Fracture Toughness Analysis of Ni–Cr–Mo Low-Alloy Steel for Advanced Nuclear Power

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

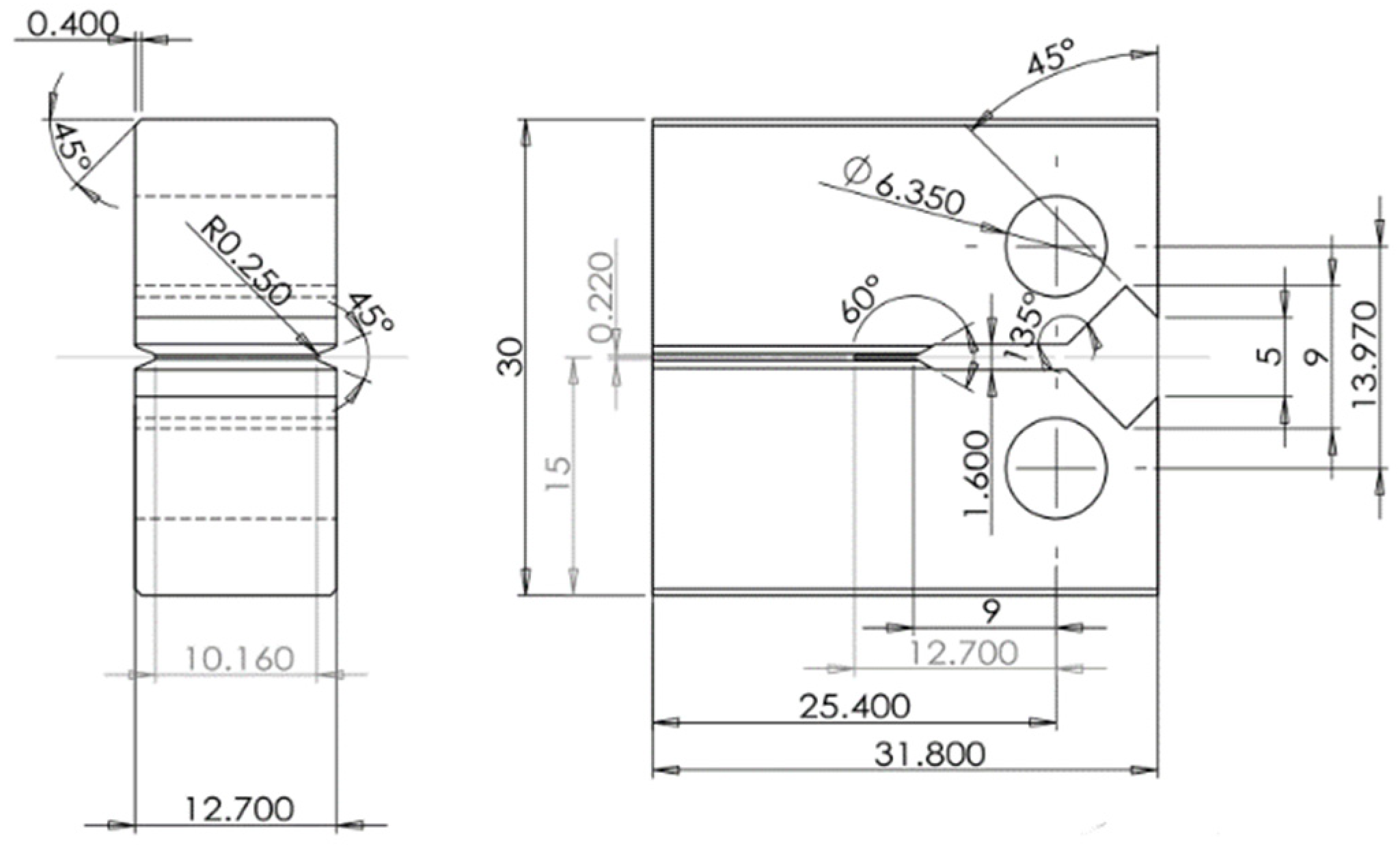

2.2. Test Methods

3. Results

3.1. Tensile Properties

3.2. Cv Impact Toughness and RTNDT

3.3. Fracture Toughness

3.4. Microstructure Analysis

3.4.1. Optical Microscope

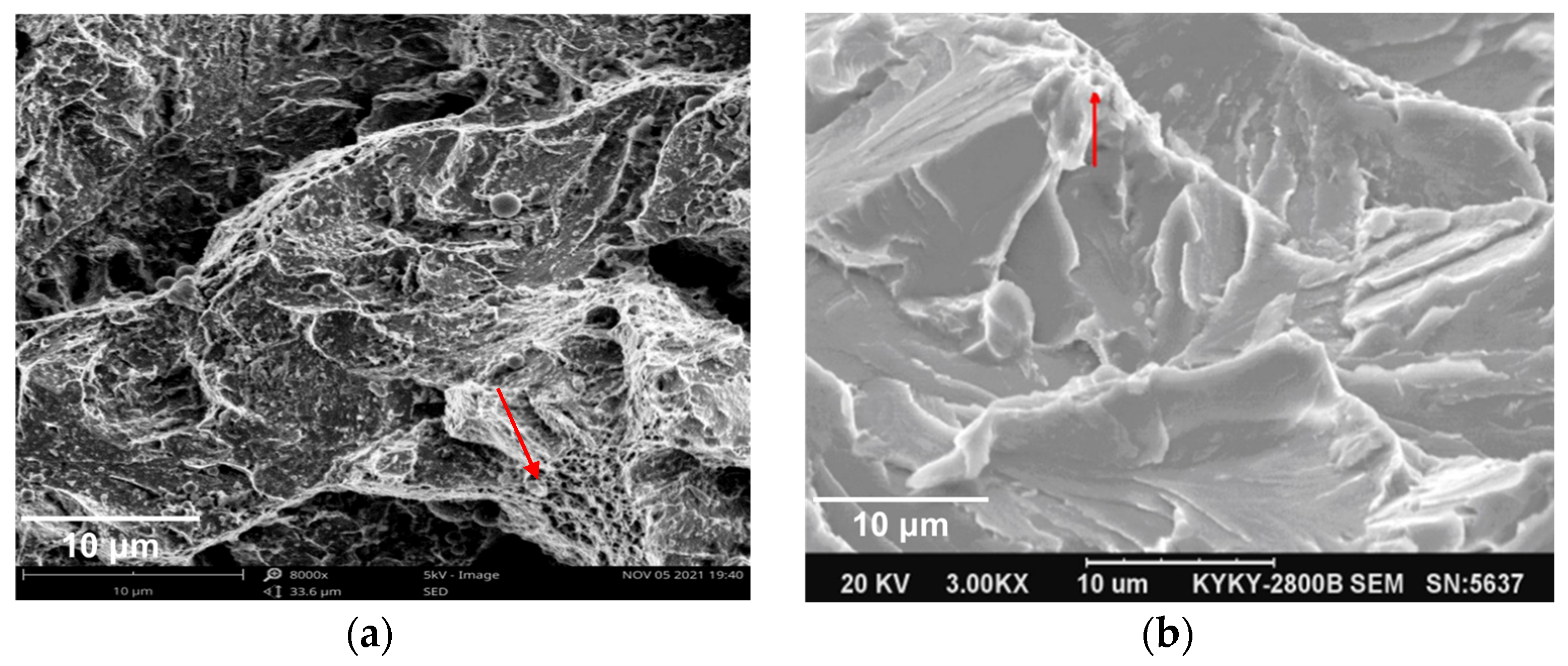

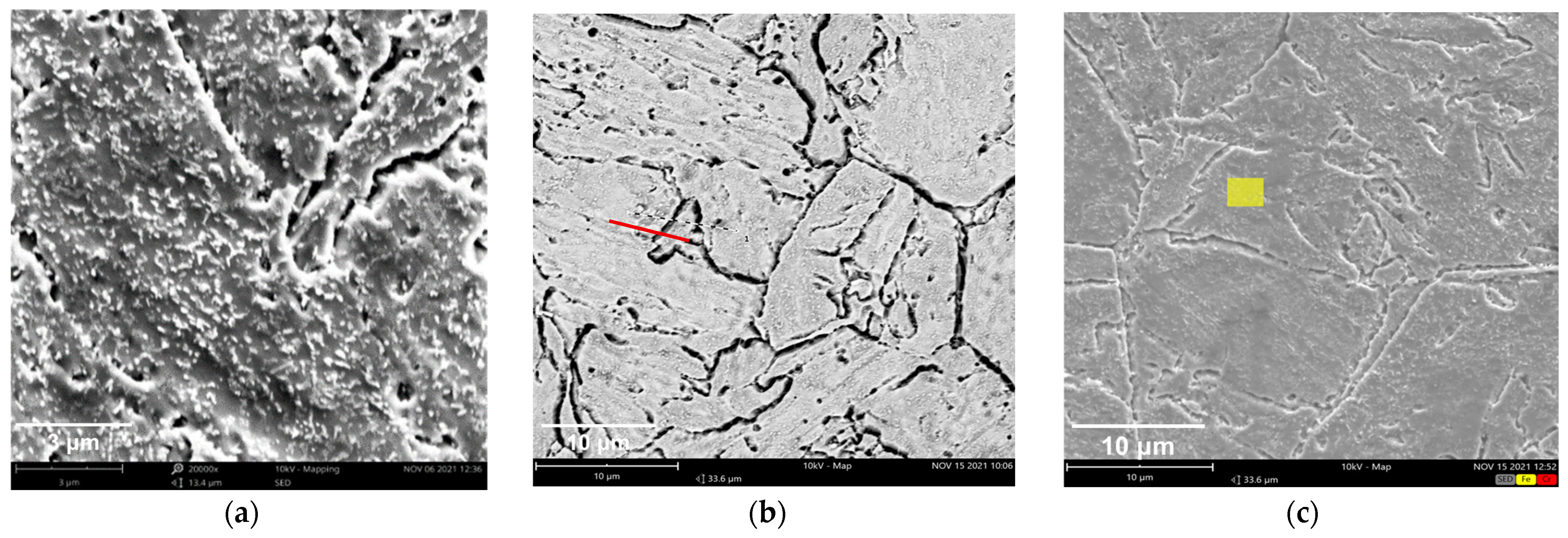

3.4.2. Scanning Electron Microscope

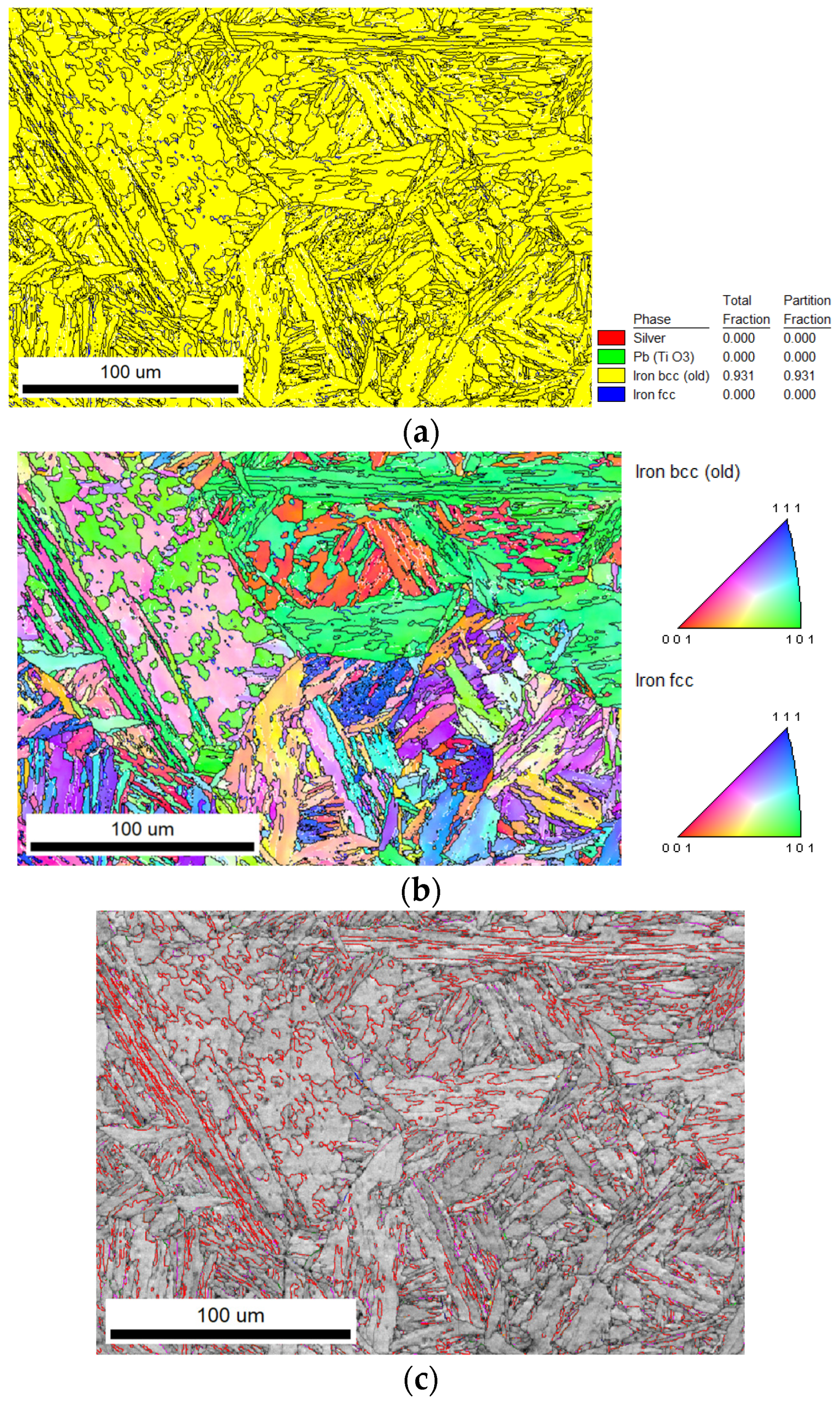

3.4.3. Electron Backscattering Diffraction Analysis

4. Discussion

4.1. Effect of Metallographic Structure on Fracture Toughness

4.2. Effect of Precipitation on Relative Fracture Toughness

4.3. Effect of Grain Boundary Structure on Fracture Toughness

5. Conclusions

- Compared with SA508 Gr.3 steel, SA508 Gr.4N steel showed much better mechanical properties than SA508 Gr.3 steel in terms of tensile strength, impact energy and fracture toughness. In the selection of RPV steel, SA508 Gr.4N steel may be the optimal choice in terms of strength and toughness.

- The size of martensite lath in SA508 Gr.4N steel is smaller than that of bainite in SA508 Gr.3 steel, which can create more sub-structural interfaces. Moreover, the CSL grain boundaries in SA508 Gr.4N steel have moderate grain boundary energy, which can not only block the crack propagation but also does not attract the segregation of impurity elements. It can improve the fracture toughness of the material.

- The fine and diffuse carbide precipitates in SA508 Gr.4N steel can inhibit the crack propagation and dislocation slip. These precipitates make an important contribution to improving the cleavage fracture toughness and low-temperature toughness in the transition zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Little, E.A. Development of radiation resistant materials for advanced nuclear power plant. Mater. Sci. Technol. 2006, 22, 491–518. [Google Scholar] [CrossRef]

- Ballesteros, A.; Brumoský, M.; Davies, L.M.; Davies, L.M.; Debarberis, L.; Jumel, S.; Kang, K.S.; Kryukov, A.; Kupca, L.; Langer, R.; et al. Integrity of reactor pressure vessels in nuclear power plants: Assessment of irradiation embrittlement effects in reactor pressure vessel steels. In Integrity of Reactor Pressure Vessels in NPPs; IAEA Nuclear Energy Series; No. NP-T-3.11; International Atomic Energy Agency: Vienna, Austria, 2009. [Google Scholar]

- Phythian, W.J.; English, C.A. Microstructural evolution in reactor pressure vessel steels. J. Nucl. Mater. 1993, 205, 162–177. [Google Scholar] [CrossRef]

- Zhou, L.; Dai, J.; Li, Y.; Dai, X.; Xie, C.; Li, L.; Chen, L. Research Progress of Steels for Nuclear Reactor Pressure Vessels. Materials 2022, 15, 8761. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Kasada, R.; Kimura, A.; Lee, B.S.; Suh, D.W.; Lee, H.C. Effect of nickel content on the neutron irradiation embrittlement of Ni-Mo-Cr steels. Met. Mater. Int. 2013, 19, 1203–1208. [Google Scholar] [CrossRef]

- Kim, M.C.; Lee, B.S. Comparison of SA508 Gr.3 and SA508 Gr.4N Low Alloy Steels for Reactor Pressure Vessel Steel; KAERI/TR-3965; International Atomic Energy Agency: Vienna, Austria, 2009.

- Lee, K.H.; Park, S.G.; Kim, M.C.; Lee, B.S. Cleavage fracture toughness of tempered martensitic Ni–Cr–Mo low alloy steel with different martensite fraction. Mater. Sci. Eng. A 2012, 534, 75–82. [Google Scholar] [CrossRef]

- Odette, G.R.; He, M.Y.; Yamamoto, T. On the relation between irradiation induced changes in the master curve reference temperature shift and changes in strain hardened flow stress. J. Nucl. Mater. 2007, 367–370 Pt A, 561–567. [Google Scholar] [CrossRef]

- Kim, M.C.; Park, S.G.; Lee, K.H.; Lee, B.S. Comparison of fracture properties in SA508 Gr.3 and Gr.4N high strength low alloy steels for advanced pressure vessel materials. Int. J. Pres. Ves. Pip. 2015, 131, 60–66. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, M.C.; Lee, B.S.; Wee, D.W. Analysis of the master curve approach on the fracture toughness properties of SA508 Gr.4N Ni–Mo–Cr low alloy steels for reactor pressure vessels. Mater. Sci. Eng. A 2010, 527, 3329–3334. [Google Scholar] [CrossRef]

- Jiang, Y.K.; Li, C.W.; Wang, S.X.; Mao, X.F.; Guo, Z.H.; Gu, J.F. Effect of microstructure on fracture mode of SA508 Gr.3 steel. Trans. Mater. Heat. Treat. 2019, 40, 98–105. [Google Scholar]

- Park, S.G.; Lee, K.H.; Kim, M.C.; Lee, B.S. Effects of boundary characteristics on resistance to temper embrittlement and segregation behavior of Ni–Cr–Mo low alloy steel. Mater. Sci. Eng. A 2013, 561, 277–284. [Google Scholar] [CrossRef]

- Park, S.G.; Lee, K.H.; Min, K.D.; Kim, M.C.; Lee, B.S. Characterization of phase fractions and misorientations on tempered Bainitic/Martensitic Ni-Cr-Mo low alloy RPV steel with various Ni content. Met. Mater. Int. 2013, 19, 49–54. [Google Scholar] [CrossRef]

- ASTM A370; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E21; Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E208; Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E1921; Standard Test Method for Determination of Reference Temperature, T0, for Ferritic Steels in the Transition Range. ASTM International: West Conshohocken, PA, USA, 2019.

- Bonade, R.; Spatig, P.; Baluc, N. Fracture toughness properties in the transition region of the Eurofer97 tempered martensitic steel. J. Nucl. Mater. 2007, 367–370, 581–586. [Google Scholar] [CrossRef]

- Mueller, P.; Sp€atig, P.; Bonade, R.; Odette, G.R.; Gragg, D. Fracture toughness master curve analysis of the tempered martensitic steel Eurofer97. J. Nucl. Mater. 2009, 386–388, 323–327. [Google Scholar] [CrossRef]

- Park, S.G.; Kim, M.C.; Lee, B.S.; Wee, D.M. Correlation of the thermodynamic calculation and the experimental observation of Ni-Mo-Cr low alloy steel changing Ni, Mo, and Cr contents. J. Nucl. Mater. 2010, 407, 126–135. [Google Scholar] [CrossRef]

- Li, S.C.; Zhu, G.M.; Kang, Y.L. Effect of substructure on mechanical properties and fracture behavior of lath martensite in 0.1 C-1.1Si-1.7Mn Steel. J. Alloys Compd. 2016, 675, 104–115. [Google Scholar] [CrossRef]

- Yang, Z.Q. A Study on Toughness-Brittleness of SA508 Gr.4N Steel Forgings Used for Nuclear Pressure Vessels. Doctoral Thesis, Iron and Steel Research Institute, Beijing, China, 2018. [Google Scholar]

- Lee, B.S.; Kim, M.C.; Yoon, J.H.; Hong, J.H. Characterization of high strength and high toughness Ni–Mo–Cr low alloy steels for nuclear application. Int. J. Pres. Ves. Pip. 2010, 87, 74–80. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, M.C.; Yang, W.J.; Lee, B.S. Evaluation of microstructural parameters controlling cleavage fracture toughness in Mn-Mo-Ni low alloy steels. Mater. Sci. Eng. A 2013, 565, 158–164. [Google Scholar] [CrossRef]

- Lee, S.; Kim, S.; Hwang, B.; Lee, B.S.; Lee, C.G. Effect of carbide distribution on the fracture toughness in the transition temperature region of an SA508 steel. Acta Mater. 2002, 50, 4755–4762. [Google Scholar] [CrossRef]

- Yuan, X.H. Multi-Scale Strengthening-Toughening Mechanisms and Fatigue Resistance of High-Alloy Cr-Co-Mo Bearing Steel. Doctoral Thesis, Kunming University of Science and Technology, Kunming, China, 2015. [Google Scholar]

- Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 1, 16019. [Google Scholar] [CrossRef]

- Shen, Y.F.; Lu, L.; Lu, Q.H.; Jin, Z.H.; Lu, K. Tensile properties of copper with nano-scale twins. Scripta. Mater. 2005, 52, 989–994. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Ni | Mo | Cr | V | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| SA508 Gr.4N | 0.18 | 0.26 | 0.37 | 0.002 | 0.0002 | 3.46 | 0.54 | 1.76 | 0.006 | 0.02 |

| SA508 Gr.3 | 0.19 | 0.18 | 1.44 | 0.005 | 0.002 | 0.74 | 0.51 | 0.14 | 0.005 | 0.02 |

| Designation | Temp (°C) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Reduction (%) |

|---|---|---|---|---|---|

| SA508 Gr.4N | Room | 666 | 786 | 26 | 75 |

| SA508 Gr.3 | 431 | 568 | 29 | 76.5 | |

| SA508 Gr.4N | 290 | 548 | 719 | 25 | 72 |

| SA508 Gr.3 | 379 | 540 | 28 | 78 |

| Designation | T41J (°C) | T68J (°C) | USE (J) | RTNDT (°C) |

|---|---|---|---|---|

| SA508 Gr.4N | −130 | −111.7 | 222.8 | −120 |

| SA508 Gr.3 | −60 | −50.5 | 198.5 | −32 |

| Element Symbol | Area (b) | Area (c) |

|---|---|---|

| Fe | 89.34 | 97.20 |

| O | 5.94 | / |

| Cr | 2.92 | 2.80 |

| C | 1.80 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, X.; Huang, Y.; Guo, M.; He, C.; Hu, Q. Fracture Toughness Analysis of Ni–Cr–Mo Low-Alloy Steel for Advanced Nuclear Power. Materials 2025, 18, 3743. https://doi.org/10.3390/ma18163743

Zeng X, Huang Y, Guo M, He C, Hu Q. Fracture Toughness Analysis of Ni–Cr–Mo Low-Alloy Steel for Advanced Nuclear Power. Materials. 2025; 18(16):3743. https://doi.org/10.3390/ma18163743

Chicago/Turabian StyleZeng, Xiaochuan, Yili Huang, Mingjie Guo, Cuizhu He, and Qiaodan Hu. 2025. "Fracture Toughness Analysis of Ni–Cr–Mo Low-Alloy Steel for Advanced Nuclear Power" Materials 18, no. 16: 3743. https://doi.org/10.3390/ma18163743

APA StyleZeng, X., Huang, Y., Guo, M., He, C., & Hu, Q. (2025). Fracture Toughness Analysis of Ni–Cr–Mo Low-Alloy Steel for Advanced Nuclear Power. Materials, 18(16), 3743. https://doi.org/10.3390/ma18163743