The Effect of Geometric and Material Nonlinearities on the Development of Membrane Resistance in Reinforced Concrete Flat Slab–Column Buildings

Abstract

1. Introduction

- Demonstrating that CMA and TMA mechanisms do not arise when only geometric or only material nonlinearity is included;

- Establishing that their numerical occurrence in slab-type structures is feasible only when both geometric and material nonlinearities are incorporated simultaneously.

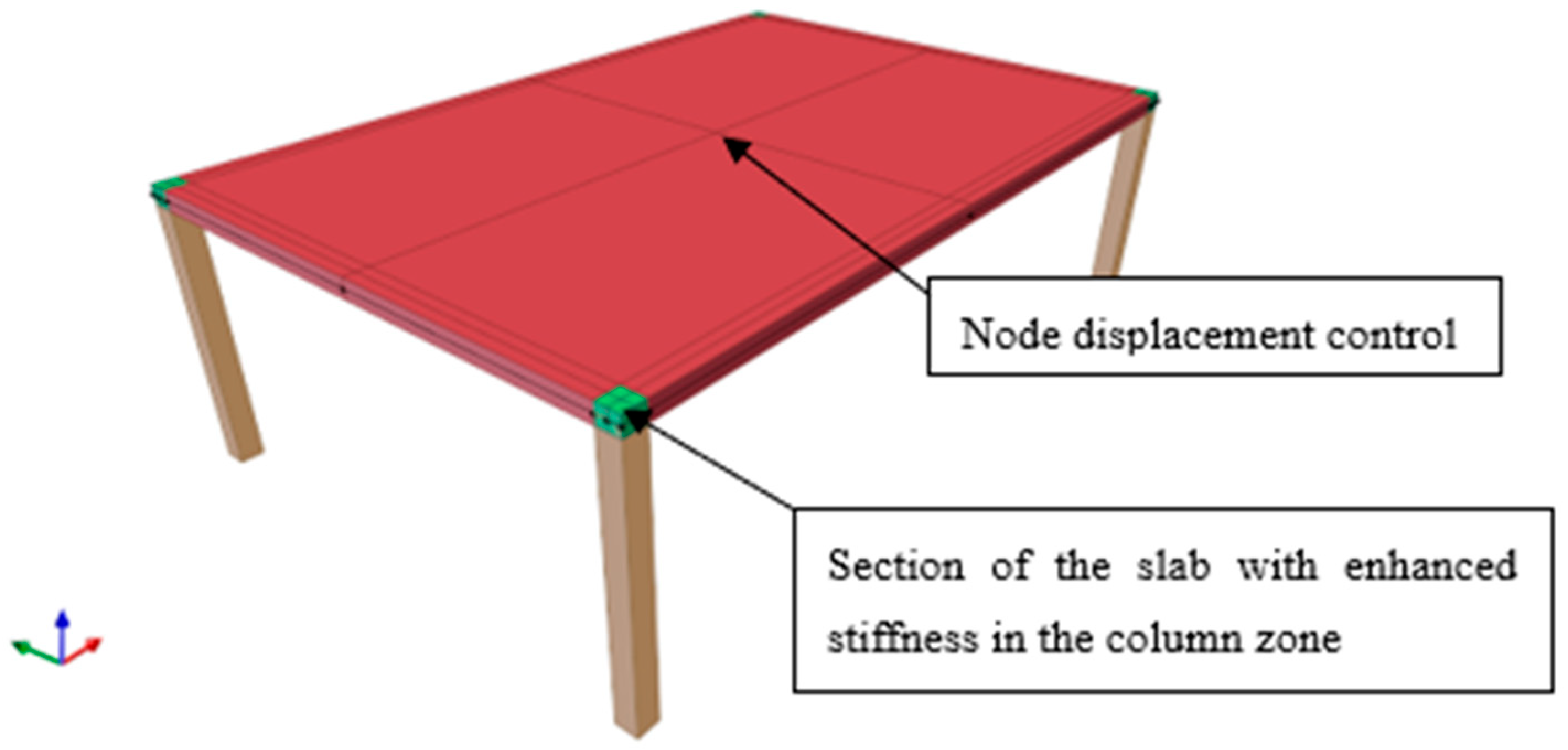

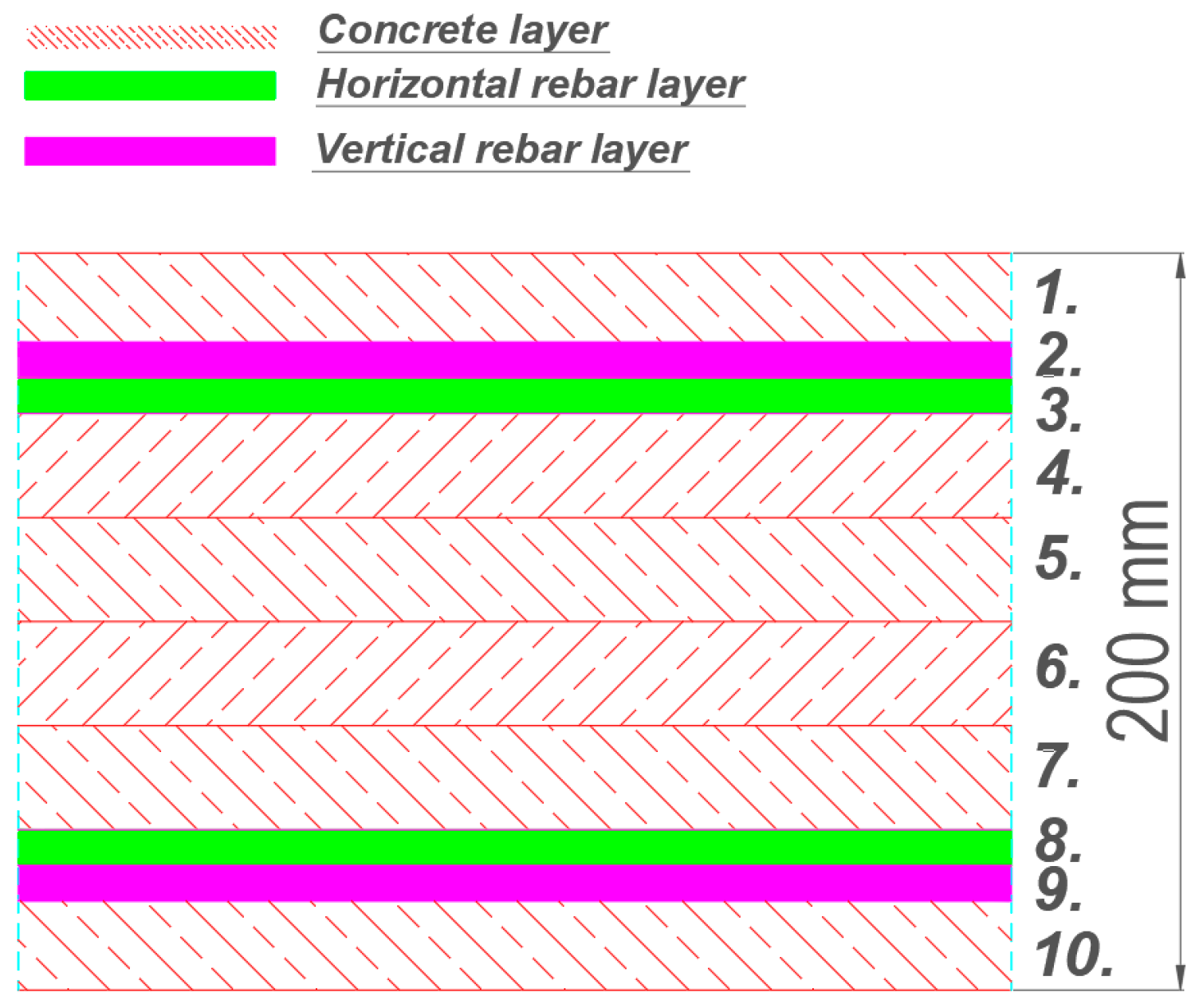

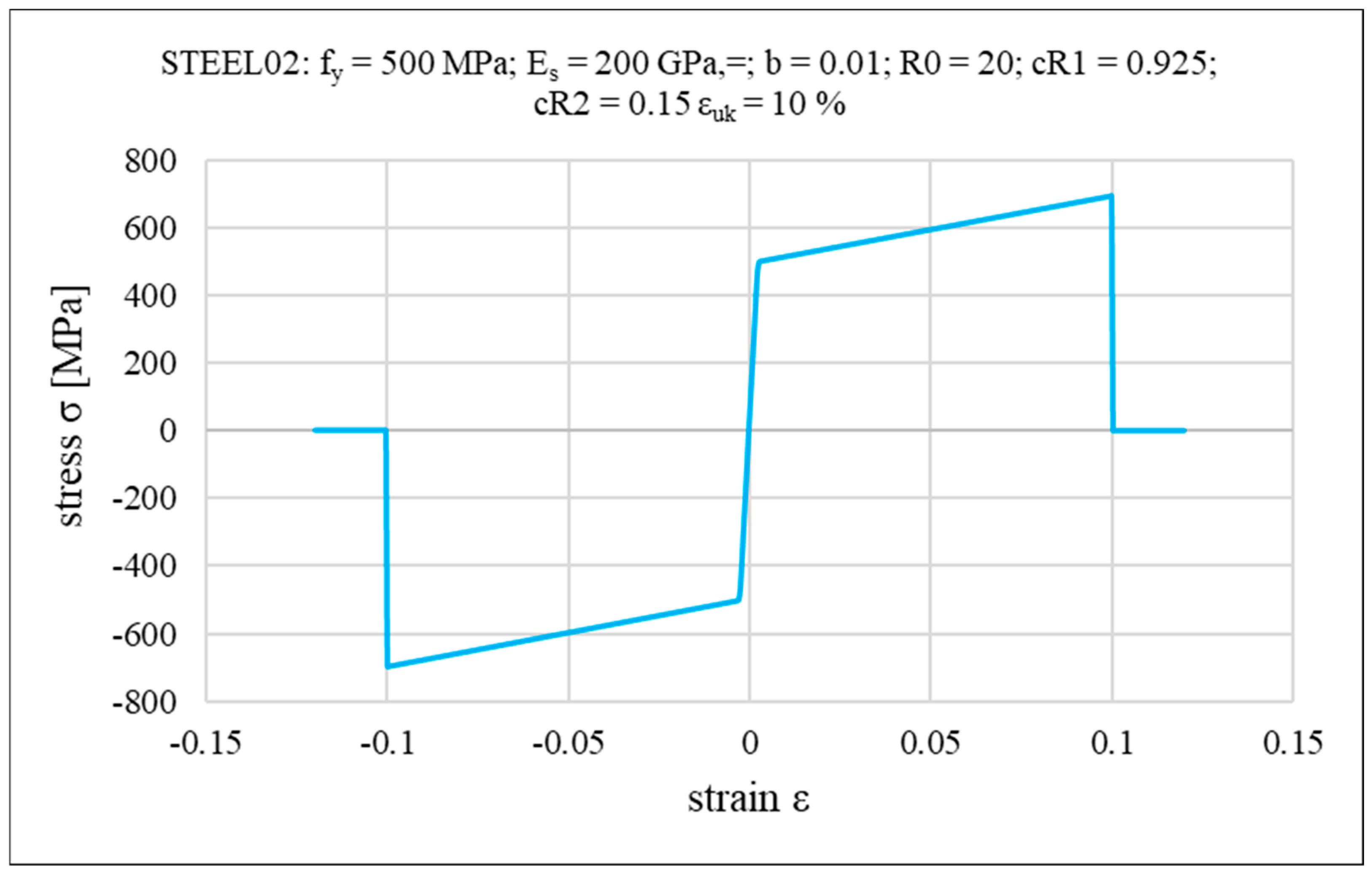

2. Computational Model of the Analyzed Structure

- No slip is allowed between reinforcing bars and the surrounding concrete (perfect bond assumption);

- Bar pull-out failure in the connections is not considered;

- Out-of-plane shear failure of the slab is not taken into account;

- Failure of the columns is not taken into account;

- The influence of strain rate on structural strength is neglected.

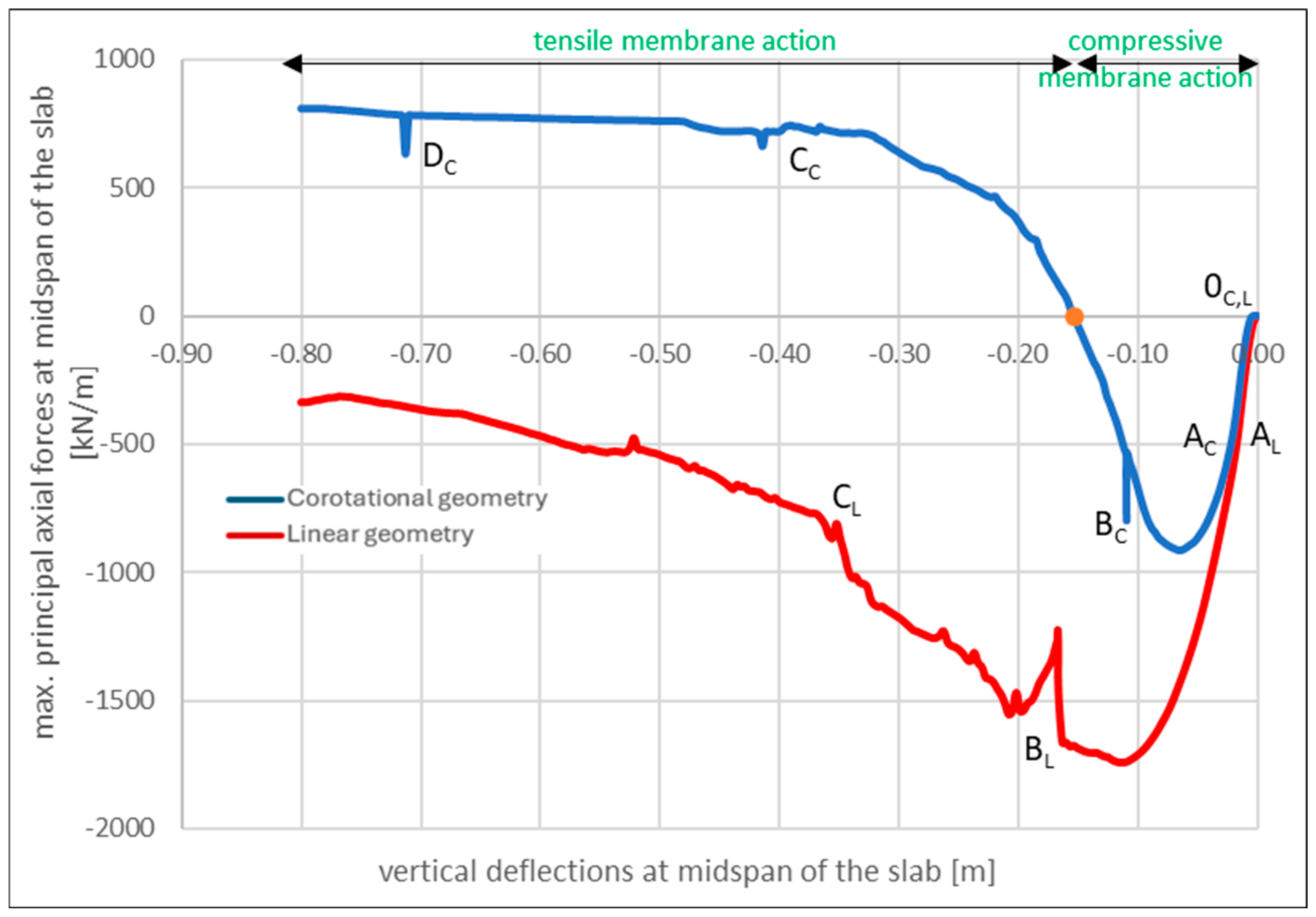

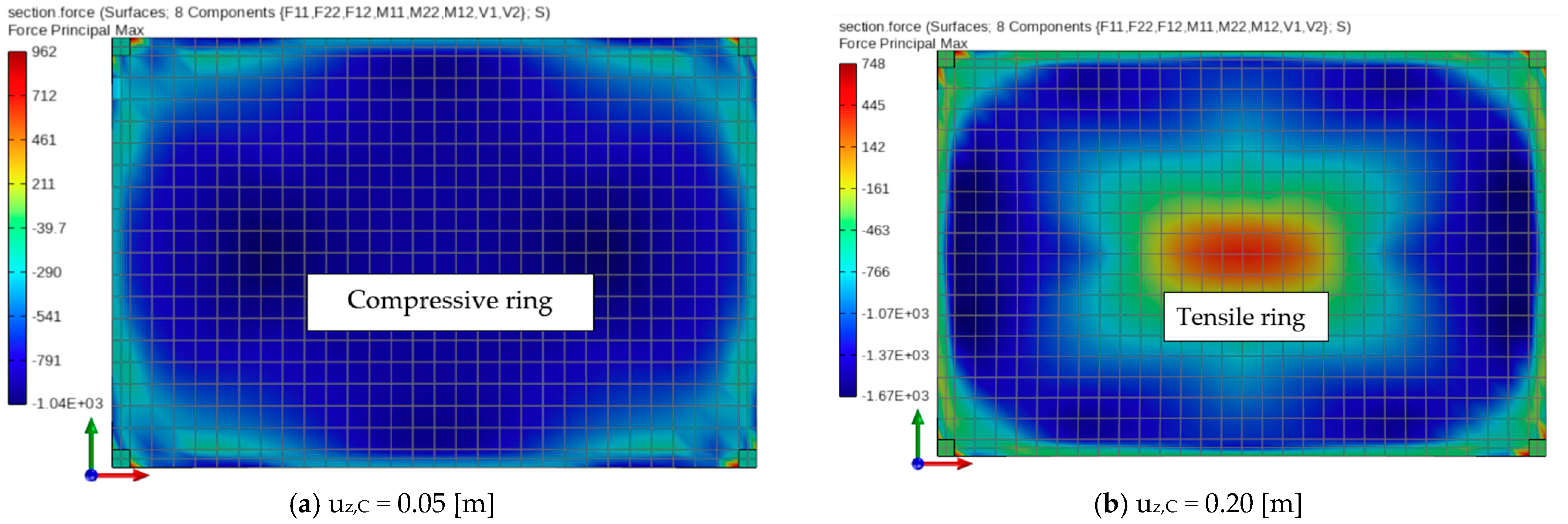

3. Slab with Linear Concrete Material

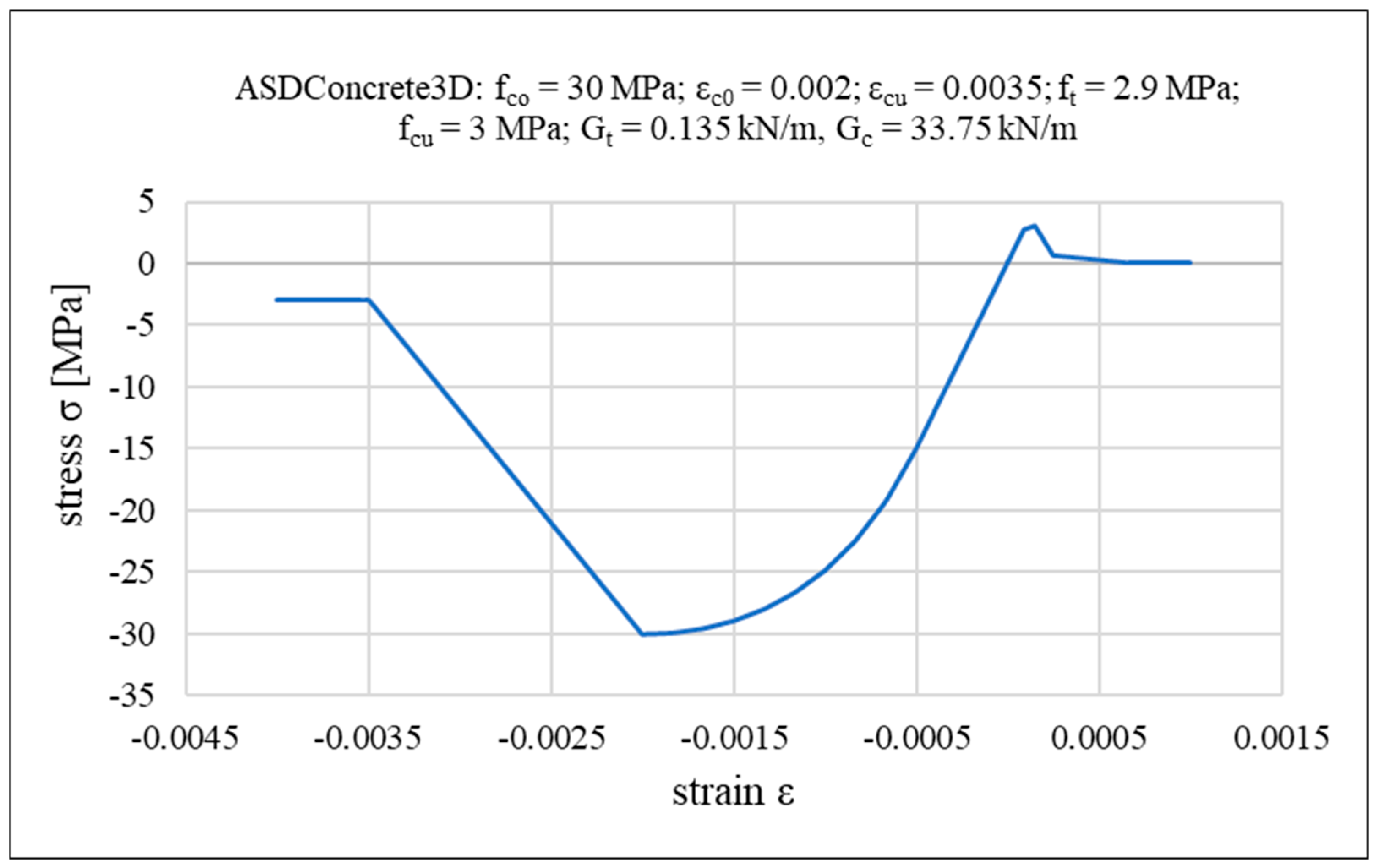

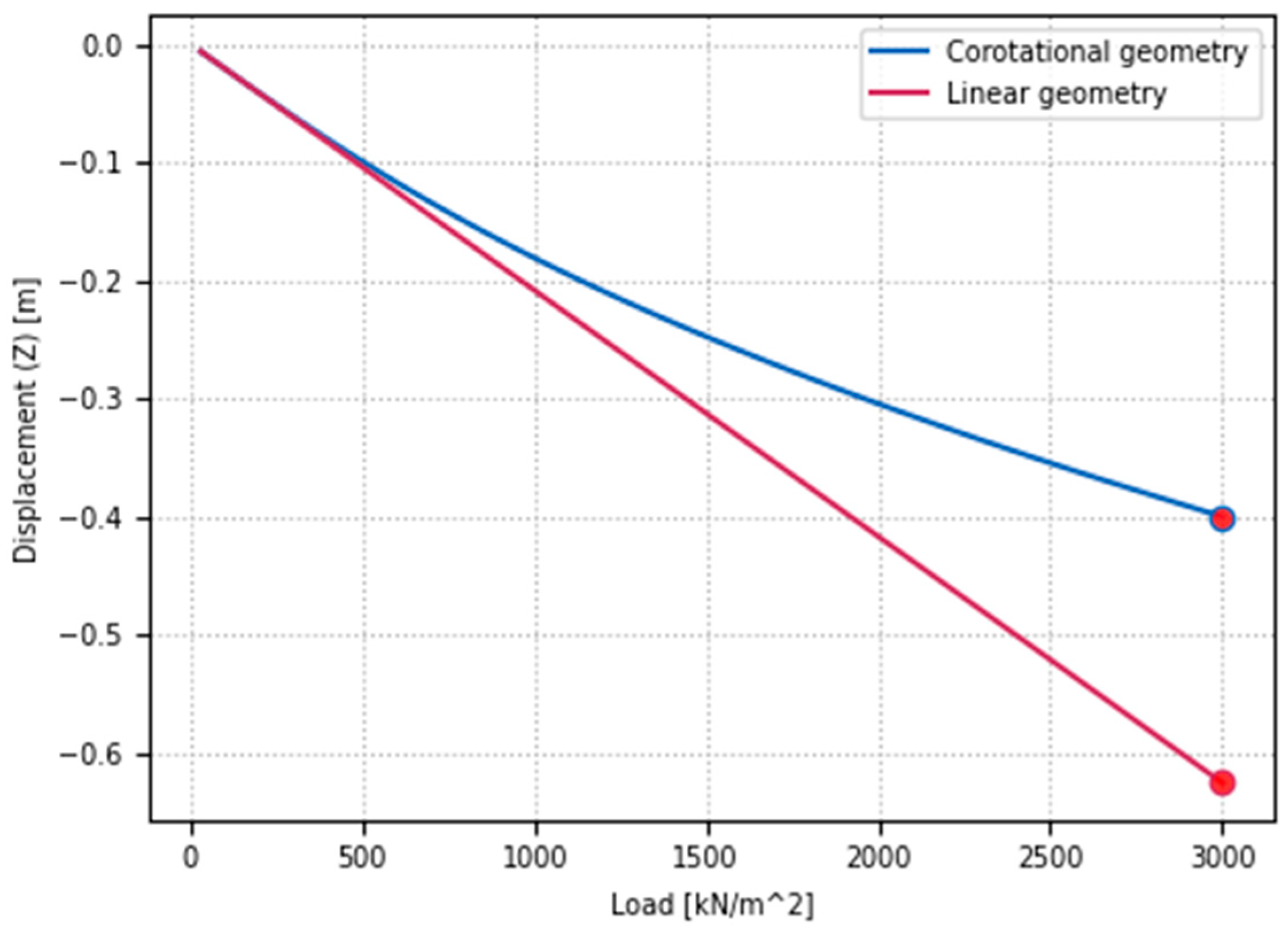

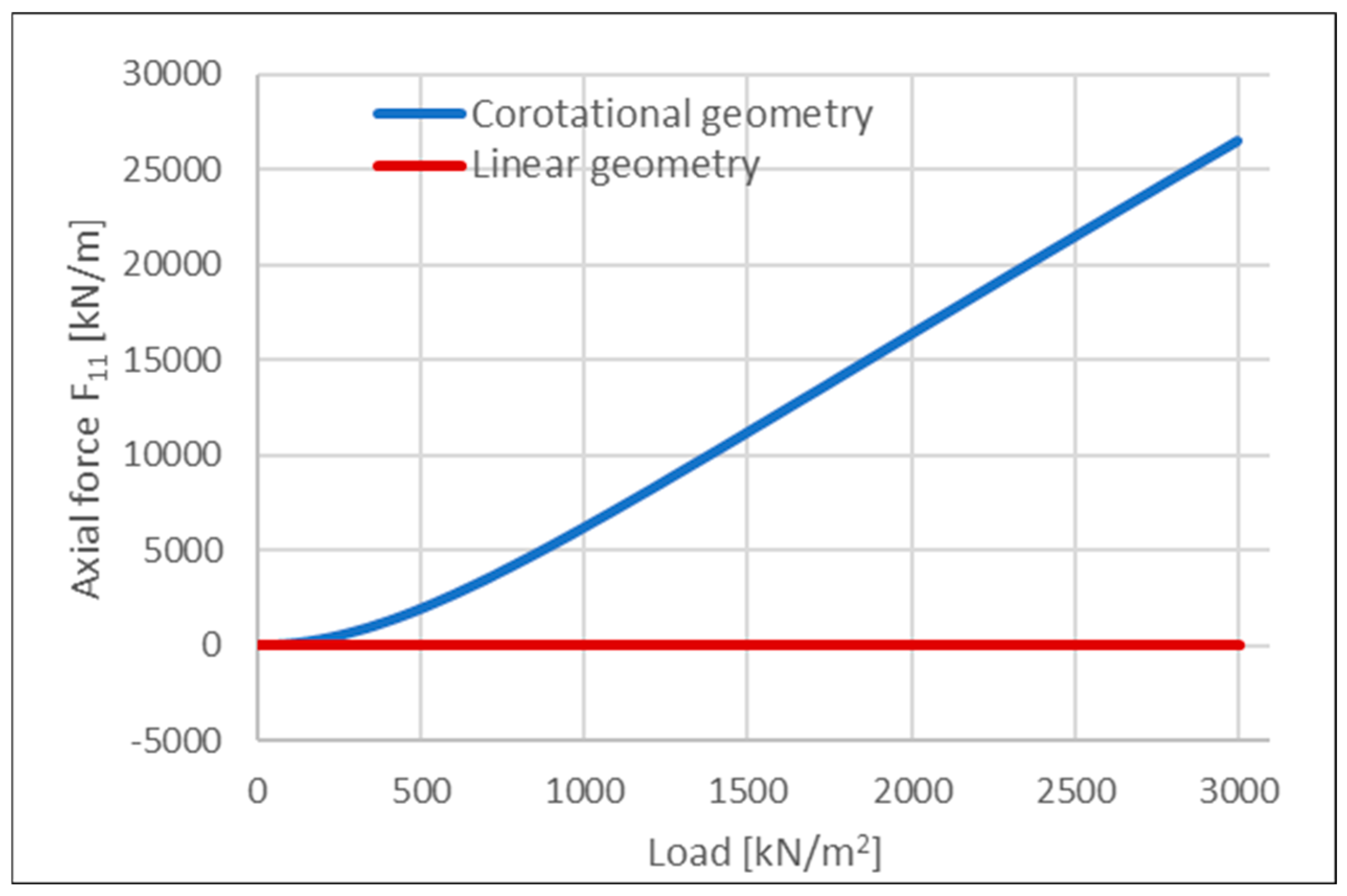

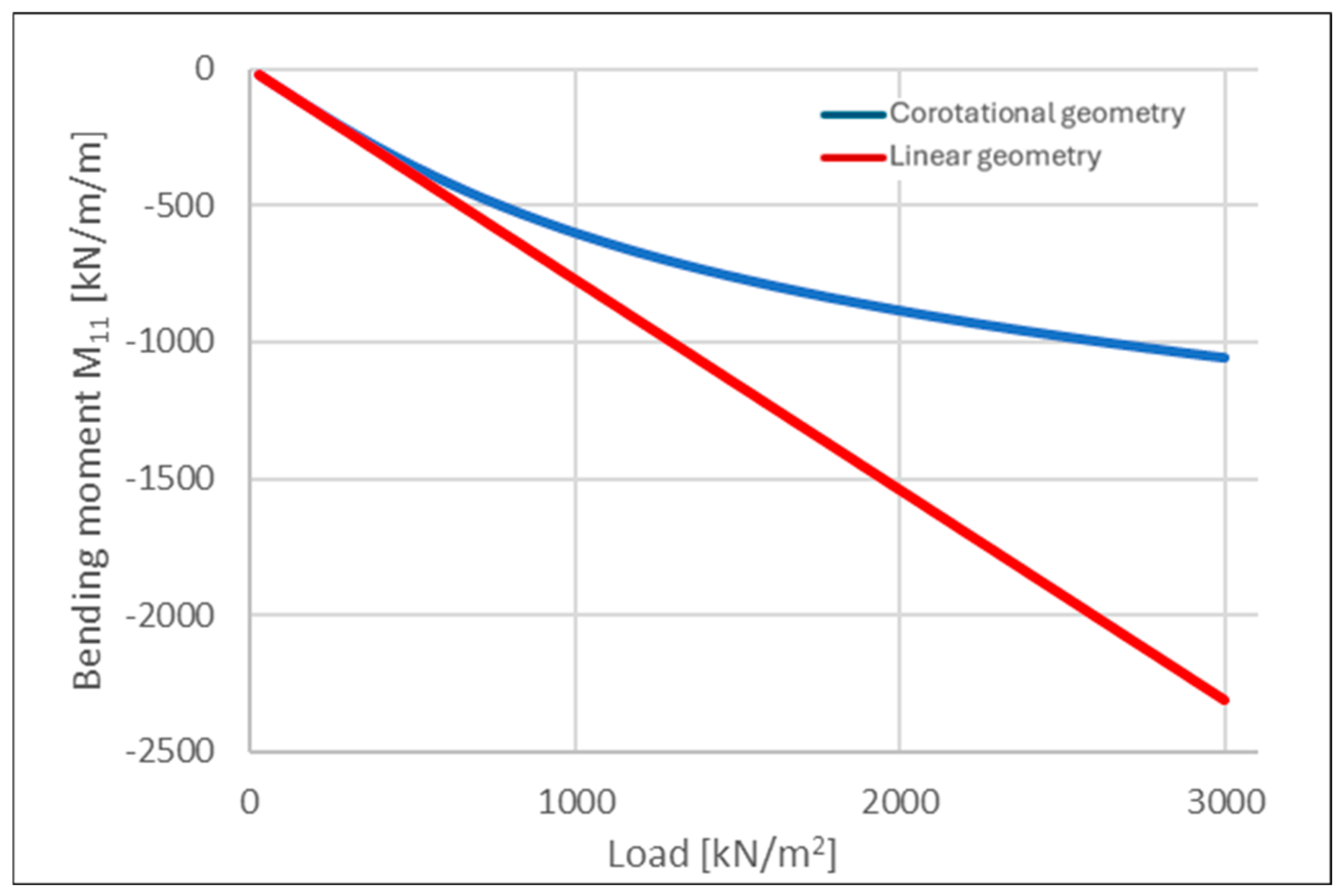

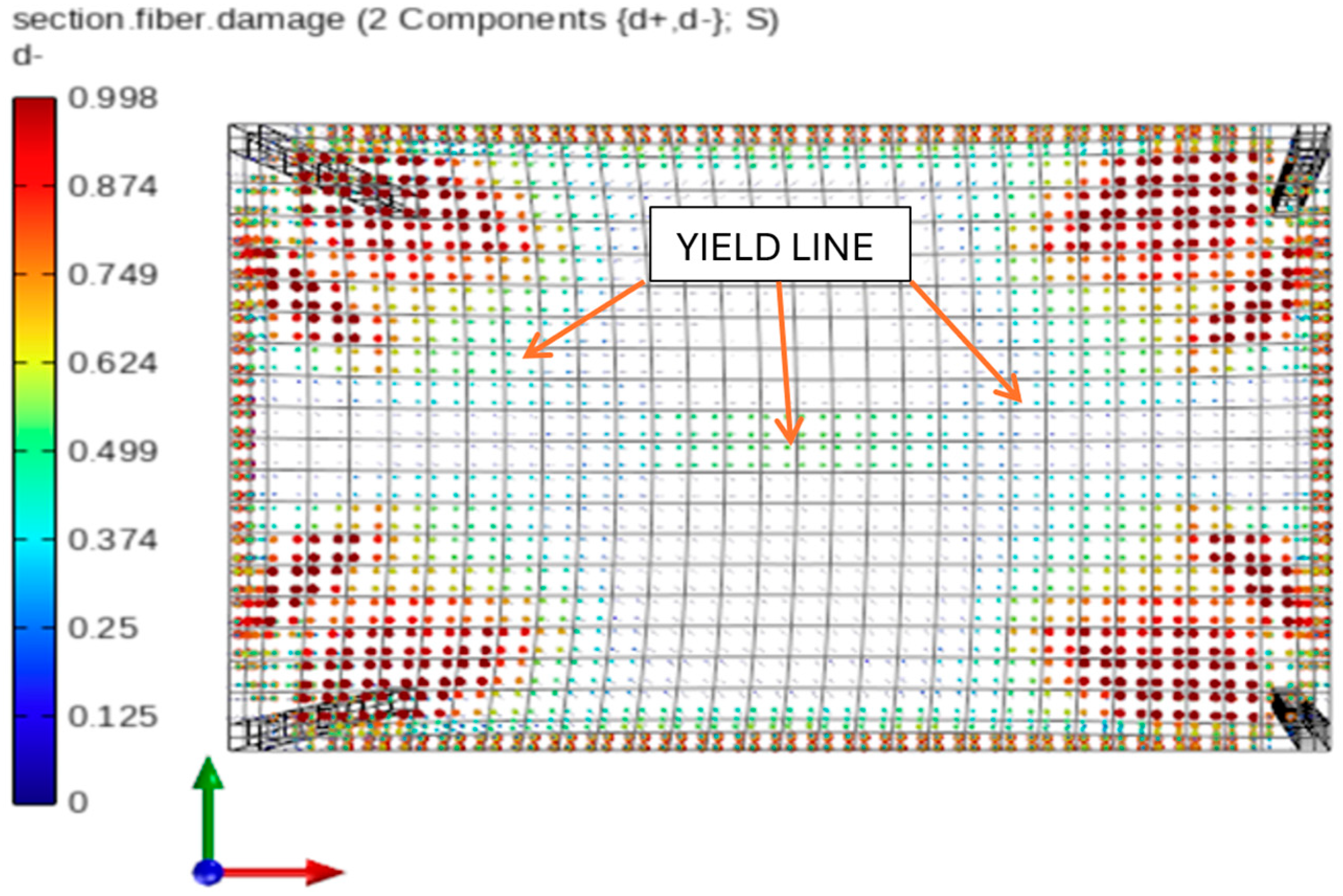

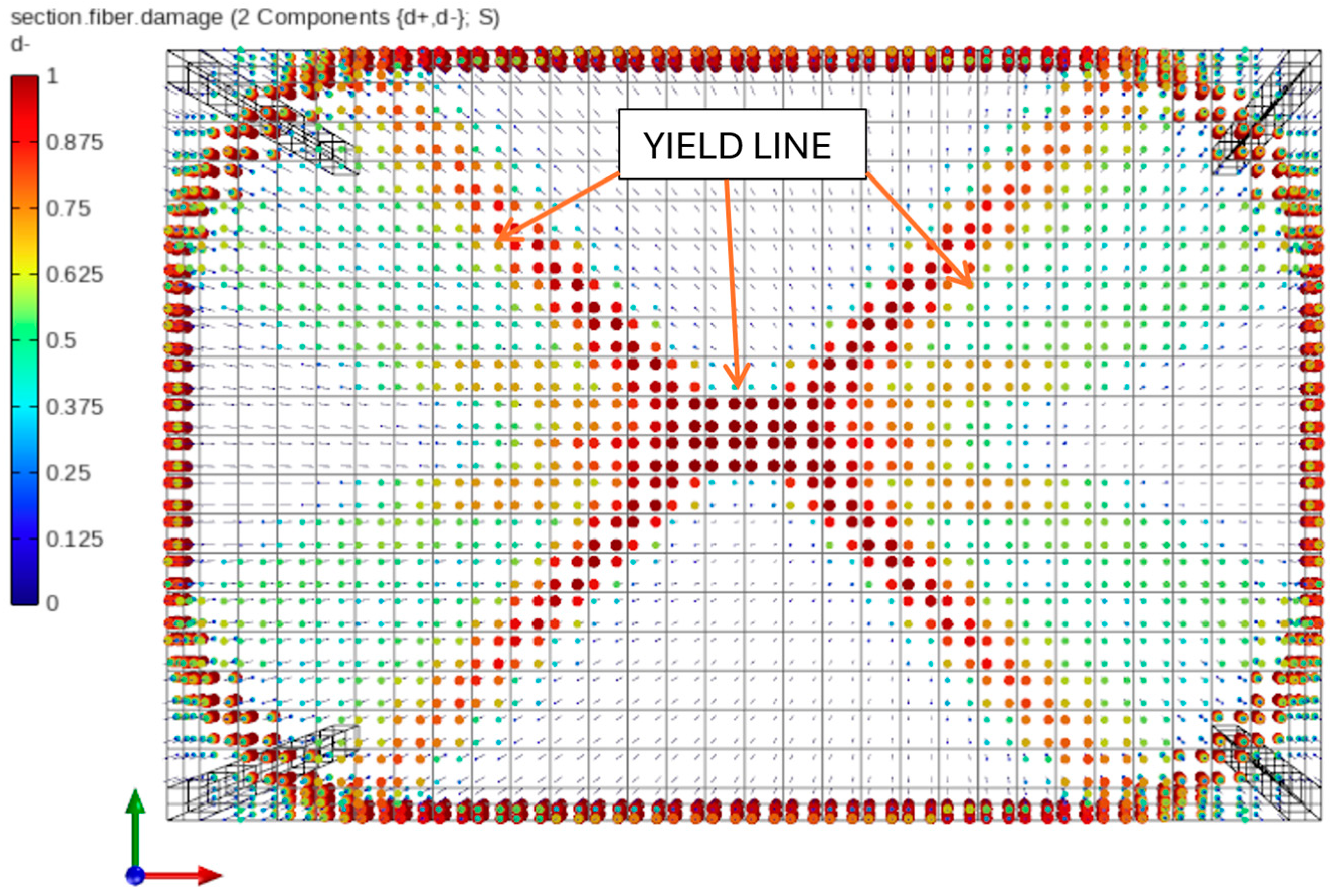

4. Slab with Nonlinear Concrete Material—Nonlinear Static Pushdown Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| STKO | Scientific Toolkit for OpenSees |

| OpenSees | Open System for Earthquake Engineering Simulation |

| FEM | Finite Element Method |

| CAA | Compressive arch action |

| CTA | Catenary tension action |

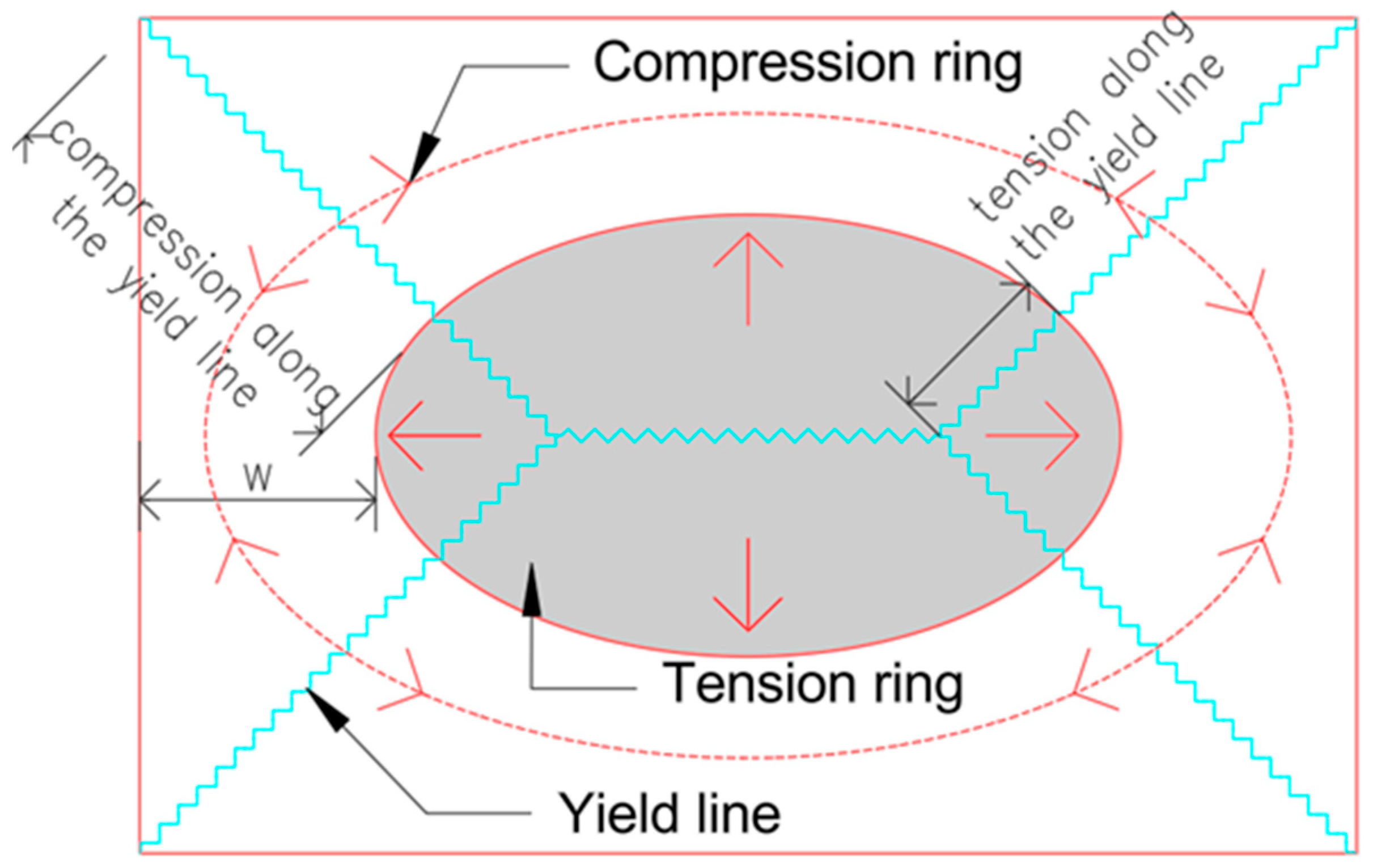

| TMA | Tension membrane action |

| CMA | Compression membrane action |

References

- EN 1991-1-7; Eurocode 1: Actions on Structures—Part 1–7: Accidental Actions. European Union: Brussels, Belgium, 2006.

- BS 6399; Loading for Buildings: Part 1: Code of Practice for Dead and Imposed Loads. British Standards Institute: London, UK, 1996.

- Department of Defense (DoD) Unified Facilities Criteria (UFC). Design of Buildings to Resist Progressive Collapse; UFC 4-023-03; United States Department of Defense: The Pentagon, VA, USA, 2009. [Google Scholar]

- Departments of the Army, the Navy and the Air Force. Structures to Resist the Effects of Accidental Explosions; ARMY TM 5-1300; Departments of the Army, the Navy and the Air Force: The Pentagon, VA, USA, 1990. [Google Scholar]

- Office of Chief Architects. General Services Administration (GSA) Progressive Collapse Analysis and Design Guidelines for New Federal Office Buildings and Major Modernization Projects; Office of Chief Architects: Washington, DC, USA, 2003. [Google Scholar]

- Office of Chief Architects. General Services Administration (GSA) Alternative Path Analysis and Design Guidelines for Progressive Collapse Resistance; Office of Chief Architects: Washington, DC, USA, 2013. [Google Scholar]

- National Institute of Standards and Technology. Best Practices for Reducing the Potential for Progressive Collapse in Buildings; NIST Technical Note 7396; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007. [Google Scholar]

- National Institute of Standards and Technology. An Experimental and Computational Study of Reinforced Concrete Assemblies Under a Column Removal Scenario; NIST Technical Note 1720; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2011. [Google Scholar]

- Pearson, C.; Delatte, N. Ronan Point Apartment Tower Collapse and Its Effect on Building Codes. J. Perform. Constr. Facil. 2005, 19, 172–177. [Google Scholar] [CrossRef]

- Russell, J.M.; Sagaseta, J.; Cormie, D.; Jones, A.E.K. Historical Review of Prescriptive Design Rules for Robustness after the Collapse of Ronan Point. Structures 2019, 20, 365–373. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Le, J.-L.; Greening, F.R.; Benson, D.B. What Did and Did Not Cause Collapse of World Trade Center Twin Towers in New York? J. Eng. Mech. 2008, 134, 892–906. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Verdure, M. Mechanics of Progressive Collapse: Learning from World Trade Center and Building Demolitions. J. Eng. Mech. 2007, 133, 308–319. [Google Scholar] [CrossRef]

- Kazemi-Moghaddam, A.; Sasani, M. Progressive Collapse Evaluation of Murrah Federal Building Following Sudden Loss of Column G20. Eng. Struct. 2015, 89, 162–171. [Google Scholar] [CrossRef]

- Mlakar, P.F., Sr.; Corley, W.G.; Sozen, M.A.; Thornton, C.H. The Oklahoma City Bombing: Analysis of Blast Damage to the Murrah Building. J. Perform. Constr. Facil. 1998, 12, 113–119. [Google Scholar] [CrossRef]

- Osteraas, J.D. Murrah Building Bombing Revisited: A Qualitative Assessment of Blast Damage and Collapse Patterns. J. Perform. Constr. Facil. 2006, 20, 330–335. [Google Scholar] [CrossRef]

- Corley, W.G. Applicability of Seismic Design in Mitigating Progressive Collapse. In Proceedings of the National Workshop on Prevention of Progressive Collapse, Rosemont, IL, USA, 10–12 July 2002; p. 13. [Google Scholar]

- Matsumoto, M.; Shirato, H.; Yagi, T.; Shijo, R.; Eguchi, A.; Tamaki, H. Effects of Aerodynamic Interferences between Heaving and Torsional Vibration of Bridge Decks: The Case of Tacoma Narrows Bridge. J. Wind Eng. Ind. Aerodyn. 2003, 91, 1547–1557. [Google Scholar] [CrossRef]

- Agarwal, J.; Haberland, M.; Holický, M.; Sykora, M.; Thelandersson, S. Robustness of Structures: Lessons from Failures. Struct. Eng. Int. 2012, 22, 105–111. [Google Scholar] [CrossRef]

- Abdelwahed, B. A Review on Building Progressive Collapse, Survey and Discussion. Case Stud. Constr. Mater. 2019, 11, e00264. [Google Scholar] [CrossRef]

- Kiakojouri, F.; De Biagi, V.; Chiaia, B.; Sheidaii, M.R. Progressive Collapse of Framed Building Structures: Current Knowledge and Future Prospects. Eng. Struct. 2020, 206, 110061. [Google Scholar] [CrossRef]

- Kiakojouri, F.; Sheidaii, M.R.; De Biagi, V.; Chiaia, B. Progressive Collapse of Structures: A Discussion on Annotated Nomenclature. Structures 2021, 29, 1417–1423. [Google Scholar] [CrossRef]

- Adam, J.M.; Parisi, F.; Sagaseta, J.; Lu, X. Research and Practice on Progressive Collapse and Robustness of Building Structures in the 21st Century. Eng. Struct. 2018, 173, 122–149. [Google Scholar] [CrossRef]

- Xu, J.; Wang, S.; Liu, K.; Quan, X.; Dong, F. Study on Collapse Resistance of RC Frame under the Corner Column Removal Scenario. Materials 2021, 14, 7157. [Google Scholar] [CrossRef]

- Arshian, A.H.; Morgenthal, G. Three-Dimensional Progressive Collapse Analysis of Reinforced Concrete Frame Structures Subjected to Sequential Column Removal. Eng. Struct. 2017, 132, 87–97. [Google Scholar] [CrossRef]

- Arshian, A.H.; Morgenthal, G.; Narayanan, S. Influence of Modelling Strategies on Uncertainty Propagation in the Alternate Path Mechanism of Reinforced Concrete Framed Structures. Eng. Struct. 2016, 110, 36–47. [Google Scholar] [CrossRef]

- Sasani, M.; Werner, A.; Kazemi, A. Bar Fracture Modelling in Progressive Collapse Analysis of Reinforced Concrete Structures. Eng. Struct. 2011, 33, 401–409. [Google Scholar] [CrossRef]

- Brunesi, E.; Nascimbene, R. Extreme Response of Reinforced Concrete Buildings through Fiber Force-Based Finite Element Analysis. Eng. Struct. 2014, 69, 206–215. [Google Scholar] [CrossRef]

- Li, X.; Dong, T.; Wang, C.; Zhang, W.; Liu, R.; Wang, J. A Review on the Progressive Collapse of Reinforced Concrete Flat Slab–Column Structures. Materials 2025, 18, 2056. [Google Scholar] [CrossRef]

- Xue, H.; Guan, H.; Gilbert, B.P.; Lu, X.; Li, Y. Comparative and Parametric Studies on Behavior of RC-Flat Plates Subjected to Interior-Column Loss. J. Struct. Eng. 2020, 146, 04020183. [Google Scholar] [CrossRef]

- Qian, K.; Li, B. Resilience of Flat Slab Structures in Different Phases of Progressive Collapse. ACI Struct. J. 2016, 113, 537–548. [Google Scholar] [CrossRef]

- Russell, J.M.; Owen, J.S.; Hajirasouliha, I. Nonlinear Behaviour of Reinforced Concrete Flat Slabs after a Column Loss Event. Adv. Struct. Eng. 2018, 21, 2169–2183. [Google Scholar] [CrossRef]

- Sasani, M. Response of a Reinforced Concrete Infilled-Frame Structure to Removal of Two Adjacent Columns. Eng. Struct. 2008, 30, 2478–2491. [Google Scholar] [CrossRef]

- Mehrdad, S.; Sagiroglu, S. Gravity Load Redistribution and Progressive Collapse Resistance of 20-Story Reinforced Concrete Structure Following Loss of Interior Column. SJ 2010, 107, 636–644. [Google Scholar] [CrossRef]

- Adam, J.M.; Buitrago, M.; Bertolesi, E.; Sagaseta, J.; Moragues, J.J. Dynamic Performance of a Real-Scale Reinforced Concrete Building Test under a Corner-Column Failure Scenario. Eng. Struct. 2020, 210, 110414. [Google Scholar] [CrossRef]

- Kokot, S.; Anthoine, A.; Negro, P.; Solomos, G. Static and Dynamic Analysis of a Reinforced Concrete Flat Slab Frame Building for Progressive Collapse. Eng. Struct. 2012, 40, 205–217. [Google Scholar] [CrossRef]

- Lew, H.S.; Bao, Y.; Pujol, S.; Sozen, M.A. Experimental Study of Reinforced Concrete Assemblies under a Column Removal Scenario. ACI Struct. J. 2014, 111, 881–892. [Google Scholar] [CrossRef]

- Qian, K.; Weng, Y.-H.; Li, B. Impact of Two Columns Missing on Dynamic Response of RC Flat Slab Structures. Eng. Struct. 2018, 177, 598–615. [Google Scholar] [CrossRef]

- Qian, K.; Li, B. Quantification of Slab Influences on the Dynamic Performance of RC Frames against Progressive Collapse. J. Perform. Constr. Facil. 2015, 29, 04014029. [Google Scholar] [CrossRef]

- Qian, K.; Li, B.; Ma, J.-X. Load-Carrying Mechanism to Resist Progressive Collapse of RC Buildings. J. Struct. Eng. 2015, 141, 04014107. [Google Scholar] [CrossRef]

- Alañón, A.; Cerro-Prada, E.; Vázquez-Gallo, M.J.; Santos, A.P. Mesh Size Effect on Finite-Element Modelling of Blast-Loaded Reinforced Concrete Slab. Eng. Comput. 2018, 34, 649–658. [Google Scholar] [CrossRef]

- Genikomsou, A.S.; Polak, M.A. 3D Finite Element Investigation of the Compressive Membrane Action Effect in Reinforced Concrete Flat Slabs. Eng. Struct. 2017, 136, 233–244. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Qin, X.; Chen, Y.; Li, L. Performance of Practical Beam-to-SHS Column Connections against Progressive Collapse. Eng. Struct. 2016, 106, 332–347. [Google Scholar] [CrossRef]

- Alrubaidi, M.; Alhammadi, S.A. Numerical Investigation on Progressive Collapse Mitigation of Steel Beam–Column Joint Using Steel Plates. Materials 2022, 15, 7628. [Google Scholar] [CrossRef] [PubMed]

- Fascetti, A.; Kunnath, S.K.; Nisticò, N. Robustness Evaluation of RC Frame Buildings to Progressive Collapse. Eng. Struct. 2015, 86, 242–249. [Google Scholar] [CrossRef]

- Izzuddin, B.A.; Vlassis, A.G.; Elghazouli, A.Y.; Nethercot, D.A. Progressive Collapse of Multi-Storey Buildings Due to Sudden Column Loss—Part I: Simplified Assessment Framework. Eng. Struct. 2008, 30, 1308–1318. [Google Scholar] [CrossRef]

- Kisniewski, L. Nonlinear Dynamic Simulations of Progressive Collapse for a Multistory Building. Eng. Struct. 2010, 32, 1223–1235. [Google Scholar] [CrossRef]

- Lu, X.; Li, Y.; Guan, H.; Ying, M. Progressive Collapse Analysis of a Typical Super-Tall Reinforced Concrete Frame-Core Tube Building Exposed to Extreme Fires. Fire Technol. 2017, 53, 107–133. [Google Scholar] [CrossRef]

- Kokot, S. Response Spectrum of a Reinforced Concrete Frame Structure under Various Column Removal Scenarios. J. Build. Eng. 2022, 49, 103992. [Google Scholar] [CrossRef]

- Kokot, S. Reinforced Concrete Beam under Support Removal—Parametric Analysis. Materials 2021, 14, 5917. [Google Scholar] [CrossRef]

- Mohamed, O.A. Assessment of Progressive Collapse Potential in Corner Floor Panels of Reinforced Concrete Buildings. Eng. Struct. 2009, 31, 749–757. [Google Scholar] [CrossRef]

- Russell, J.M.; Owen, J.S.; Hajirasouliha, I. Dynamic Column Loss Analysis of Reinforced Concrete Flat Slabs. Eng. Struct. 2019, 198, 109453. [Google Scholar] [CrossRef]

- Ghorbani, R.; Matamoros, A.; Ghannoum, W. Multi-Axial Computational Model for Simulating the Seismic Behavior of Concrete Columns Including Axial Collapse. Eng. Struct. 2024, 307, 117821. [Google Scholar] [CrossRef]

- Bao, Y.; Kunnath, S.K.; El-Tawil, S.; Lew, H.S. Macromodel-Based Simulation of Progressive Collapse: RC Frame Structures. J. Struct. Eng. 2008, 134, 1079–1091. [Google Scholar] [CrossRef]

- Bao, Y.; Lew, H.S.; Kunnath, S.K. Modelling of Reinforced Concrete Assemblies under Column-Removal Scenario. J. Struct. Eng. 2014, 140, 04013026. [Google Scholar] [CrossRef]

- Starossek, U. Typology of Progressive Collapse. Eng. Struct. 2007, 29, 2302–2307. [Google Scholar] [CrossRef]

- Orton, S.; Jirsa, J.; Bayrak, O. Carbon Fiber-Reinforced Polymer for Continuity in Existing Reinforced Concrete Buildings Vulnerable to Collapse. SJ 2009, 106, 608–616. [Google Scholar] [CrossRef]

- Li, Y.; Lu, X.; Guan, H.; Ren, P. Numerical Investigation of Progressive Collapse Resistance of Reinforced Concrete Frames Subject to Column Removals from Different Stories. Adv. Struct. Eng. 2016, 19, 314–326. [Google Scholar] [CrossRef]

- Sasani, M.; Kazemi-Moghaddam, A. Experimental and Analytical Evaluation of Progressive Collapse Resistance of a Full-Scale Structure Following Sever Loss of Load Bearing Elements. AMM 2011, 82, 326–331. [Google Scholar] [CrossRef]

- Zhang, L.; Wei, T.; Li, H.; Zeng, J.; Deng, X. Effects of Corrosion on Compressive Arch Action and Catenary Action of RC Frames to Resist Progressive Collapse Based on Numerical Analysis. Materials 2021, 14, 2662. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Q.; Zhao, H.; Zhang, L. Experimental Study on Progressive Collapse Performance of Frame with Specially Shaped Columns Subjected to Middle Column Removal. Shock Vib. 2016, 2016, 7956189. [Google Scholar] [CrossRef]

- Yu, J.; Tan, K.H. Structural Behavior of RC Beam-Column Subassemblages under a Middle Column Removal Scenario. J. Struct. Eng. 2013, 139, 233–250. [Google Scholar] [CrossRef]

- Yu, J.; Tan, K.-H. Experimental and Numerical Investigation on Progressive Collapse Resistance of Reinforced Concrete Beam Column Sub-Assemblages. Eng. Struct. 2013, 55, 90–106. [Google Scholar] [CrossRef]

- Herraiz, B.; Vogel, T. Novel Design Approach for the Analysis of Laterally Unrestrained Reinforced Concrete Slabs Considering Membrane Action. Eng. Struct. 2016, 123, 313–329. [Google Scholar] [CrossRef]

- Yu, J.; Tang, J.; Luo, L.; Fang, Q. Effect of Boundary Conditions on Progressive Collapse Resistance of RC Beam-Slab Assemblies under Edge Column Removal Scenario. Eng. Struct. 2020, 225, 111272. [Google Scholar] [CrossRef]

- Bredean, L.A.; Botez, M.D. The Influence of Beams Design and the Slabs Effect on the Progressive Collapse Resisting Mechanisms Development for RC Framed Structures. Eng. Fail. Anal. 2018, 91, 527–542. [Google Scholar] [CrossRef]

- Dat, P.X.; Hai, T.K. Membrane Actions of RC Slabs in Mitigating Progressive Collapse of Building Structures. Eng. Struct. 2013, 55, 107–115. [Google Scholar] [CrossRef]

- Bailey, C.G. Membrane Action of Unrestrained Lightly Reinforced Concrete Slabs at Large Displacements. Eng. Struct. 2001, 23, 470–483. [Google Scholar] [CrossRef]

- Bailey, C.G.; Toh, W.S.; Chan, B.K. Simplified and Advanced Analysis of Membrane Action of Concrete Slabs. SJ 2008, 105, 30–40. [Google Scholar] [CrossRef]

- Yu, X.H.; Lu, D.G.; Qian, K.; Li, B. Uncertainty and Sensitivity Analysis of Reinforced Concrete Frame Structures Subjected to Column Loss. J. Perform. Constr. Facil. 2017, 31, 04016069. [Google Scholar] [CrossRef]

- Ren, P.; Li, Y.; Lu, X.; Guan, H.; Zhou, Y. Experimental Investigation of Progressive Collapse Resistance of One-Way Reinforced Concrete Beam–Slab Substructures under a Middle-Column-Removal Scenario. Eng. Struct. 2016, 118, 28–40. [Google Scholar] [CrossRef]

- Lu, X.; Lin, K.; Li, C.; Li, Y. New Analytical Calculation Models for Compressive Arch Action in Reinforced Concrete Structures. Eng. Struct. 2018, 168, 721–735. [Google Scholar] [CrossRef]

- McKenna, F.; Fenves, G.L.; Scott, M.H. Opensees—Open System for Earthquake Engineering Simulation; Pacific Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 2003. [Google Scholar]

- Shabani, A. A Review of Graphical User Interfaces of OpenSees Software Framework. Front. Built Environ. 2023, 9, 1233116. [Google Scholar] [CrossRef]

- May, I.M.; Naji, J.H.; Ganaba, T.H. Displacement Control for the Non-linear Analysis of Reinforced Concrete Structures. Eng. Comput. 1988, 5, 266–273. [Google Scholar] [CrossRef]

- Yousaf, M.; Siddiqi, Z.A.; Sharif, M.B.; Qazi, A.U. Force- and Displacement-Controlled Non-Linear FE Analyses of RC Beam with Partial Steel Bonded Length. Int. J. Civ. Eng. 2017, 15, 499–513. [Google Scholar] [CrossRef]

- ASDShellQ4 User Manual. Available online: https://opensees.github.io/OpenSeesDocumentation/user/manual/model/elements/ASDShellQ4.html (accessed on 20 August 2025).

- Chen, X.-M.; Cen, S.; Long, Y.-Q.; Yao, Z.-H. Membrane Elements Insensitive to Distortion Using the Quadrilateral Area Coordinate Method. Comput. Struct. 2004, 82, 35–54. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Brezzi, F. On Drilling Degrees of Freedom. Comput. Methods Appl. Mech. Eng. 1989, 72, 105–121. [Google Scholar] [CrossRef]

- Bathe, K.; Dvorkin, E.N. A Four-node Plate Bending Element Based on Mindlin/Reissner Plate Theory and a Mixed Interpolation. Int. J. Numer. Meth. Eng. 1985, 21, 367–383. [Google Scholar] [CrossRef]

- Dvorkin, E.N.; Bathe, K. A Continuum Mechanics Based Four-node Shell Element for General Non-linear Analysis. Eng. Comput. 1984, 1, 77–88. [Google Scholar] [CrossRef]

- Felippa, C.A. A Systematic Approach to the Element-Independent Corotational Dynamics of Finite Element; Department of Aerospace Engineering Sciences and Center for Aerospace Structures, University of Colorado Boulder: Boulder, CO, USA, 2000. [Google Scholar]

- Felippa, C.A.; Haugen, B. A Unified Formulation of Small-Strain Corotational Finite Elements: I. Theory. Comput. Methods Appl. Mech. Eng. 2005, 194, 2285–2335. [Google Scholar] [CrossRef]

- Xie, L.; Lu, X.; Lu, X.; Huang, Y.; Ye, L. Multi-Layer Shell Element for Shear Walls in OpenSees. In Computing in Civil and Building Engineering, Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; American Society of Civil Engineers: Orlando, FL, USA, 2014; pp. 1190–1197. [Google Scholar]

- Lu, X.; Lu, X.; Guan, H.; Ye, L. Collapse Simulation of Reinforced Concrete High-Rise Building Induced by Extreme Earthquakes. Earthq. Engng. Struct. Dyn. 2013, 42, 705–723. [Google Scholar] [CrossRef]

- Lu, X.; Xie, L.; Guan, H.; Huang, Y.; Lu, X. A Shear Wall Element for Nonlinear Seismic Analysis of Super-Tall Buildings Using OpenSees. Finite Elem. Anal. Des. 2015, 98, 14–25. [Google Scholar] [CrossRef]

- Guan, H.; Loo, Y.-C. Flexural and Shear Failure Analysis of Reinforced Concrete Slabs and Flat Plates. Adv. Struct. Eng. 1997, 1, 71–85. [Google Scholar] [CrossRef]

- Menegotto, M.; Pinto, P.E. Method of Analysis for Cyclically Loaded R.C. Plane Frames Including Changes in Geometry and Non-Elastic Behaviour of Elements Under Combined Normal Force and Bending. In Proceedings of the IABSE Symposium on Resistance and Ultimate Deformability of Structures Acted on by Well Defined Repeated Loads, Lisbon, Portugal, 13–14 September 1973. [Google Scholar] [CrossRef]

- Filippou, F.C.; Popov, E.P.; Bertero, V.V. Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints; Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 1983. [Google Scholar]

- ASDConcrete3D Material User Manual. Available online: https://opensees.github.io/OpenSeesDocumentation/user/manual/material/ndMaterials/ASDConcrete3D.html (accessed on 20 August 2025).

- Petracca, M.; Camata, G.; Spacone, E.; Pelà, L. Efficient Constitutive Model for Continuous Micro-Modelling of Masonry Structures. Int. J. Archit. Herit. 2023, 17, 134–146. [Google Scholar] [CrossRef]

- Petracca, M.; Pelà, L.; Rossi, R.; Oller, S.; Camata, G.; Spacone, E. Multiscale Computational First Order Homogenization of Thick Shells for the Analysis of Out-of-Plane Loaded Masonry Walls. Comput. Methods Appl. Mech. Eng. 2017, 315, 273–301. [Google Scholar] [CrossRef]

- Petracca, M.; Pelà, L.; Rossi, R.; Zaghi, S.; Camata, G.; Spacone, E. Micro-Scale Continuous and Discrete Numerical Models for Nonlinear Analysis of Masonry Shear Walls. Constr. Build. Mater. 2017, 149, 296–314. [Google Scholar] [CrossRef]

- Model Code 2010. 1; Bulletin/Fédération Internationale du Béton. International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2012; ISBN 978-2-88394-105-2.

- Model Code 2010. 2; Bulletin/Fédération Internationale du Béton. International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2010; ISBN 978-2-88394-096-3.

- Scott, M.H.; Fenves, G.L. Krylov Subspace Accelerated Newton Algorithm: Application to Dynamic Progressive Collapse Simulation of Frames. J. Struct. Eng. 2010, 136, 473–480. [Google Scholar] [CrossRef]

- Wilson, E.L. Three-Dimensional Static and Dynamic Analysis of Structures. A Physical Approach with Emphasis on Earthquake Engineering; Computers and Structures, Inc.: Berkeley, CA, USA, 2002. [Google Scholar]

- Yang, Z.; Guo, X.; Li, Y.; Guan, H.; Diao, M.; Wang, J.; Huang, W. Progressive Collapse Mode Induced by Slab-Column Joint Failure in RC Flat Plate Substructures: A New Perspective. Eng. Struct. 2023, 292, 116506. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walach, S.; Kokot, S.; Kus, J. The Effect of Geometric and Material Nonlinearities on the Development of Membrane Resistance in Reinforced Concrete Flat Slab–Column Buildings. Materials 2025, 18, 4053. https://doi.org/10.3390/ma18174053

Walach S, Kokot S, Kus J. The Effect of Geometric and Material Nonlinearities on the Development of Membrane Resistance in Reinforced Concrete Flat Slab–Column Buildings. Materials. 2025; 18(17):4053. https://doi.org/10.3390/ma18174053

Chicago/Turabian StyleWalach, Sylwester, Seweryn Kokot, and Juliusz Kus. 2025. "The Effect of Geometric and Material Nonlinearities on the Development of Membrane Resistance in Reinforced Concrete Flat Slab–Column Buildings" Materials 18, no. 17: 4053. https://doi.org/10.3390/ma18174053

APA StyleWalach, S., Kokot, S., & Kus, J. (2025). The Effect of Geometric and Material Nonlinearities on the Development of Membrane Resistance in Reinforced Concrete Flat Slab–Column Buildings. Materials, 18(17), 4053. https://doi.org/10.3390/ma18174053