Microstructure Evolution and Strengthening Mechanism of V-N Microalloyed Invar Alloy Processed by Mechanical Heat Treatment

Highlights

- A novel strategy to prepare high-strength and low coefficient of thermal expansion (CTE) invar alloy by combining deformation strengthening with V(C, N) precipitation strengthening mechanism.

- Prefabricated defects promote intensive nucleation of V(C, N) fine precipitates.

- The alloy achieves a tensile strength of 907 MPa and a low CTE value of 1.31 × 10−6/°C.

Abstract

1. Introduction

2. Material and Methods

2.1. Material Preparation and Heat Treatment Procedures

2.2. Material Characterization

2.3. Material Properties

3. Discussion

3.1. Mechanical Properties

3.2. Microstructure

3.2.1. Microstructure Characterization

3.2.2. Precipitation Phases Characterization

3.2.3. Microstructure Evolution

3.3. Evaluation of Strengthening Mechanism

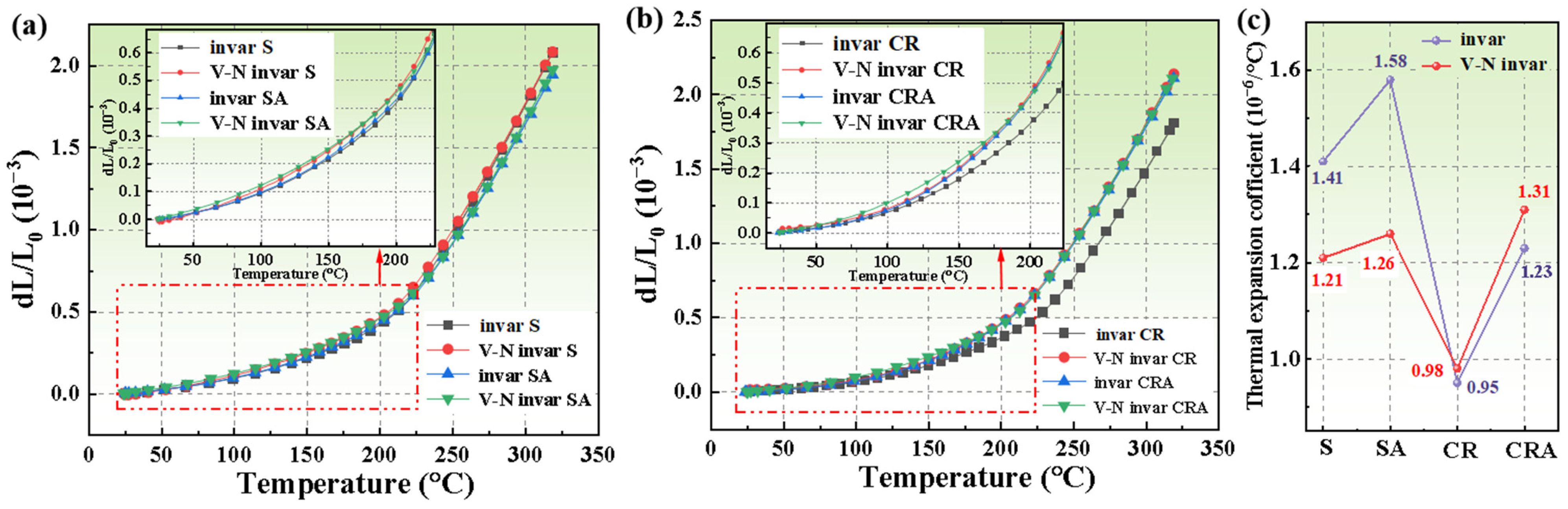

3.4. Thermal Expansion Behavior

4. Conclusions

- (1)

- The V-N microalloyed invar alloys exhibited superior mechanical properties compared to invar alloys, under both direct aging and post-deformation aging treatments. The V-N microalloyed invar alloys achieved a tensile strength of 907 MPa after cold-rolling aging at 650 °C for 3 h.

- (2)

- During direct aging, coarse V (C, N) particles contributed to limited precipitation strengthening, resulting in a relatively moderate strength enhancement in V-N microalloyed invar alloys. In contrast, cold-rolling aging significantly generated a dislocation density that promoted the intensive nucleation of V (C, N) fine precipitates. The synergistic combination of dislocation strengthening and precipitation strengthening mechanisms enabled substantial strength improvement in cold-deformed V-N microalloyed invar alloys.

- (3)

- V-N microalloyed invar alloys exhibited an increased CTE value due to finer grains and the precipitation of V (C, N) to invar alloys. However, the high density of dislocations induced by cold rolling resulted in a low CTE of 1.31 × 10−6/°C.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sahoo, A.; Medicherla, V. Fe-Ni Invar alloys: A review. Mater. Today Proc. 2021, 43, 2242–2244. [Google Scholar] [CrossRef]

- Tan, H.; Wang, Y.; Wang, G.; Zhang, F.; Fan, W.; Feng, Z.; Lin, X. Investigation on microstructure and properties of laser solid formed low expansion Invar 36 alloy. J. Mater. Res. Technol. 2020, 9, 5827–5839. [Google Scholar] [CrossRef]

- Zou, Y.; Ma, B.; Cui, H.; Lu, F.; Xu, P. Microstructure, wear, and oxidation resistance of nanostructured carbide-strengthened cobalt-based composite coatings on Invar alloys by laser cladding. Surf. Coat. Technol. 2020, 381, 125188. [Google Scholar] [CrossRef]

- Li, Y.; Wang, F.; Liu, H.; Yang, L.; Zhang, P.; Wang, Y.; Li, H. Effect of surface roughness on the performances of laser-welded Invar 36 alloy joints. Opt. Laser Technol. 2023, 162, 109397. [Google Scholar] [CrossRef]

- Chen, C.; Ma, B.; Liu, B.; He, J.; Xue, H.; Zuo, Y.; Li, X. Refinement mechanism and physical properties of arc melted invar alloy with different modifiers. Mater. Chem. Phys. 2019, 227, 138–147. [Google Scholar] [CrossRef]

- Yang, Q.; Wei, K.; Yang, X.; Xie, H.; Qu, Z.; Fang, D. Microstructures and unique low thermal expansion of Invar 36 alloy fabricated by selective laser melting. Mater. Charact. 2020, 166, 110409. [Google Scholar] [CrossRef]

- Jiao, G.; Fang, X.; Chen, X.; Xi, N.; Zhang, M.; Liu, Y.; Wu, H.; Huang, K. The origin of low thermal expansion coefficient and enhanced tensile properties of Invar alloy fabricated by directed energy deposition. J. Mech. Work. Technol. 2023, 317, 117994. [Google Scholar] [CrossRef]

- Akgul, B.; Kul, M.; Erden, F. The puzzling thermal expansion behavior of invar alloys: A review on process-structure-property relationship. Crit. Rev. Solid State Mater. Sci. 2023, 49, 254–307. [Google Scholar] [CrossRef]

- Qiu, C.; Liu, Y.; Liu, H. Influence of addition of TiAl particles on microstructural and mechanical property development in Invar 36 processed by laser powder bed fusion. Addit. Manuf. 2021, 48, 102457. [Google Scholar] [CrossRef]

- Arora, A.; Mula, S. Phase evolution characteristics, thermal stability, and strengthening processes of Fe–Ni based ODS invar steel produced by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 2022, 856, 143972. [Google Scholar] [CrossRef]

- Zhao, Q.; Wu, Y.; He, J.; Yao, Y.; Sun, Z.; Peng, H. Effect of cold drawing on microstructure and properties of the invar alloy strengthened by carbide-forming elements. J. Mater. Res. Technol. 2021, 13, 1012–1019. [Google Scholar] [CrossRef]

- Song, H.-Y.; Wang, G.-D.; Liu, H.-T. Effect of cold rolling on microstructure and texture evolution in strip casting Fe-36%Ni invar alloy foil. J. Alloys Compd. 2021, 888, 161519. [Google Scholar] [CrossRef]

- Nakama, K.; Tatsutani, S.; Sugita, K.; Shirai, Y. Strengthening of Fe-36mass%Ni low thermal expansion alloy by additions of C, V, Ti, and Cr and the effect of reducing Ni on thermal expansion. J. Jpn. Inst. Met. Mater. 2014, 78, 37–44. [Google Scholar] [CrossRef]

- Sui, Q.; He, J.; Zhang, X.; Sun, Z.; Zhang, Y.; Wu, Y.; Zhu, Z.; Zhang, Q.; Peng, H. Strengthening of the Fe-Ni invar alloy through chromium. Materials 2019, 12, 1297. [Google Scholar] [CrossRef] [PubMed]

- Nakama, K.; Sugita, K.; Shirai, Y. Effect of MC Type Carbides on Age Hardness and Thermal Expansion of Fe–36 wt%Ni–0.2 wt%C Alloy. Met. Microstruct. Anal. 2013, 2, 383–387. [Google Scholar] [CrossRef]

- Zaitsev, A.; Arutyunyan, N.; Koldaev, A. Hot Ductility, Homogeneity of the Composition, Structure, and Properties of High-Strength Microalloyed Steels: A Critical Review. Metals 2023, 13, 1066. [Google Scholar] [CrossRef]

- Su, Y.; Yang, X.; Meng, T.; He, X.; Wu, D.; Li, W.; Yin, S. Strengthening mechanism and forming control of linear friction welded GH4169 alloy joints. Chin. J. Aeronaut. 2024, 37, 609–626. [Google Scholar] [CrossRef]

- Sobotka, E.; Kreyca, J.; Fuchs, N.; Wojcik, T.; Kozeschnik, E.; Povoden-Karadeniz, E. The Role of MX Carbonitrides for the Particle-Stimulated Nucleation of Ferrite in Microalloyed Steel. Met. Mater. Trans. A 2023, 54, 2903–2923. [Google Scholar] [CrossRef]

- Sui, Q.; Li, J.; Zhai, Y.; Sun, Z.; Wu, Y.; Zhao, H.; Feng, J.; Sun, M.; Yang, C.; Chen, B.; et al. Effect of alloying with V and Ti on microstructures and properties in Fe–Ni–Mo–C invar alloys. Materialia 2019, 8, 100474. [Google Scholar] [CrossRef]

- Yun, A.; Yun, S.; Ha, T.; Song, J.; Lee, K. Effects of V and C additions on the Thermal Expansion and Tensile Properties of a High Strength Invar Base Alloy. Trans. Mater. Process. 2015, 24, 44–51. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Zhou, Y.; Dong, X.; Zhang, C.; Cao, G.; Schneider, R.; Gerthsen, D. Effect of precipitation of (Ti,V)N and V(C,N) secondary phases on mechanical properties of V and N microalloyed 1Cr steels. Mater. Sci. Eng. A 2018, 738, 203–212. [Google Scholar] [CrossRef]

- Wang, Z.; Hui, W.; Chen, Z.; Zhang, Y.; Zhao, X. Effect of vanadium on microstructure and mechanical properties of bainitic forging steel. Mater. Sci. Eng. A 2020, 771, 138653. [Google Scholar] [CrossRef]

- Ren, J.-K.; Chen, Q.-Y.; Chen, J.; Liu, Z.-Y. Role of vanadium additions on tensile and cryogenic-temperature charpy impact properties in hot-rolled high-Mn austenitic steels. Mater. Sci. Eng. A 2021, 811, 141063. [Google Scholar] [CrossRef]

- Zhao, F.; Wu, M.; Jiang, B.; Zhang, C.; Xie, J.; Liu, Y. Effect of nitrogen contents on the microstructure and mechanical properties of V-Ti microalloyed steels for the forging of crankshafts. Mater. Sci. Eng. A 2018, 731, 360–368. [Google Scholar] [CrossRef]

- Wei, D.; Gong, W.; Wang, L.; Tang, B.; Kawasaki, T.; Harjo, S.; Kato, H. Strengthening of high-entropy alloys via modulation of cryo-pre-straining-induced defects. J. Mater. Sci. Technol. 2022, 129, 251–260. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Chandiran, E.; Dong, H.-K.; Kamikawa, N.; Miyamoto, G.; Furuhara, T. Current Understanding of Microstructure and Properties of Micro-Alloyed Low Carbon Steels Strengthened by Interphase Precipitation of Nano-Sized Alloy Carbides: A Review. JOM 2021, 73, 3214–3227. [Google Scholar] [CrossRef]

- Yang, H.; Li, K.; Bu, Y.; Wu, J.; Fang, Y.; Meng, L.; Liu, J.; Wang, H. Nanoprecipitates induced dislocation pinning and multiplication strategy for designing high strength, plasticity and conductivity Cu alloys. Scr. Mater. 2021, 195, 113741. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, X.; Lei, M.; Fang, X.; Li, S.; Wu, Y.; Mi, Z. Microstructure evolution and strengthening mechanism of air-hardening steel subjected to the austenitizing annealing treatment. Mater. Res. Express 2023, 10, 106502. [Google Scholar] [CrossRef]

- Park, S.J.; Jo, S.-H.; Kim, J.G.; Kim, J.; Lee, R.; Oh, Y.-S.; Kim, S.-J.; Lee, H.W.; Kang, S.-H.; Jung, J. Evolution of Microstructure, Mechanical Properties and Residual Stress of a Cold Rolled Invar Sheet Due to Heat Treatment. Metals 2022, 12, 110. [Google Scholar] [CrossRef]

- Boudekhani-Abbas, S.; Tirsatine, K.; Azzeddine, H.; Alili, B.; Helbert, A.L.; Brisset, F.; Baudin, T.; Bradai, D. Texture, microstructure and mechanical properties evolution in Fe-x (x = 36 and 48 wt.%) Ni alloy after accumulative roll bonding. IOP Conf. Ser. Mater. Sci. Eng. 2018, 375, 012034. [Google Scholar] [CrossRef]

- Yang, M.; Huang, C.; Han, J.; Wu, H.; Zhao, Y.; Yang, T.; Jin, S.; Wang, C.; Li, Z.; Shu, R.; et al. Development of the high-strength ductile ferritic alloys via regulating the intragranular and grain boundary precipitation of G-phase. J. Mater. Sci. Technol. 2022, 136, 180–199. [Google Scholar] [CrossRef]

- Dong, L.; Yang, F.; Xu, M.; Hu, X.; Fang, F. Effect of Cold-Drawn Deformation on Microstructure and Properties of Invar Alloy Wires. J. Mater. Eng. Perform. 2024, 34, 6500–6509. [Google Scholar] [CrossRef]

- Yao, Y.; Zhao, Q.; Zhang, C.; He, J.; Wu, Y.; Meng, G.; Chen, C.; Sun, Z.; Peng, H. Effect of warm rolling on microstructures and properties of the high strength invar alloy. J. Mater. Res. Technol. 2022, 19, 3046–3058. [Google Scholar] [CrossRef]

- Yong, Q. Secondary Phase in Steels; Metallurgical Industry Press: Bejing, China, 2006. [Google Scholar]

- Zhang, J.-W.; Cao, Y.-G.; Zhang, C.-G.; Li, Z.-D.; Wang, W.-X. Effect of Nb addition on microstructure and mechanical properties of 25CrNiMoV (DZ2) steel for high-speed railway axles. J. Iron Steel Res. Int. 2021, 29, 802–809. [Google Scholar] [CrossRef]

- Zeng, T.; Zhang, S.; Shi, X.; Wang, W.; Yan, W.; Yang, K. Effect of NbC and VC carbides on microstructure and strength of high-strength low-alloyed steels for oil country tubular goods. Mater. Sci. Eng. A 2021, 824, 141845. [Google Scholar] [CrossRef]

- Gu, J.; Li, J.; Chang, R.; Li, L. Comprehensive effect of nitrogen on Cr-Mo-V hot-working die steel with enhanced strength and toughness. Mater. Sci. Eng. A 2019, 766, 138386. [Google Scholar] [CrossRef]

- Kondorsky, E.I.; Sedov, V.L. Antiferromagnetism of Iron in Face-Centered Crystalline Lattice and the Causes of Anomalies in Invar Physical Properties. J. Appl. Phys. 1960, 31, S331–S335. [Google Scholar] [CrossRef]

- Kul, M.; Akgül, B.; Karabay, Y.Z.; Pehlivanoğlu, K.; Türkyaman, B. A study of the effect of Ti-Al-V microalloying on the mechanical and physical properties of invar 36. Mater. Today Commun. 2024, 39, 109050. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Feng, L.; Wang, Y.; Sun, Z.; Zhang, J. Promoting nanoprecipitates via prefabricated defects to pin dislocations and grain boundaries for trading off high-strength and low-thermal-expansion of invar alloys. J. Alloys Compd. 2024, 994, 174770. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, Y.; Jiang, Z.; Huang, J. Effects of Trace Additions of Magnesium on Microstructure and Properties of Fe–36Ni Invar Alloy. Steel Res. Int. 2023, 94, 2300047. [Google Scholar] [CrossRef]

- Li, W.; Vittorietti, M.; Jongbloed, G.; Sietsma, J. The combined influence of grain size distribution and dislocation density on hardness of interstitial free steel. J. Mater. Sci. Technol. 2020, 45, 35–43. [Google Scholar] [CrossRef]

- Kul, M.; Akgul, B.; Karabay, Y.Z. The relationship of hot and cold rolling processes with the structure and properties of invar 36. Mater. Chem. Phys. 2022, 295, 127215. [Google Scholar] [CrossRef]

| Scheme | C | Si | Mn | S | P | V | N | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| invar | 0.022 | 0.17 | 0.31 | 0.001 | 0.006 | - | - | 36.10 | Bal |

| V-N invar | 0.300 | 0.16 | 0.31 | 0.001 | 0.008 | 1.0 | 0.022 | 36.02 | Bal |

| Invar S | V-N Invar S | Invar SA | V-N Invar SA | |

|---|---|---|---|---|

| ε (microstrain) | 0.0195 | 0.1000 | 0.0025 | 0.0510 |

| Dislocation density (m−2) | 1.70 × 1012 | 2.30 × 1013 | 2.18 × 1011 | 1.17 × 1013 |

| Invar CR | Invar CRA | V-N Invar CR | V-N Invar CRA | |

|---|---|---|---|---|

| ε (microstrain) | 0.1345 | 0.1015 | 0.1824 | 0.1759 |

| Dislocation density (m−2) | 1.69 × 1013 | 1.28 × 1013 | 10.74 × 1013 | 9.76 × 1013 |

| Samples | σ0/MPa | σss/MPa | σg/MPa | σdis/MPa | σp/MPa | σcal/MPa | σexp/MPa |

|---|---|---|---|---|---|---|---|

| SA-2 h | 54 | 50.7 | 102.1 | 107.9 | 6.1 | 320.8 | 315 |

| CRA-3 h | 54 | 37.4 | 162.5 | 311.8 | 270.0 | 835.7 | 835 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Liu, X.; Liu, H.; Yu, Y.; Chang, C.; Di, Y. Microstructure Evolution and Strengthening Mechanism of V-N Microalloyed Invar Alloy Processed by Mechanical Heat Treatment. Materials 2025, 18, 3934. https://doi.org/10.3390/ma18173934

Zhang S, Liu X, Liu H, Yu Y, Chang C, Di Y. Microstructure Evolution and Strengthening Mechanism of V-N Microalloyed Invar Alloy Processed by Mechanical Heat Treatment. Materials. 2025; 18(17):3934. https://doi.org/10.3390/ma18173934

Chicago/Turabian StyleZhang, Shuo, Xueting Liu, Hui Liu, Yanchong Yu, Cong Chang, and Yanjun Di. 2025. "Microstructure Evolution and Strengthening Mechanism of V-N Microalloyed Invar Alloy Processed by Mechanical Heat Treatment" Materials 18, no. 17: 3934. https://doi.org/10.3390/ma18173934

APA StyleZhang, S., Liu, X., Liu, H., Yu, Y., Chang, C., & Di, Y. (2025). Microstructure Evolution and Strengthening Mechanism of V-N Microalloyed Invar Alloy Processed by Mechanical Heat Treatment. Materials, 18(17), 3934. https://doi.org/10.3390/ma18173934