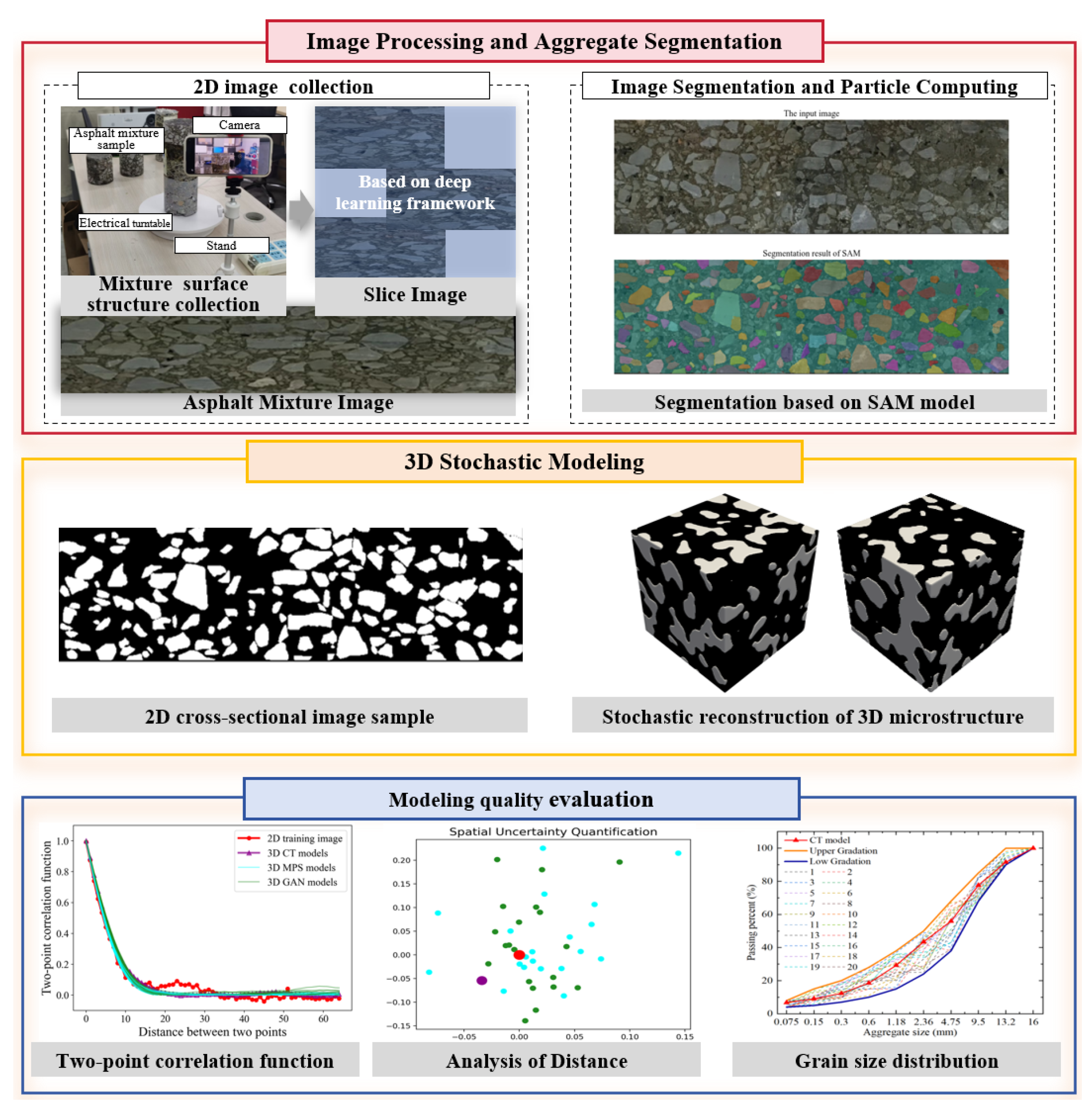

Machine-Learning-Driven Stochastic Modeling Method for 3D Asphalt Mixture Reconstruction from 2D Images

Abstract

1. Introduction

- • We explore a data-effective and low-cost way to generate high-quality 3D asphalt mixture models.

- • With the objective to realize accurate semantic segmentation and grain identification, the powerful generalization ability of the Segment Anything Model is employed to tackle 2D asphalt mixture images.

- • Based on 2D asphalt mixture images, Multiple-Point Statistics and Nearest Neighbor Simulation are employed to reproduce spatial patterns and generate diverse 3D models.

2. Image Processing and Aggregate Segmentation

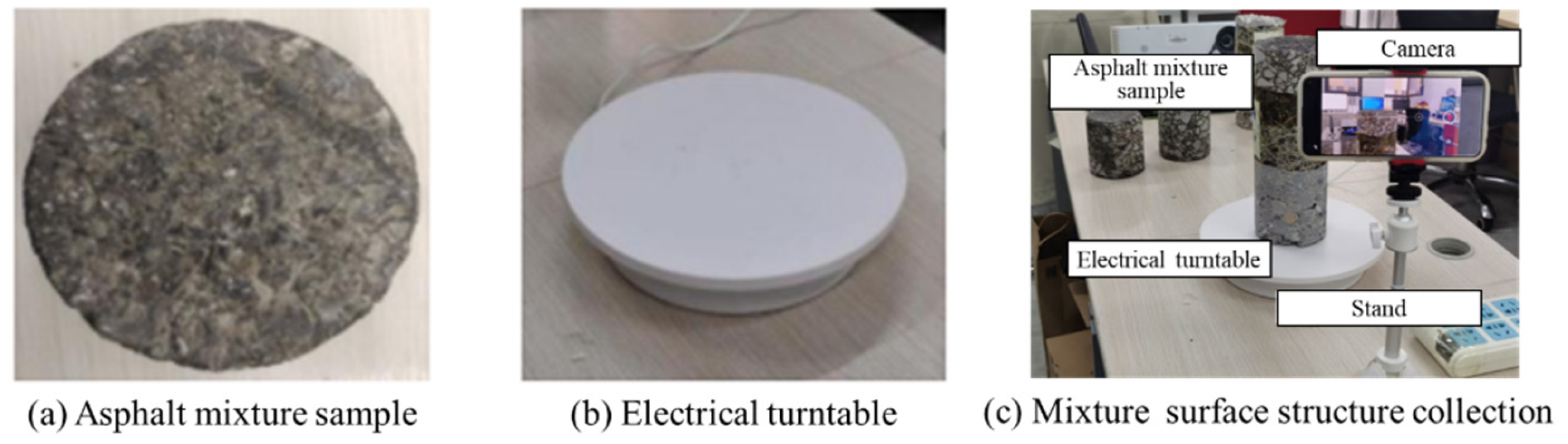

2.1. Image Acquisition with Smartphone-Based Multi-Angle Imaging System

2.2. Large-Size Surface Image Synthesis via Deep-Learning-Based Image Quilting

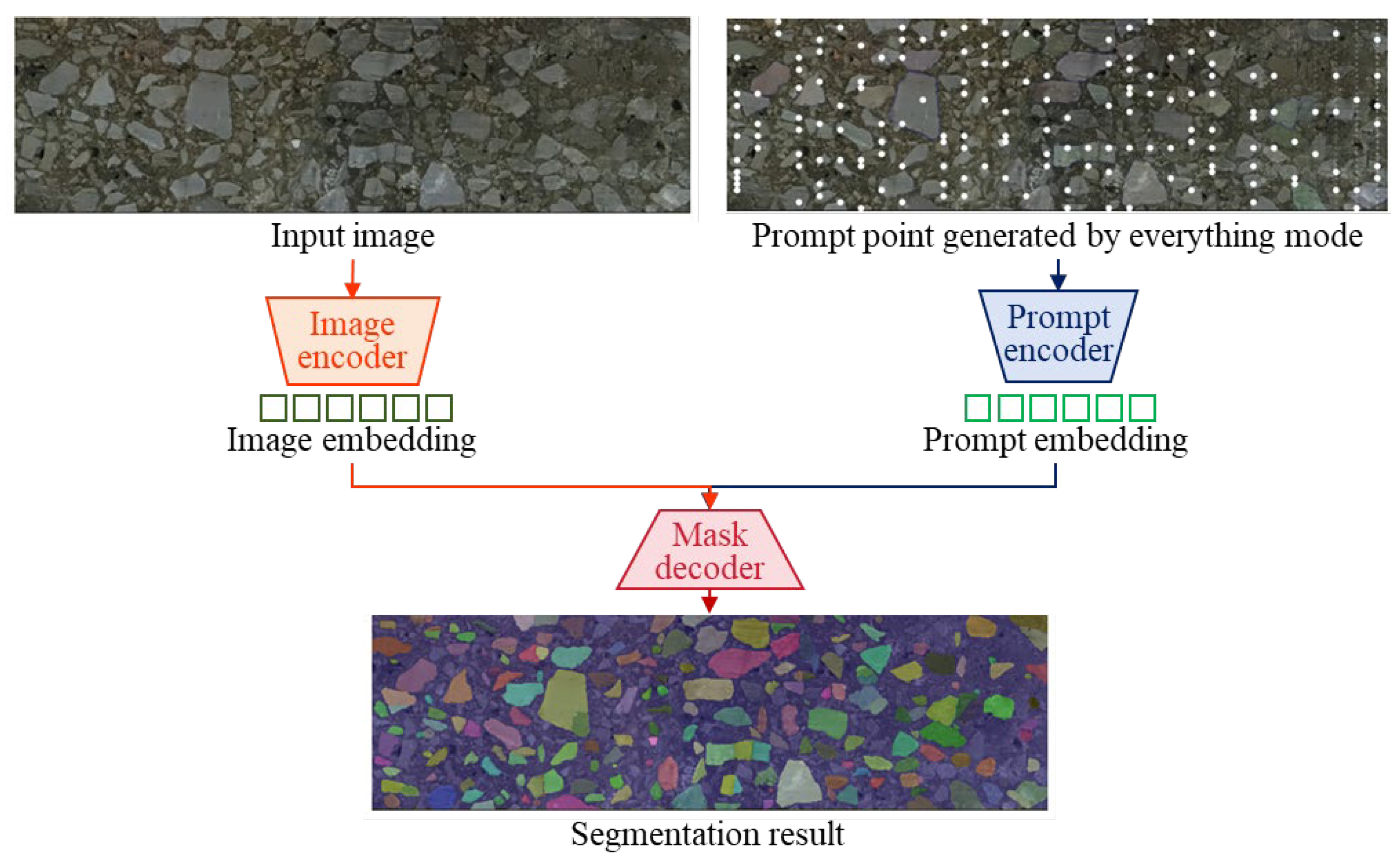

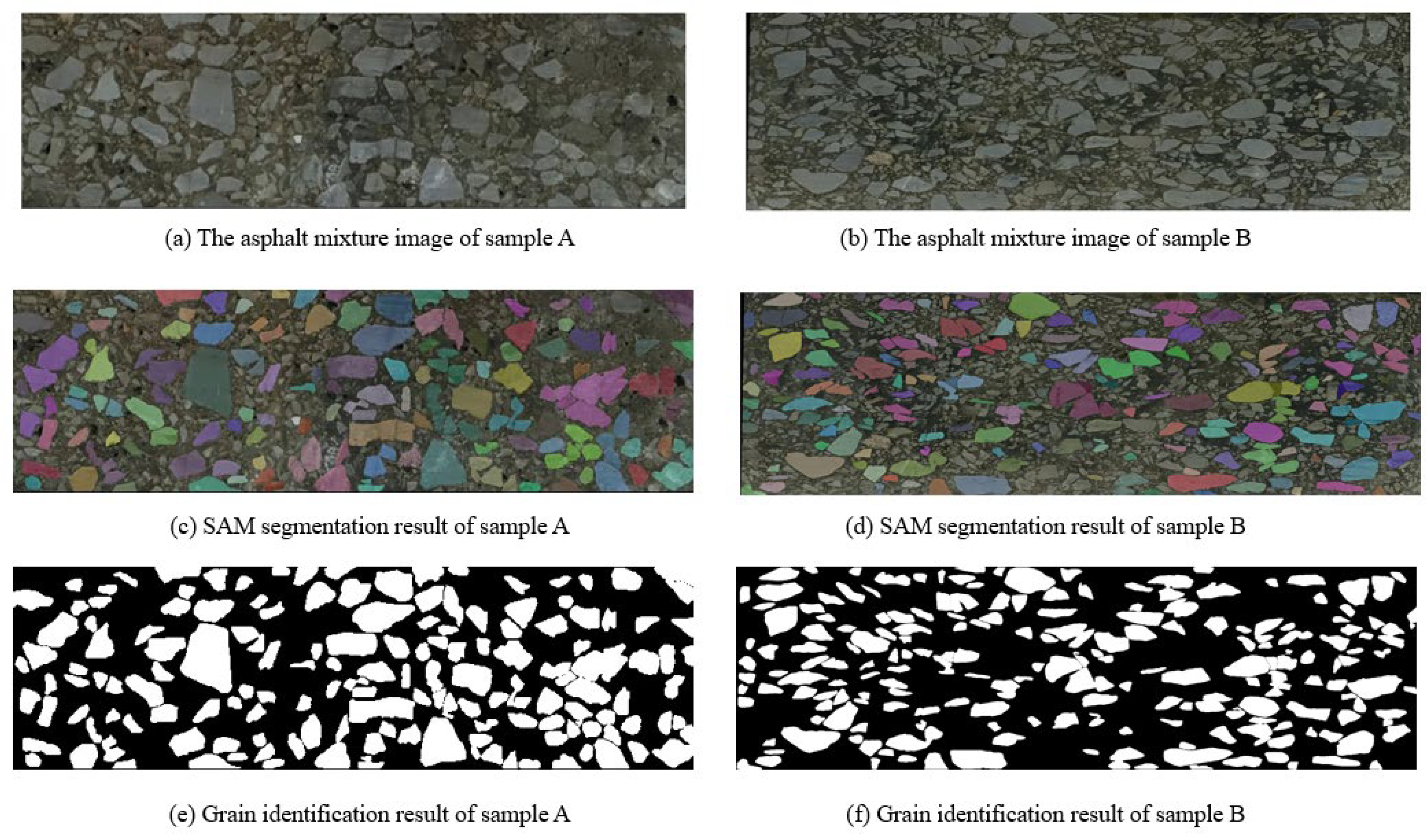

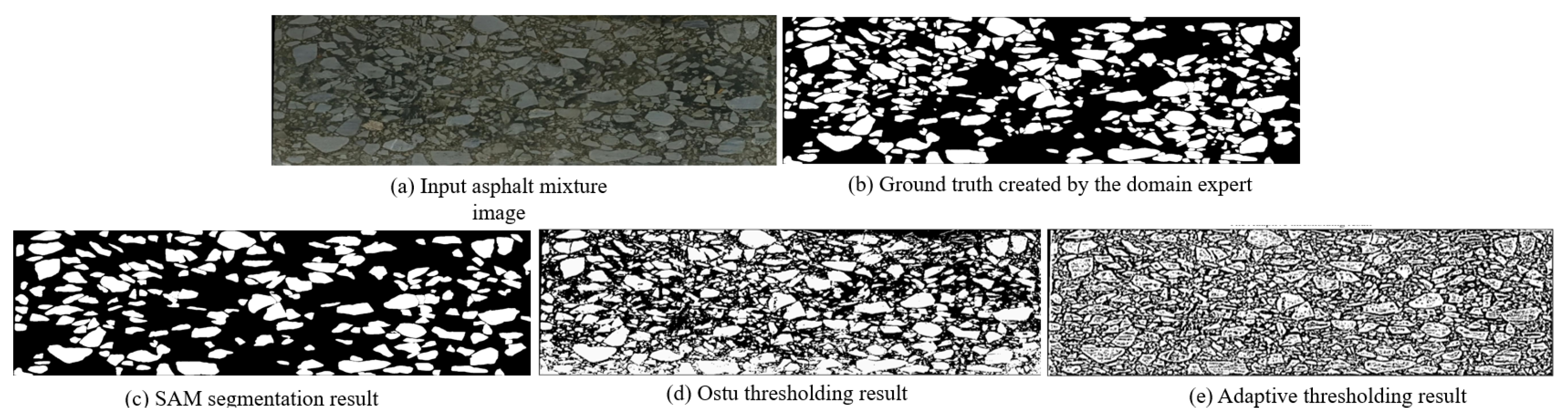

2.3. Automated Grain Segmentation with Segment Anything Model

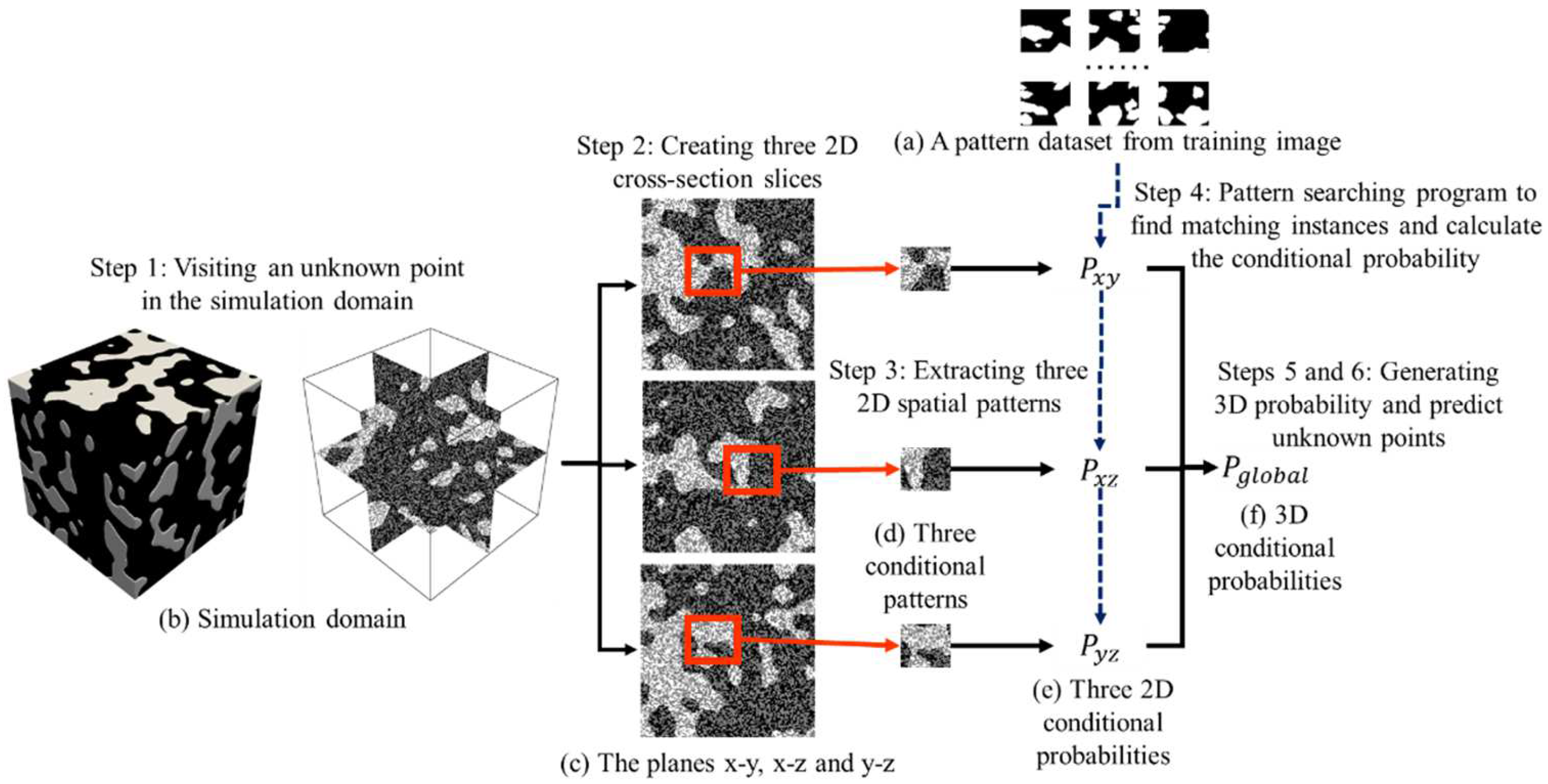

3. Three-Dimensional Stochastic Modeling from Two-Dimensional Training Image

3.1. Principles of Stochastic Modeling and Multiple-Point Statistics

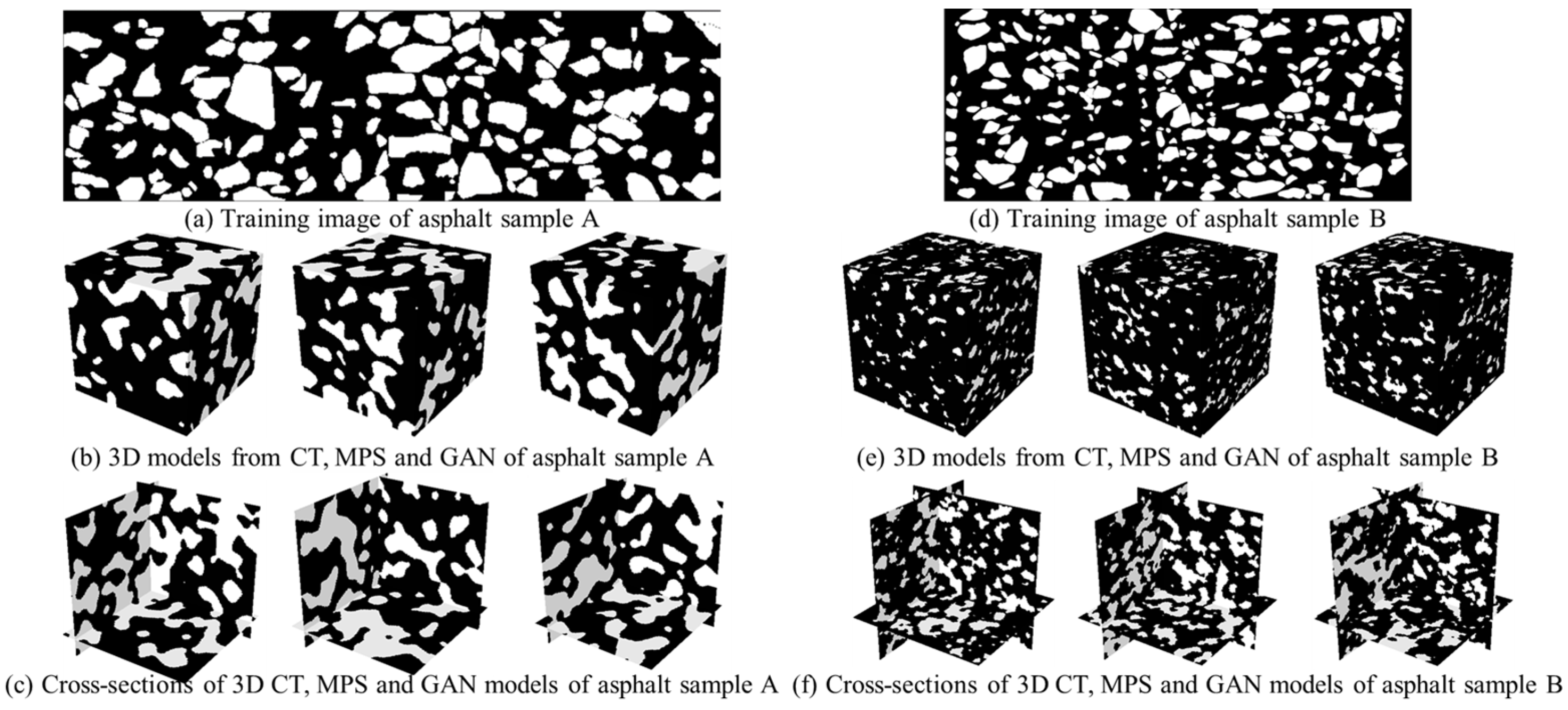

3.2. Three-Dimensional Modeling Based on Two-Dimensional Training Images

| Algorithm 1 Probability Aggregation with the Bordley Formula |

| Input: Training image TI, three 2D conditional probabilities , and , weight Output: 3D conditional probability 1. Calculate the prior probability of each facies according to training image TI 2. Create an empty list Odd = { } 3. Calculate 4. for each probability in the list {, , , }: 5. Compute the 6. Store into the list Odd 7. end 8. Calculate the = 9. for each odd term in the list Odd: 10. 11. end 12. Calculate the global probability |

4. Numerical Simulation of Geometrical Characteristics and Physical Property

4.1. Modeling Quality Evaluation Based on Statistical Characteristics

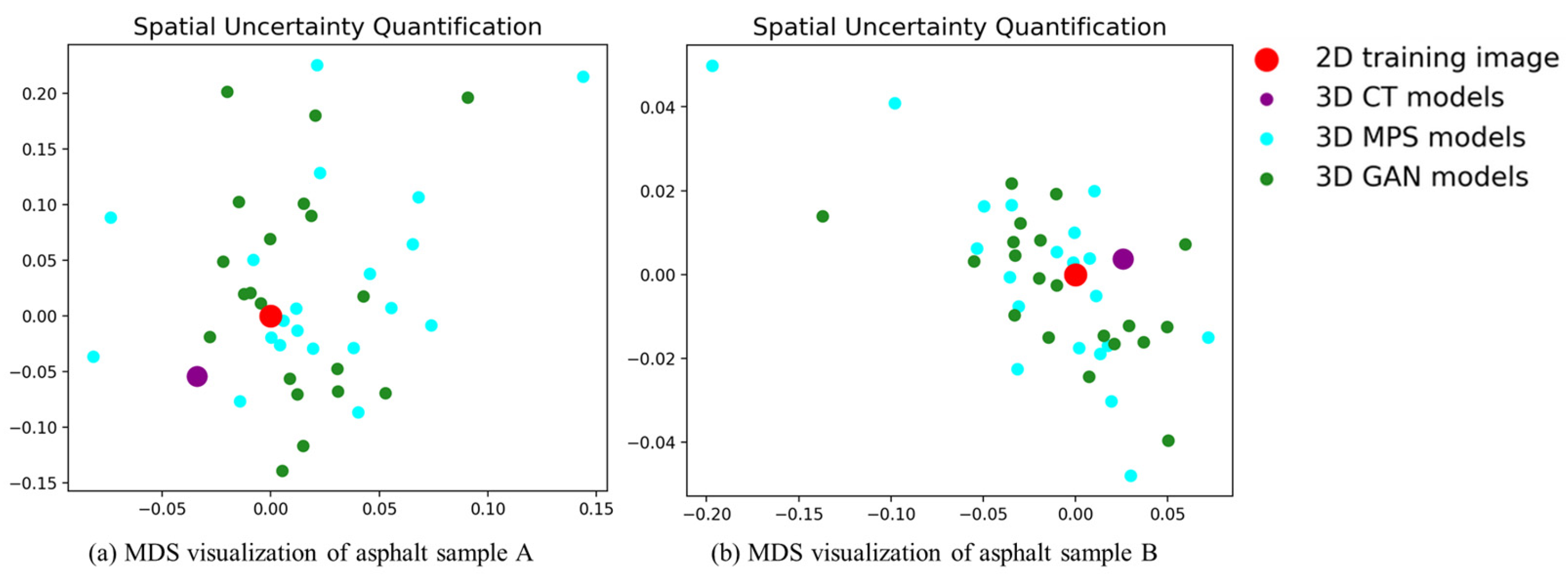

4.2. Modeling Uncertainty Quantification Based on Analysis of Distance

4.3. Physical Property Estimation Based on Aggregation Grain Distribution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baldovino, J.D.J.A.; Palma Calabokis, O.; Saba, M. From Bibliometric Analysis to Experimental Validation: Bibliometric and Literature Review of Four Cementing Agents in Soil Stabilization with Experimental Focus on Xanthan Gum. Sustainability 2024, 16, 5363. [Google Scholar] [CrossRef]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A Review on Solutions for Improving Rutting Resistance of Asphalt Pavement and Test Methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Deng, C.; Xue, J.; Chen, Z. Investigation into the Performance of Asphalt Mixture Designed Using Different Methods. Constr. Build. Mater. 2018, 177, 378–387. [Google Scholar] [CrossRef]

- Peng, C.; Wang, Z.C.; Zhu, C.Z.; Kuang, D.M. 3D Reconstruction of Asphalt Mixture Based on 2D Images. Constr. Build. Mater. 2025, 462, 139938. [Google Scholar] [CrossRef]

- Jin, C.; Zou, F.; Yang, X.; Liu, K. 3-D Virtual Design and Microstructural Modeling of Asphalt Mixture Based on a Digital Aggregate Library. Comput. Struct. 2021, 242, 106378. [Google Scholar] [CrossRef]

- Han, D.; Liu, G.; Zhao, Y.; Pan, Y.; Yang, T. Research on Thermal Properties and Heat Transfer of Asphalt Mixture Based on 3D Random Reconstruction Technique. Constr. Build. Mater. 2021, 270, 121393. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, X.N.; Li, Z.; Chen, Z.Q. Research on the Homogeneity of Asphalt Pavement Quality Using X-Ray Computed Tomography (CT) and Fractal Theory. Constr. Build. Mater. 2014, 68, 587–598. [Google Scholar] [CrossRef]

- Chen, B.; Wang, R.; Yu, X.; Dong, F.; Ding, G. Identifying the Influence of Asphalt Mixture Workability Improvement on the Characteristics of Asphalt, Aggregate and Void after Compaction Utilizing CT Scanning Technology. Constr. Build. Mater. 2024, 448, 138172. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Al-Mayah, A. A Review of Microstructure Characterization of Asphalt Mixtures Using Computed Tomography Imaging: Prospects for Properties and Phase Determination. Constr. Build. Mater. 2023, 385, 131419. [Google Scholar] [CrossRef]

- Liu, Z.; Gu, X.; Ren, H.; Zhou, Z.; Wang, X.; Tang, S. Analysis of the Dynamic Responses of Asphalt Pavement Based on Full-Scale Accelerated Testing and Finite Element Simulation. Constr. Build. Mater. 2022, 325, 126429. [Google Scholar] [CrossRef]

- Yang, E.; Tang, Y.; Li, L.; Yan, W.; Huang, B.; Qiu, Y. Research on the recurrent neural network-based fatigue damage model of asphalt binder and the finite element analysis development. Constr. Build. Mater. 2021, 267, 121761. [Google Scholar] [CrossRef]

- Li, X.; Shi, L.; Liao, W.; Wang, Y.; Nie, W. Study on the Influence of Coarse Aggregate Morphology on the Meso-Mechanical Properties of Asphalt Mixtures Using Discrete Element Method. Constr. Build. Mater. 2024, 426, 136252. [Google Scholar] [CrossRef]

- Ai, X.; Yi, J.; Pei, Z.; Zhou, W.; Feng, D. Advances in Discrete Element Modeling of Asphalt Mixture: A Literature Review. Arch. Comput. Methods Eng. 2024, 31, 4003–4029. [Google Scholar] [CrossRef]

- Polaczyk, P.; Ma, Y.; Jarrar, Z.; Jiang, X.; Xiao, R.; Huang, B. Quantification of Asphalt Mixture Interlocking Utilizing 2D and 3D Image Processing. J. Mater. Civ. Eng. 2023, 35, 04022382. [Google Scholar] [CrossRef]

- Fan, X.; Lv, S.; Xia, C.; Ge, D.; Liu, C.; Lu, W. Strength Prediction of Asphalt Mixture under Interactive Conditions Based on BPNN and SVM. Case Stud. Constr. Mater. 2024, 21, e03489. [Google Scholar] [CrossRef]

- Gong, H.; Sun, Y.; Hu, W.; Polaczyk, P.A.; Huang, B. Investigating Impacts of Asphalt Mixture Properties on Pavement Performance Using LTPP Data through Random Forests. Constr. Build. Mater. 2019, 204, 203–212. [Google Scholar] [CrossRef]

- Li, C.; Guo, J.; Porikli, F.; Ping, Y. LightenNet: A Convolutional Neural Network for Weakly Illuminated Image Enhancement. Pattern Recognit. Lett. 2018, 104, 15–22. [Google Scholar] [CrossRef]

- Cano-Ortiz, S.; Sainz-Ortiz, E.; Lloret Iglesias, L.; Martínez Ruiz del Árbol, P.; Castro-Fresno, D. Leveraging a Deep Learning Generative Model to Enhance Recognition of Minor Asphalt Defects. Sci. Rep. 2024, 14, 28904. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Lin, C.; Ren, L.; Yan, W.; An, S.; Chen, B.; Wang, Y.; Zhang, X.; You, C.; Zhang, Y. Reconstruction of 3D Porous Media Using Multiple-Point Statistics Based on a 3D Training Image. J. Nat. Gas Sci. Eng. 2018, 51, 129–140. [Google Scholar] [CrossRef]

- Zuo, C.; Pan, Z.; Yin, Z.; Guo, C. A Nearest Neighbor Multiple-Point Statistics Method for Fast Geological Modeling. Comput. Geosci. 2022, 167, 105208. [Google Scholar] [CrossRef]

- Tan, X.; Tahmasebi, P.; Caers, J. Comparing Training-Image-Based Algorithms Using an Analysis of Distance. Math. Geosci. 2014, 46, 149–169. [Google Scholar] [CrossRef]

- Mohammadi, F.S.; Shabani, H.; Zarei, M. Fast and Robust Feature-Based Stitching Algorithm for Microscopic Images. Sci. Rep. 2024, 14, 13304. [Google Scholar] [CrossRef] [PubMed]

- Thore, P.; Shtuka, A.; Lecour, M.; Ait-Ettajer, T.; Cognot, R. Structural Uncertainties: Determination, Management, and Applications. Geophysics 2002, 67, 840–852. [Google Scholar] [CrossRef]

- Mariethoz, G.; Renard, P.; Straubhaar, J. The Direct Sampling Method to Perform Multiple-Point Geostatistical Simulations. Water Resour. Res. 2010, 46, W11536. [Google Scholar] [CrossRef]

- Öngün, C.; Temizel, A. Paired 3D Model Generation with Conditional Generative Adversarial Networks. In Proceedings of the European Conference on Computer Vision (ECCV 2018), Munich, Germany, 8–14 September 2018; Springer International Publishing: Cham, Switzerland, 2018; pp. 473–487. [Google Scholar]

- Angiulli, F. Fast Condensed Nearest Neighbor Rule. In Proceedings of the 22nd International Conference on Machine Learning (ICML 2005), Bonn, Germany, 7–11 August 2005; Association for Computing Machinery: New York, NY, USA, 2005; pp. 25–32. [Google Scholar]

- Strebelle, S. Conditional Simulation of Complex Geological Structures Using Multiple-Point Statistics. Math. Geol. 2002, 34, 1–21. [Google Scholar] [CrossRef]

- Bordley, R.F. A Multiplicative Formula for Aggregating Probability Assessments. Manag. Sci. 1982, 28, 1137–1148. [Google Scholar] [CrossRef]

- Feng, J.; Teng, Q.; He, X.; Wu, X. Accelerating multi-point statistics reconstruction method for porous media via deep learning. Acta Mater. 2018, 159, 296–308. [Google Scholar] [CrossRef]

- Jiao, Y.; Stillinger, F.H.; Torquato, S. Modeling Heterogeneous Materials via Two-Point Correlation Functions: Basic Principles. Phys. Rev. E 2007, 76, 031110. [Google Scholar] [CrossRef]

- Cohn, H.; Kumar, A. Universally Optimal Distribution of Points on Spheres. J. Am. Math. Soc. 2007, 20, 99–148. [Google Scholar] [CrossRef]

| Sample | Segmentation Method | Pixel Accuracy | Intersection of Union | Dice Coefficient | Hausdorff Distance |

|---|---|---|---|---|---|

| Sample A | SAM | 0.9456 | 0.8830 | 0.9379 | 7.0711 |

| Ostu thresholding | 0.8003 | 0.6402 | 0.7807 | 8.0000 | |

| Adaptive thresholding | 0.7650 | 0.6264 | 0.7703 | 9.4868 | |

| Sample B | SAM | 0.9442 | 0.8525 | 0.9204 | 20.6155 |

| Ostu thresholding | 0.7749 | 0.6016 | 0.7513 | 35.3836 | |

| Adaptive thresholding | 0.6870 | 0.4946 | 0.6619 | 34.6699 |

| Index | MPS for Sample A | MPS for Sample B | ||

|---|---|---|---|---|

| Statistic | p-Value | Statistic | p-Value | |

| 1 | 0.3133 | 0.2769 | 0.2129 | 0.3807 |

| 2 | 0.3026 | 0.3146 | 0.1479 | 0.6589 |

| 3 | 0.3226 | 0.2472 | 0.1787 | 0.5532 |

| 4 | 0.3188 | 0.2589 | 0.1670 | 0.6015 |

| 5 | 0.3479 | 0.1777 | 0.1258 | 0.6912 |

| 6 | 0.3169 | 0.2650 | 0.1853 | 0.5222 |

| 7 | 0.3185 | 0.2599 | 0.1357 | 0.6808 |

| 8 | 0.321 | 0.2521 | 0.1811 | 0.5423 |

| 9 | 0.2965 | 0.3377 | 0.1506 | 0.6526 |

| 10 | 0.3552 | 0.1605 | 0.1677 | 0.5989 |

| 11 | 0.3245 | 0.2414 | 0.1400 | 0.6743 |

| 12 | 0.3288 | 0.2284 | 0.1303 | 0.6872 |

| 13 | 0.3148 | 0.2720 | 0.1978 | 0.4601 |

| 14 | 0.3282 | 0.2303 | 0.2334 | 0.2705 |

| 15 | 0.2825 | 0.3951 | 0.2380 | 0.2462 |

| 16 | 0.3492 | 0.1746 | 0.1414 | 0.6719 |

| 17 | 0.3159 | 0.2684 | 0.1164 | 0.6965 |

| 18 | 0.3215 | 0.2506 | 0.2018 | 0.4396 |

| 19 | 0.3228 | 0.2463 | 0.1460 | 0.6631 |

| 20 | 0.3207 | 0.2530 | 0.1343 | 0.6827 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Huang, L. Machine-Learning-Driven Stochastic Modeling Method for 3D Asphalt Mixture Reconstruction from 2D Images. Materials 2025, 18, 3787. https://doi.org/10.3390/ma18163787

Zhang J, Huang L. Machine-Learning-Driven Stochastic Modeling Method for 3D Asphalt Mixture Reconstruction from 2D Images. Materials. 2025; 18(16):3787. https://doi.org/10.3390/ma18163787

Chicago/Turabian StyleZhang, Jiayu, and Liang Huang. 2025. "Machine-Learning-Driven Stochastic Modeling Method for 3D Asphalt Mixture Reconstruction from 2D Images" Materials 18, no. 16: 3787. https://doi.org/10.3390/ma18163787

APA StyleZhang, J., & Huang, L. (2025). Machine-Learning-Driven Stochastic Modeling Method for 3D Asphalt Mixture Reconstruction from 2D Images. Materials, 18(16), 3787. https://doi.org/10.3390/ma18163787