Waste By-Products in Asphalt Concrete Pavement Construction: A Review

Abstract

1. Introduction

2. Incorporation of Mining Wastes as Bitumen Modifiers

2.1. Bitumen

2.2. Steel Slag

2.3. Fly Ash

2.4. Silica Fume

2.5. Red Mud

2.6. Physical Properties

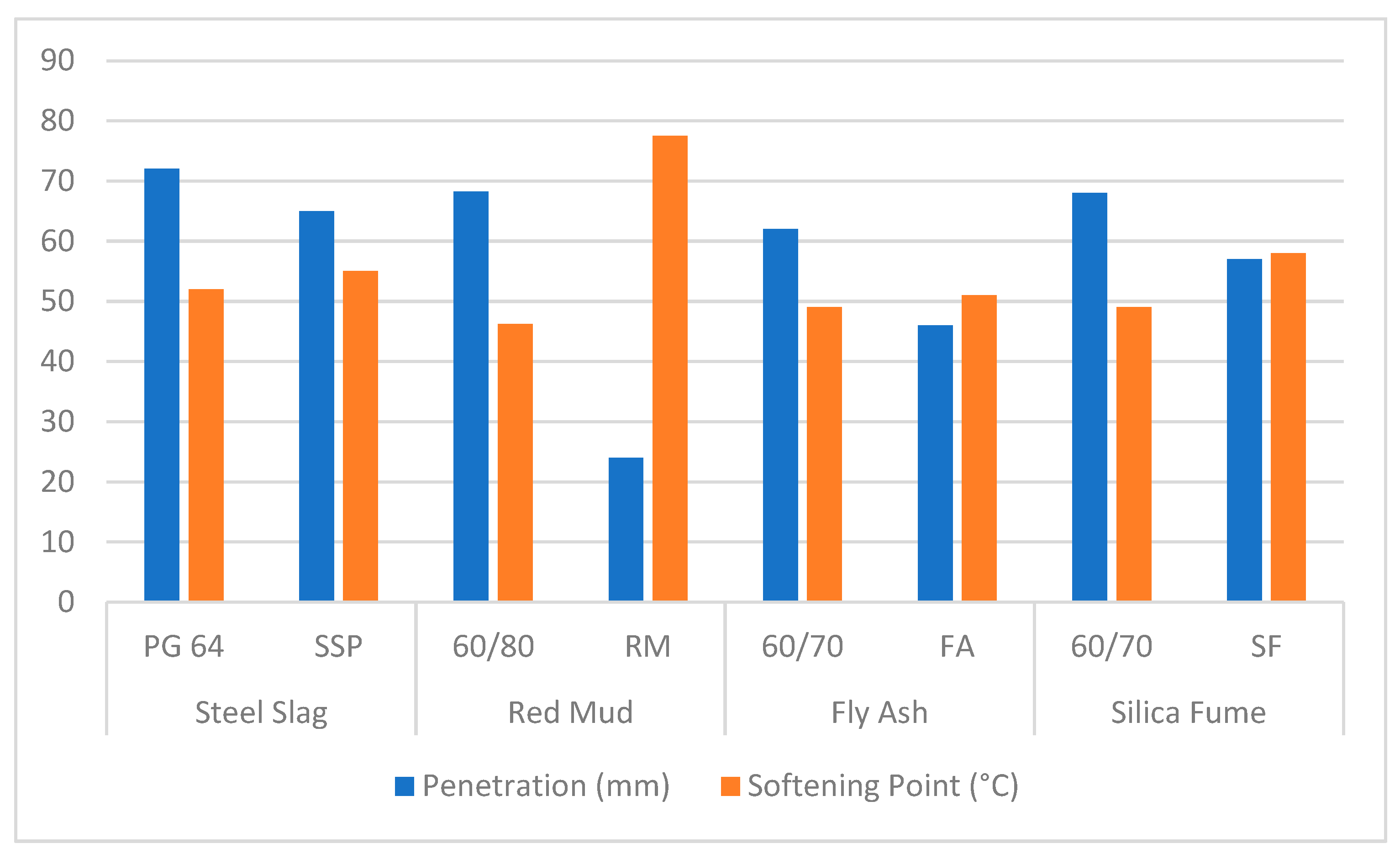

2.6.1. Penetration Value

2.6.2. Softening Point

2.6.3. Viscosity

2.6.4. Dynamic Shear Rheometer

2.6.5. Aging

2.7. Mechanical Properties

2.8. Chemical Properties

2.8.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.8.2. Attenuated Total Reflectance (ATR)

2.8.3. Differential Scanning Calorimetry (DSC)

2.8.4. X-Ray Diffraction (XRD)

2.9. Microstructural Properties

2.9.1. Scanning Electron Microscopy

2.9.2. Field Emission Scanning Electron Microscopy

2.9.3. Mapping and Phase Profiling

2.9.4. Energy Dispersive X-Ray Analysis

2.9.5. Atomic Force Microscopy

3. Use of Mining Wastes as Fillers and Aggregates in Asphalt Mixtures

3.1. Steel Slag

3.2. Fly Ash

3.3. Silica Fume

3.4. Red Mud

3.5. Mechanical Properties

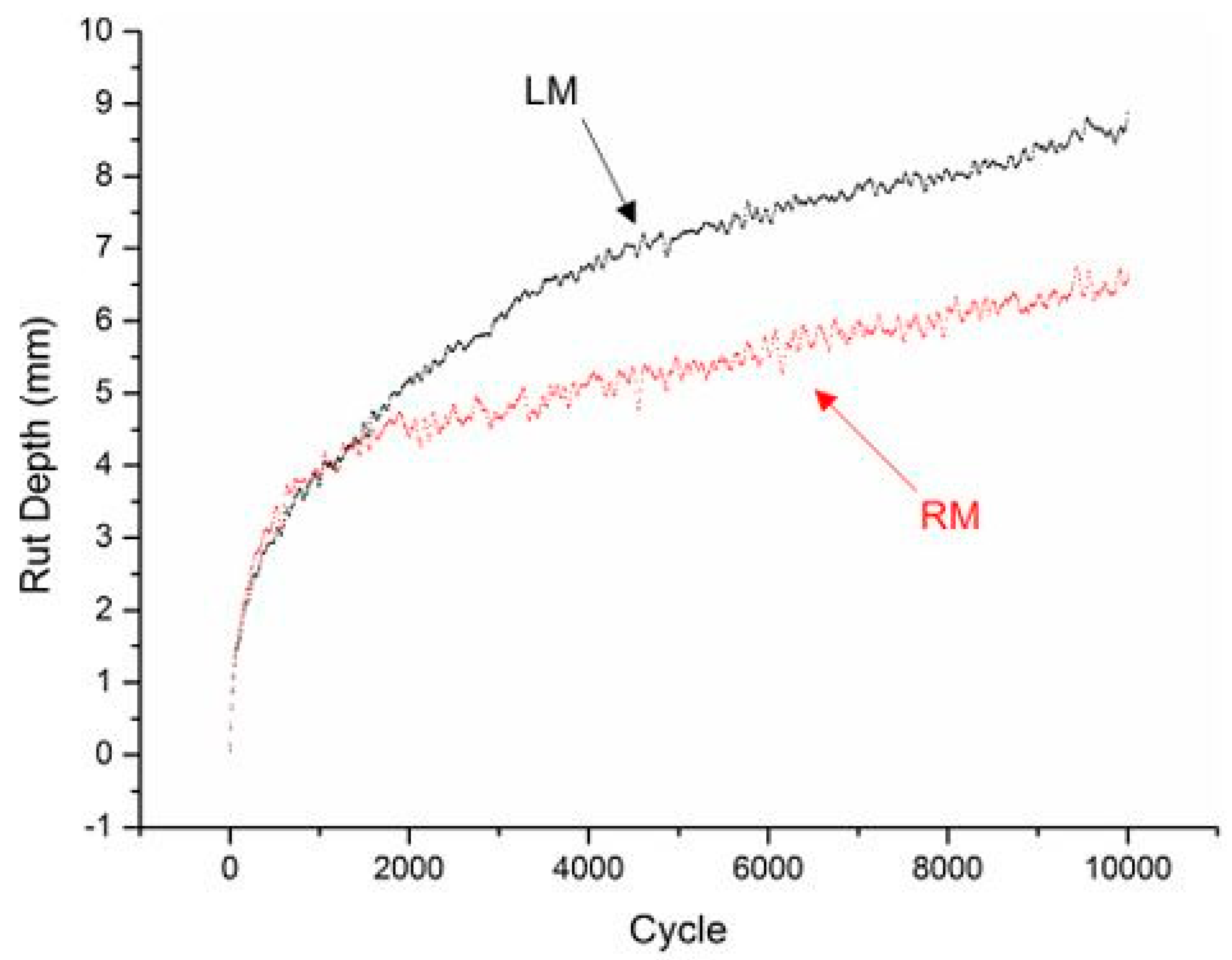

3.5.1. Rutting Resistance

3.5.2. Cracking Resistance

3.5.3. Fatigue Resistance

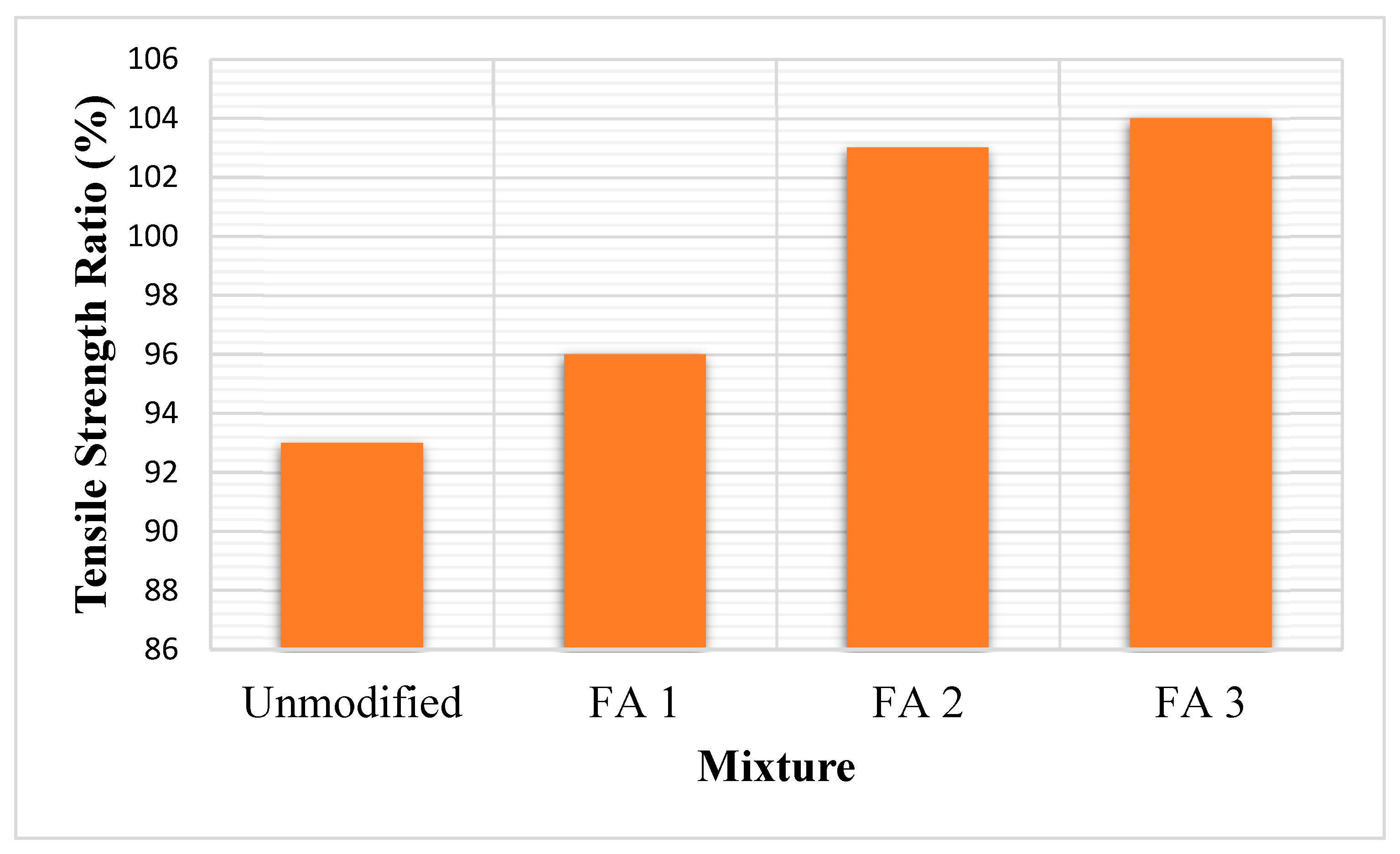

3.5.4. Moisture Susceptibility

3.6. Environmental and Circular Economy

4. Conclusions

- Sustainable Resource Utilization:Mining wastes, once viewed as environmentally burdensome by-products of metallurgical and mining operations, are now recognized as valuable secondary resources. Their integration into asphalt mixtures offers a promising pathway to improve pavement performance while promoting sustainable material use.

- Environmental Benefits:Utilizing these wastes as alternative fillers or aggregates reduces the dependency on virgin materials, which are typically sourced through environmentally damaging quarrying activities. This contributes to lower greenhouse gas emissions, reduced habitat destruction, and less energy consumption during material extraction and processing.

- Waste Diversion and the Circular Economy:Incorporating waste-derived materials into asphalt mixtures not only minimizes industrial waste stockpiling and landfilling but also supports closed-loop material recovery, aligning with circular economy principles.

- Pollution Mitigation:Some mining wastes, such as red mud, pose significant environmental risks due to their high alkalinity and potential for heavy metal leaching. Repurposing these materials in asphalt pavements can prevent environmental contamination and reduce the need for costly long-term storage or remediation strategies.

- Enhanced Material Performance:The inclusion of materials like steel slag and silica fume has been shown to enhance the mechanical properties of asphalt concrete, including increased stiffness, durability, and resistance to rutting and moisture damage.

5. Future Research Directions

- Standardization of Characterization and Material Processing: Consistent procedures are required for the handling and classification of mining wastes, including fly ash, steel slag, and red mud. Binder compatibility and long-term performance are impacted by differences in particle size and chemical makeup. For dependable use, future research should develop uniform pre-treatment and mixing protocols.

- Long-Term Durability and Field Validation: To date, most research has been restricted to laboratory-scale assessments. Validating laboratory results requires field testing and performance monitoring in real-world settings (such as traffic, loads, and cli-mate). It is necessary to evaluate the changed mixtures’ long-term aging, rutting, and cracking behavior over prolonged service times.

- Life Cycle Assessment (LCA) and Cost–Benefit Analysis: To measure environmental savings, more thorough LCA studies spanning various waste kinds and mix designs are required. Finding the most economical and environmentally friendly waste management techniques will be made easier by combining LCA with techno-economic analysis.

- Leaching and Environmental Safety: Leaching concerns may arise from the presence of heavy metals or alkaline chemicals in some mining wastes. To guarantee safe use, long-term environmental impact assessments are necessary, particularly in applica-tions that are porous or exposed to water.

- Optimization: Studies relating to the optimal dosage of mining wastes using optimi-zation methods have not been carried out. Hence, the development of an optimal dosage is needed to ensure optimum results for road construction as well as for in-dustrial-scale production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Majer, S.; Budziński, B.; Lehner, P. Elastic modulus of Cement Bound Granular Material (CBGM). Procedia Struct. Integr. 2024, 63, 51–57. [Google Scholar] [CrossRef]

- Yao, L.; Gao, W.; Ma, X.; Fu, H. Properties Analysis of Asphalt Binders Containing Bayer Red Mud. Materials 2020, 13, 1122. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Z.; Wang, K.; Wang, F.; Jiang, H.; Liang, M.; Wei, J.; Airey, G. Sustainable utilization of bauxite residue (Red Mud) as a road material in pavements: A critical review. Constr. Build. Mater. 2021, 270, 121419. [Google Scholar] [CrossRef]

- Niu, D.; Zhang, Z.; Meng, J.; Yang, Z.; Jing, R.; Liu, X.; Lin, P.; Sheng, Y. Surface Modification of Steel Slag Aggregate for Engineering Application in Asphalt Mixture. Buildings 2022, 13, 16. [Google Scholar] [CrossRef]

- Zhang, J.; Li, P.; Liang, M.; Jiang, H.; Yao, Z.; Zhang, X.; Yu, S. Utilization of red mud as an alternative mineral filler in asphalt mastics to replace natural limestone powder. Constr. Build. Mater. 2019, 237, 117821. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Application of waste materials as fillers in bituminous mixes. Waste Manag. 2018, 78, 417–425. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, H.; Zhang, Y.; Wang, D.; Harvey, J.; Wang, H. Performance enhancement of porous asphalt pavement using red mud as alternative filler. Constr. Build. Mater. 2018, 160, 707–713. [Google Scholar] [CrossRef]

- Divandari, H.; Heidari, M.; Zalnezhad, M.; Zalnezhad, A. The study of the feasibility and manufacture of slurry seal surface treatment with steel slag industry wastes: Use of basic oxygen furnace (BOF) slag filler as raw material replacement. Road Mater. Pavement Des. 2023, 25, 967–987. [Google Scholar] [CrossRef]

- Liu, J.; Guo, R. Applications of Steel Slag Powder and Steel Slag Aggregate in Ultra-High Performance Concrete. Adv. Civ. Eng. 2018, 2018, 1426037. [Google Scholar] [CrossRef]

- Jasim, E.; Joni, H. Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag. Open Eng. 2024, 14, 20220551. [Google Scholar] [CrossRef]

- Woszuk, A.; Bandura, L.; Franus, W. Fly ash as low cost and environmentally friendly filler and its effect on the properties of mix asphalt. J. Clean. Prod. 2019, 235, 493–502. [Google Scholar] [CrossRef]

- Mehmood, S.A.; Khan, M.I.; Ahmed, S.; Al-Nawasir, R.; Choudhry, R.M. From waste to roads: Improving pavement performance and achieving sustainability with recycled steel slag and low-density polyethylene. Buildings 2025, 15, 476. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, C.; Li, P.; Liang, M.; Jiang, H.; Yao, Z. Experimental study on rheological properties and moisture susceptibility of asphalt mastic containing red mud waste as a filler substitute. Constr. Build. Mater. 2019, 211, 159–166. [Google Scholar] [CrossRef]

- Al-Shabani, Z.J.; Obaid, I.A. The Effect of Using Various Types of Mineral Fillers on Moisture Damage of Hot Mix Asphalt. In Proceedings of the 3rd International Conference for Civil Engineering Science, Chicago, Ad Diwaniyah, Iraq, 15–16 March 2023. [Google Scholar]

- Keymanesh, M.R.; Ziari, H.; Zalnezhad, H.; Zalnezhad, M. Mix design and performance evaluation of micro-surfacing containing electric arc furnace (EAF) steel slag filler. Constr. Build. Mater. 2020, 269, 121336. [Google Scholar] [CrossRef]

- Guo, J.; Wei, J.; Xu, F.; Xu, Q.; Kang, L.; Wu, W.; Shi, W.; Yan, X. Research on Pavement Performance of Steel Slag Asphalt Mastic and Mixtures. Coatings 2025, 15, 525. [Google Scholar] [CrossRef]

- Alnadish, A.M.; Ramu, M.B.; Kasim, N.; Alawag, A.M.; Baarimah, A.O. A Bibliometric Analysis and Review on Applications of Industrial By-Products in Asphalt Mixtures for Sustainable Road Construction. Buildings 2024, 14, 3240. [Google Scholar] [CrossRef]

- Muhammad, J.; Peng, T.; Zhang, W.; Cheng, H.; Waqas, H.; Abdul, S.; Chen, K.; Zhou, Y. Moisture susceptibility and fatigue performance of asphalt binder modified by bone glue and coal fly ash. Constr. Build. Mater. 2021, 308, 125135. [Google Scholar] [CrossRef]

- Cheraghian, G.; Wistuba, M.P.; Kiani, S.; Barron, A.R.; Behnood, A. Rheological, physicochemical, and micro-structural properties of asphalt binder modified by fumed silica nanoparticles. Sci. Rep. 2021, 11, 11455. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Ramakrishna, G. Sustainable Use of Red Mud and Reclaimed Asphalt Pavement Wastes in Roller Compacted Concrete. Int. J. Pavement Res. Technol. 2022, 17, 291–305. [Google Scholar] [CrossRef]

- Holý, M.; Remišová, E. Analysis of influence of bitumen composition on the properties represented by empirical and viscosity test. Transp. Res. Procedia 2021, 40, 34–41. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. The Use of Steel Slags in Asphalt Pavements: A State-of-the-Art Review. Sustainability 2023, 15, 8817. [Google Scholar] [CrossRef]

- Benavides, D.; Bizinotto, M.B.; López, T.; Aponte, D. Study of adhesion between steel slag aggregates and bitumen taking into consideration internal factors influencing moisture damage. Constr. Build. Mater. 2023, 367, 130369. [Google Scholar] [CrossRef]

- Prasad, D.; Suman, S.K.; Singh, B. Rutting behaviour of cold bitumen emulsion mix containing alternate fillers. Int. J. Pavement Eng. 2025, 26, 2447476. [Google Scholar] [CrossRef]

- Xing, X.; Han, K.; Liu, R.; Chen, Z.; Li, H.; Li, P.; Zhou, Q.; Wen, Y. Study on the Rheological Properties of Fly Ash Modified Asphalt Mastics. Coatings 2023, 13, 1307. [Google Scholar] [CrossRef]

- Nassar, A.I.; Mohammed, M.K.; Thom, N.; Parry, T. Mechanical, durability and microstructure properties of Cold Asphalt Emulsion Mixtures with different types of filler. Constr. Build. Mater. 2016, 114, 352–363. [Google Scholar] [CrossRef]

- Sarsam, S.I. Monitoring the Rheological Properties of Asphalt Cement after Digestion with Micro and Nano Size Additives. Int. J. Darshan Inst. Eng. Res. Emerg. Technol. 2023, 12, 5–12. [Google Scholar] [CrossRef]

- Zheng, X.; Xu, W.; Feng, H.; Cao, K. High and Low Temperature Performance and Fatigue Properties of Silica Fume/SBS Compound Modified Asphalt. Materials 2020, 13, 4446. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Hajibabaei, M.; Thives, L.P.; Haritonovs, V.; Buttgereit, A.; Queiroz, C.; Gschösser, F. Environ-mental potentials of asphalt mixtures fabricated with red mud and fly ash. Road Mater. Pavement Des. 2021, 22, S690–S701. [Google Scholar] [CrossRef]

- Salehi, S.; Arashpour, M.; Kodikara, J.; Guppy, R. Sustainable pavement construction: A systematic literature review of environmental and economic analysis of recycled materials. J. Clean. Prod. 2021, 313, 127936. [Google Scholar] [CrossRef]

- Victory, W. A review on the utilization of waste material in asphalt pavements. Environ. Sci. Pollut. Res. 2022, 29, 27279–27282. [Google Scholar] [CrossRef]

- Hernandez-Fernandez, N.; García-Mejía, T.A.; Zamora, R.M.R.; Díaz, R.O.; Ossa, A. Effect of application of metallurgical slag powders on physical and rheological properties of asphalt. Constr. Build. Mater. 2021, 292, 123432. [Google Scholar] [CrossRef]

- Alexandre, N.P.; Freitas, A.D.; Uchoa, A.F.; Rocha, W.S.; Feitosa, J.P.; Soares, J.B.; Soares, S.A.; Loiola, A.R. The effect of incorporating magnetic fly ash in asphalt binders with respect to permanent deformation and fatigue. Constr. Build. Mater. 2023, 411, 134214. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, S.; Yao, Z.; Wu, S.; Jiang, H.; Liang, M.; Qiao, Y. Environmental aspects and pavement properties of red mud waste as the replacement of mineral filler in asphalt mixture. Constr. Build. Mater. 2018, 180, 605–613. [Google Scholar] [CrossRef]

- Rasheed, S.S.; Joni, H.H.; Al-Rubaee, R.H.; Karkush, M. Enhancement of Physical Properties of Asphalt Binder by Using Silica Powder. In Proceedings of the E3S Web of Conferences, Baghdad, Iraq, 17–19 May 2023; Volume 427, p. 03031. [Google Scholar]

- Iqbal, M.; Hussain, A.; Khattak, A.; Ahmad, K. Improving the Aging Resistance of Asphalt by Addition of Polyethylene and Sulphur. Civ. Eng. J. 2020, 6, 1017–1030. [Google Scholar] [CrossRef]

- Ziaee, S.A.; Behnia, K. Evaluating the effect of electric arc furnace steel slag on dynamic and static mechanical behavior of warm mix asphalt mixtures. J. Clean. Prod. 2020, 274, 123092. [Google Scholar] [CrossRef]

- Kök, B.V.; İrhan, B.; Yılmaz, M.; Yalçın, E. Research on the rheological properties of bitumen modified with waste photopolymer. Constr. Build. Mater. 2022, 346, 128446. [Google Scholar] [CrossRef]

- Malinowski, S.; Woszuk, A.; Wróbel, M.; Kwaśniewska, A.; Gładyszewski, G.; Škulteckė, J.; Vaitkus, A.; Franus, W. Anti-ageing and rheological performance of bitumen modified with polyaniline nanofibres. Constr. Build. Mater. 2024, 437, 136810. [Google Scholar] [CrossRef]

- Owaid, K.A.; Ghazal, R.Y.; Abdelzaher, M.A. Study of the Effect of Modification of Asphalt on the Rheological Properties Employing Microwave Radiation—An Aging Study. Recycling 2023, 8, 65. [Google Scholar] [CrossRef]

- Chandra, K.S.; Krishnaiah, S.; Reddy, N.G.; Hossiney, N.; Peng, L. Strength Development of Geopolymer Composites Made from Red Mud–Fly Ash as a Subgrade Material in Road Construction. J. Hazard. Toxic Radioact. Waste 2021, 25, 04020068. [Google Scholar] [CrossRef]

- Mucsi, G.; Szabo, R.; Racz, A.; Kumar, S.; Kristály, F. Combined Utilization of Red Mud and Mechanicall activated Fly Ash in Geopolymers. Rud.Geološko Naft. Zb. 2019, 34. [Google Scholar]

- Saberi, N.; Vriens, B. Compositional heterogeneity of secondary minerals in mine waste rock: Origins and implications for water quality. J. Hazard. Mater. 2025, 487, 137163. [Google Scholar] [CrossRef] [PubMed]

- Xian, H.; He, P.; Lan, D.; Qi, Y.; Wang, R.; Lü, F.; Zhang, H.; Long, J. Predicting the elemental compositions of solid waste using ATR-FTIR and machine learning. Front. Environ. Sci. Eng. 2023, 17, 121. [Google Scholar] [CrossRef]

- Fernández, J.M.; Plaza, C.; Polo, A.; Plante, A.F. Use of Thermal Analysis Techniques (TG–DSC) for the Characterization of Diverse Organic Municipal Waste Streams to Predict Biological Stability Prior to Land Application. Waste Manag. 2011, 32, 158–164. [Google Scholar] [CrossRef]

- Alam, M.F.; Kumar, A.; Kumar, R. A Review on Utilization of Industrial Wastes and Byproducts in Highway Construction. Am. J. Sci. Learn. Dev. 2023, 2, 9. [Google Scholar]

- Cao, Y.; Mei, Y.; Yao, H.; Hu, B. Mechanical and microstructural characterization of one-part binder incorporated with alkali-thermal activated red mud. Case Stud. Constr. Mater. 2021, 21, e03634. [Google Scholar] [CrossRef]

- Sun, E.; Zhao, Y.; Wang, G. Analysis of nanoscale evolution features of microstructure of asphalt based on atomic force microscopy. Constr. Build. Mater. 2023, 409, 133958. [Google Scholar] [CrossRef]

- Veytskin, Y.; Bobko, C.; Castorena, C.; Kim, Y.R. Nanoindentation investigation of asphalt binder and mastic cohesion. Constr. Build. Mater. 2015, 100, 163–171. [Google Scholar] [CrossRef]

- Zghair, H.H.; Hasan, H. Experimental investigation of physical characteristics of asphalt binder containing nano and micro steel slag. In Proceedings of the Fifth Scientific Conference for Engineering and Postgraduate Research, Baghdad, Iraq, 23–24 December 2020. [Google Scholar]

- Zhai, D.; Sun, Q.; Wang, Y.; Li, J. Microstructure and mechanical performance of polyurethane-fly ash composites (PU-FAC) under different effect factors. Case Stud. Constr. Mater. 2024, 21, e03405. [Google Scholar] [CrossRef]

- Hesami, S.; Mahzari, M.; Sobhi, S.; Bay, M.A. Investigating the rheological properties and microstructural analysis of Nano-expanded Perlite modified asphalt binder. Case Stud. Constr. Mater. 2025, 22, e04208. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Baheri, F.T.; Cavalli, M.C.; Poulikakos, L.D.; Bueno, M. Microstructure analysis and mechanical performance of crumb rubber modified asphalt concrete using the dry process. Constr. Build. Mater. 2020, 259, 119662. [Google Scholar] [CrossRef]

- Hu, Y.; Yin, Y.; Sreeram, A.; Si, W.; Airey, G.D.; Li, B.; Singh, B.; Özdemir, D.K.; Zhou, L. Atomic force microscopy (AFM) based microstructural and micromechanical analysis of bitumen during ageing and rejuvenation. Constr. Build. Mater. 2025, 467, 140387. [Google Scholar] [CrossRef]

- Tiwari, N.; Rondinella, F.; Satyam, N.; Baldo, N. Experimental and Machine Learning Approach to Investigate the Mechanical Performance of Asphalt Mixtures with Silica Fume Filler. Appl. Sci. 2023, 13, 6664. [Google Scholar] [CrossRef]

- Liu, J.; Jing, H.; Wang, Z.; Wang, X.; Zhang, L. Recycling of steel slag in sustainable bituminous mixtures: Self-healing performance, mechanism, environmental and economic analyses. J. Clean. Prod. 2023, 429, 139496. [Google Scholar] [CrossRef]

- Benavides, D.; Rangel, R.L.; Franci, A.; Aponte, D. Effect of steel slag on compaction times of asphalt mixtures based on prediction of cooling curves. Constr. Build. Mater. 2024, 421, 135550. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, N.; Cui, S.; You, Z. A comprehensive evaluation of steel slag asphalt mixtures: Performance, functional applications, and ecological considerations. J. Mater. Cycles Waste Manag. 2025, 12, 1–22. [Google Scholar] [CrossRef]

- Šimun, M.; Dimter, S.; Grubješić, G.; Vukelić, K. Contribution to the Research on the Application of Bio-Ash as a Filler in Asphalt Mixtures. Appl. Sci. 2023, 13, 6555. [Google Scholar] [CrossRef]

- Zhao, X.; Ge, D.; Wang, J.; Wu, D.; Liu, J. The Performance Evaluation of Asphalt Mortar and Asphalt Mixture Containing Municipal Solid Waste Incineration Fly Ash. Materials 2022, 15, 1387. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, W. Aging Resistance of Silica Fume/Styrene-Butadiene-Styrene Composite-Modified Asphalt. Materials 2021, 14, 6536. [Google Scholar] [CrossRef]

- Hou, G.; Xue, Y.; Li, Z.; Lu, W. Rheological Properties of Silica-Fume-Modified Bioasphalt and Road Performance of Mixtures. Materials 2024, 17, 2090. [Google Scholar] [CrossRef]

- Tang, N.; Deng, Z.; Dai, J.-G.; Yang, K.; Chen, C.; Wang, Q. Geopolymer as an additive of warm mix asphalt: Preparation and properties. J. Clean. Prod. 2018, 192, 906–915. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Performance evaluation of bauxite residue modified asphalt concrete mixes. Eur. J. Environ. Civ. Eng. 2019, 26, 978–994. [Google Scholar] [CrossRef]

- Rashidian, S.; Hosseini, S.A.; Korandeh, M.E. Investigation of red mud effects on microsurfacing asphalt performance: Quality enhancement and industrial waste reduction. Constr. Build. Mater. 2025, 483, 141798. [Google Scholar] [CrossRef]

- Bhupathi, S.; Adepu, R.; Sastri, M.; Vijayapuri, V.R.; Murthy, D. Experimental evaluation of eco-friendly asphalt mixtures with recycled fine aggregates and steel slag. Innov. Infrastruct. Solutions 2025, 10, 18. [Google Scholar] [CrossRef]

- Raposeiras, A.C.; Movilla-Quesada, D.; Muñoz-Cáceres, O.; Andrés-Valeri, V.C.; Lagos-Varas, M. Production of asphalt mixes with copper industry wastes: Use of copper slag as raw material replacement. J. Environ. Manag. 2021, 293, 112867. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.J.; Park, H.M.; Suh, Y.C.; Lee, J.-S. Performance Evaluation of Asphalt Mixtures with 100% EAF and BOF Steel Slag Aggregates Using Laboratory Tests and Mechanistic Analyses. KSCE J. Civ. Eng. 2022, 26, 4542–4551. [Google Scholar] [CrossRef]

- Sayadi, M.; Hesami, S. Performance evaluation of using electric arc furnace dust in asphalt binder. J. Clean. Prod. 2017, 143, 1260–1267. [Google Scholar] [CrossRef]

- Elmagarhe, A.; Lu, Q.; Alharthai, M.; Alamri, M.; Elnihum, A. Performance of Porous Asphalt Mixtures Containing Recycled Concrete Aggregate and Fly Ash. Materials 2022, 15, 6363. [Google Scholar] [CrossRef]

- Mahto, S.K.; Sinha, S. Moisture Susceptibility of Warm-Mix Asphalt Containing Wax- and Chemical-Based Additives. J. Transp. Eng. Part B Pavements 2024, 150, 3. [Google Scholar] [CrossRef]

- Plati, C.; Tsakoumaki, M.; Loizos, A. Quality Assurance of Steel Slag Asphalt Mixtures for Sustainable Pavement Surface Courses. Recycling 2024, 9, 91. [Google Scholar] [CrossRef]

- Mojapelo, K.S.; Kupolati, W.K.; Burger, E.A.; Ndambuki, J.M.; Snyman, J.; Achi, C.G.; Quadri, A.I. Performance Evaluation and Future Prospects of the Wastewater Sludge Ash as a Filler Material in Asphalt Mixture. Mater. Circ. Econ. 2025, 7, 16. [Google Scholar] [CrossRef]

- Segui, P.; Safhi, A.E.M.; Amrani, M.; Benzaazoua, M. Mining Wastes as Road Construction Material: A Re-view. Minerals 2023, 13, 90. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Dassanayake, C. Rutting and Aging Properties of Recycled Polymer-Modified Pavement Materials. Recycling 2025, 10, 60. [Google Scholar] [CrossRef]

- Mashaan, N.; Yogi, B. Mining Waste Materials in Road Construction. Encyclopedia 2025, 5, 83. [Google Scholar] [CrossRef]

- Mashaan, N.S.; De Silva, A. Review on Assessment and Performance Mechanism Evaluation of Non-Structural Concrete Incorporating Waste Materials. Appl. Mech. 2024, 5, 579–599. [Google Scholar] [CrossRef]

| Component | Red Mud | Steel Slag | Fly Ash |

|---|---|---|---|

| Iron Oxide | 25–30% | 15–20% | 10–15% |

| Aluminum Oxide | 10–15% | 5–7% | 20–25% |

| Silicone Oxide | 8–12% | 10–12% | 50–60% |

| Calcium Oxide | 2–5% | 35–45% | 1–3% |

| Sodium and Potassium Oxides | 4–6% | <1% | 2–4% |

| Mining Wastes | Main Findings | References |

|---|---|---|

| Red Mud | High concentration of iron oxide contributes to increased binder stiffness, adhesion, and improved fatigue resistance, making it effective in enhancing the mechanical performance of asphalt mixtures. | [20] |

| Steel Slag | High calcium oxide is beneficial for improving moisture resistance and enhancing the alkalinity of the mixture, which gives better binder adhesion. | [10] |

| Fly Ash | Has the a content of aluminum oxide, which is important for pozzolanic activity and improved bonding, contributing to increased durability. Acts as strong filler material that enhances packing density and thermal stability due to high content of silicon oxide. | [5] |

| Physical Property | Main Findings | References |

|---|---|---|

| Penetration Value | Decreased values with red mud, fly ash, and steel slag indicate increased stiffness and improved rutting resistance. | [10] |

| Softening Point | Increased softening point (by 8–15 °C) due to electric arc furnace slag, copper slag, and red mud improves thermal resistance. | [14,23,32] |

| Viscosity | Higher viscosity from fly ash/red mud improves coating, durability, and moisture resistance; warm mix and sulfur additives lower compaction temperatures. | [15,37,40] |

| Dynamic Shear Rheometer | Mining waste additives increase G*/sinδ and improve fatigue and rutting resistance. Increased G* and decreased δ with additives indicate improved deformation resistance. | [15,39,40,41] |

| Aging | Pozzolanic and antioxidant properties in red mud, fly ash, and slags mitigate oxidation and aging effects. | [42,43] |

| Compound | Red Mud (%) |

|---|---|

| Fe2O3 | 28.4 |

| Al2O3 | 17.5 |

| SiO2 | 12.6 |

| CaO | 4.8 |

| TiO2 | 2.1 |

| Na2O | 4.3 |

| K2O | 1.9 |

| Others | <1.0 |

| Properties | Key Findings | Relevant Mining Waste | References |

|---|---|---|---|

| FTIR and ATR | Detected functional groups, such as –OH, C=O, and Si–OH, indicating improved interaction between mining waste and bitumen, enhancing filler–binder bonding. | Red Mud, Steel Slag, and Silica Fume | [5,38,45] |

| DSC | Revealed enhanced thermal stability and altered glass transition temperatures (Tg) in modified binders, improving elasticity and temperature resistance. | Steel Slag | [12,15,46] |

| XRD | Identified crystalline phases like hematite, quartz, and gibbsite, confirming increased crystallinity and physical stability in modified binders. | Red Mud and Fly Ash | [10,14,44] |

| XRF | Quantified high levels of oxides (Fe2O3, Al2O3, SiO2, CaO), supporting improved stiffness, adhesion, and reduced moisture susceptibility in bitumen. | Red Mud, Fly Ash, and Steel Slag | [20,44,45] |

| Technique | Key Findings | References |

|---|---|---|

| SEM (Scanning Electron Microscopy) | Reveals rough surface morphology and particle dispersion; red mud and steel slag enhance bonding; cohesive microstructure improves durability and resistance to rutting. | [9,20,48,52] |

| FESEM (Field Emission Scanning Electron Microscopy) | Visualizes nanoscale features and confirms element dispersion; FESEM shows oxides, like Fe, Al, and Si, uniformly embedded, enhancing filler–matrix bonding. | [20,50,51] |

| MAPP (Mapping and Phase Profiling) | Combines SEM with spectroscopy to analyze phase distribution; shows uniform mineral dispersion, smoother surfaces, and fewer voids, leading to better compatibility and reduced air voids. | [12,53,54] |

| EDAX/EDS (Energy-Dispersive X-ray Analysis) | Identifies elemental composition, such as Ca, Si, Al, and Fe, in fillers; confirms the chemical components that enhance binder reactivity and mechanical strength. | [47] |

| AFM (Atomic Force Microscopy) | Analyzes surface roughness and adhesion at the nanoscale; nanostructures improve fatigue and moisture resistance; higher elasticity and stress distribution. | [49,55,56] |

| Mining Waste | Key Benefits | Performance Findings | References |

|---|---|---|---|

| Steel Slag | High angularity, hardness, improves rutting resistance, Marshall stability, and moisture resistance | Used as coarse and fine aggregate; BOF and EAF slags improve fatigue life and stiffness modulus | [8,23,24,57,58] |

| Fly Ash | Enhances binder stiffness, improves workability and fatigue resistance, good filler replacement | Classes F and C fly ash improve water resistance; spherical particles aid mastic stiffness and packing | [10,11] |

| Silica Fume | Improves fatigue and rutting resistance, promotes adhesion and filler–binder interactions | Used in hot-/cold-mix; fills micro-voids, improves cohesion and aggregate adhesion | [2,12,15] |

| Red Mud (Iron Oxide) | Enhances thermal conductivity, aging and UV resistance, improves Marshall stability and high-temp performance | Requires additives to reduce fatigue life impact and voids; 3–7% inclusion improves rut depth and stability | [3,7,13,20,61,64,65] |

| Technique | Key Findings | References |

|---|---|---|

| Rutting Resistance | Steel slag improves load distribution and shear resistance; red mud enhances high-temp stiffness; 3–7% red mud reduces rut depth | [3,7,57,66] |

| Cracking Resistance | Silica fume and fly ash enhance binder flexibility and compaction; 6% silica fume reduces low-temp cracking | [10,11,12,28] |

| Fatigue Resistance | Steel slag and silica fume improve fatigue life through better binder interaction; enhances resistance to cyclic loading | [2,8,23,28] |

| Moisture Susceptibility | Steel slag and fly ash improve adhesion and reduce water damage; red mud needs anti-stripping agents due to porosity | [6,8,11,13,66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mashaan, N.S.; Oguntayo, D.O.; Dassanayake, C. Waste By-Products in Asphalt Concrete Pavement Construction: A Review. Materials 2025, 18, 4092. https://doi.org/10.3390/ma18174092

Mashaan NS, Oguntayo DO, Dassanayake C. Waste By-Products in Asphalt Concrete Pavement Construction: A Review. Materials. 2025; 18(17):4092. https://doi.org/10.3390/ma18174092

Chicago/Turabian StyleMashaan, Nuha S., Daniel O. Oguntayo, and Chathurika Dassanayake. 2025. "Waste By-Products in Asphalt Concrete Pavement Construction: A Review" Materials 18, no. 17: 4092. https://doi.org/10.3390/ma18174092

APA StyleMashaan, N. S., Oguntayo, D. O., & Dassanayake, C. (2025). Waste By-Products in Asphalt Concrete Pavement Construction: A Review. Materials, 18(17), 4092. https://doi.org/10.3390/ma18174092