Industrial-Scale Application of Polymer Dewatering for Fine Tailings Disposal

Abstract

1. Introduction

2. Materials and Methods

2.1. Mineral Sample

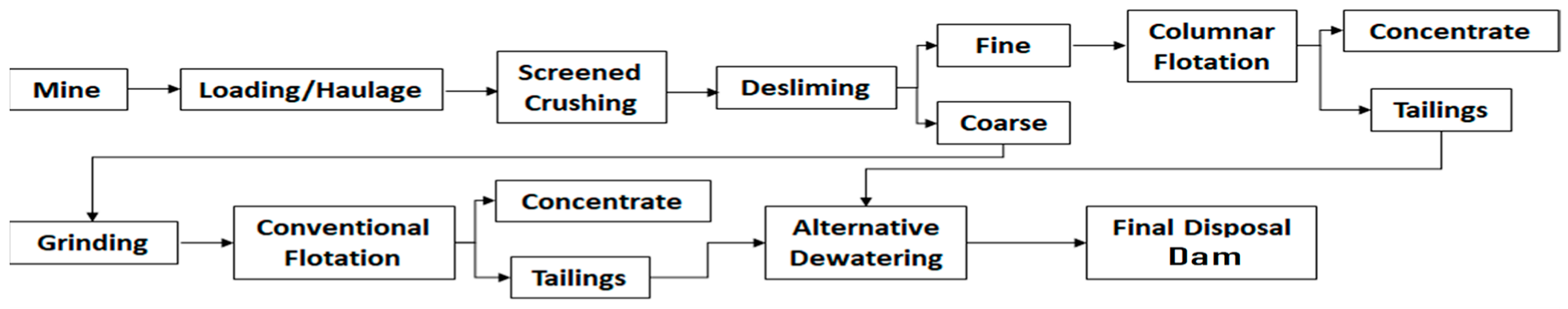

2.2. Alternatives for Tailings Dewatering

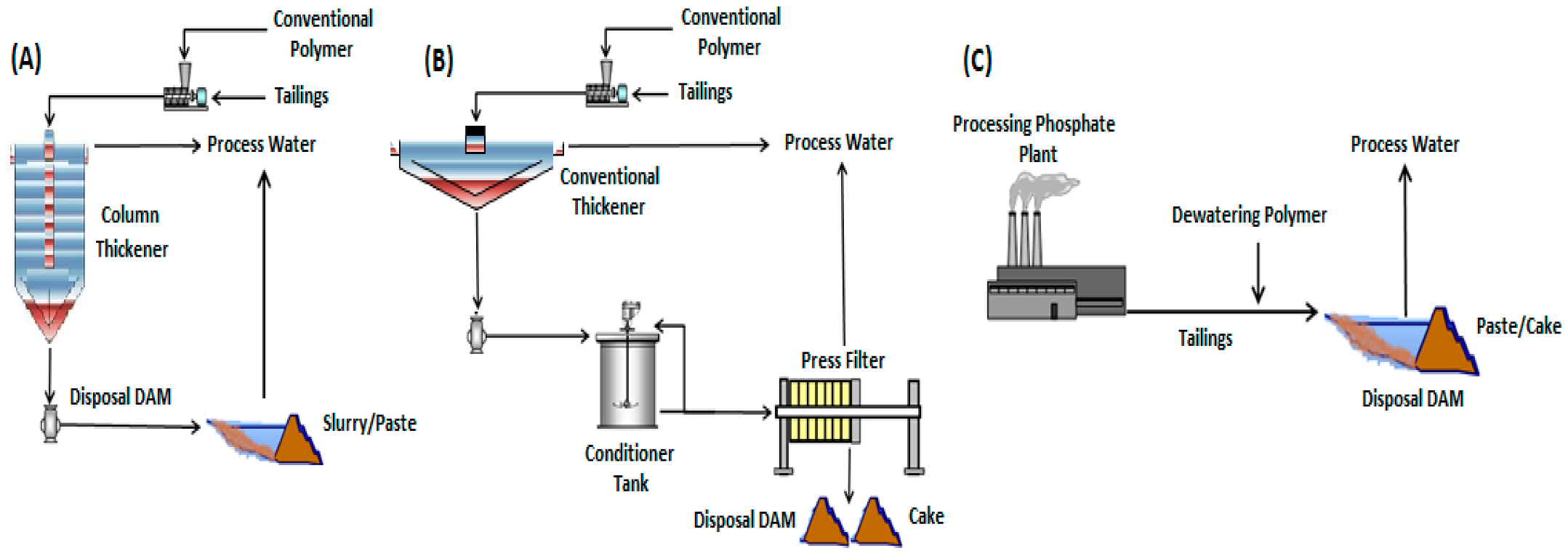

2.3. Alternative Use of Column Thickener with Conventional Polymer

2.4. Alternative Use of Horizontal Filter Press

2.5. Alternative Use of Dewatering Polymer

3. Results and Discussion

3.1. Characterization of Mineral Sample

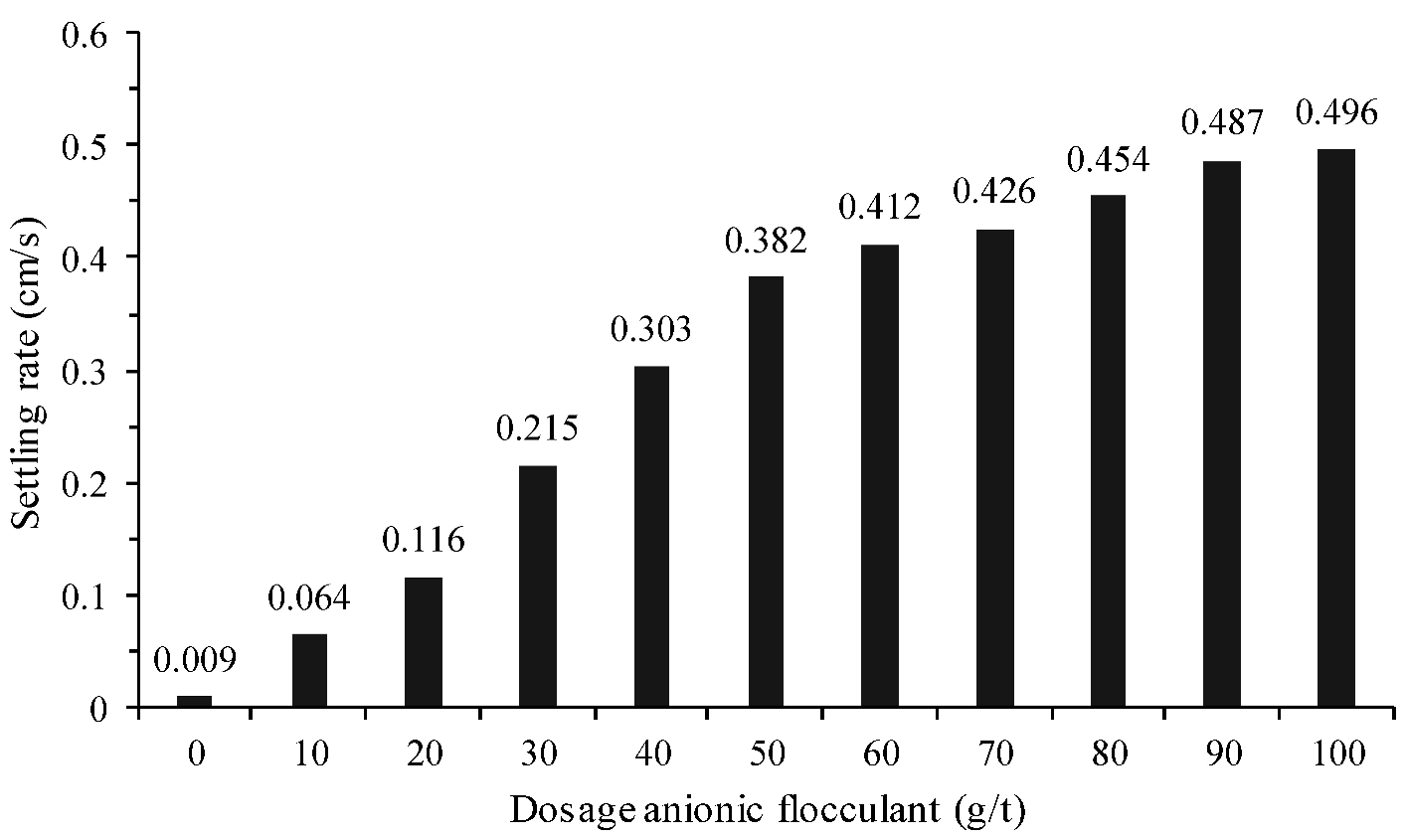

3.2. Tests Using a Column Thickener Using Conventional Polymer

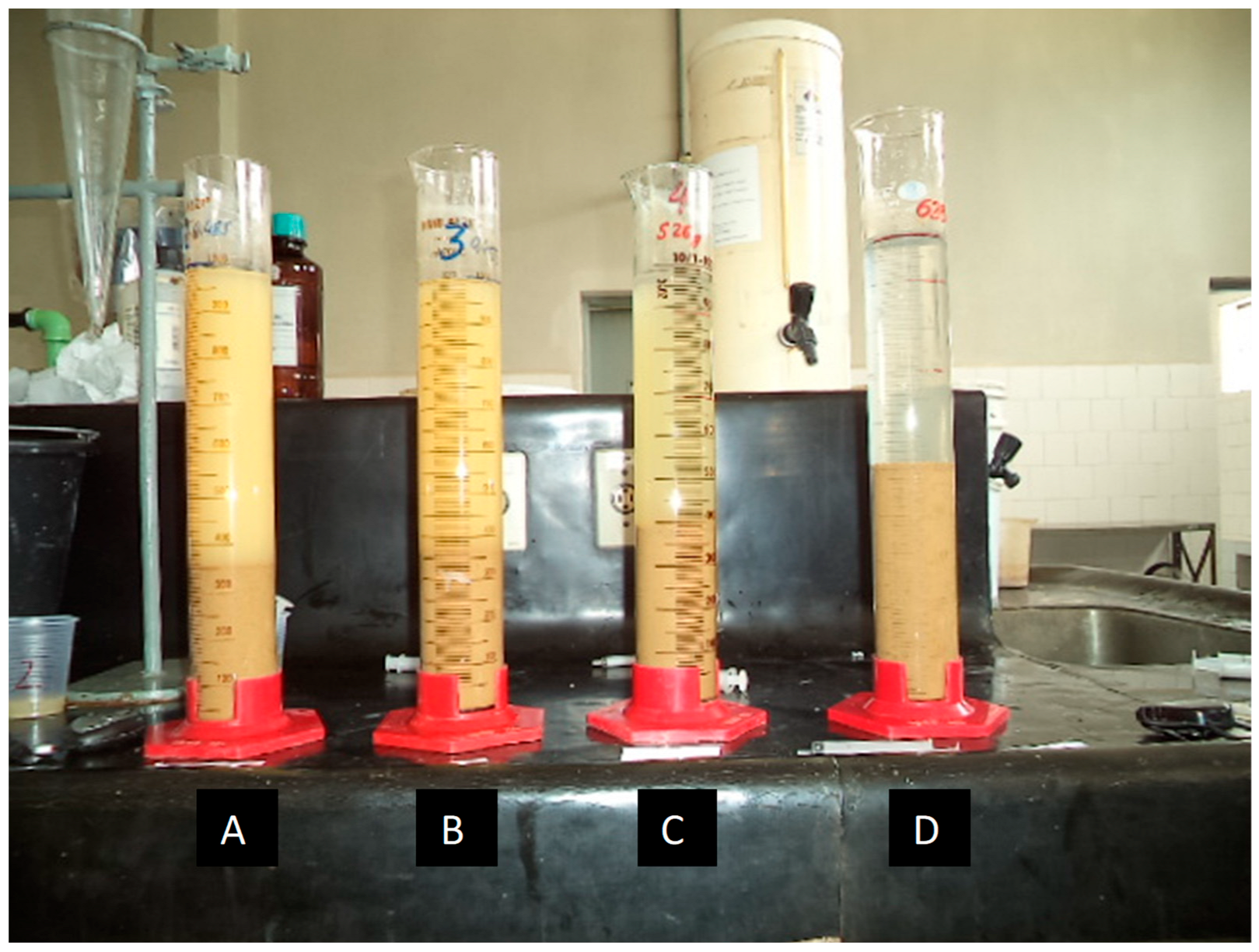

3.3. Tests Using a Horizontal Filter Press

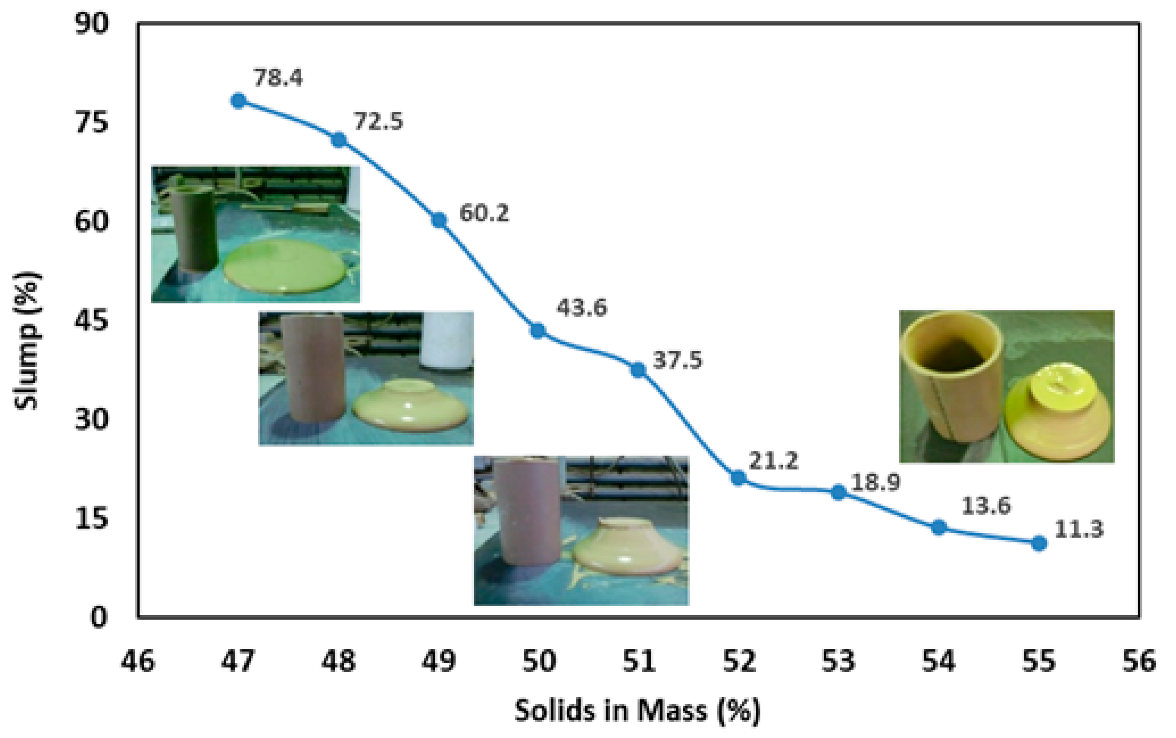

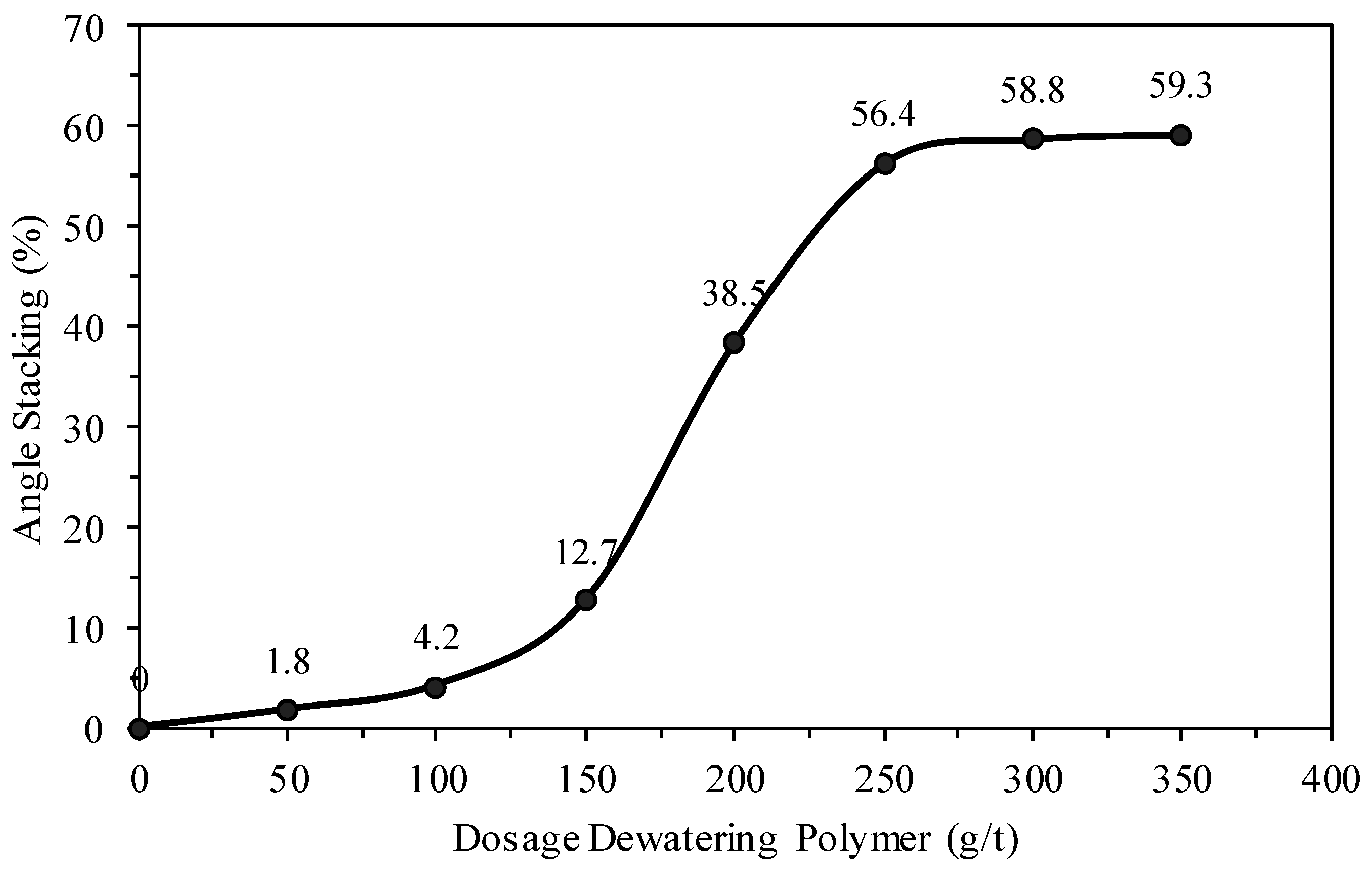

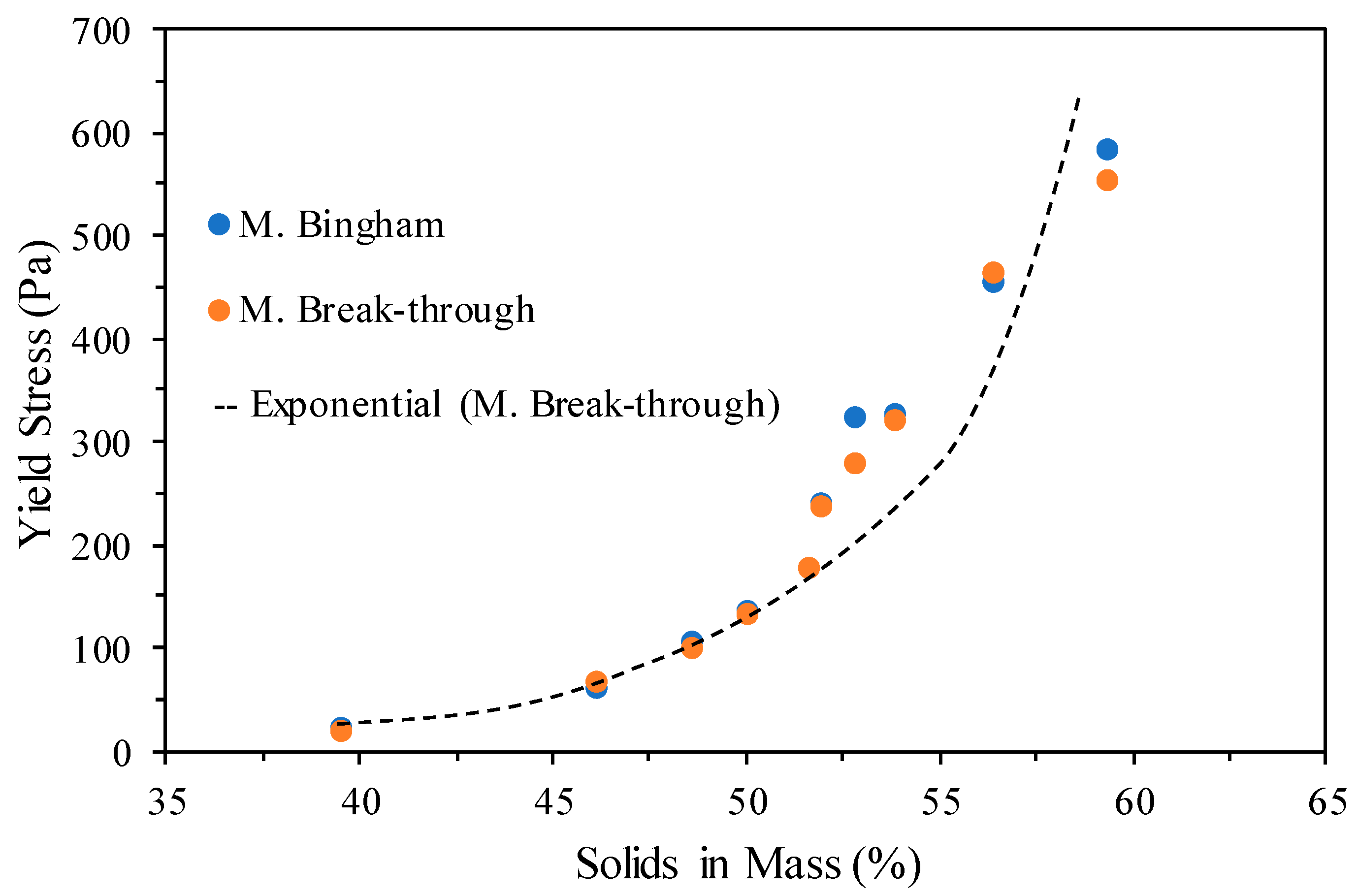

3.4. Test Using Dewatering Polymer

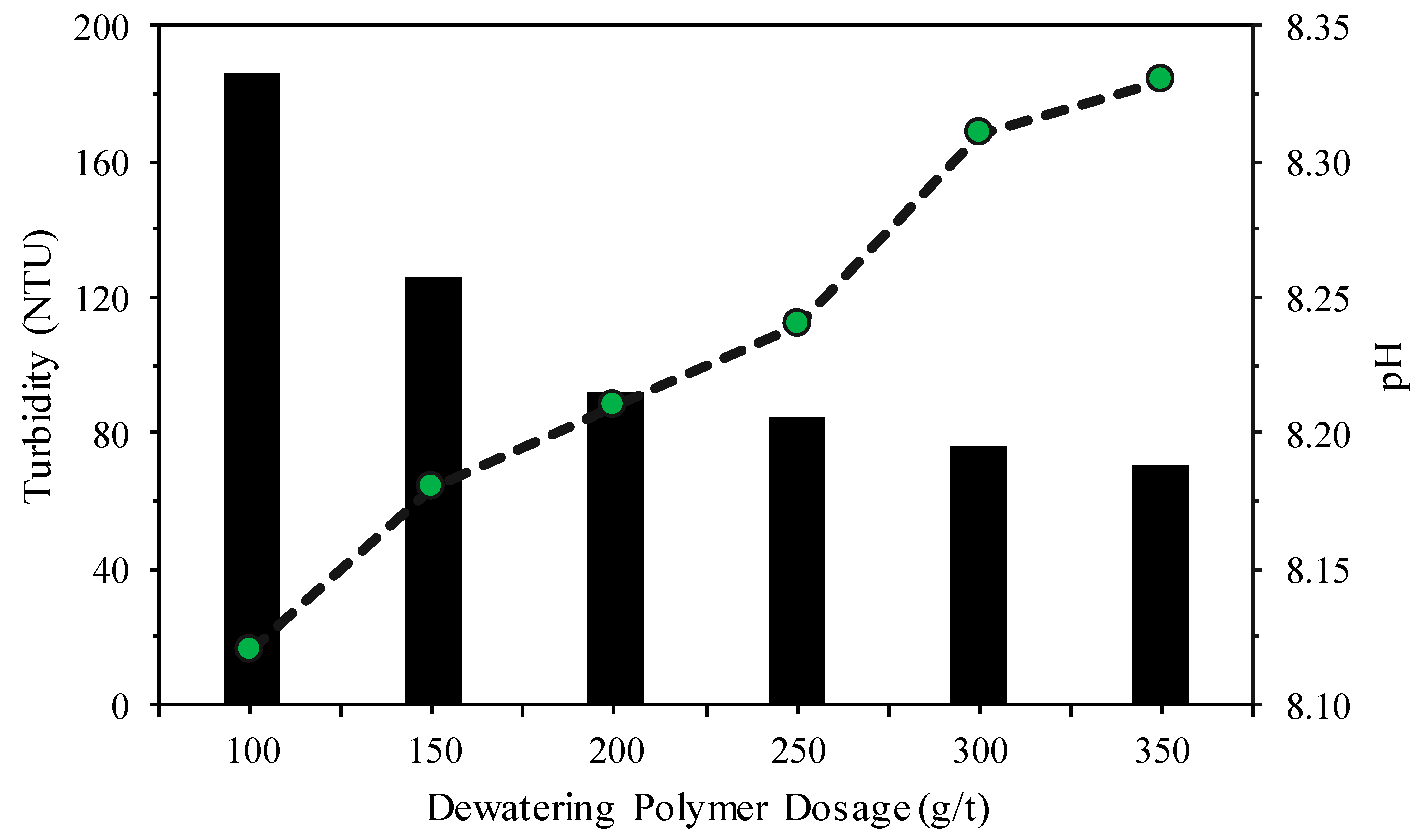

3.5. Analysis of Supernatant and Filtrate Waters from Dewatering Tests

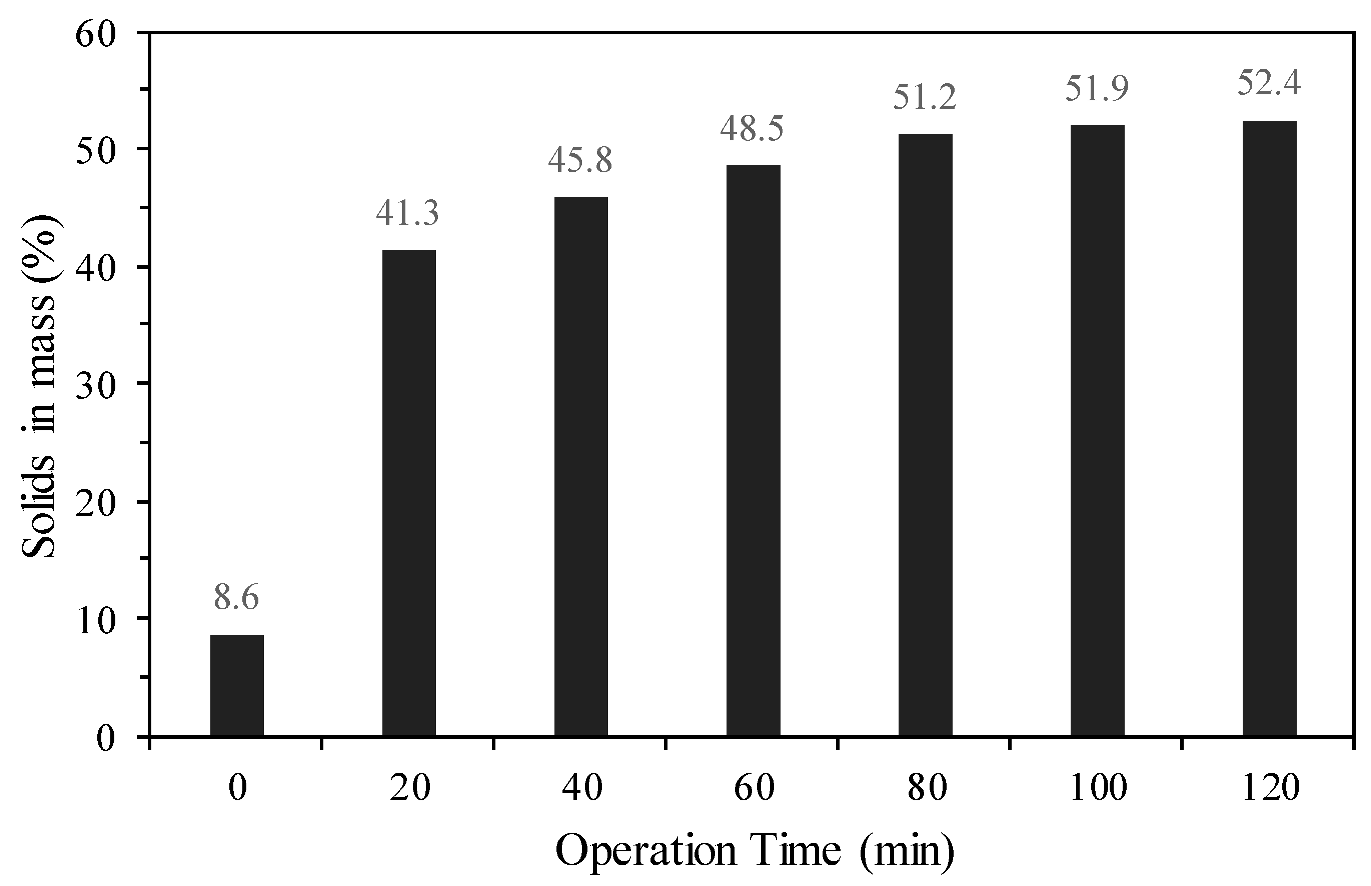

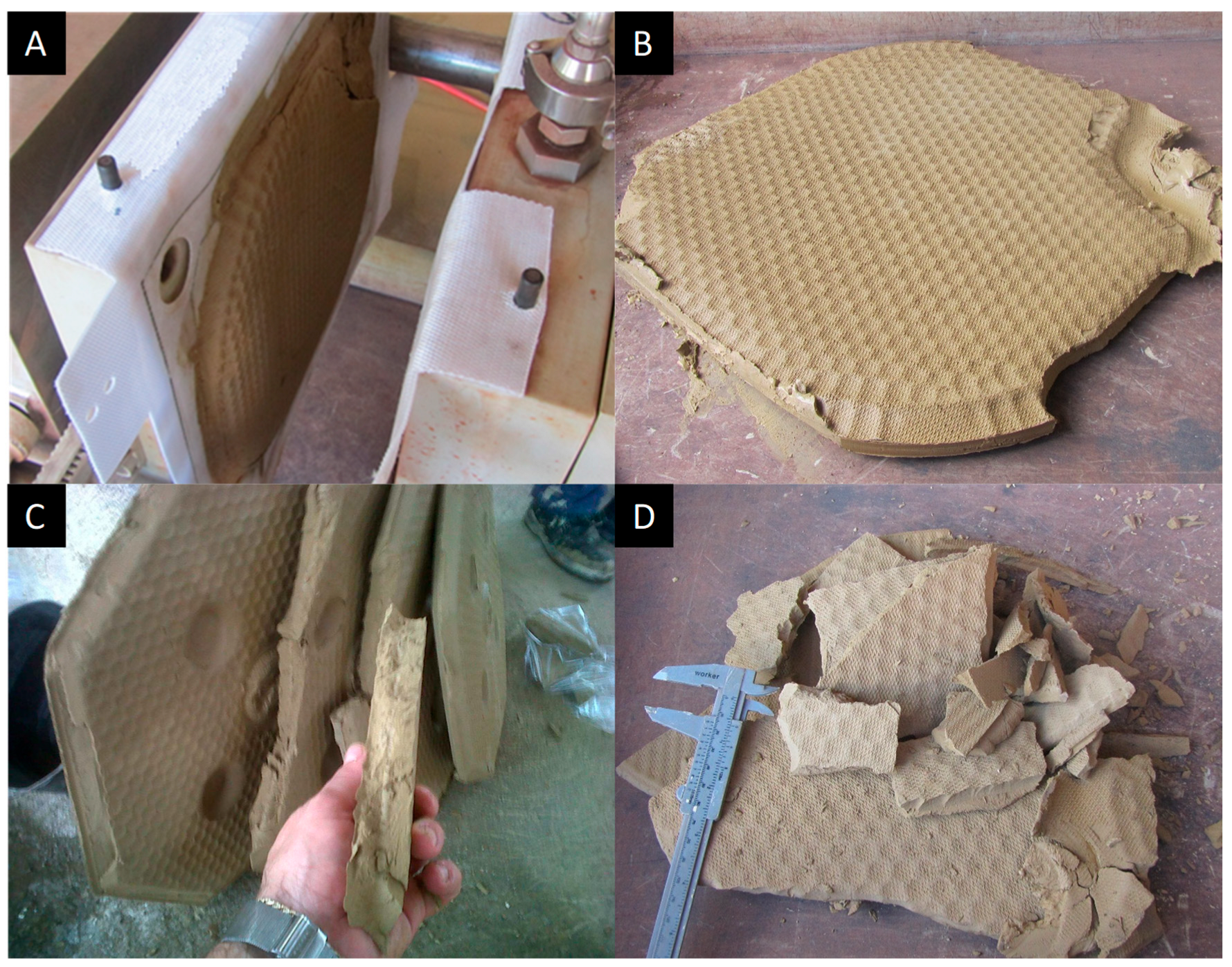

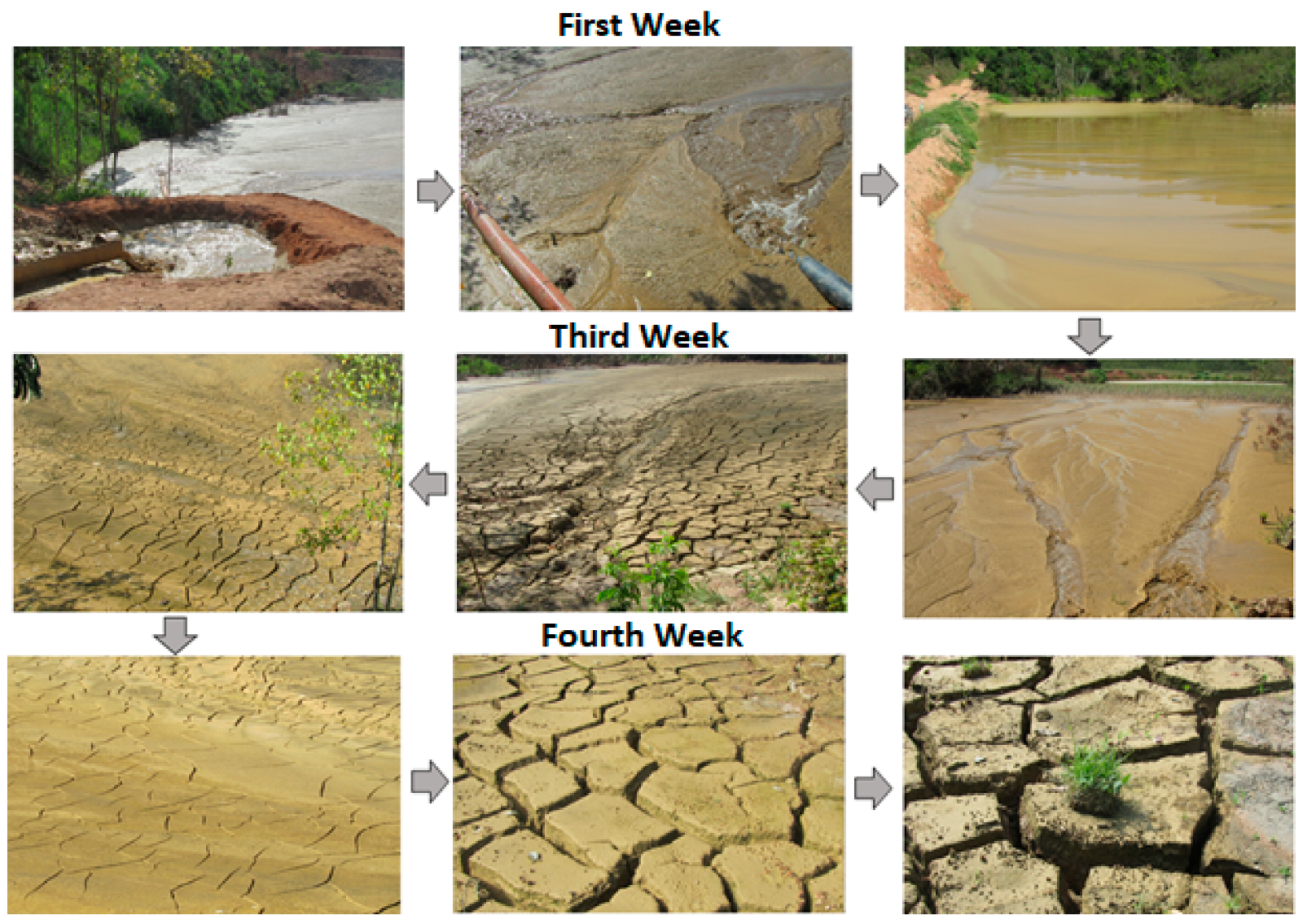

3.6. Industrial Test with Application of Dewatering Polymer

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Qian, W.; Wu, S.; Fang, M.; Qian, X. Water Scarcity in Hebei Province, China: A Predictive Model and Analysis of Contributing Factors. Desalination Water Treat. 2025, 1, 101136. [Google Scholar] [CrossRef]

- Jain, S.K.; Singh, V.P. Water Resources Systems Planning and Management; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Scanlon, B.R.; Fakhreddine, S.; Rateb, A.; de Graaf, I.; Famiglietti, J.; Gleeson, T.; Grafton, R.Q.; Jobbagy, E.; Kebede, S.; Kolusu, S.R.; et al. Global water resources and the role of groundwater in a resilient water future. Nat. Rev. Earth Environ. 2023, 4, 87–101. [Google Scholar] [CrossRef]

- Azadi, Y.; Yaghoubi, J.; Gholizadeh, H.; Gholamrezai, S.; Rahimi-Feyzabad, F. Social barriers to water scarcity adaptation: A grounded theory exploration in arid and semi-arid regions. Agric. Water Manag. 2025, 309, 1093338. [Google Scholar] [CrossRef]

- Tihin, G.L.; Mo, K.H.; Onn, C.C.; Ong, H.C.; Taufiq-Yap, Y.; Lee, H.V. Overview of municipal solid wastes-derived refuse-derived fuels for cement co-processing. Alex. Eng. J. 2023, 84, 153–174. [Google Scholar] [CrossRef]

- Ross, A.G.; Connolly, K.; Vögele, S.; Kuckshinrichs, W. A macro-level analysis of the socio-economic impacts of climate change driven water scarcity: Incorporating behavioural and resilience aspects. Water Res. X 2024, 23, 100223. [Google Scholar] [CrossRef]

- Galvão, A.; Martins, D.; Rodrigues, A.; Manso, M.; Ferreira, J.; Silva, C.M. Green walls with recycled filling media to treat greywater. Sci. Total Environ. 2022, 842, 156748. [Google Scholar] [CrossRef] [PubMed]

- Roshani, A.; Fall, M.; Kennedy, K. Effect of wetting–drying cycles on the desiccation of tailings pre-dewatered with super absorbent polymer. Environ. Geotech. 2024, 11, 673–687. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.; Zhang, S.; Cheng, J.; Wang, Z. Hydraulic analysis of advanced spillway systems in tailings dams under extreme weather conditions. Alex. Eng. J. 2024, 109, 102–111. [Google Scholar] [CrossRef]

- Doi, A.; Nguyen, T.A.; Nguyen, N.N.; Nguyen, C.V.; Raji, F.; Nguyen, A.V. Enhancing shear strength and handleability of dewatered clay-rich coal tailings for dry-stacking. J. Environ. Manag. 2023, 344, 118488. [Google Scholar] [CrossRef]

- Mullett, M. Treatment of tailings water for re-use in an antimony mine. Desalination Water Treat. 2011, 34, 330–335. [Google Scholar] [CrossRef]

- Xu, W.; She, F.; Zeng, W.; Wang, S.; Ding, J.; Yao, X.; Liu, G.; Li, L. Hysteresis of unfrozen water content of tailing mud with freeze-thaw and its correlation with electrical conductivity. Cold Reg. Sci. Technol. 2025, 229, 104362. [Google Scholar] [CrossRef]

- Zhang, L.; Dai, S.; Dai, H.; Xiong, Y.; Jing, X.; Lan, J.; Zhao, X. Fast-dissolving twin-tail hydrophobic association polymers drag reducer with salt endurable and shear resistant for slick-water fracturing fluids. Colloids Surf. A Physicochem. Eng. Asp. 2025, 709, 136171. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, J.; Wang, Y.; Liu, G.; Song, K.; Wu, S.; Tian, L.; Lyu, H. The evaluation of Small River water pollution caused by tailing spill in the Northeast of China using high-resolution images. EIA Rev. 2024, 109, 107633. [Google Scholar] [CrossRef]

- Pereira, P.; Fernandes, L.F.S.; Junior, R.F.D.V.; Silva, M.M.A.P.d.M.; Valera, C.A.; de Melo, M.C.; Pissarra, T.C.T.; Pacheco, F.A.L. The water cycle of small catchments impacted with tailings mudflows: A study in the Ferro-Carvao watershed after the breakup of B1 dam in Brumadinho. Sci. Total Environ. 2024, 949, 174971. [Google Scholar] [CrossRef]

- Conesa, H.M.; Párraga-Aguado, I.M.; Jiménez, F.J.; Querejeta, J.I. Evaluation of the trade-off between water use efficiency and nutrient use efficiency in two semiarid coniferous tree species growing on an organic amended metalliferous mine tailing substrate. Sci. Total Environ. 2024, 940, 173607. [Google Scholar] [CrossRef] [PubMed]

- Alberts, M.E.; Meulen, I.J.V.; Degenhardt, D.; Peru, K.M.; McMartin, D.W.; Headley, J.V. Chemical succession of naphthenic acid fraction compounds in reclamation landscape mesocosms established on centrifuged and co-mixed fluid fine tailings from the Athabasca oil sands. Sci. Total Environ. 2024, 957, 177856. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Sun, Q.; Sun, W.; Han, X.; Zhang, K. Preparation and sintering mechanism of foamed ceramics from iron tailings and feldspar powder. Ceram. Int. 2025, 51, 24123–24135. [Google Scholar] [CrossRef]

- Burchell, J.J.; le Roux, J.; Craig, I. Nonlinear model predictive control for improved water recovery and throughput stability for tailings reprocessing. Control. Eng. Pract. 2023, 131, 105385. [Google Scholar] [CrossRef]

- Ruppen, D.; Runnalls, J.; Tshimanga, R.M.; Wehrli, B.; Odermatt, D. Optical remote sensing of large-scale water pollution in Angola and DR Congo caused by the Catoca mine tailings spill. Int. J. Appl. Earth Obs. Geoinf. 2023, 118, 103237. [Google Scholar] [CrossRef]

- Ettoumi, M.; Jouini, M.; Neculita, C.; Bouhlel, S.; Coudert, L.; Haouech, I.; Benzaazoua, M. Characterization of Kef Shfeir phosphate sludge (Gafsa, Tunisia) and optimization of its dewatering. J. Environ. Manag. 2020, 254, 109801. [Google Scholar] [CrossRef] [PubMed]

- Walan, P.; Davidsson, S.; Johansson, S.; Höök, M. Phosphate rock production and depletion: Regional disaggregated modeling and global implications. Resour. Conserv. Recycl. 2014, 93, 178–187. [Google Scholar] [CrossRef]

- Filippelli, G.M. Phosphate rock formation and marine phosphorus geochemistry: The deep time perspective. Chemosphere 2011, 84, 759–766. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Lin, Z.; Zhang, R. Impact of phosphate mining and separation of mined materials on the hydrology and water environment of the Huangbai River basin, China. Sci. Total Environ. 2016, 543, 347–356. [Google Scholar] [CrossRef] [PubMed]

- Bergani, A.; Taha, Y.; Ait-Khouia, Y.; Hakkou, R.; Benzaazoua, M. Enhancing flocculation and dewatering performance of fine phosphate tailings: A sustainable approach for water resources management. Sep. Purif. Technol. 2025, 359, 130377. [Google Scholar] [CrossRef]

- Reid, C.; Bécaert, V.; Aubertin, M.; Rosenbaum, R.K.; Deschênes, L. Life cycle assessment of mine tailings management in Canada. J. Clean. Prod. 2009, 17, 471–479. [Google Scholar] [CrossRef]

- Toprak, N.A.; Altun, O. Considering hydrocyclone operation for tailings dewatering purpose and its effects on product specifications of paste backfill operations. Miner. Eng. 2021, 173, 107176. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Chan, B.; Bouzalakos, S.; Dudeney, A. Integrated waste and water management in mining and metallurgical industries. Trans. Nonferrous Met. Soc. China 2008, 18, 1497–1505. [Google Scholar] [CrossRef]

- Sharma, R.; Al-Busaidi, T. Groundwater pollution due to a tailings dam. Eng. Geol. 2001, 60, 235–244. [Google Scholar] [CrossRef]

- Ghandashtani, M.B.; Costine, A.; Edraki, M.; Baumgartl, T. The impacts of high salinity and polymer properties on dewatering and structural characteristics of flocculated high-solids tailings. J. Clean. Prod. 2022, 342, 130726. [Google Scholar] [CrossRef]

- Sabah, E.; Cengiz, I. An evaluation procedure for flocculation of coal preparation plant tailings. Water Res. 2004, 38, 1542–1549. [Google Scholar] [CrossRef]

- Arjmand, R.; Massinaei, M.; Behnamfard, A. Improving flocculation and dewatering performance of iron tailings thickeners. J. Water Process Eng. 2019, 31, 100873. [Google Scholar] [CrossRef]

- Grabsch, A.F.; Fawell, P.D.; Adkins, S.J.; Beveridge, A. The impact of achieving a higher aggregate density on polymer-bridging flocculation. Int. J. Miner. Process. 2013, 124, 83–94. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A.; Chen, Q.; Tang, X.; Zhang, Q.; Gao, R. Data-driven modelling of the flocculation process on mineral processing tailings treatment. J. Clean. Prod. 2018, 196, 505–516. [Google Scholar] [CrossRef]

- Mamghaderi, H.; Aghababaei, S.; Gharabaghi, M.; Noaparast, M.; Albijanic, B.; Rezaei, A. Investigation on the effects of chemical pretreatment on the iron ore tailing dewatering. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126855. [Google Scholar] [CrossRef]

- Hakkinen, A.; Ekberg, B. Dewatering of iron ore slurry by a ceramic vacuum disc filter. Chem. Eng. Trans. 2009, 17, 1431–1436. [Google Scholar] [CrossRef]

- Dias, C.L.P.; Valadão, G.E.S.; Araujo, A.C.; Peres, A.E.C.; Amarante, S.C. The effect of reagents on ultrafine iron ore vacuum filtration. Filtr. Sep. 2003, 40, 36–39. [Google Scholar] [CrossRef]

- Olcay, R.H.; Valadão, G.E.; Araujo, A.C.; Reyes, I.A.; Flores, M.U. Dewatering of Fine Tailings for Disposal in Dams Using a Column Thickener, Deep Cone Classifier, and Hyperbaric Filtration. Min. Metall. Explor. 2024, 41, 335–344. [Google Scholar] [CrossRef]

- Lv, L.; Zheng, D.; Tang, S.; Zhang, T.; Liu, W. Phosphate ore particles dissolution kinetics in hydrochloric acid based on a structure-related segmented model. Powder Technol. 2021, 392, 141–149. [Google Scholar] [CrossRef]

- Cacciuttolo Vargas, C.; Marinovic Pulido, A. Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance. Sustainability 2022, 14, 10901. [Google Scholar] [CrossRef]

- Wu, A.; Ruan, Z.; Wang, J. Rheological behavior of paste in metal mines. Int. J. Miner. Metall. Mater. 2022, 29, 717–726. [Google Scholar] [CrossRef]

| Component | % | Component | % |

|---|---|---|---|

| P2O5 | 2.34 | SiO2 | 60.59 |

| Fe2O3 | 5.27 | Al2O3 | 14.83 |

| MgO | 1.18 | CaO | 9.12 |

| Technique Used | Specific Surface Area (m2/g) |

|---|---|

| BET | 0.937 |

| Blaine | 0.894 |

| Settling Rate/Turbidity Cationic Polymer | Settling Rate/Turbidity Anionic Polymer | Settling Rate/Turbidity Non-Ionic Polymer |

|---|---|---|

| CF1: 0.142/187 | AF1: 0.287/74 | NIF1: 0.112/154 |

| CF2: 0.217/241 | AF2: 0.382/86 | NIF2: 0.181/179 |

| CF3: 0.259/284 | AF3: 0.311/83 | NIF3: 0.105/143 |

| Type of Water | pH | Ca (ppm) | Mg (ppm) | Turbidity (NTU) | Hardness |

|---|---|---|---|---|---|

| Water before the process overflow | 8.1 | 7.2 | 3.6 | <100 | 31.2 |

| Column thickener | 8.5 | 11.9 | 4.9 | <100 | 56.5 |

| Filtration (hyperbaric filter) | 9.2 | 12.1 | 5.8 | <100 | 60.9 |

| Polymer dewatering overflow | 8.3 | 10.4 | 4.7 | <100 | 51.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olcay, R.H.; Ordóñez, S.; Valadão, G.E.; Patiño, F.; Henriques, A.B.; Reyes, I.A.; Juárez, J.C.; Flores, M.U. Industrial-Scale Application of Polymer Dewatering for Fine Tailings Disposal. Materials 2025, 18, 3872. https://doi.org/10.3390/ma18163872

Olcay RH, Ordóñez S, Valadão GE, Patiño F, Henriques AB, Reyes IA, Juárez JC, Flores MU. Industrial-Scale Application of Polymer Dewatering for Fine Tailings Disposal. Materials. 2025; 18(16):3872. https://doi.org/10.3390/ma18163872

Chicago/Turabian StyleOlcay, Rubén H., Sayra Ordóñez, George E. Valadão, Francisco Patiño, Andréia B. Henriques, Iván A. Reyes, Julio C. Juárez, and Mizraim U. Flores. 2025. "Industrial-Scale Application of Polymer Dewatering for Fine Tailings Disposal" Materials 18, no. 16: 3872. https://doi.org/10.3390/ma18163872

APA StyleOlcay, R. H., Ordóñez, S., Valadão, G. E., Patiño, F., Henriques, A. B., Reyes, I. A., Juárez, J. C., & Flores, M. U. (2025). Industrial-Scale Application of Polymer Dewatering for Fine Tailings Disposal. Materials, 18(16), 3872. https://doi.org/10.3390/ma18163872