Evolution of Pore Structure and Damage Mechanism Analysis of Cement–Silt-Modified Eolian Sand Under Freeze–Thaw Cycles

Abstract

1. Introduction

2. Materials and Methods

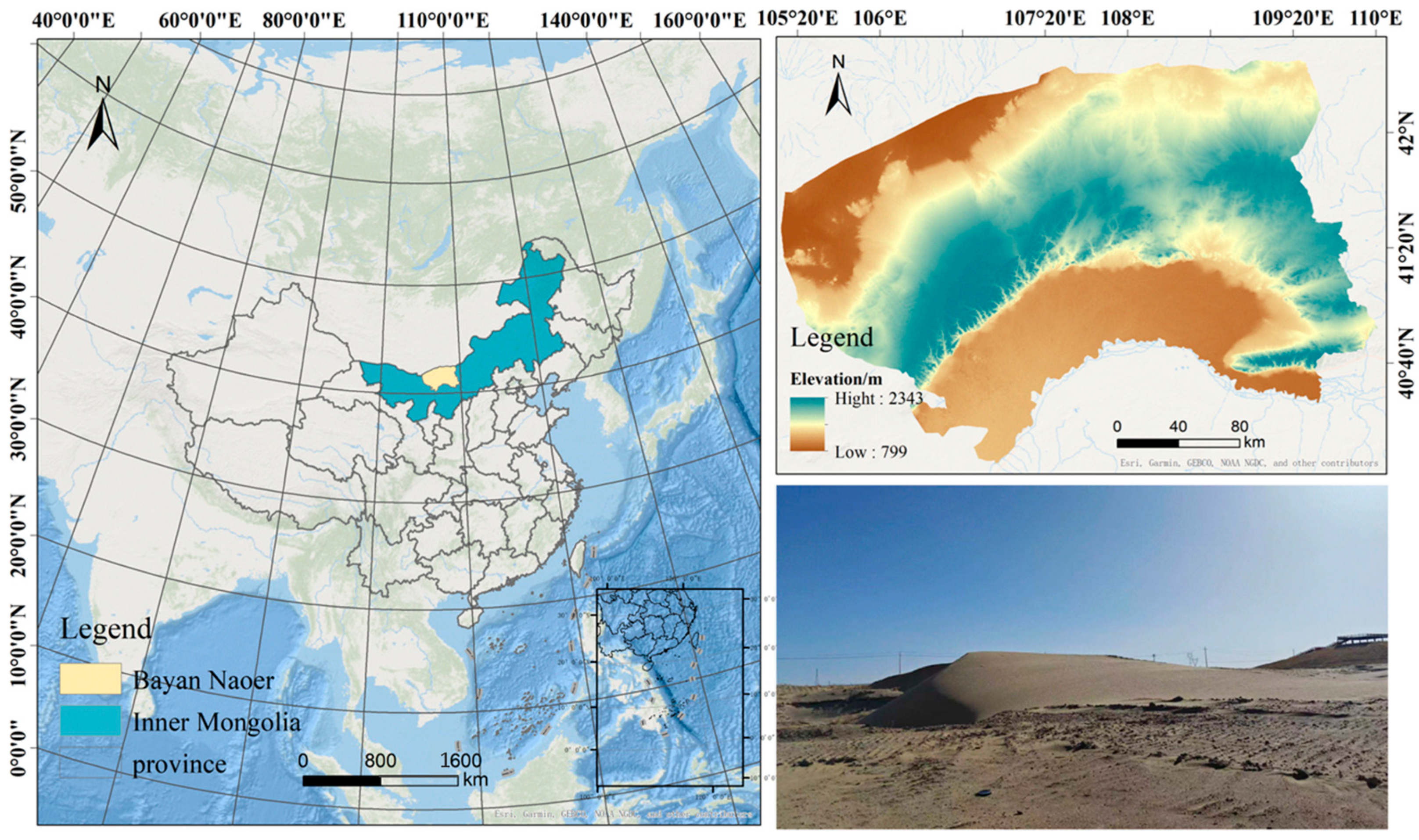

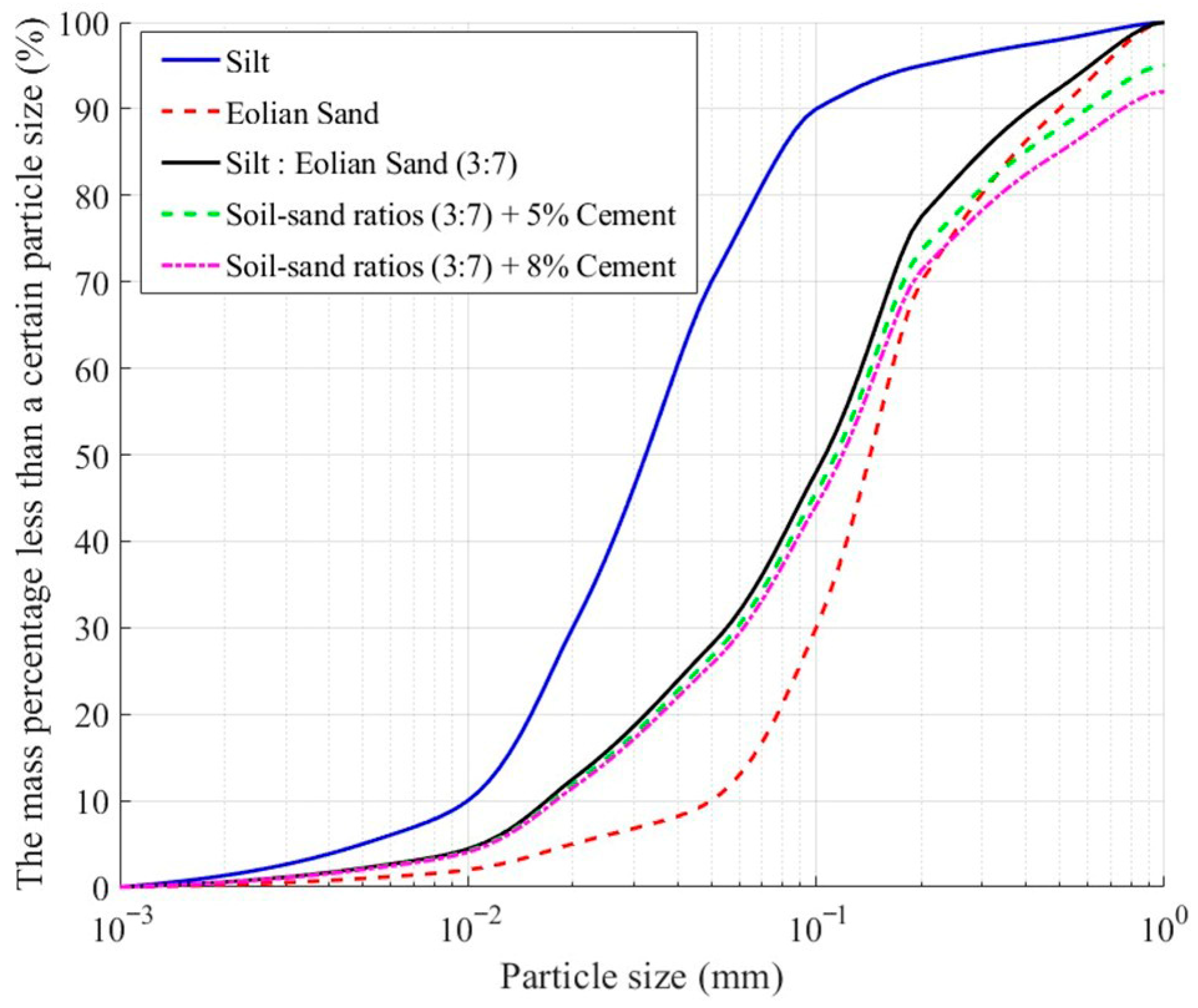

2.1. Test Material

2.2. Sample Preparation

2.3. Test Methods

2.3.1. Freeze–Thaw Cycle Test

2.3.2. Unconfined Compressive Strength Test

2.3.3. SEM Testing

3. Test Results

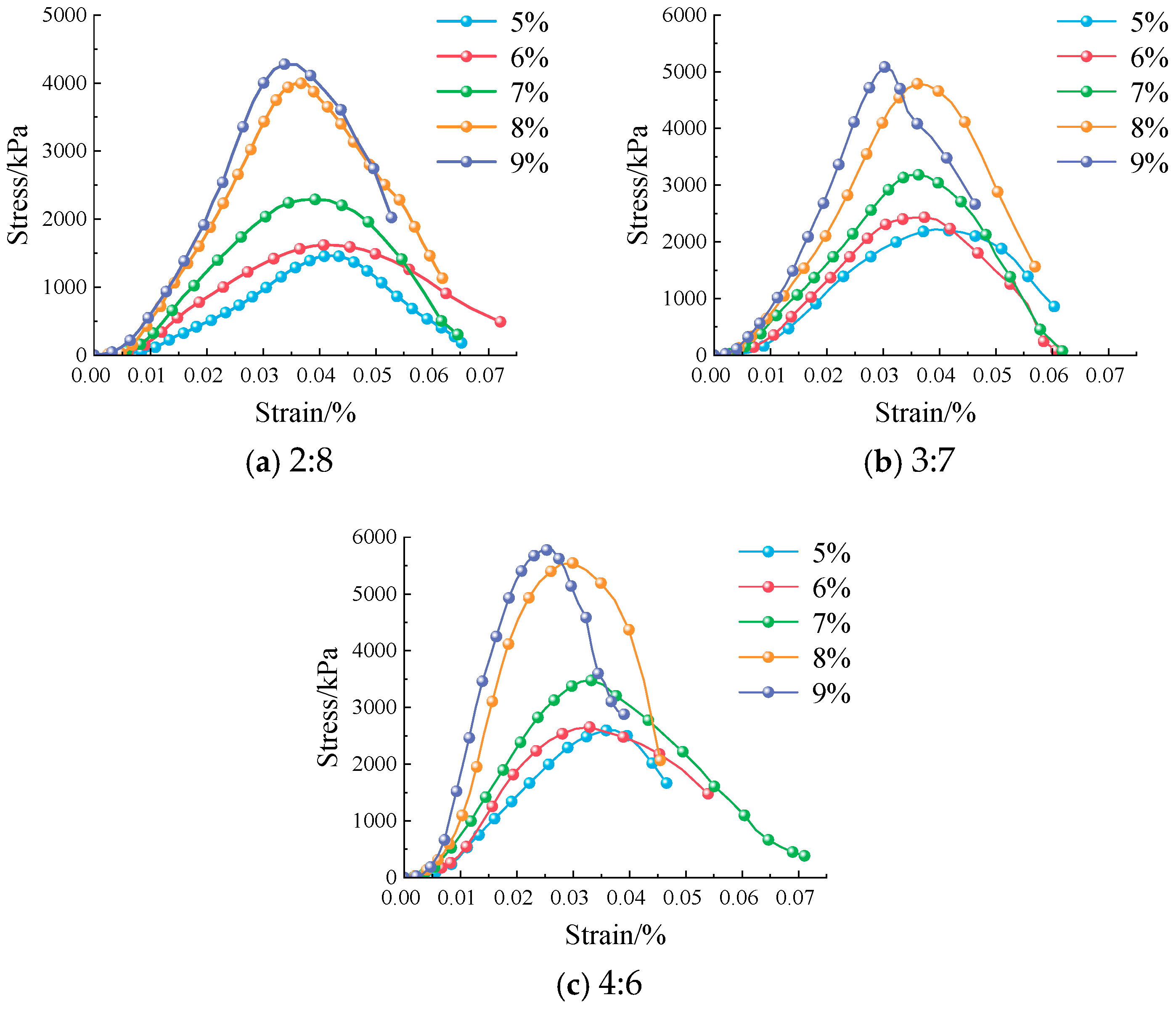

3.1. Preliminary Analysis of Compressive Strength

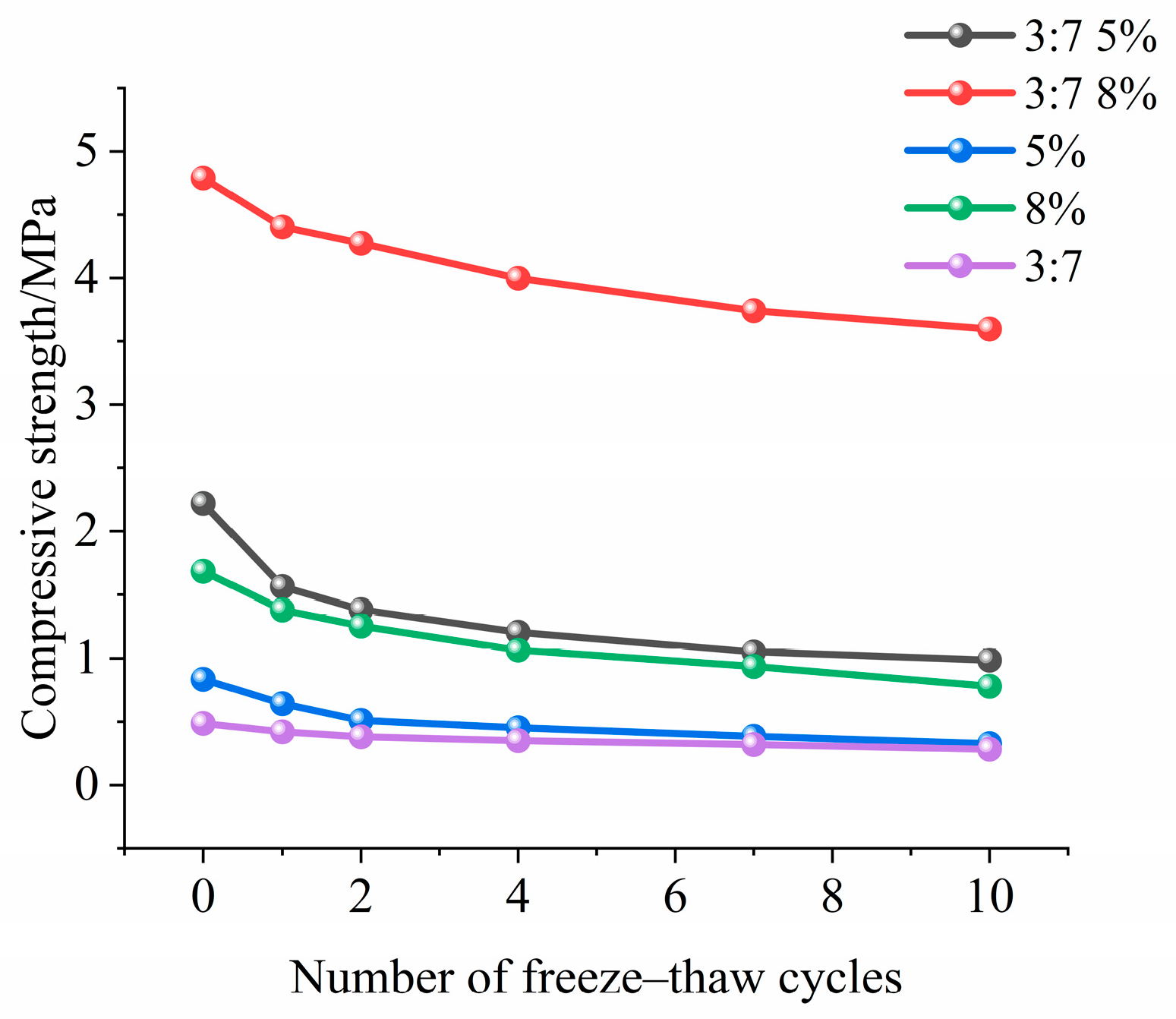

3.2. Effect of F-T Cycles on Compressive Strength of Modified Eolian Sand

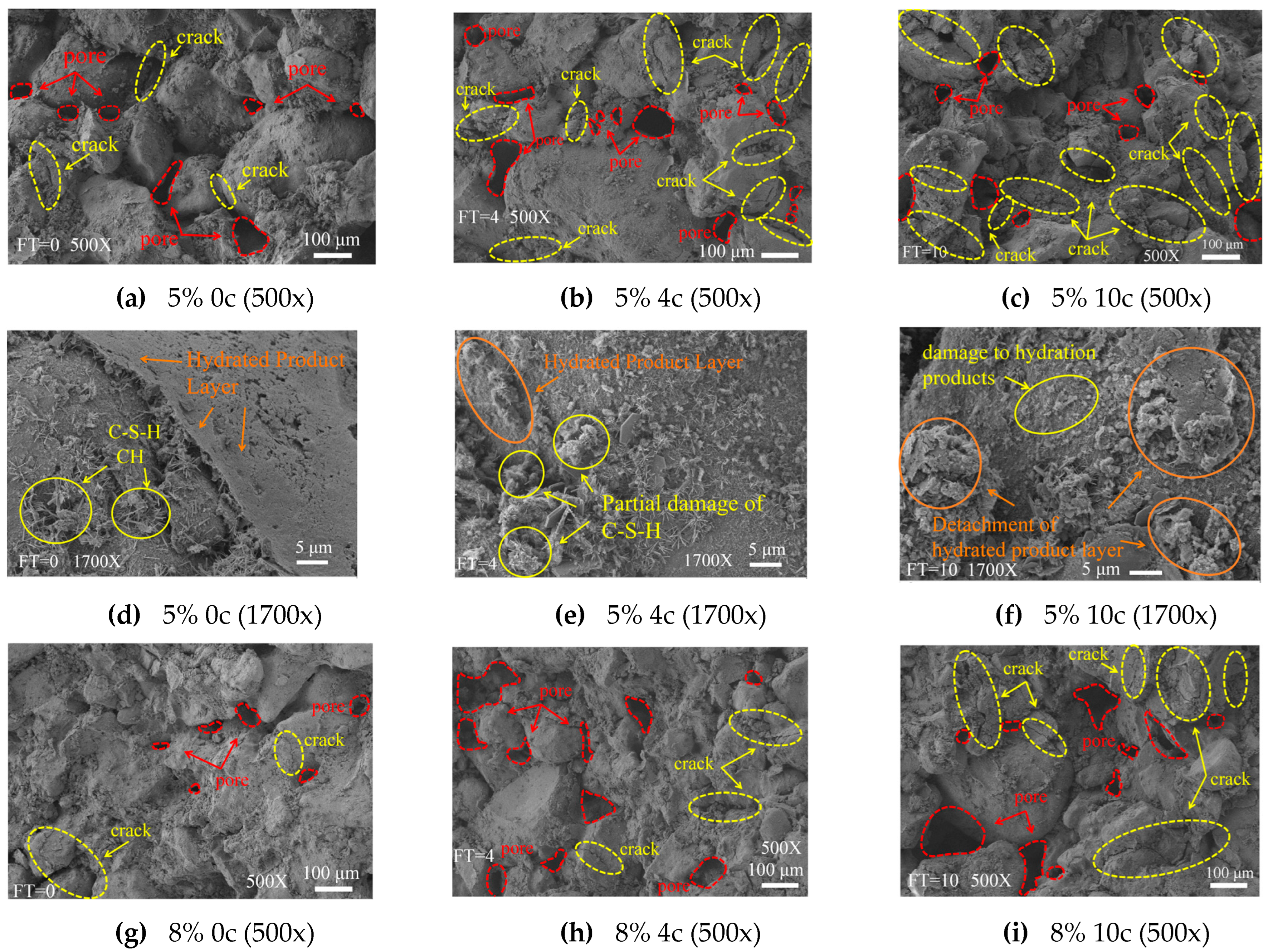

3.3. Qualitative Analysis of Microstructure

3.4. Quantitative Analysis of Microstructure

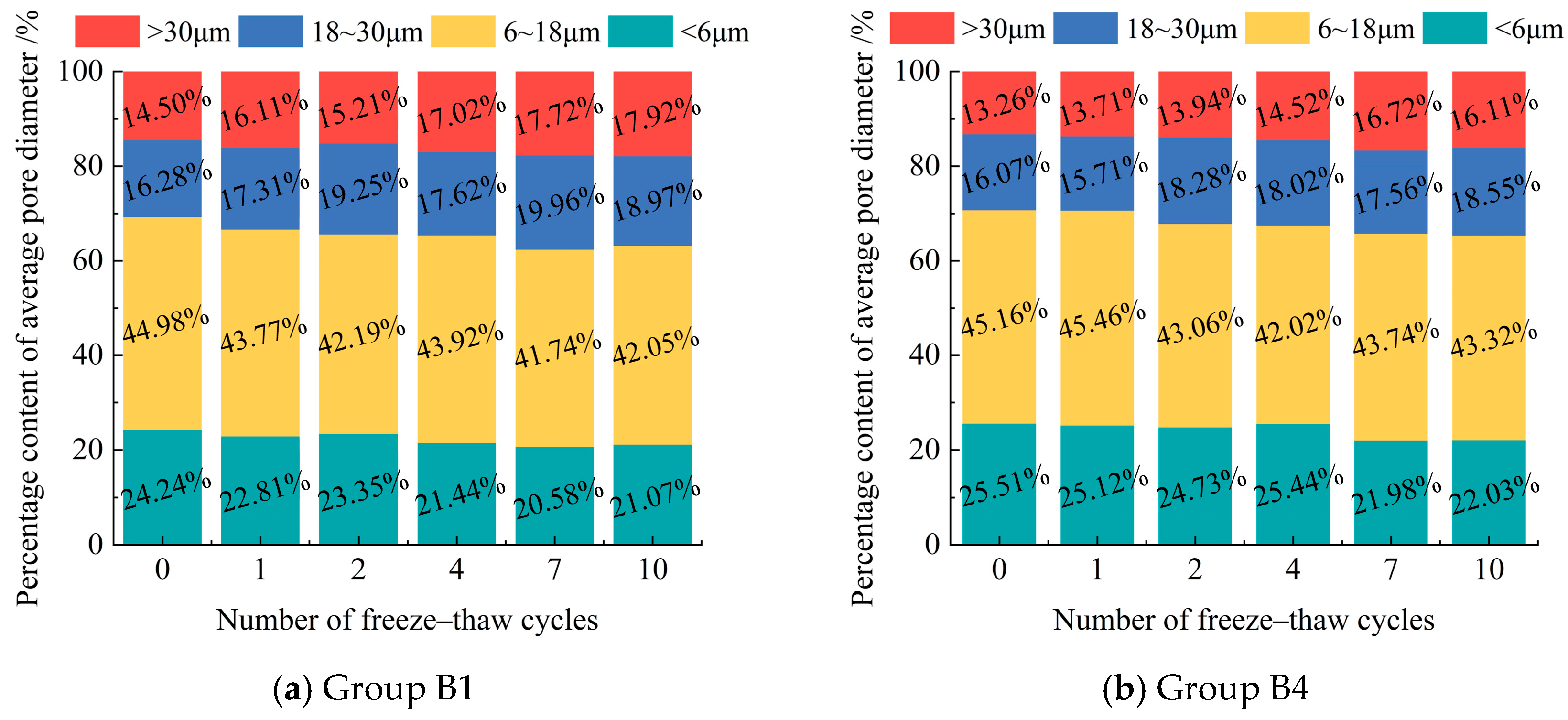

3.4.1. Pore Distribution Changes

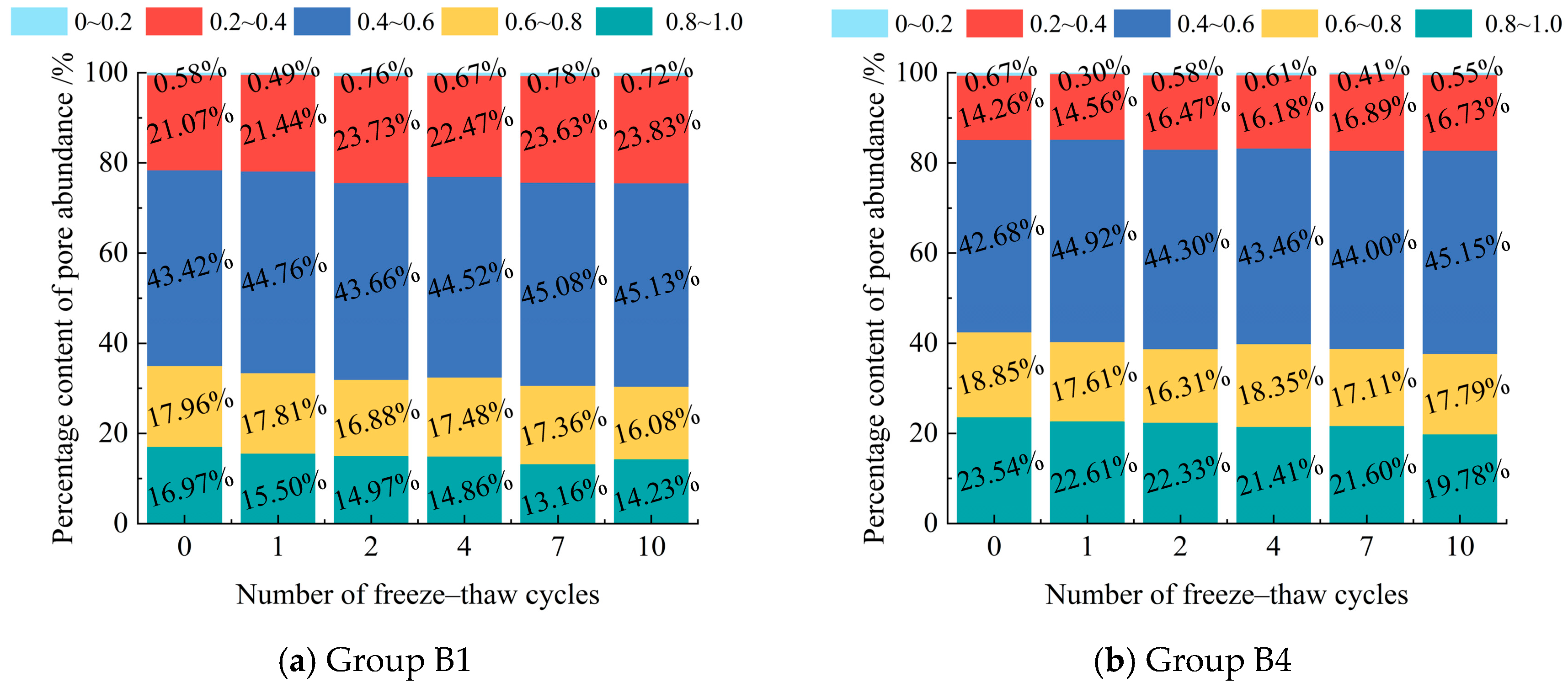

3.4.2. Evolution of Pore Morphology

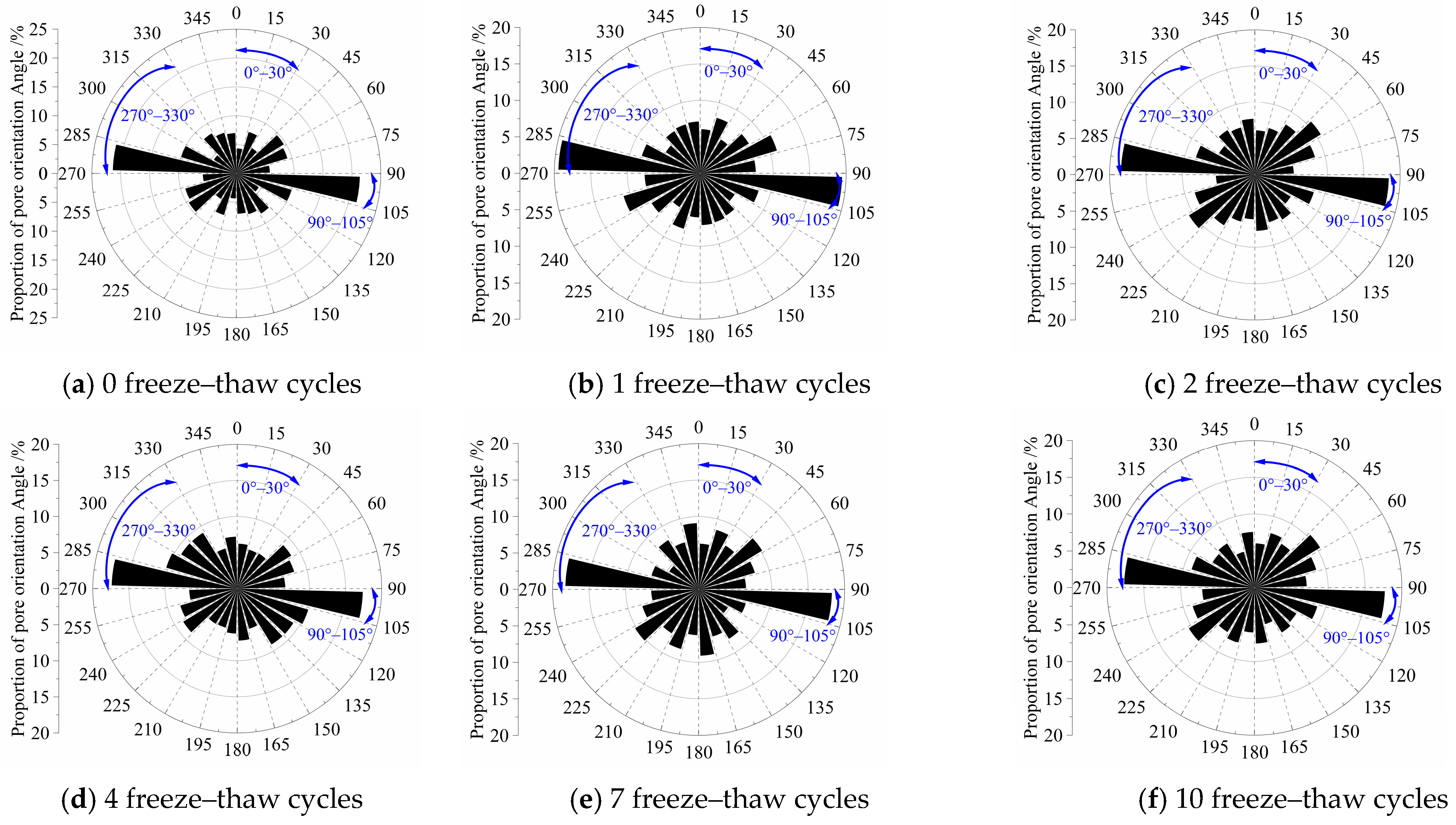

3.4.3. Pore Orientation

3.5. Relationship Between Pore Parameters and Compressive Strength

4. Discussion

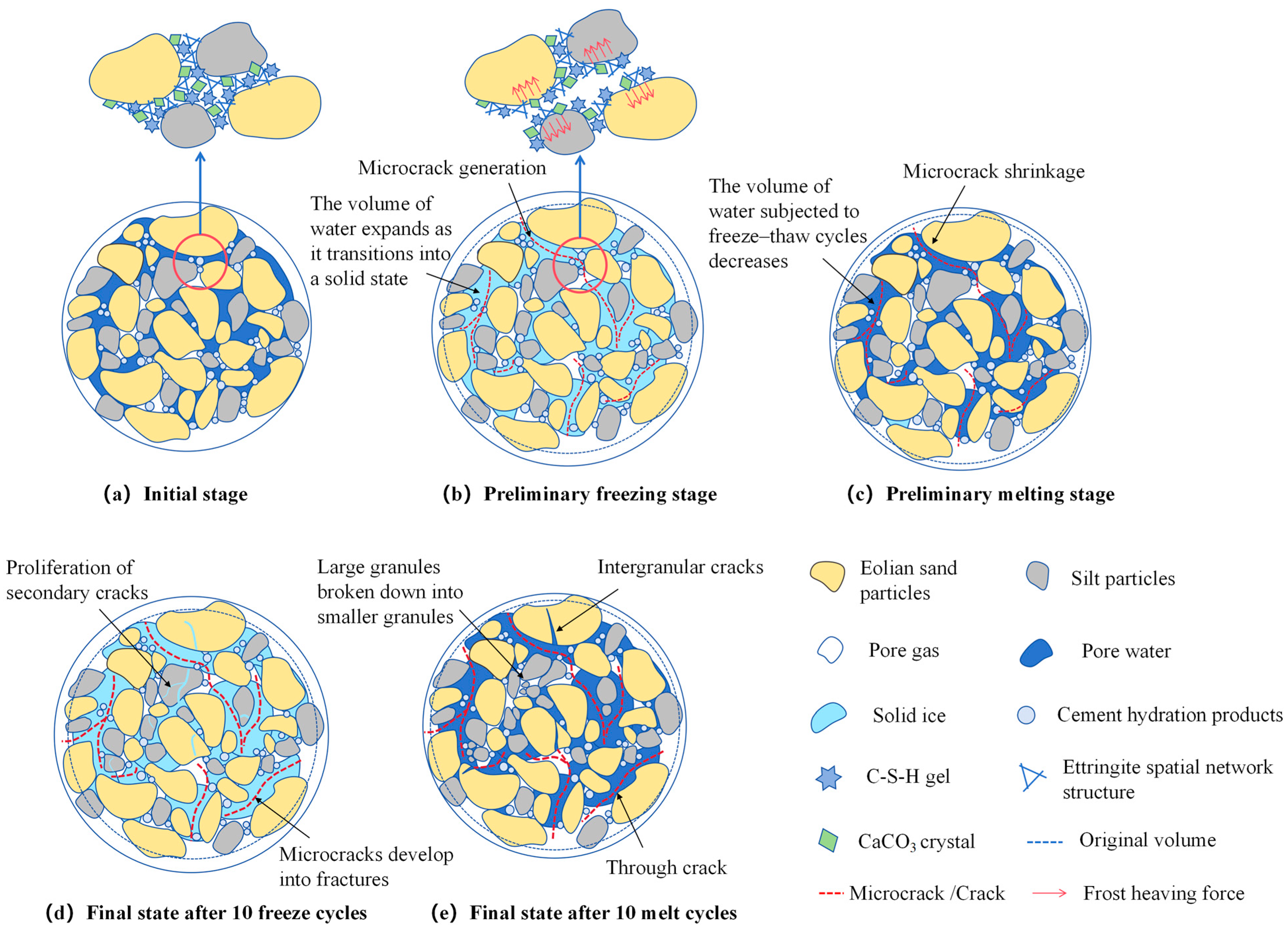

4.1. Freeze–Thaw Damage Mechanism Analysis

4.1.1. Physical Structural Changes

4.1.2. Chemical Change

4.2. Limitation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amhadi, T.S.; Assaf, G.J. Improvement of Pavement Subgrade by Adding Cement and Fly Ash to Natural Desert Sand. Infrastructures 2021, 6, 151. [Google Scholar] [CrossRef]

- Ghrieb, A.; Mitiche-Kettab, R.; Bali, A. Stabilization and Utilization of Dune Sand in Road Engineering. Arab. J. Sci. Eng. 2014, 39, 1517–1529. [Google Scholar] [CrossRef]

- AlKarni, A.; ElKholy, S.M. Improving geotechnical properties of dune sands through cement stabilization. J. Eng. Comput. Sci. 2012, 5, 1–19. [Google Scholar]

- He, R.; Han, D.; Li, L.; Li, R.; Hu, Y. Application Review of Aeolian Sand Used in Road Engineering. China J. Highw. Transp. 2025, 38, 1–30. [Google Scholar]

- Zhang, Z.; Gong, H.; Xie, Y.; Yang, X. The Engineering Property of Aeolian Sand in Inner Mongolia. J. Hebei Univ. Technol. 2006, 35, 112–117. [Google Scholar]

- Li, R.; Li, X. State-of-the-art review on aeolian sand subgrade engineering characteristic and stability protection in desert highway. Ground Improv. 2022, 4, 105–114. [Google Scholar]

- Pan, L.; Xu, J.; Gong, Z.; Zhang, S.; Tian, Z.; Gan, T. Study on compaction and shearcharacteristics of silt modified aeoliansand as embankment filling material. Water Resour. Hydropower Eng. 2023, 54, 187–195. [Google Scholar]

- Cui, Q.; Liu, G.; Zhang, Z.; Fang, Y.; Gu, X. Experimental Investigation on the Strength and Microscopic Properties of Cement-Stabilized Aeolian Sand. Buildings 2023, 13, 395. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Z.; Li, H.; Wang, Y.; Liu, C.; Ge, X. Experimental Study on lmproving Compressive Strength of Cement Stabilized Aeolian Sand by Fiber and Silt. Water Resour. Power 2025, 2, 123–127. [Google Scholar]

- Cui, B.; Xu, J.; Shao, X.; Xu, D.; Zhang, B. Static Mechanical Properties of Aeolian Sand Improved with Silt Subjected to Varying Temperature and Pressure. Buildings 2024, 14, 3801. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Z.; Wang, Y.; Wang, X. Aeolian sand stabilized by using fiber- and silt-reinforced cement: Mechanical properties, microstructure evolution, and reinforcement mechanism. Constr. Build. Mater. 2024, 411, 134750. [Google Scholar] [CrossRef]

- Lopez-Querol, S.; Arias-Trujillo, J.; Maria, G.E.; Matias-Sanchez, A.; Cantero, B. Improvement of the bearing capacity of confined and unconfined cement-stabilized aeolian sand. Constr. Build. Mater. 2017, 153, 374–384. [Google Scholar] [CrossRef]

- Liu, J.; Wang, B.; Hu, C.; Chen, J.; Zhu, S.; Xu, X. Multiscale study of the road performance of cement and fly ash stabilized aeolian sand gravel base. Constr. Build. Mater. 2023, 397, 131842. [Google Scholar] [CrossRef]

- Yang, H.; Qian, Z.; Yue, B.; Xie, Z. Effects of Cement Dosage, Curing Time, and Water Dosage on the Strength of Cement-Stabilized Aeolian Sand Based on Macroscopic and Microscopic Tests. Materials 2024, 17, 3946. [Google Scholar] [CrossRef]

- Ruan, B.; Zheng, S.; Ding, H.; Nie, R.; Ruan, C. Experimental Research on the Unconfined compressive Strength of Cement lmproved Aeolian Sand under High Temperature Curing Condition. J. Railw. Eng. 2021, 38, 02010. [Google Scholar]

- Ruan, B.; Zheng, S.; Ding, H.; Nie, R.; Ruan, C.; Chen, D. Experimental study on unconfined compressive strength of cement-stabilized aeolian sand cured at low temperature. J. Railw. Sci. Eng. 2020, 17, 2540–2548. [Google Scholar]

- Bao, S.; Liu, D.; Shangguan, Y.; Liu, M.; Gu, Q. Mechanical properties of aeolian sand improved by cement under freeze.thaw cycles. J. Jilin Jianzhu Univ. 2023, 40, 1–6. [Google Scholar]

- Zhang, S.; Shao, S.; Shao, S.J.; Wu, H.; Wang, Z. Three-Dimensional Mechanical Properties of Salinized Cement-Stabilized Aeolian Sand Under Freeze-Thaw Cycles. J. Basic Sci. Eng. 2024, 32, 1648–1663. [Google Scholar]

- Wang, L.; Luo, W.; Wang, H.; Li, X. Performance of Foundation Pit Filler with Cement-Based Drift-Sand Modified Soil under Salt-Freeze Coupling Effects. Bull. Chin. Ceram. Soc. 2020, 39, 2912–2918. [Google Scholar]

- Ruan, B.; Cheng, Y.; Lu, Z.; Zhang, X.; Nie, R. Effects of freeze-thaw cycles on splitting tensile strength of cement stabilized aeolian sand reinforced with basalt fiber. J. Railw. Sci. Eng. 2023, 20, 2521–2529. [Google Scholar]

- Hua, S.; Chen, S.; Lu, Q.; Chen, X.; Li, D. Study on Frost Heave-Thaw Settlement Characteristics of Artificially Frozen Cement lmproved Soil. For. Eng. 2024, 40, 196–208. [Google Scholar]

- Li, J.; Wang, F.; Yi, F.; Wu, F.; Liu, J.; Lin, Z. Effect of Freeze-Thaw Cycles on Triaxial Strength Property Damage to Cement Improved Aeolian Sand (CIAS). Materials 2019, 12, 2801. [Google Scholar] [CrossRef]

- Yi, F.; Li, F.; Li, J. Fractal Study on Freeze-thaw Damage of Cement Modified Aeolian Sand Based on Statistical Rule. J. Highw. Transp. Res. Dev. 2023, 40, 18–27. [Google Scholar]

- Cao, S.; Bao, D. Experimental Study on Salt-Freezing Resistance of Cement Concrete for Seasonal Frozen Region Roads. J. China Foreign Highw. 2020, 40, 291–294. [Google Scholar]

- de Jesús Arrieta Baldovino, J.; dos Santos Izzo, R.L.; Rose, J.L. Effects of Freeze–thaw Cycles and Porosity/cement index on Durability, Strength and Capillary Rise of a Stabilized Silty Soil Under Optimal Compaction Conditions. Geotech. Geol. Eng. 2021, 39, 481–498. [Google Scholar] [CrossRef]

- Seyed, H.S.; Meysam, B.; Mohsen, M.; Mohsen, S. Freeze–Thaw Durability of Cement-Stabilized Soil Reinforced with Polypropylene/Basalt Fibers. J. Mater. Civ. Eng. 2021, 33, 04021232. [Google Scholar]

- Yang, T.; Yang, S.; Sun, Z.; Wang, S.; Pang, R. Deterioration mechanism of alkali-activated slag and fly ash blended recycled aggregate concrete under freeze-thaw cycles. J. Build. Eng. 2025, 99, 111555. [Google Scholar] [CrossRef]

- Jianwen, B.; Yanru, Z.; Jinna, S.; Xiaoyan, H. Damage degradation model of aeolian sand concrete under freeze–thaw cycles based on macro-microscopic perspective. Constr. Build. Mater. 2022, 327, 126885. [Google Scholar]

- Chen, Y.; Cheng, J.; Duan, Y.; Yin, D.; Dong, H.; Li, Y. Properties of saline soil stabilized with fly ash and modified aeolian sand. Case Stud. Constr. Mater. 2024, 21, e03503. [Google Scholar] [CrossRef]

- Jumassultan, A.; Sagidullina, N.; Kim, J.; Ku, T.; Moon, S.W. Performance of cement-stabilized sand subjected to freeze-thaw cycles. Geomech. Eng. 2021, 25, 41–48. [Google Scholar]

- Zhao, H.; Tian, Z.; Xu, J.; Lu, Y.; Gong, Z.; Li, J. Analysis on freeze-thaw properties of aeolian sands improved by cement-silt mixtures. Adv. Sci. Technol. Water Resour. 2022, 42, 107–113. [Google Scholar]

- Liu, W.; Tian, Z.; Lu, Y.; Xu, J.; Gong, Z.; Wu, Y. Study on triaxial compression characteristies of improved aeolian sand mixed with cement silt. Adv. Sci. Technol. Water Resour. 2023, 43, 51–57. [Google Scholar]

- Zhang, Y.; Li, Y.Q.; Zhang, D.W.; Hou, J.; Pan, X.J.; Tang, Z.Q. Road performance and field test of expansive soil improved by silt. Rock Soil Mech. 2023, 44, 2942–2952. [Google Scholar]

- Liu, B.; Gao, R.; He, Y.; Zhao, L.; Li, D.; Sun, Y. Experiment research on unfrozen water content and porecharacteristic of cement improved soil under freeze-thaw cycle. J. Min. Sci. Technol. 2023, 8, 791–802. [Google Scholar]

- TB 10102-2023; National Railway Administration. Technical Specification for Geotechnical Testing of Railway Engineering. China Railway Publishing House: Beijing, China, 2023.

- GB/T 50123-2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. China Planning Press: Beijing, China, 2019.

- JTG 3430-2020; Ministry of Transport of the People’s Republic of China. Test Methods of Soils for Highway Engineering. China Railway Publishing House: Beijing, China, 2020.

- JY/T 0584-2020; Ministry of Education of the People’s Republic of China. General Rules for Analytical Methods of Scanning Electron Microscopy. Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

- Zhang, C.; Hong, Y.; Cheng, Z.; Jin, L.; Ling, H. Mechanical Properties and Microstructure of High Ductility Solidified Silt. J. Yangtze River Sci. Res. Inst. 2025, 42, 155–164. [Google Scholar]

- Sheng, M.; Zou, C.; Qian, Z.; Lu, X. Experiments on the bearing capacity of aeolian sand stabilized by cement stabilizers. Bull. Geol. Sci. Technol. 2022, 41, 147–153. [Google Scholar]

- Huang, R.; Yuan, Z.; Ruan, B. Influencing factors analysis on unconfined compressive strength of cemented aeolian sand. J. Railw. Sci. Eng. 2023, 20, 2858–2867. [Google Scholar]

- Bai, J.; Zhao, Y.; Shi, J.; He, X. Cross-scale Study on the Mechanical Properties and Frost Resistance Durability of Aeolian Sand Concrete. KSCE J. Civ. Eng. 2021, 25, 4386–4402. [Google Scholar] [CrossRef]

- Cui, H.H.; Zhu, C.J.; Yang, S.L.; Hu, S.Q. Road Performance of Improved Silty Clay Under the Action of Drying-Wetting Cycles. J. S. China Univ. Technol. 2022, 50, 42–49. [Google Scholar]

- Dong, W.; Li, J.X.; Liu, X.; Xue, G. Prediction model for compressive strength of basalt fiber pisha sandstone cement-soil. CNKI 2025. [Google Scholar] [CrossRef]

- Ma, C.; Zheng, S.L.; Ruan, B.; Zhang, X.J.; Xu, B. Nuclear Magnetic Resonance Experimental Study on Cemented Aeolian Sand under Different Curing Temperatures. J. Railw. Sci. Eng. 2022, 19, 1270–1278. [Google Scholar]

- Nguyen, T.T.H.; Cui, Y.J.; Ferber, V.; Herrier, G.; Ozturk, T.; Plier, F.; Puiatti, D.; Salager, S.; Tang, A.M. Effect of freeze-thaw cycles on mechanical strength of lime-treated fine-grained soils. Transp. Geotech. 2019, 21, 100281. [Google Scholar] [CrossRef]

- Cheng, Y.; Yan, Z.Q.; Xu, Y.F.; Wang, W.Z.; Wang, H.; Bai, Y.F. Soil fractal model for pore structure of cement stabilized. J. Eng. Geol. 2025, 33, 482–490. [Google Scholar]

- Tao, G.L.; Wu, X.K.; Yang, X.H.; Liu, W.S.; He, J.; Chen, Y. Meability pore distribution of cement-soil and its effect on per-meability. J. Eng. Geol. 2018, 26, 1243–1249. [Google Scholar]

- Fang, C.; Zhao, T.; Yu, W.; Wang, P.; Zhang, Z.; An, B.; Wu, G.; Liu, S. Effect of pore shape on uniaxial compressive behaviour of porous rock-like materials: DEM simulation. Case Stud. Constr. Mater. 2025, 23, e04938. [Google Scholar] [CrossRef]

- Zeng, W.; Yang, S.; Tian, W. Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng. Fract. Mech. 2018, 200, 430–450. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.; Wang, B.; Yu, Y.; Zhang, C. Characterization of the Porous Structure and Its Influence on Mechanica Properties of High-Content Steel Slag Powder-Cement Foamed Concrete. Mater. Rep. 2025, 39, 181–189. [Google Scholar]

- Yu, S.; Huang, S.; Liu, F.; Ca, H.; Ye, Y. Quantification of pore structure evolution and its correlation with the macroscopic properties of sandstones under freeze–thaw action. Bull Eng Geol Environ. 2024, 83, 3. [Google Scholar] [CrossRef]

- Li, S.; Zhang, M.; Tian, Y.; Pei, W.; Zhong, H. Experimental and numerical investigations on frost damage mechanism of a canal in cold regions. Cold Reg. Sci. Technol. 2015, 116, 1–11. [Google Scholar] [CrossRef]

- Yuan, C.; Qu, S.; Bai, W.; Guan, J.; Xie, Y. Study on the mechanical properties and mesoscopic damage mechanism of recycled aggregate concrete under different dynamic strain rates after freeze-thaw cycles. Case Stud. Constr. Mater. 2025, 22, e04182. [Google Scholar] [CrossRef]

- Gong, Y.; Song, J.; Wu, S.; Zhang, Y. Evolution of pore structure and analysis of freeze damage in granite during cyclic freeze-thaw using NMR technique. Eng. Geol. 2024, 335, 107545. [Google Scholar] [CrossRef]

- Wu, Y.; Dang, F.; Nimbalkar, S.; Chen, Y.; Zhang, F. Property Evolution Law and Damage Mechanism of Pervious Concrete under Different Cycle Modes. J. Build. Mater. 2025, 28, 9–18. [Google Scholar]

- Junyue, Z.; Guibin, W.; Huandui, L.; Mengmeng, Y. Study on the evolution of microscopic pore structure of sandstone under freeze-thaw cycles. Cold Reg. Sci. Technol. 2024, 217, 104018. [Google Scholar]

- De Kock, T.; Boone, M.A.; De Schryver, T.; Van Stappen, J.; Derluyn, H.; Masschaele, B.; De Schutter, G.; Cnudde, V. A Pore-Scale Study of Fracture Dynamics in Rock Using X-ray Micro-CT Under Ambient Freeze–Thaw Cycling. Environ. Sci. Technol. 2015, 49, 2867–2874. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Y.; Wang, S.; Cai, Z.; Mu, Y. Effects of freeze-thaw cycles on mechanical properties of expansive soils at different compaction degrees. Chin. J. Rock Mech. Eng. 2023, 42, 4299–4309. [Google Scholar]

- Yao, X.; Feng, Z.; Wang, F.; Guan, J. Property of multiple admixture concrete in multi-salt soaking under wetting-drying and freezing-thawing cycles. Acta Mater. Compos. Sin. 2018, 35, 690–698. [Google Scholar]

- Sanchez, L.F.M.; Drimalas, T.; Fournier, B. Assessing condition of concrete affected by internal swelling reactions (ISR) through the Damage Rating Index (DRI). Cement 2020, 1, 100001. [Google Scholar] [CrossRef]

- Dehwah, O.H.A.; Xi, Y. Theoretical model for the coupling effect of moisture transport on chloride penetration in concrete. Cem. Concr. Res. 2024, 177, 107431. [Google Scholar] [CrossRef]

- Xiao, Z.; Lai, Y. Study on water and salt transfer mechanism in saline soil under freezing-thawing and dry-wet conditions. Chin. J. Rock Mech. Eng. 2018, 37, 3738–3746. [Google Scholar]

- Luo, C.; Yu, Y.; Zhang, J.; Xie, Y.; Zhang, T.; Du, Q.; Cao, Y.; Cui, W. Study of Heat–Mass Transfer and Salt–Frost Expansion Mechanism of Sulfate Saline Soil during the Unidirectional Freezing Process. Int. J. Geomech. 2024, 24, 04024227. [Google Scholar] [CrossRef]

- Li, Y.G.; Zhang, H.M.; Chen, S.J.; Hu, D.W.; Gao, W. Multi-scale Degradation Mechanism of Aeolian Sand Concrete under Salt-Frost Conditions. Acta Mater. Compos. Sin. 2023, 40, 2331–2342. [Google Scholar]

| Type | Particle Density (g/cm−3) | Optimal Dry Density (g/cm−3) | Optimal Moisture Content (%) | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index |

|---|---|---|---|---|---|---|

| Eolian sand | 2.65 | 1.71 | 6.17 | \ | 14.8 | 6.4 |

| Silt | 2.67 | 1.8 | 18 | 12.3 | 22.6 | 9.3 |

| Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | SO3 | Cl− | Free-CaO | Others | H |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content/% | 57.57 | 19.5 | 6.45 | 3.08 | 1.21 | 0.25 | 1.35 | 2.01 | 0.03 | 0.81 | 0.77 | 6.97 |

| Number | Soil–Sand Ratios | Cement Content/% | Curing Age/d |

|---|---|---|---|

| A1, A2, A3, A4, A5 | 2:8 | 5, 6, 7, 8, 9 | 7 |

| B1, B2, B3, B4, B5 | 3:7 | ||

| C1, C2, C3, C4, C5 | 4:6 | ||

| B1, B4 | Pure Eolian Sand | 5, 8 |

| Number | Soil–Sand Ratios | Cement Content/% | Curing Age/d | Freeze–Thaw Cycle Times/Times |

|---|---|---|---|---|

| B1 | 3:7 | 5 | 7 | 0, 1, 2, 4, 7, 10 |

| B4 | 8 | |||

| B1 | Pure Eolian Sand | 5 | ||

| B4 | 8 |

| Aperture Parameters | Microporosity Percentage | Small-Hole Ratio | Medium Pore Percentage | Large Pore Percentage | Ultra-Low Abundance | Lower Abundance | Medium Abundance | Higher Abundance | Extremely High Abundance | Directed Probability Entropy | Fractal Dimension |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5% | 0.785 | 0.764 | 0.705 | 0.803 | 0.822 | 0.728 | 0.651 | 0.738 | 0.708 | 0.751 | 0.763 |

| 8% | 0.803 | 0.769 | 0.672 | 0.817 | 0.837 | 0.733 | 0.672 | 0.762 | 0.743 | 0.702 | 0.778 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Miao, C.; Shi, Z. Evolution of Pore Structure and Damage Mechanism Analysis of Cement–Silt-Modified Eolian Sand Under Freeze–Thaw Cycles. Materials 2025, 18, 3800. https://doi.org/10.3390/ma18163800

Li X, Miao C, Shi Z. Evolution of Pore Structure and Damage Mechanism Analysis of Cement–Silt-Modified Eolian Sand Under Freeze–Thaw Cycles. Materials. 2025; 18(16):3800. https://doi.org/10.3390/ma18163800

Chicago/Turabian StyleLi, Xunchang, Chenyu Miao, and Zhengzheng Shi. 2025. "Evolution of Pore Structure and Damage Mechanism Analysis of Cement–Silt-Modified Eolian Sand Under Freeze–Thaw Cycles" Materials 18, no. 16: 3800. https://doi.org/10.3390/ma18163800

APA StyleLi, X., Miao, C., & Shi, Z. (2025). Evolution of Pore Structure and Damage Mechanism Analysis of Cement–Silt-Modified Eolian Sand Under Freeze–Thaw Cycles. Materials, 18(16), 3800. https://doi.org/10.3390/ma18163800