Side Oscillation Milling: Modeling, Analysis, and Compensation of Cutting Forces Through Feed Optimization

Abstract

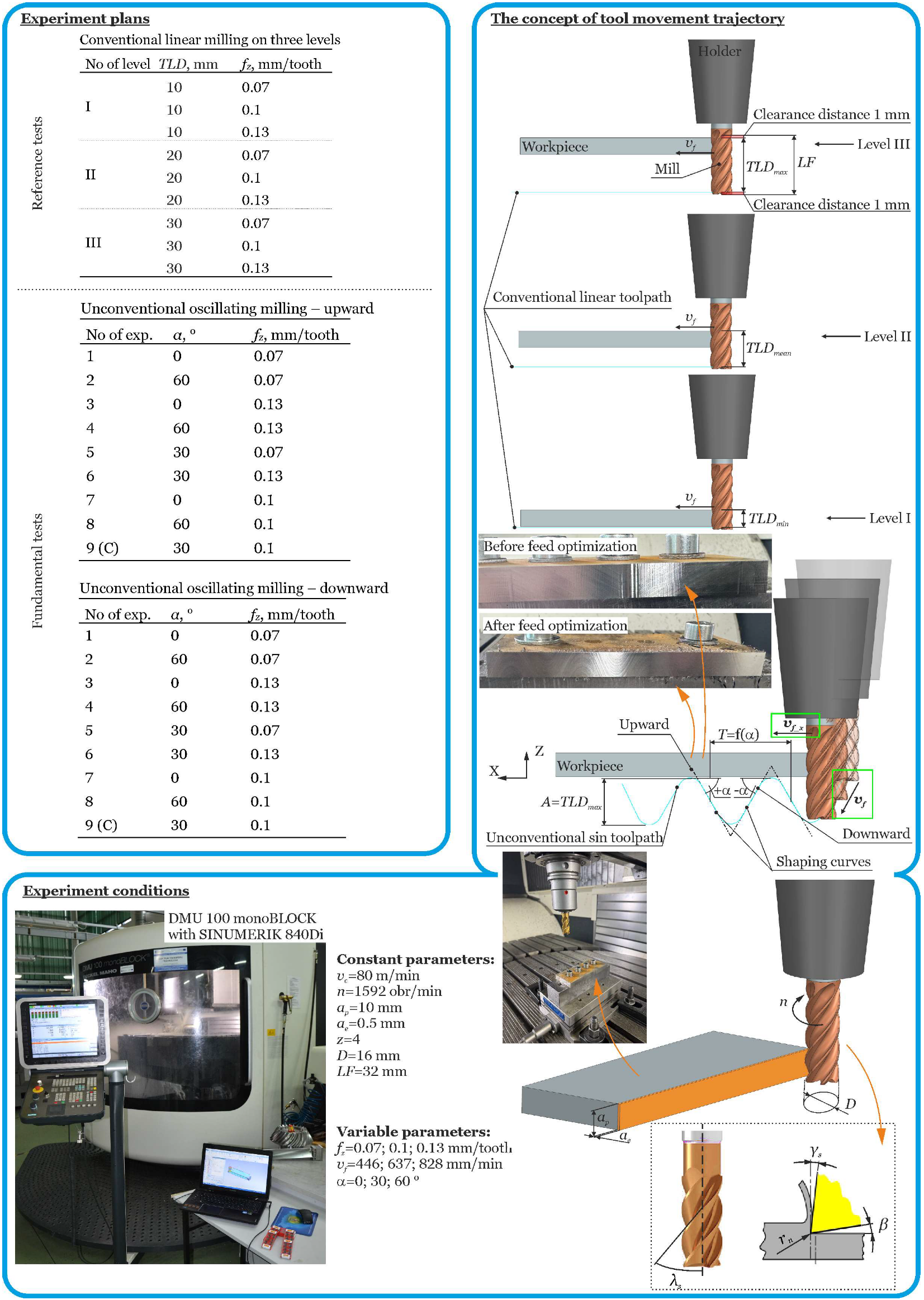

1. Introduction

- The proposal of a sinusoidal tool path in the process of side milling of hardened steel and the development of a relationship that optimizes the feed rate on this path relative to commonly programmed linear paths;

- In addition, a method for determining the period of the sinusoidal path based on the angle of the surface shaping line of the workpiece has been proposed and developed.

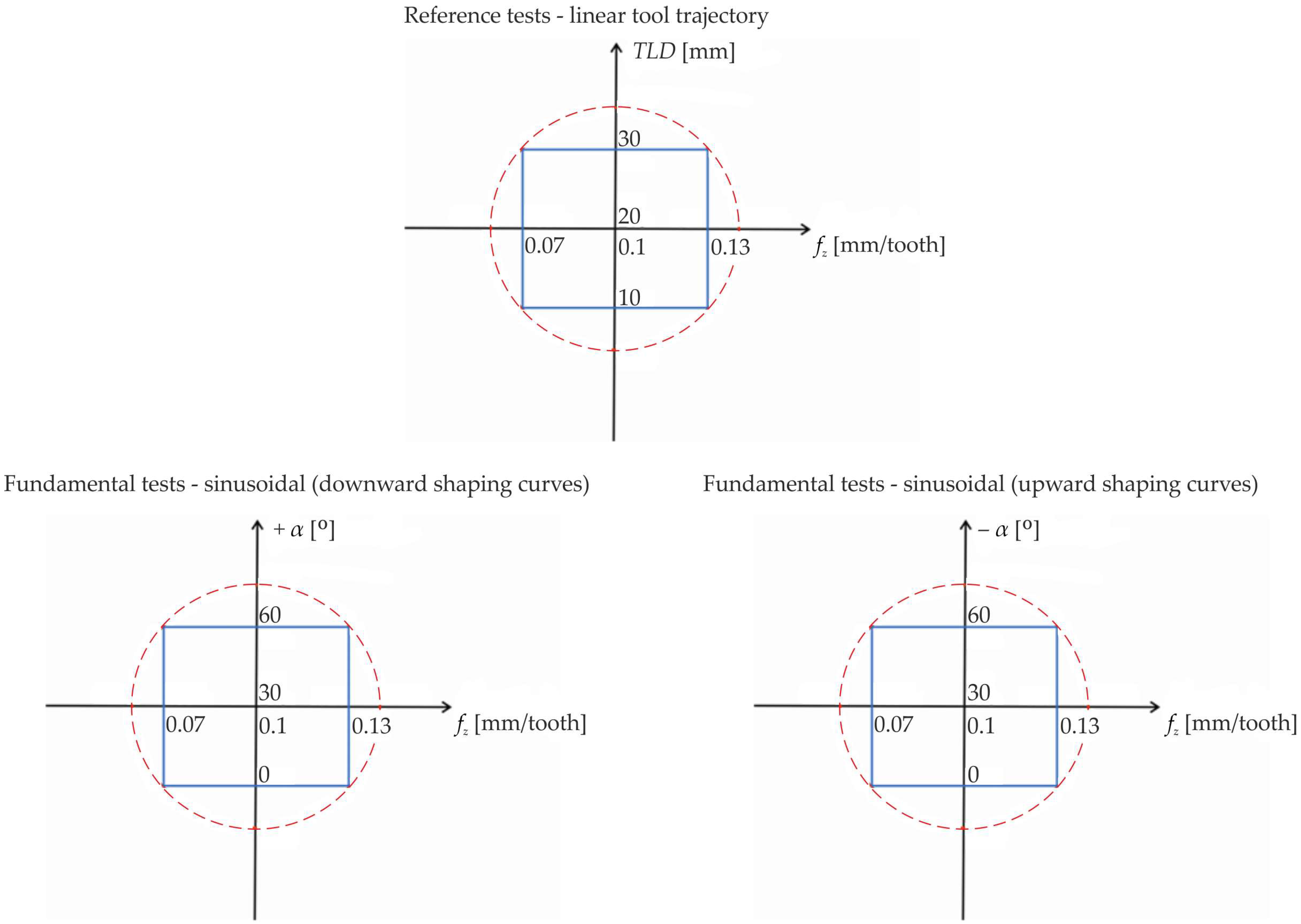

2. Materials and Methods

3. Results and Discussion

3.1. Reference Tests—Models and Analysis

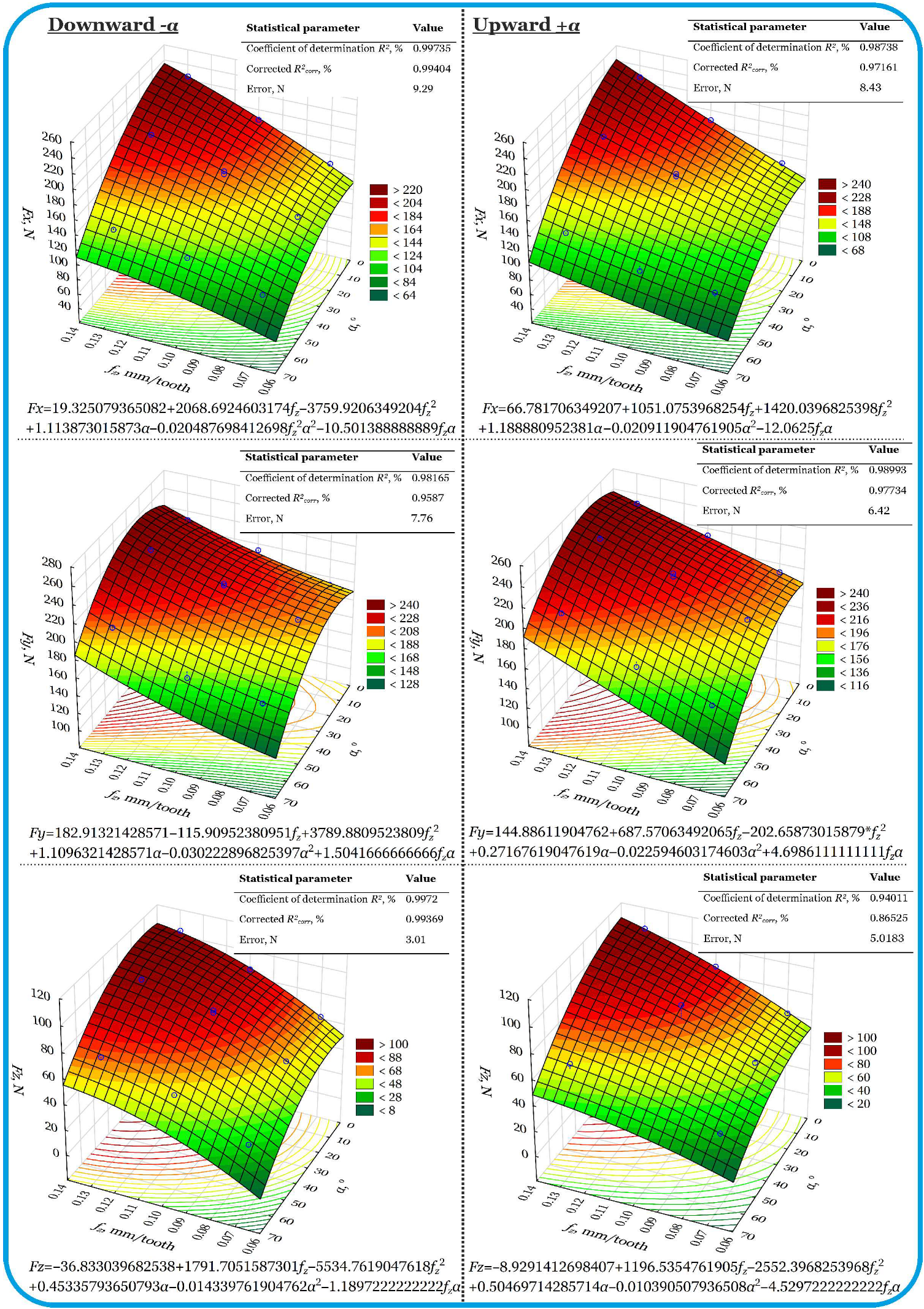

3.2. Fundamental Tests—Models and Analysis

3.2.1. Downward (α−)

3.2.2. Upward (α+)

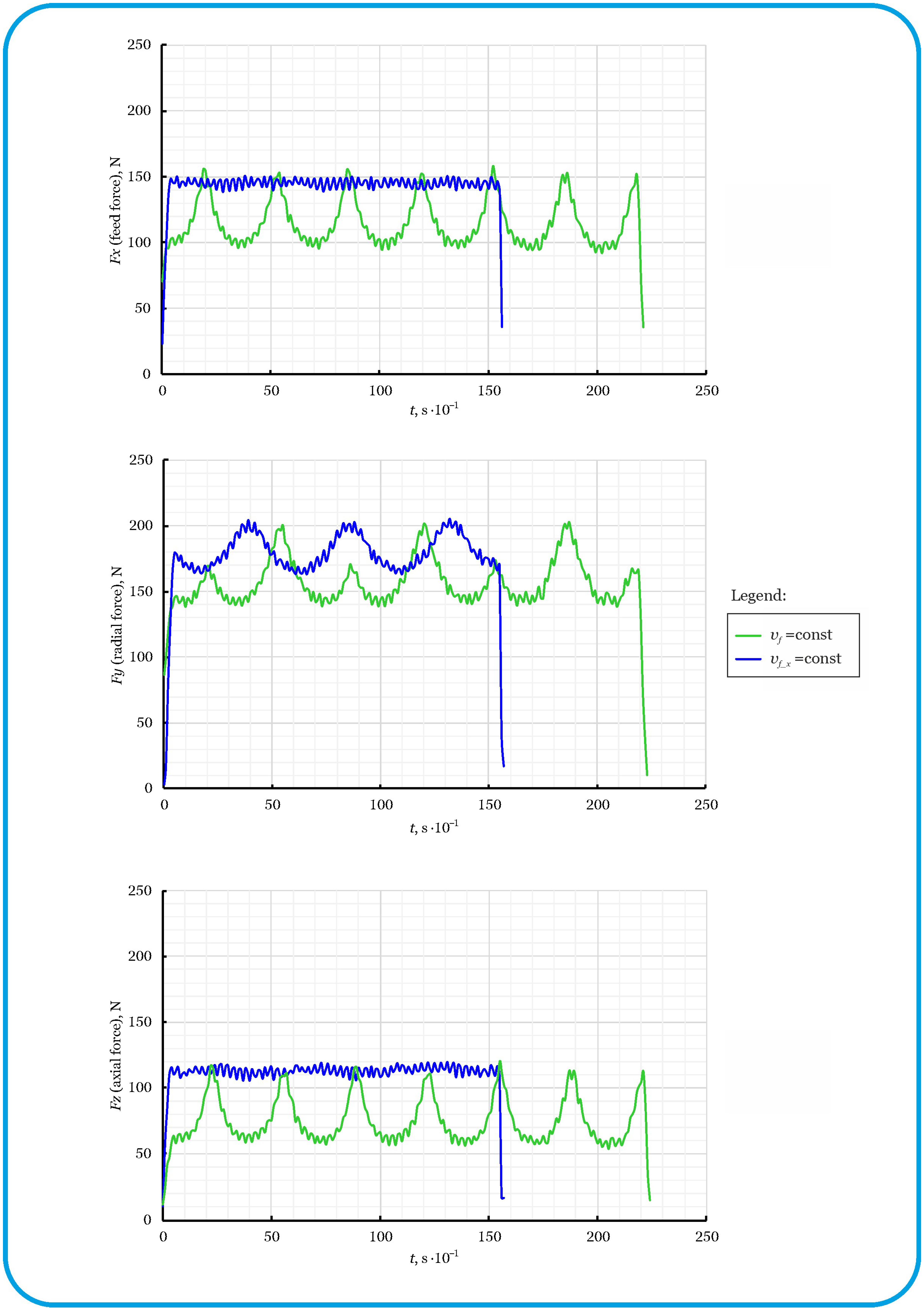

3.3. Fundamental Tests—Compensation

4. Conclusions

- Sinusoidal motion (especially upward) introduces strong interactions between the feed and toolpath geometry (angle α).

- The feed force Fx and the radial force Fy are strongly dependent on the angle of inclination α of the sinusoidal curve that shapes the side surface of the workpiece—a higher inclination (α = 60°) significantly increases the load on the tool, especially at high feed rates.

- The axial force Fz is least sensitive to changes in the parameter α, but interactions with the feed are significant.

- The RSM models have very high coefficients of determination, most above 99%, which confirms their usefulness for predicting and optimizing the oscillating side milling process.

- In terms of minimizing cutting forces, a low feed rate and moderate angle α (e.g., 30°) are recommended; at 60°, the geometric effect and the servo mechanism tracking errors of the machine tool outweigh the technological benefits.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibaraki, S.; Shimizu, T. A Long-Term Control Scheme of Cutting Forces to Regulate Tool Life in End Milling Processes. Precis. Eng. 2010, 34, 675–682. [Google Scholar] [CrossRef]

- Pittalà, G.M.; Linguanotto, S. A Study of Machinability of Al7075-T6 with Solid Carbide End Mills. Procedia CIRP 2022, 115, 148–153. [Google Scholar] [CrossRef]

- Tillmann, W.; Meijer, A.L.; Platt, T.; Biermann, D.; Stangier, D.; Lopes Dias, N.F. Cutting Performance of TiAlN-Based Thin Films in Micromilling High-Speed Steel AISI M3:2. Manuf. Lett. 2024, 40, 6–10. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Gökcen, M.-G.; Bouzakis, E.; Bouzakis, A.; Ipekoglu, M.; Osmanoglu, E.; Batuk, A.-U. Extracting Information from the Cutting Force Signal to Explain and Exploit Its Discrepancy between up and down Slot Milling at the Same Chip Thickness. J. Mater. Process. Technol. 2024, 331, 118492. [Google Scholar] [CrossRef]

- Pleta, A.; Nithyanand, G.; Niaki, F.A.; Mears, L. Identification of Optimal Machining Parameters in Trochoidal Milling of Inconel 718 for Minimal Force and Tool Wear and Investigation of Corresponding Effects on Machining Affected Zone Depth. J. Manuf. Process. 2019, 43, 54–62. [Google Scholar] [CrossRef]

- Damir, A.; Sadek, A.; Attia, H. On the Performance of Cryogenic Technology in Milling of Hardened H13 Tool Steel. Procedia CIRP 2024, 122, 384–389. [Google Scholar] [CrossRef]

- Das, C.R.; Ghosh, A. Performance of Carbide End Mills Coated with New Generation Nano-Composite TiAlSiN in Machining of Austenitic Stainless Steel under near-Dry (MQL) and Flood Cooling Conditions. J. Manuf. Process. 2023, 104, 418–442. [Google Scholar] [CrossRef]

- He, Y.; Sheikh-Ahmad, J.; Zhu, S.; Zhao, C. Cutting Force Analysis Considering Edge Effects in the Milling of Carbon Fiber Reinforced Polymer Composite. J. Mater. Process. Technol. 2020, 279, 116541. [Google Scholar] [CrossRef]

- Ding, M.; Yue, C.; Zhen, R.; Liu, X.; Sun, S.; Liang, S.Y.; Wang, L. Cutting Force Modeling of the Gradient Helix Edge End Mill Based on Helix Angle Differentiation. Thin-Walled Struct. 2025, 215, 113537. [Google Scholar] [CrossRef]

- Uhlmann, E.; Kuche, Y.; Polte, J.; Polte, M. Influence of Cutting Edge Micro-Geometry in Micro-Milling of Copper Alloys with Reduced Lead Content. Procedia CIRP 2018, 77, 662–665. [Google Scholar] [CrossRef]

- Muthuswamy, P. Investigation on Sustainable Machining Characteristics of Tools with Serrated Cutting Edges in Face Milling of AISI 304 Stainless Steel. Procedia CIRP 2022, 105, 865–871. [Google Scholar] [CrossRef]

- Lu, Y.; Zhao, J.; Tang, X.; Li, A.; Li, J. Milling Force Prediction in Titanium Alloy Thin-Walled Components Side Milling Based on Tri-Dexel Model with Comprehensive Consideration of Tool Runout and Workpiece Deflection. J. Manuf. Process. 2025, 141, 1211–1234. [Google Scholar] [CrossRef]

- Meijer, A.L.; Lopes Dias, N.F.; Tillmann, W.; Biermann, D. Preparation of Asymmetrical Cutting Edge Geometries on Micro End Mills Using Pressurized Wet Abrasive Jet Machining for Hard Micromachining of AISI M3:2. CIRP J. Manuf. Sci. Technol. 2024, 51, 252–262. [Google Scholar] [CrossRef]

- Guo, L.; Liao, X.; Yang, W.; Sun, J. An Oscillating Milling Strategy Based on the Uniform Wear Theory for Improving Service Life of the Ball-End Cutter. J. Mater. Process. Technol. 2023, 317, 117993. [Google Scholar] [CrossRef]

- Szallies, K.; Siebert, N.; Bergmann, J.P. Low Frequency Oscillated Milling of Carbon Fiber-Reinforced Plastics. Procedia CIRP 2017, 66, 153–158. [Google Scholar] [CrossRef]

- Guo, L.; Yang, W.; Sun, J. A Continuous Oscillating Milling Strategy Based on Uniform Wear Theory for Improving the Service Life of the Ball-End Cutter. Tribol. Int. 2024, 192, 109318. [Google Scholar] [CrossRef]

- Lopes Da Silva, R.H.; Hassui, A. Cutting Force and Surface Roughness Depend on the Tool Path Used in Side Milling: An Experimental Investigation. Int. J. Adv. Manuf. Technol. 2018, 96, 1445–1455. [Google Scholar] [CrossRef]

- Vila, C.; Siller, H.R.; Rodriguez, C.A.; Bruscas, G.M.; Serrano, J. Economical and Technological Study of Surface Grinding versus Face Milling in Hardened AISI D3 Steel Machining Operations. Int. J. Prod. Econ. 2012, 138, 273–283. [Google Scholar] [CrossRef][Green Version]

- Vavruska, P.; Bartos, F.; Stejskal, M.; Pesice, M.; Zeman, P.; Heinrich, P. Increasing Tool Life and Machining Performance by Dynamic Spindle Speed Control along Toolpaths for Milling Complex Shape Parts. J. Manuf. Process. 2023, 99, 283–297. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G.; Alexandre, R.; Fecheira, J.S.; Silva, F.P.N. Study of the Wear Behaviour of TiAlSiN and TiAlN PVD Coated Tools on Milling Operations of Pre-Hardened Tool Steel. Wear 2021, 476, 203695. [Google Scholar] [CrossRef]

- Dharmendra, P.D.; Lalwani, D.I. A Spiral Toolpath for Machining of Elliptical Pockets Using Partial Differential Equation. Mater. Today Proc. 2015, 2, 3394–3402. [Google Scholar] [CrossRef]

- Guo, Q.; Zhao, B.; Jiang, Y.; Zhao, W. Cutting Force Modeling for Non-Uniform Helix Tools Based on Compensated Chip Thickness in Five-Axis Flank Milling Process. Precis. Eng. 2018, 51, 659–681. [Google Scholar] [CrossRef]

- Zan, S.; Liao, Z.; Robles-Linares, J.A.; Garcia Luna, G.; Axinte, D. Machining of Long Ceramic Fibre Reinforced Metal Matrix Composites–How Could Temperature Influence the Cutting Mechanisms? Int. J. Mach. Tools Manuf. 2023, 185, 103994. [Google Scholar] [CrossRef]

- Smith, S.; Woody, B.; Barkman, W.; Tursky, D. Temperature Control and Machine Dynamics in Chip Breaking Using CNC Toolpaths. CIRP Ann. 2009, 58, 97–100. [Google Scholar] [CrossRef]

- Marin, F.; Fagali De Souza, A.; Da Silva Gaspar, H.; Calleja-Ochoa, A.; López De Lacalle, L.N. Topography Simulation of Free-Form Surface Ball-End Milling through Partial Discretization of Linearised Toolpaths. Eng. Sci. Technol. Int. J. 2024, 55, 101757. [Google Scholar] [CrossRef]

- Zhang, K.; Xiao, W.; Fan, X.; Zhao, G. CAM as a Service with Dynamic Toolpath Generation Ability for Process Optimization in STEP-NC Compliant CNC Machining. J. Manuf. Syst. 2025, 80, 294–308. [Google Scholar] [CrossRef]

- Stejskal, M.; Vavruska, P.; Zeman, P.; Lomicka, J. Optimization of Tool Axis Orientations in Multi-Axis Toolpaths to Increase Surface Quality and Productivity. Procedia CIRP 2021, 101, 69–72. [Google Scholar] [CrossRef]

- Darzi, S.; Kinsey, B.L.; Ha, J. Reforming Toolpath Effect on Deformation Mechanics in Double-Sided Incremental Forming. Int. J. Mech. Sci. 2024, 280, 109548. [Google Scholar] [CrossRef]

- Zhang, T.; Ma, W.; Yao, W.; Wu, J.; Zhang, Y.; Cong, J.; Shan, L.; Dong, J.; Yu, T.; Zhao, J. Surface Profile Prediction Modeling of Spiral Toolpath for Axial Ultrasonic Vibration-Assisted Polishing. Ceram. Int. 2023, 49, 23654–23668. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, Y.; Ding, Y. Toolpath Generation for Robotic Flank Milling via Smoothness and Stiffness Optimization. Robot. Comput.-Integr. Manuf. 2024, 85, 102640. [Google Scholar] [CrossRef]

- LopezdeLacalle, L.N.L.; Lamikiz, A.; Sanchez, J.A.; de Bustos, I.F. Simultaneous Measurement of Forces and Machine Tool Position for Diagnostic of Machining Tests. IEEE Trans. Instrum. Meas. 2005, 54, 2329–2335. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; De Lacalle, L.N.L.; Urbikain, G.; Pereira, O.; Martínez, S.; Bris, J. On the Relationship between Cutting Forces and Anisotropy Features in the Milling of LPBF Inconel 718 for near Net Shape Parts. Int. J. Mach. Tools Manuf. 2021, 170, 103801. [Google Scholar] [CrossRef]

- López De Lacalle, L.N.; Lamikiz, A.; Sánchez, J.A.; Salgado, M.A. Toolpath Selection Based on the Minimum Deflection Cutting Forces in the Programming of Complex Surfaces Milling. Int. J. Mach. Tools Manuf. 2007, 47, 388–400. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Gao, L.; Shao, X. A New Approach for Predicting and Collaborative Evaluating the Cutting Force in Face Milling Based on Gene Expression Programming. J. Netw. Comput. Appl. 2013, 36, 1540–1550. [Google Scholar] [CrossRef]

- Shi, K.; Shi, X.; Li, J.; Qiang, B.; Ren, J.; Shi, Y. A Novel Method for Predicting Cutting Force Considering Tool Wear by Power Consumption in Milling Process. J. Manuf. Process. 2025, 149, 632–646. [Google Scholar] [CrossRef]

- Hu, M.; Li, B.; Zhang, B.; Wang, R.; Chen, L. Improved SVR Method for Predicting the Cutting Force of a TBM Cutter Using Linear Cutting Machine Test Data. KSCE J. Civ. Eng. 2021, 25, 4425–4442. [Google Scholar] [CrossRef]

- Baraheni, M.; Amini, S. Mathematical Model to Predict Cutting Force in Rotary Ultrasonic Assisted End Grinding of Si3N4 Considering Both Ductile and Brittle Deformation. Measurement 2020, 156, 107586. [Google Scholar] [CrossRef]

- Bharat, N.; Bose, P.S.C. Predictive Modeling of Cutting Forces in Laser-Assisted Turning of AA7178-Nano SiC Composite Using Different Backpropagation Neural Networks. Measurement 2025, 245, 116673. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, Y.; Huang, Y.; Gong, S.; Sun, M.; Liu, M. Study on Developing Predicted System Model of Cutting-Edge Trajectory for Micro-Milling Process Based on Tool Runout Error, Chip Thickness and Force Signal. Mech. Syst. Signal Process. 2025, 228, 112410. [Google Scholar] [CrossRef]

- Li, C.P.; Kim, M.-Y.; Islam, M.d.M.; Ko, T.J. Mechanism Analysis of Hybrid Machining Process Comprising EDM and End Milling. J. Mater. Process. Technol. 2016, 237, 309–319. [Google Scholar] [CrossRef]

- Żyłka, Ł.; Flejszar, R.; Krupa, K.; Lajmert, P. Redefinition of Precision in Finishing Milling: Exploring the Influence of Tool Margin and Edge Micro-Radius on Surface Roughness. Manuf. Lett. 2024, 41, 52–58. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gdula, M.; Żurek, P. Side Oscillation Milling: Modeling, Analysis, and Compensation of Cutting Forces Through Feed Optimization. Materials 2025, 18, 3789. https://doi.org/10.3390/ma18163789

Gdula M, Żurek P. Side Oscillation Milling: Modeling, Analysis, and Compensation of Cutting Forces Through Feed Optimization. Materials. 2025; 18(16):3789. https://doi.org/10.3390/ma18163789

Chicago/Turabian StyleGdula, Michał, and Piotr Żurek. 2025. "Side Oscillation Milling: Modeling, Analysis, and Compensation of Cutting Forces Through Feed Optimization" Materials 18, no. 16: 3789. https://doi.org/10.3390/ma18163789

APA StyleGdula, M., & Żurek, P. (2025). Side Oscillation Milling: Modeling, Analysis, and Compensation of Cutting Forces Through Feed Optimization. Materials, 18(16), 3789. https://doi.org/10.3390/ma18163789