Analysis of the Possibility of Increasing the Load-Bearing Capacity and Fatigue Life of CFRP Material Mechanical Joints

Abstract

1. Introduction

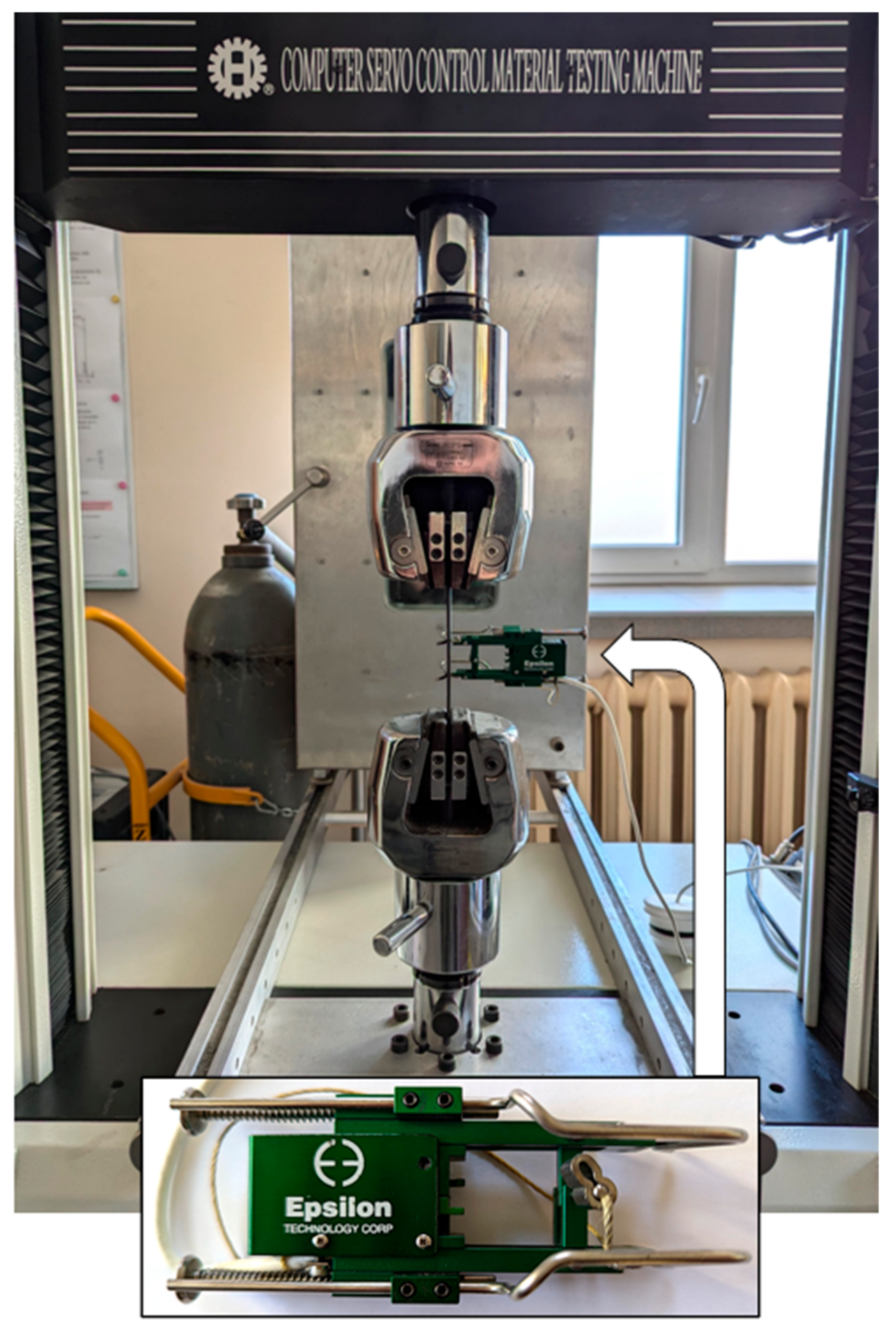

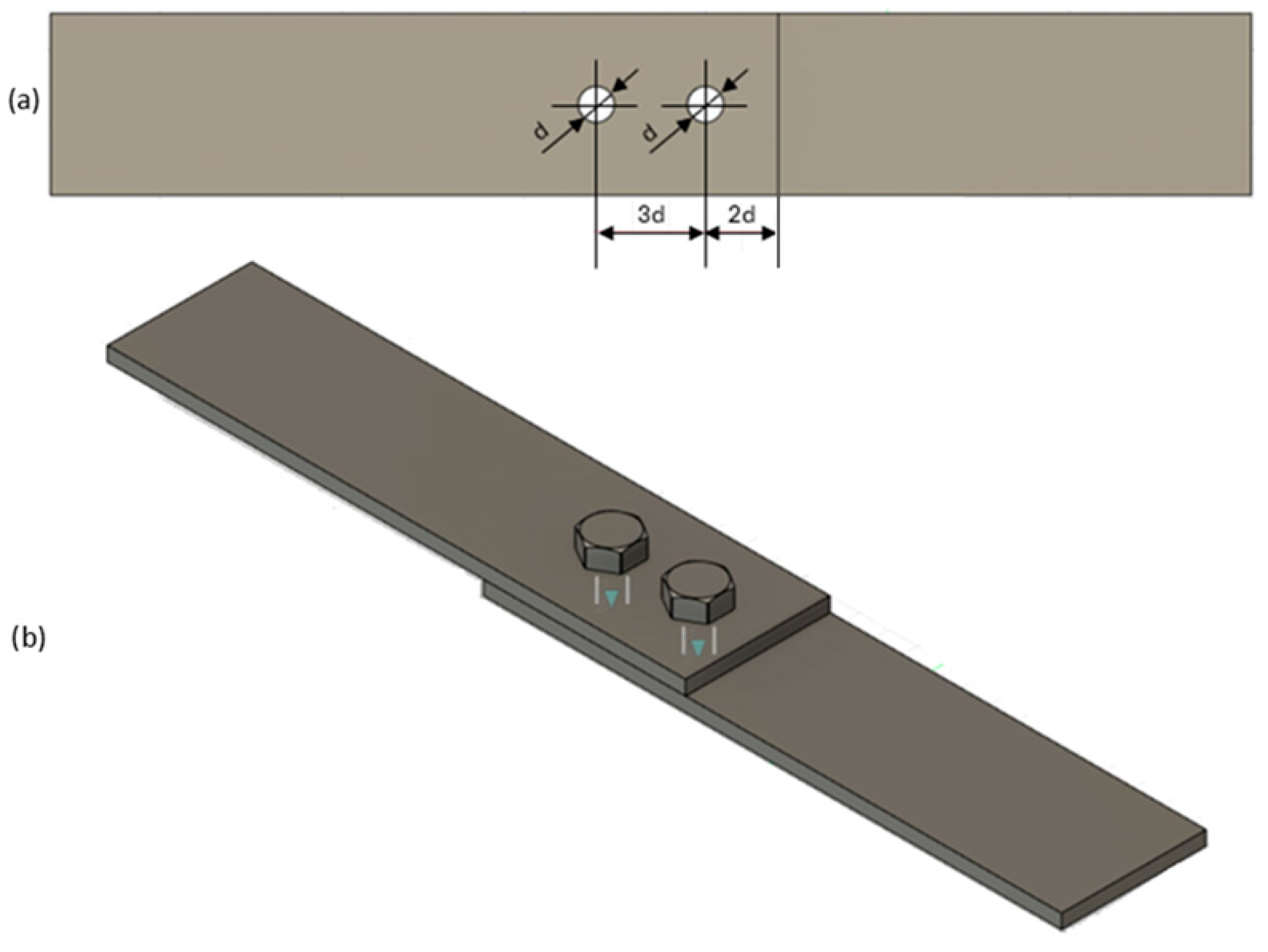

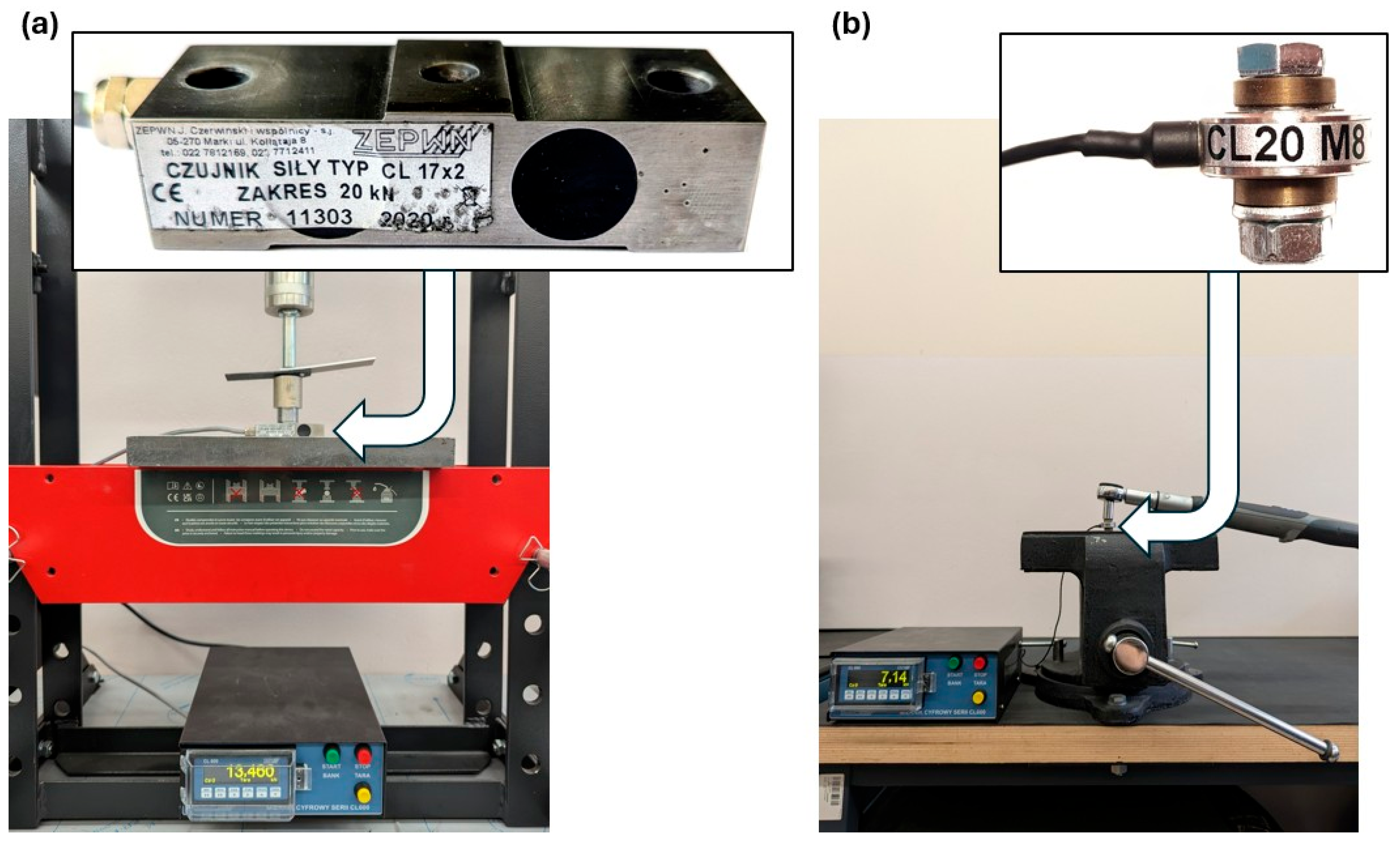

2. Materials and Methods

2.1. Joint Material

2.2. Joint Preparation Process

3. Results

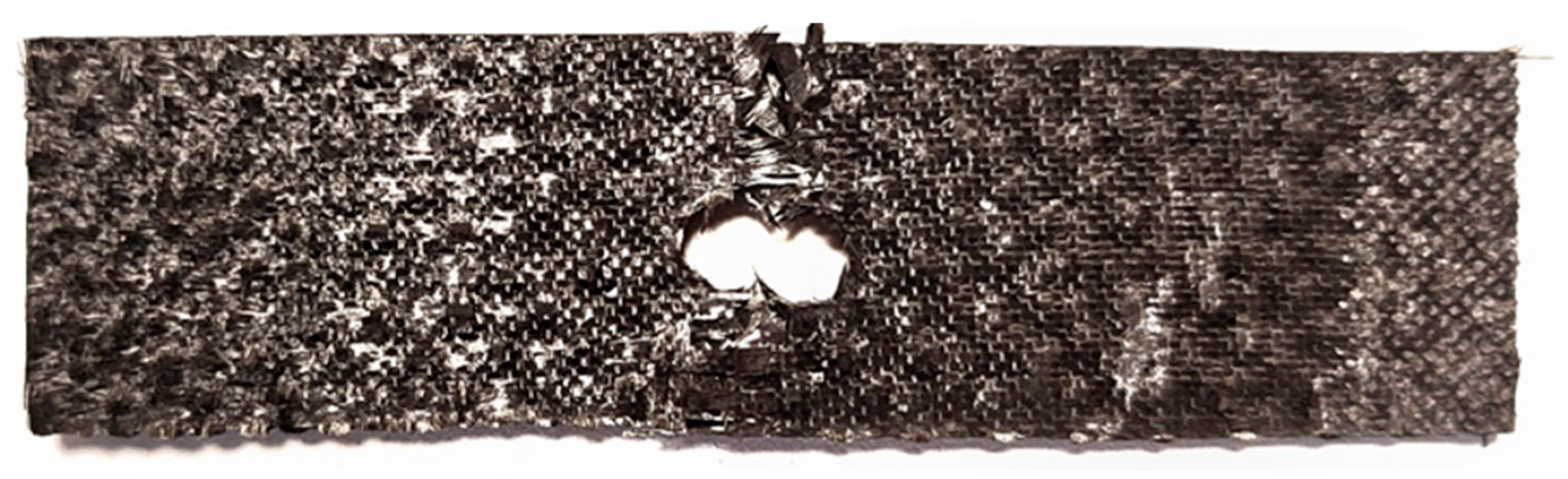

3.1. Influence of Notch on the Strength of CFRP Material

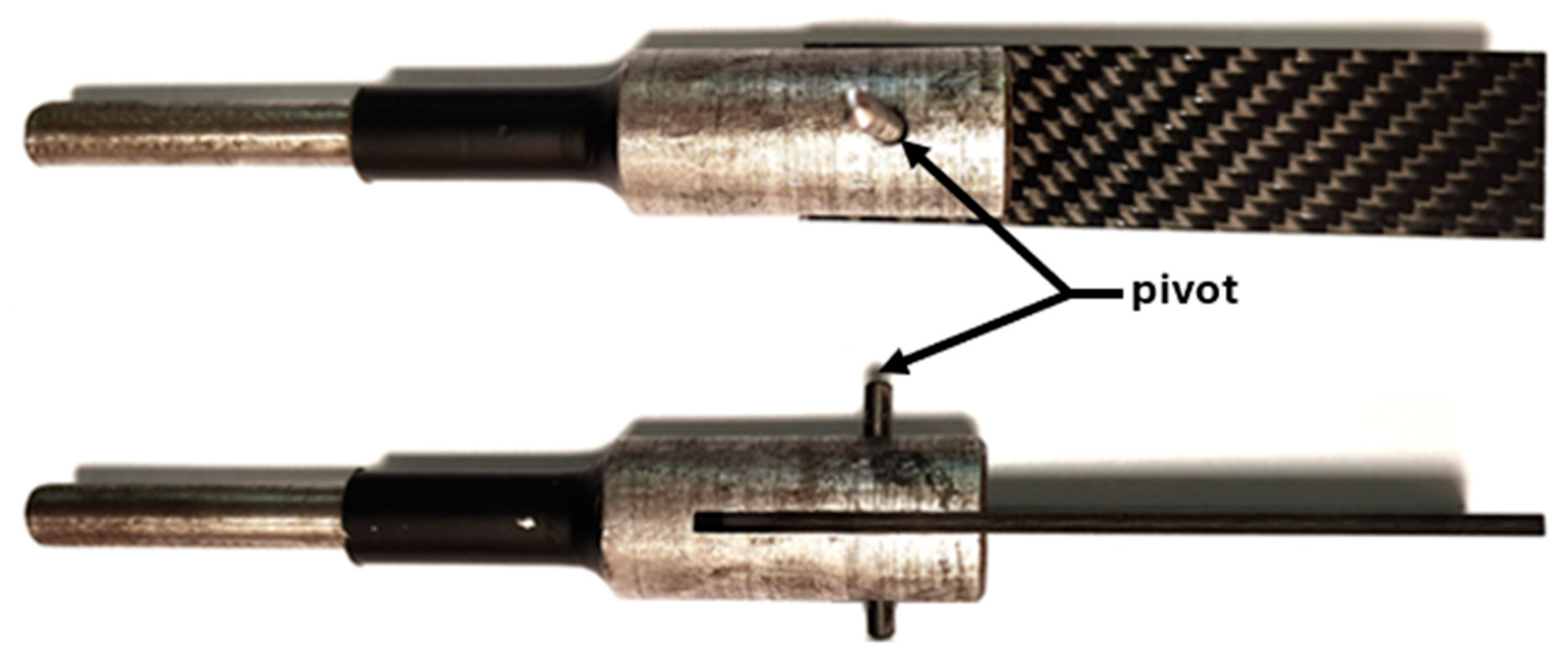

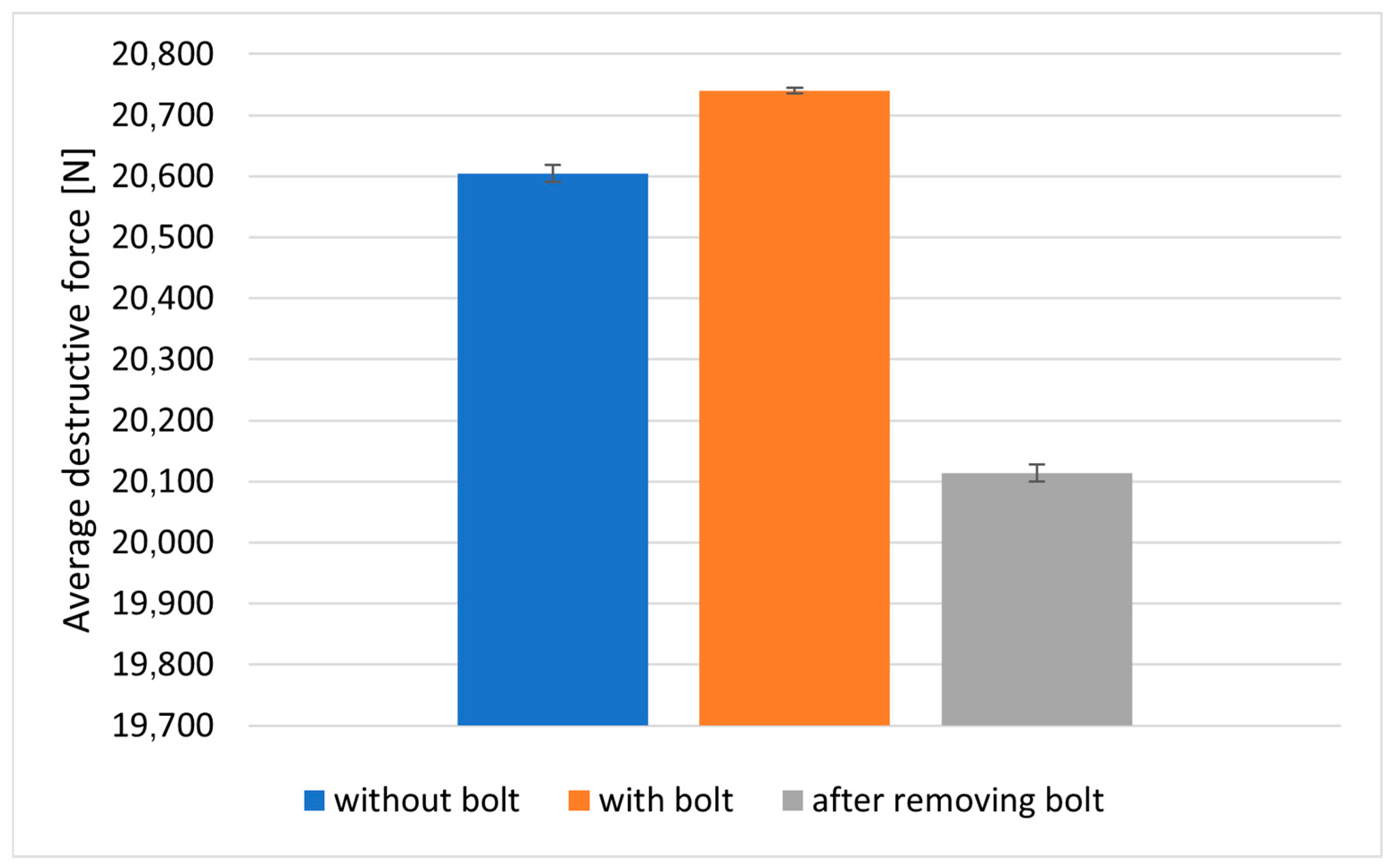

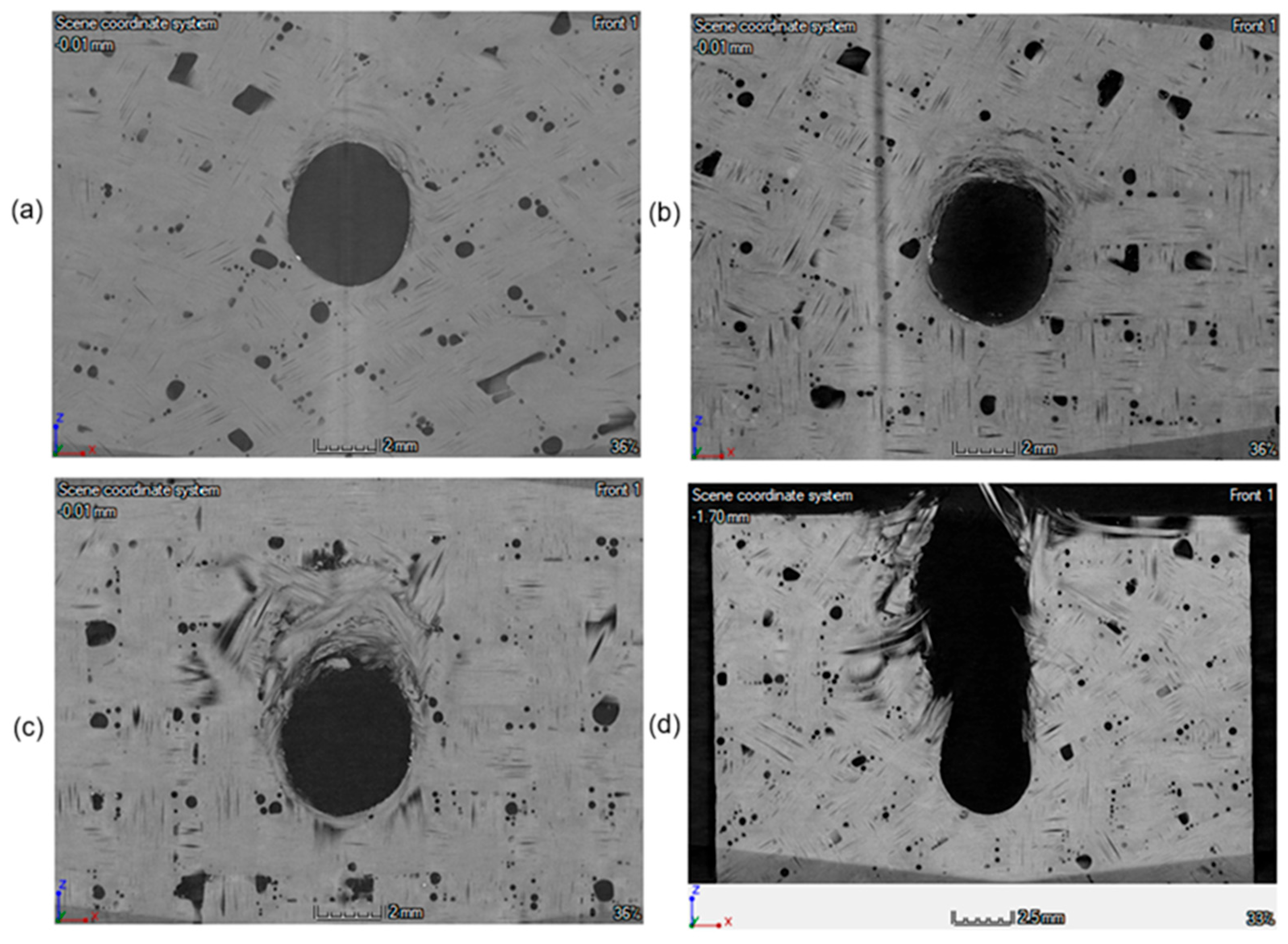

3.2. Influence of Pivot Action on Composite Material

3.3. Load-Bearing Capacity of Riveted and Bolted Joints

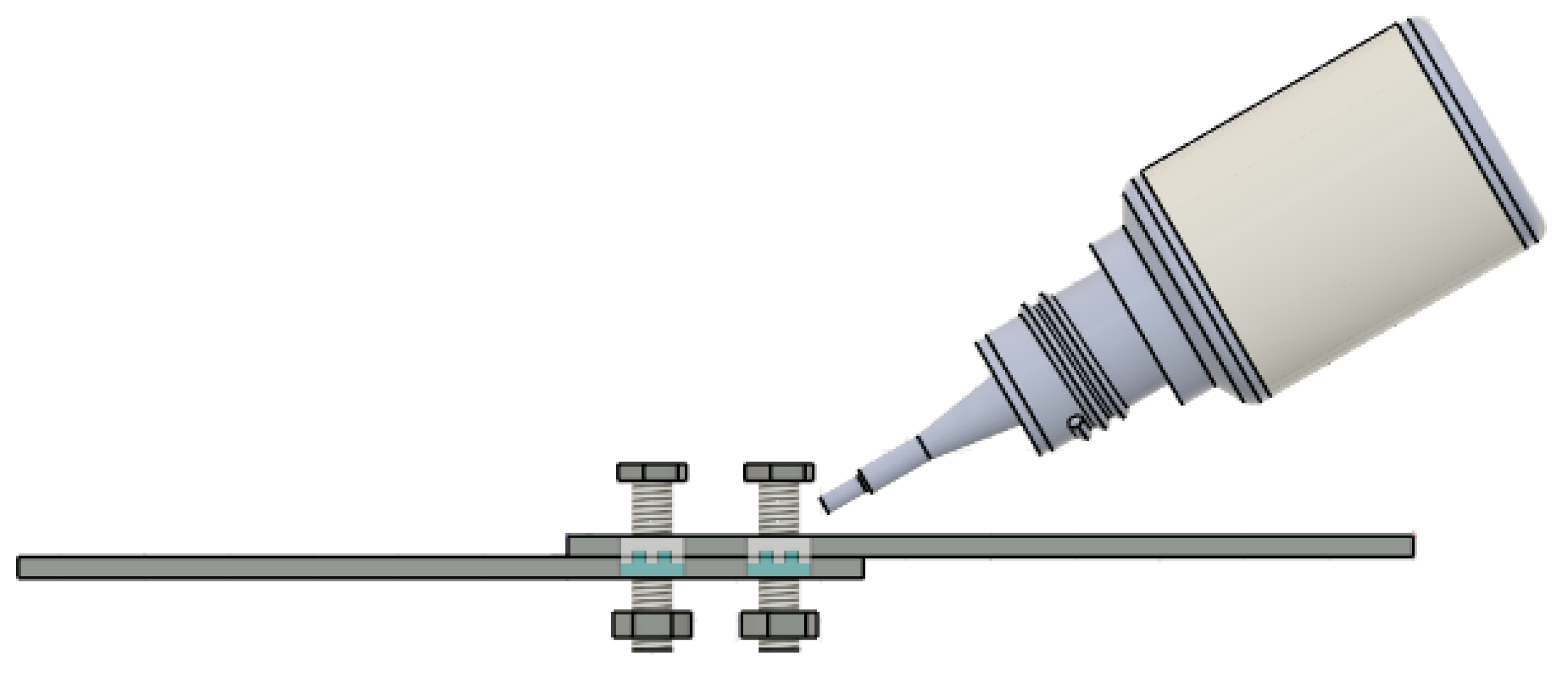

3.4. Influence of the Use of Adhesive Plastic During the Assembly of Bolted Joints

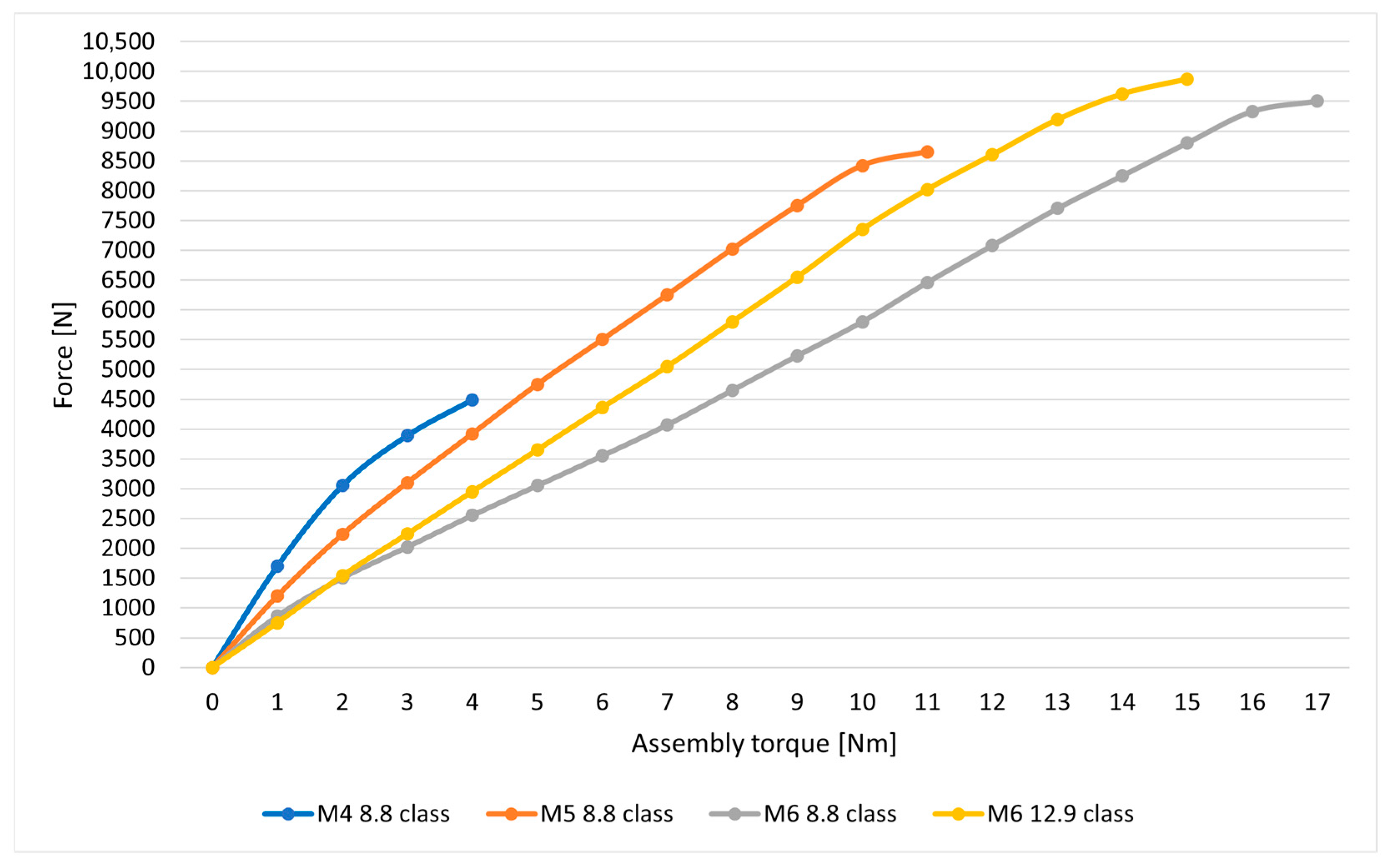

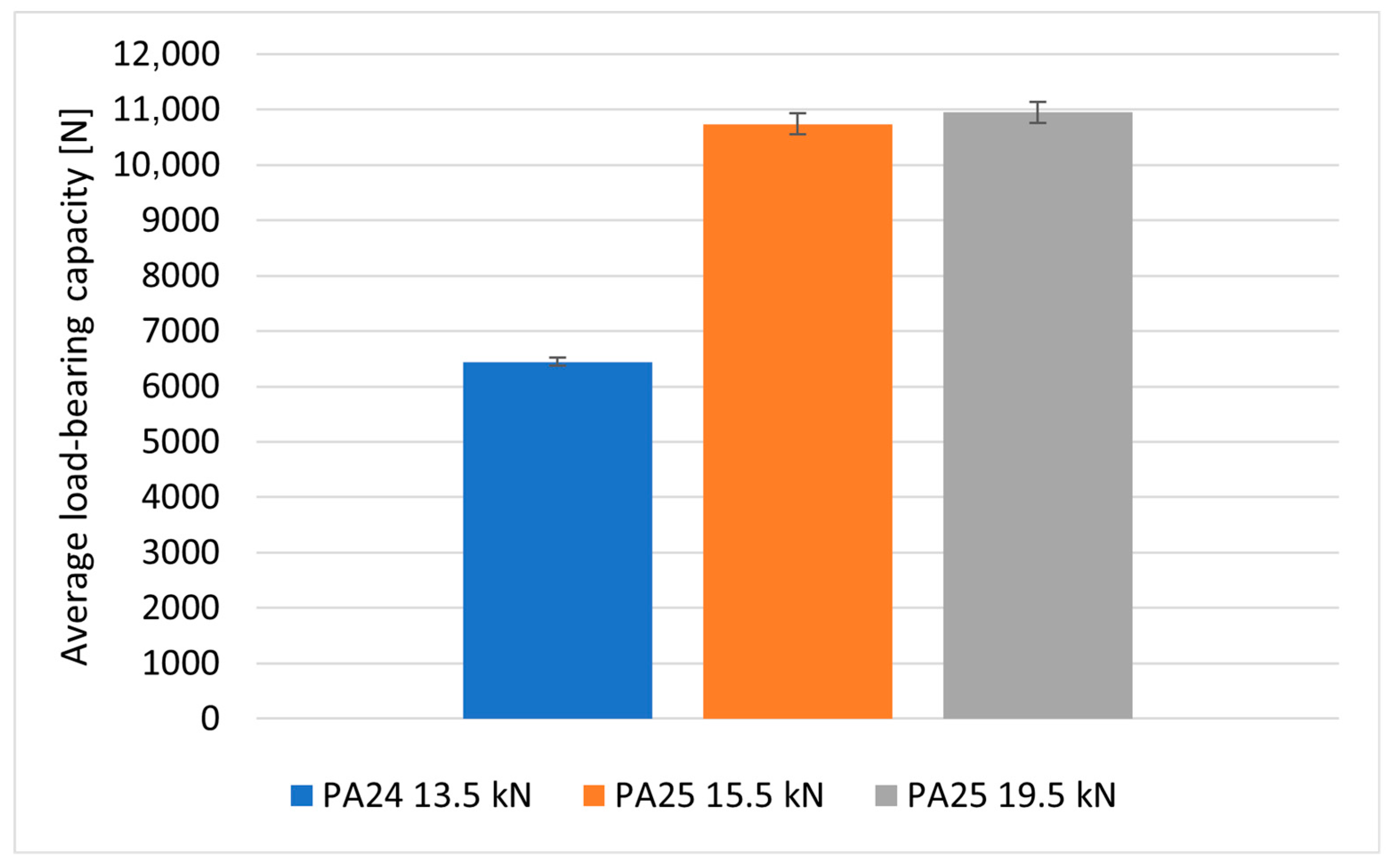

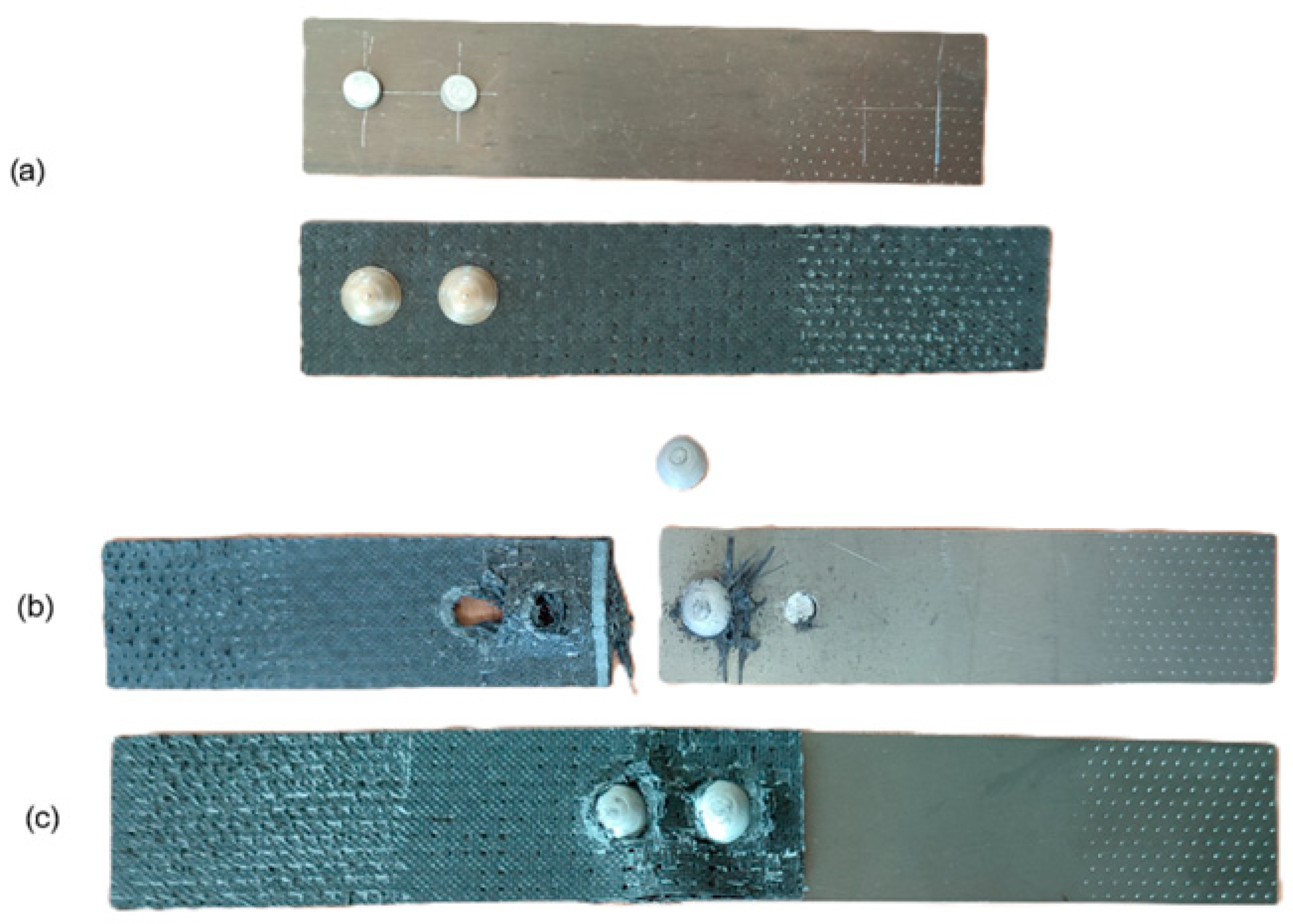

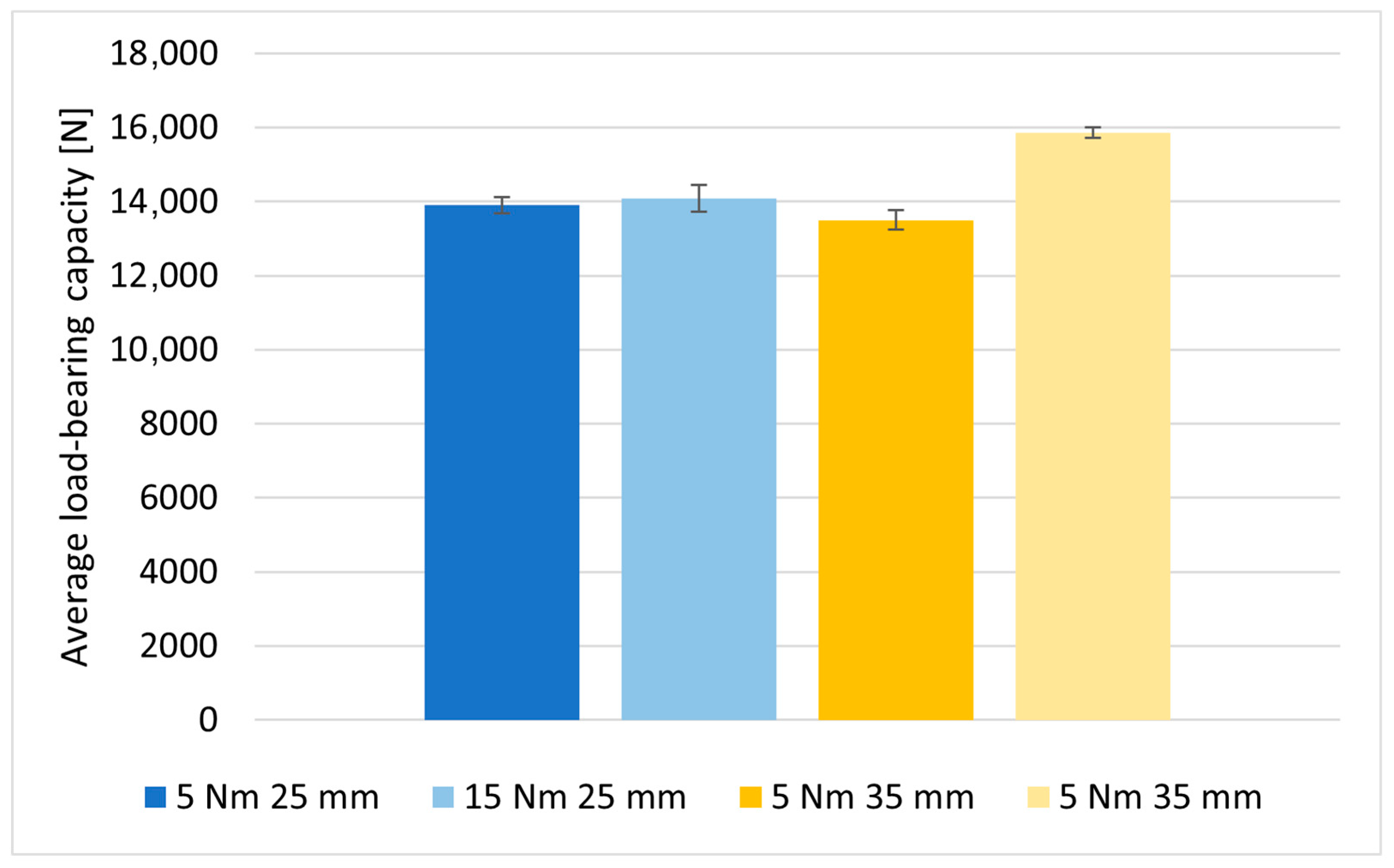

3.5. Influence of Assembly Torque on Load-Bearing Capacity of the Joints

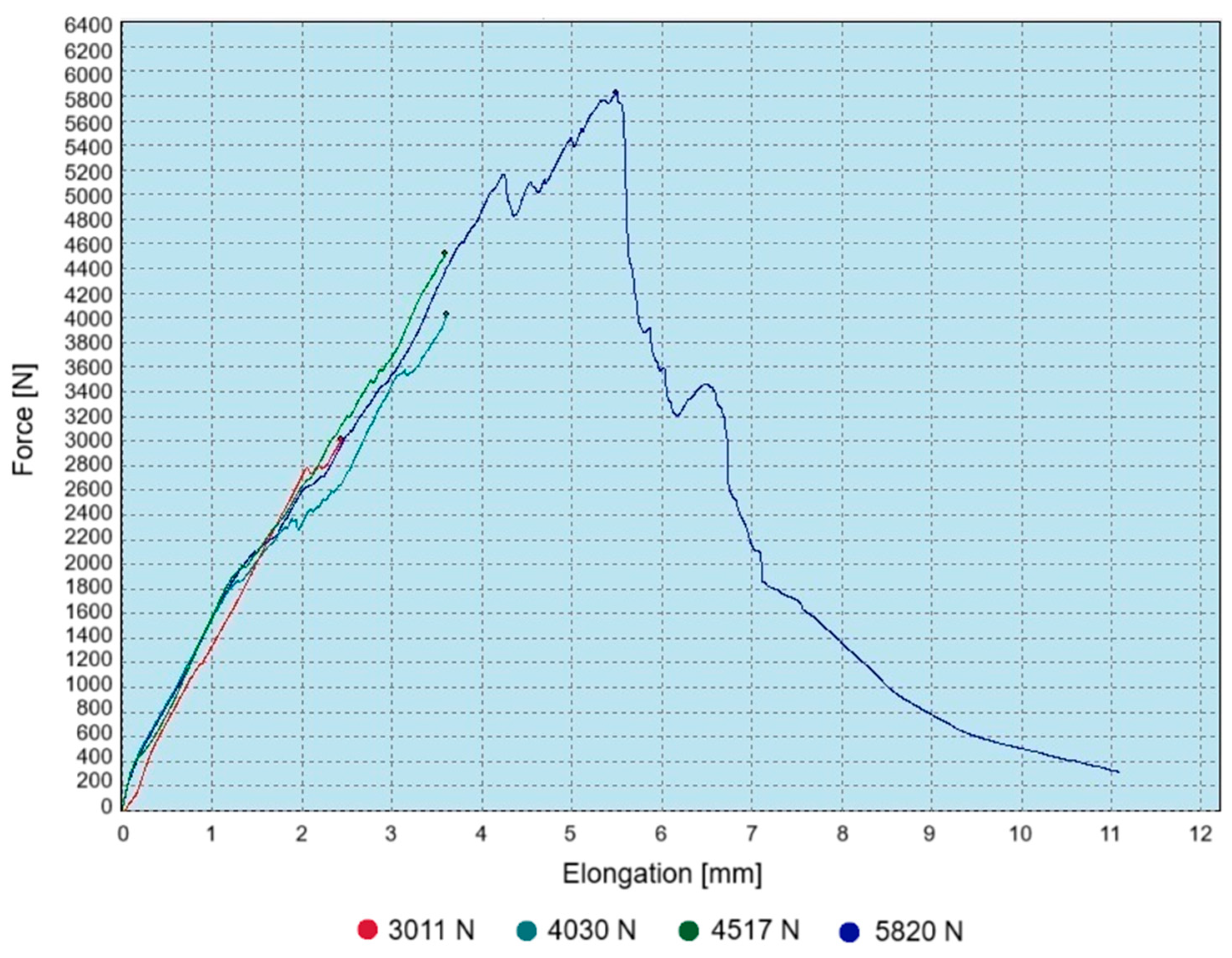

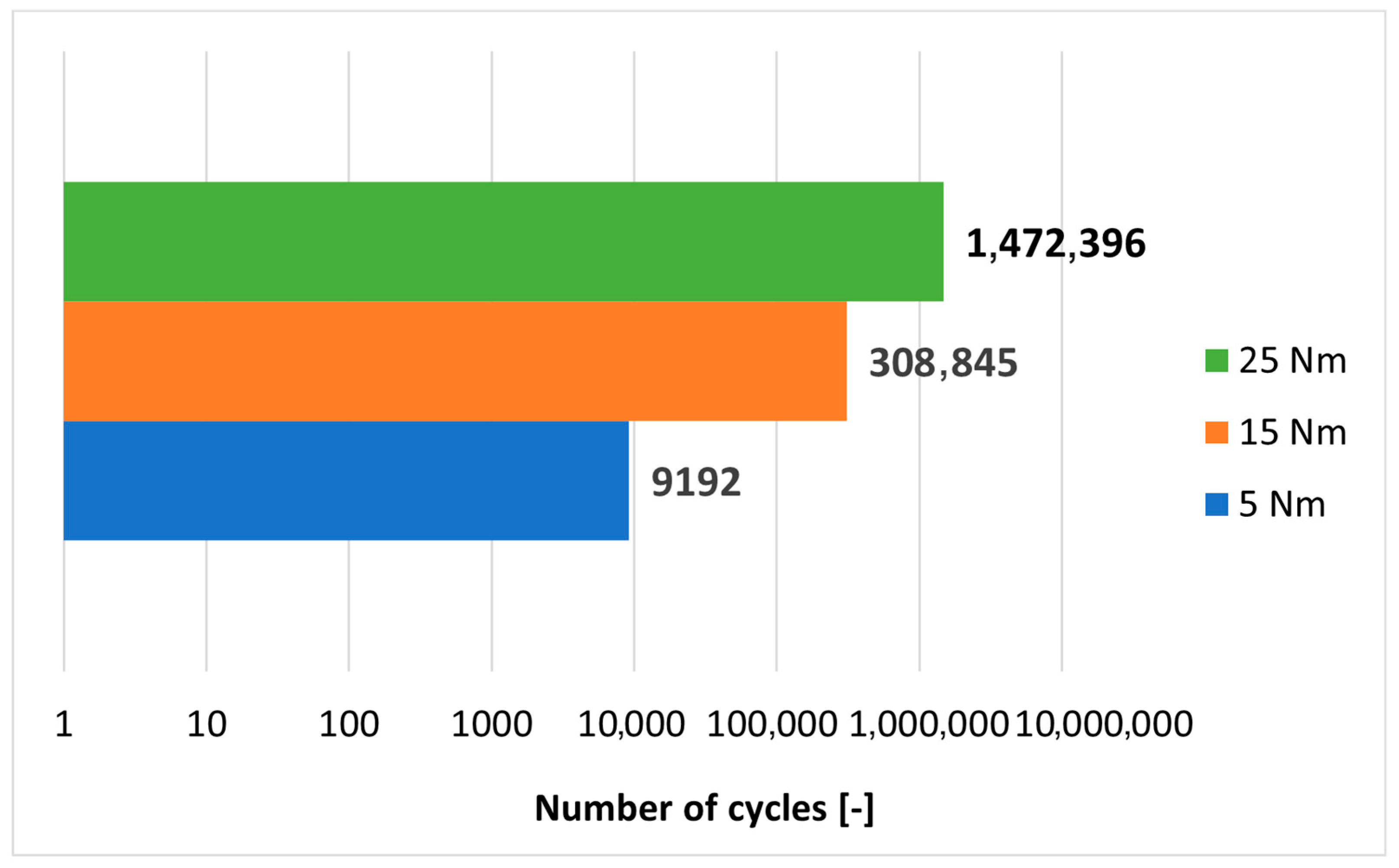

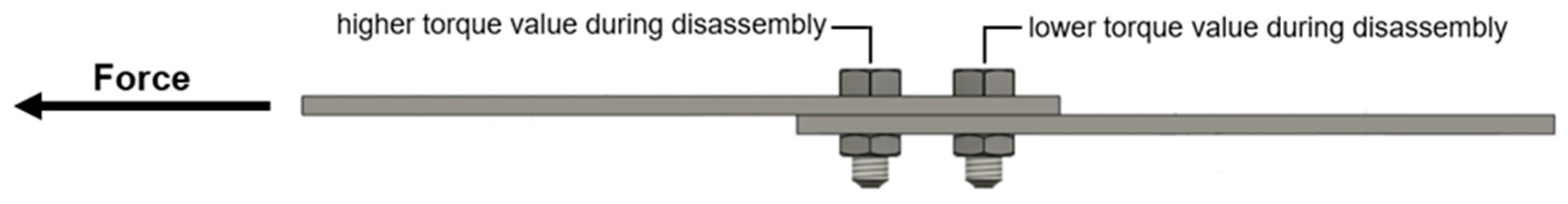

3.6. Influence of Assembly Torque on Fatigue Life of Joints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFRP | Carbon Fiber Reinforced Polymer |

References

- Mangalgiri, P.D. Composite materials for aerospace applications. Bull. Mater. Sci. 1999, 22, 657–664. [Google Scholar] [CrossRef]

- Vol’mir, A.S.; Pavlenko, V.F.; Ponomarev, A.T. Use of composite materials in airframes. Polym. Mech. 1972, 8, 89–95. [Google Scholar] [CrossRef]

- Rafi, H. Impact of composite materials on aircraft weight reduction, fuel efficiency, and performance in commercial aviation. Int. J. Mech. Eng. 2024, 4, 21–35. [Google Scholar] [CrossRef]

- Halpin, J.C. Opportunities for Polymeric-Based Composite Applications for Transport Aircraft. In Composite Materials. A Vision for the Future; Nicolais, L., Meo, M., Milella, E., Eds.; Springer: London, UK, 2011; pp. 51–68. [Google Scholar]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Prince, P.M.; Harsh, P.N.; Shyam, K.D. Properties of Carbon Fiber and its Applications. Int. J. Eng. Res. Technol. 2013, 2, 554–557. [Google Scholar]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials, 2nd ed.; Clarke, D.R., Suresh, S., Ward, I.M., Eds.; Cambridge University Press: Cambridge, UK, 1996; pp. 43–55. [Google Scholar]

- Murčinková, Z.; Postawa, P.; Winczek, J. Parameters Influence on the Dynamic Properties of Polymer-Matrix Composites Reinforced by Fibres, Particles, and Hybrids. Polymers 2022, 14, 3060. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Basic Experimental Characterization of Polymer Matrix Composite Materials. Polym. Rev. 2013, 53, 277–302. [Google Scholar] [CrossRef]

- Chowdhury, I.; Summerscales, J. Woven Fabrics for Composite Reinforcement: A Review. J. Compos. Sci. 2024, 8, 280. [Google Scholar] [CrossRef]

- Cameron, C.J.; Larsson, J.; Loukil, M.S.; Murtagh, T.; Wennhage, P. Bearing strength performance of mixed thin/thick-ply, quasi-isotropic composite laminates. Compos. Struct. 2021, 261, 113312. [Google Scholar] [CrossRef]

- Kamali, G.; Ashokkumar, N.; Sugash, K.; Magesh, V. Advanced Composite Materials of the Future in Aerospace Engineering. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 610–614. [Google Scholar] [CrossRef]

- Budzik, M.; Wolfahr, M.; Reis, P.; Kozłowski, M.; Sena-Cruz, J.; Papadakis, L.; Saleh, M.; Machalická, K.; De Freitas, T.; Vassilopoulos, A. Testing mechanical performance of adhesively bonded composite joints in engineering applications: An overview. J. Adhes. 2021, 98, 2133–2209. [Google Scholar] [CrossRef]

- Ramírez, F.; Moura, M.; Moreira, R.; Silva, F. A review on the environmental degradation effects on fatigue behaviour of adhesively bonded joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1307–1326. [Google Scholar] [CrossRef]

- Gualberto, H.; Amorim, F.; Costa, H. A review of the relationship between design factors and environmental agents regarding adhesive bonded joints. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 389. [Google Scholar] [CrossRef]

- German, J. Podstawy Mechaniki Kompozytów Włóknistych; Krakow University of Technology: Krakow, Poland, 1996. [Google Scholar]

- Godzimirski, J. Technologia Produkcji Płatowców; Military University of Technology: Warsaw, Poland, 2000. [Google Scholar]

- Patil, M.J.; Patil, R. The Strength Analysis of Hybrid (Bolted and Bonded) Single Lap joints for Composite Materials. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 4689–4692. [Google Scholar] [CrossRef]

- Jiang, L.; Xiao, S.; Dong, D.; Yang, B.; Chen, D.; Yang, G.; Zhu, T.; Wang, M. Experimental study of bonded, bolted, and hybrid braided CFRP joints with different stacking sequences and lapping patterns. Thin-Walled Struct. 2022, 177, 109408. [Google Scholar] [CrossRef]

- Paliwal, I.; Ramji, M. A detailed study on the damage evolution and failure assessment of single-lap hybrid joints in CFRP laminates under tensile loading. Compos. Struct. 2022, 299, 116021. [Google Scholar] [CrossRef]

- Thoppul, S.D.; Finegan, J.; Gibson, R.F. Mechanics of mechanically fastened joints in polymer-matrix composite structures—A review. Compos. Sci. Technol. 2009, 69, 301–329. [Google Scholar] [CrossRef]

- Bielawski, R. Badanie i Modelowanie Połączeń Nitowych w Lotniczych Strukturach Kompozytowych. Ph.D. Thesis, Warsaw University of Technology, Warsaw, Poland, 2016. [Google Scholar]

- Godzimirski, J.; Rośkowicz, M.; Jasztal, M.; Barca, I. Static and Fatigue Strength and Failure Mechanisms of Riveted Lap Joints of CFRP Composites. Materials 2023, 16, 1768. [Google Scholar] [CrossRef]

- Kłonica, M.; Bielawski, R. Strength of Joints with “Hi-Lok” Fasteners. Adv. Sci. Technol. Res. J. 2019, 13, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Yanishevsky, M.; Li, G.; Shi, G.; Backman, D. Fractographic examination of coupons representing aircraft structural joints with and without hole cold expansion. Eng. Fail. Anal. 2013, 30, 74–90. [Google Scholar] [CrossRef]

- Xiao, Y.; Ishikawa, T. Bearing strength and failure behavior of bolted composite joints (part I: Experimental investigation). Compos. Sci. Technol. 2005, 65, 1022–1031. [Google Scholar] [CrossRef]

- Prasad, H.S.D. Bearing Strength and Failure Behavior of Hybrid Composite Laminates. Master’s Thesis, Linköping University, Linköping, Sweden, 2020. [Google Scholar]

- Karny, M. Wpływ Klimatyzowania na Wytrzymałość Kompozytu Węglowego na Naciski; The Institute of Aviation: Warsaw, Poland, 2016. [Google Scholar]

- Kim, D.U.; Seo, H.S.; Jang, H.Y. Study on Mechanical Bearing Strength and Failure Modes of Composite Materials for Marine Structures. Compos. Mater. Mar. Struct. 2021, 9, 726. [Google Scholar] [CrossRef]

- Yoon, D.; Kim, S.; Kim, J.; Doh, Y. Study on bearing strength and failure mode of a carbon-epoxy composite laminate for designing bolted joint structures. Compos. Struct. 2020, 239, 112023. [Google Scholar] [CrossRef]

- Bielawski, R.; Piskur, P. Degradacje mechaniczne kompozytów polimerowych wzmocnionych włóknem ciągłym w aspekcie ich połączeń nitonakrętkowych. Przetwórstwo Tworzyw 2018, 2, 5–14. [Google Scholar]

- Wojtkun, F.; Sołncew, J.P. Materiały Specjalnego Przeznaczenia; Politechnika Radomska: Radom, Poland, 2001. [Google Scholar]

- Łazarkiewicz, S.; Szymański, H. Mały Poradnik Mechanika. Nauki Matematyczno-Fizyczne i Ogólnotechniczne; Wydawnictwa Naukowo-Techniczne: Warsaw, Poland, 1969. [Google Scholar]

| Bolt Type | Maximum Force [N] | Cross- Sectional Area [mm2] | Yield Strength Determined Experimentally [MPa] | Literature Yield Strength [MPa] | |

|---|---|---|---|---|---|

| M4 | 8.8 | 4490 | 7.75 | 579 | 640 1 |

| M5 | 8730 | 12.7 | 687 | ||

| M6 | 9600 | 17.9 | 536 | ||

| M6 | 12.9 | not designated | not designated | 1080 1 | |

| Joint Parameters | Without Bolt | With Bolt | After Removing Bolt |

|---|---|---|---|

| 1 | 21,275 | 20,800 | 20,800 |

| 2 | 21,358 | 21,000 | 19,200 |

| 3 | 18,783 | 20,500 | 19,058 |

| 4 | 21,000 | 20,000 | 21,392 |

| 5 | 16,200 | 21,400 | 16,542 |

| Average destructive force | 20,604 ± 1377 | 20,740 ± 463 | 20,113 ± 1308 |

| Destructive stresses | 433.77 ± 29 | 436.00 ± 10 | 423.43 ± 28 |

| Notch action factor | 1.054 | 1.048 | 1.079 |

| Joint Parameters | PA24 Ø 4 mm | PA25 Ø 5 mm | |

|---|---|---|---|

| 13.5 kN | 15.5 kN | 19.5 kN | |

| 1 | 6487 | 10,613 | 10,660 |

| 2 | 6363 | 10,893 | 11,483 |

| 3 | 6190 | 11,283 | 11,058 |

| 4 | 6577 | 10,200 | 10,330 |

| 5 | 6613 | 10,703 | 11,200 |

| Average load-bearing capacity of joints | 6446 ± 151 | 10,739 ± 371 | 10,946 ± 392 |

| Bearing stresses of rivet shanks | 322 | 430 | 438 |

| Assembly pressures of rivet heads during their swelling | 232 | 377 | 474 |

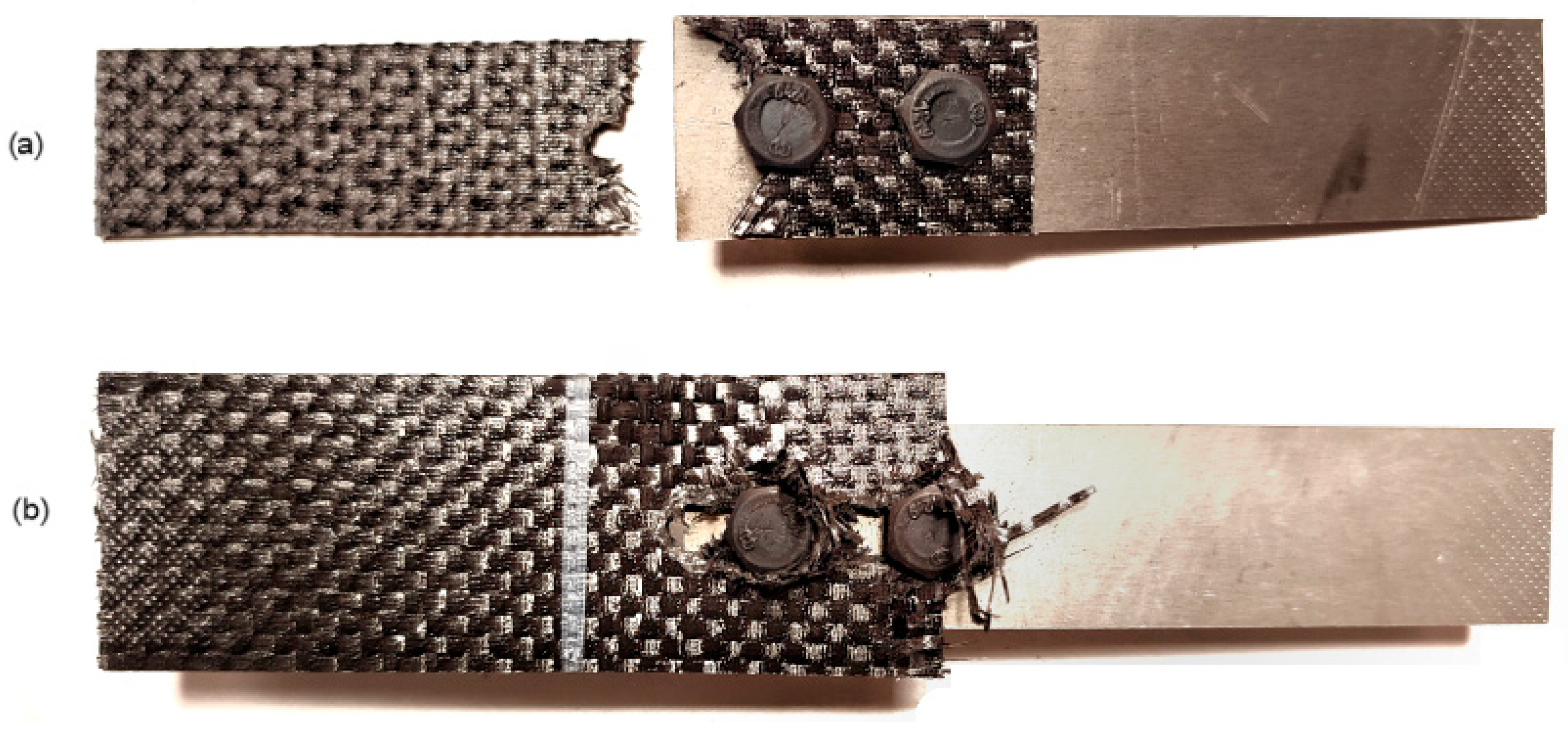

| Form of joint damage | shearing of rivets | shearing of rivets and composite | shearing of rivets |

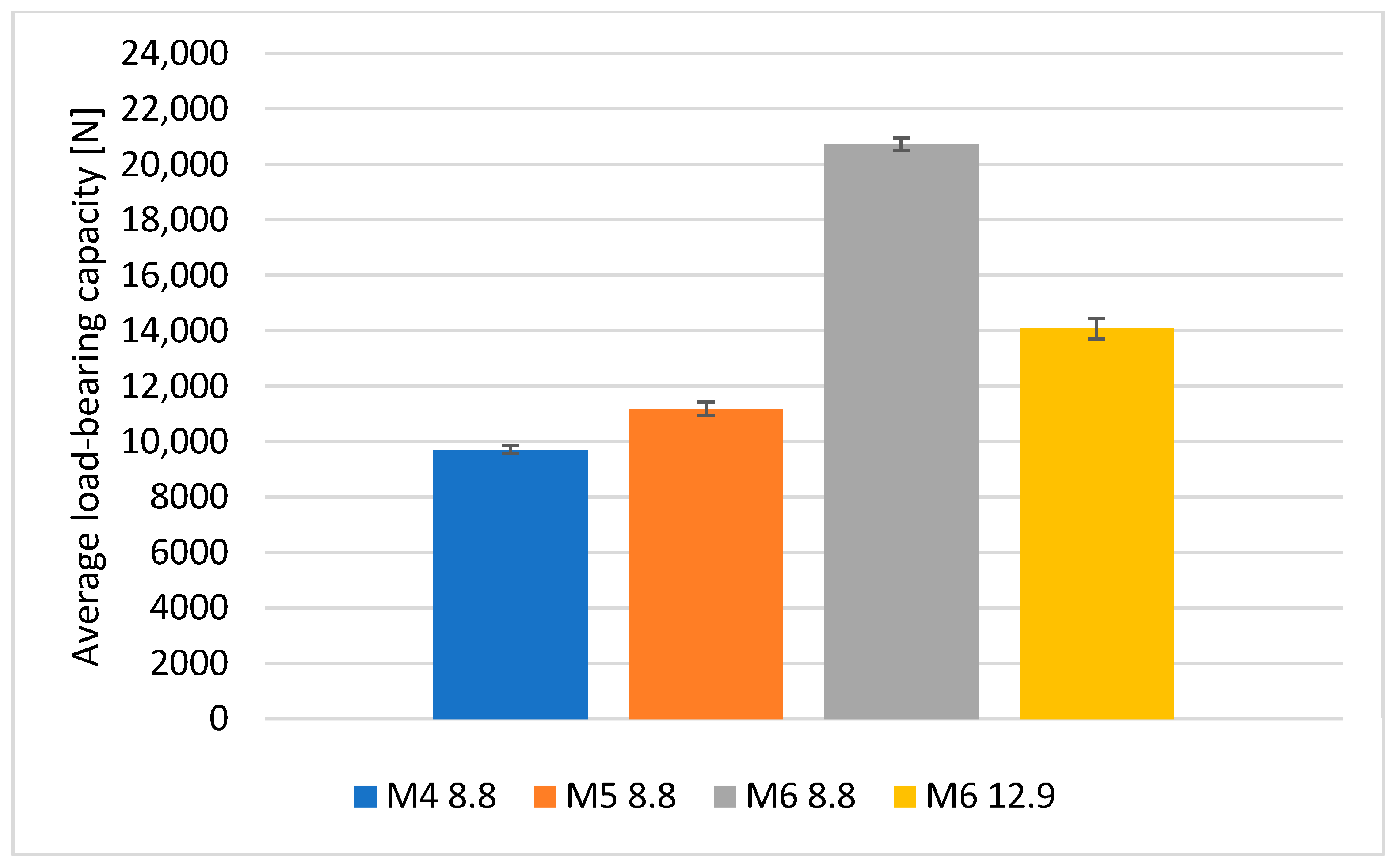

| Joint Parameters | M4 | M5 | M6 | M6 |

|---|---|---|---|---|

| 8.8 | 12.9 | |||

| 4 Nm | 5 Nm | 11 Nm | 15 Nm | |

| 1 | 9547 | 10,520 | 20,800 | 14,100 |

| 2 | 10,073 | 11,375 | 21,000 | 13,900 |

| 3 | 10,047 | 11,325 | 20,500 | 14,800 |

| 4 | 9600 | 10,727 | 20,000 | 14,400 |

| 5 | 9323 | 11,983 | 21,400 | 13,200 |

| Average load-bearing capacity of joints | 9718 ± 289 | 11,186 ± 509 | 20,740 ± 463 | 14,080 ± 722 |

| Assembly pressures of bolt heads | 147 | 124 | 63 | 157 |

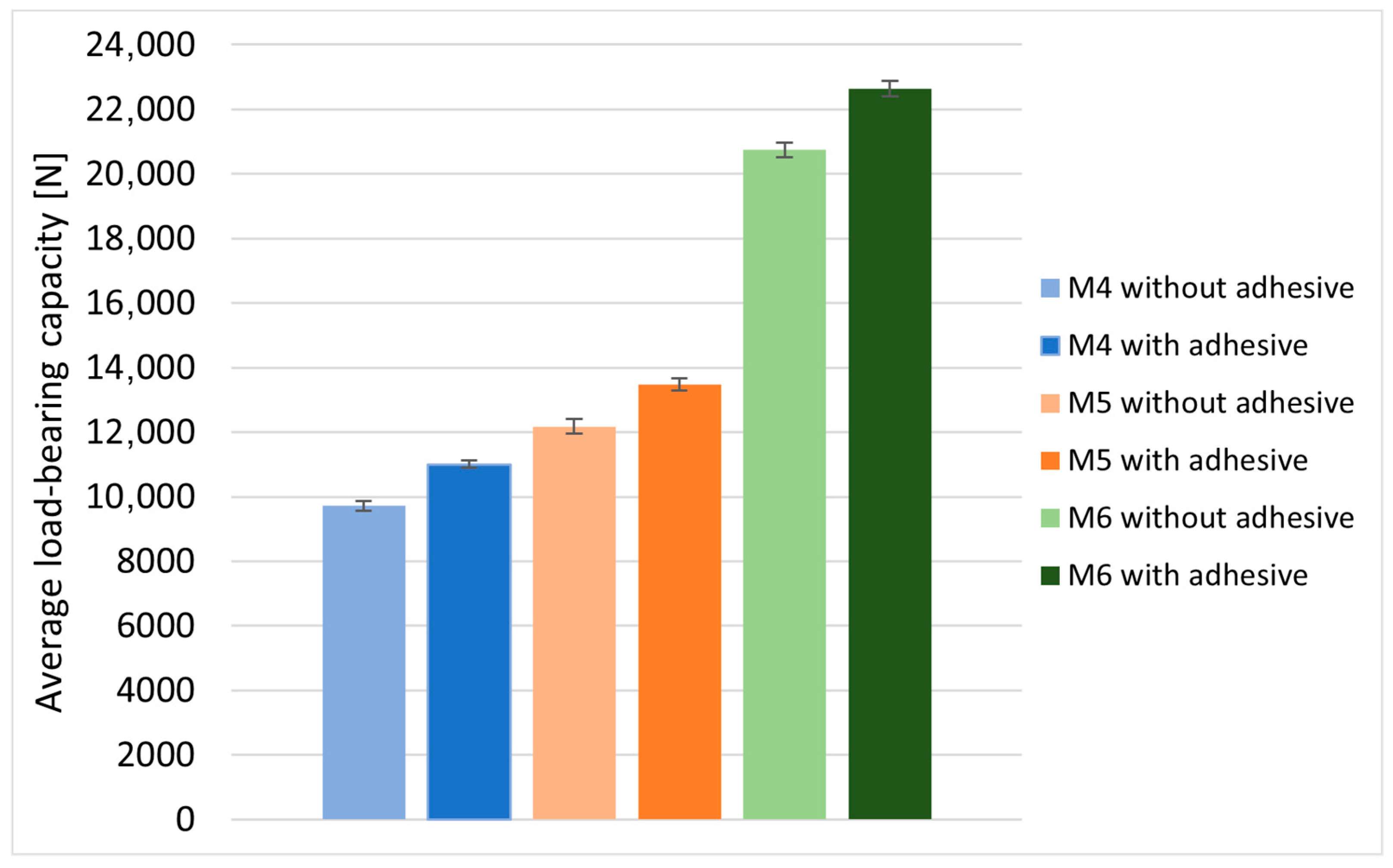

| Joint Parameters | M4 | M5 | M6 | |||

|---|---|---|---|---|---|---|

| 8.8 | ||||||

| 4 Nm | 8 Nm | 11 Nm | ||||

| Without Adhesive Plastic | With Adhesive Plastic | Without Adhesive Plastic | With Adhesive Plastic | Without Adhesive Plastic | With Adhesive Plastic | |

| 1 | 9547 | 10,850 | 12,383 | 13,991 | 20,800 | 23,600 |

| 2 | 10,073 | 11,258 | 12,491 | 13,299 | 21,000 | 22,200 |

| 3 | 10,047 | 10,763 | 12,849 | 13,841 | 20,500 | 22,400 |

| 4 | 9600 | 10,980 | 11,492 | 13,225 | 20,000 | 22,600 |

| 5 | 9323 | 11,167 | 12,158 | 13,016 | 21,400 | 22,400 |

| Average load-bearing capacity of joints | 9718 ± 289 | 1100 ± 235 | 12,275 ± 442 | 13,475 ± 358 | 20,740 ± 463 | 22,640 ± 487 |

| Assembly pressures of bolt heads | 147 | 183 | 63 | |||

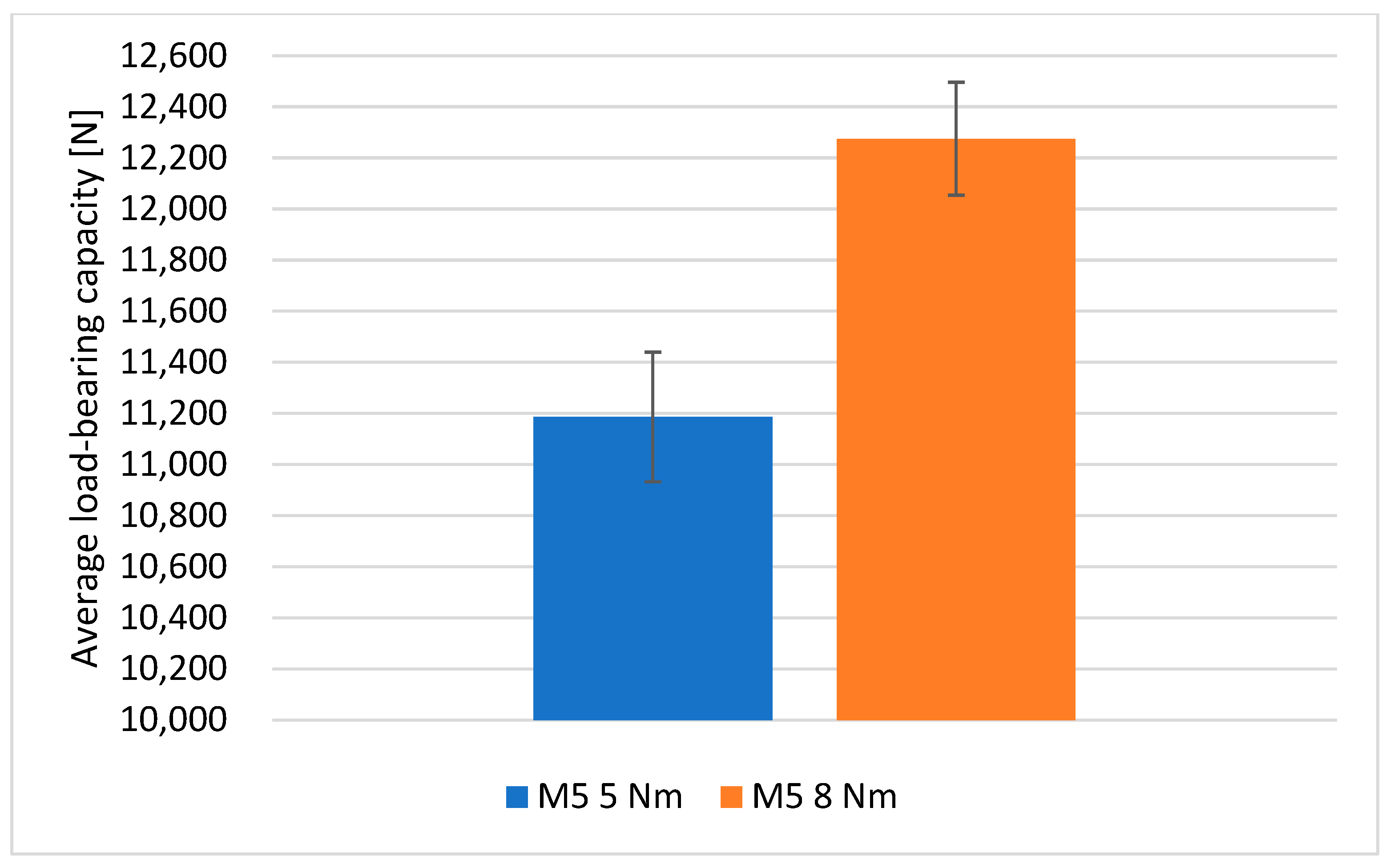

| Joint Parameters | 5 Nm | 8 Nm |

|---|---|---|

| 1 | 10,520 | 12,383 |

| 2 | 11,375 | 12,491 |

| 3 | 11,325 | 12,849 |

| 4 | 10,727 | 11,492 |

| 5 | 11,983 | 12,158 |

| Average load-bearing capacity | 11,186 ± 509 | 12,275 ± 442 |

| Assembly pressures of bolt heads | 124 | 183 |

| Assembly Torque | 5 Nm | 15 Nm | 5 Nm | 15 Nm |

|---|---|---|---|---|

| Width of the Composite Element | 25 mm | 35 mm | ||

| 1 | 13,600 | 14,100 | 13,700 | 15,600 |

| 2 | 14,300 | 13,900 | 13,800 | 15,700 |

| 3 | 14,000 | 14,800 | 13,200 | 16,100 |

| 4 | 14,100 | 14,400 | 12,900 | 15,900 |

| 5 | 13,500 | 13,200 | 13,900 | 16,000 |

| Average load-bearing capacity of joints | 13,900 ± 421 | 14,080 ± 722 | 13,500 ± 534 | 15,860 ± 277 |

| Assembly pressures of bolt heads | 57 | 157 | 57 | 157 |

| Assembly Torque | Number of Cycles | Disassembly Torque |

|---|---|---|

| 5 Nm | 9192 | 0.00 Nm |

| 3.51 Nm | ||

| 15 Nm | 308,845 | 3.34 Nm |

| 6.05 Nm | ||

| 25 Nm | 1,472,396 | 7.60 Nm |

| 14.50 Nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arkuszyńska, A.; Rośkowicz, M. Analysis of the Possibility of Increasing the Load-Bearing Capacity and Fatigue Life of CFRP Material Mechanical Joints. Materials 2025, 18, 3735. https://doi.org/10.3390/ma18163735

Arkuszyńska A, Rośkowicz M. Analysis of the Possibility of Increasing the Load-Bearing Capacity and Fatigue Life of CFRP Material Mechanical Joints. Materials. 2025; 18(16):3735. https://doi.org/10.3390/ma18163735

Chicago/Turabian StyleArkuszyńska, Angelika, and Marek Rośkowicz. 2025. "Analysis of the Possibility of Increasing the Load-Bearing Capacity and Fatigue Life of CFRP Material Mechanical Joints" Materials 18, no. 16: 3735. https://doi.org/10.3390/ma18163735

APA StyleArkuszyńska, A., & Rośkowicz, M. (2025). Analysis of the Possibility of Increasing the Load-Bearing Capacity and Fatigue Life of CFRP Material Mechanical Joints. Materials, 18(16), 3735. https://doi.org/10.3390/ma18163735