Effects of Temperature-Control Admixtures on Shrinkage and Mechanical Properties of Fly Ash Concrete: Experiments and Modeling

Abstract

1. Introduction

2. Experimental Program

2.1. Raw Materials and Mix Design

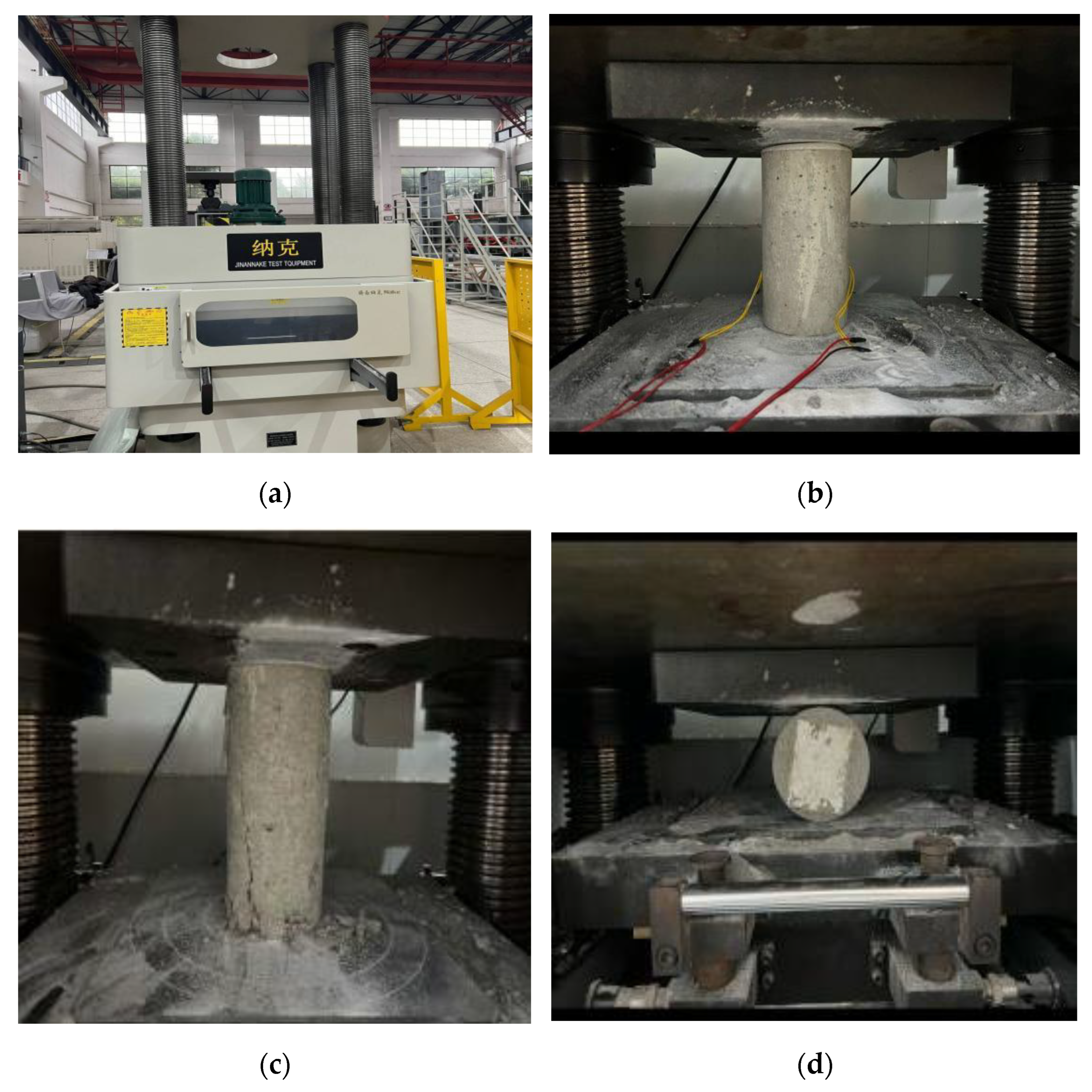

2.2. Mechanical Properties’ Test

2.3. Shrinkage Test

3. Test Results and Discussions

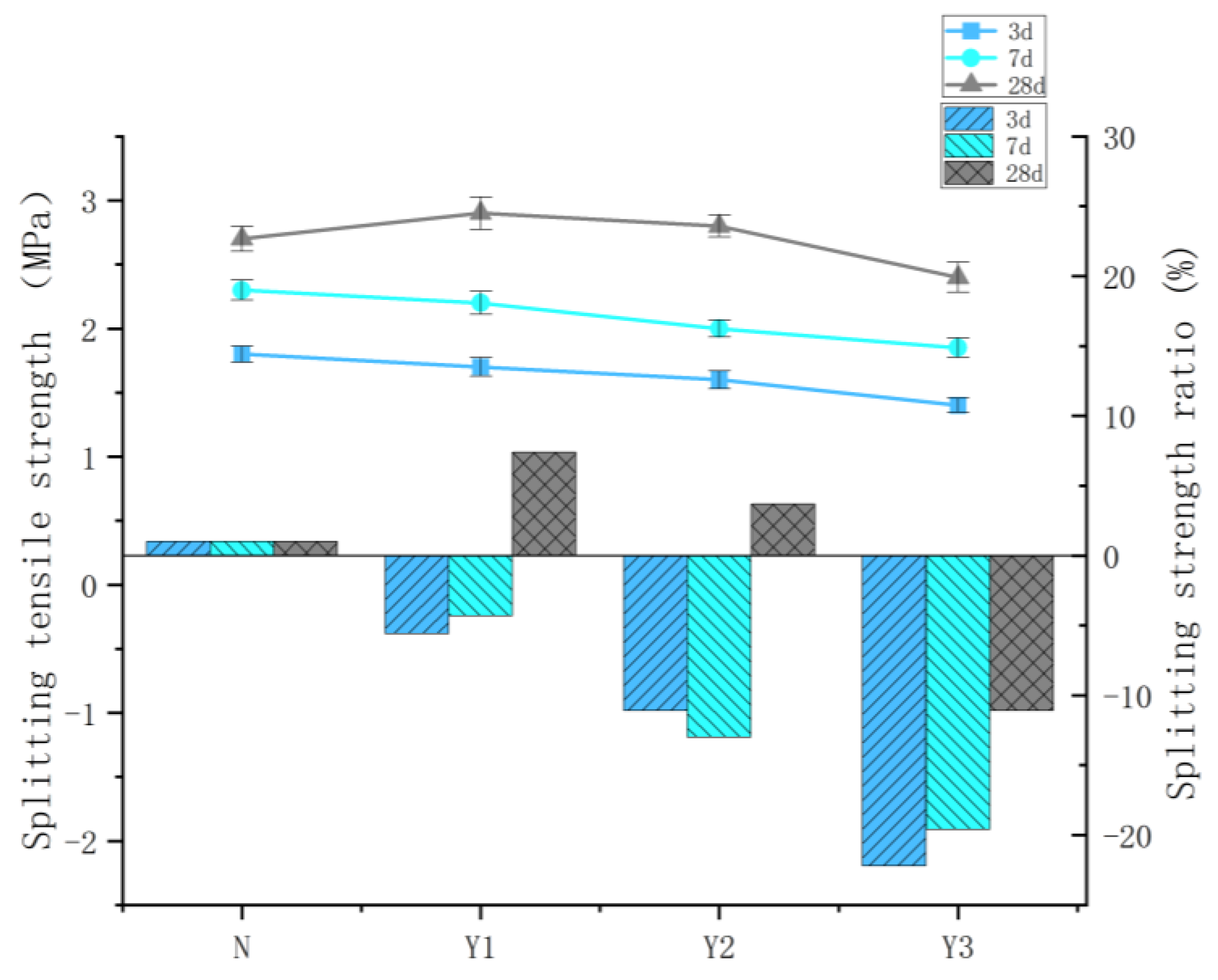

3.1. Mechanical Properties’ Test Results

3.2. Shrinkage Test Results

4. Modeling of Concrete Shrinkage

4.1. Review of Shrinkage Models in Existing Codes

4.1.1. Eurocode 2

4.1.2. Fib Model Code 2010

4.1.3. AS 3600:2018

4.1.4. Bazant B4 Model

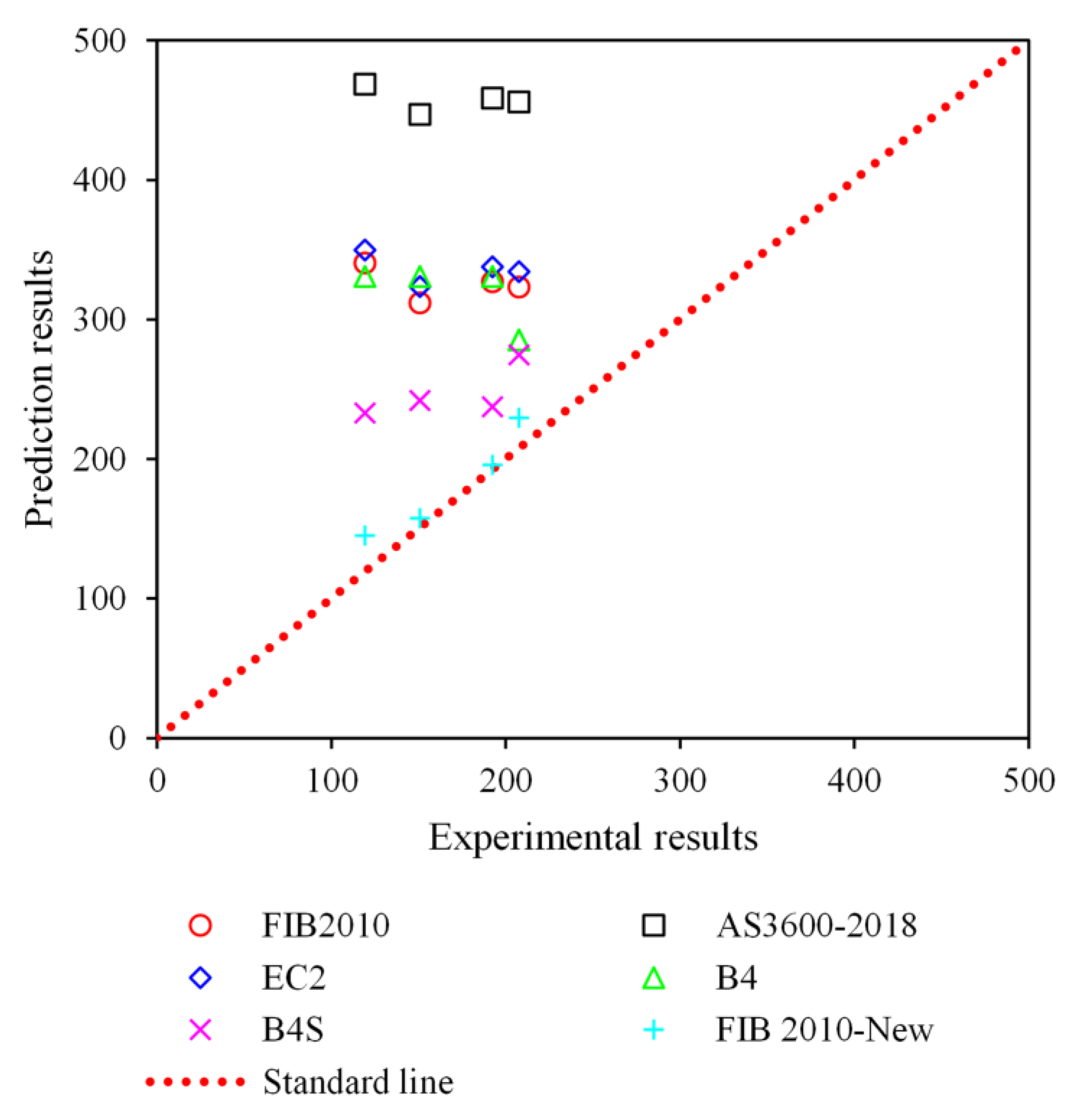

4.2. Comparison Between Experimental Data and Model Predictions

4.3. Development of a New Shrinkage Prediction Model

4.4. Validation of the Proposed Model

4.5. Clarification and Limitations of the Modified Model

4.5.1. Origin and Interpretation of Coefficients

4.5.2. Validity Domain and Assumptions

4.5.3. Limitations of the Proposed Model

4.5.4. Future Research Directions

5. Conclusions

- The incorporation of the temperature-control admixture significantly reduced both the early-age and long-term shrinkage of concrete. As the dosage of the admixture increased, the total shrinkage strain progressively decreased. At 28 days, concretes with 0.05, 0.10, and 0.15% admixture content exhibited reductions in shrinkage of 6.4, 9.1, and 24.5%, respectively, compared to the control concrete.

- While the temperature-control admixture slightly suppressed the early-age development of mechanical properties, it did not adversely affect the long-term strength. At 28 days, the compressive strength, splitting tensile strength, and elastic modulus of concrete with appropriate admixture dosages (especially 0.10%) were comparable to or exceeded those of the control concrete.

- Existing shrinkage prediction models, including Eurocode 2, fib Model Code 2010, AS 3600, and the Bazant B4 model, generally underestimated the shrinkage strains of concrete incorporating temperature-control admixtures. This discrepancy highlights the need for model adjustments to accommodate the modified hydration and moisture transport characteristics induced by such admixtures.

- A modified shrinkage prediction model was developed by extending the fib Model Code 2010 through the incorporation of a fly ash–dependent correction factor and a dosage-sensitive time-development function for TCAs. The model was calibrated using experimental data and achieved substantially lower prediction errors than conventional code-based models, particularly for concrete mixtures incorporating TCAs.

- While the model demonstrates reliable performance within the tested parameter range, including a fly ash replacement rate of 35% and TCA dosages up to 0.15%, it remains semi-empirical in nature, and its applicability to other concrete systems or environmental conditions requires further validation. Nevertheless, it provides a scientifically grounded framework for the improved prediction of drying shrinkage in modified concretes and offers practical support for the design and long-term durability assessment of mass concrete structures where shrinkage control is essential.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TCA | Temperature-Control Admixture |

| JX-E | JX-E is commercial TCA from Jinhua Xinsheng (JX) Co., E is the TCA. |

| OPC | Ordinary Portland Cement |

| FA | Fly Ash |

| w/b | Water-to-Binder Ratio |

| ASTM | American Society for Testing and Materials |

| GB | Guobiao (Chinese National Standard) |

| SD | Standard Deviation |

| AFt | Ettringite |

| SEM | Scanning Electron Microscopy |

| MC2010 | fib Model Code 2010 |

| EC2 | Eurocode 2 |

| AS 3600 | Australian Standard for Concrete Structures |

| B4 | B4 Model |

References

- Li, B.; Zhang, L.; Shen, Y.; Zhang, G.; Wang, C.; Li, Z.; Gao, C. Syneristic effects of polypropylene fiber and expansive agent on early age volume stability of concrete. J. Build. Eng. 2024, 95, 110056. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, Y.; Yan, Q. Challenges of Progress in, and Prospects of Ultra-Long Deep Tunnels in the Extremely Complex Environment of the Qinghai–Tibet Plateau. Engineering 2025, 44, 162–183. [Google Scholar] [CrossRef]

- Yang, G.; Zhao, H.; Hu, Z.; Zhang, W.; Xiang, Y.; Jin, M.; Wan-Wendner, R.; Liu, J. Prediction of restrained stress for UHPC: Considering relationship between long-term and in-situ creep. Constr. Build. Mater. 2025, 484, 141722. [Google Scholar] [CrossRef]

- Liu, J.; Tian, Q.; Wang, Y.; Li, H.; Xu, W. Evaluation method and mitigation strategies for shrinkage cracking of modern concrete. Engineering 2021, 7, 348–357. [Google Scholar] [CrossRef]

- ElSafty, A.; Graeff, M.K.; El-Gharib, G.; Abdel-Mohti, A.; Jackson, N.M. Analysis, prediction, and case studies of early-age cracking in bridge decks. Int. J. Adv. Struct. Eng. 2016, 8, 193–212. [Google Scholar] [CrossRef][Green Version]

- Długosz, A.; Pokorska, I.; Jaskulski, R.; Glinicki, M. Evolutionary identification method for determining thermophysical parameters of hardening concrete. Arch. Civ. Mech. Eng. 2021, 21, 35. [Google Scholar] [CrossRef]

- Teng, L.; Khayat, K. Effect of overlay thickness, fiber volume, and shrinkage mitigation on flexural behavior of thin bonded ultra-high-performance concrete overlay slab. Cem. Concr. Compos. 2022, 134, 104752. [Google Scholar] [CrossRef]

- Ghasabeh, M.; Göktepe, S. Phase-field modeling of thermal cracking in hardening mass concrete. Eng. Fract. Mech. 2023, 289, 109398. [Google Scholar] [CrossRef]

- Xiang, Y.; Zhao, H.; Liu, J.; Yang, G.; Hu, Z.; Chen, J. Damage and fracture in in-service concrete structures subjected to large diurnal temperature variations based on phase-field approach. Structures 2024, 65, 106600. [Google Scholar] [CrossRef]

- Babalola, O.; Awoyera, P.; Le, D.; Romero, L. A review of residual strength properties of normal and high strength concrete exposed to elevated temperatures: Impact of materials modification on behaviour of concrete composite. Constr. Build. Mater. 2021, 296, 123448. [Google Scholar] [CrossRef]

- Ismail, K.; Lino, F.; Machado, P.; Teggar, M.; Arıcı, M.; Alves, T.; Teles, M. New potential applications of phase change materials: A review. J. Energy Storage 2022, 53, 105202. [Google Scholar] [CrossRef]

- Teng, L.; Addai-Nimoh, A.; Khayat, K. Effect of lightweight sand and shrinkage reducing admixture on structural build-up and mechanical performance of UHPC. J. Build. Eng. 2023, 68, 106144. [Google Scholar] [CrossRef]

- Yunpeng, H.; Mingming, Z.; Ji, D.; Chunrong, C.; Junfu, L.; Dongping, Z.; Chao, Z.; Chunchi, M. Study on the thermo-mechanical properties of adaptive thermal control anchoring materials in high-geothermal tunnels. Constr. Build. Mater. 2024, 447, 138156. [Google Scholar] [CrossRef]

- Jung, S.; Choi, Y.; Choi, S. Use of ternary blended concrete to mitigate thermal cracking in massive concrete structures—A field feasibility and monitoring case study. Constr. Build. Mater. 2017, 137, 208–215. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, K.; Liu, Z.; Yao, H. Preparation of a double-layer thermal reflective and insulation coating system and its effect on the temperature field of concrete. J. Build. Eng. 2025, 103, 112186. [Google Scholar] [CrossRef]

- Mao, J.; Xia, Y.; Li, H.; Dai, F.; Guan, S.; Ren, J. Feasibility and application of novel electrical curing method for constant-temperature hardening of concrete at cold regions. J. Build. Eng. 2024, 97, 110899. [Google Scholar] [CrossRef]

- Zhan, P.; He, Z. Application of shrinkage reducing admixture in concrete: A review. Constr. Build. Mater. 2019, 201, 676–690. [Google Scholar] [CrossRef]

- Amadi, I.; Amadi-Oparaeli, K. Effect of admixtures on strength and permeability of concrete. Int. J. Eng. Sci. 2018, 7, 1–7. [Google Scholar]

- Ahmed, M.; Mallick, J.; AlQadhi, S.; Kahla, N.B. Development of concrete mixture design process using MCDM approach for sustainable concrete quality management. Sustainability 2020, 12, 8110. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Lv, K.; Wu, L. A review on mixture design methods for self-compacting concrete. Constr. Build. Mater. 2015, 84, 387–398. [Google Scholar] [CrossRef]

- Zou, J.; Liu, Z.; Guo, Q. Comprehensive utilisation of blast furnace slag. Can. Metall. Q. 2024, 63, 927–934. [Google Scholar] [CrossRef]

- Farahi, B.; Manjili, M.; Ghahremani, M.; Aghayan, I.; Faheem, A.; Sobolev, K. The effective use of portland cement as binder replacement in reactive powder-based hybrid asphalt concrete. J. Clean. Prod. 2025, 495, 144879. [Google Scholar] [CrossRef]

- Raman, S.; Nateriya, R. Synthesizing sustainable construction paradigms: A comprehensive review and bibliometric analysis of granite waste powder utilization and moisture correction in concrete. Rev. Adv. Mater. Sci. 2024, 63, 20240084. [Google Scholar] [CrossRef]

- Dada, H.; Belaidi, A.; Soualhi, H.; Kadri, E.; Benabed, B. Influence of temperature on the rheological behaviour of eco-mortar with binary and ternary cementitious blends of natural pozzolana and marble powder. Powder Technol. 2021, 384, 223–235. [Google Scholar] [CrossRef]

- Javed, M.; Nimmo, W.; Mahmood, A.; Irfan, N. Effect of oxygenated liquid additives on the urea based SNCR process. J. Environ. Manag. 2009, 90, 3429–3435. [Google Scholar] [CrossRef]

- Thongtha, A.; Maneewan, S.; Fazlizan, A. Enhancing Thermal Performance of Autoclaved Aerated Concrete (AAC) Incorporating Sugar Sediment Waste and Recycled AAC with Phase Change Material-Coated Applications for Sustainable Energy Conservation in Building. Sustainability 2023, 15, 14226. [Google Scholar] [CrossRef]

- Wang, S.; Wei, K.; Shi, W.; Cheng, P.; Shi, J.; Ma, B. Study on the rheological properties and phase-change temperature regulation of asphalt modified by high/low-temperature phase change material particles. J. Energy Storage 2022, 56, 105970. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Chen, J.; Yan, Z.; Liu, X.; Zhang, H. Effect of Microencapsulated Temperature Rise Inhibitor on the Temperature Rise of Medium-Sized Concrete. Materials 2025, 18, 1230. [Google Scholar] [CrossRef] [PubMed]

- Kim, H. Urea additives for reduction of hydration heat in cement composites. Constr. Build. Mater. 2017, 156, 790–798. [Google Scholar] [CrossRef]

- Sun, X.; Liu, X.; Wang, S.; He, R.; Guo, J.; Bai, X.; Gao, R.; Niu, X.; Xie, Z.; Wang, Z.; et al. Effect of functional groups of hydration heat controlling materials on cement hydration and its mechanism. J. Sustain. Cem.-Based Mater. 2024, 13, 1193–1207. [Google Scholar] [CrossRef]

- Phan, T.; Park, D.; Kim, H. Utilization of micro encapsulated phase change material in asphalt concrete for improving low-temperature properties and delaying black ice. Constr. Build. Mater. 2022, 330, 127262. [Google Scholar] [CrossRef]

- Betancourt-Jimenez, D.; Montoya, M.; Haddock, J.; Youngblood, J.; Martinez, C. Regulating asphalt pavement temperature using microencapsulated phase change materials (PCMs). Constr. Build. Mater. 2022, 350, 128924. [Google Scholar] [CrossRef]

- Yang, G.; Zhao, H.; Wang, H.; Zhang, X.; Xiang, Y.; Chen, S.; He, J.; Jin, M. Improved TSTM for shrinkage cracking characterization of UHPC with expansive agent under various degrees of restraint. J. Build. Eng. 2025, 107, 112783. [Google Scholar] [CrossRef]

- Wang, X.; Chang, H.; Li, S.; Jia, Y.; Kong, Z.; Wang, Y.; Liu, J.; Feng, P. Influence of low vacuum and high temperature condition on moisture transport and dry shrinkage of mature concrete. J. Build. Eng. 2024, 95, 110262. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Hu, Z.; Liu, Z.; Xu, D.; Liu, J. Assessment of determination methods for time-zero of autogenous shrinkage in cement mortars. Cem. Concr. Compos. 2024, 152, 105607. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.; Yin, X.; Wang, Y.; Huang, D. A multiscale prediction model and simulation for autogenous shrinkage deformation of early-age cementitious materials. Constr. Build. Mater. 2019, 215, 482–493. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, C.; Rong, H.; Liu, S.; Shi, Y.; Wang, H.; Wang, Q.; Zhang, X.; Han, J.; Jing, K.; et al. The shrinkage and durability performance evaluations for concrete exposed to temperature variation environments at early-age. J. Build. Eng. 2025, 104, 112457. [Google Scholar] [CrossRef]

- Liu, J.; Wang, M.; Liu, N.; Teng, L.; Wang, Y.; Chen, Z.; Shi, C. Development of ultra-fine SAP powder for lower-shrinkage and higher-strength cement pastes made with ultra-low water-to-binder ratio. Compos. Part B Eng. 2023, 262, 110810. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, C.; Yang, Y.; Wang, Y. Hygro-thermal–mechanical coupling analysis for early shrinkage of cast in situ concrete slabs of composite beams: Theory and experiment. Constr. Build. Mater. 2023, 372, 130774. [Google Scholar] [CrossRef]

- Teng, L.; Valipour, M.; Khayat, K. Design and performance of low shrinkage UHPC for thin bonded bridge deck overlay. Cem. Concr. Compos. 2021, 118, 103953. [Google Scholar] [CrossRef]

- Rong, H.; Wang, B.; Huang, J.B.; Shi, Y.; Zheng, X. Role of coupled environmental factors on shrinkage properties of concrete at high altitude. J. Build. Eng. 2025, 99, 111560. [Google Scholar] [CrossRef]

- Rong, H.; Wang, B.; Huang, J.B.; Shi, J.; Zheng, X. The mechanical properties of concrete exposed to harsh and complex environments of plateaus at early ages. J. Build. Eng. 2024, 97, 110808. [Google Scholar] [CrossRef]

- Eurocode 2 and EN 19920101; Design of Concrete Structures. General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- Du Béton, F.I. fib Model Code for Concrete Structures; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010. [Google Scholar]

- AS3600-2018; Australian Standard for Concrete Structures. Standards Australia: Sydney, Australia, 2018.

- Bazant, Z. RILEM draft recommendation: TC-242-MDC multi-decade creep and shrinkage of concrete: Material model and structural analysis* Model B4 for creep, drying shrinkage and autogenous shrinkage of normal and high-strength concretes with multi-decade applicability. Mater. Struct. 2015, 48, 753–770. [Google Scholar]

- GB175-2023; Common Portland Cement. China Standard Press: Beijing, China, 2023.

- Mao, Y.; Liu, J.; Shi, C. Autogenous shrinkage and drying shrinkage of recycled aggregate concrete: A review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Zhang, M.; Tam, C.; Leow, M. Effect of water-to-cementitious materials ratio and silica fume on the autogenous shrinkage of concrete. Cem. Concr. Res. 2003, 33, 1687–1694. [Google Scholar] [CrossRef]

- Aitcin, P.; Neville, A.; Acker, P. Integrated view of shrinkage deformation. Concr. Int. 1997, 19, 35–41. [Google Scholar]

- Lee, H.; Lee, K.; Kim, B. Autogenous shrinkage of high-performance concrete containing fly ash. Mag. Concr. Res. 2003, 55, 507–515. [Google Scholar] [CrossRef]

- Abdalhmid, J.; Ashour, A.; Sheehan, T. Long-term drying shrinkage of self-compacting concrete: Experimental and analytical investigations. Constr. Build. Mater. 2019, 202, 825–837. [Google Scholar] [CrossRef]

- Atiş, C. High-volume fly ash concrete with high strength and low drying shrinkage. J. Mater. Civ. Eng. 2003, 15, 153–156. [Google Scholar] [CrossRef]

| Chemical Oxides | SiO2 | CaO | Al2O3 | SO3 | Fe2O3 | K2O | MgO | Na2O | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| OPC | 20.31 | 65.5 | 4.8 | 2.1 | 4.99 | 0.4 | 1.3 | 0.15 | 0.39 |

| FA | 46.59 | 4.98 | 38.52 | 0.66 | 3.93 | 0.66 | 0.96 | 0.2 | 1.69 |

| Properties | Specification Value |

|---|---|

| Temperature reduction rate (%) | ≥30 |

| Initial temperature rises time difference for 5 °C (h) | ≤48 |

| Permeability height (28 days) (mm) | ≤100 |

| Compressive strength ratio (28 days) (%) | ≥90 |

| Relative durability (%) | ≥150 |

| Sample ID | Cement | Fly Ash | Fine Aggregate | Coarse Aggregate | Water | TCA |

|---|---|---|---|---|---|---|

| N | 280 | 150 | 675 | 1175 | 180 | 0 |

| Y1 | 280 | 150 | 675 | 1175 | 180 | 0.05% |

| Y2 | 280 | 150 | 675 | 1175 | 180 | 0.10% |

| Y3 | 280 | 150 | 675 | 1175 | 180 | 0.15% |

| Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Values | 0.016 | −0.33 | −0.06 | −0.10 | 360 × 10−6 | −0.80 | 1.10 | 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, H.; Zhang, H.; Zhou, X.; Xu, Z.; Liu, Z. Effects of Temperature-Control Admixtures on Shrinkage and Mechanical Properties of Fly Ash Concrete: Experiments and Modeling. Materials 2025, 18, 3757. https://doi.org/10.3390/ma18163757

Zhang Y, Li H, Zhang H, Zhou X, Xu Z, Liu Z. Effects of Temperature-Control Admixtures on Shrinkage and Mechanical Properties of Fly Ash Concrete: Experiments and Modeling. Materials. 2025; 18(16):3757. https://doi.org/10.3390/ma18163757

Chicago/Turabian StyleZhang, Yingda, Haiyang Li, Haojie Zhang, Xianliang Zhou, Ziyi Xu, and Zihao Liu. 2025. "Effects of Temperature-Control Admixtures on Shrinkage and Mechanical Properties of Fly Ash Concrete: Experiments and Modeling" Materials 18, no. 16: 3757. https://doi.org/10.3390/ma18163757

APA StyleZhang, Y., Li, H., Zhang, H., Zhou, X., Xu, Z., & Liu, Z. (2025). Effects of Temperature-Control Admixtures on Shrinkage and Mechanical Properties of Fly Ash Concrete: Experiments and Modeling. Materials, 18(16), 3757. https://doi.org/10.3390/ma18163757