Mix Design Optimization of Coal Gangue-Based Geopolymer Foamed Concrete Using Response Surface Methodology

Abstract

1. Introduction

2. Experimental Overview

2.1. Raw Materials

2.2. Experimental Design

2.3. Experimental Methods

2.3.1. Preparation Procedure and Curing Regime

2.3.2. Testing Methods

3. Results and Discussion

3.1. Model Fitting and Accuracy Analysis

3.2. Effects of Individual Factors and Their Interactions on Response Variables

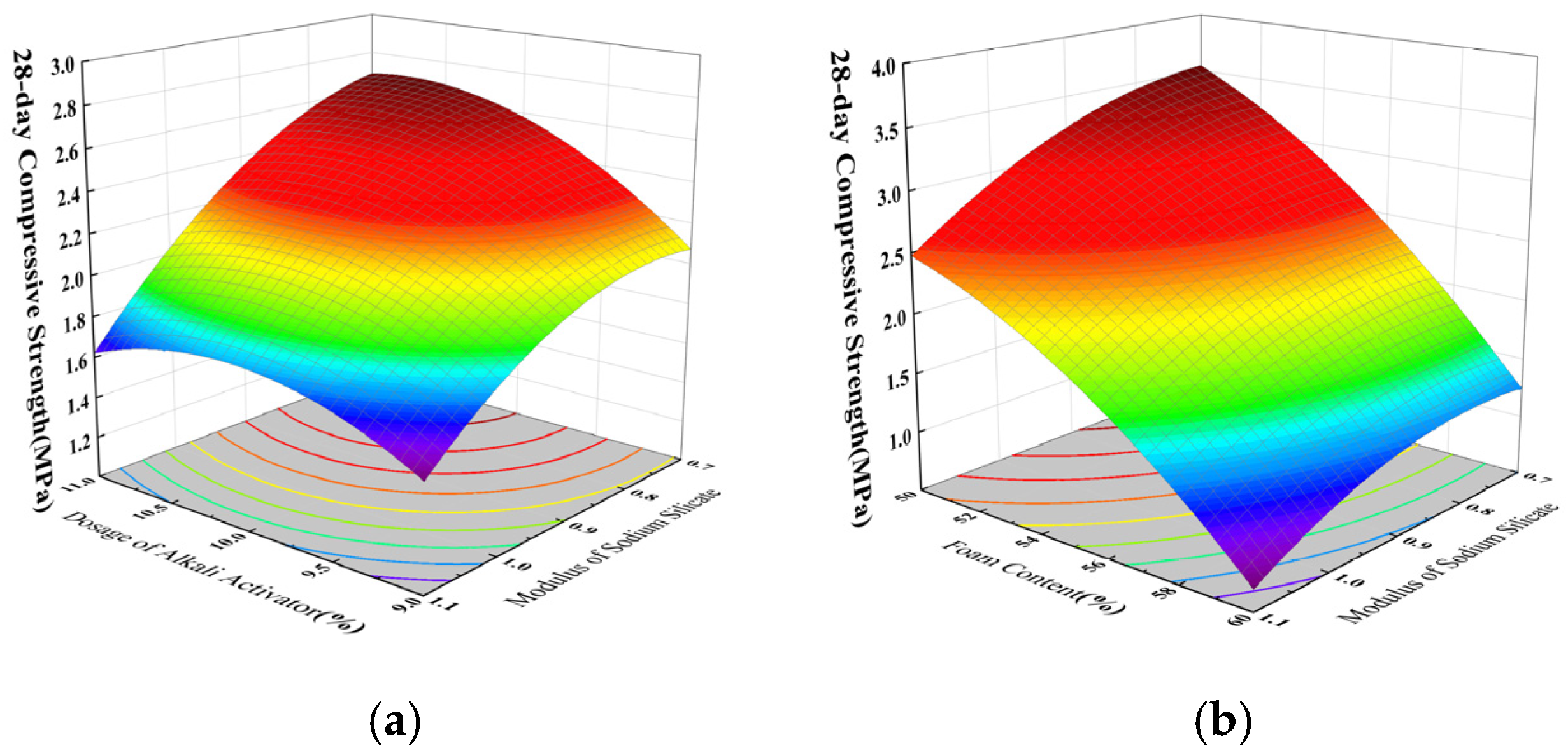

3.2.1. The 28-Day Compressive Strength

3.2.2. Thermal Conductivity

3.3. Optimization and Validation of Response Surface Results

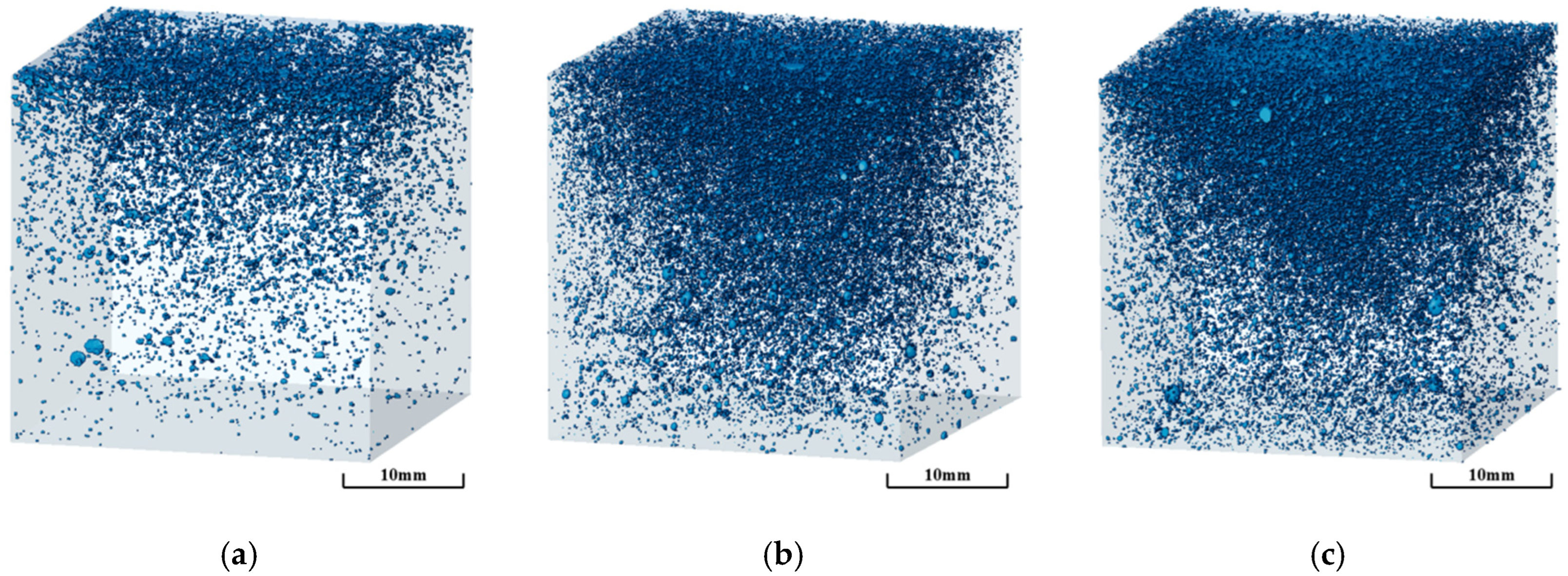

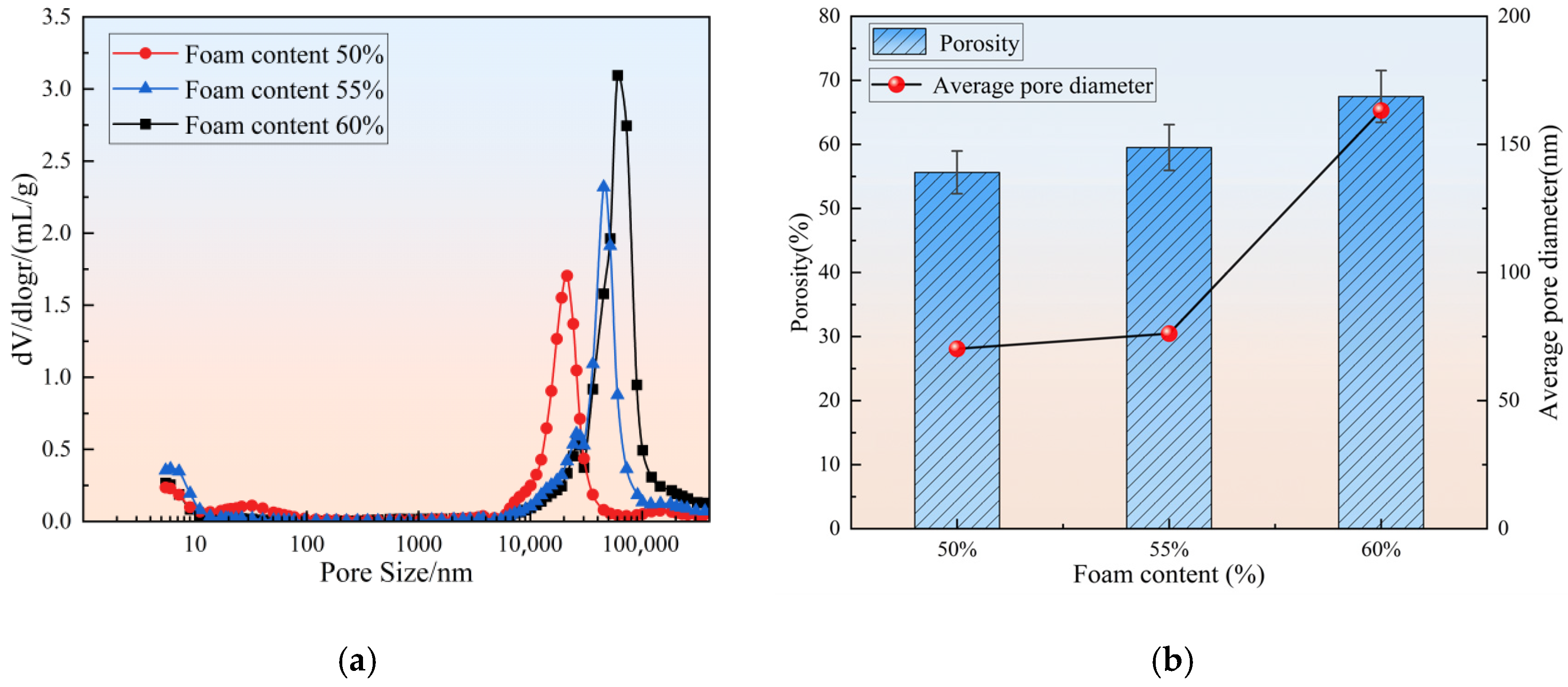

3.4. Microstructural Analysis

4. Conclusions

- The optimal mix proportion was determined to be 9.1% alkali activator dosage, sodium silicate modulus of 1.07, water-to-binder ratio of 0.44, and 50% foam content. Under these conditions, the 28-day compressive strength reached 2.30 MPa while maintaining a low thermal conductivity of 0.0781 W/(m·K). Compared with other geopolymer foam concretes and conventional cement-based foam concretes, the developed material demonstrates significantly enhanced thermal insulation performance without compromising mechanical strength. Furthermore, the utilization of solid waste materials effectively reduces carbon emissions, meeting the technical requirements for building wall materials in severely cold regions.

- A second-order regression model was developed based on the BBD to relate four key factors—alkali activator dosage, sodium silicate modulus, water-to-binder ratio, and foam content—to two performance indicators: 28-day compressive strength and thermal conductivity. The model exhibited high reliability, with R2 values exceeding 0.99 and prediction errors below 5%, demonstrating its applicability for optimizing the mix design of coal gangue–slag-based geopolymer foamed concrete.

- Among the single-factor effects, foam content had the most significant impact on both 28-day compressive strength and thermal conductivity. Regarding two-factor interactions, the interaction between sodium silicate modulus and foam content exerted the most pronounced influence on both performance indicators, with a significantly greater effect than other interaction combinations.

- As the foam content increases, the reduction in gel product content promotes the coalescence of small bubbles, resulting in a complex and disordered pore structure. This structural disorder leads to a decline in mechanical strength, while the increased porosity effectively enhances thermal performance. The study quantitatively reveals the correlation between pore structure parameters and macroscopic properties, providing important theoretical support for the development of thermal insulation building materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiu, J.; Zhu, M.; Zhou, Y.; Guan, X. Effect and mechanism of coal gangue concrete modification by fly ash. Constr. Build. Mater. 2021, 294, 123563. [Google Scholar] [CrossRef]

- Mischinenko, V.; Vasilchenko, A.; Lazorenko, G. Effect of Waste Concrete Powder Content and Microwave Heating Parameters on the Properties of Porous Alkali-Activated Materials from Coal Gangue. Materials 2024, 17, 5670. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wu, Y.; Li, X.; Li, Y.; Tang, W.; Dan, J.; Hong, C.; Wang, J.; Yang, X. Effect of Triterpenoid Saponins as Foaming Agent on Mechanical Properties of Geopolymer Foam Concrete. Materials 2024, 17, 3921. [Google Scholar] [CrossRef]

- Xin, Q.; Lu, S.; Shao, P.; Zhang, H.; Zhang, M. The enhancement of compressive strength and copper ion adsorption of foamed concrete by recycled glass fiber reinforced plastic powder. Constr. Build. Mater. 2025, 475, 141242. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, G.; Man, X.; Wang, Q. Climate and resource characteristics-based zoning of heat source retrofit for heating systems and implications for heat consumption of urban settlements in cold regions of China. Energy 2025, 314, 134261. [Google Scholar] [CrossRef]

- Lo Bianco, A.; Calvino, M.; Cavallaro, G.; Lisuzzo, L.; Pasbakhsh, P.; Milioto, S.; Lazzara, G.; Lvov, Y. Flame-resistant inorganic films by self-assembly of clay nanotubes and their conversion to geopolymer for CO2 capture. Small 2024, 20, 2406812. [Google Scholar] [CrossRef]

- Ren, J.; Matar, M.; Tonin, N.; Pu, C.; White, C.; Srubar, W., III. Understanding the effects of hematite and brucite additions on fresh-and hardened-state properties of metakaolin-based geopolymer cements. Appl. Clay Sci. 2025, 276, 107932. [Google Scholar] [CrossRef]

- Shen, R.; Li, X.; Li, S. Study on Mechanical Properties of Alkali-Activated Coal Gasification Slag Concrete. Materials 2025, 18, 3240. [Google Scholar] [CrossRef]

- Calvino, M.M.; Lisuzzo, L.; Cavallaro, G.; Lazzara, G.; Milioto, S. Halloysite-based geopolymers filled with wax microparticles as sustainable building materials with enhanced thermo-mechanical performances. J. Environ. Chem. Eng. 2022, 10, 108594. [Google Scholar] [CrossRef]

- Korniejenko, K.; Pławecka, K.; Bazan, P.; Figiela, B.; Kozub, B.; Mróz, K.; Łach, M. Green building materials for circular economy—Geopolymer foams. Proc. Eng. Technol. Innov. 2023, 25, 26–34. [Google Scholar] [CrossRef]

- Yang, X.; Wu, S.; Xu, S.; Chen, D.; Zhao, Z.; Chen, B.; Liang, X. Development of a novel emulsified asphalt enhanced steel slag-based geopolymer foamed concrete. Constr. Build. Mater. 2024, 456, 139287. [Google Scholar] [CrossRef]

- Bazan, P.; Figiela, B.; Kozub, B.; Łach, M.; Mróz, K.; Melnychuk, M.; Korniejenko, K. Geopolymer Foam with Low Thermal Conductivity Based on Industrial Waste. Materials 2024, 17, 6143. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Yang, G.; Liang, K. Development of fly ash and slag-based high-strength alkali-activated foam concrete. Cem. Concr. Compos. 2022, 128, 104447. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, K.; Liu, S.; Li, M.; Zhang, X.; Yuan, Z. Low-Carbon Foamed Concrete Based on Alkali Residue and GGBS versus Conventional Foamed Concrete: Comparative Experimental Research. J. Mater. Civ. Eng. 2025, 37, 04024479. [Google Scholar] [CrossRef]

- Nandipati, S.; Degloorkar, N.; Pullagura, G.; Barik, D.; Paramasivam, P.; Althaqafi, E.; Islam, S.; Al-Sareji, O. Evaluating energy consumption patterns in novel foamed ternary alkali-activated masonry blocks. Sci. Rep. 2025, 15, 2206. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Zhang, X.; Liu, M.; Fang, B.; Wang, C.; Mi, H. Compatibility of sodium hydroxide, sodium silicate and calcium-enriched additives in alkali-activated materials: From the perspectives of flowability, strength and microstructure. Constr. Build. Mater. 2023, 403, 133102. [Google Scholar] [CrossRef]

- Song, Q.; Bao, J.; Xue, S.; Zhang, P.; Mu, S. Collaborative disposal of multisource solid waste: Influence of an admixture on the properties, pore structure and durability of foam concrete. J. Mater. Res. Technol. 2021, 14, 1778–1790. [Google Scholar] [CrossRef]

- Zhang, S.; Qi, X.; Guo, S.; Zhang, L.; Ren, J. A systematic research on foamed concrete: The effects of foam content, fly ash, slag, silica fume and water-to-binder ratio. Constr. Build. Mater. 2022, 339, 127683. [Google Scholar] [CrossRef]

- Dang, J.; Tang, X.; Xiao, J.; Duan, Z.; Han, A. Early Stability Behavior and Mechanism of Alkali-Activated Foamed Concrete. J. Build. Mater. 2023, 26, 746–754. [Google Scholar]

- Wang, H.; Gao, S.; Meng, Z.; Wu, Y.; Liu, X. Micro-pore Structure and Macro-properties of Fly Ash-Slag Based Foam Geopolymer. J. Build. Mater. 2024, 27, 461–470. [Google Scholar]

- Rong, X.; Zhang, X.; Zhang, J.; Xu, W.; Zhang, Z. Study on mechanical and thermal properties of alkali-excited fly ash aerogel foam concrete. Constr. Build. Mater. 2023, 408, 133770. [Google Scholar] [CrossRef]

- Pantongsuk, T.; Kittisayarm, P.; Muenglue, N.; Benjawan, S.; Thavorniti, P.; Tippayasam, C.; Nilpairach, S.; Heness, G.; Chaysuwan, D. Effect of hydrogen peroxide and bagasse ash additions on thermal conductivity and thermal resistance of geopolymer foams. Mater. Today Commun. 2021, 26, 102149. [Google Scholar] [CrossRef]

- Cao, D.; Zhang, H.; Dong, H.; Zhao, Y. Effect of reactive magnesia on dry shrinkage of geopolymer concrete and its bond property with BFRP bar. Constr. Build. Mater. 2025, 465, 140208. [Google Scholar] [CrossRef]

- Gan, Y.; Li, C.; Chen, A.; Li, Y.; Wu, S. A model of pyrolysis carbon black and waste chicken feather using a response surface method in hot-mix asphalt mixtures. J. Mater. Civ. Eng. 2022, 34, 04022278. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, J. Application of response surface methodology to optimize alkali-activated slag mortar with limestone powder and glass powder. Struct. Concr. 2021, 22, E430–E441. [Google Scholar] [CrossRef]

- Feng, Z.; Wu, X.; Chen, H.; Qin, Y.; Zhang, L.; Skibniewski, M. An energy performance contracting parameter optimization method based on the response surface method: A case study of a metro in China. Energy 2022, 248, 123612. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Zhao, W.; Wang, Z.; Wang, Z.; Wang, Y. Research on optimizing performance of new slurries for EPBS soil conditioning based on response surface method. Constr. Build. Mater. 2023, 375, 130818. [Google Scholar] [CrossRef]

- Chelladurai, S.; Murugan, K.; Ray, A.; Upadhyaya, M.; Narasimharaj, V.; Gnanasekaran, S. Optimization of process parameters using response surface methodology: A review. Mater. Today Proc. 2021, 37, 1301–1304. [Google Scholar] [CrossRef]

- Maaze, M.; Shrivastava, S. Design optimization of a recycled concrete waste-based brick through alkali activation using Box-Behnken design methodology. J. Build. Eng. 2023, 75, 106863. [Google Scholar] [CrossRef]

- Shi, Q.; Zhou, M.; Bai, J.; Zhang, K.; Li, D. Influence of coal gangue on the properties of coal-based solid waste geopolymer grouting material. J. Build. Mater. 2025, 1–10. Available online: http://kns.cnki.net/kcms/detail/31.1764.TU.20250106.1521.004.html (accessed on 17 January 2025).

- JG/T 266-2011; Foamed Concrete. China Standard Press: Beijing, China, 2011.

- GB/T 10294-2008; Thermal Insulation-Determination of Steady-State Thermal Resistance and Related Properties-Guarded Hot Plate Apparatus. State General Administration of the People’s Republic of China for Quality Supervision and Inspection and Quarantine, Standardization Administration of China: Beijing, China, 2008.

- Aziz, A.; Driouich, A.; Felaous, K.; Bellil, A. Box-Behnken design-based optimization and characterization of new eco-friendly building materials based on slag activated by diatomaceous earth. Constr. Build. Mater. 2023, 375, 131027. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.; Liew, M.; Wahab, M. Modelling and multi-objective optimization of the fresh and mechanical properties of self-compacting high volume fly ash ECC (HVFA-ECC) using response surface methodology (RSM). Case Stud. Constr. Mater. 2021, 14, e00525. [Google Scholar] [CrossRef]

- Zhou, Y.; Xie, L.; Kong, D.; Peng, D.; Zheng, T. Research on optimizing performance of desulfurization-gypsum-based composite cementitious materials based on response surface method. Constr. Build. Mater. 2022, 341, 127874. [Google Scholar] [CrossRef]

- Ren, C.; Wang, L.; Kong, D.; Yang, R.; Wang, Y.; Tian, Y.; Tao, T. Performance study and effect mechanism of red mud manufactured sand foam concrete using a single-factor experiment. Constr. Build. Mater. 2025, 458, 139629. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D. Effects of silica fume, latex, methylcellulose, and carbon fibers on the thermal conductivity and specific heat of cement paste. Cem. Concr. Res. 1997, 27, 1799–1804. [Google Scholar] [CrossRef]

- Ding, K.; Zeng, C. Study on the compressive strength, pore structure characteristics, and fractal dimension of the ecological porous concrete specimens based on ordinary Portland cement. Constr. Build. Mater. 2025, 483, 141795. [Google Scholar] [CrossRef]

- Yu, G.; Li, Z.; Li, S.; Zhang, Q.; Hua, Y.; Liu, H.; Zhao, X.; Dhaidhai, D.; Li, W.; Wang, X. The selection of internal architecture for porous Ti alloy scaffold: A compromise between mechanical properties and permeability. Mater. Des. 2020, 192, 108754. [Google Scholar] [CrossRef]

- Liu, C.; Liu, G. Characterization of pore structure parameters of foam concrete by 3D reconstruction and image analysis. Constr. Build. Mater. 2021, 267, 120958. [Google Scholar] [CrossRef]

- Jaya, N.; Liew, Y.; Heah, C.; Abdullah, M.; Hussin, K. Correlation between pore structure, compressive strength, and thermal conductivity of porous metakaolin geopolymer. Constr. Build. Mater. 2020, 247, 118641. [Google Scholar] [CrossRef]

- Zhao, D.; Xu, J.; Han, Z.; Liu, Y.; Liu, Y.; Yang, X. Study on the correlation between pore structure characterization and early mechanical properties of foamed concrete based on X-CT. Constr. Build. Mater. 2024, 450, 138603. [Google Scholar] [CrossRef]

| Material | Mass Fraction/% | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | FeO | Fe2O3 | MgO | TiO2 | Others | |

| Coal Gangue | 51.88 | 44.80 | 0.15 | / | 0.42 | 0.09 | 2.33 | 0.33 |

| Slag Powder | 38.2 | 7.76 | 39.7 | 1.09 | / | 11.02 | / | 2.23 |

| Factors | Code | Levels | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| Alkali Activator Dosage | X1 | 9% | 10% | 11% |

| Sodium Silicate Modulus | X2 | 0.7 | 0.9 | 1.1 |

| Water-to-binder ratio | X3 | 0.43 | 0.44 | 0.45 |

| Foam Content | X4 | 50% | 55% | 60% |

| Test Number | Alkali Activator Dosage/% | Sodium Silicate Modulus | Water-to-Binder Ratio | Foam Content/% | 28-Day Compressive Strength/MPa | Thermal Conductivity/W/(m·K) |

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | Y1 | Y2 | |

| 1 | 9 | 0.7 | 0.44 | 55 | 2.1 | 0.1131 |

| 2 | 11 | 0.7 | 0.44 | 55 | 2.7 | 0.1165 |

| 3 | 9 | 1.1 | 0.44 | 55 | 1.5 | 0.0832 |

| 4 | 11 | 1.1 | 0.44 | 55 | 1.6 | 0.0996 |

| 5 | 10 | 0.9 | 0.43 | 50 | 2.7 | 0.1022 |

| 6 | 10 | 0.9 | 0.45 | 50 | 3.4 | 0.1150 |

| 7 | 10 | 0.9 | 0.43 | 60 | 0.8 | 0.0811 |

| 8 | 10 | 0.9 | 0.45 | 60 | 1.2 | 0.0873 |

| 9 | 9 | 0.9 | 0.44 | 50 | 2.8 | 0.1008 |

| 10 | 11 | 0.9 | 0.44 | 50 | 3.1 | 0.1158 |

| 11 | 9 | 0.9 | 0.44 | 60 | 0.7 | 0.0798 |

| 12 | 11 | 0.9 | 0.44 | 60 | 1.1 | 0.0850 |

| 13 | 10 | 0.7 | 0.43 | 55 | 2.1 | 0.1151 |

| 14 | 10 | 1.1 | 0.43 | 55 | 1.4 | 0.0823 |

| 15 | 10 | 0.7 | 0.45 | 55 | 2.8 | 0.1166 |

| 16 | 10 | 1.1 | 0.45 | 55 | 1.8 | 0.0992 |

| 17 | 9 | 0.9 | 0.43 | 55 | 1.6 | 0.0946 |

| 18 | 11 | 0.9 | 0.43 | 55 | 1.8 | 0.1018 |

| 19 | 9 | 0.9 | 0.45 | 55 | 2.0 | 0.1027 |

| 20 | 11 | 0.9 | 0.45 | 55 | 2.5 | 0.1126 |

| 21 | 10 | 0.7 | 0.44 | 50 | 3.5 | 0.1239 |

| 22 | 10 | 1.1 | 0.44 | 50 | 2.5 | 0.0910 |

| 23 | 10 | 0.7 | 0.44 | 60 | 1.2 | 0.0869 |

| 24 | 10 | 1.1 | 0.44 | 60 | 0.7 | 0.0781 |

| 25 | 10 | 0.9 | 0.44 | 55 | 2.5 | 0.1165 |

| 26 | 10 | 0.9 | 0.44 | 55 | 2.5 | 0.1168 |

| 27 | 10 | 0.9 | 0.44 | 55 | 2.5 | 0.1144 |

| 28 | 10 | 0.9 | 0.44 | 55 | 2.4 | 0.1157 |

| 29 | 10 | 0.9 | 0.44 | 55 | 2.4 | 0.1158 |

| Response | R2 | Adjusted R2 | Predicted R2 | Adequate Precision | C.V./% |

|---|---|---|---|---|---|

| Y1 | 0.9987 | 0.9974 | 0.9955 | 100.5503 | 1.92 |

| Y2 | 0.9969 | 0.9939 | 0.9848 | 59.4500 | 1.10 |

| Response Variable | Source | Sum of Squares | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Y1 | Model | 17.04 | 1.22 | 774.71 | <0.0001 | Significant |

| X1 | 0.3675 | 0.3675 | 233.86 | <0.0001 | ||

| X2 | 2.00 | 2.00 | 1273.26 | <0.0001 | ||

| X3 | 0.9075 | 0.9075 | 577.50 | <0.0001 | ||

| X4 | 12.61 | 12.61 | 8022.95 | <0.0001 | ||

| X1X2 | 0.0625 | 0.0625 | 39.77 | <0.0001 | ||

| X1X3 | 0.0225 | 0.0225 | 14.32 | 0.0020 | ||

| X1X4 | 0.0025 | 0.0025 | 1.59 | 0.2278 | ||

| X2X3 | 0.0225 | 0.0225 | 14.32 | 0.0020 | ||

| X2X4 | 0.0625 | 0.0625 | 39.77 | <0.0001 | ||

| X3X4 | 0.0225 | 0.0225 | 14.32 | 0.0020 | ||

| X12 | 0.4935 | 0.4935 | 314.06 | <0.0001 | ||

| X22 | 0.3308 | 0.3308 | 210.52 | <0.0001 | ||

| X32 | 0.2616 | 0.2616 | 166.49 | <0.0001 | ||

| X42 | 0.4081 | 0.4081 | 259.71 | <0.0001 | ||

| Residual | 0.0220 | 0.0016 | ||||

| Lack of fit | 0.0100 | 0.0100 | 0.3333 | 0.9277 | Not significant | |

| Y2 | Model | 0.0058 | 0.0004 | 324.8 | <0.0001 | Significant |

| X1 | 0.0003 | 0.0003 | 213.79 | <0.0001 | ||

| X2 | 0.0016 | 0.0016 | 1261.46 | <0.0001 | ||

| X3 | 0.0003 | 0.0003 | 207.84 | <0.0001 | ||

| X4 | 0.0019 | 0.0019 | 1485.23 | <0.0001 | ||

| X1X2 | 0 | 0 | 33.25 | <0.0001 | ||

| X1X3 | 1.823 | 1.823 | 1.43 | 0.2510 | ||

| X1X4 | 0 | 0 | 18.89 | 0.0007 | ||

| X2X3 | 0.0001 | 0.0001 | 46.65 | <0.0001 | ||

| X2X4 | 0.0001 | 0.0001 | 114.26 | <0.0001 | ||

| X3X4 | 0 | 0 | 8.57 | 0.0110 | ||

| X12 | 0.0003 | 0.0003 | 220.59 | <0.0001 | ||

| X22 | 0.0003 | 0.0003 | 220.59 | <0.0001 | ||

| X32 | 0.0002 | 0.0002 | 180.64 | <0.0001 | ||

| X42 | 0.0013 | 0.0013 | 986.03 | <0.0001 | ||

| Residual | 0 | 1.271 | ||||

| Lack of fit | 0 | 1.434 | 1.66 | 0.3299 | Not significant |

| Numerical Values | 28-Day Compressive Strength/MPa | Thermal Conductivity/W/(m·K) |

|---|---|---|

| Predicted values | 2.30 | 0.0781 |

| Average value | 2.23 | 0.0819 |

| Error/% | 3.04 | 4.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Shan, W.; Li, R.; Song, Z.; Guo, L. Mix Design Optimization of Coal Gangue-Based Geopolymer Foamed Concrete Using Response Surface Methodology. Materials 2025, 18, 3801. https://doi.org/10.3390/ma18163801

Wang D, Shan W, Li R, Song Z, Guo L. Mix Design Optimization of Coal Gangue-Based Geopolymer Foamed Concrete Using Response Surface Methodology. Materials. 2025; 18(16):3801. https://doi.org/10.3390/ma18163801

Chicago/Turabian StyleWang, Dan, Wendong Shan, Rongjie Li, Zhiqiang Song, and Lanhui Guo. 2025. "Mix Design Optimization of Coal Gangue-Based Geopolymer Foamed Concrete Using Response Surface Methodology" Materials 18, no. 16: 3801. https://doi.org/10.3390/ma18163801

APA StyleWang, D., Shan, W., Li, R., Song, Z., & Guo, L. (2025). Mix Design Optimization of Coal Gangue-Based Geopolymer Foamed Concrete Using Response Surface Methodology. Materials, 18(16), 3801. https://doi.org/10.3390/ma18163801