1. Introduction

The noise control of automotive air-conditioning ducts is of great significance for improving vehicle sound quality. In the air-conditioning ventilation duct system, due to the narrow space and the generally low noise frequency, it is difficult for traditional sound-absorbing materials and structures to achieve effective noise reduction without increasing the volume. Therefore, developing new low-frequency noise reduction materials with compact structures and superior performance has become a key direction in current research.

Acoustic metamaterials are a class of artificially structured materials with unconventional physical properties, possessing acoustic characteristics not found in ordinary materials, such as negative mass density, negative equivalent elastic modulus, and negative refractive index. This material typically has three core characteristics: (1) its structure is artificially designed and constructed into composite units with specific functions; (2) the physical properties it exhibits are not possessed by conventional materials in nature; (3) its macroscopic acoustic properties depend mainly on the configuration rather than the inherent properties of the constituent materials. In recent years, these materials have become a research hotspot in the field of acoustic noise reduction [

1,

2,

3]. In 2000, Liu et al. [

4] first introduced the concept of “acoustic metamaterials” and proposed phononic crystals based on local resonance, which can achieve strong reflection of 400 Hz sound waves. With a thickness of only 2 cm, they can break through the traditional sound insulation limit. In 2002, Liu et al. [

5] further explored three-component composite structural acoustic metamaterials, using multiple scattering theory to regulate resonant bandgaps and Bragg bandgaps, realizing precise control over the propagation characteristics of elastic waves. In 2007, Ding et al. [

6] proposed a zinc blende-structured double-negative acoustic metamaterial which can simultaneously exhibit negative bulk modulus, negative mass density, and negative Poisson’s ratio near the resonant frequency, demonstrating typical resonant metamaterial properties. In the same year, Ambati et al. [

7] studied surface resonance states in acoustic metamaterials and proposed the concept of an “acoustic superlens”, bringing new directions to ultrasonic imaging technology. In 2009, Liang et al. [

8] designed a one-dimensional acoustic diode structure composed of a superlattice coupled with a strongly nonlinear medium, and verified the application potential of metamaterials in asymmetric wave transmission through numerical simulations. In 2015, Popa et al. [

9] proposed active acoustic metamaterials whose responses can be controlled in real time by digital circuits, showing the potential to break through the diffraction limit in terms of lenses, beam imaging, and harmonic functions. In the same year, Shen et al. [

10] constructed a broadband hyperbolic acoustic metamaterial. Through multiple groups of thin plate arrays oriented in the y-direction, it exhibited negative density and hyperbolic dispersion at low frequencies, realizing subwavelength focusing and excellent low-frequency sound absorption capacity. Dario [

11] investigated the vibro-acoustic properties of square unit cells of porous acoustic materials containing circular inclusions using the shifted unit technique. The proposed design of embedding periodic inclusions into the porous layer has a significant effect in improving acoustic performance (e.g., transmission loss). Magliacano et al. [

12] employed the displacement unit technique to study the dispersion characteristics of periodic porous materials under the equivalent fluid model and their correlation with acoustic properties, and found that the equivalent transmission loss curves obtained from eigenvalue analysis are in good agreement with the results of classical methods.

Among various acoustic metamaterials in the field of noise reduction, Helmholtz resonators stand out as one of the most representative types due to their simple structure, clear frequency response, and low cost, exhibiting excellent performance in low-frequency noise control. In 2005, Tang [

13] conducted research on Helmholtz resonators with conical necks, revealing that a larger cone angle and a larger cavity lead to more significant low-frequency absorption effects. Wang et al. [

14] proposed a new type of metamaterial combining Helmholtz resonant cavities with porous material modulation crowns, enabling ultra-broadband and high-efficiency sound absorption. Ryoo et al. [

15] paralleled microperforated plates with Helmholtz resonant cavities, achieving 90% absorption in the range of 380–790 Hz. Wang et al. [

16] designed a combined structure of microperforated plates and extended-neck resonators through optimization algorithms, realizing broadband and high-efficiency absorption of noise below 500 Hz in a small area. Additionally, Yaw et al. [

17] introduced rough-neck structures, achieving strong absorption in the low-frequency range below 200 Hz; Mei et al. [

18] designed segmented Helmholtz metamaterials with embedded necks, attaining over 90% sound absorption efficiency in the range of 450–1750 Hz. Chen et al. [

19] proposed a compact side-slit Helmholtz resonator, with an absorption coefficient exceeding 0.8 in the range of 470–930 Hz, making it suitable for practical application scenarios. In 2024, Zhang et al. [

20] developed ventilated Helmholtz acoustic metamaterials, where the double-layer structure achieves nearly perfect absorption at approximately 687 Hz, and the four-layer structure exhibits broadband performance in the range of 454–698 Hz. Domingo-Roca et al. [

21] combined membrane structures to realize directional low-frequency sound absorption, expanding the application potential in open environments.

In addition to the optimization of structural units themselves, research on introducing Helmholtz resonant structures into pipeline mufflers has also achieved significant results. Wu et al. [

22] proposed a new muffler design method that combines the advantages of quarter-wavelength tubes and Helmholtz mufflers, and verified that their method features a wider noise elimination frequency band and a smaller radial size. Nguyen et al. [

23] designed a double-layer slit structure, achieving 30 dB noise reduction in the range of 480–950 Hz. Shao et al. [

24] proposed a muffler with a membrane structure and multiple Helmholtz cavities, and confirmed that the noise elimination frequency can be adjusted by changing the number of membranes. Liu et al. [

25] proposed a new metamaterial structure combining multi-sized Helmholtz cavities with porous materials, achieving excellent sound absorption performance in the 250–1600 Hz frequency band. Wu et al. [

26] focused on the control of air duct modulation noise, verifying significant noise reduction effects at the first four blade frequencies. Cho and Lee [

27] constructed a multi-unit combined structure with the help of generative design technology, meeting the overall noise reduction target of 25 dB in the 100–6000 Hz frequency band. Furthermore, Gao et al. [

28] realized a frequency-tunable Helmholtz muffler by regulating the cavity volume with a stepping motor, which is adapted to rectangular ventilation systems.

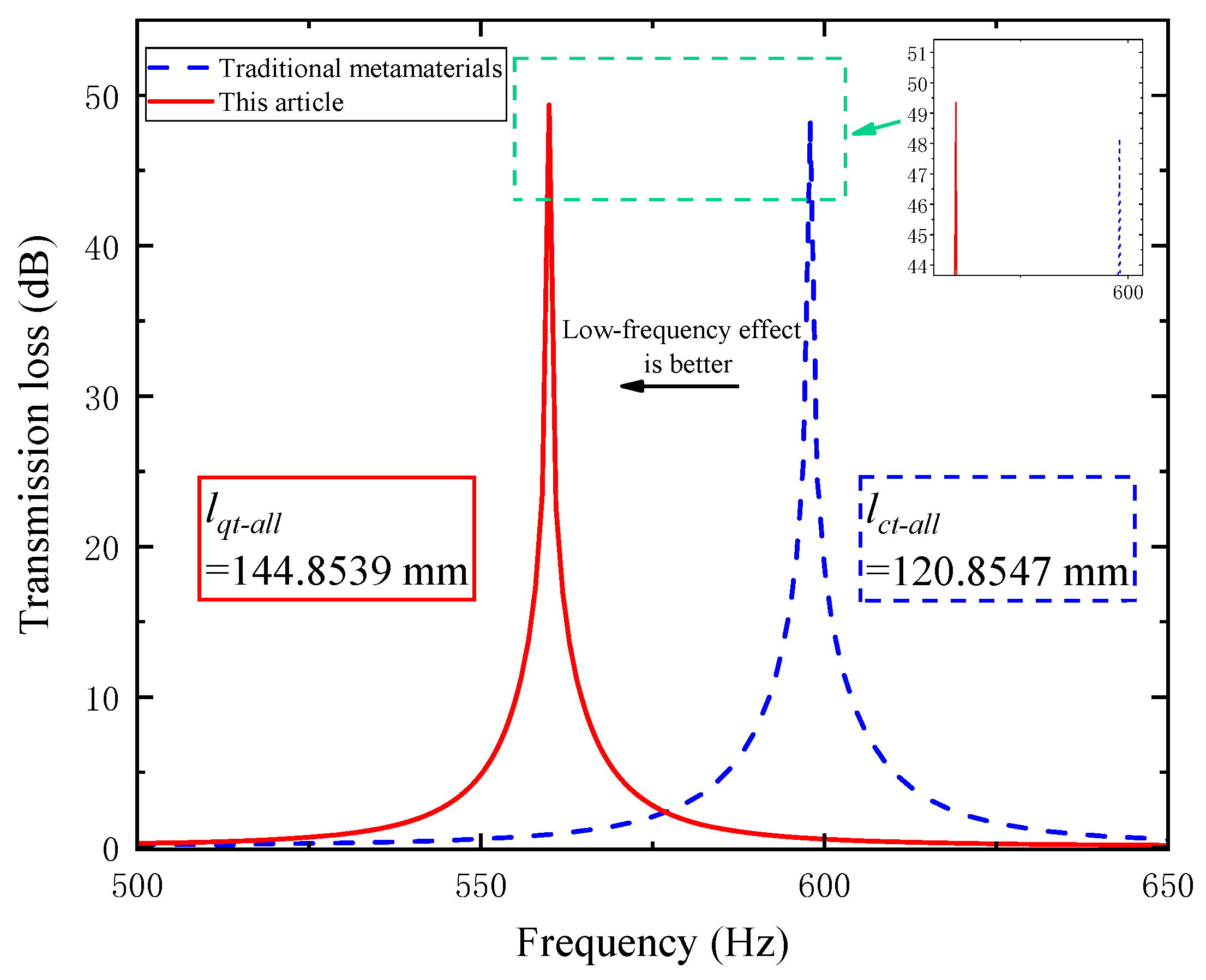

In conclusion, although acoustic metamaterials based on Helmholtz resonators have made significant progress in the field of low-frequency noise reduction, they suffer from three common issues: insufficient resonance paths when structural dimensions are limited, making it difficult to achieve effective low-frequency absorption; a single resonance peak resulting in a narrow absorption frequency band, which fails to cover actual broadband noise; and conflicts between structural design and ventilation requirements, restricting applications in duct systems. This study suggests a novel kind of perforated tortuous-characteristic metamaterial duct muffler based on Helmholtz to overcome these problems. It improves low-frequency broadband sound absorption performance, increases energy dissipation, and extends the sound wave propagation path inside a constrained space by introducing a structural form that combines a perforated panel with a multi-channel tortuous cavity. This study provides theoretical support and a design basis for the engineering application of high-efficiency low-frequency noise reduction devices by systematically investigating the impact of important structural parameters on transmission loss through the combination of acoustic theoretical modeling, finite element simulation, and parametric optimization.

2. Acoustic Theoretical Modeling of Perforated Tortuous-Characteristic Metamaterial Mufflers

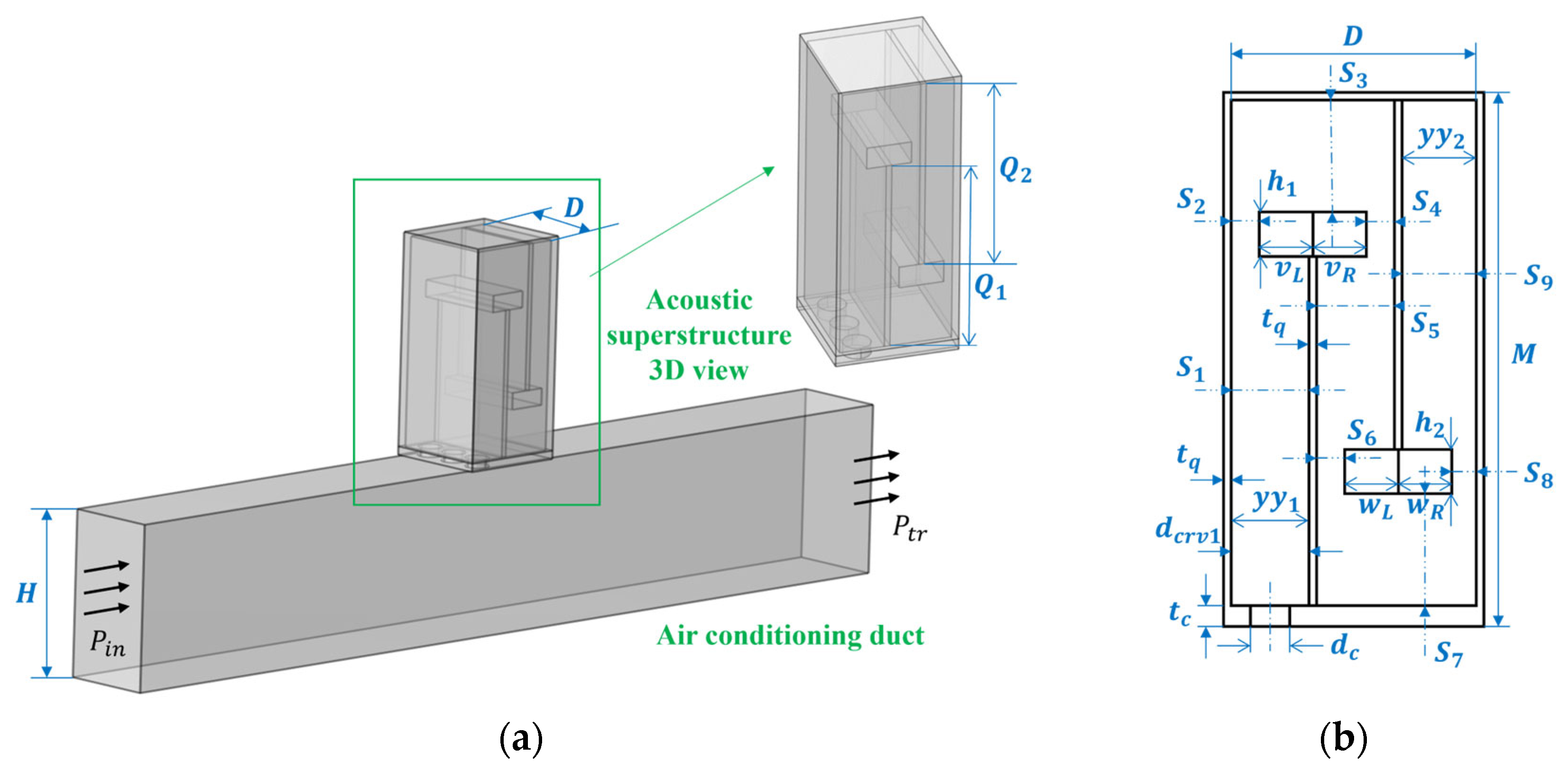

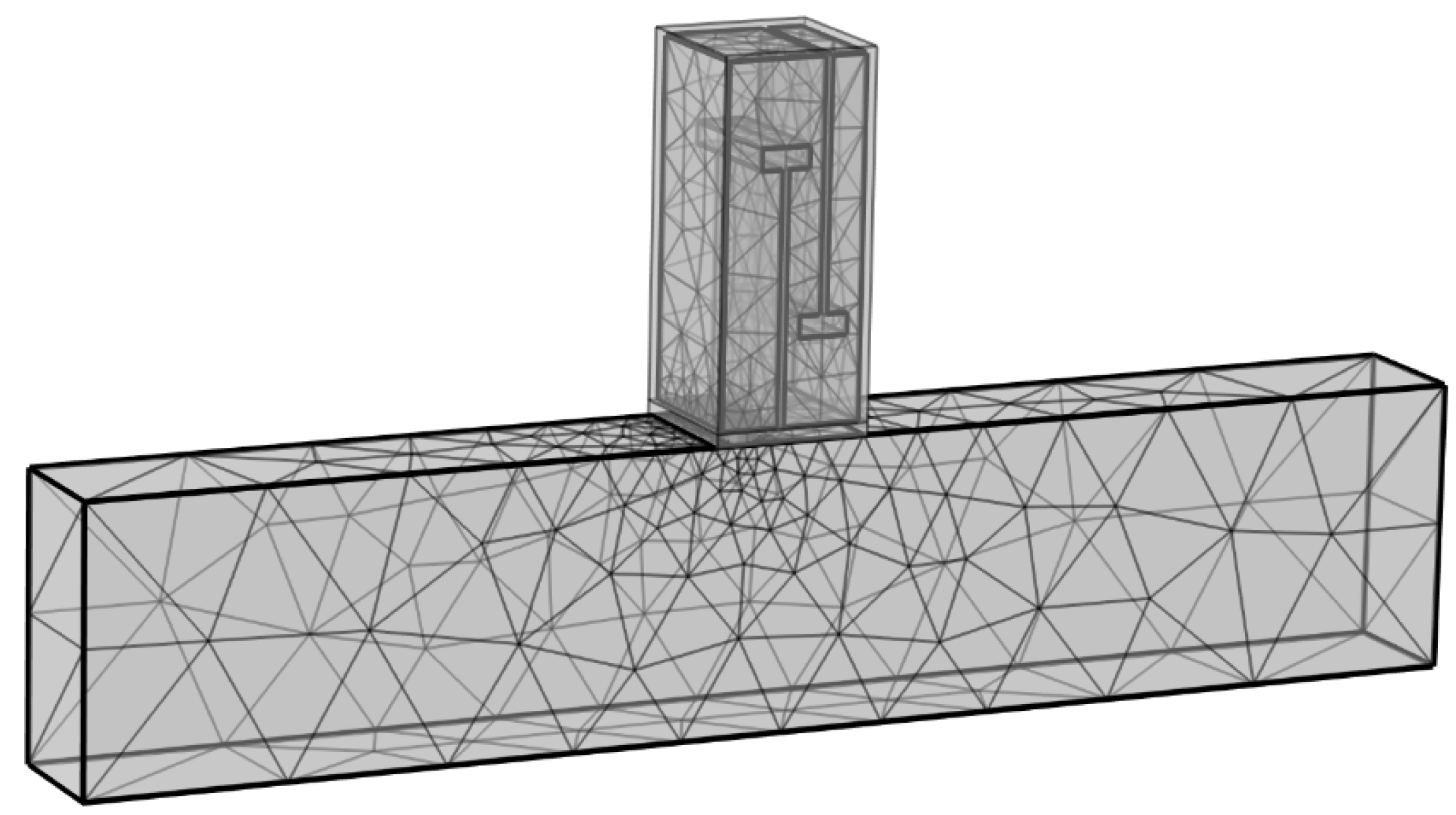

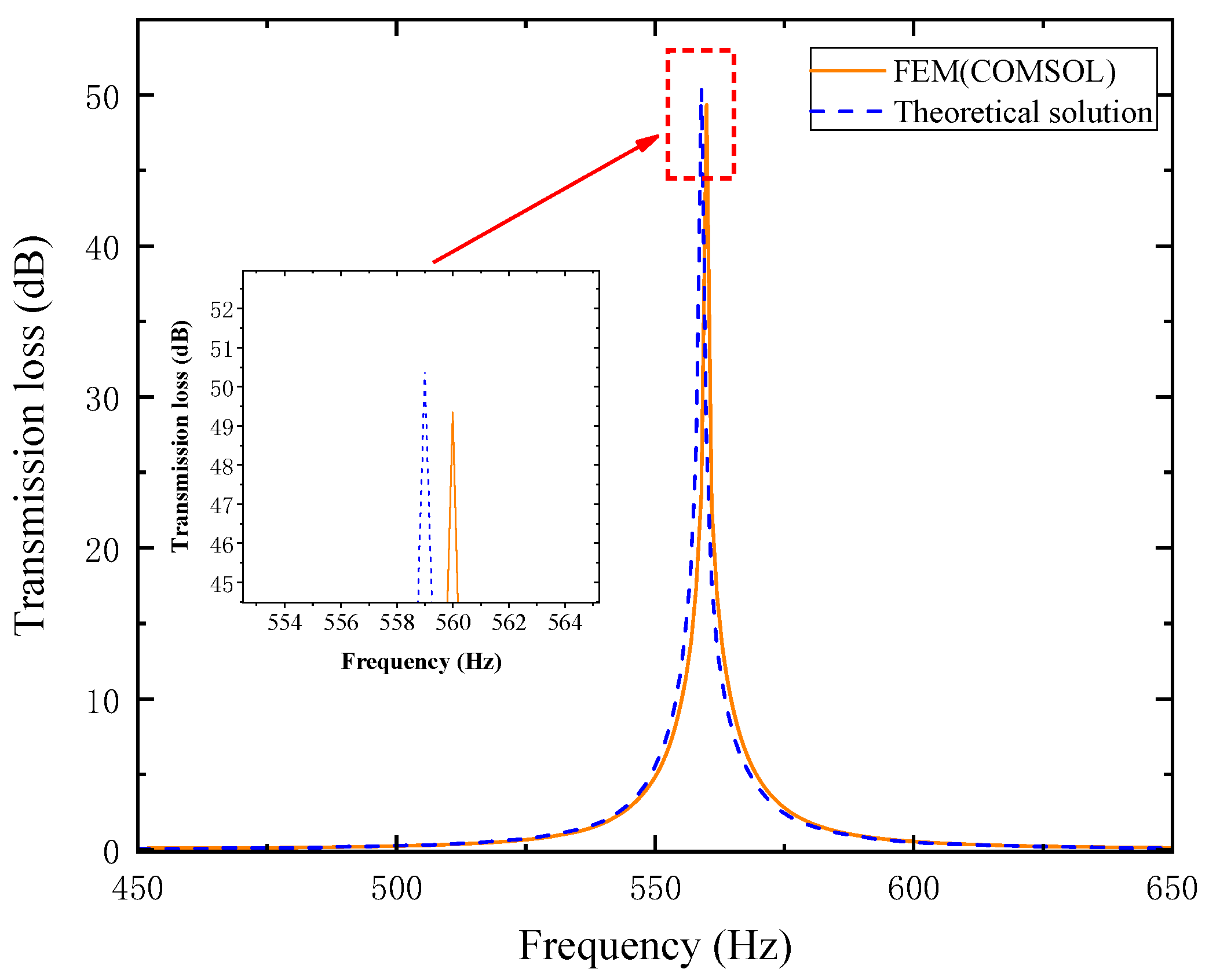

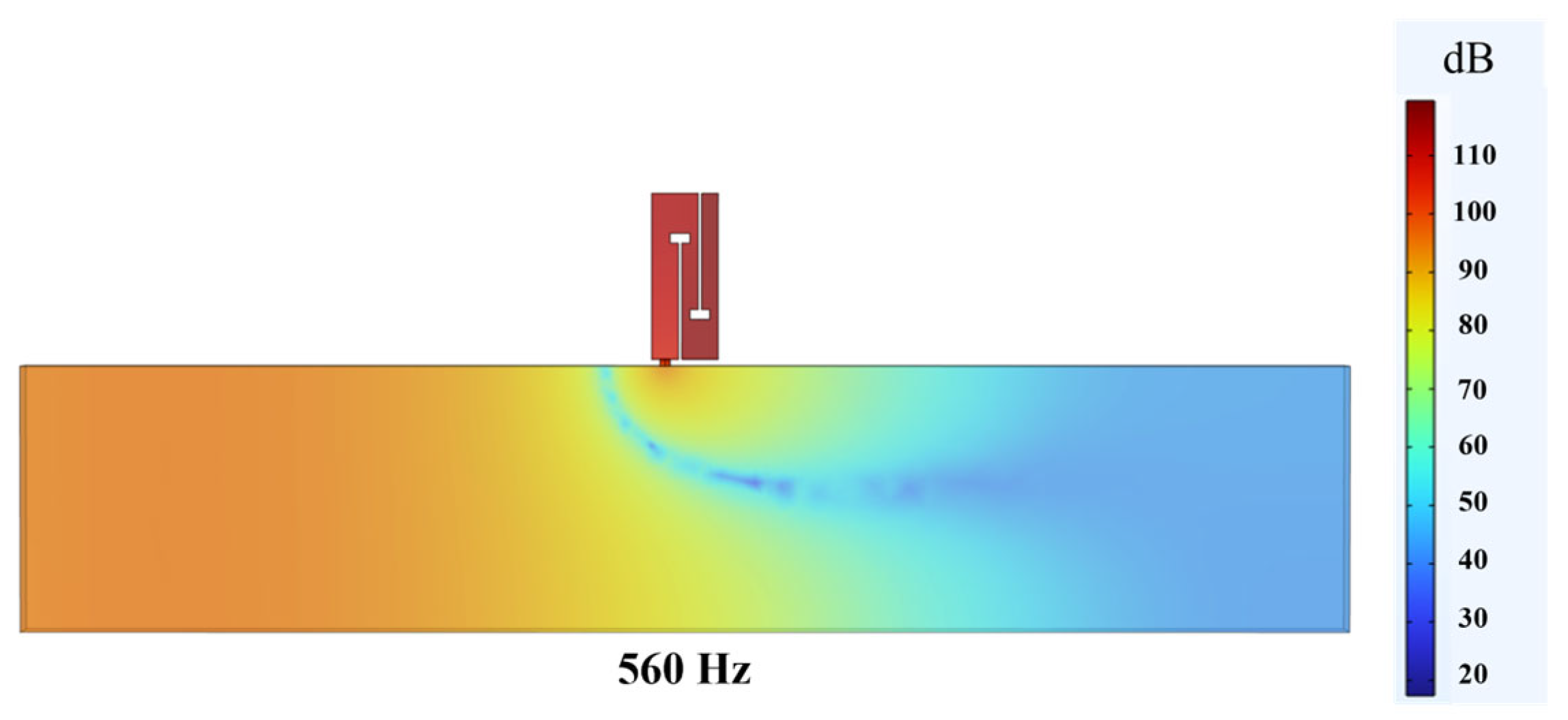

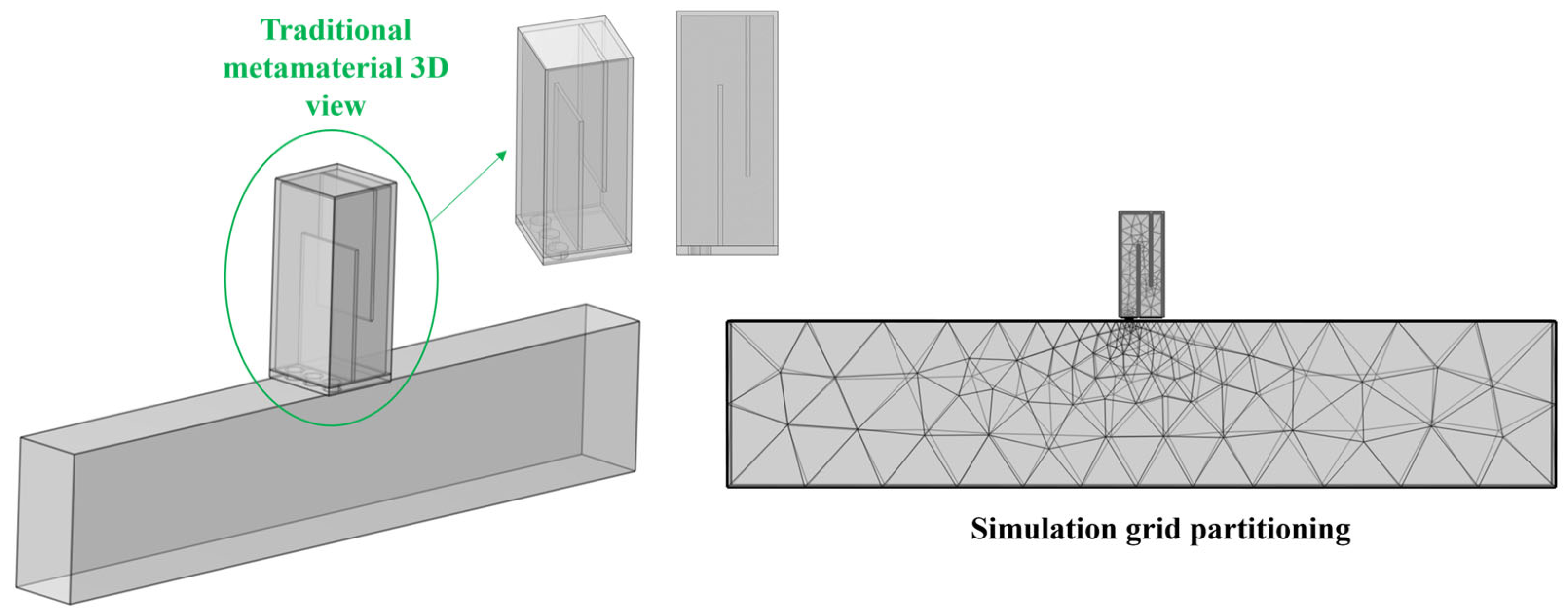

Figure 1 shows a new type of perforated tortuous-characteristic acoustic superstructure, which is composed of a surface perforated plate and a tortuous-characteristic structure, and is installed on the muffling duct. When sound waves pass through the perforated tortuous-characteristic metamaterial structure on the duct, they first enter the perforations of the perforated plate at the inlet, then propagate in a coupled manner into the tortuous cavity, and continue to propagate along the tortuous channels. Each tortuous cavity can be equivalent to a series of multiple tube channels. Throughout this process, frequent refraction and reflection of sound waves occur, and the energy of the sound waves is gradually converted into heat through the friction effect between the inner wall of the structure and the airflow medium for dissipation. This sound energy loss mechanism is the main path through which the Helmholtz resonator achieves energy attenuation. Based on this design concept, sound wave transmission is simulated in the form of an equivalent fluid [

12]; on the basis of a fixed structural thickness, the sound wave propagation path can be effectively extended by changing the channel length, thereby obtaining a good effect that is more conducive to absorbing low- to mid-frequency noise.

The

Table 1 includes the meanings of all the formulas mentioned below.The acoustic characteristic impedance of the total surface of the entire rigid-backed perforated tortuous acoustic metasurface structure is as follows:

In the above formula, the physical quantities and stand for acoustic resistance and acoustic reactance, respectively.

Based on the idea of the acoustical–electrical analogy method, the perforated panel and the tortuous cavity channel are analogous to a series relationship in an electrical circuit, and the total surface acoustic impedance

of the structure can be expressed as

In the above formula,

is the acoustic characteristic impedance of the perforated plate structure,

is the surface acoustic characteristic impedance at the first inlet of the tortuous cavity channel resonator, and

is the correction coefficient, whose value is

. Here,

is the cross-sectional area of the perforated panel, and

is as shown in

Figure 1b.

2.1. Acoustic Theoretical Modeling of Perforated Plate Structures

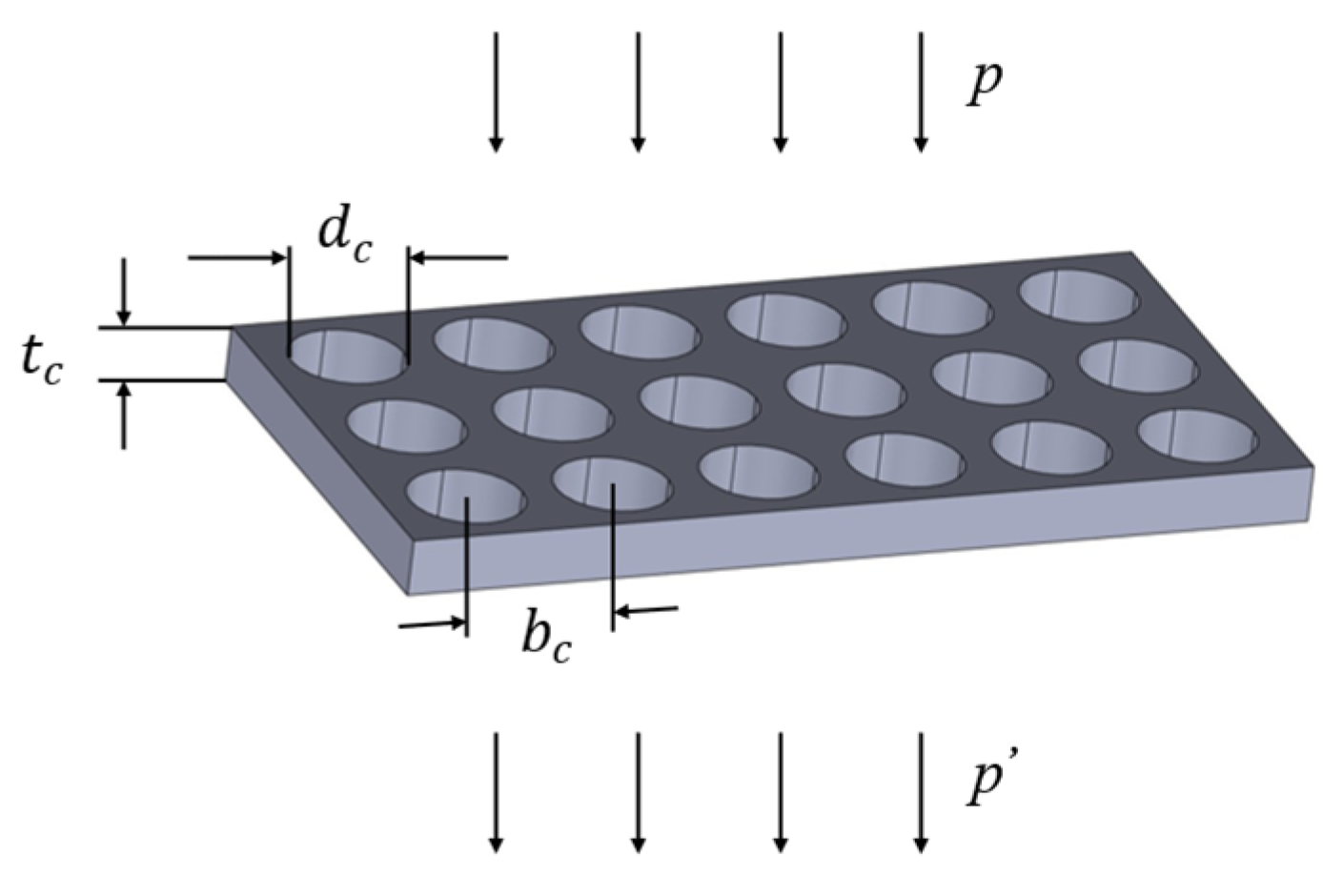

A perforated plate can be regarded as a structure composed of multiple short tubes connected in parallel. Sound waves propagating inside the short tubes interact with the inner walls of the tubes, and then are converted into heat energy and dissipated due to frictional effects, mainly through the actions of viscosity and heat conduction. On the premise that the tube walls are considered rigid bodies, the micro-vibration of the tube walls themselves will not change the acoustic characteristics of the microtubes, as shown in

Figure 2 below.

For the airflow inside the microtube, an increase in the microtube aperture will lead to a corresponding reduction in fluid resistance, whereas a decrease in the microtube aperture will enhance the resistance. When the microtube aperture is reduced to a certain extent, the fluid resistance will increase sharply. If a region is filled with densely arranged fine tube holes, this region has the potential to become a high-performance acoustic material. Based on the transition function [

29], the unified calculation formula for the acoustic characteristic impedance

of a single perforation is

The perforation constant k of the orifice plate is

In the above formula, and are the density and dynamic viscosity coefficient of air under standard atmospheric pressure (101.325 kPa) and normal temperature (15 °C), with values of 1.226 kg/m3 and 1.85 × 10−5 Pa·s, respectively; is the angular frequency; is the central axis length of the micro-short tube; and is the aperture.

Based on the idea of the acoustical–electrical analogy method for series and parallel connections [

29], the perforated plate is equivalent to a parallel combination of multiple single holes. Thus, the acoustic characteristic impedance

of the perforated plate structure can be obtained by solving the following equations, (5) to (7), simultaneously:

In the above formula,

and

are calculated as follows, where

is the acoustic resistivity constant,

is the acoustic mass constant,

is the speed of sound, and

is the perforation rate of the perforated plate:

2.2. Acoustic Theoretical Modeling of Mufflers

For the tortuous channel, its transfer matrix

is expressed as

Based on the Stinson model [

30], calculations are performed using the acoustic transfer matrix method, where the transfer matrix and characteristic impedance can be expressed as

For the first term on the right-hand side of Equation (9),

is the radiation correction matrix from the resonator opening to the waveguide discontinuity, which can be expressed as

In the above equation,

denotes the wavenumber of sound waves in air,

represents the acoustic characteristic impedance of air, and

denotes the corresponding radiation correction length, where

represents the inlet width (the width of the

cavity). Based on Mechel’s theory [

31], it can be derived as

For the second term on the right-hand side of Equation (9),

denotes the acoustic transfer matrix from the opening to the bottom of the resonator cavity:

Herein,

represents the effective wavenumber of the resonator cavity,

denotes the approximate effective length of each cavity channel in the tortuous-characteristic acoustic metamaterial structure (this is merely a variable for theoretical derivation; the values of each effective length of the novel metamaterial studied in this paper will be further elaborated upon later in the text), and

stands for the channel characteristic impedance, with its value taken as follows:

Based on thermoacoustic principles, considering viscous losses in the channel, the effective complex density

and complex bulk modulus of gas

in the tortuous cavity are calculated via the Stinson model [

30], and are given by the following equations:

In Equations (15) and (16),

is the atmospheric pressure of air under standard conditions,

is the dynamic viscosity coefficient of air at 15 °C and standard atmospheric pressure,

is the specific heat ratio with a value of 1.4,

is the thermal conductivity of air with a value of 0.0258 W/(m·K), and

is the specific heat capacity at constant volume with a numerical value of 0.717 kJ/(kg·K). The function

is given by

Herein,

; the zero-order Bessel function and first-order Bessel function are

and

, respectively; and the expression for the function

is

By consolidating the above derivations, and based on the effective complex density and complex bulk modulus of gas, to determine the surface acoustic characteristic impedance

at the first inlet of the resonator with tortuous cavity channels in this metamaterial structure, the corresponding impedance for each variation in cross-sectional area and channel length can be calculated via the above impedance transfer method as follows:

Herein, is the effective cross-sectional area of the cavity channel, is the number of effective cavity channels, and is the equivalent length of the i-th channel. An exception is the calculation of the impedance for the last channel, which is derived using the impedance transfer formula for a rigid-backed termination. It does not account for internal thermoviscous losses and serves as a necessary condition for initiating the recursion of the entire formula. The recursive equation can only be solved when the terminal impedance is known.

Substituting Equations (3) and (19) into Equation (2), the total surface acoustic impedance

of the perforated tortuous-characteristic acoustic metamaterial structure can be obtained.

is the surface area of the perforated plate; when

≪1, the formula is as follows:

The sound transmission coefficient

is given by

By simultaneously solving Equations (2), (21) and (22), the sound transmission loss (STL) formula for this metamaterial muffler is derived as

4. Investigation on the Influence of Structural Parameters on the Noise Reduction Performance of Air Ducts

To further explore the influence of regulatory laws of different structural parameters on the sound transmission loss (STL) performance of the muffler in this perforated tortuous-characteristic acoustic metamaterial, this section, based on the unit cell structure of the perforated tortuous-characteristic acoustic metamaterial, investigates the influences of the diameter of holes in the metamaterial’s perforated plate, the number of holes in the perforated plate, the length of internal partitions of the metamaterial, the position of internal partitions of the metamaterial, and the length and thickness of the left and right trailing additional plates of each internal partition of the metamaterial on the noise reduction performance of the air duct.

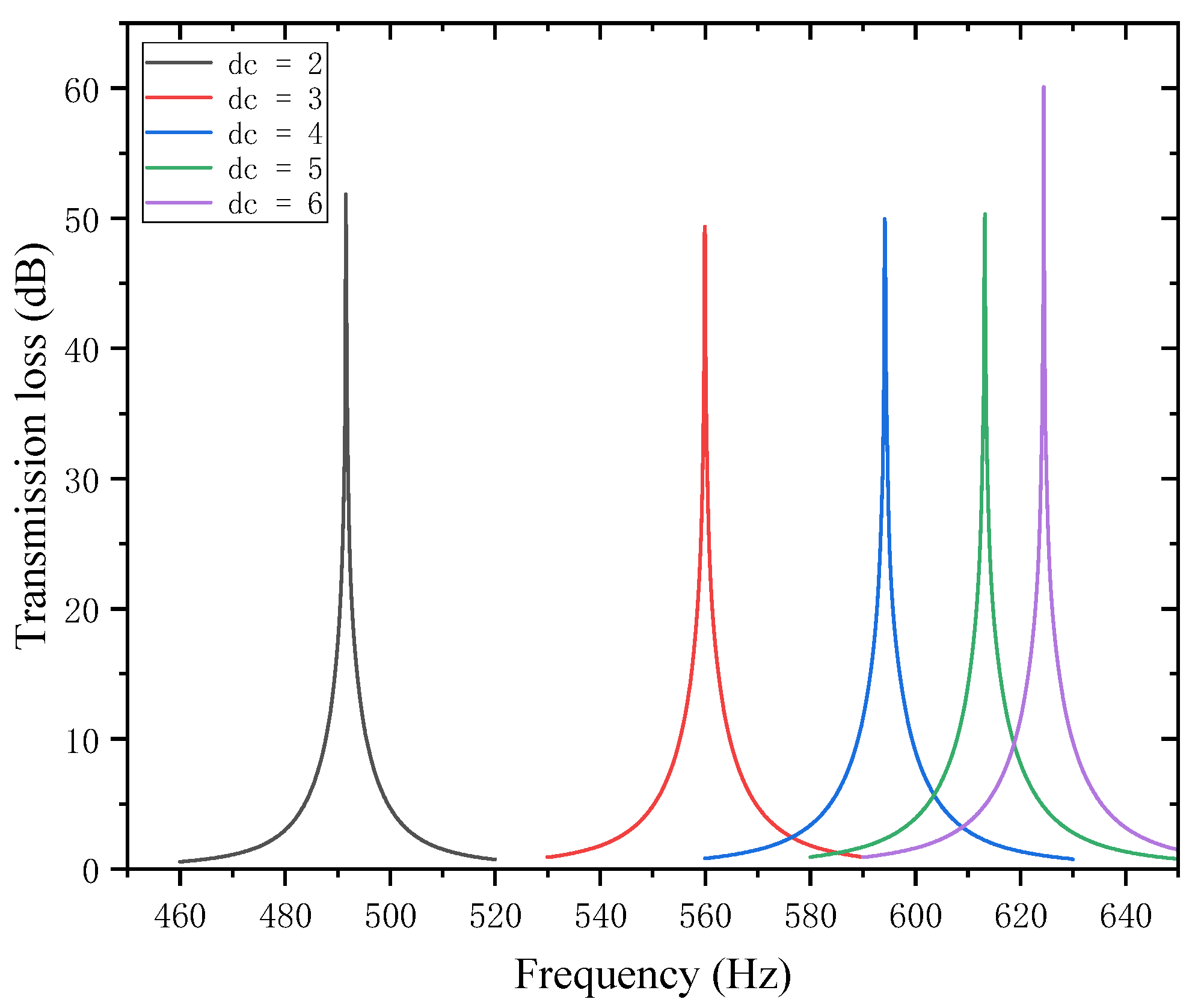

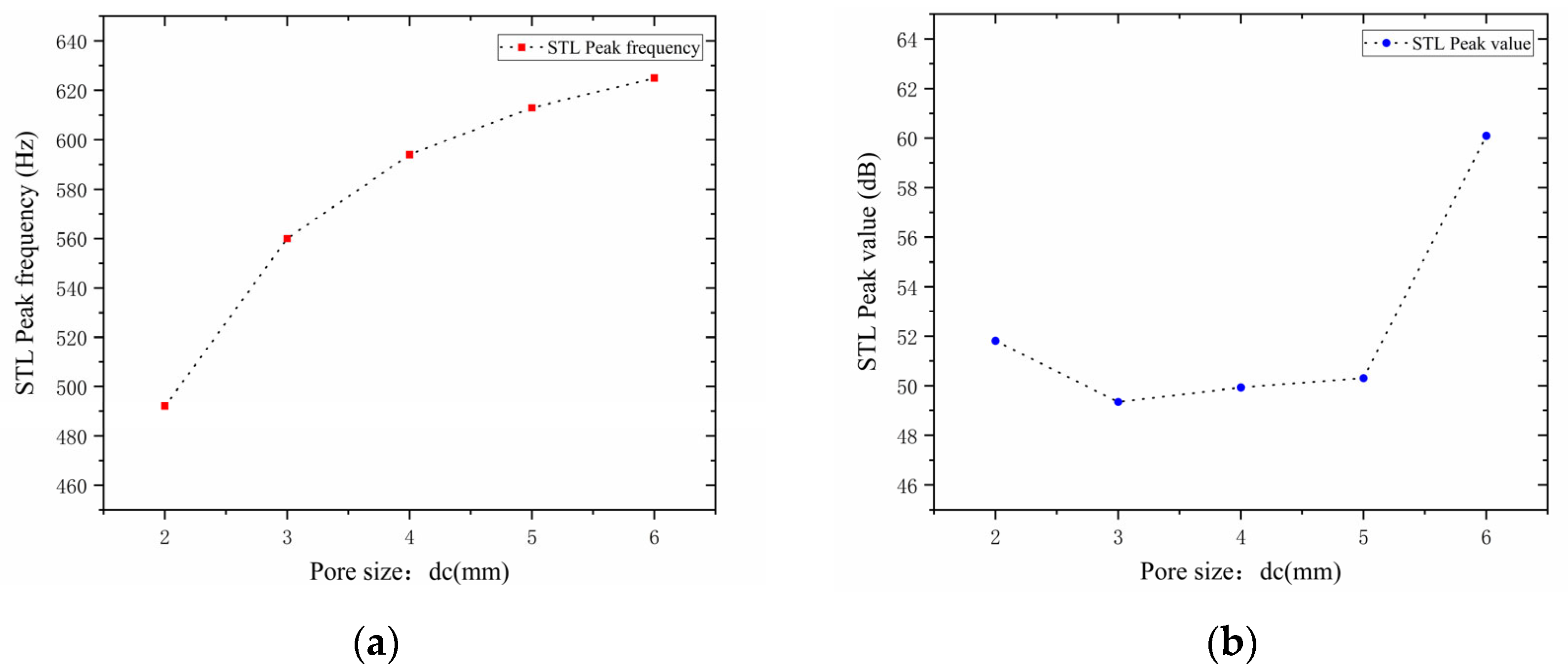

4.1. Influence of Perforation Diameter

When designing parameters for the perforated tortuous-characteristic acoustic metamaterial targeting specific frequency points or bands, the perforation diameter of the perforated plate is a critical parameter, significantly affecting the sound transmission loss (STL) of duct mufflers. Both noise reduction mechanisms and studies in the literature indicate that with a fixed number of holes, a smaller diameter shifts the STL peak to lower frequencies, while a larger diameter shifts it to higher frequencies. Keeping other structural parameters constant, the STL amplitude–frequency characteristic curves under different hole diameters (

= 2, 3, 4, 5, 6 mm) are calculated and presented in

Figure 10. The STL peak frequency, a key indicator of muffler performance, corresponds to the noise reduction level at that frequency; an increase/decrease in the peak frequency indicates a shift of the STL curve to higher/lower frequencies, with performance comparisons shown in

Figure 11.

Analysis of

Figure 10 and

Figure 11 reveals that the perforation diameter

of the perforated plate affects both the STL peak frequency and magnitude. As the perforation diameter increases, the peak frequency of STL shifts to higher frequencies, and the peak magnitude first decreases, then increases, with the turning point occurring at

. This phenomenon can be explained as follows: a larger perforation diameter allows more sound waves to pass through the perforated plate, leading to more significant energy dissipation and scattering in the high-frequency range, thus shifting the peak frequency toward higher frequencies. In the range of 2–3 mm, increasing the perforation diameter weakens the acoustic damping effect, resulting in a decrease in noise reduction; in the range of 3–5 mm, the resonant noise reduction characteristic becomes prominent, and the noise reduction increases due to the matching of sound waves with the resonant frequency; in the range of 5–6 mm, airflow passes more easily, the acoustic impedance decreases, and the low-frequency resonance effect is enhanced, thereby improving the noise reduction performance.

Further observations reveal that for each 1mm increase in hole diameter, the shifting rate of the peak frequency decreases gradually; that is, a larger hole diameter results in a slower shift toward higher frequencies. The STL peak magnitude decreases slightly in the range of 2–3 mm, increases gently at 3–5 mm, and rises sharply at 5–6 mm. This indicates that the noise reduction effect of the perforated plate is inferior when the diameter is in the intermediate range compared to when it is extremely small or large. Therefore, when designing for target frequencies, it is necessary to reasonably adjust the perforation diameter, balancing both the STL peak frequency and magnitude to achieve optimal noise reduction performance.

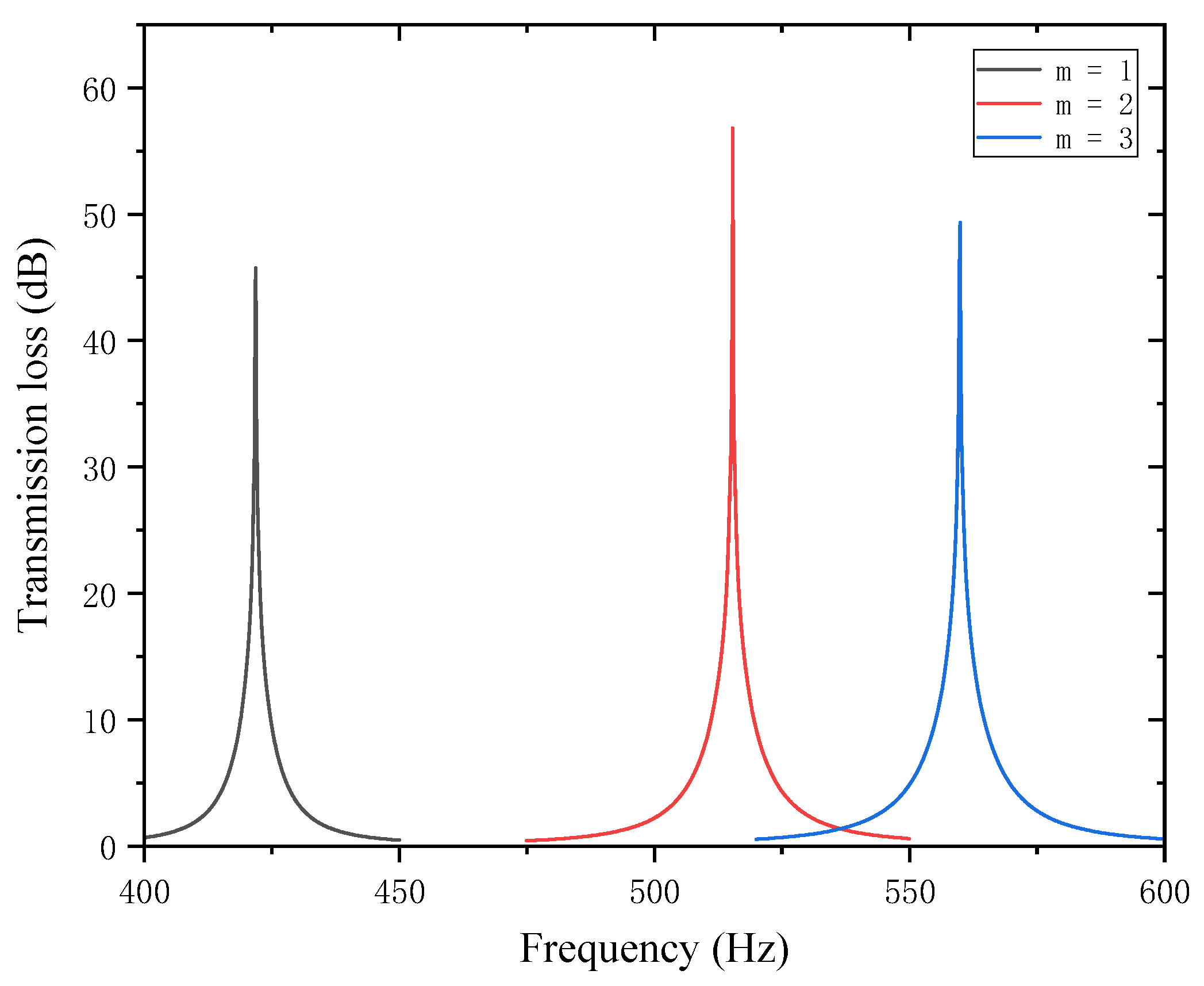

4.2. Influence of Number of Perforations

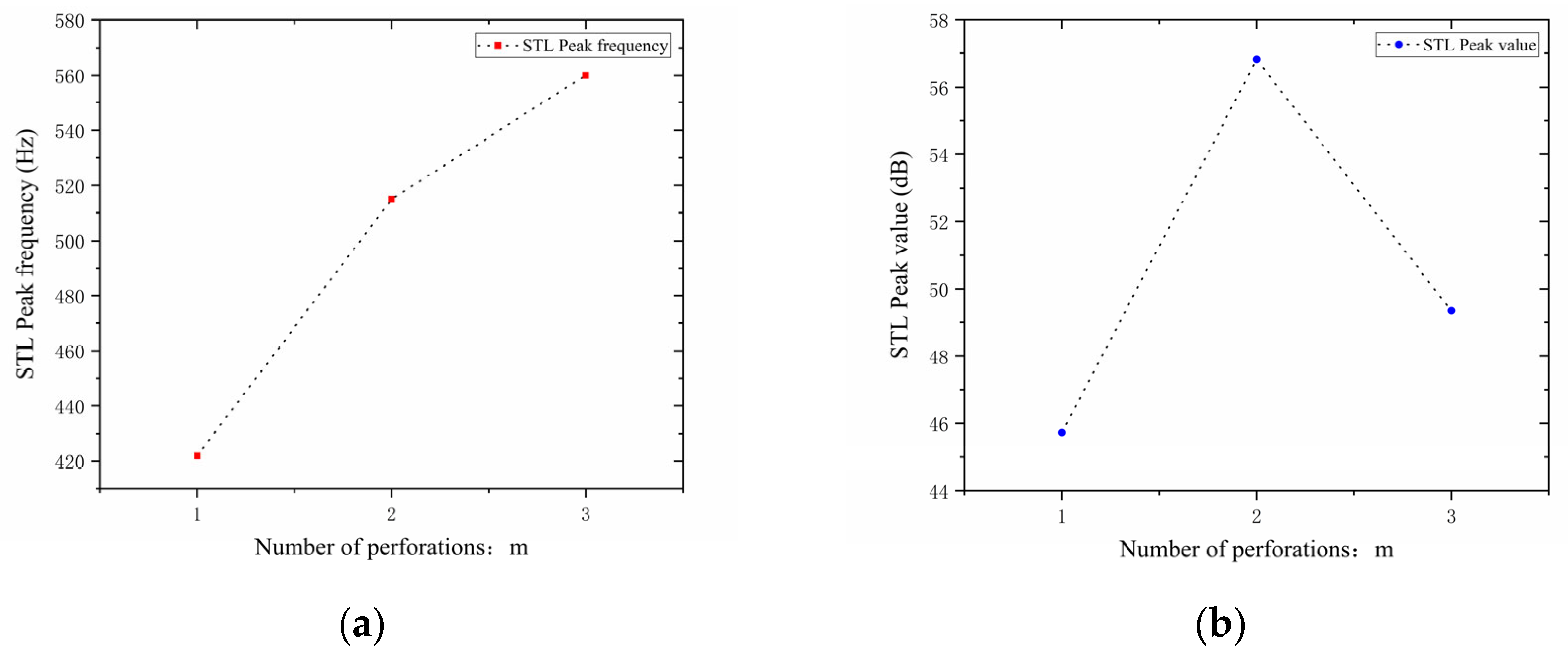

In the design of the perforated tortuous-characteristic acoustic metamaterial, the number of perforations significantly affects the STL of the muffler. Based on the noise reduction mechanism of perforated plates and the literature experience, it is known that a greater number of perforations

leads to a higher STL peak frequency and a wider bandwidth; conversely, fewer perforations result in a lower peak frequency and a narrower bandwidth. With other structural parameters kept unchanged, the number of perforations

was set to 1, 2, and 3, and the corresponding sound transmission loss curves of the acoustic metamaterial under these parameters were obtained, as shown in

Figure 12. The comparative curves of noise reduction performance are shown in

Figure 13.

As can be seen from

Figure 12 and

Figure 13, the number of perforations

affects both the STL peak frequency and magnitude. With an increase in

, the STL peak frequency shifts toward higher frequencies, while the peak magnitude first increases and then decreases, with the turning point at

. When the number of perforations increases, the perforation rate rises, the surface area of the holes and airflow channels increase, the acoustic impedance decreases, and sound transmission increases. This changes the propagation and reflection characteristics of sound waves, leading to an increase in sound transmission loss in high-frequency components and a shift of the resonance frequency toward higher frequencies. When

, the obstruction to sound wave propagation is small, resulting in insufficient scattering and interference, thus leading to low sound transmission loss. When

, the interference between sound waves through the two holes is enhanced, the standing wave distribution and coupling between holes reach an optimal state, and the sound transmission loss increases sharply. When

, the coupling between the acoustic cavity and the folded structure weakens, the standing wave field becomes unstable, the efficiency of acoustic energy dissipation decreases, and the noise reduction amount decreases.

In addition, each time an additional perforation is added to the perforated plate, the growth rate of the peak frequency gradually slows down. The STL peak magnitude increases sharply when changing from a single hole to two holes, but drops sharply when changing from two holes to three holes. This indicates that there exists an optimal matching value for the number of perforations; either too many or too few perforations will significantly reduce the STL peak of noise reduction. Therefore, when setting the number of perforations for target frequencies, comprehensive consideration is required to balance the peak frequency and magnitude, so as to achieve the desired noise reduction performance.

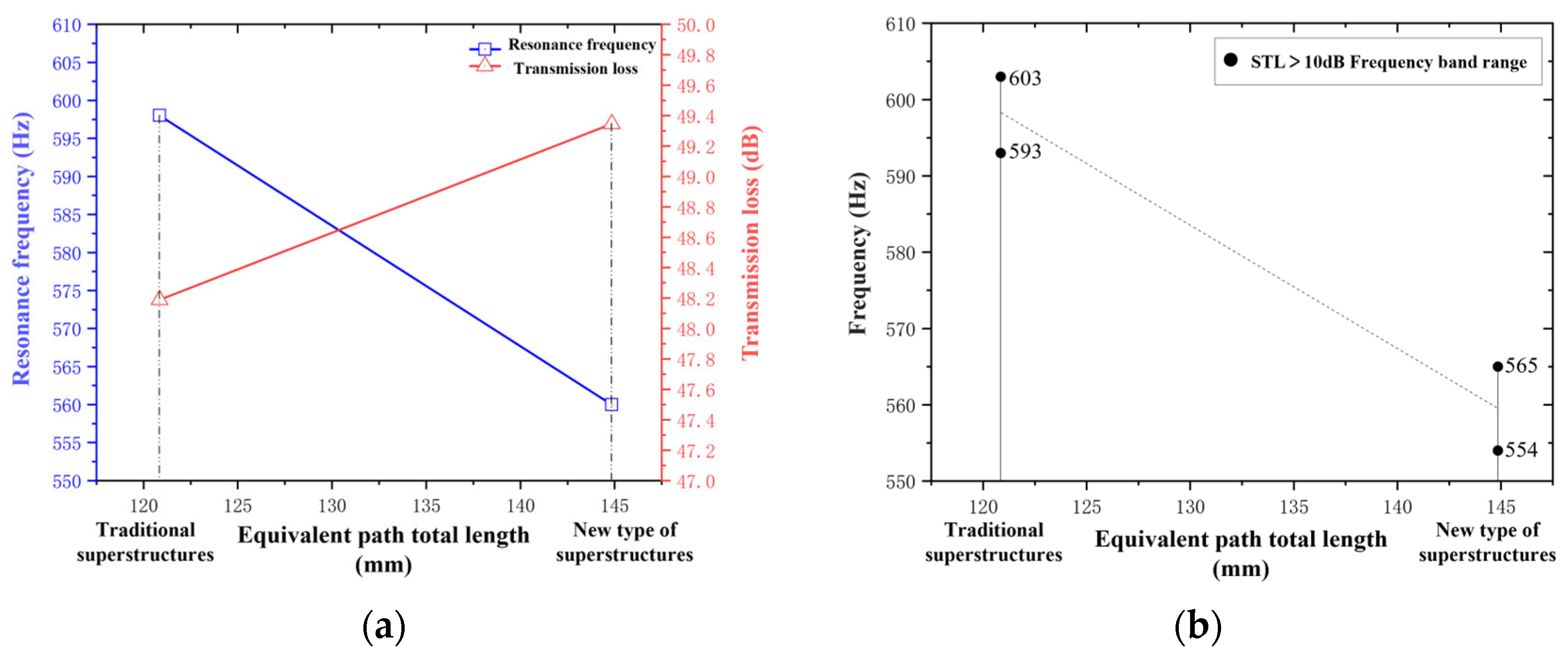

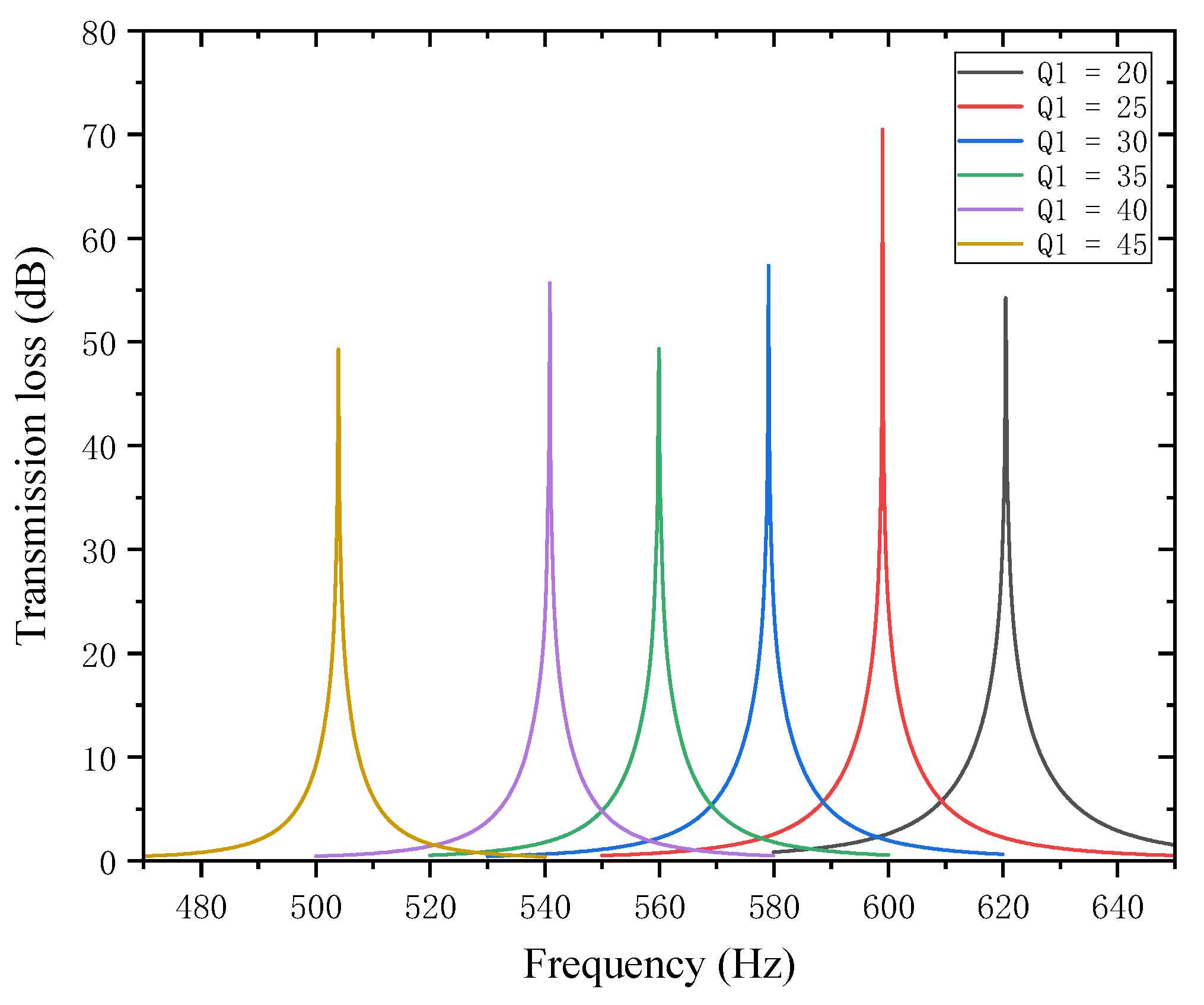

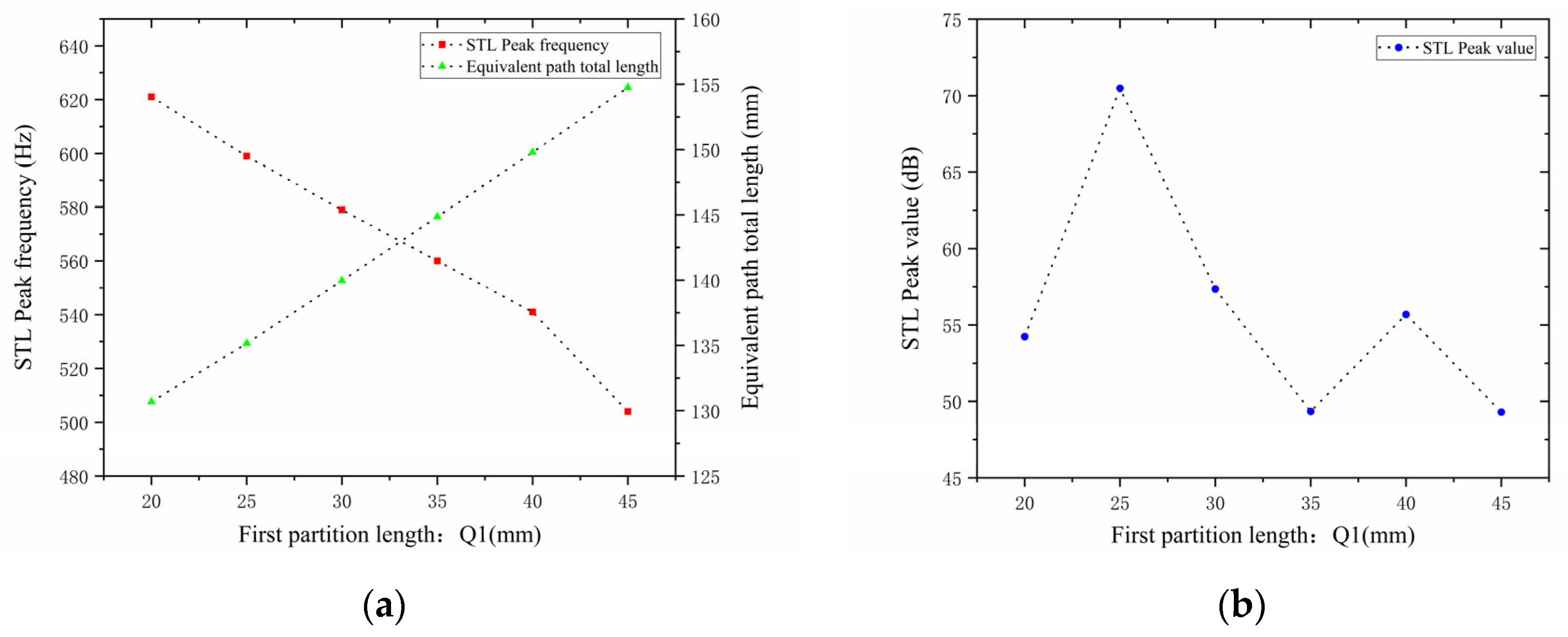

4.3. Influence of Internal Partition Length

The lengths of the two baffles,

and

, are the subject of this paper’s research. By changing the total equivalent path length

of the cavity channel, changes in partition length influence the noise reduction frequency. They also have an impact on the acoustic impedance, interference patterns, and the path taken by the sound waves, all of which ultimately affect how much noise is reduced. The length of the first partition

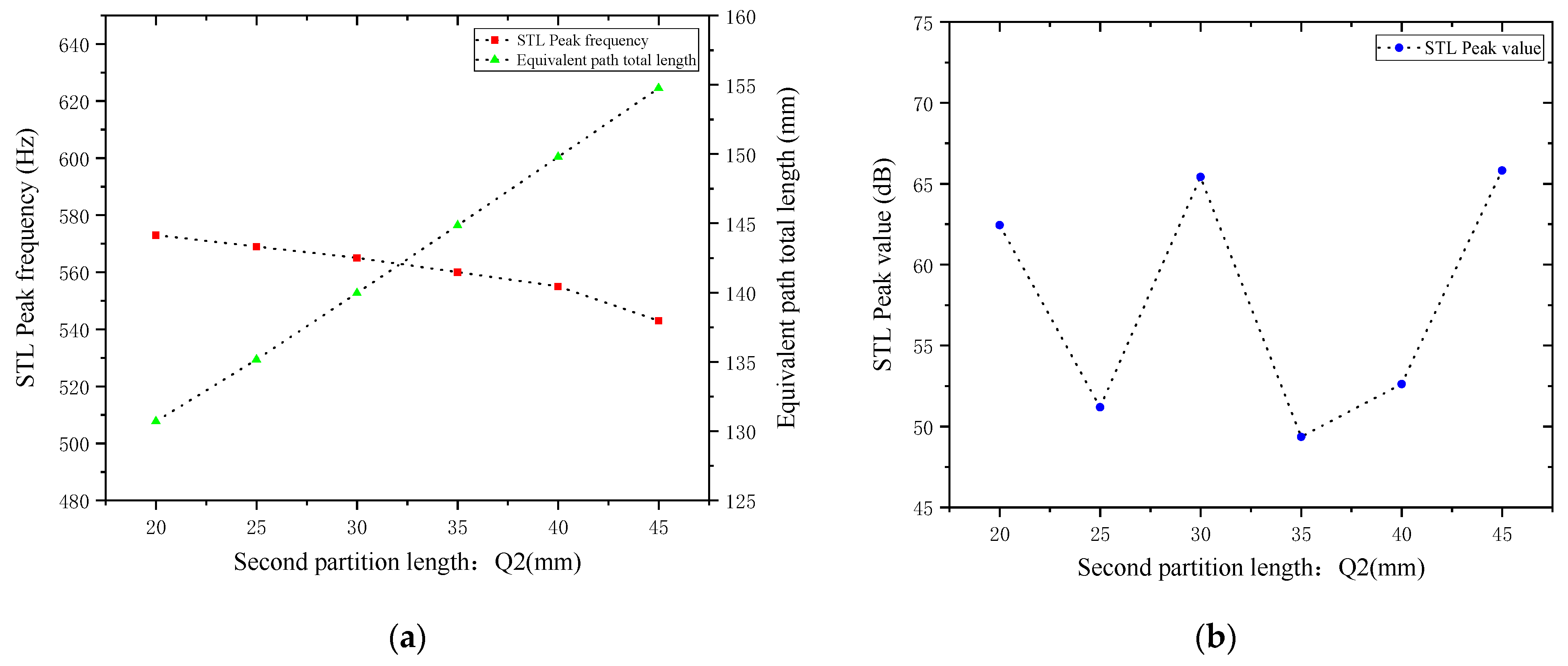

was set to 20, 25, 30, 35, 40, and 45 mm while maintaining all other parameters constant.

Figure 14 displays the corresponding sound transmission loss curves under these conditions, while

Figure 15 displays the comparative noise reduction performance curves.

As can be seen from

Figure 14 and

Figure 15, changes in

affect both the STL peak frequency and magnitude. With an increase in

, the total equivalent path length increases, causing the STL peak frequency to shift toward lower frequencies, while the peak magnitude first increases and then decreases, with the turning point at

. All peak magnitudes exceed 45 dB. For every 5 mm increase in

, the increment amplitude of the total equivalent path length gradually increases, and the rate at which the peak frequency shifts toward lower frequencies is slow initially and then accelerates, with a sharp drop in resonance frequency in the 40–45 mm range. The STL peak magnitude increases sharply in the 20–25 mm range, indicating that sound wave interference is most intense and acoustic impedance is maximized in this interval. Therefore, when setting the length of the first partition, the size should be reasonably adjusted to achieve optimal noise reduction performance.

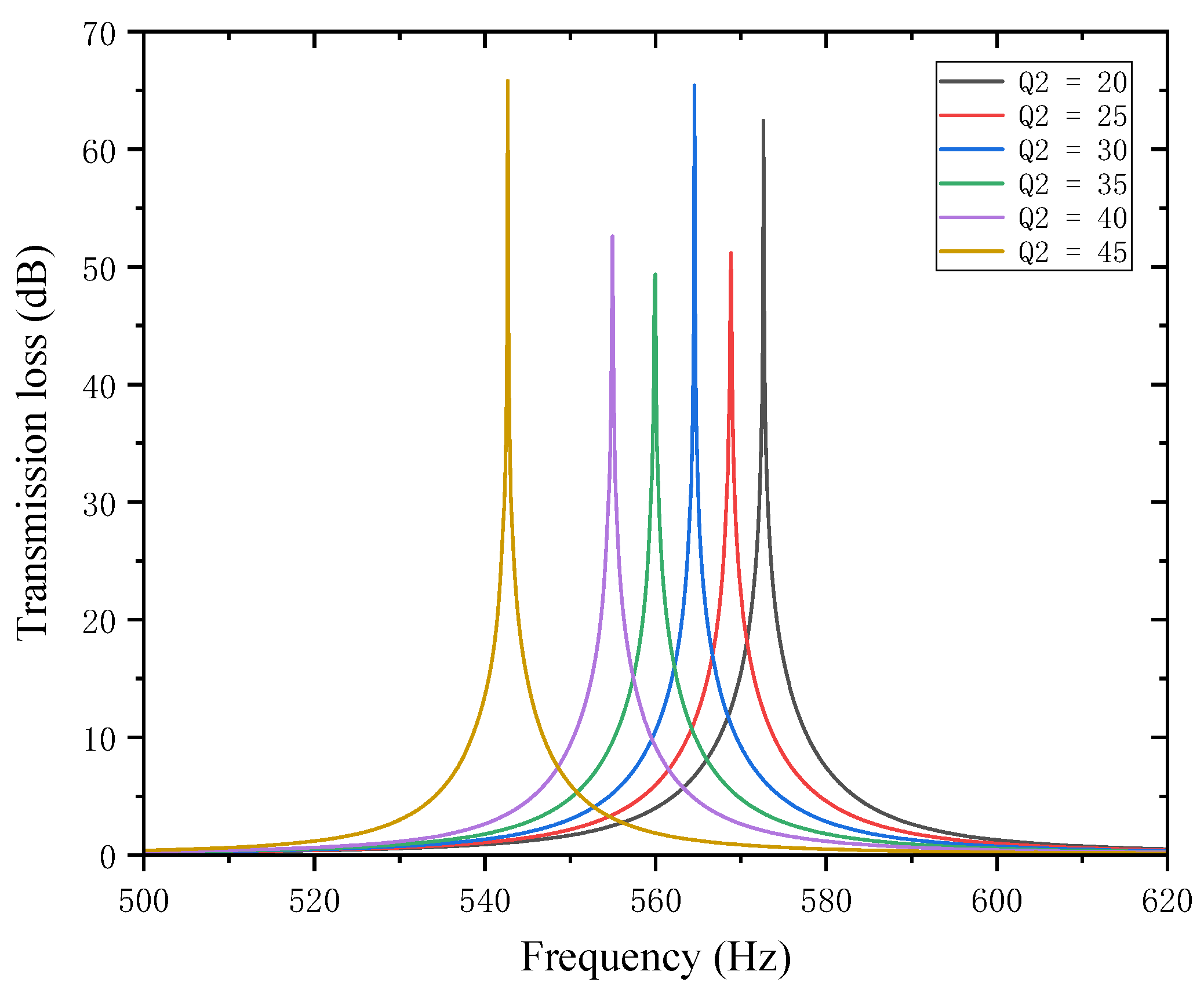

Similarly, while keeping other parameters unchanged, the length of the second partition

was set to 20, 25, 30, 35, 40, and 45 mm. The corresponding sound transmission loss curves under these parameters are shown in

Figure 16, and the comparative curves of noise reduction performance are shown in

Figure 17.

As can be seen from

Figure 16 and

Figure 17, changes in

also affect both the STL peak frequency and magnitude. With an increase in

, the total equivalent path length increases, causing the peak frequency to shift toward lower frequencies, and the shifting rate gradually accelerates, with a sharp drop in resonance frequency in the 40–45 mm range. Compared with the first partition,

results in a smaller decrease in the STL peak frequency, indicating that the first partition plays a primary regulatory role, while the second partition functions as a fine-tuning element. When

is 20, 30, and 45 mm, the STL peak magnitude exceeds 60 dB, and in other cases, it also exceeds 45 dB. Therefore, when setting the length of the second partition, it should be reasonably adjusted to exert its fine-tuning effect and optimize the noise reduction performance.

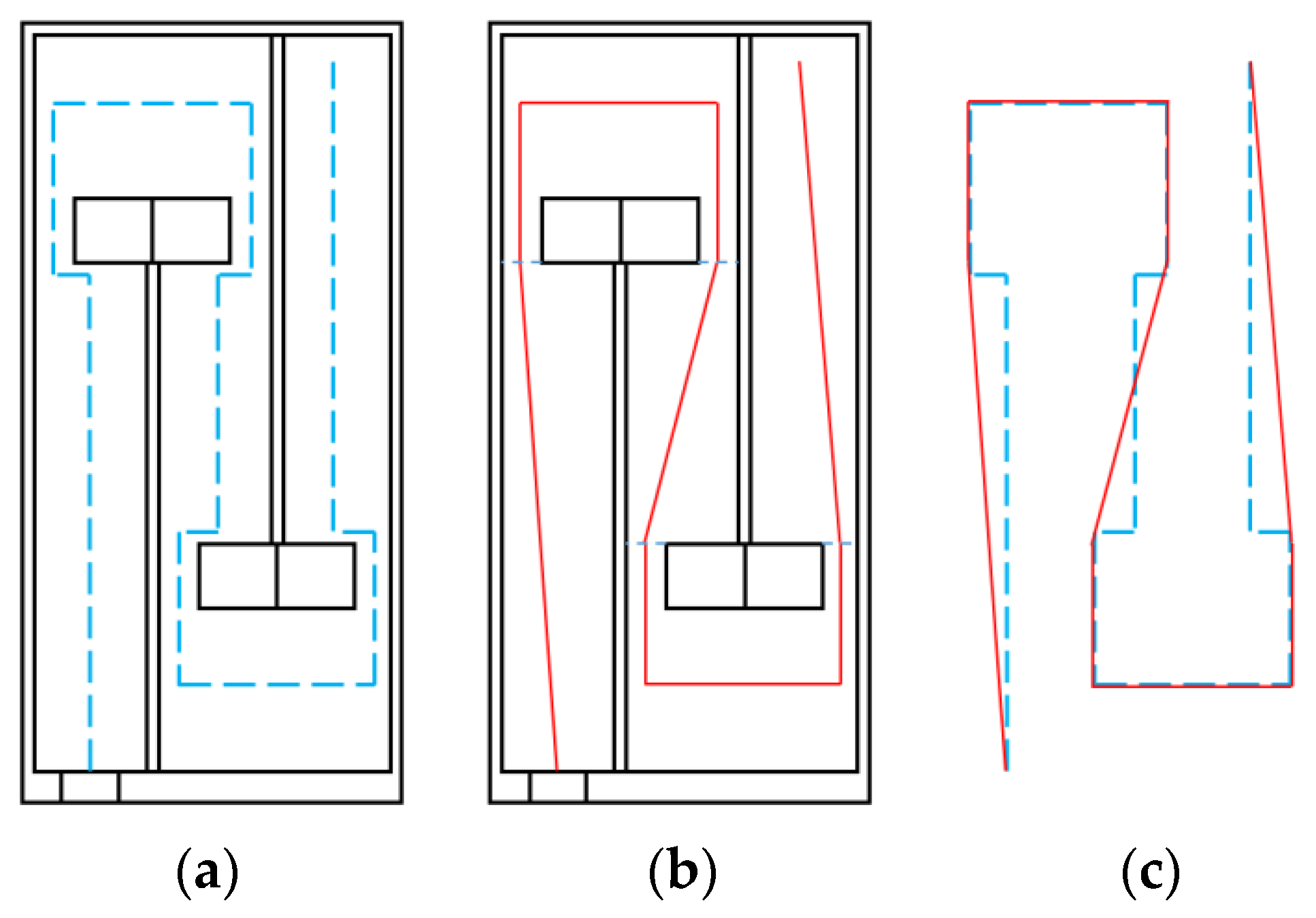

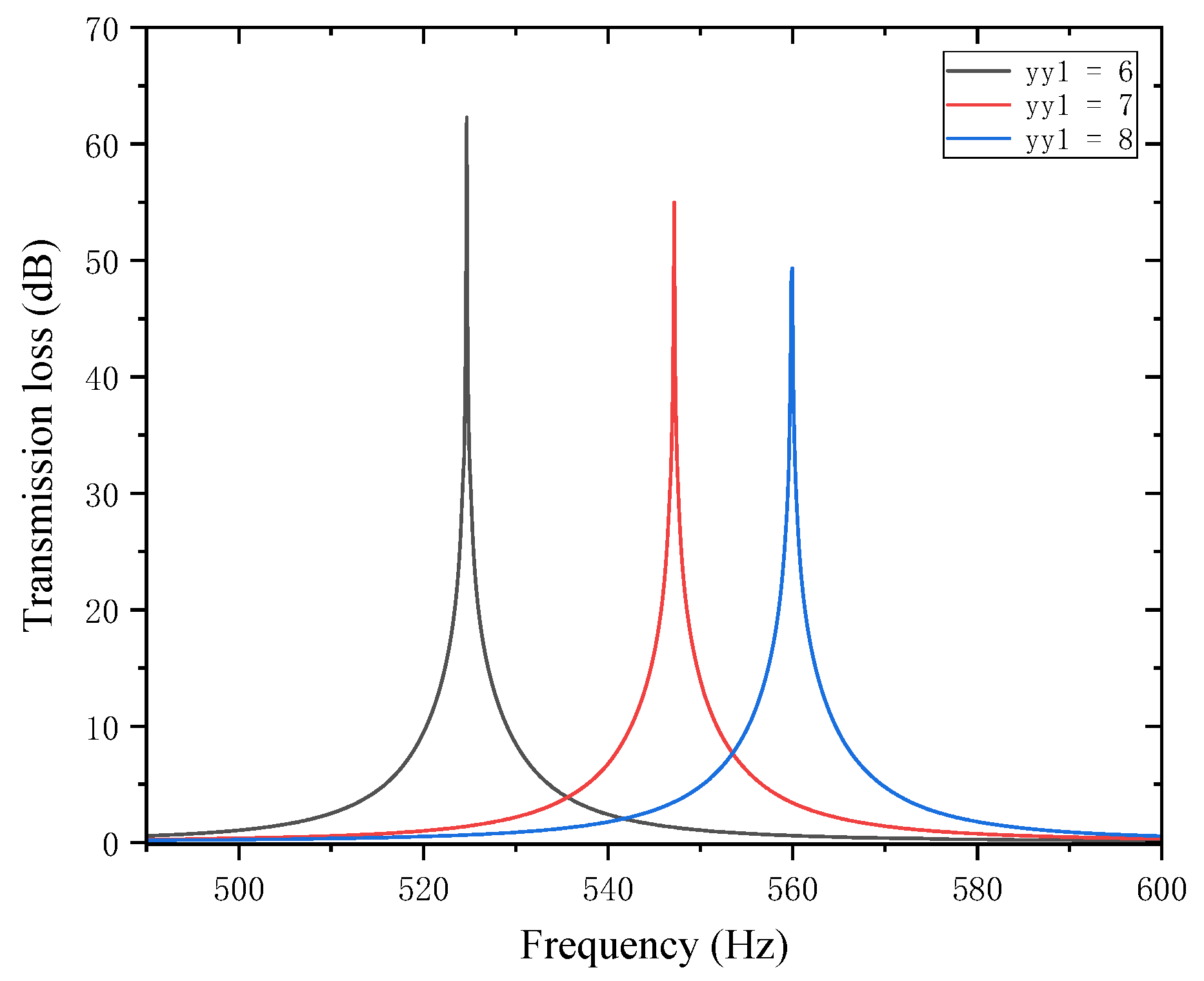

4.4. Influence of Internal Partition Positions

This section investigates the influence of the positions of two partitions in the perforated tortuous-characteristic acoustic metamaterial on the noise reduction performance of air ducts. When the positions of the internal partitions change, the volume of each chamber changes accordingly, which is equivalent to altering the internal structure of the muffler. This further affects the sound wave transmission path and resonance frequency, and thus the peak frequency of sound transmission loss may shift. In other words, the movement of partitions changes the equivalent length of the channel, thereby altering the resonance frequency. The movement of partitions also changes the cross-sectional area of each channel, which may enhance or weaken the formation of standing waves at certain frequencies, affect the energy dissipation of sound waves in the channel, alter the impedance matching of the muffler, and influence the reflection and transmission coefficients of sound waves. With other structural parameters of the perforated tortuous-characteristic acoustic metamaterial kept unchanged, the position of the first partition

was adjusted to 6, 7, and 8 mm, and the corresponding sound transmission loss curves of the acoustic metamaterial under these parameters were calculated. The amplitude–frequency characteristic curves are shown in

Figure 18 below, and the comparative curves of noise reduction performance are shown in

Figure 19.

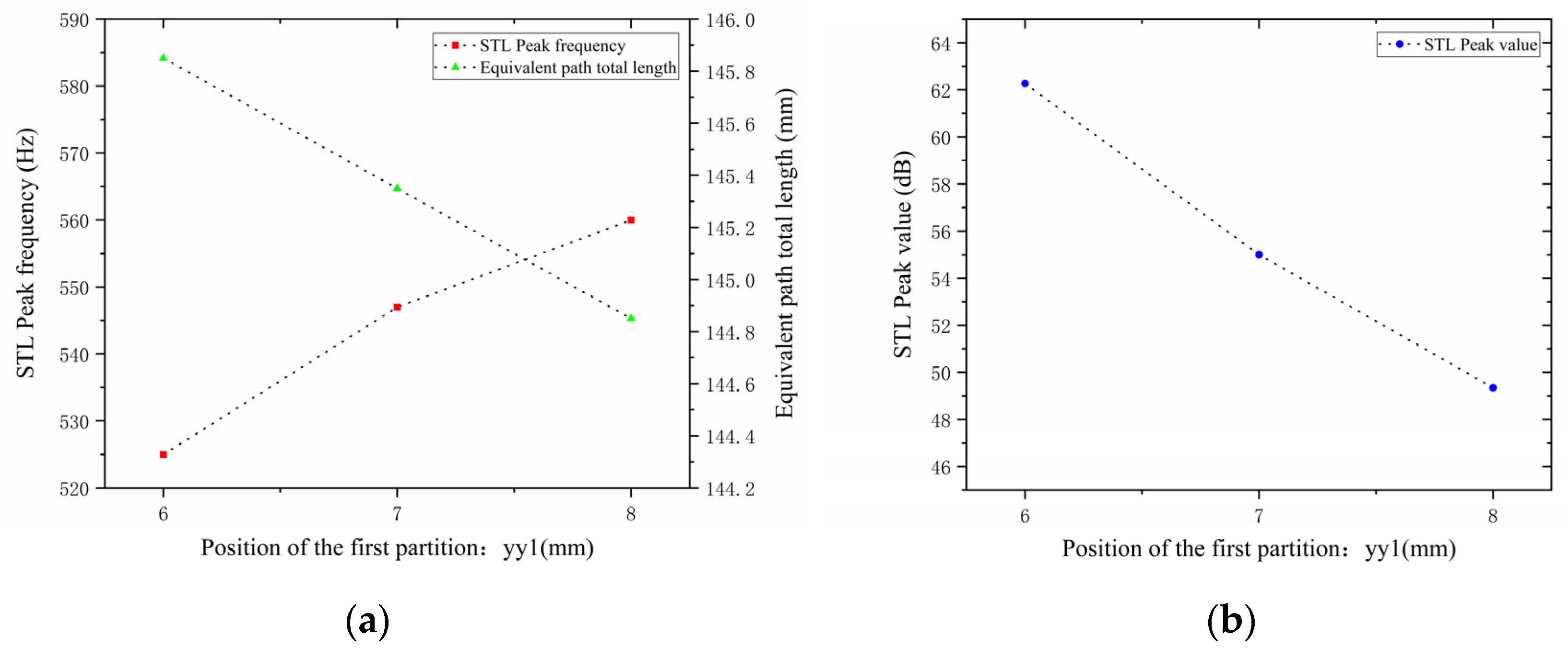

As can be seen from

Figure 18 and

Figure 19, changes in

affect both the STL peak frequency and magnitude. With an increase in

, the total equivalent path length decreases, causing the peak frequency to shift toward higher frequencies, and the shifting rate gradually slows down—rising sharply in the 6–7 mm range and gently in the 7–8 mm range. Meanwhile, as

increases, the peak magnitude decreases, with the decreasing rate slowing down gradually. Therefore, when setting the position of the first partition, it should be reasonably adjusted to optimize the noise reduction performance.

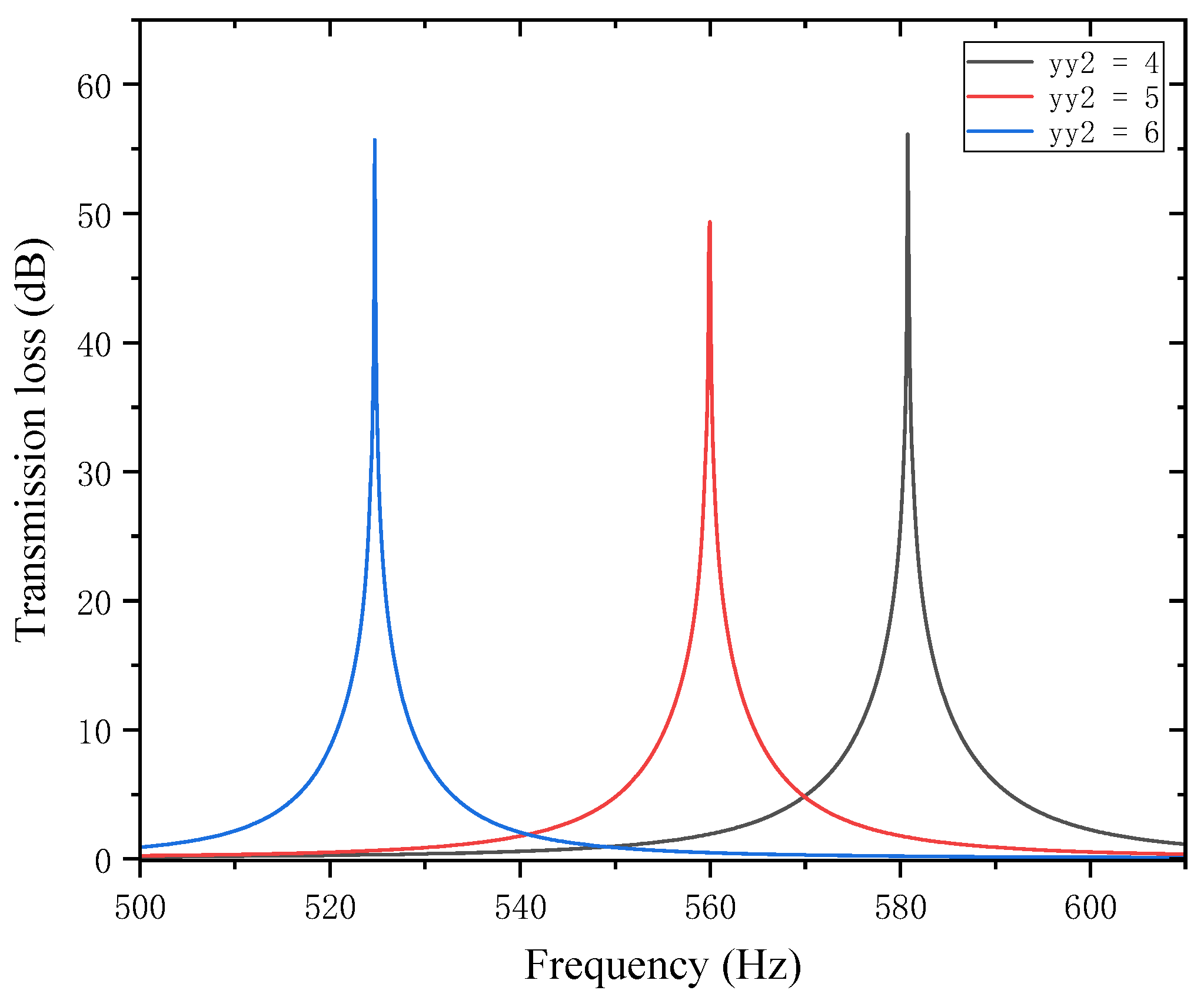

Similarly, with other structural parameters of the perforated tortuous-characteristic acoustic metamaterial kept unchanged, the position of the second partition

was adjusted to 4, 5, and 6 mm. The corresponding sound transmission loss curves of the acoustic metamaterial under these parameters were calculated, and the amplitude–frequency characteristic curves are shown in

Figure 20 below. The comparative curves of noise reduction performance are shown in

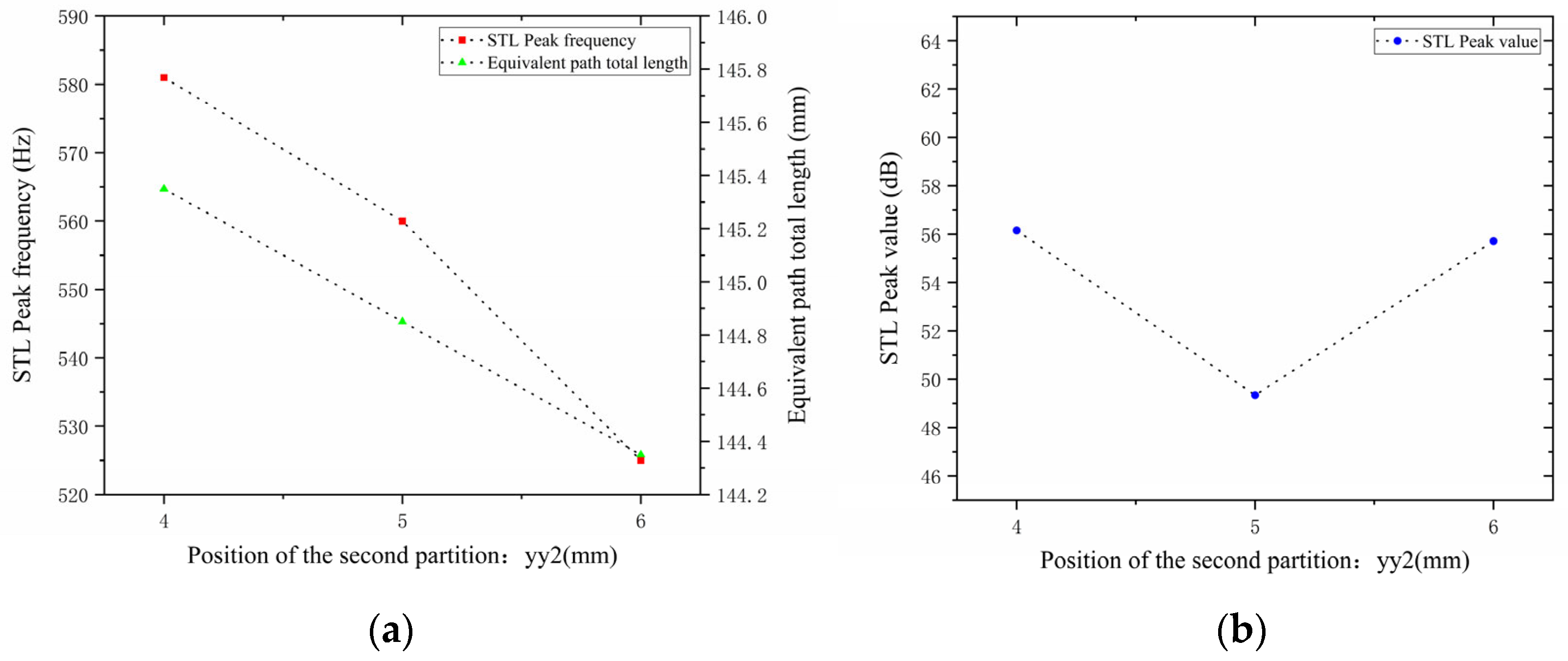

Figure 21.

As can be seen from

Figure 20 and

Figure 21, changes in the second partition position

affect both the position and magnitude of the STL peak frequency, with a pattern different from that of the first partition. As

increases, the total equivalent path length decreases, but the peak frequency shifts toward lower frequencies. This is because the movement of the partition alters the sound wave propagation path, causing changes in wavelength and perceived frequency. For each 1 mm increase in

, the total equivalent path length decreases by 0.5 mm, and the rate at which its peak frequency shifts toward lower frequencies accelerates gradually. The STL peak magnitude first decreases and then increases, with all values exceeding 48 dB. Compared with the first partition,

has a greater impact on the variation range of the STL peak frequency and plays a primary regulatory role, while the first partition functions as a fine-tuning element. Therefore, when setting the position of the second partition, it should be reasonably adjusted to achieve the optimal noise reduction effect.

4.5. Influence of Trailing Plates Attached to Internal Partitions

4.5.1. Length of the Trailing Plate

For the perforated tortuous-characteristic superstructure in this paper, each baffle end is connected with a trailing additional plate. Each trailing additional plate is divided into left and right trailing additional plates by taking the central axis of the baffle it is connected to as the boundary. Therefore, their influences on the noise reduction performance of the air duct are discussed separately. Changes in the length of the trailing additional plates will affect the total equivalent path length and cross-sectional area of the cavity channel, thereby regulating the noise elimination frequency.

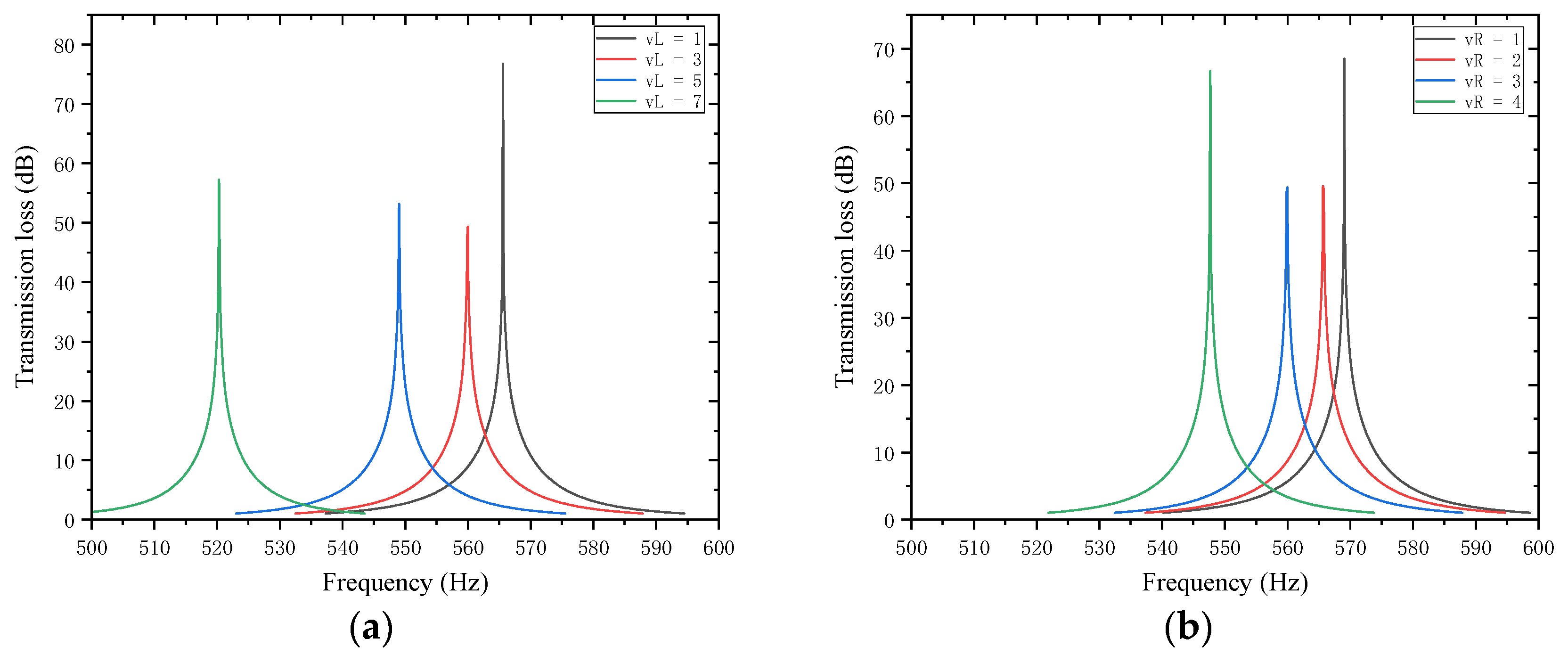

When studying the trailing plates attached to the first partition, with other parameters kept unchanged, the length of the left trailing plate

was set to 1, 3, 5, and 7 mm, and the length of the right trailing plate

was set to 1, 2, 3, and 4 mm. The sound transmission loss curves of the acoustic metamaterial under these corresponding parameters were calculated, and the amplitude–frequency characteristic curves are shown in

Figure 22 below, with the comparative curves of noise reduction performance shown in

Figure 23.

As shown in

Figure 22 and

Figure 23, variations in the lengths

and

of the left and right trailing plates of the first partition affect the STL peak frequency and magnitude. When

increases, the total equivalent path length increases, causing the peak frequency to shift toward lower frequencies with a gradually increasing shifting rate, while the STL peak magnitude first drops sharply and then rises slowly. When

increases, the total equivalent path length increases, leading the peak frequency to shift toward lower frequencies, and the peak magnitude first decreases and then increases.

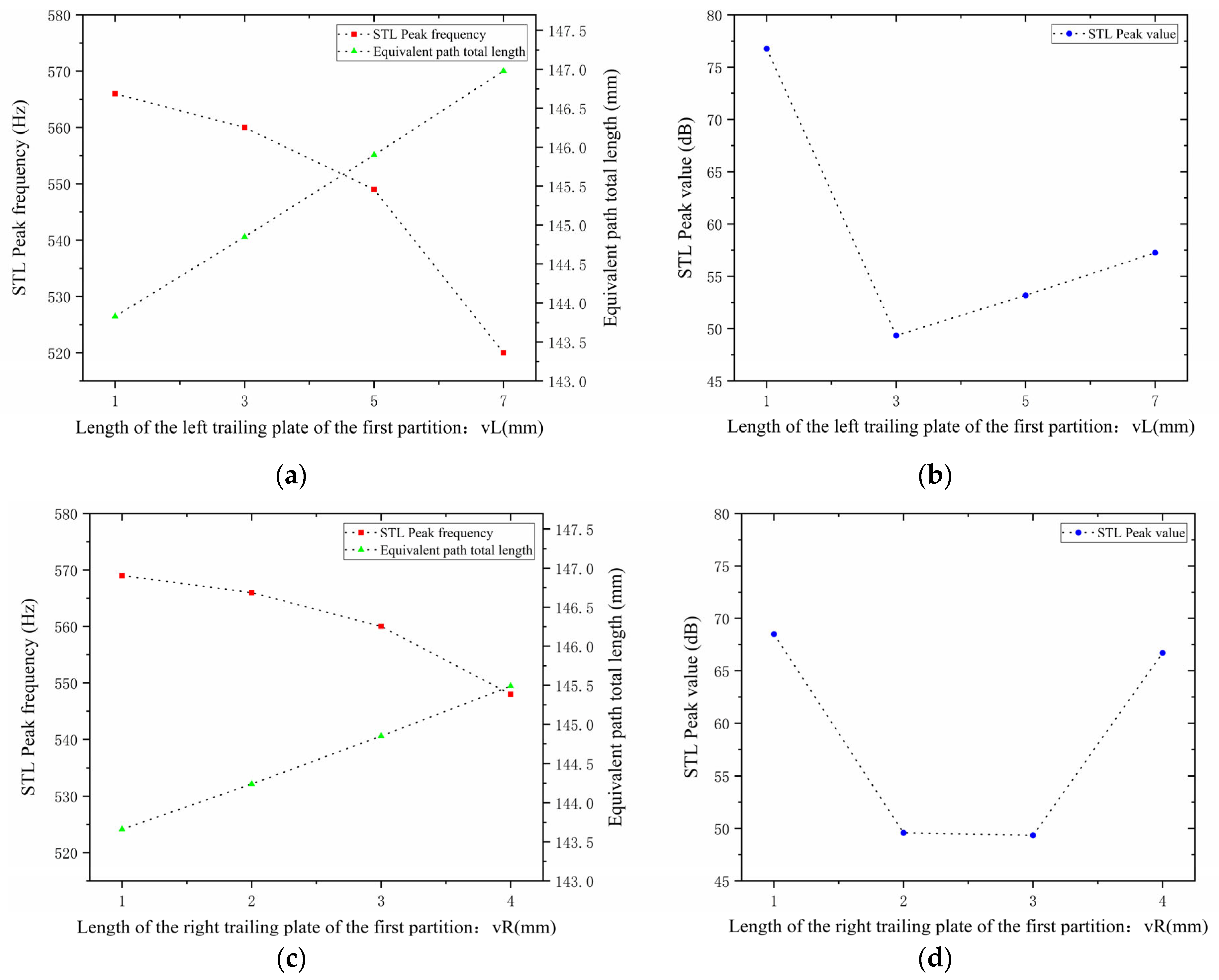

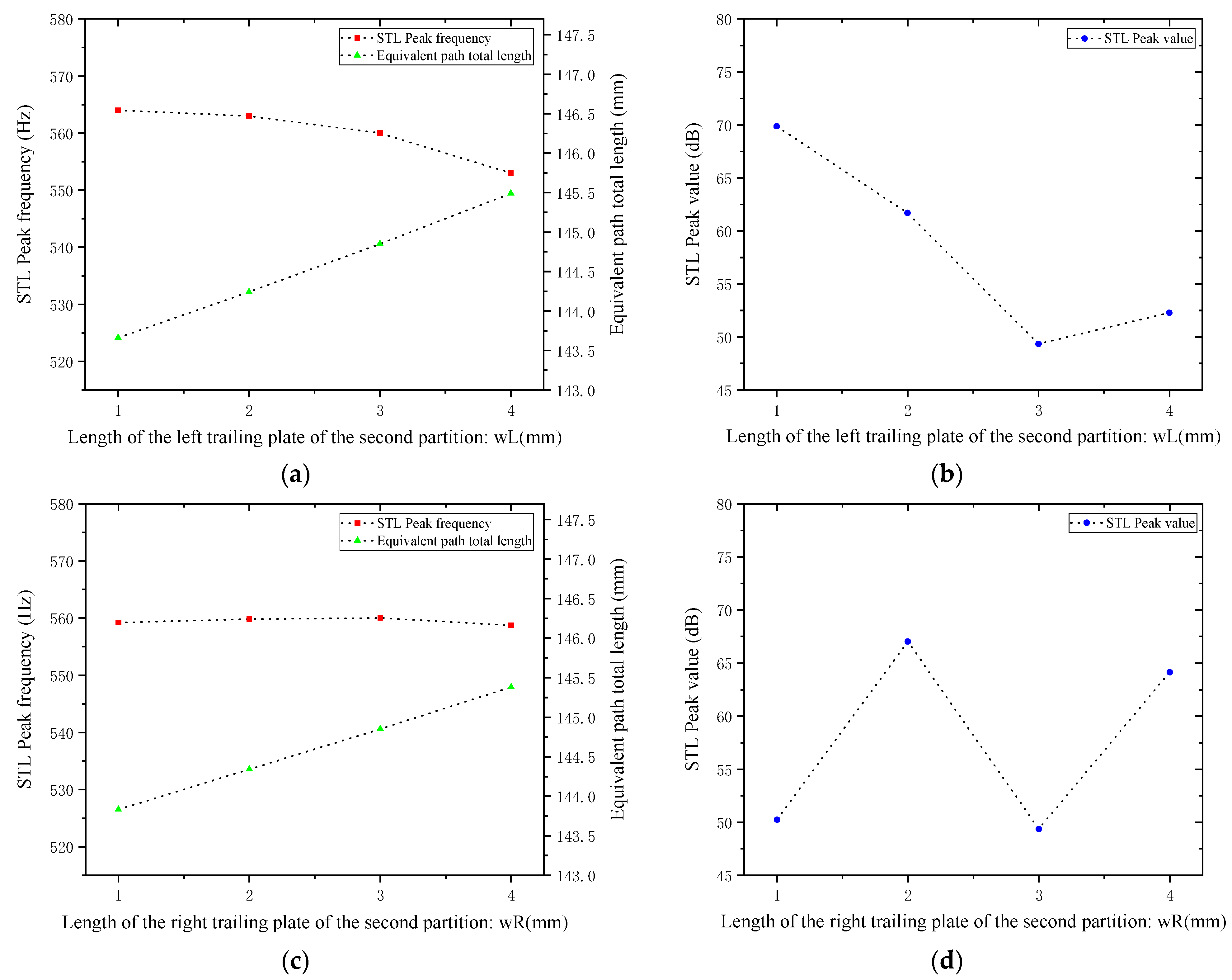

Similarly, for the trailing plates attached to the second partition, with other parameters kept unchanged, the length of the left trailing plate

and the length of the right trailing plate

were both adjusted to 1, 2, 3, and 4 mm. The sound transmission loss curves of the acoustic metamaterial under these corresponding parameters were calculated, and the amplitude–frequency characteristic curves are shown in

Figure 24 below, with the comparative curves of noise reduction performance shown in

Figure 25.

As can be seen from

Figure 24 and

Figure 25, increasing

and

results in an increase in the total equivalent path length, with the peak frequency shifting toward lower frequencies. Specifically, an increase in

leads to a decrease in the peak frequency; in contrast, an increase in

causes only negligible changes in the peak frequency. Notably, the STL peak magnitude reaches approximately 65 dB at 2 mm and 4 mm. Therefore, the length of the partition trailing appendage plates should be adjusted appropriately to optimize the sound attenuation performance.

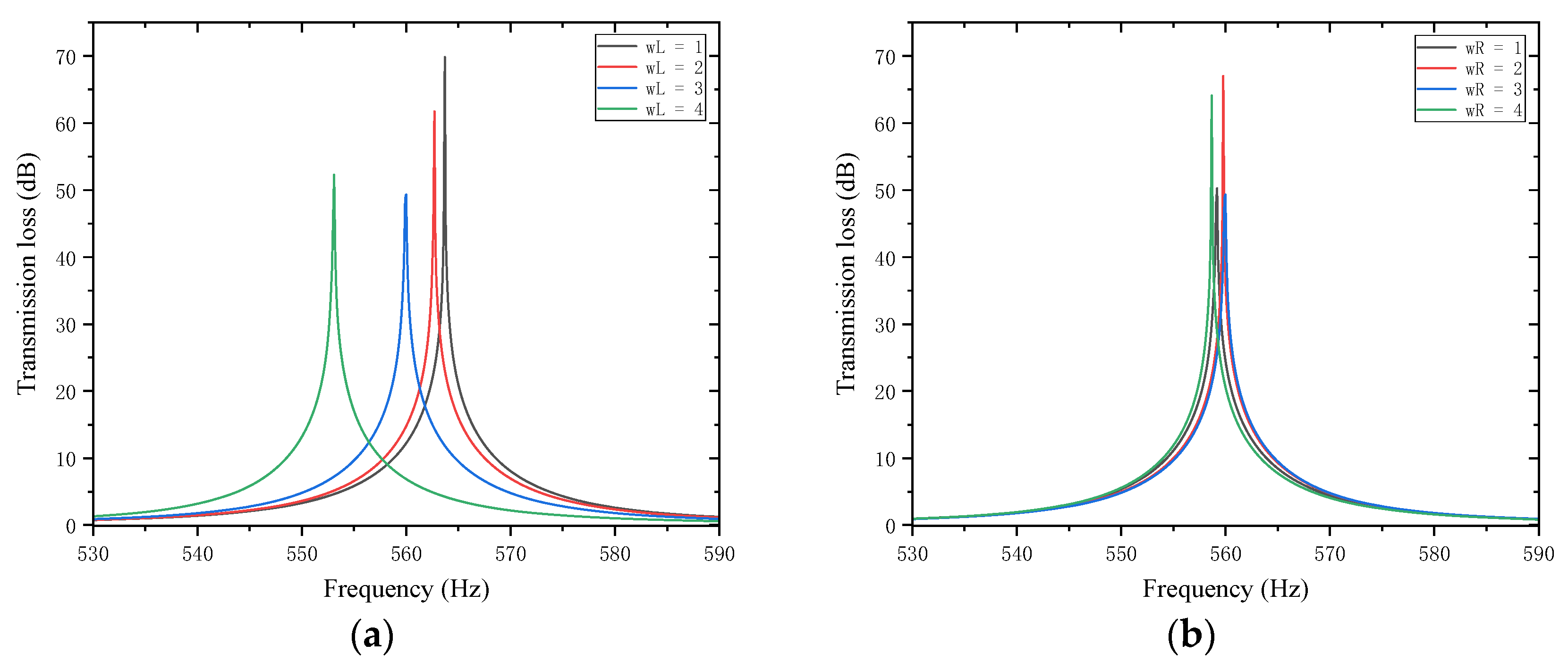

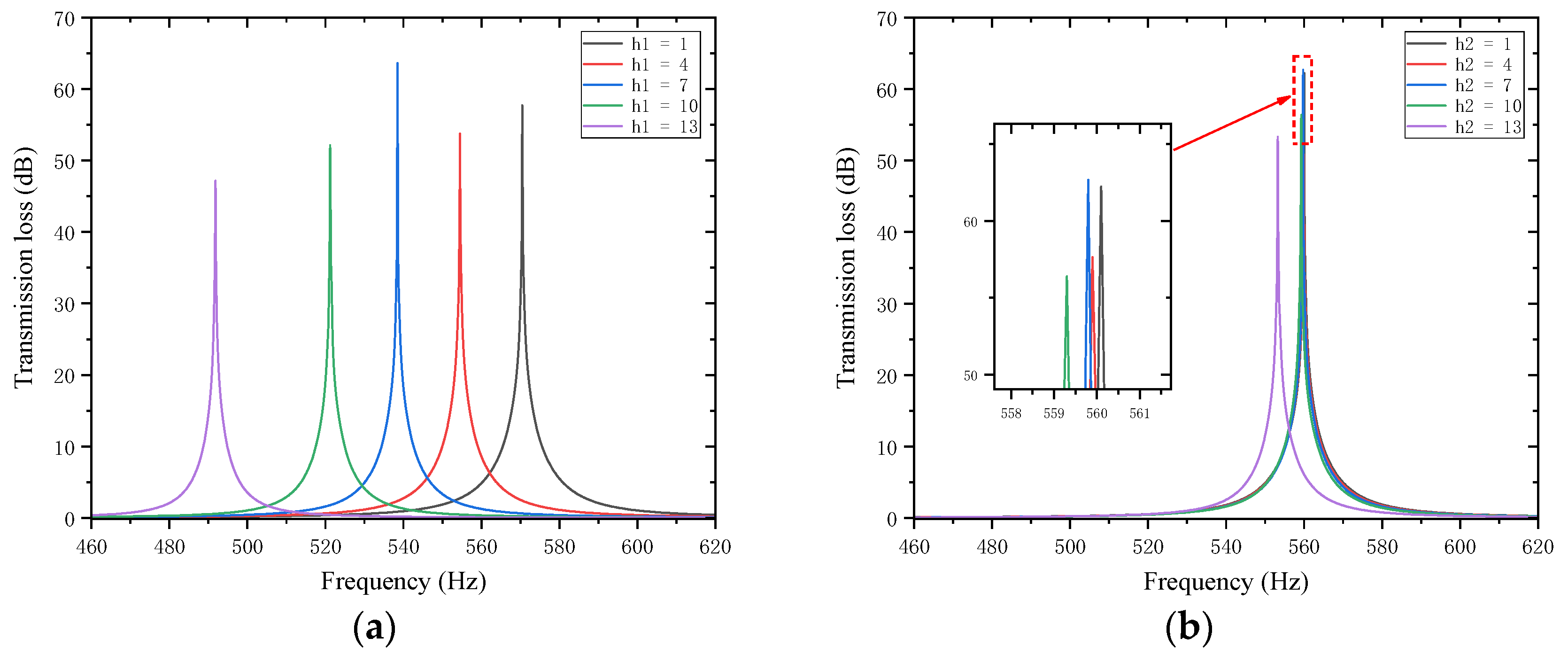

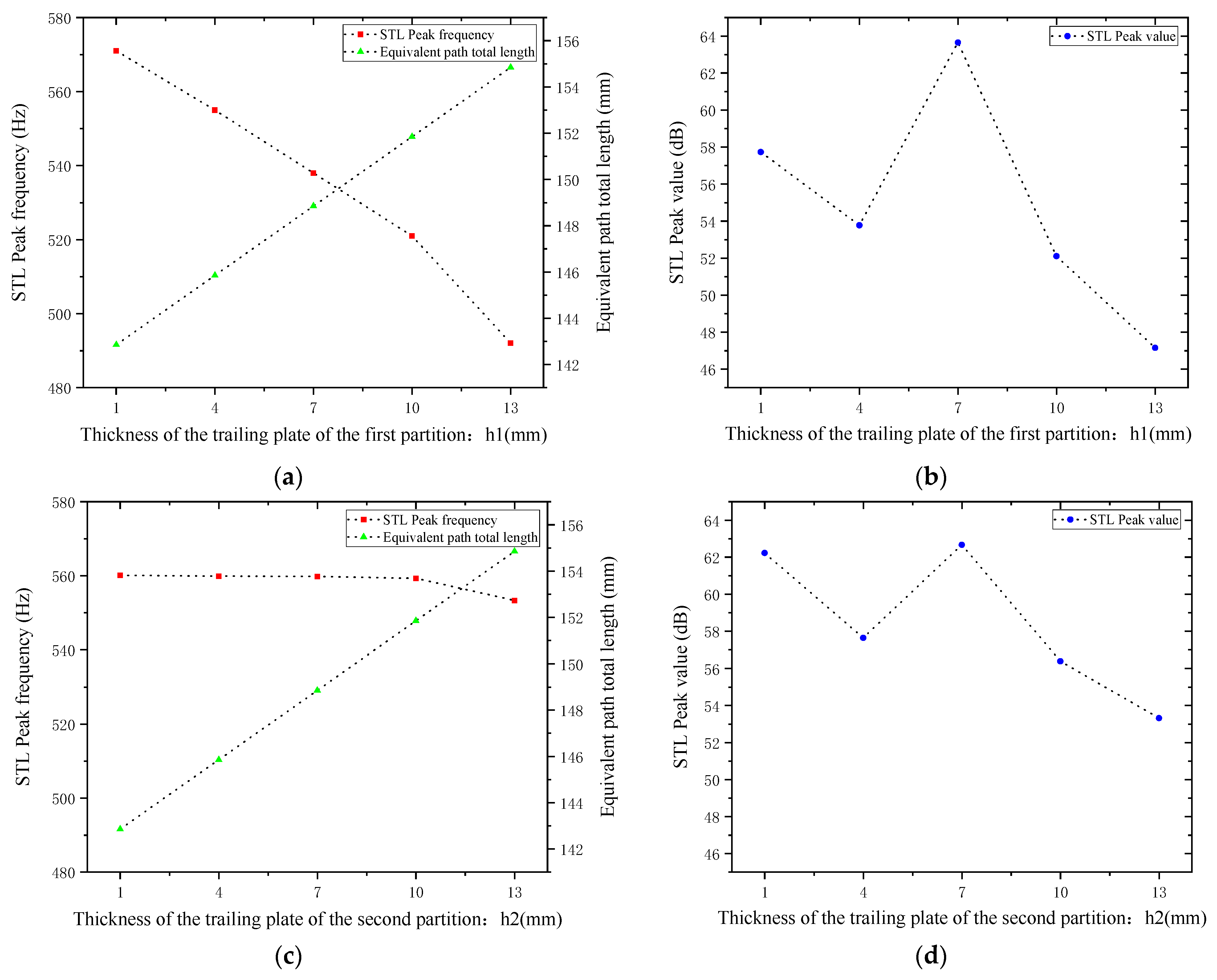

4.5.2. Thickness of the Trailing Plates

Sound waves’ interference patterns and overall equivalent path length and resonance frequency are also impacted by variations in the thickness of the trailing plates that are attached to the first and second partitions. With other parameters kept unchanged, the thicknesses of the trailing plates attached to the first and second partitions

and

were adjusted to 1, 4, 7, 10, and 13 mm, respectively. The sound transmission loss curves of the acoustic metamaterial under these corresponding parameters were calculated, and the amplitude–frequency characteristic curves are shown in

Figure 26 below, with the comparative curves of noise reduction performance shown in

Figure 27.

As shown in

Figure 26 and

Figure 27, increasing

and

leads to an increase in the total equivalent path length, with the peak frequency shifting toward lower frequencies. The STL peak magnitude exhibits the same trend: it first decreases, then increases, and decreases again as the length increases. Specifically, the STL peak magnitude reaches the maximum when

is 7 mm and when

is 1 mm or 7 mm, which is attributed to intense interference and high acoustic impedance. Moreover, the peak magnitudes are almost all above 50 dB. Therefore, the thickness of the partition trailing appendage plates should be adjusted appropriately to achieve the optimal sound attenuation effect.