The Development of a Fatigue Failure Prediction Model for Bitumen Based on a Novel Accelerated Cyclic Shear Test

Abstract

1. Introduction

2. Methodology

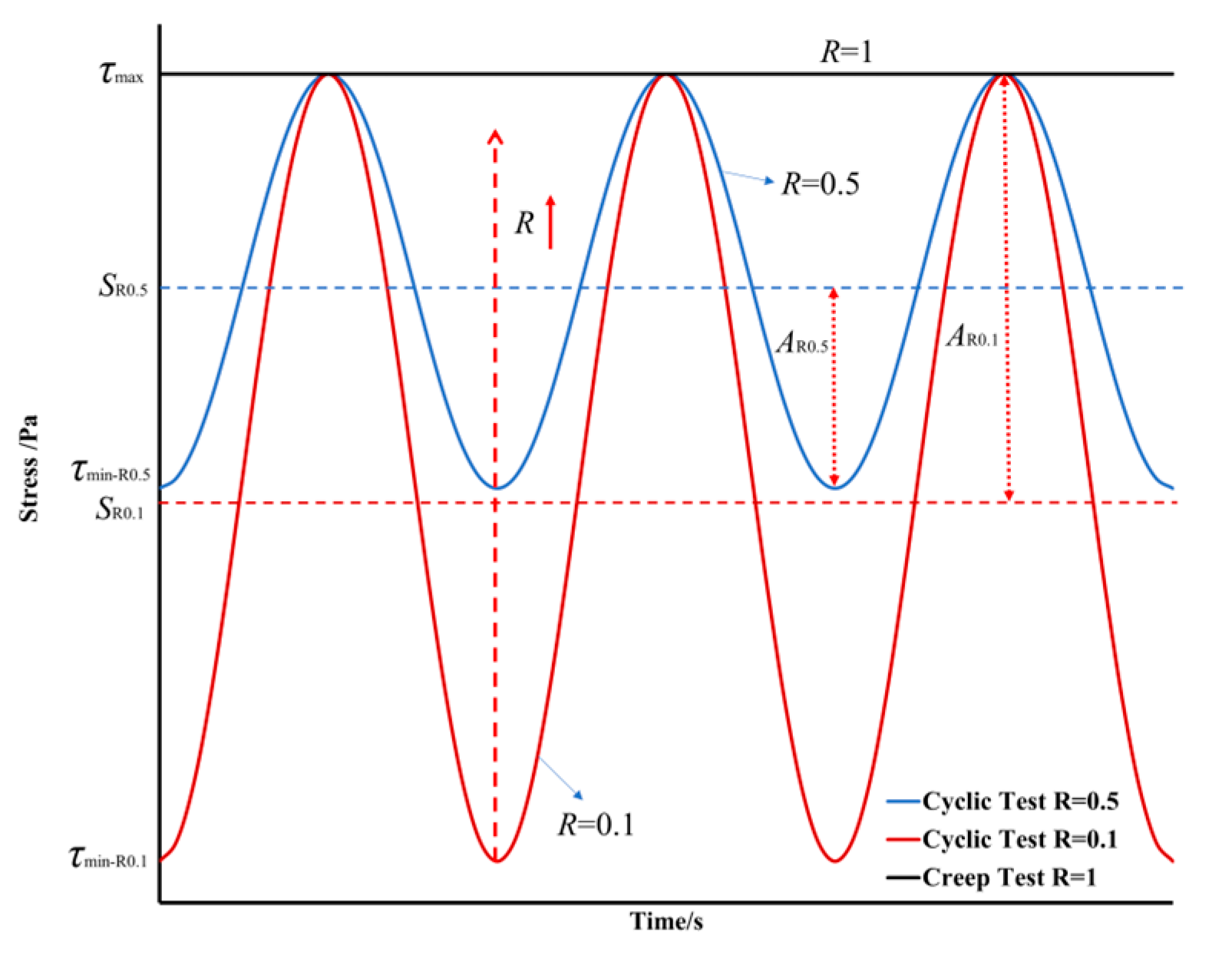

2.1. Accelerated Cyclic Shear Test

2.2. Materials and Experiments

3. Results and Analysis

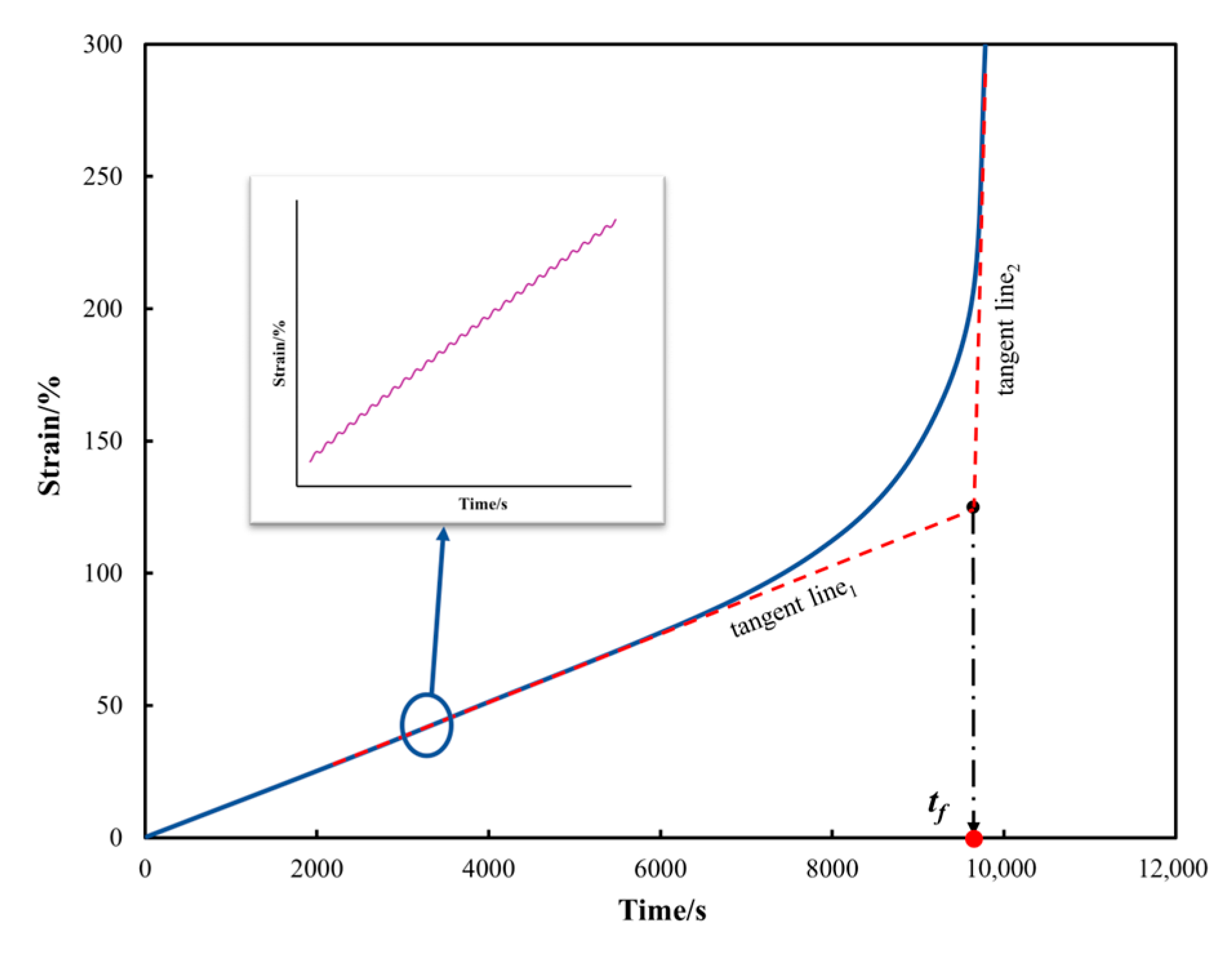

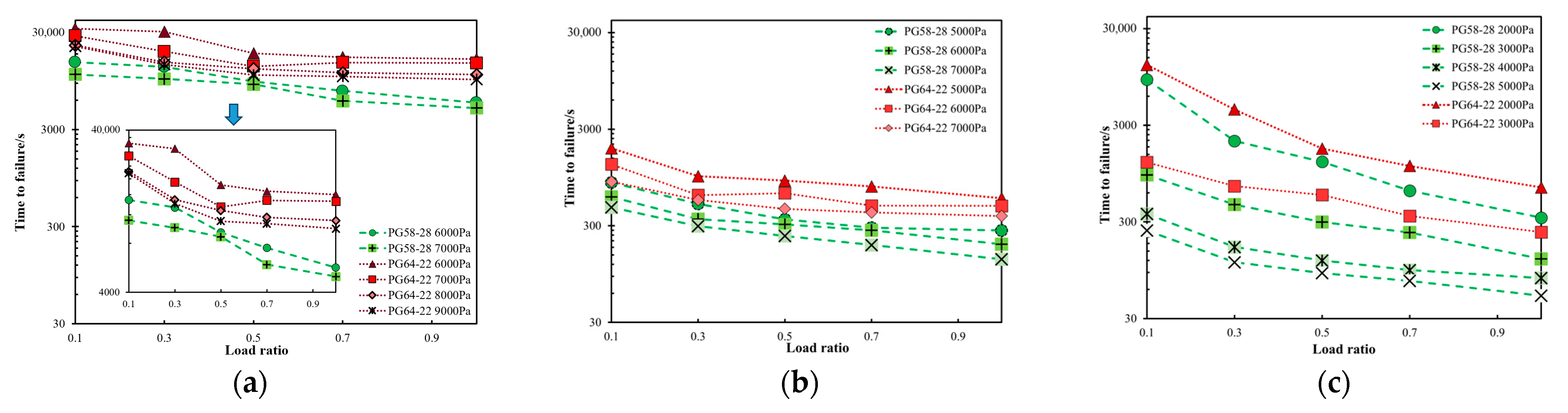

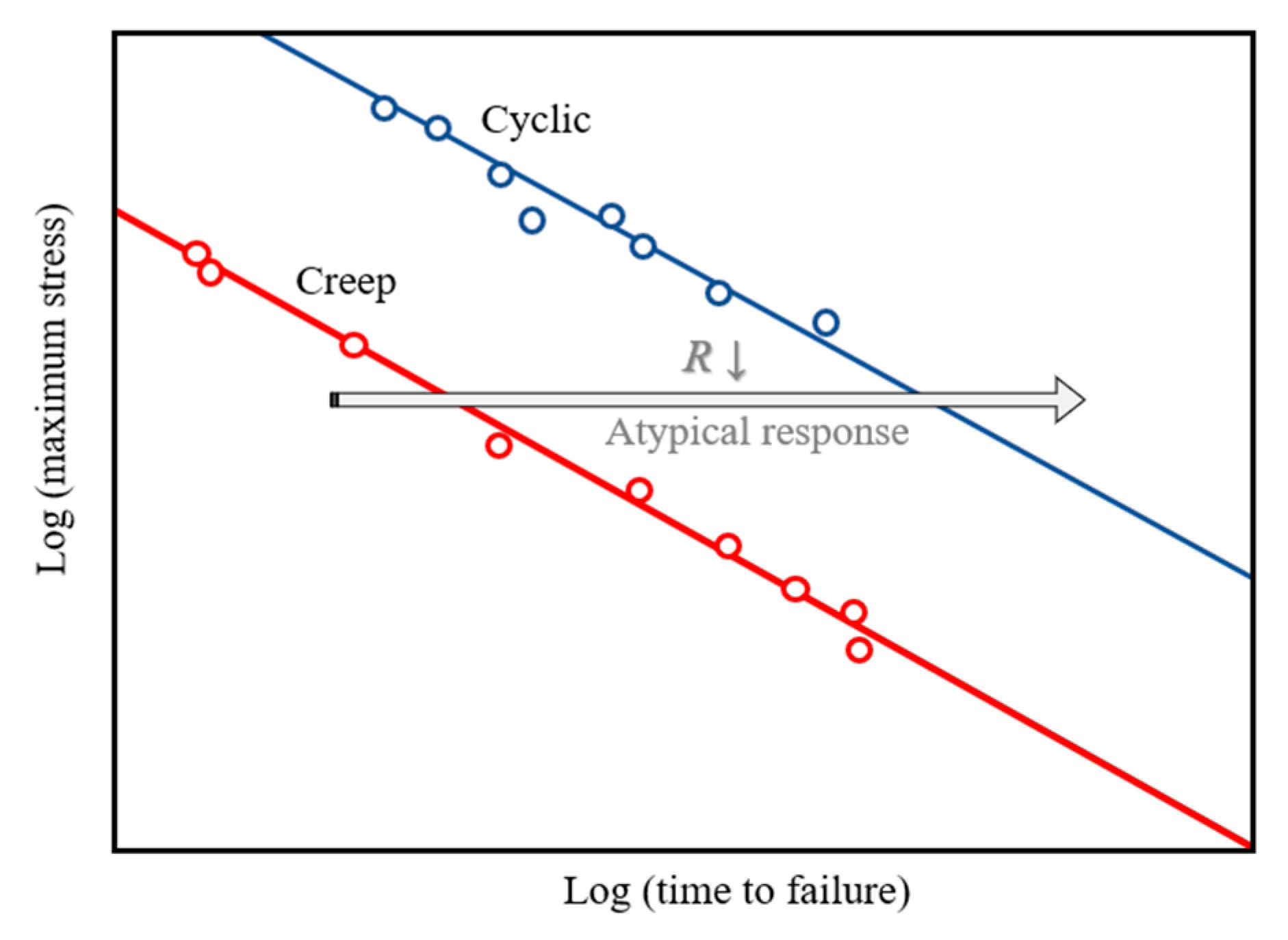

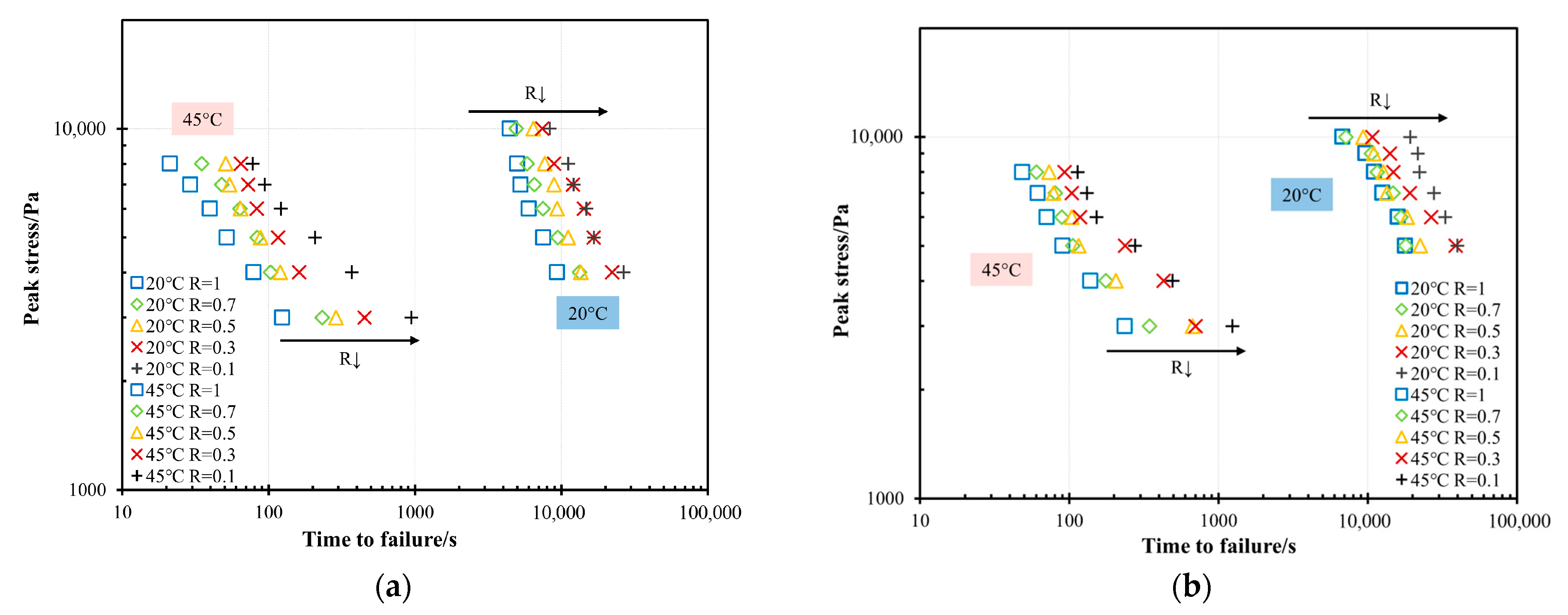

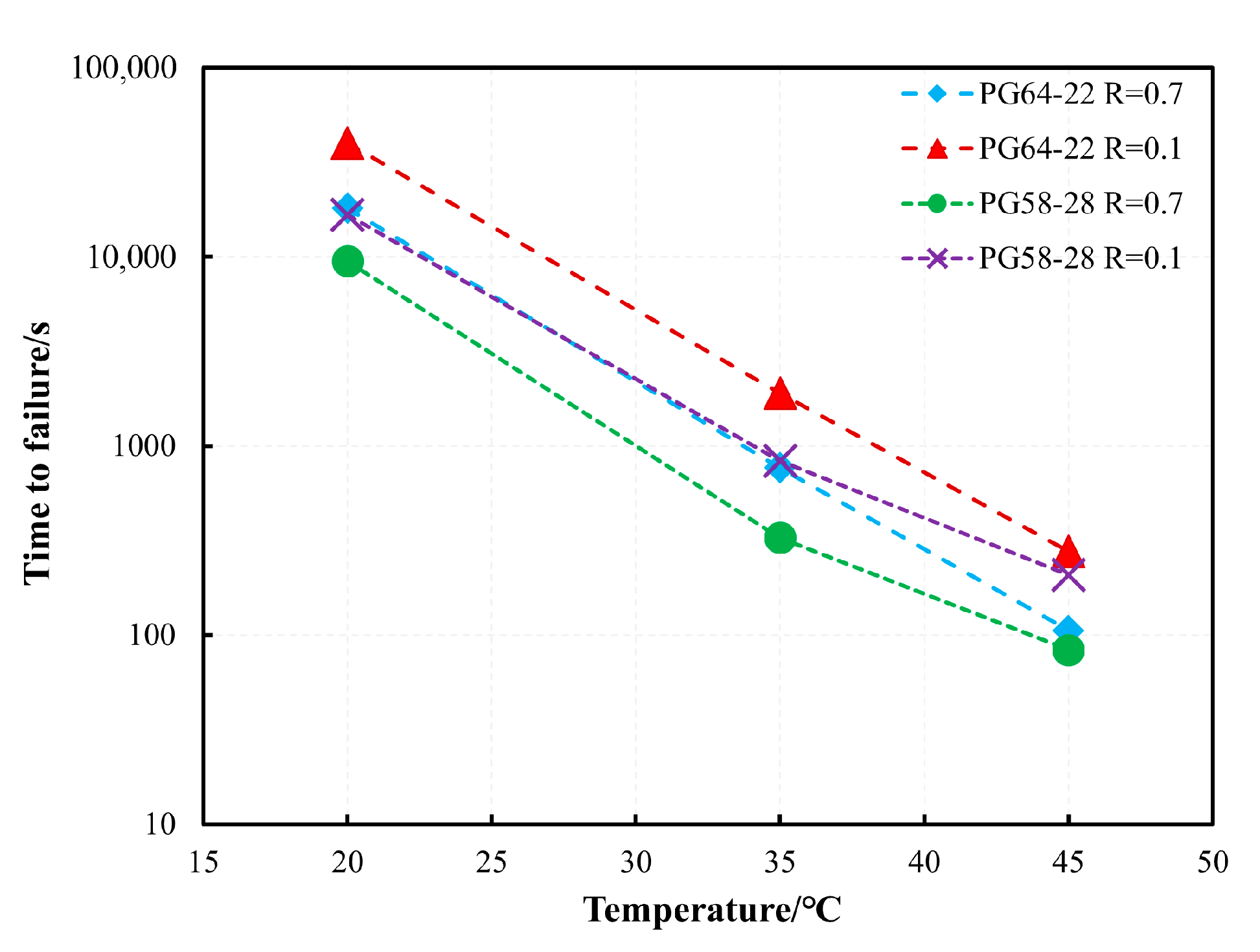

3.1. Time-to-Failure

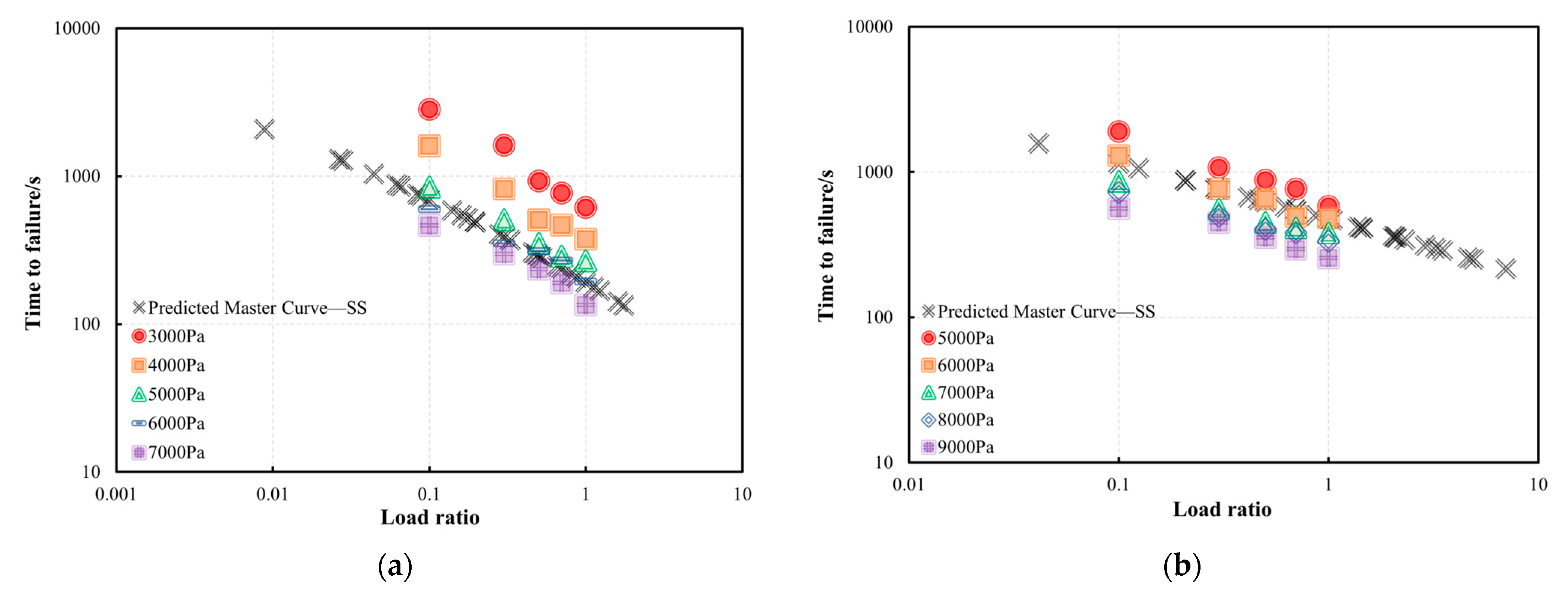

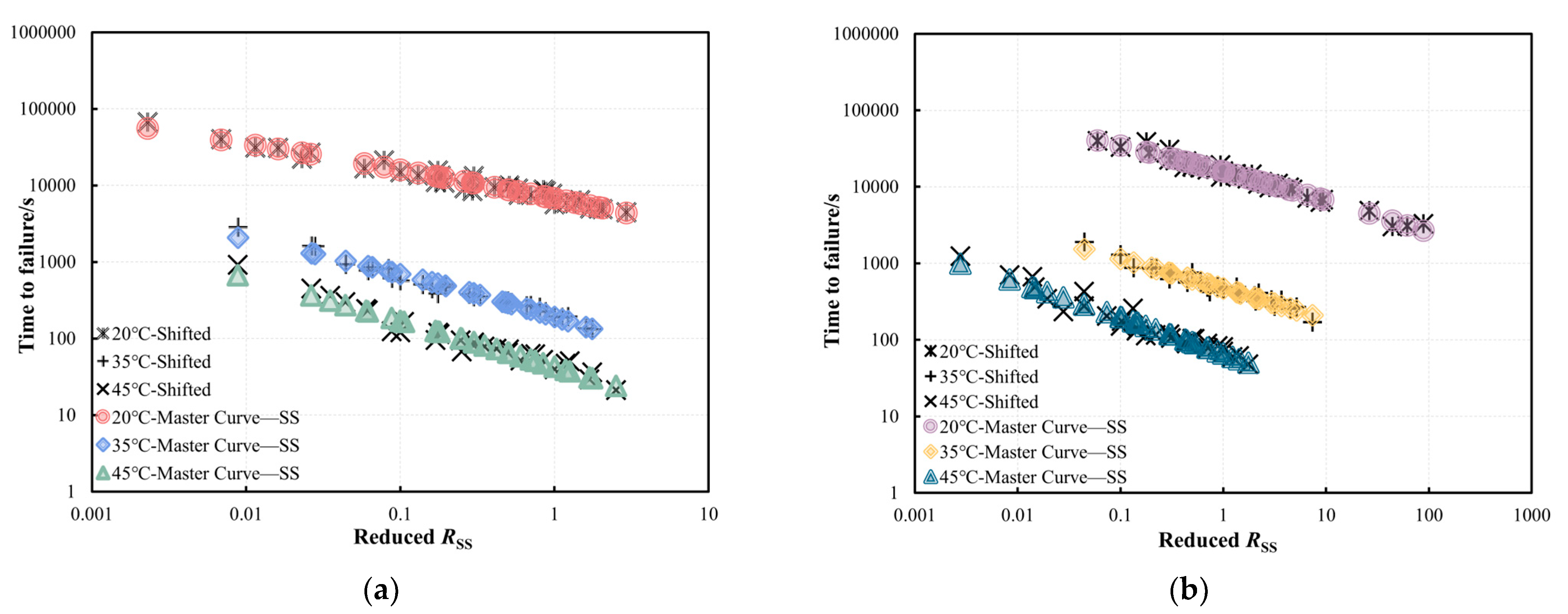

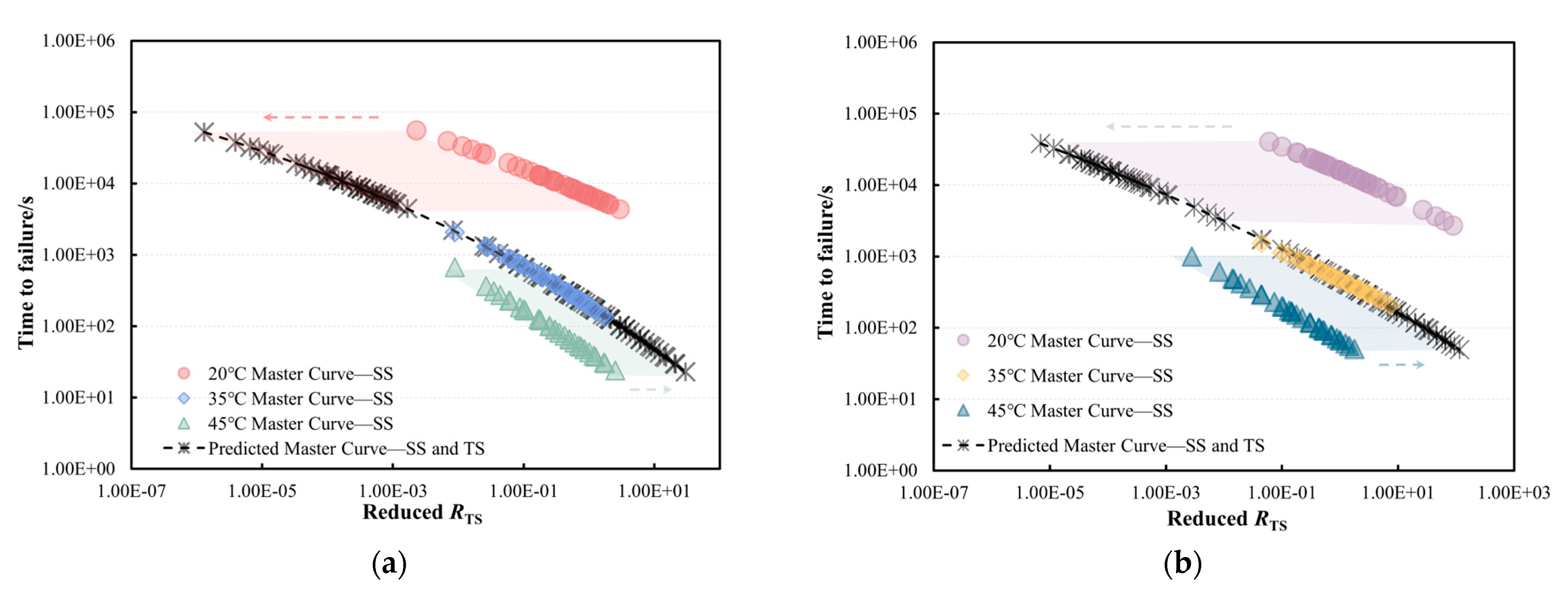

3.2. Model Development

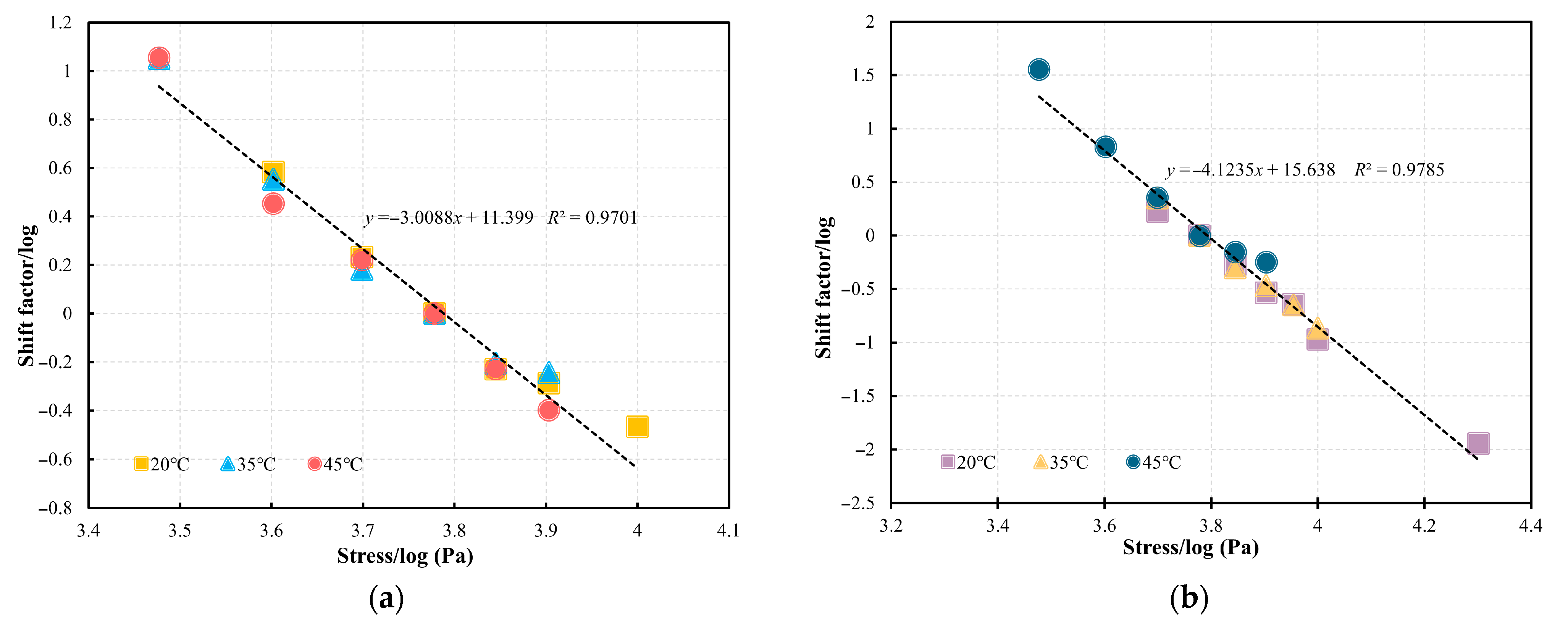

3.2.1. Stress Shift

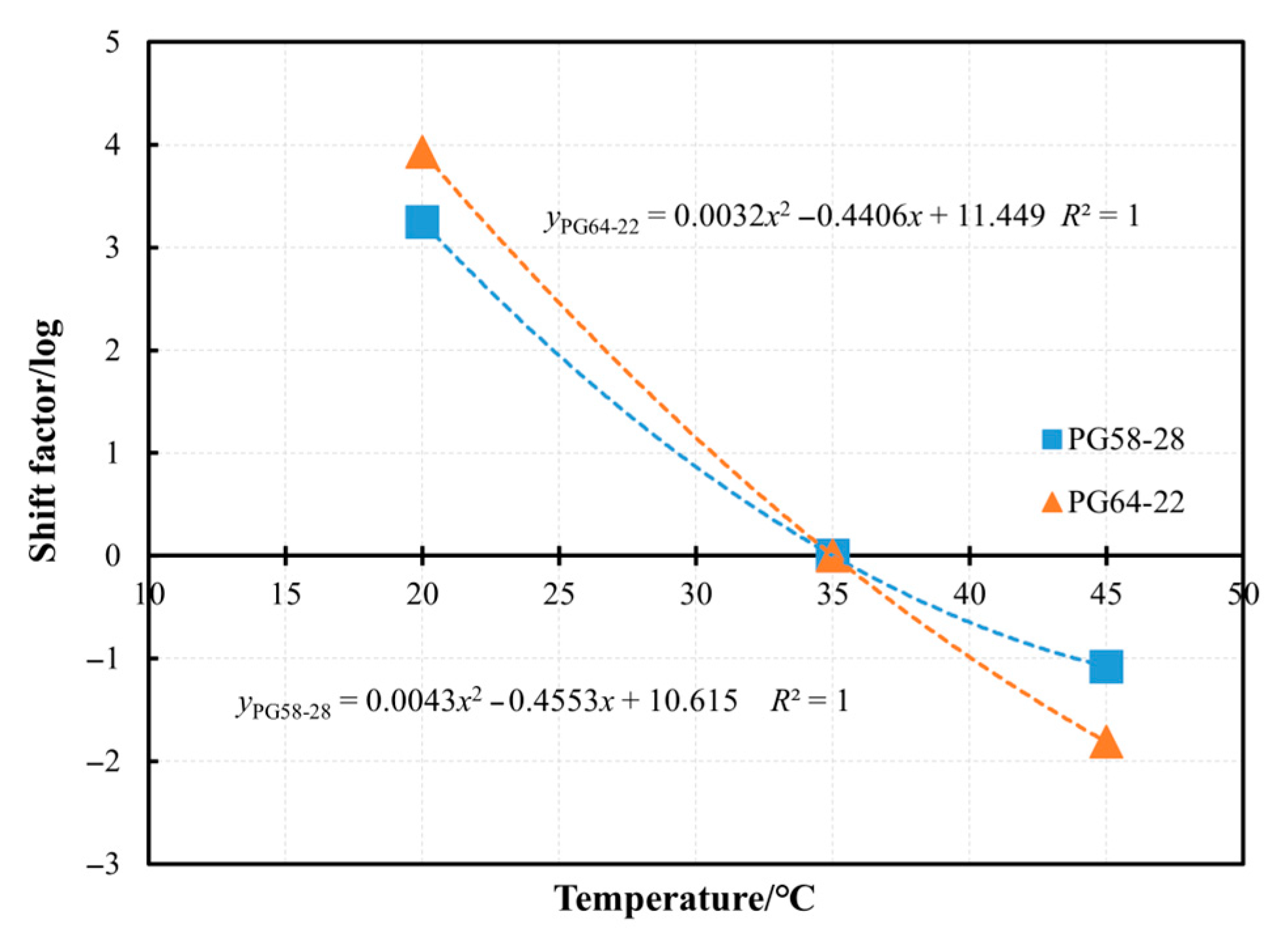

3.2.2. Temperature Shift

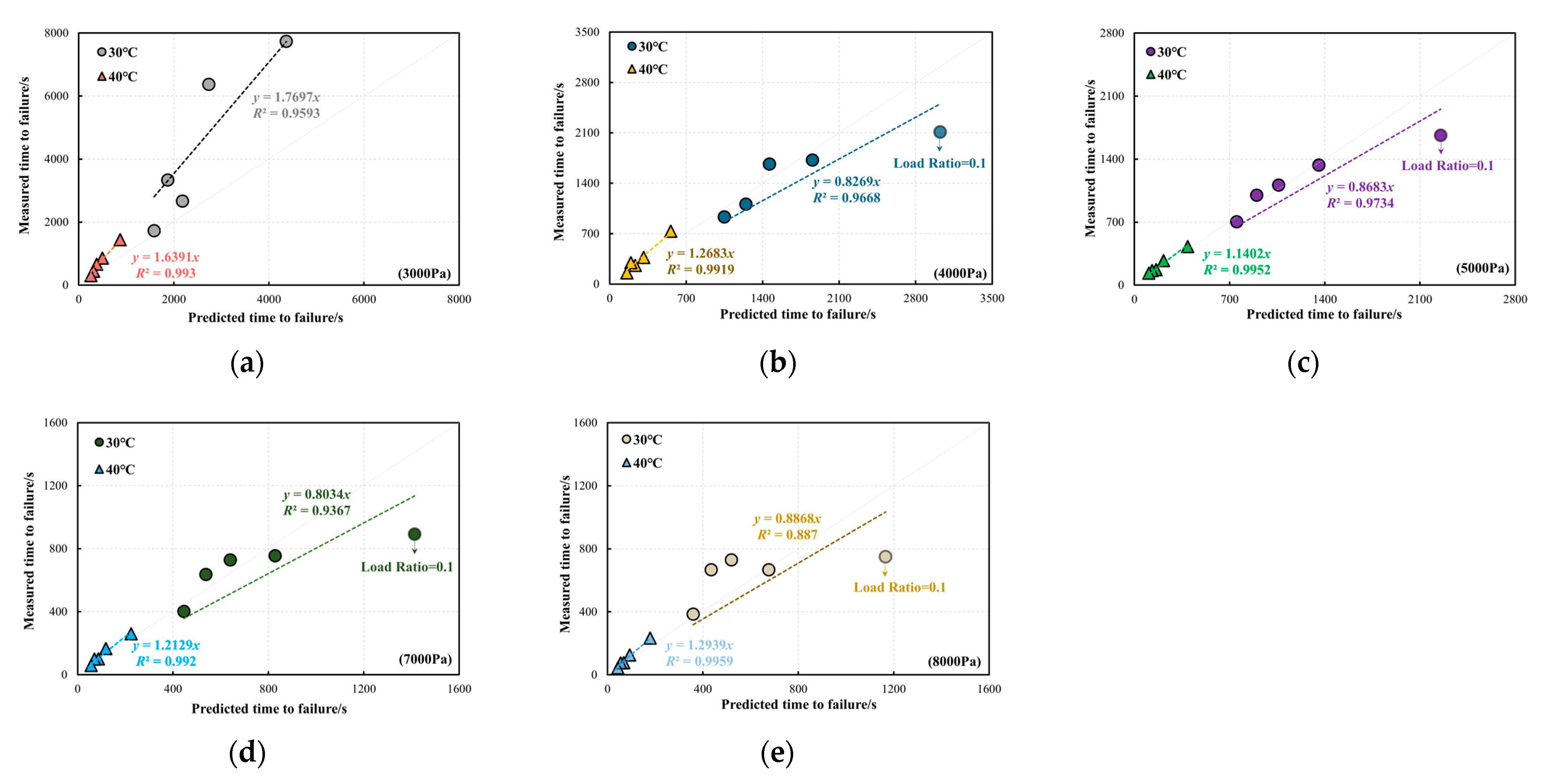

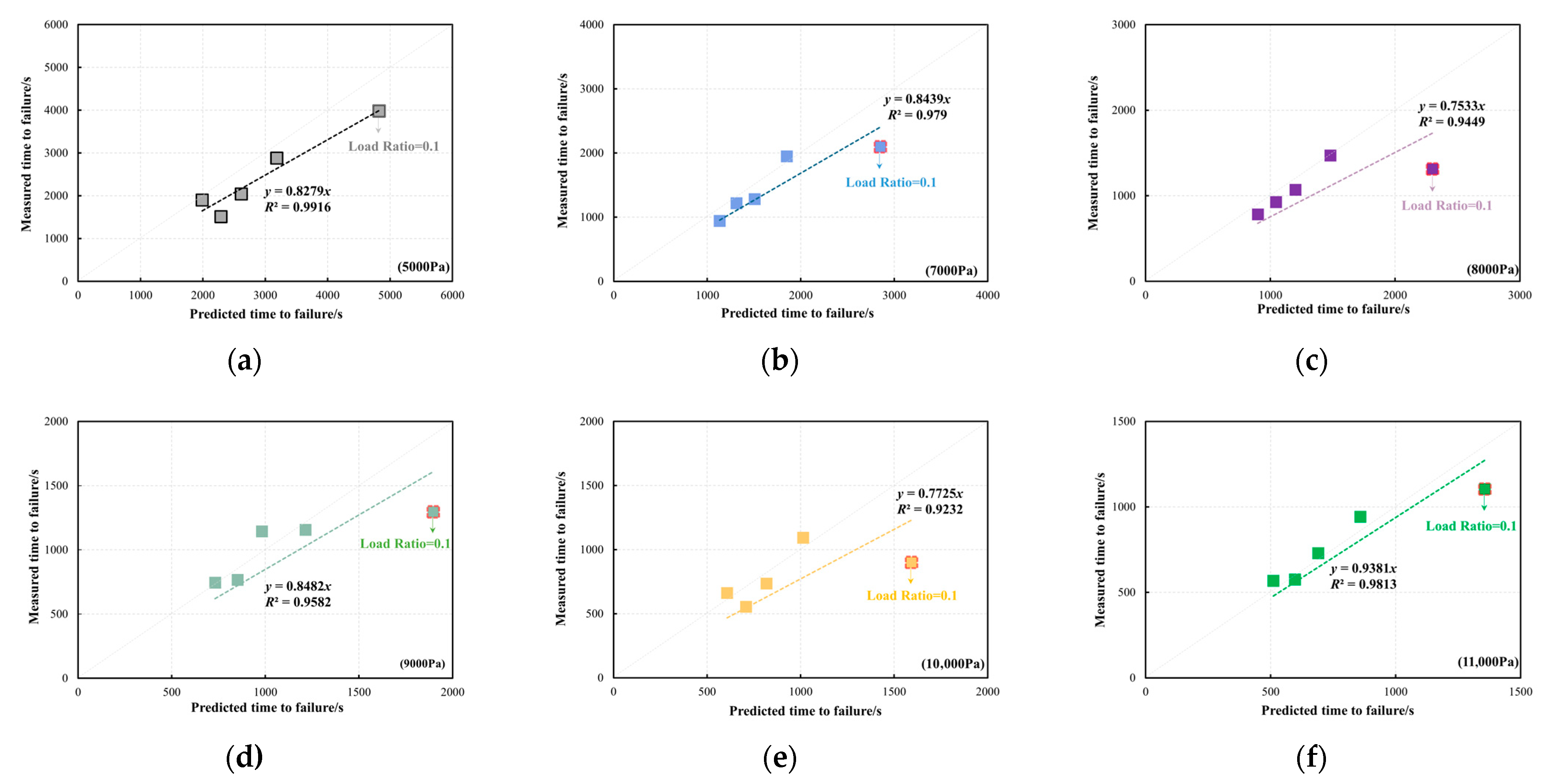

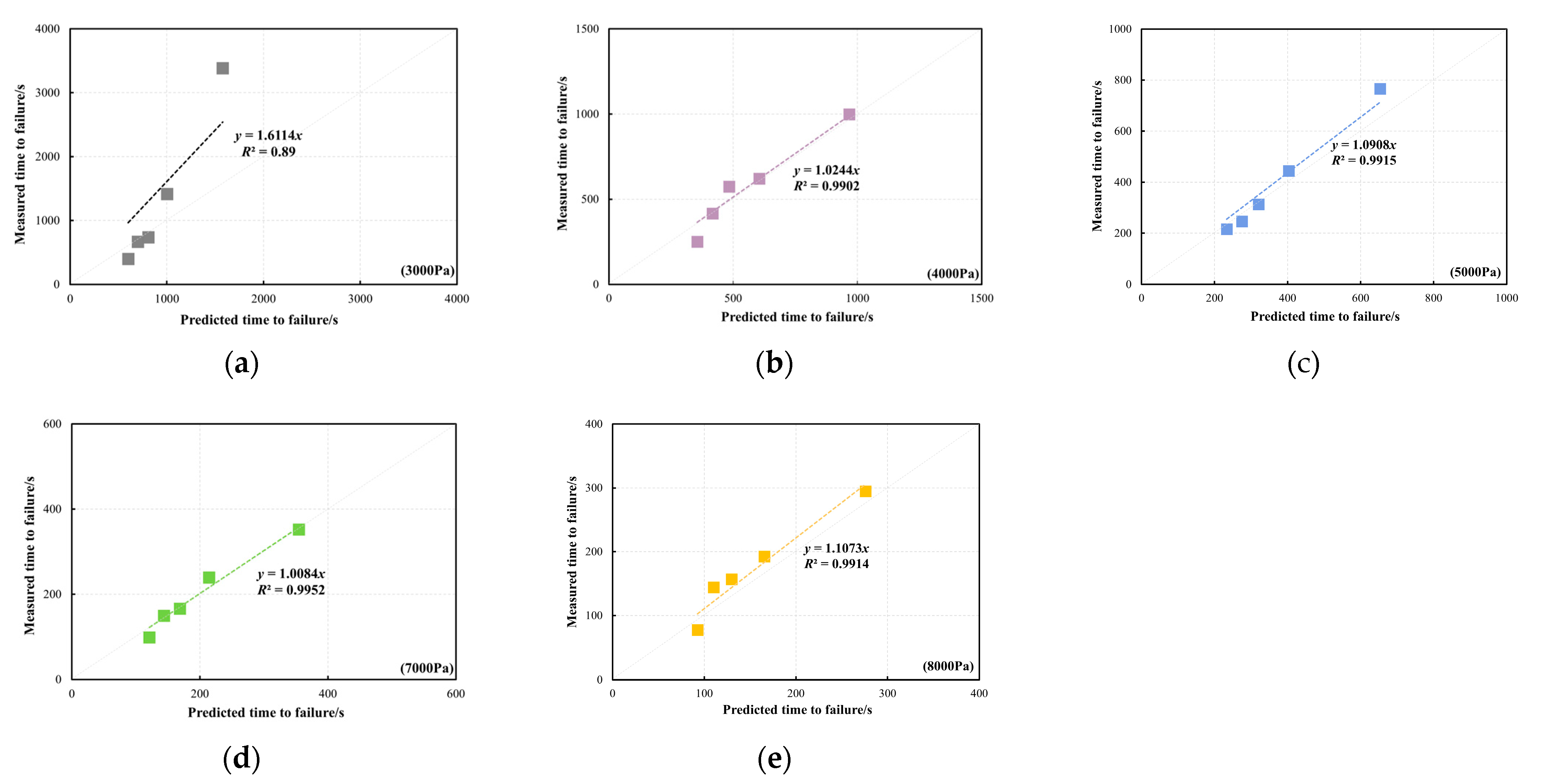

3.3. Model Validation

4. Conclusions and Recommendations

4.1. Conclusions

- (1)

- The proposed novel accelerated cyclic shear test establishes a link between creep and cyclic loading modes by precisely controlling R. Experimental results demonstrated that lower load ratios (e.g., R = 0.1) significantly reduce plastic strain accumulation, resulting in notably extended tf compared to static loading (R = 1). This finding supports the existence of a plasticity-controlled fatigue failure mechanism, which is distinct from viscoelastic fatigue behaviour.

- (2)

- The tf was validated as a robust and sensitive indicator for plasticity-induced fatigue failure. The observed “atypical response”—longer fatigue lifetimes at lower R despite identical peak stresses—is consistent with findings in thermoplastic and polymer fatigue research. This supports the assertion that mean stress significantly governs the evolution of failure in bitumen under these conditions.

- (3)

- A master curve model based on a sigmoidal function incorporating stress and temperature shifts was developed and validated. Although the approach deviates from traditional time–temperature superposition principles used for the viscoelastic behaviour of bitumen, the temperature and stress shift techniques accurately predicted tf across a wide range of conditions. The model achieved high correlation coefficients (R2 > 0.95) at validation temperatures (30 °C and 40 °C), which confirms its predictive accuracy.

- (4)

- The study employed two original bitumen types (PG58-28 and PG64-22), which were randomly sourced. Despite differences in their material properties, both showed similar fatigue trends and were well-described by the proposed model, with variations captured by model parameters. The results in this study provide evidence of the approach’s initial reproducibility and potential generalizability under the studied conditions. However, to further validate the robustness of the conclusions and ensure applicability across a broader range of materials, future work will extend the testing and modelling framework to include modified and aged bitumen.

4.2. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ye, Y.; Yang, X.; Chen, C. Experimental researches on visco-elastoplastic constitutive model of asphalt mastic. Constr. Build. Mater. 2009, 23, 3161–3165. [Google Scholar] [CrossRef]

- Das, B.P.; Das, S.; Siddagangaiah, A.K. Probabilistic modeling of fatigue damage in asphalt mixture. Constr. Build. Mater. 2021, 269, 121300. [Google Scholar] [CrossRef]

- Qiu, X.; Xiao, S.; Yang, Q.; Luo, X.; Wang, Y.; Wang, F. Asphalt-Aggregate Interface Failure Mechanism and Its Characterization Methods. Transp. Res. Congr. 2016, 2016, 182–194. [Google Scholar] [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; Li, R.; Liu, P.; Wang, D. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Rieksts, K.; Pettinari, M.; Haritonovs, V. The influence of filler type and gradation on the rheological performance of mastics. Road Mater. Pavement Des. 2018, 20, 964–978. [Google Scholar] [CrossRef]

- Zhou, F.; Mogawer, W.; Li, H.; Andriescu, A.; Copeland, A. Evaluation of fatigue tests for characterizing asphalt binders. J. Mater. Civ. Eng. 2013, 25, 610–617. [Google Scholar] [CrossRef]

- Bonnetti, K.S.; Nam, K.; Bahia, H.U. Measuring and defining fatigue behavior of asphalt binders. Transp. Res. Rec. 2002, 1810, 33–43. [Google Scholar] [CrossRef]

- Sabouri, M.; Mirzaiyan, D.; Moniri, A. Effectiveness of Linear Amplitude Sweep (LAS) asphalt binder test in predicting asphalt mixtures fatigue performance. Constr. Build. Mater. 2018, 171, 281–290. [Google Scholar] [CrossRef]

- Uwanuakwa, I.D.; Okafor, G.; Mgbemena, I.; Udom, D.; Agwa, S. Artificial intelligence prediction of rutting and fatigue parameters in modified asphalt binders. Appl. Sci. 2020, 10, 7764. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Z.; Xiao, F.; Xu, J.; Li, G.; Huang, B. Identifying fatigue failure in asphalt binder time sweep tests. Constr. Build. Mater. 2016, 121, 535–546. [Google Scholar] [CrossRef]

- Glover, C.J.; Davison, R.R.; Domke, C.H.; Ruan, Y.; Juristyarini, P.; Knorr, D.B.; Jung, S.H. Development of a New Method for Assessing Asphalt Binder Durability with Field Validation No. FHWA/TX-05/1872-2; Texas Transportation Institute, Texas A&M University: College Station, TX, USA, 2005. [Google Scholar]

- Rowe, G.M. Prepared discussion for the AAPT paper by Anderson et al.: Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asphalt Paving Technol. 2011, 80, 649–662. [Google Scholar]

- Ilyin, S.O.; Yadykova, A.Y. Eco-friendly bitumen binders from heavy crude oil and a relaxation approach to predicting their resistance to rutting and cracking. J. Clean. Prod. 2024, 434, 139942. [Google Scholar] [CrossRef]

- Yue, M.; Yue, J.; Wang, R.; Xiong, Y. Evaluating the fatigue characteristics and healing potential of asphalt binder modified with Sasobit® and polymers using linear amplitude sweep test. Constr. Build. Mater. 2021, 289, 123054. [Google Scholar] [CrossRef]

- Ameri, M.; Seif, M.; Abbasi, M.; Molayem, M.; KhavandiKhiavi, A. Fatigue performance evaluation of modified asphalt binder using dissipated energy approach. Constr. Build. Mater. 2017, 136, 184–191. [Google Scholar] [CrossRef]

- Akbari, A.; Modarres, A. Evaluating the effect of nano-clay and nano-alumina on the fatigue response of bitumen using strain and time sweep tests. Int. J. Fatigue 2018, 114, 311–322. [Google Scholar] [CrossRef]

- Underwood, B.S. A continuum damage model for asphalt cement and asphalt mastic fatigue. Int. J. Fatigue 2016, 82, 387–401. [Google Scholar] [CrossRef]

- Lv, S.; Wang, X.; Li, Y.; Zhang, Q.; Chen, Z. Laboratory investigation of fatigue parameters characteristics of aging asphalt mixtures: A dissipated energy approach. Constr. Build. Mater. 2020, 230, 116972. [Google Scholar] [CrossRef]

- Subhy, A.; Presti, D.L.; Airey, G. New simplified approach for obtaining a reliable plateau value in fatigue analysis of bituminous materials. Eng. Fail. Anal. 2017, 79, 263–273. [Google Scholar] [CrossRef]

- Cao, W.; Wang, C. Fatigue performance characterization and prediction of asphalt binders using the linear amplitude sweep based viscoelastic continuum damage approach. Int. J. Fatigue 2019, 119, 112–125. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Bahia, H.U. The role of binders in mixture cracking resistance measured by ideal-CT test. Int. J. Fatigue 2021, 142, 105947. [Google Scholar] [CrossRef]

- Johnson, C.; Bahia, H.U. Evaluation of an accelerated procedure for fatigue characterization of asphalt binders. Road Mater. Pavement Des. 2010. submitted. [Google Scholar]

- Underwood, B.S.; Bahia, H.U.; Kelly, J.A.; von Quintus, H. Response and fatigue performance modeling of ALF pavements using 3-D finite element analysis and a simplified viscoelastic continuum damage model. Asphalt Paving Technol. 2009, 2009, 829–868. [Google Scholar]

- Liu, J.; Wang, Y.D.; Liu, J. Implementation of the linear amplitude sweep test to evaluate fatigue resistance of highly polymerized asphalt binders. J. Mater. Civ. Eng. 2022, 34, 04022070. [Google Scholar] [CrossRef]

- Meneses, J.P.C.; Silva, H.R.; Ibanez, J. Asphalt binder linear amplitude sweep test: Contribution related to the α-value estimation. J. Mater. Civ. Eng. 2021, 33, 04020459. [Google Scholar] [CrossRef]

- Zhang, Z.; Oeser, M. Understanding the damage mechanism of asphalt binder under controlled-stress fatigue loads in dynamic shear rheometer. Constr. Build. Mater. 2021, 292, 123463. [Google Scholar] [CrossRef]

- Shi, C.; Cai, X.; Yi, X.; Wang, T.; Yang, J. Energy-based characterization of the fatigue crack density evolution of asphalt binders through controlled-stress fatigue testing. Constr. Build. Mater. 2021, 300, 124275. [Google Scholar] [CrossRef]

- Erartsın, O.; van Drongelen, M.; Govaert, L.E. Identification of plasticity-controlled creep and fatigue failure mechanisms in transversely loaded unidirectional thermoplastic composites. J. Compos. Mater. 2021, 55, 1947–1965. [Google Scholar] [CrossRef]

- Visser, H.A.; van Drongelen, M.; Schipper, D.; Govaert, L.E. Lifetime assessment of load-bearing polymer glasses: The influence of physical ageing. Macromol. Mater. Eng. 2010, 295, 1066–1081. [Google Scholar] [CrossRef]

- Klompen, E.T.J.; Bourdet, C.; van der Klift, F.; Govaert, L.E.; Peters, G.W.M. Quantitative prediction of long-term failure of polycarbonate. Macromolecules 2005, 38, 7009–7017. [Google Scholar] [CrossRef]

- Kanters, M.J.; Kurokawa, T.; Govaert, L.E. Competition between plasticity-controlled and crack-growth controlled failure in static and cyclic fatigue of thermoplastic polymer systems. Polym. Test. 2016, 50, 101–110. [Google Scholar] [CrossRef]

- Engels, T.A.; Fokker, P.; Akkerman, R.; Govaert, L.E.; Drongelen, M.V. Time-dependent failure of amorphous polylactides in static loading conditions. J. Mater. Sci. Mater. Med. 2010, 21, 89–97. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Shi, Y.; Zhao, Y.; Li, Y.; Yu, R. Analysis and application of relationships between low-temperature rheological performance parameters of asphalt binders. Constr. Build. Mater. 2010, 24, 471–478. [Google Scholar] [CrossRef]

- Li, R.; Zhu, X.; Wang, Y. Investigation of the physicochemical interactions and modification effects of polyurethane on asphalt binder. Transp. Res. Rec. 2024, 2678, 876–890. [Google Scholar] [CrossRef]

- AASHTO T 315 2022; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Kanters, M.J.; Remerie, K.; Govaert, L.E. A new protocol for accelerated screening of long-term plasticity-controlled failure of polyethylene pipe grades. Polym. Eng. Sci. 2016, 56, 676–688. [Google Scholar] [CrossRef]

- Chudnovsky, A.; Fleck, N.; Krawczak, P.; Govaert, L.; van Drongelen, M. Lifetime assessment of engineering thermoplastics. Int. J. Eng. Sci. 2012, 59, 108–139. [Google Scholar] [CrossRef]

- Wen, H.; Bahia, H. Characterizing fatigue of asphalt binders with viscoelastic continuum damage mechanics. Transp. Res. Rec. 2009, 2126, 55–62. [Google Scholar] [CrossRef]

- Dorleans, V.; Nechyporchuk, O.; van Drongelen, M.; Govaert, L.E. Time-temperature superposition in viscoelasticity and viscoplasticity for thermoplastics. Polym. Test. 2021, 101, 107287. [Google Scholar] [CrossRef]

| Indicator | PG 58-28 | PG 64-22 |

|---|---|---|

| Flash Point (°C) | 300 | 315 |

| Viscosity at 135 °C (Pa·s) | 0.42 | 0.47 |

| RTFO Mass Loss (%) | 0.36 | 0.40 |

| G */sinδ (Original) (kPa) | 1.23 | 1.35 |

| G */sinδ (RTFO-aged) (kPa) | 2.98 | 3.10 |

| Maximum Load τmax (Pa) | Load Ratio (R) | Temperature (°C) | ||||

|---|---|---|---|---|---|---|

| 20 | 30 | 35 | 40 | 45 | ||

| 2000 | 0.1, 0.3, 0.5, 0.7, 1 | B1 | B1, B2 | |||

| 3000 | B1 | B1 | B1, B2 | B1, B2 | ||

| 4000 | B1 | B1 | B1 | B1, B2 | B1, B2 | |

| 5000 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | |

| 6000 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | |

| 7000 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | |

| 8000 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | B1, B2 | |

| 9000 | B1, B2 | B2 | B2 | |||

| 10,000 | B1, B2 | B2 | B2 | |||

| 11,000 | B2 | |||||

| Bitumen | Temperatures (°C) | Sigmoidal Model Parameters After SS | |||

|---|---|---|---|---|---|

| a | b | d | e | ||

| PG58-28 | 20 | −57.582 | 65.280 | 2.765 | −0.108 |

| 35 | −329.003 | 334.193 | 4.735 | −0.216 | |

| 45 | −165.391 | 176.014 | 2.922 | −0.073 | |

| PG64-22 | 20 | −49.260 | 56.536 | 2.855 | −0.122 |

| 35 | −173.211 | 182.647 | 3.258 | −0.061 | |

| 45 | −173.521 | 185.299 | 2.869 | −0.052 | |

| Temperature (°C) | Temperature Shift Factors | Load Ratio R | Reduced RTS | ||

|---|---|---|---|---|---|

| PG58-28 | PG64-22 | PG58-28 | PG64-22 | ||

| 30 | 6.699 | 12.912 | 0.1 | 0.0149 | 0.0077 |

| 0.3 | 0.0448 | 0.0232 | |||

| 0.5 | 0.0746 | 0.0387 | |||

| 0.7 | 0.1045 | 0.05421 | |||

| 1 | 0.1493 | 0.0774 | |||

| 40 | 0.192 | 0.0881 | 0.1 | 0.5212 | 1.1350 |

| 0.3 | 1.5636 | 3.4050 | |||

| 0.5 | 2.6060 | 5.6751 | |||

| 0.7 | 3.6484 | 7.9451 | |||

| 1 | 5.2120 | 11.3501 | |||

| Verified Stress (Pa) | Stress Shift Factor (30 °C/40 °C) | |

|---|---|---|

| PG58-28 | PG64-22 | |

| 3000 | 8.6504 | 19.9568 |

| 4000 | 3.6402 | 6.0940 |

| 5000 | 1.8601 | 2.4283 |

| 6000 | 1.0747 | 1.1449 |

| 7000 | 0.6759 | 0.6064 |

| 8000 | 0.4523 | 0.3496 |

| 9000 | - | 0.2151 |

| 10,000 | - | 0.1393 |

| 11,000 | - | 0.0940 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Y.; Wang, L. The Development of a Fatigue Failure Prediction Model for Bitumen Based on a Novel Accelerated Cyclic Shear Test. Materials 2025, 18, 3729. https://doi.org/10.3390/ma18163729

Wen Y, Wang L. The Development of a Fatigue Failure Prediction Model for Bitumen Based on a Novel Accelerated Cyclic Shear Test. Materials. 2025; 18(16):3729. https://doi.org/10.3390/ma18163729

Chicago/Turabian StyleWen, Yankai, and Lin Wang. 2025. "The Development of a Fatigue Failure Prediction Model for Bitumen Based on a Novel Accelerated Cyclic Shear Test" Materials 18, no. 16: 3729. https://doi.org/10.3390/ma18163729

APA StyleWen, Y., & Wang, L. (2025). The Development of a Fatigue Failure Prediction Model for Bitumen Based on a Novel Accelerated Cyclic Shear Test. Materials, 18(16), 3729. https://doi.org/10.3390/ma18163729