18(17):4156. https://doi.org/10.3390/ma18174156

Chicago/Turabian StyleStruszczyk, Marcin Henryk, Małgorzata Kudlińska, Tomasz Miedzianowski, Marzena Fejdyś, Agnieszka Gutowska, Katarzyna Kośla, and Piotr Suchocki. 2025. "Aspects of Design Thinking, Material and Usability Engineering in the Design of Suit for Police Officers Operating on Motorcycles—Part I: Design and Safety Aspects" Materials 18, no. 17: 4156. https://doi.org/10.3390/ma18174156

APA StyleStruszczyk, M. H., Kudlińska, M., Miedzianowski, T., Fejdyś, M., Gutowska, A., Kośla, K., & Suchocki, P. (2025). Aspects of Design Thinking, Material and Usability Engineering in the Design of Suit for Police Officers Operating on Motorcycles—Part I: Design and Safety Aspects. Materials, 18(17), 4156. https://doi.org/10.3390/ma18174156