Synergistic Thresholds Governing Performance Evolution in Red Mud-Fly Ash-Coal Gangue Ternary Solid Waste Concrete (RFCTSWC)

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Cementitious Materials

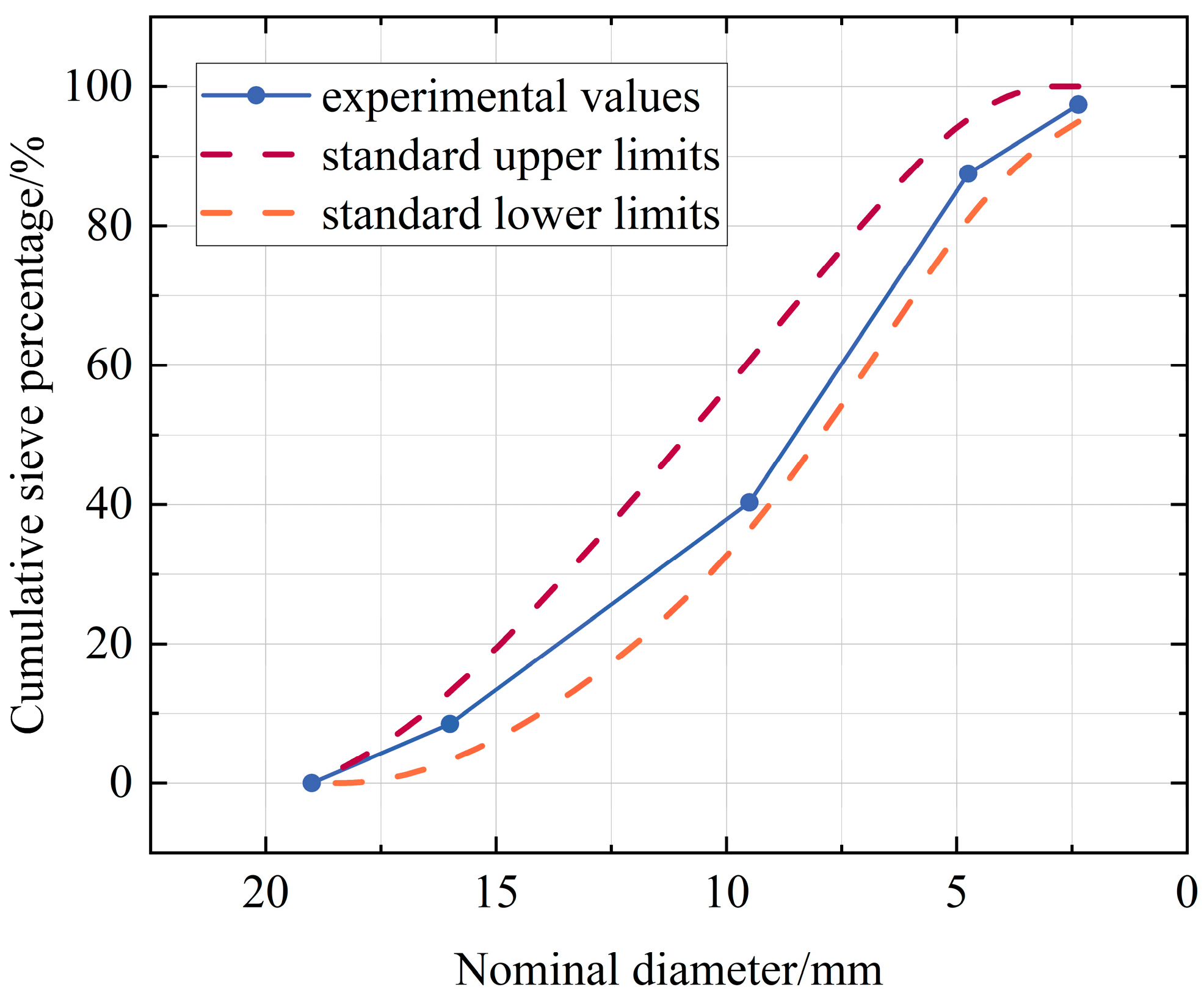

2.1.2. Coarse and Fine Aggregates

2.1.3. Admixtures and Water

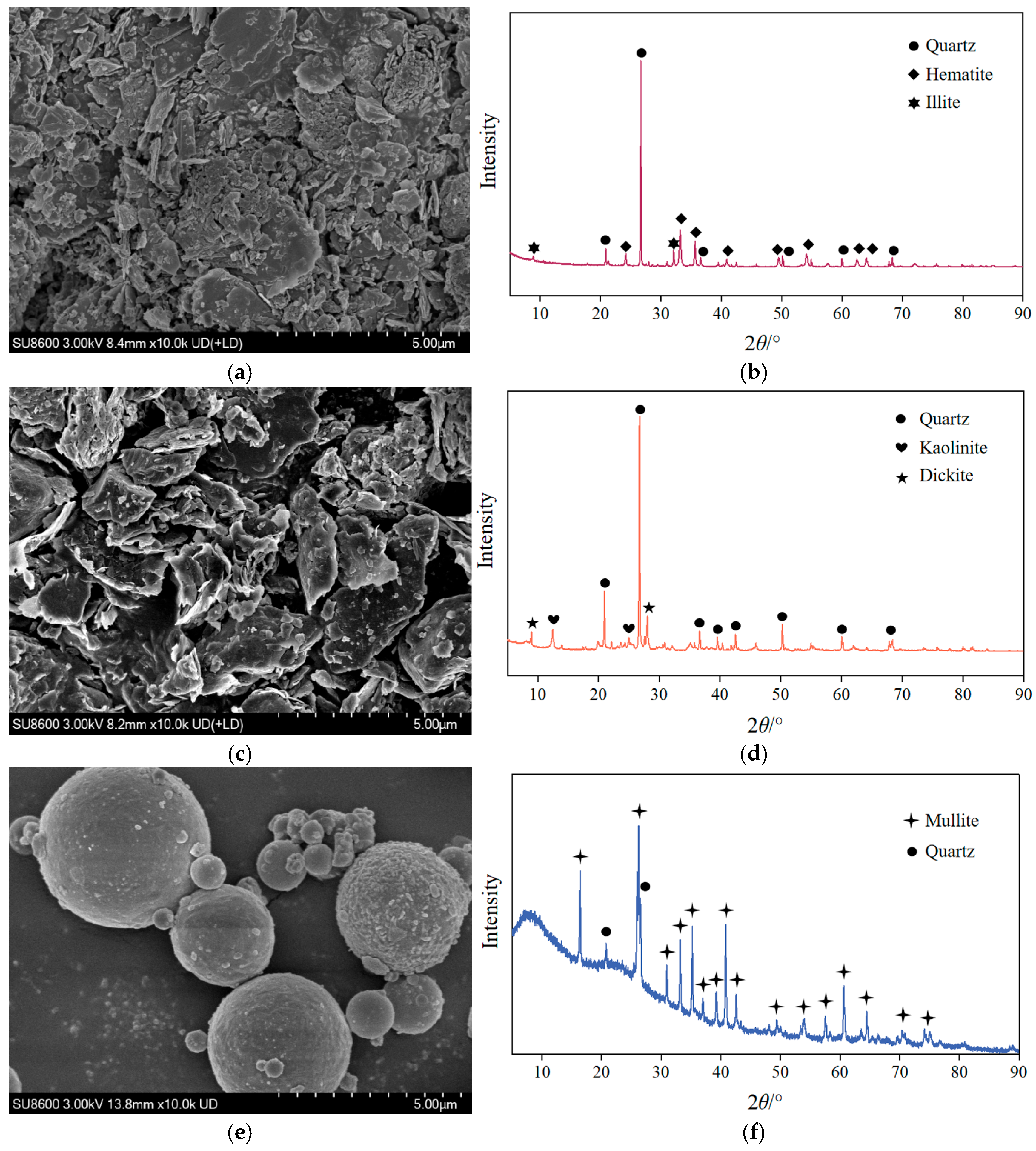

2.1.4. Microscopic Characterization of Raw Materials

2.2. Mix Proportions Design

2.3. Sample Preparation

2.4. Test Methods

2.4.1. Macro Testing

2.4.2. Microscopic Characterization

3. Results and Analysis

3.1. Experiment Results

3.2. Orthogonal Test Analysis

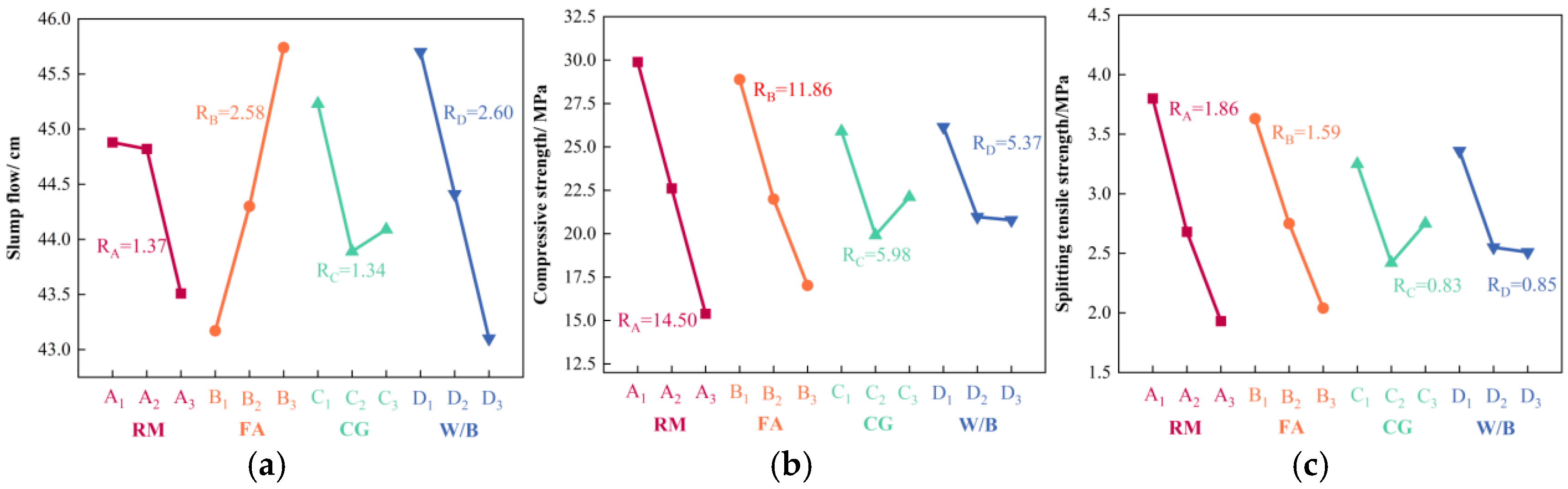

3.2.1. Slump Analysis

3.2.2. Compressive Strength Analysis

3.2.3. Splitting Tensile Strength Analysis

3.3. Frost Resistance Durability

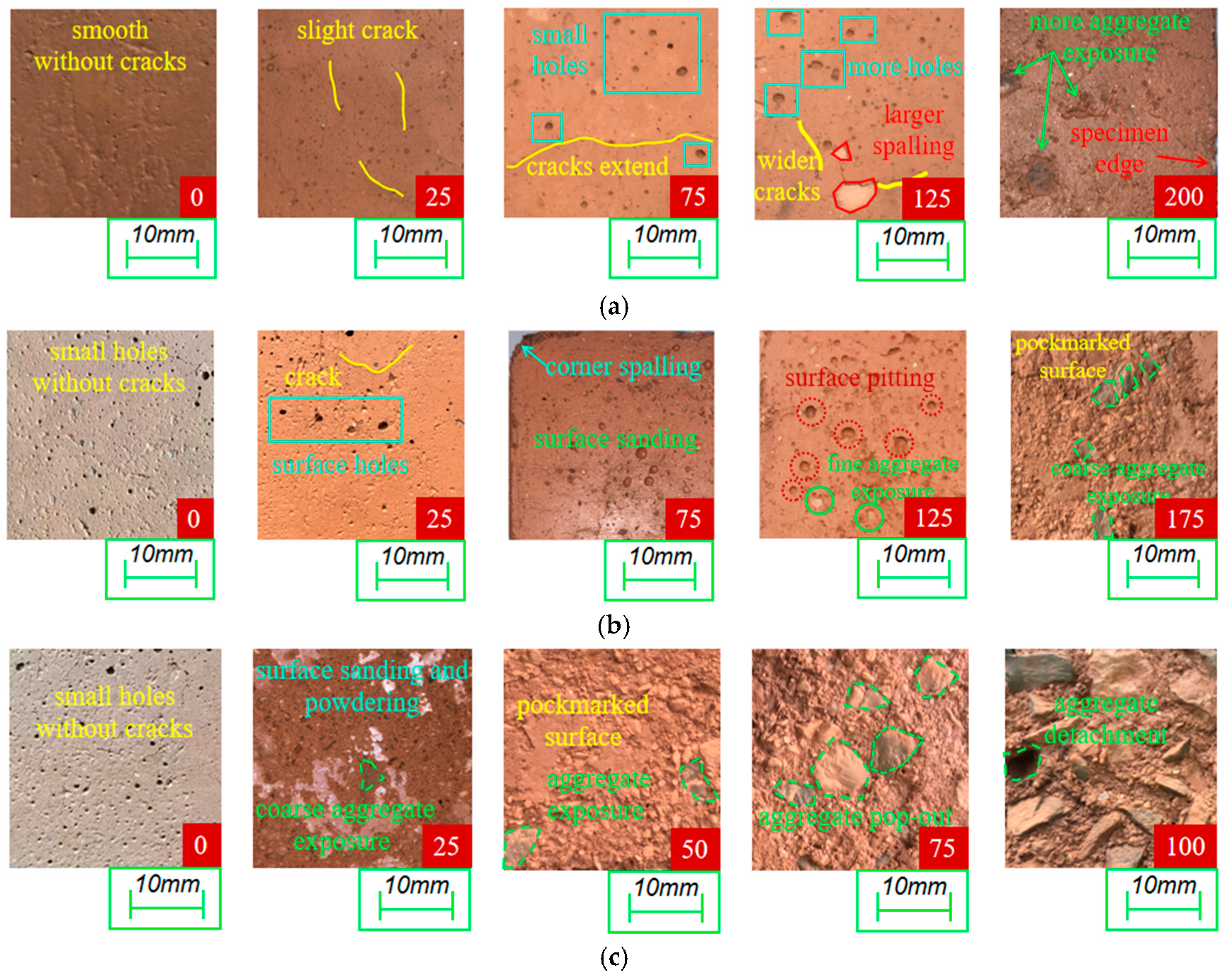

3.3.1. Appearance Changes

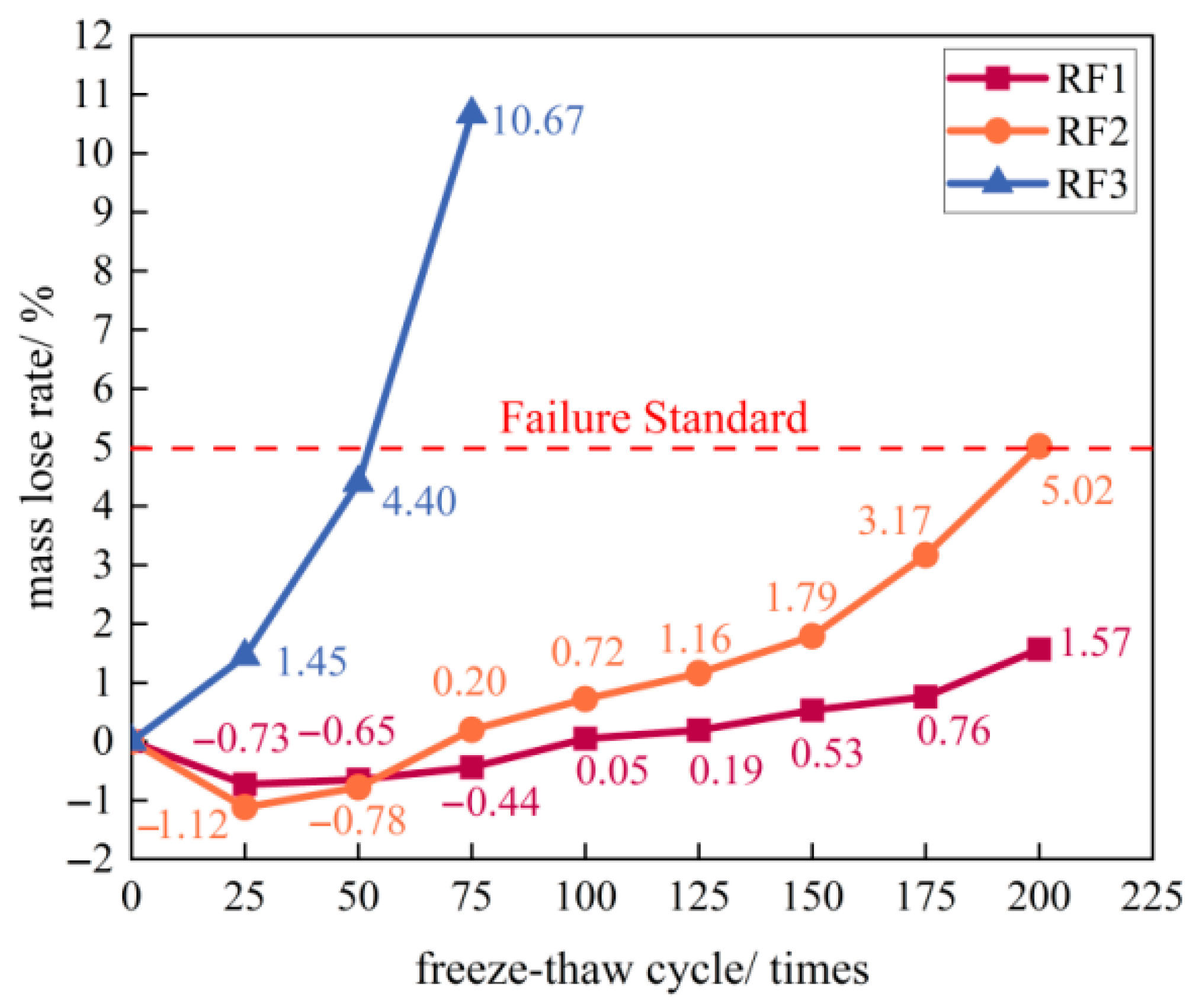

3.3.2. Quality Loss Rate

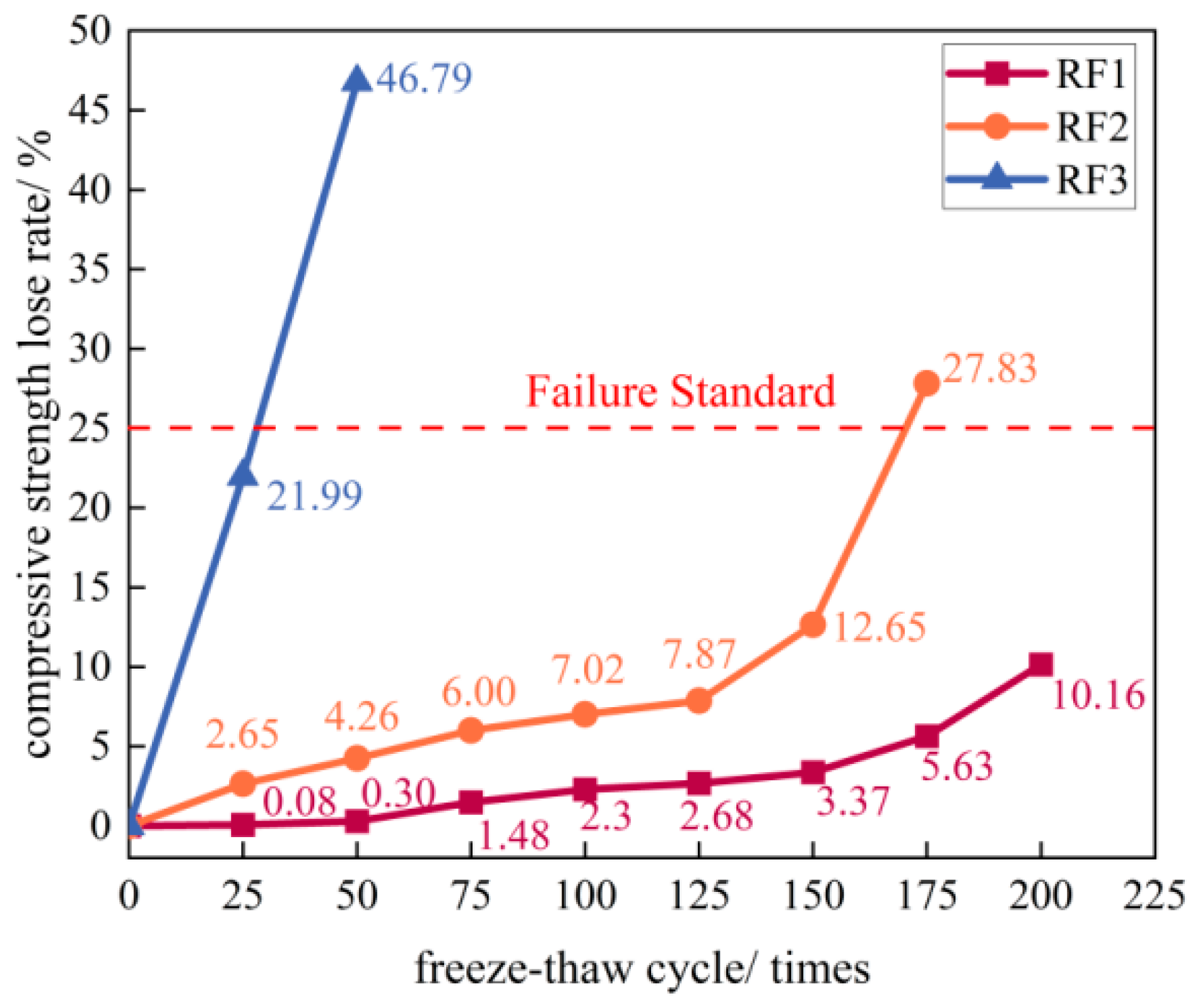

3.3.3. Loss Rate of Compressive Strength

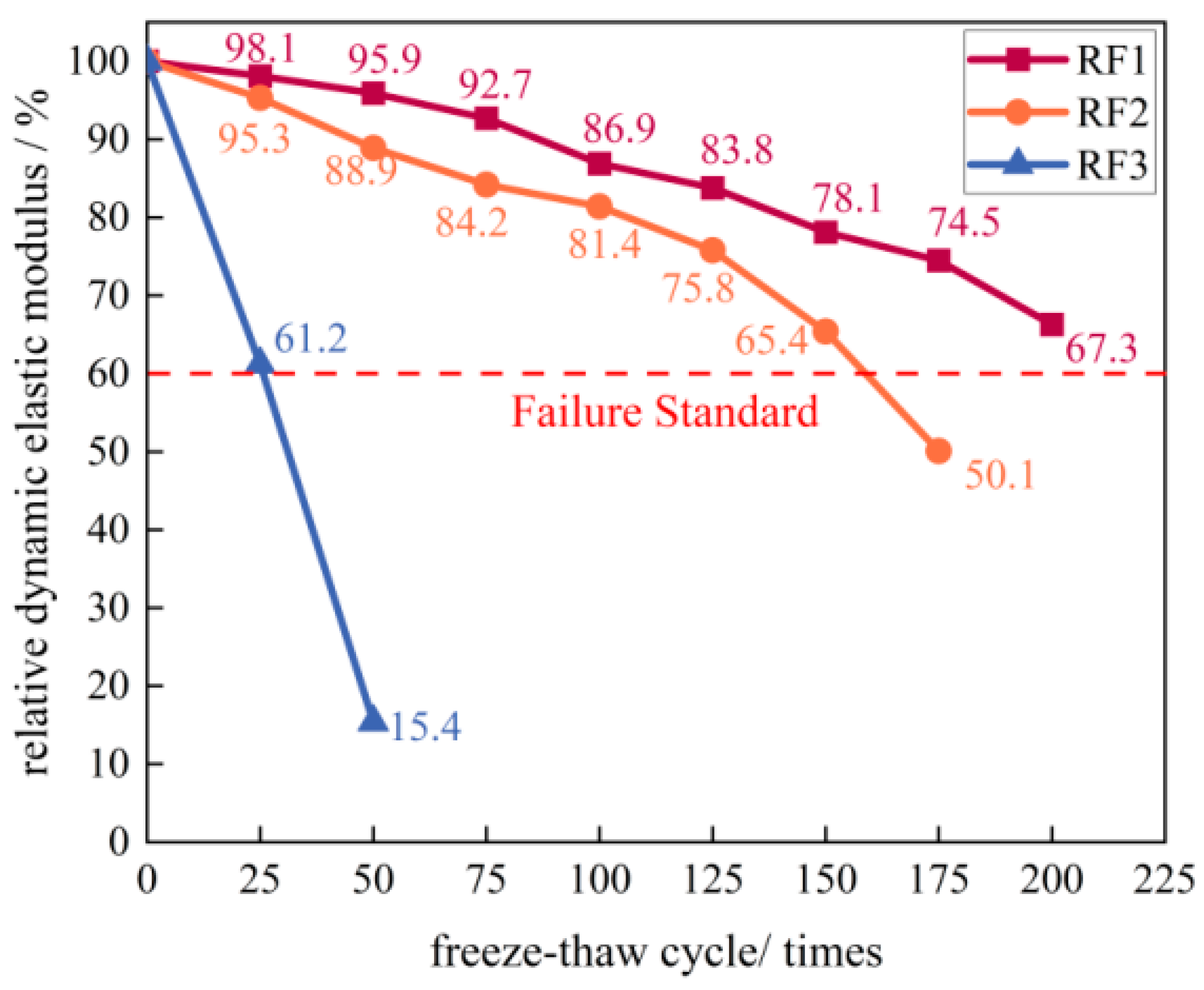

3.3.4. Relative Dynamic Elastic Modulus

3.3.5. Quantitative Relationship Between Freeze–Thaw Damage and Physical and Mechanical Properties of RFCTSWC

3.4. Microstructure Characterization

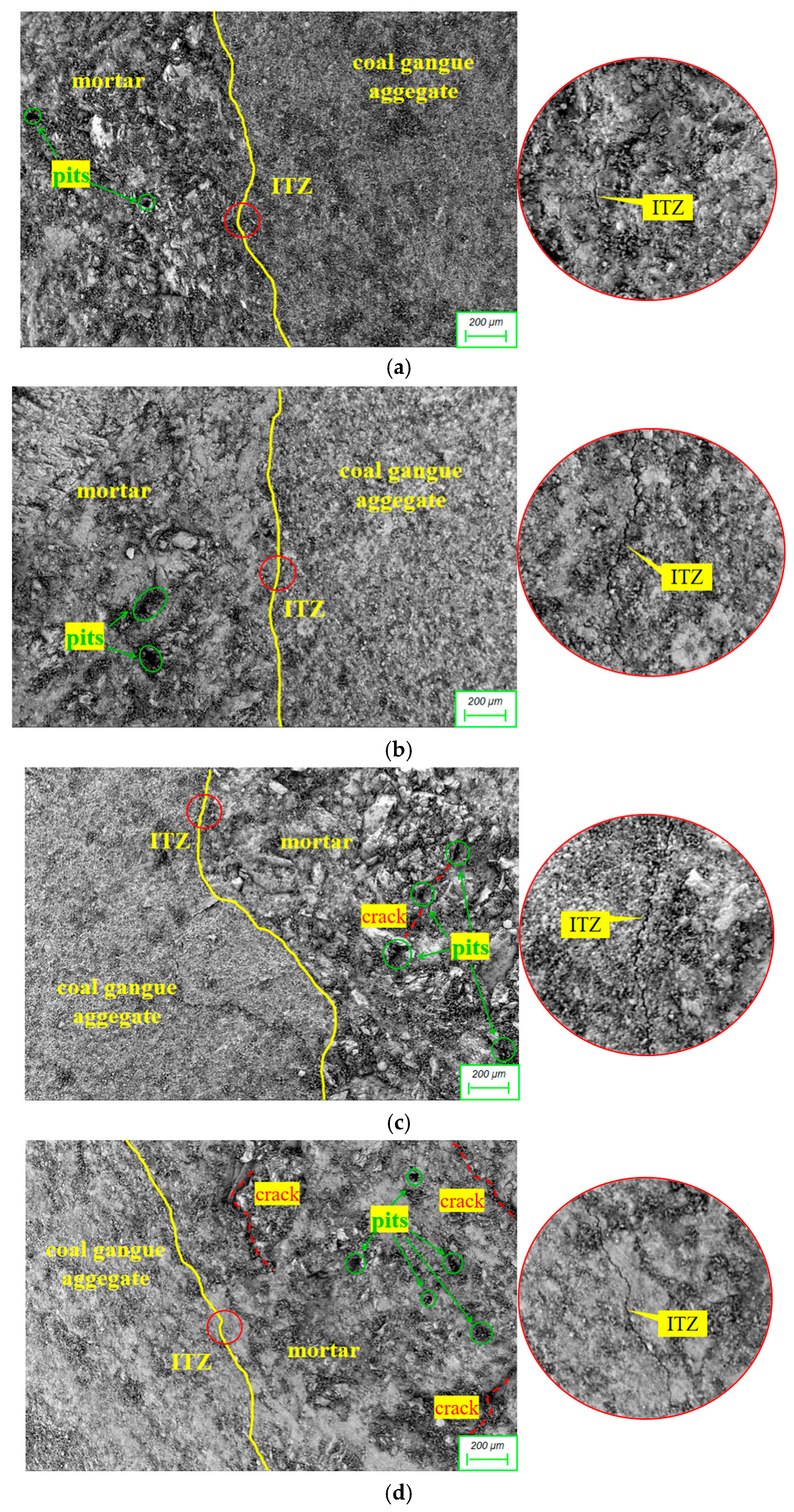

3.4.1. Microscopic Morphology Characteristics

3.4.2. SEM-EDS Element Distribution

4. Discussion

4.1. Comparative Analysis with Existing Studies

4.2. Interrelationships Between Key Properties

4.3. Engineering Applications and Sustainability Implications

5. Conclusions

- (1)

- Slump is primarily governed by W/B, while FA’s micro-aggregate effect notably enhances fluidity. Compressive and split tensile strengths are most significantly affected by RM content. Increasing the combined dosage of RM and FA reduces cementitious hydration products, leading to a linear decline in mechanical properties. Optimal mechanical performance is achieved with low RM and FA dosages synergistically combined with 20% CGA and a W/B of 0.45.

- (2)

- Increasing the combined RM and FA dosage reduces frost resistance durability. Specimens in group RF3 (30% RM + 55% FA) exhibited significant surface deterioration 100 and 50 freeze–thaw cycles earlier than groups RF1 (10% RM + 35% FA) and RF2 (20% RM + 45% FA), respectively, with accelerated deterioration rates. After 200 cycles, RF1 specimens showed no durability indicators reaching failure thresholds. RF2 specimens reached failure thresholds between cycles 175 and 200, while RF3 specimens approached thresholds in mass loss, strength loss, and relative dynamic modulus of elasticity as early as cycle 25th. An established decay model linking freeze–thaw damage to physical-mechanical properties indicates that higher RM-FA dosages not only accelerate performance degradation but also weaken the material’s initial properties.

- (3)

- A significant synergistic effect exists between the combined RM-FA dosage and the micro-morphology/mechanical properties of the concrete. At fixed RM content, increasing FA content reduces C-S-H gel formation, enhances pore connectivity, and lowers the Ca/Si ratio. At fixed FA content, increasing RM content exacerbates structural fragmentation and elevates the Al/Si ratio. A synergistic threshold occurs at 20% RM and 45% FA, characterized by uniformly distributed C-S-H gel and narrow cracks, corresponding to a superior compressive strength of 24.96 MPa compared to other blends (10% RM + 45% FA; 10% RM + 55% FA). However, excessive incorporation (30% RM + 55% FA) causes localized aggregation of unhydrated particles and increased porosity, validating the continuous decline in macroscopic strength.

- (4)

- Synergistic complementarity among solid wastes was observed, but excellent concrete performance requires low-to-medium solid waste dosages. Future research should explore targeted strategies like raw material activation, nano-modification, or fiber reinforcement to balance the conflict between solid waste content and performance, thereby promoting the high-value utilization of industrial solid wastes in low-carbon building materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, F.R.; Chen, K.J.; Tian, Z.; Zhang, Y. The investment and treatment efficiencies of industrial solid waste in China’s Yangtze and non-Yangtze river economic belts. J. Mater. Cycles Waste Manag. 2022, 24, 900–916. [Google Scholar] [CrossRef]

- Wu, H.; Chen, C.; Song, W.; Hou, W. High-capacity utilization of coal gangue as supplementary cementitious material, geopolymer, and aggregate: A review. Constr. Build. Mater. 2024, 435, 136857. [Google Scholar] [CrossRef]

- Qureshi, H.J.; Ahmad, J.; Majdi, A.; Saleem, M.U.; Al Fuhaid, A.F.; Arifuzzaman, M. A study on sustainable concrete with partial substitution of cement with Red Mud: A Review. Materials 2022, 15, 7761. [Google Scholar] [CrossRef]

- Querol, X.; Izquierdo, M.; Monfort, E.; Alvarez, E.; Font, O.; Moreno, T.; Alastuey, A.; Zhuang, X.; Lu, W.; Wang, Y. Environmental characterization of burnt coal gangue banks at Yangquan, Shanxi Province, China. Int. J. Coal Geol. 2008, 75, 93–104. [Google Scholar] [CrossRef]

- Arroyo, F.; Luna-Galiano, Y.; Leiva, C.; Vilches, L.F.; Fernández-Pereira, C. Environmental risks and mechanical evaluation of Recycling Red Mud in bricks. Environ. Res. 2020, 186, 109537. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Wen, Q.; Hu, L.; Gong, M.; Tang, Z. Feasibility Study on the application of coal gangue as landfill liner material. Waste Manag. 2017, 63, 161–171. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Liu, M.; Wang, Q.; Wang, L.; Guo, Q.; Zhou, S. Analysis of industrial solid waste and the possibility of recycling and utilization. Green Chem. Lett. Rev. 2025, 18, 2493155. [Google Scholar] [CrossRef]

- Gong, J.; Chen, C.; Liu, J.; Li, Z.; Shi, X. Synergistic upcycling of municipal solid waste incineration fly ash and class F fly ash to prepare a sustainable ternary cementitious composite. J. Build. Eng. 2025, 105, 112474. [Google Scholar] [CrossRef]

- Yao, Y.; Li, Y.; Liu, X.; Jiang, S.; Feng, C.; Rafanan, E. Characterization on a cementitious material composed of red mud and coal industry byproducts. Constr. Build. Mater. 2013, 47, 496–501. [Google Scholar] [CrossRef]

- Yan, P.; Chen, B.; Aminul Haque, M.; Liu, T. Influence of red mud on the engineering and microstructural properties of sustainable ultra-high performance concrete. Constr. Build. Mater. 2023, 396, 132404. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q.; Mao, S. Investigation of the bond strength and microstructure of the interfacial transition zone between cement paste and aggregate modified by Bayer Red Mud. J. Hazard. Mater. 2021, 403, 123482. [Google Scholar] [CrossRef]

- Singh, S.; Aswath, M.U.; Ranganath, R.V. Effect of mechanical activation of red mud on the strength of geopolymer binder. Constr. Build. Mater. 2018, 177, 91–101. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.; Javed, S.; Baig, R.U. Optimization of alkaline activator on the strength properties of geopolymer concrete. Polymers 2022, 14, 2434. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Liu, Q.; Long, H.; Deng, H.; Chen, Z.; Hui, D. Influence of nano-SIO2 and steel fiber on mechanical and microstructural properties of red mud-based geopolymer concrete. Constr. Build. Mater. 2023, 364, 129990. [Google Scholar] [CrossRef]

- Yao, N.; Zhou, X.; Liu, Y.; Shi, J. Synergistic effect of Red Mud and fly ash on passivation and corrosion resistance of 304 stainless steel in alkaline concrete pore solutions. Cem. Concr. Compos. 2022, 132, 104637. [Google Scholar] [CrossRef]

- Ge, X.; Hu, X.; Shi, C. Mechanical properties and microstructure of circulating fluidized bed fly ash and Red Mud-based geopolymer. Constr. Build. Mater. 2022, 340, 127599. [Google Scholar] [CrossRef]

- Tian, K.; Wang, Y.; Dong, B.; Fang, G.; Xing, F. Engineering and micro-properties of alkali-activated slag pastes with Bayer Red Mud. Constr. Build. Mater. 2022, 351, 128869. [Google Scholar] [CrossRef]

- Jiang, M.; Qian, Y.; Sun, Q. Preparation of controlled low-strength materials from alkali-excited red mud-slag-iron tailings sand and a study of the reaction mechanism. Environ. Sci. Pollut. Res. 2022, 30, 22232–22248. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, S.; Guo, L. Application of coal gangue as a coarse aggregate in green concrete production: A Review. Materials 2021, 14, 6803. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Z.; Zhang, Y.; Zhang, H.; Zhou, M.; Fang, Y. Influence of coarse coal gangue aggregates on elastic modulus and drying shrinkage behaviour of concrete. J. Build. Eng. 2020, 32, 101748. [Google Scholar] [CrossRef]

- Huang, M.; Duan, J.; Wang, J. Research on basic mechanical properties and fracture damage of coal gangue concrete subjected to freeze-thaw cycles. Adv. Mater. Sci. Eng. 2021, 2021, 6701628. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Zhu, Y.; Dai, J.-G.; Xu, Q.; Liu, K.; Hao, F.; Sun, D. Manufacturing ultra-high performance geopolymer concrete (UHPGC) with activated coal gangue for both binder and aggregate. Compos. Part B Eng. 2024, 284, 111723. [Google Scholar] [CrossRef]

- Jiao, Y.; Qiao, J.; Ke, G. The Influence of Carbon Imperfections on the Physicochemical Characteristics of Coal Gangue Aggregates. Constr. Build. Mater. 2023, 409, 133965. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, A. Study on mechanical properties of pet fiber-reinforced coal gangue fine aggregate concrete. Geofluids 2021, 2021, 6627447. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Zhang, Z.; Dai, J.-G.; Liu, K.; Wang, Y.; Chu, Y.; Sun, D. Hybrid fiber reinforced ultra-high performance coal gangue geopolymer concrete (UHPGC): Mechanical properties, enhancement mechanism, carbon emission and economic analysis. J. Build. Eng. 2024, 96, 110428. [Google Scholar] [CrossRef]

- Yuan, Q.; Wang, L.; Kong, D.; Han, Y.; Ren, C.; Tian, Y.; Zhu, G. Synergistic action and effect mechanism of coal gangue powder and red mud on the properties of concretes. J. Build. Eng. 2024, 98, 110999. [Google Scholar] [CrossRef]

- Koshy, N.; Dondrob, K.; Hu, L.; Wen, Q.; Meegoda, J.N. Synthesis and characterization of geopolymers derived from coal gangue, fly ash and Red Mud. Constr. Build. Mater. 2019, 206, 287–296. [Google Scholar] [CrossRef]

- Yao, Z.; Fang, Y.; Kong, W.; Huang, X.; Wang, X. Experimental Study on Dynamic Mechanical Properties of Coal Gangue Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 8874191. [Google Scholar] [CrossRef]

- Guler, S. Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review. Sustainability 2024, 16, 4905. [Google Scholar] [CrossRef]

- GB/T 1596-2017; Fly Ash Used in Cement and Concrete. China Standards Press: Beijing, China, 2017.

- JGJ55-2011; Code for Design of Mix Proportions of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2011.

- GB/T 50080-2016; Standard for Test Methods of Performance of Ordinary Concrete Mixtures. China Architecture & Building Press: Beijing, China, 2016.

- GB/T 50081-2019; Standard for Test Methods of Physical and Mechanical Properties of Concrete. China Architecture & Building Press: Beijing, China, 2019.

- GB/T 50082-2024; Standard Test Methods for Long-Term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2024.

- Institute of Mathematics, Chinese Academy of Sciences. Analysis of Variance; Science Press: Beijing, China, 1976. [Google Scholar]

- Li, H.; Xu, D.; Feng, S.; Shang, B. Microstructure and performance of fly ash micro-beads in cementitious material system. Constr. Build. Mater. 2014, 52, 422–427. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.S.; Soudki, K.A. Flowing ability of the mortars formulated from self-compacting concretes incorporating rice husk ash. Constr. Build. Mater. 2011, 25, 973–978. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, Y.; Wang, Y.; Yu, Y.; Chen, Q.; Wu, Z. Insights into hydraulic conductivity, mechanical properties, and microstructure of fly ash-modified clay anti-seepage layer to Red Mud Leachate. Case Stud. Constr. Mater. 2025, 22, e04190. [Google Scholar] [CrossRef]

- Jing, H.; Zhang, C.; Gao, M.; Ding, R. Grading Optimization and Performance Study of Skeleton-dense Cement-stabilized Coal Gangue. Mater. Rep. 2025, 39, 22040252-7. [Google Scholar] [CrossRef]

- Jin, S.; Zhao, X.; Tai, Y.; Zhou, J. Multiscale model for the scale effect of tensile strength of hardened cement paste based on pore size distribution. Constr. Build. Mater. 2022, 325, 126775. [Google Scholar] [CrossRef]

- Liu, S.; Rui, D.; Kim, M.; Ji, M.; Zhang, J.; Zhang, P. Study on freeze-thaw resistance and na+ leaching characteristics of red mud-fly ash-phosphogypsum multiple solid waste road base material. Cold Reg. Sci. Technol. 2025, 233, 104448. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, R.; Guan, X.; Cheng, K.; Gao, Y.; Xiao, Z. Deterioration characteristics of coal gangue concrete under the combined action of cyclic loading and freeze-thaw cycles. J. Build. Eng. 2022, 60, 105165. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, S.; Wang, R.; Shen, L.; Wang, Q. Utilization of raw coal gangue as coarse aggregates in pavement concrete. Constr. Build. Mater. 2023, 378, 131062. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Ge, Y.; Liu, P.; Zhang, A. Analysis of freeze-thaw damage and pore structure deterioration of mortar by low-field NMR. Constr. Build. Mater. 2022, 319, 126097. [Google Scholar] [CrossRef]

- Zhu, C.; Wan, Y.; Wang, L.; Ye, Y.; Yu, H.; Yang, J. Strength characteristics and microstructure analysis of alkali-activated slag–fly ash cementitious material. Materials 2022, 15, 6169. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, X.; Tang, B.; Li, Y.; Zhang, W.; Xue, Y. Effect of ca/(si + al) on red mud based eco-friendly revetment block: Microstructure, durability and environmental performance. Constr. Build. Mater. 2021, 304, 124618. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, P.; Shao, R.; Zhao, Q.; Yang, T.; Wu, C. A comprehensive review of multisource solid wastes in sustainable concrete: From material properties to engineering application. Constr. Build. Mater. 2024, 435, 136775. [Google Scholar] [CrossRef]

- Moura, T.M.D.S.; Rocha, J.C. Valorization of red mud and bottom ash as precursors for the synthesis of alkaline activation in metakaolin-based binder. J. Mater. Civ. Eng. 2025, 37, 04025240. [Google Scholar] [CrossRef]

- Elyamany, H.E.; Elmoaty, A.E.M.A.; Diab, A.R.A. Properties of slag geopolymer concrete modified with fly ash and silica fume. Can. J. Civ. Eng. 2022, 49, 183–191. [Google Scholar] [CrossRef]

- Jia, Z.; Deng, X.; Wang, R.; Zhao, B.; Deng, L.; Wu, Q. Review on Frost Resistance Durability of Concrete in High Altitude and Cold Regions. J. Xi Technol. Univ. 2024, 44, 584–597. [Google Scholar] [CrossRef]

| Raw Materials | Chemical Composition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | CaO | Fe2O3 | Na2O | K2O | MgO | TiO2 | LOI | |

| Red mud | 16.45 | 12.36 | 2.56 | 50.35 | 8.10 | 0.22 | - | 1.78 | 8.18 |

| Fly ash | 28.57 | 48.15 | 6.68 | 6.36 | 2.57 | 1.21 | 0.83 | 0.85 | 4.78 |

| Cement | 6.68 | 18.24 | 65.15 | 2.88 | 0.68 | 0.57 | 4.25 | - | 1.55 |

| Category | Fineness Modulus | Close Packing Density (kg/m3) | Packing Density (kg/m3) | Relative Density (kg/m3) | Rock Content (%) | Particle Gradation |

|---|---|---|---|---|---|---|

| medium sand | 2.6 | 1847.5 | 1635 | 2600 | 11.95 | Zone Ⅱ |

| Sample | Factor Level Value | Proportion of RFCTSWC (kg/m3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RM | FA | CGA | W/B | RM | Cement | CGA | WRA | Sand | Gravel Aggregate | FA | Water | |

| 1 | 10% | 35% | 20% | 0.45 | 39.68 | 213.50 | 227.38 | 4.76 | 667.70 | 909.51 | 138.89 | 178.58 |

| 2 | 10% | 45% | 40% | 0.5 | 35.72 | 155.96 | 697.14 | 4.76 | 682.38 | 464.76 | 160.72 | 178.58 |

| 3 | 10% | 55% | 60% | 0.55 | 35.72 | 105.63 | 472.94 | 4.76 | 694.39 | 709.41 | 178.58 | 178.58 |

| 4 | 20% | 35% | 40% | 0.55 | 64.94 | 141.35 | 709.41 | 4.76 | 694.39 | 427.94 | 113.64 | 178.58 |

| 5 | 20% | 45% | 60% | 0.45 | 79.37 | 134.13 | 454.76 | 4.76 | 667.70 | 682.14 | 178.58 | 178.58 |

| 6 | 20% | 55% | 20% | 0.5 | 71.43 | 84.53 | 232.38 | 4.76 | 682.38 | 929.51 | 196.43 | 178.58 |

| 7 | 30% | 35% | 60% | 0.5 | 107.15 | 120.24 | 464.76 | 4.76 | 682.38 | 697.14 | 125.00 | 178.58 |

| 8 | 30% | 45% | 20% | 0.55 | 97.40 | 76.41 | 236.47 | 4.76 | 694.39 | 945.88 | 146.11 | 178.58 |

| 9 | 30% | 55% | 40% | 0.45 | 119.05 | 54.77 | 682.14 | 4.76 | 667.70 | 454.76 | 218.26 | 178.58 |

| Sample | Slump | Compressive Strength | Splitting Tensile Strength | |||

|---|---|---|---|---|---|---|

| Average Value (cm) | Cv (%) | Average Value (cm) | Cv (%) | Average Value (cm) | Cv (%) | |

| 1 | 19.8 | 1.05 | 42.91 | 1.70 | 5.62 | 2.98 |

| 2 | 18.3 | 1.38 | 24.87 | 5.62 | 3.10 | 4.39 |

| 3 | 18.6 | 2.69 | 21.90 | 1.67 | 2.67 | 3.93 |

| 4 | 15.8 | 2.86 | 24.28 | 3.58 | 2.82 | 4.60 |

| 5 | 19.7 | 1.34 | 24.96 | 1.11 | 3.13 | 3.68 |

| 6 | 21.0 | 0.48 | 18.59 | 3.10 | 2.11 | 1.36 |

| 7 | 16.0 | 2.20 | 19.46 | 1.94 | 2.44 | 1.41 |

| 8 | 16.9 | 1.70 | 16.15 | 3.01 | 2.03 | 4.58 |

| 9 | 19.6 | 1.28 | 10.57 | 0.97 | 1.33 | 4.10 |

| Test Index | Range Analysis | Factor | Optimum Level | |||

|---|---|---|---|---|---|---|

| k1 | k2 | k3 | R | |||

| Slump | A | 18.88 | 18.82 | 17.51 | 1.37 | 1 |

| B | 17.17 | 18.30 | 19.74 | 2.58 | 3 | |

| C | 19.23 | 17.89 | 18.09 | 1.34 | 1 | |

| D | 19.70 | 18.41 | 17.10 | 2.60 | 1 | |

| Influence degree: D > B > A >C | ||||||

| Compressive strength | A | 29.89 | 22.61 | 15.39 | 14.50 | 1 |

| B | 28.88 | 21.99 | 17.02 | 11.86 | 1 | |

| C | 25.89 | 19.91 | 22.11 | 5.98 | 1 | |

| D | 26.15 | 20.97 | 20.78 | 5.37 | 1 | |

| Influence degree: A > B > C > D | ||||||

| Splitting tensile strength | A | 3.80 | 2.69 | 1.93 | 1.86 | 1 |

| B | 3.63 | 2.75 | 2.04 | 1.59 | 1 | |

| C | 3.25 | 2.42 | 2.75 | 0.83 | 1 | |

| D | 3.36 | 2.55 | 2.51 | 0.85 | 1 | |

| Influence degree: A > B > D > C | ||||||

| Test Index | Source of Variance | Sum of Squares of Deviation | Degree of Freedom | Mean Square | F Value | p Value | Significant |

|---|---|---|---|---|---|---|---|

| Slump | A | 10.7696 | 2 | 5.3848 | 2.9587 | 0.0775 | - |

| B | 30.0474 | 2 | 15.0237 | 8.2548 | 0.0029 | * | |

| C | 9.4719 | 2 | 4.7359 | 2.6022 | 0.1017 | - | |

| D | 30.4207 | 2 | 15.2104 | 8.3573 | 0.0027 | * | |

| Compressive strength | A | 946.0597 | 2 | 473.0299 | 56.6330 | 1.7143 × 10−8 | ** |

| B | 638.1683 | 2 | 319.0842 | 38.2020 | 3.3307 × 10−7 | ** | |

| C | 164.6754 | 2 | 82.3377 | 9.8578 | 0.0013 | * | |

| D | 166.9952 | 2 | 83.4976 | 9.9967 | 0.0012 | * | |

| Splitting tensile strength | A | 15.8440 | 2 | 7.9220 | 21.7790 | 1.5627 × 10−5 | ** |

| B | 11.4747 | 2 | 5.7373 | 15.7730 | 0.0001 | ** | |

| C | 3.1591 | 2 | 1.5796 | 4.3425 | 0.0289 | * | |

| D | 4.1683 | 2 | 2.0842 | 5.7298 | 0.0119 | * |

| Dosage Combination | Fitting Relation | Fitting Result | |||

|---|---|---|---|---|---|

| A1 | y0 | t1 | R2 | ||

| RF1 | RDEM-FTc | −16.98327 | 117.48665 | −182.64386 | 0.995 |

| CS-FTc | −0.09108 | 42.25935 | −52.3791 | 0.979 | |

| RF2 | RDEM-FTc | −9.83674 | 107.60959 | −100.57775 | 0.985 |

| CS-FTc | −0.03134 | 24.56594 | −33.10658 | 0.963 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, J.; Tian, Y.; Liu, J.; Zhou, R.; Mao, H. Synergistic Thresholds Governing Performance Evolution in Red Mud-Fly Ash-Coal Gangue Ternary Solid Waste Concrete (RFCTSWC). Materials 2025, 18, 3754. https://doi.org/10.3390/ma18163754

Qu J, Tian Y, Liu J, Zhou R, Mao H. Synergistic Thresholds Governing Performance Evolution in Red Mud-Fly Ash-Coal Gangue Ternary Solid Waste Concrete (RFCTSWC). Materials. 2025; 18(16):3754. https://doi.org/10.3390/ma18163754

Chicago/Turabian StyleQu, Jin, Yujie Tian, Jiale Liu, Runfang Zhou, and Haitao Mao. 2025. "Synergistic Thresholds Governing Performance Evolution in Red Mud-Fly Ash-Coal Gangue Ternary Solid Waste Concrete (RFCTSWC)" Materials 18, no. 16: 3754. https://doi.org/10.3390/ma18163754

APA StyleQu, J., Tian, Y., Liu, J., Zhou, R., & Mao, H. (2025). Synergistic Thresholds Governing Performance Evolution in Red Mud-Fly Ash-Coal Gangue Ternary Solid Waste Concrete (RFCTSWC). Materials, 18(16), 3754. https://doi.org/10.3390/ma18163754