Effects of Traveling Magnetic Field on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetals Prepared by Compound Casting

Abstract

1. Introduction

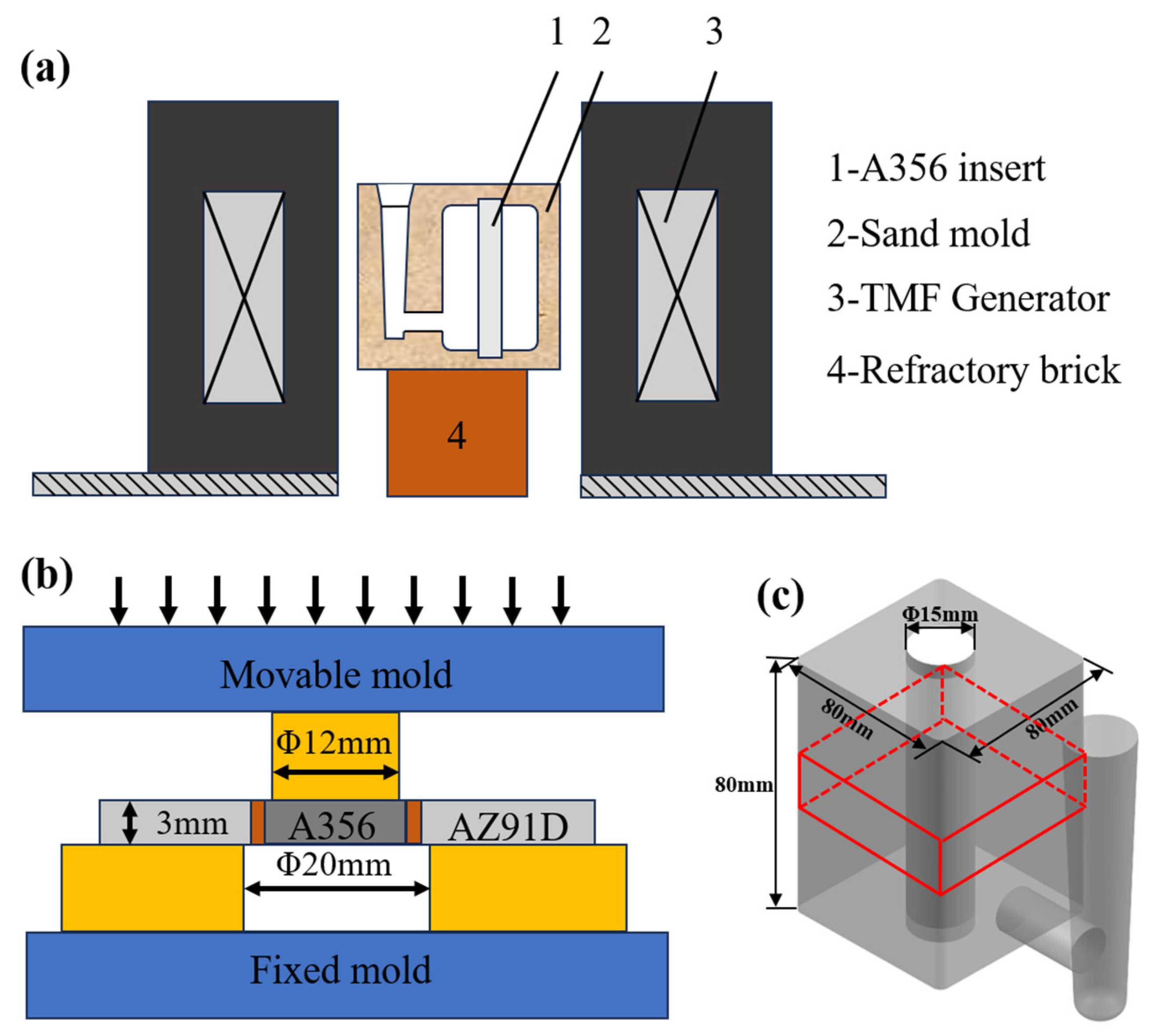

2. Materials and Methods

2.1. Material Preparation

2.2. Characterization

3. Results

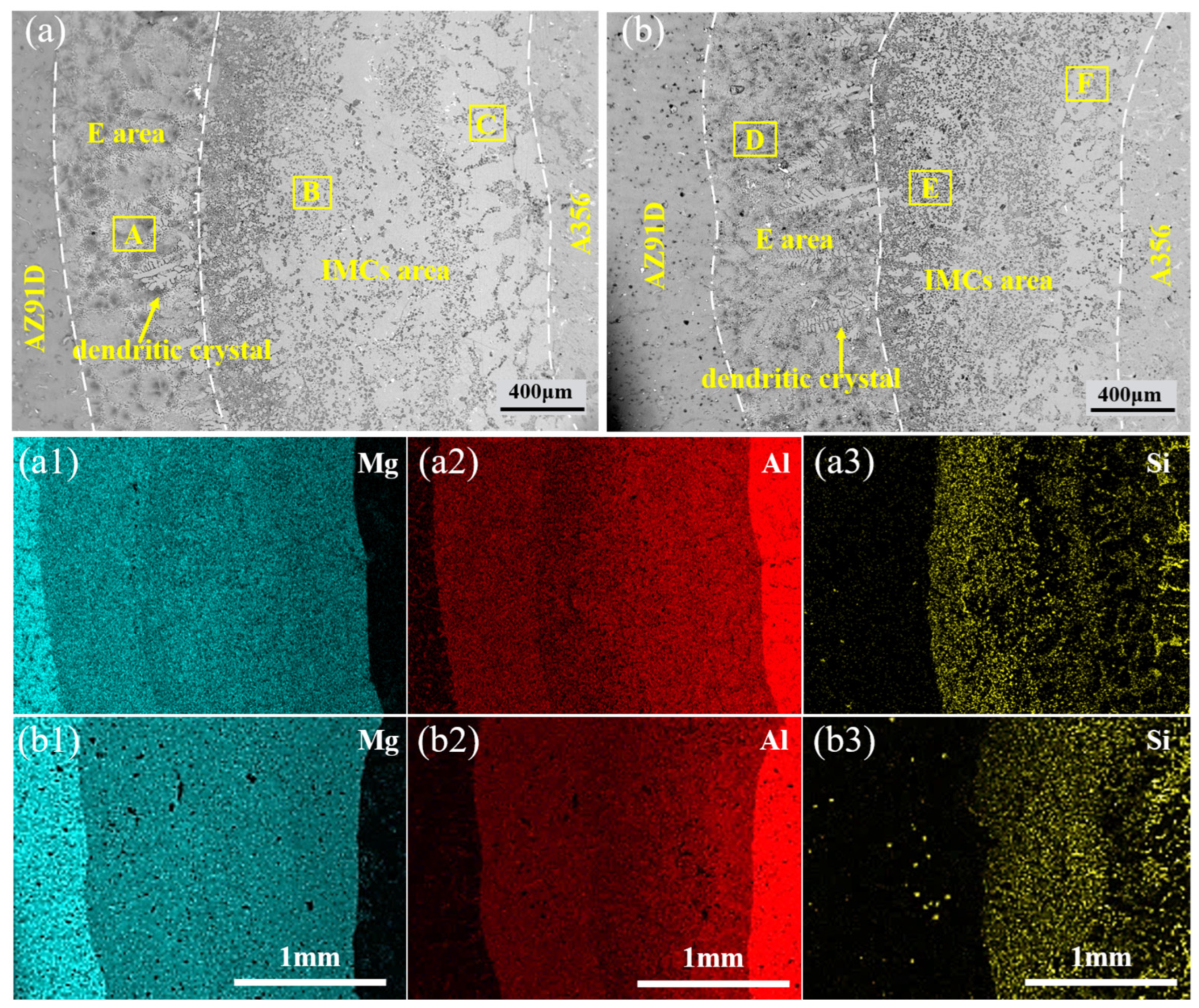

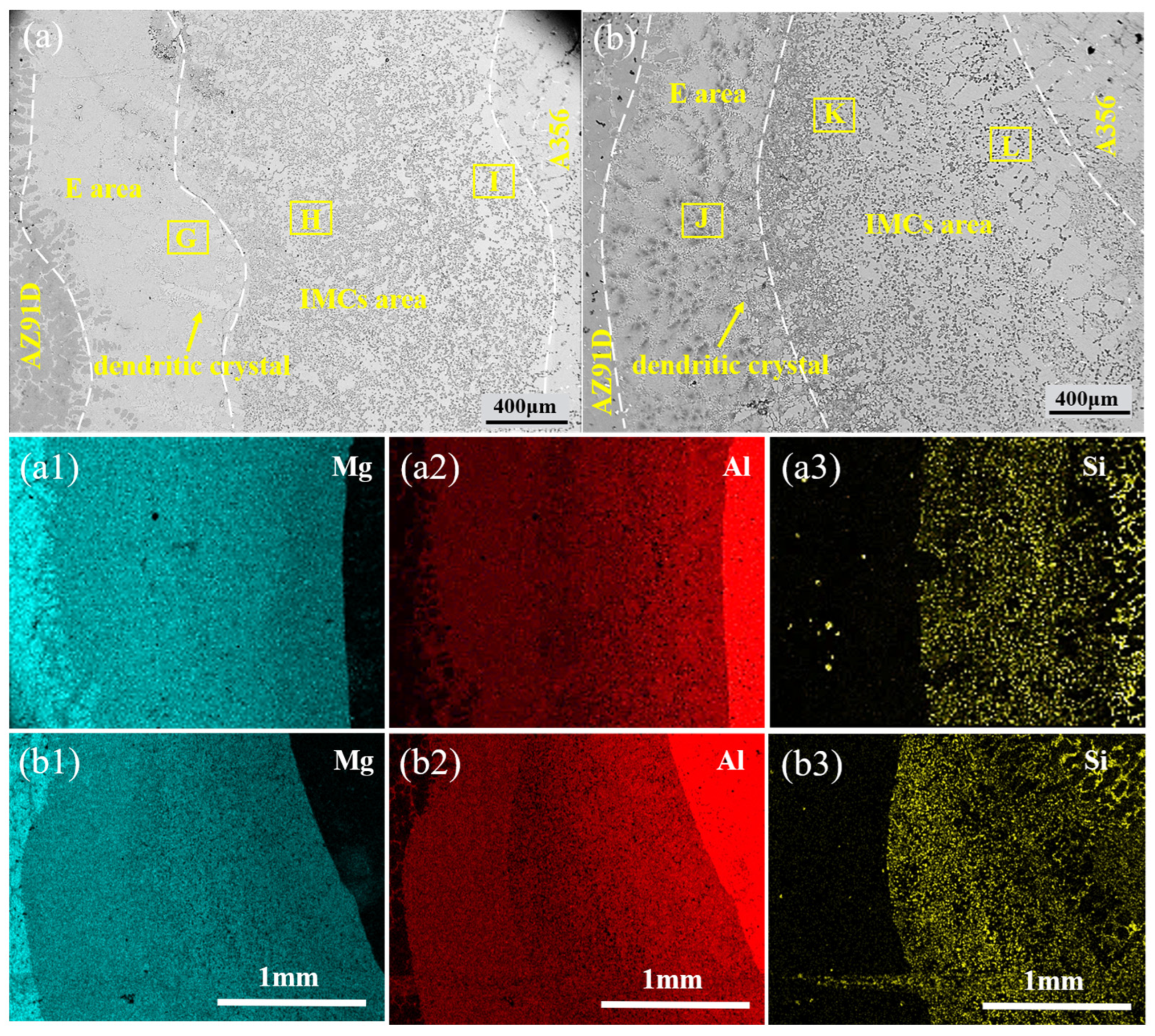

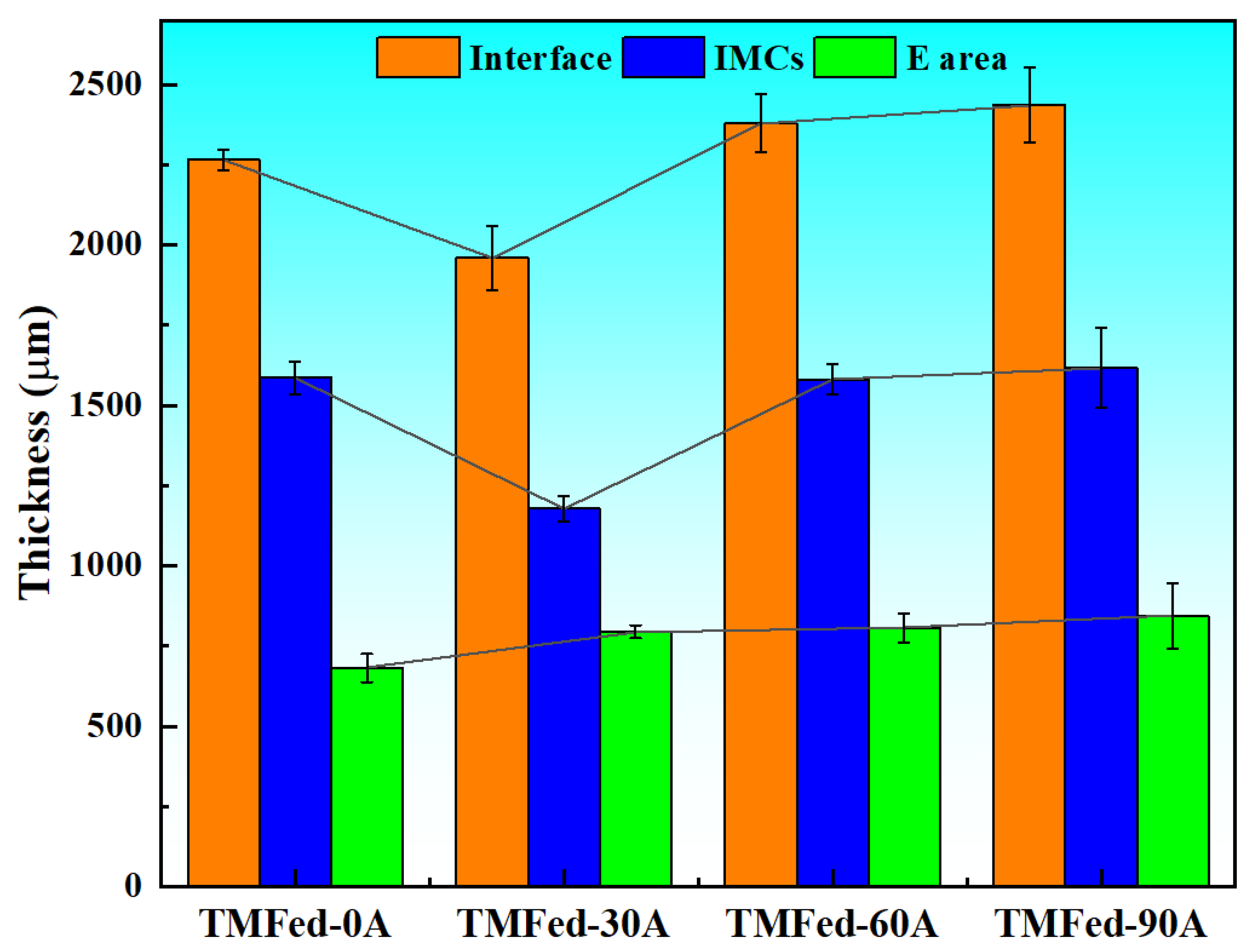

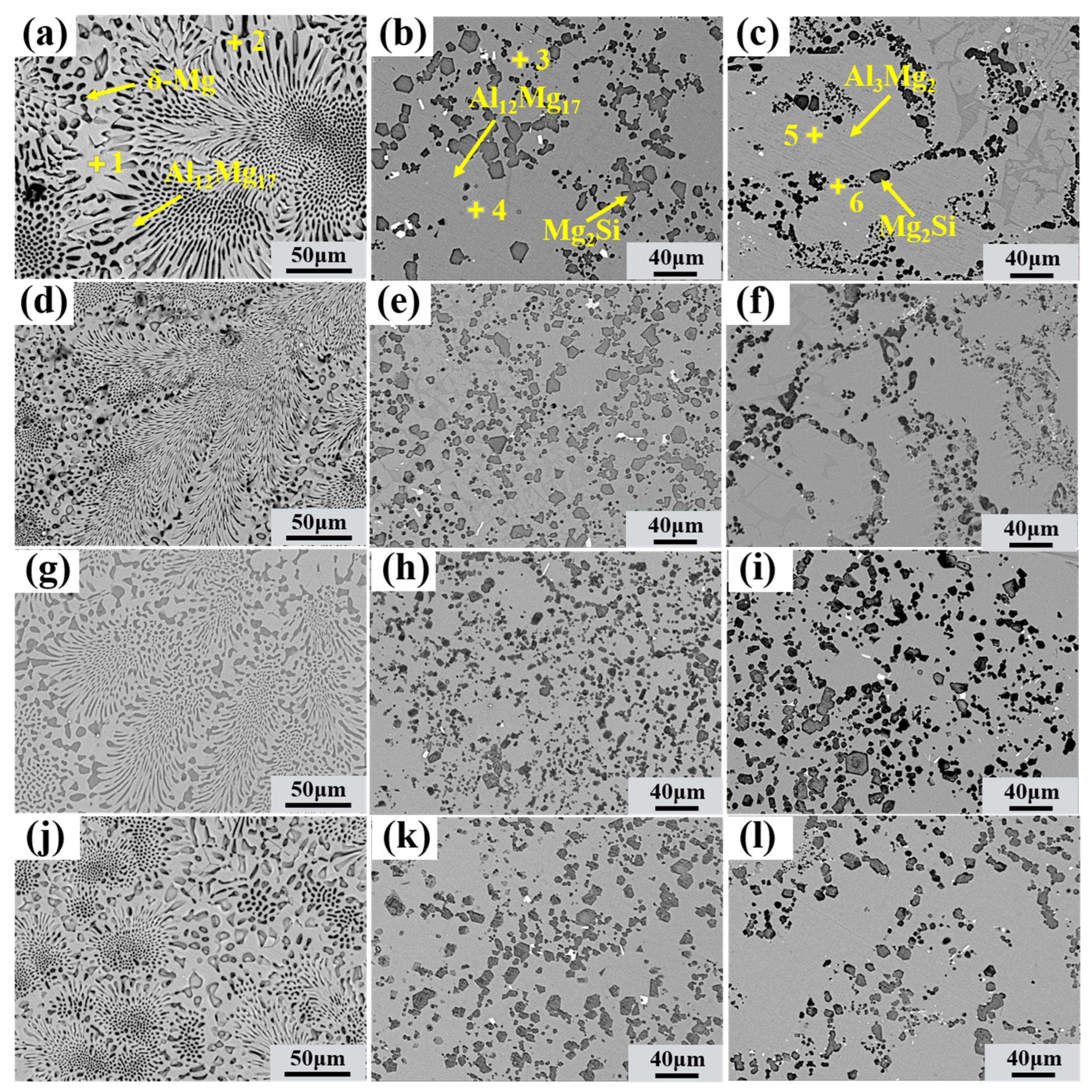

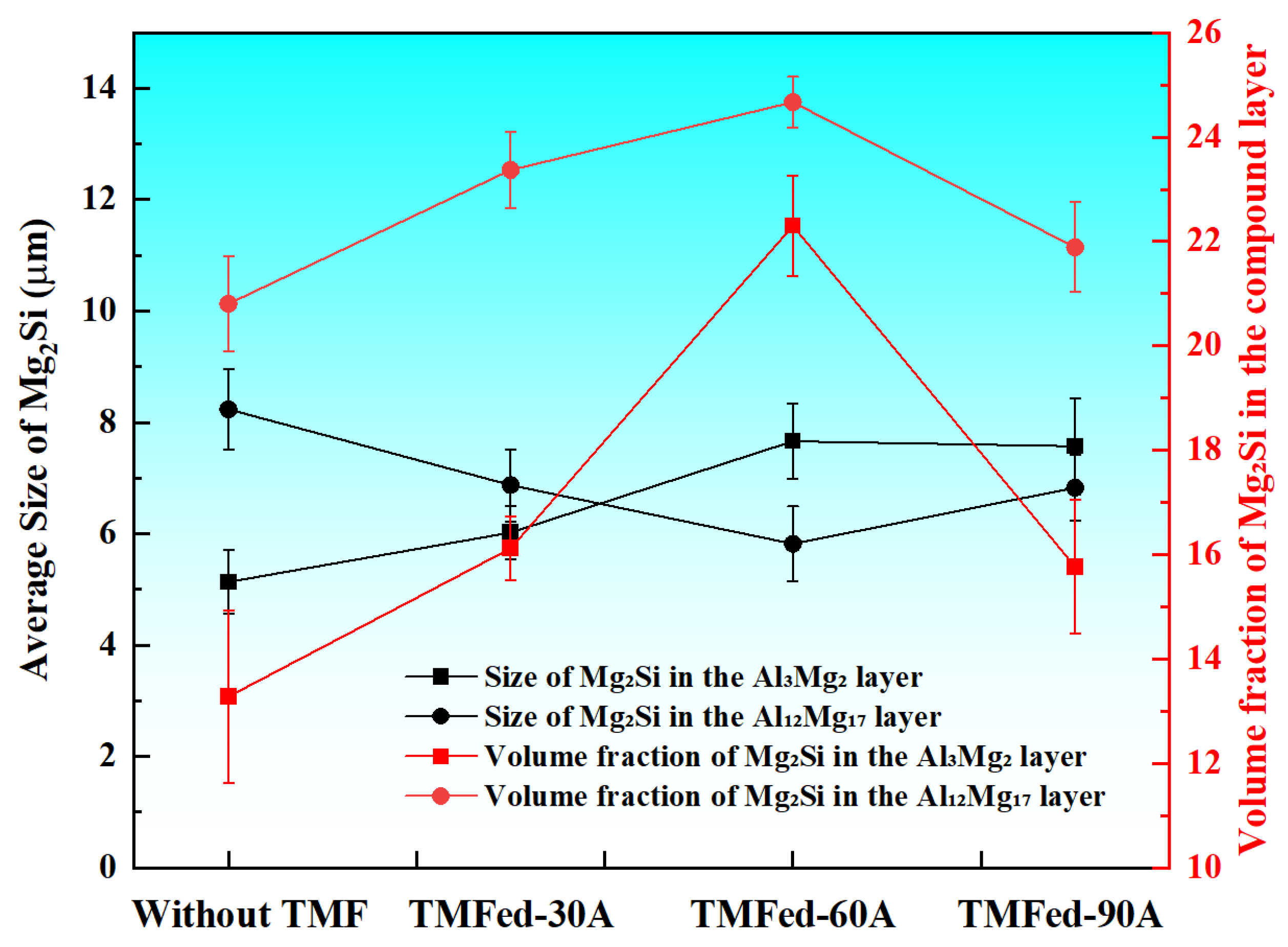

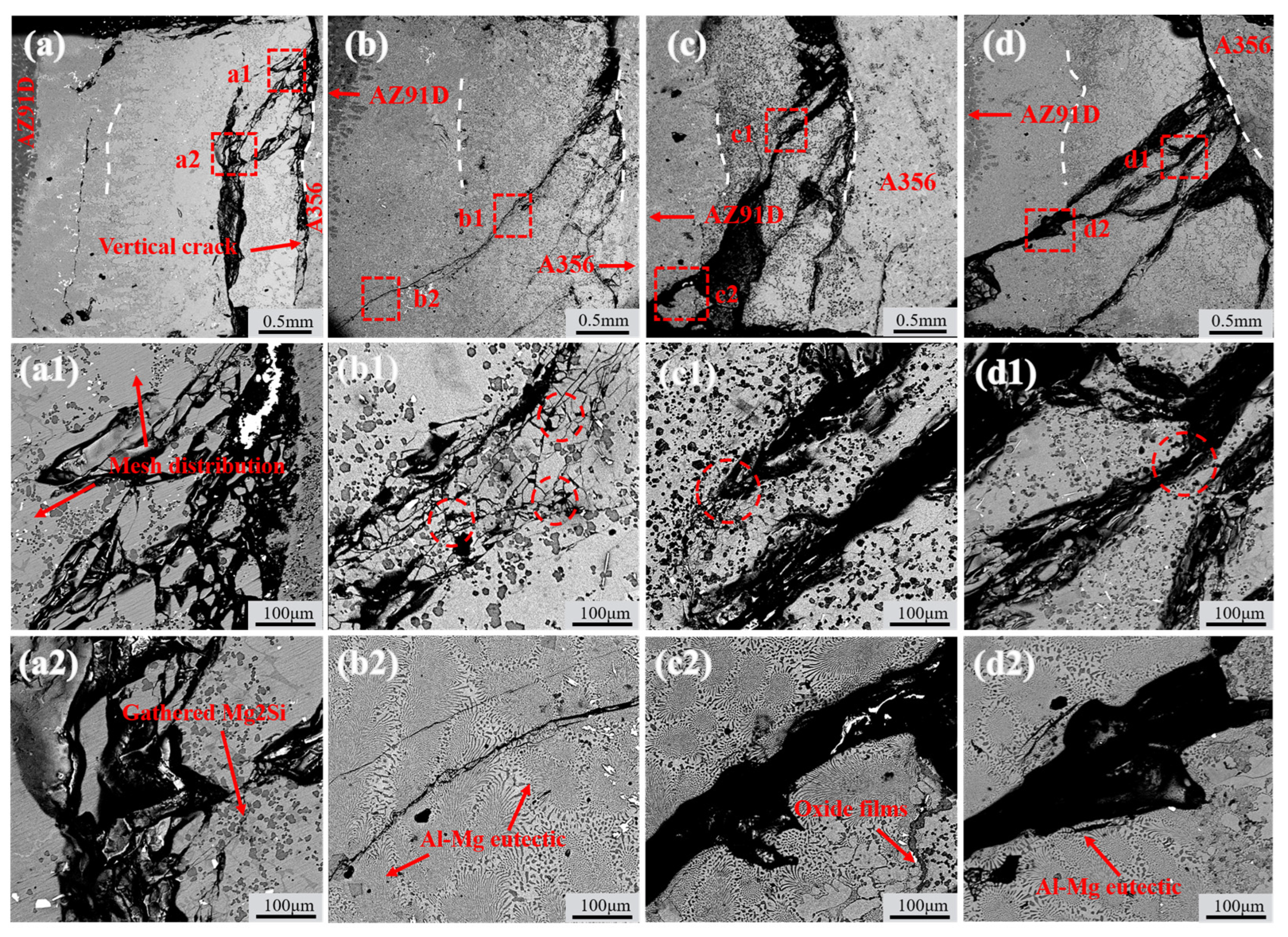

3.1. Microstructure Evolution

3.2. Mechanical Properties

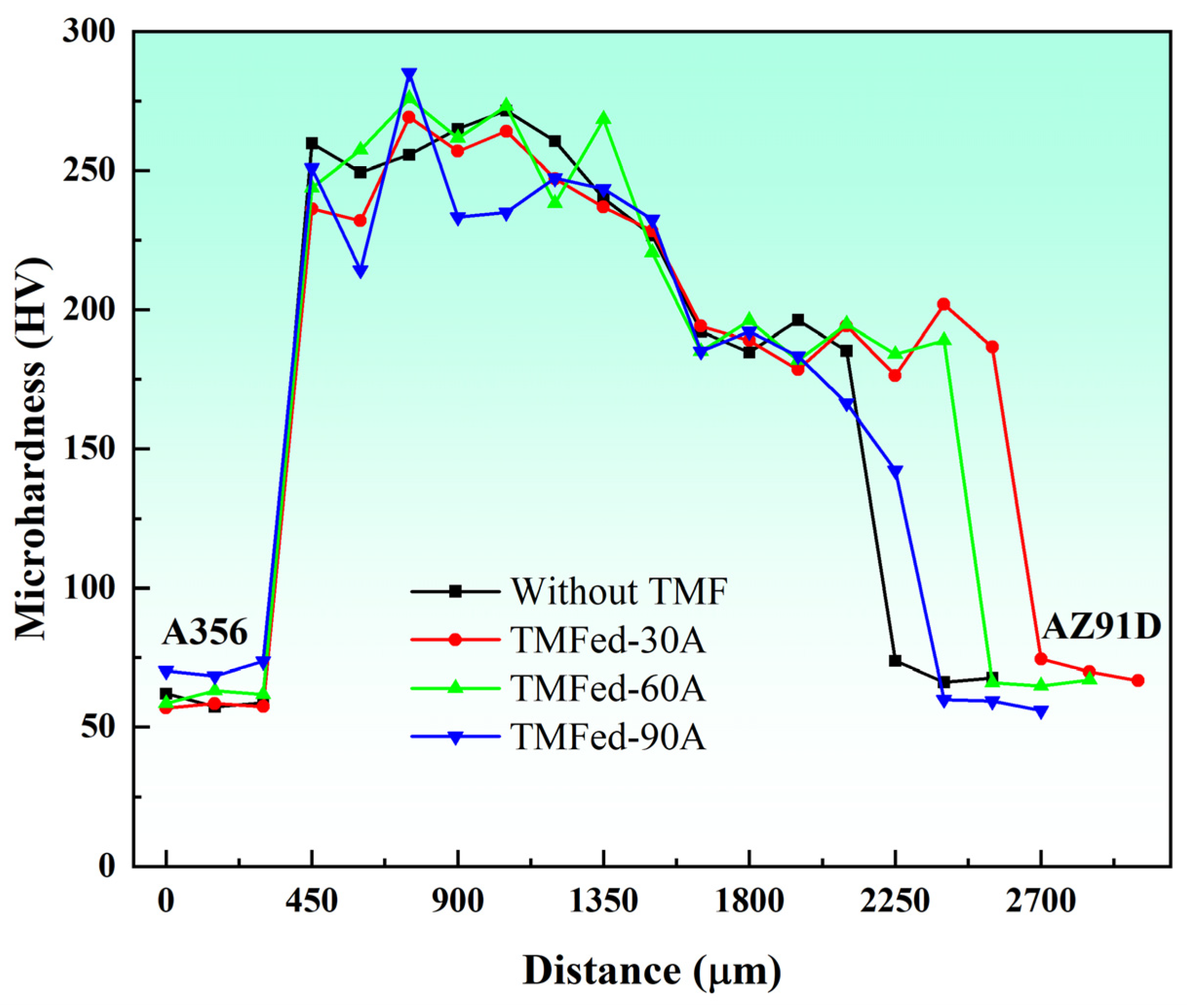

3.2.1. Microhardness

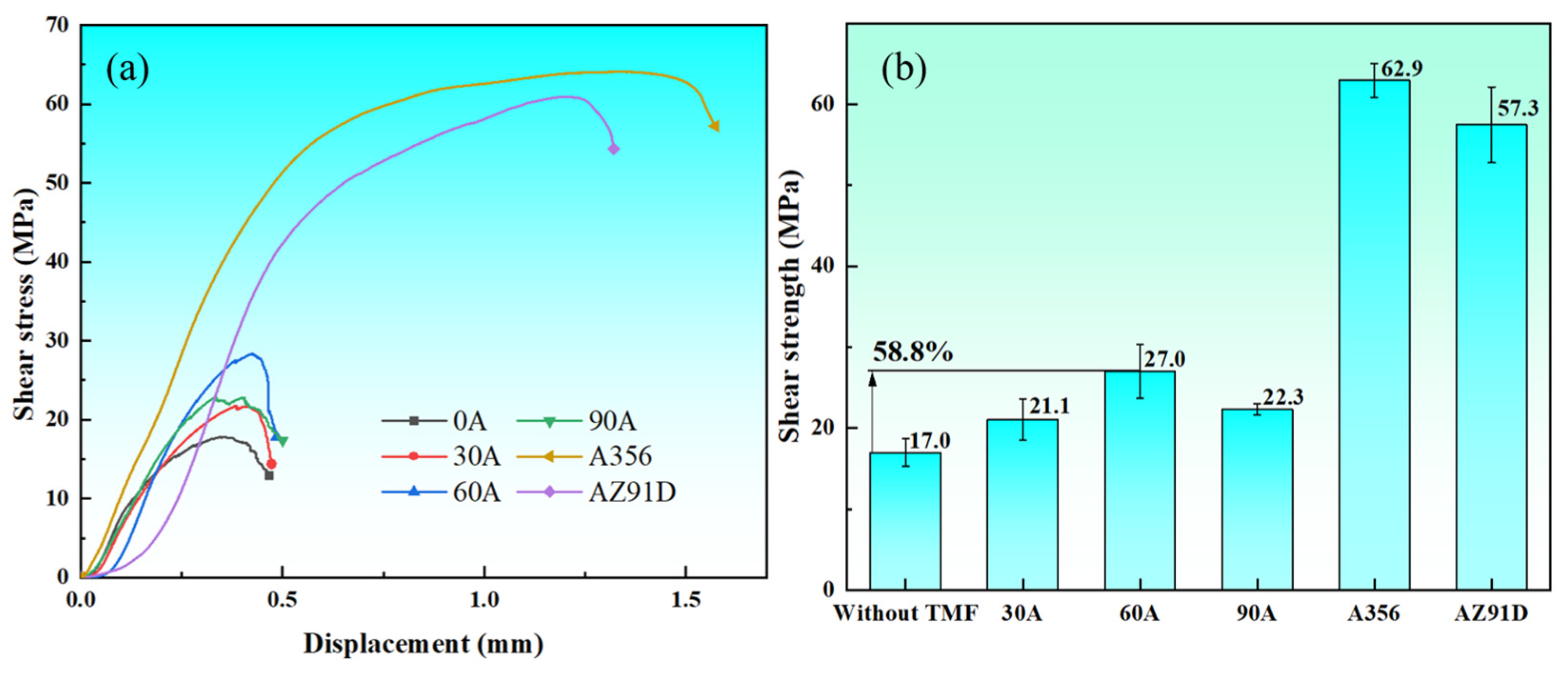

3.2.2. Shear Strength

4. Discussion

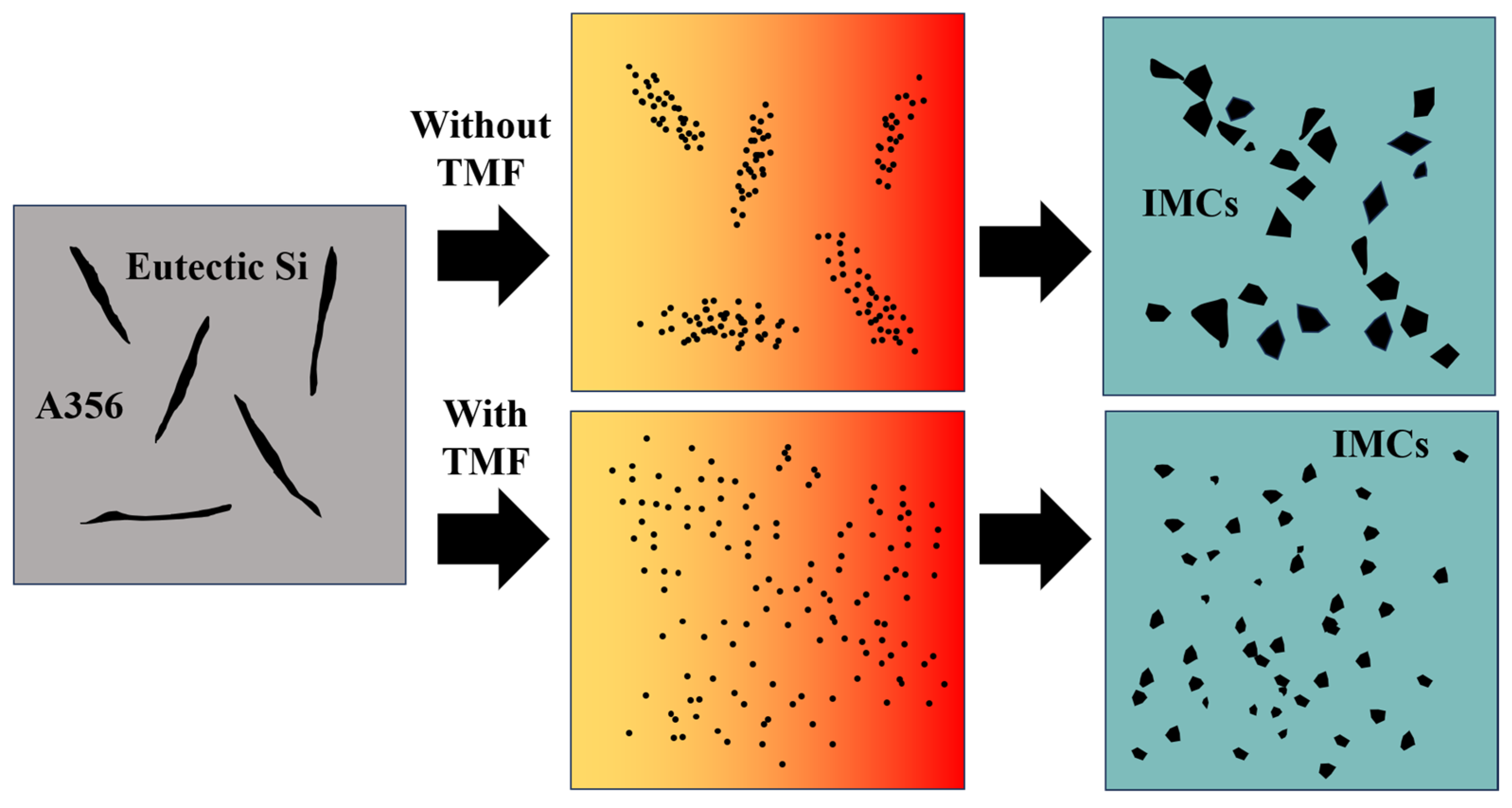

4.1. The Effect of TMF on the Microstructure of Al/Mg Bimetallic Interface

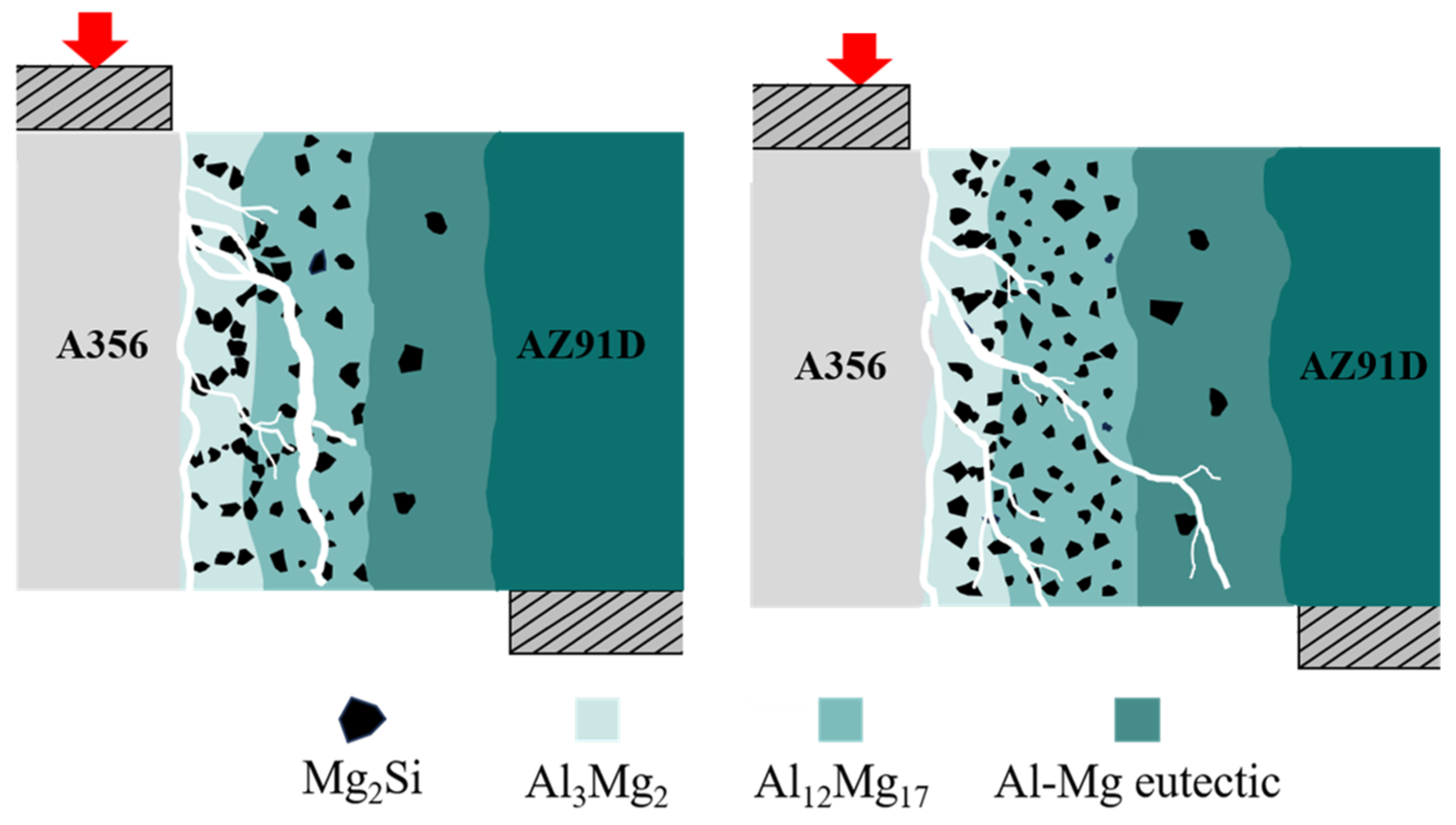

4.2. Strengthening Mechanism of the Al/Mg Bimetal

5. Conclusions

- Al/Mg bimetallic interfaces without the TMF showed non-uniform microstructures composed of Al-Mg IMC regions (Al3Mg2 + Mg2Si, Al12Mg17 + aggregated Mg2Si) and Al-Mg eutectic areas (Al12Mg17 + δ-Mg). TMF increased Al/Mg interface eutectic layer thickness, increasing with current intensity, and interface morphology changed from flat to irregular.

- The traveling magnetic field promotes the refinement and dispersion of Mg2Si particles. An appropriate current intensity (such as 60 A) can effectively refine the Mg2Si particles in the Al12Mg17 layer and achieve a relatively uniform distribution without altering the phase composition in the IMC region, thereby suppressing Mg2Si segregation and improving interfacial homogeneity.

- TMF improved Al/Mg interface shear strength. TMFed-60 A’s Al/Mg bimetals achieved shear strength of 27 MPa, representing a 58.8% improvement over Al/Mg bimetals without the TMF. This can be attributed to more uniform microstructures, and uniformly dispersed Mg2Si particles, which contribute to longer crack propagation paths.

- The TMF-assisted compound casting demonstrates significant potential for industrial applications. The technique achieved a remarkable 58.8% improvement in shear strength with the TMFed-60 A treatment while optimizing microstructures without changing phase compositions. Moreover, the process can be easily integrated into existing casting processes with minimal additional equipment, thus providing a cost-effective solution for enhancing bimetals in engineering applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Jiang, W.; Li, Q.; Yu, L.; Yu, X.; Fan, Z. Combined Effects of Ultrasonic Vibration and FeCoNiCrCu Coating on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetal by Compound Casting. China Foundry 2024, 21, 588–598. [Google Scholar] [CrossRef]

- Hu, Q.; Jiang, Z.; Jiang, W.; Li, G.; Guan, F.; Jiang, H.; Fan, Z. Interface Characteristics of Mg/Al Bimetal Produced by a Novel Liquid-Liquid Compound Casting Process with an Al Interlayer. Int. J. Adv. Manuf. Technol. 2019, 101, 1125–1132. [Google Scholar] [CrossRef]

- Fan, S.; Jiang, W.; Li, G.; Mo, J.; Fan, Z. Fabrication and Microstructure Evolution of Al/Mg Bimetal Using a near-Net Forming Process. Mater. Manuf. Process. 2017, 32, 1391–1397. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, W.; Li, Q.; Niu, Y.; Yu, L.; Li, G.; Fan, Z. Significantly Improved Bonding Strength of Al/Mg Bimetallic Interface by Compound Casting via FeCoNiCrCu High Entropy Alloy Coating. J. Mater. Res. Technol.-JMRT 2024, 30, 6870–6876. [Google Scholar] [CrossRef]

- Luo, C.; Liang, W.; Chen, Z.; Zhang, J.; Chi, C.; Yang, F. Effect of High Temperature Annealing and Subsequent Hot Rolling on Microstructural Evolution at the Bond-Interface of Al/Mg/Al Alloy Laminated Composites. Mater. Charact. 2013, 84, 34–40. [Google Scholar] [CrossRef]

- Jafarian, M.; Khodabandeh, A.; Manafi, S. Evaluation of Diffusion Welding of 6061 Aluminum and AZ31 Magnesium Alloys without Using an Interlayer. Mater. Des. (1980–2015) 2015, 65, 160–164. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, W.; Xu, Y.; Yu, L.; Peng, Z.; Li, G.; Fan, Z. Achieving High Strength of Al/Mg Bimetal Interface with Multiple Strengthening Mechanisms via a Novel Combination Treatment of La Addition and Ultrasonic Vibration. J. Alloys Compd. 2025, 1018, 179312. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Guan, F.; Zhang, Z.; Wang, J.; Yu, Y.; Fan, Z. Preparation, Interfacial Regulation and Strengthening of Mg/Al Bimetal Fabricated by Compound Casting: A Review. J. Magnes. Alloys 2023, 11, 3059–3098. [Google Scholar] [CrossRef]

- Li, G.; Guan, F.; Jiang, W.; Xu, Y.; Zhang, Z.; Fan, Z. Effects of Mechanical Vibration on Filling and Solidification Behavior, Microstructure and Performance of Al/Mg Bimetal by Lost Foam Compound Casting. China Foundry 2023, 20, 469–479. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Yang, W.; Jiang, Z.; Guan, F.; Jiang, H.; Fan, Z. New Insights into the Characterization and Formation of the Interface of A356/AZ91D Bimetallic Composites Fabricated by Compound Casting. Metall. Mater. Trans. A 2019, 50, 1076–1090. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Guan, F.; Zhu, J.; Yu, Y.; Fan, Z. Microstructure Evolution, Mechanical Properties and Fracture Behavior of Al-xSi/AZ91D Bimetallic Composites Prepared by a Compound Casting. J. Magnes. Alloys 2024, 12, 1944–1964. [Google Scholar] [CrossRef]

- Wen, F.; Zhao, J.; Yuan, M.; Wang, J.; Zheng, D.; Zhang, J.; He, K.; Shangguan, J.; Guo, Y. Influence of Ni Interlayer on Interfacial Microstructure and Mechanical Properties of Ti-6Al-4V/AZ91D Bimetals Fabricated by a Solid-Liquid Compound Casting Process. J. Magnes. Alloys 2021, 9, 1382–1395. [Google Scholar] [CrossRef]

- Yang, H.K.; Qiu, J.; Cao, C.; Li, Y.D.; Song, Z.X.; Liu, W.J. Theoretical Design and Experimental Study of the Interlayer of Al/Mg Bimetallic Composite Plate by Solid-Liquid Cast Rolling. Mater. Sci. Eng. A 2022, 835, 142677. [Google Scholar] [CrossRef]

- Meng, Y.; Fu, J.; Gong, M.; Zhang, S.; Gao, M.; Chen, H. Laser Dissimilar Welding of Al/Mg Lap-Joint with Ti Interlayer through Optimized 8-Shaped Beam Oscillation. Opt. Laser Technol. 2023, 162, 109304. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Guan, F.; Zhu, J.; Yu, Y.; Fan, Z. Effect of Different Ni Interlayers on Interfacial Microstructure and Bonding Properties of Al/Mg Bimetal Using a Novel Compound Casting. J. Manuf. Process. 2020, 50, 614–628. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Guan, F.; Zhu, J.; Yu, Y.; Fan, Z. Improving Mechanical Properties of AZ91D Magnesium/A356 Aluminum Bimetal Prepared by Compound Casting via a High Velocity Oxygen Fuel Sprayed Ni Coating. J. Magnes. Alloys 2022, 10, 1075–1085. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Guan, F.; Zhu, J.; Yu, Y.; Fan, Z. Design and Achievement of Metallurgical Bonding of Mg/Al Interface Prepared by Liquid–Liquid Compound Casting via a Co-Deposited Cu–Ni Alloy Coating. Metall. Mater. Trans. A 2022, 53, 3520–3527. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, W.; Li, Q.; Yu, L.; Yu, X.; Peng, Z.; Fan, Z. Superior Bonding of Al/Mg Interface by Introducing Nanocrystals via High-Entropy Alloy Coating and Ultrasonic Vibration. Mater. Res. Lett. 2025, 13, 131–139. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, W.; Li, G.; Wang, J.; Guan, F.; Jie, G.; Fan, Z. Effect of La on Microstructure, Mechanical Properties and Fracture Behavior of Al/Mg Bimetallic Interface Manufactured by Compound Casting. J. Mater. Sci. Technol. 2022, 105, 214–225. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, W.; Li, G.; Wang, J.; Guan, F.; Jie, G.; Fan, Z. Improved Interface Bonding of Al/Mg Bimetal Fabricated by Compound Casting with Nd Addition. Mater. Sci. Eng. A 2021, 826, 141998. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, W.; Guan, F.; Wang, J.; Li, G.; Fan, Z. Understanding the Microstructural Evolution and Strengthening Mechanism of Al/Mg Bimetallic Interface via the Introduction of Y. Mater. Sci. Eng. A 2022, 840, 142974. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, W.; Guan, F.; Li, G.; Fan, Z. Interface Formation and Strengthening Mechanisms of Al/Mg Bimetallic Composite via Compound Casting with Rare Earth Ce Introduction. Mater. Sci. Eng. A 2022, 854, 143830. [Google Scholar] [CrossRef]

- Xu, G.; Luo, A.A.; Chen, Y.; Sachdev, A.K. Interfacial Phenomena in Magnesium/Aluminum Bi-Metallic Castings. Mater. Sci. Eng. A 2014, 595, 154–158. [Google Scholar] [CrossRef]

- Chen, L.; Bai, S.-L. The Anti-Corrosion Behavior under Multi-Factor Impingement of Hastelloy C22 Coating Prepared by Multilayer Laser Cladding. Appl. Surf. Sci. 2018, 437, 1–12. [Google Scholar] [CrossRef]

- Mola, R.; Bucki, T. Characterization of the Bonding Zone in AZ91/AlSi12 Bimetals Fabricated by Liquid-Solid Compound Casting Using Unmodified and Thermally Modified AlSi12 Alloy. Stroj. Vestn.-J. Mech. Eng. 2020, 66, 439–448. [Google Scholar] [CrossRef]

- Li, Q.; Guan, F.; Xu, Y.; Zhang, Z.; Fan, Z.; Jiang, W. Development of Al/Mg Bimetal Processed by Ultrasonic Vibration-Assisted Compound Casting: Effects of Ultrasonic Vibration Treatment Duration Time. Materials 2023, 16, 5009. [Google Scholar] [CrossRef]

- Guan, F.; Jiang, W.; Zhang, Z.; Li, G.; Wang, J.; Fan, Z. Significantly Enhanced Mg/Al Bimetallic Interface by Compound Casting via Combination of Gd Addition and Vibration. Metall. Mater. Trans. A Phys. Metall. Mater. 2023, 54, 3389–3399. [Google Scholar] [CrossRef]

- Guan, F.; Fan, S.; Wang, J.; Li, G.; Zhang, Z.; Jiang, W. Effect of Vibration Acceleration on Interface Microstructure and Bonding Strength of Mg-Al Bimetal Produced by Compound Casting. Metals 2022, 12, 766. [Google Scholar] [CrossRef]

- Guan, F.; Jiang, W.; Wang, J.; Li, G.; Zhang, Z.; Fan, Z. Development of High Strength Mg/Al Bimetal by a Novel Ultrasonic Vibration Aided Compound Casting Process. J. Mater. Process. Technol. 2022, 300, 117441. [Google Scholar] [CrossRef]

- Qie, X.; Zhang, Z.; Li, Q.; Guan, F.; Fan, Z.; Jiang, W. Strengthening of Compound Casting Al/Mg Bimetallic Interface with Ni Interlayer by Vibration Assisted Treatment. J. Mater. Res. Technol. 2023, 26, 1736–1742. [Google Scholar] [CrossRef]

- Liao, Q.; Le, Q.; Zhao, D.; Bao, L.; Wang, T.; Jia, Y. Research Progress on Semi-Continuous Casting of Magnesium Alloys under External Field. China Foundry 2024, 21, 516–524. [Google Scholar] [CrossRef]

- Liu, W.; Yang, Y.; Duan, W.; Bao, J.; Yuan, M.; Zhao, Z.; Cui, J.; Zhang, Z. Scalable DC Casting of Large-Size AZ80 Magnesium Alloy Slab under out-of-Phase Pulsed Magnetic Field: Experiment and Simulation. J. Mater. Res. Technol. 2024, 31, 1864–1870. [Google Scholar] [CrossRef]

- Wang, B.; Yang, Y.-S.; Sun, M.-L. Microstructure Refinement of AZ31 Alloy Solidified with Pulsed Magnetic Field. Trans. Nonferrous Met. Soc. China 2010, 20, 1685–1690. [Google Scholar] [CrossRef]

- Zuo, Y.; Cui, J.; Zhao, Z.; Zhang, H.; Qin, K. Effect of Low Frequency Electromagnetic Field on Casting Crack during DC Casting Superhigh Strength Aluminum Alloy Ingots. Mater. Sci. Eng. A 2005, 406, 286–292. [Google Scholar] [CrossRef]

- Jie, J.C.; Yue, S.P.; Liu, J.; StJohn, D.H.; Zhang, Y.B.; Guo, E.Y.; Wang, T.M.; Li, T.J. Revealing the Mechanisms for the Nucleation and Formation of Equiaxed Grains in Commercial Purity Aluminum by Fluid-Solid Coupling Induced by a Pulsed Magnetic Field. Acta Mater. 2021, 208, 116747. [Google Scholar] [CrossRef]

- Xuan, W.; Liu, H.; Li, C.; Ren, Z.; Zhong, Y.; Li, X.; Cao, G. Effect of a High Magnetic Field on Microstructures of Ni-Based Single Crystal Superalloy During Seed Melt-Back. Metall. Mater. Trans. B 2016, 47, 828–833. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, G.; Lv, W.; Xu, H.; Xu, C. Improved Microstructure and Shear Strength of the Al/Steel Bimetal Prepared by Compound Casting under Magnetic Field. J. Alloys Compd. 2023, 932, 167343. [Google Scholar] [CrossRef]

- Yu, L.H.; Ma, Y.X.; Li, Q.Q.; Xu, Y.C.; Yu, X.P.; Peng, Z.W.; Jiang, W.M. Effect of Electromagnetic Stirring on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetal Produced by Lost Foam Compound Casting. J. Mater. Res. Technol.-JMRT 2024, 33, 2101–2111. [Google Scholar] [CrossRef]

- Li, Y.; Shao, C.; Zhang, M.; Cui, H.; Tang, X.; Huang, S. Improved Microstructure and Enhanced Mechanical Properties of Laser Fusion Brazed AA5083/TA5 Dissimilar Butt Joints by Electromagnetic Stirring. J. Manuf. Process. 2025, 141, 1729–1751. [Google Scholar] [CrossRef]

- Li, Y. Reducing Sensitivity of Mechanical Properties to Assembly Gap Size in AA5083/TA5 Dissimilar Joints via a Transverse Alternating Magnetic Field in Laser Fusion Brazing Process. Mater. Charact. 2025, 223, 114929. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, W.; Xu, Y.; Yu, L.; Niu, Y.; Fan, Z. Development of Prominent Bonding Strength in Al/Mg Bimetal Composites Prepared by Ultrasonic Vibration-Assisted Compound Casting: Effects of Ultrasonic Powers. J. Mater. Sci. Technol. 2024, 197, 78–93. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, W.; Xu, Y.; Yu, L.; Yu, X.; Fan, Z. New Insights into the Influencing Mechanism of Ultrasonic Vibration on Interface of Al/Mg Bimetal Composites by Compound Casting Using Simulation Calculation and Experimental Verification. Compos. Part B-Eng. 2024, 284, 111726. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Y.; Niu, Y.; Fan, Z.; Yu, L.; Jiang, W. Development of Al/Mg Bimetal Prepared by Ultrasonic Vibration-Assisted Compound Casting: Effects of Interface Treatment Temperatures. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2024, 890, 145911. [Google Scholar] [CrossRef]

- Duan, W.; Yin, S.; Liu, W.; Zhao, Z.; Hu, K.; Wang, P.; Cui, J.; Zhang, Z. Numerical and Experimental Studies on Solidification of AZ80 Magnesium Alloy under Out-of-Phase Pulsed Magnetic Field. J. Magnes. Alloys 2021, 9, 166–182. [Google Scholar] [CrossRef]

- Chen, Q.; Shen, H. Numerical Study on Solidification Characteristics under Pulsed Magnetic Field. Int. J. Heat Mass Transf. 2018, 120, 997–1008. [Google Scholar] [CrossRef]

- Li, G.; Yang, W.; Jiang, W.; Guan, F.; Jiang, H.; Wu, Y.; Fan, Z. The Role of Vacuum Degree in the Bonding of Al/Mg Bimetal Prepared by a Compound Casting Process. J. Mater. Process. Technol. 2019, 265, 112–121. [Google Scholar] [CrossRef]

- Guan, F.; Jiang, W.; Li, G.; Zhu, J.; Wang, J.; Jie, G.; Fan, Z. Effect of Vibration on Interfacial Microstructure and Mechanical Properties of Mg/Al Bimetal Prepared by a Novel Compound Casting. J. Magnes. Alloys 2022, 10, 2296–2309. [Google Scholar] [CrossRef]

| Alloy | Mass | Fraction (%) | |||||

|---|---|---|---|---|---|---|---|

| Mg | Al | Si | Ti | Mn | Fe | Zn | |

| A356 | 0.439 | Bal. | 6.81 | 0.017 | - | 00.205 | - |

| AZ91D | Bal. | 9.08 | - | - | 0.62 | - | 0.23 |

| Point No. | Element Compositions (at.%) | Possible Phase | ||

|---|---|---|---|---|

| Mg | Al | Si | ||

| 1 | 61.92 | 38.08 | - | Al12Mg17 |

| 2 | 90.71 | 9.29 | - | δ-Mg |

| 3 | 55.39 | 44.61 | - | Al12Mg17 |

| 4 | 54.87 | - | 45.13 | Mg2Si |

| 5 | 38.37 | 61.63 | - | Al3Mg2 |

| 6 | 66.48 | - | 33.52 | Mg2Si |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Q.; Li, G.; Hu, J.; Jiang, W.; Fan, X.; Wang, Y.; Wang, X.; Kang, X. Effects of Traveling Magnetic Field on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetals Prepared by Compound Casting. Materials 2025, 18, 4077. https://doi.org/10.3390/ma18174077

Zeng Q, Li G, Hu J, Jiang W, Fan X, Wang Y, Wang X, Kang X. Effects of Traveling Magnetic Field on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetals Prepared by Compound Casting. Materials. 2025; 18(17):4077. https://doi.org/10.3390/ma18174077

Chicago/Turabian StyleZeng, Qiantong, Guangyu Li, Jiaze Hu, Wenming Jiang, Xiuru Fan, Yuejia Wang, Xiaoqiong Wang, and Xing Kang. 2025. "Effects of Traveling Magnetic Field on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetals Prepared by Compound Casting" Materials 18, no. 17: 4077. https://doi.org/10.3390/ma18174077

APA StyleZeng, Q., Li, G., Hu, J., Jiang, W., Fan, X., Wang, Y., Wang, X., & Kang, X. (2025). Effects of Traveling Magnetic Field on Interfacial Microstructure and Mechanical Properties of Al/Mg Bimetals Prepared by Compound Casting. Materials, 18(17), 4077. https://doi.org/10.3390/ma18174077