Performance Study on Preparation of Mine Backfill Materials Using Industrial Solid Waste in Combination with Construction Waste

Abstract

1. Introduction

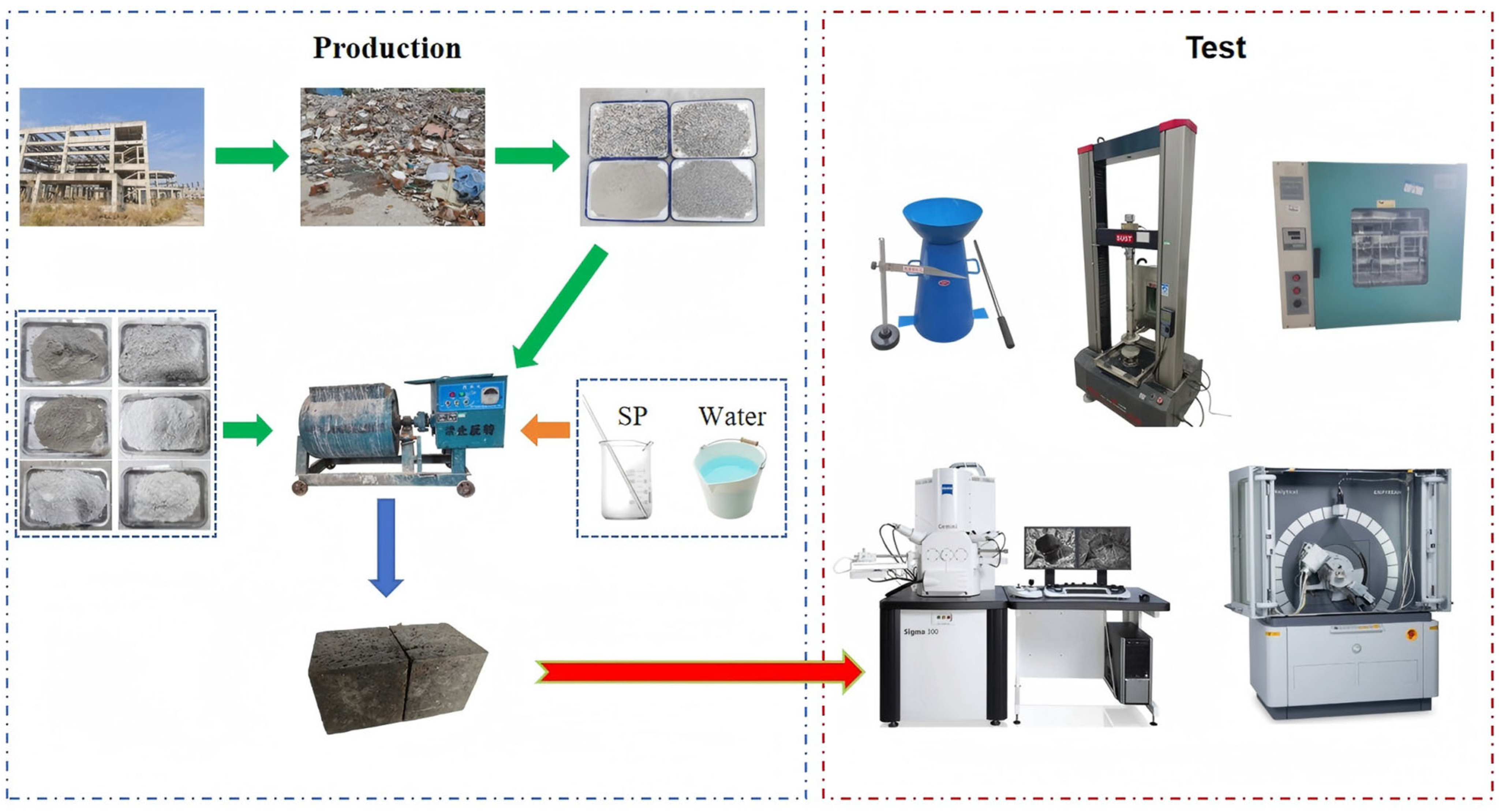

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Procedures

2.3. Experimental Methods

3. Results and Discussion

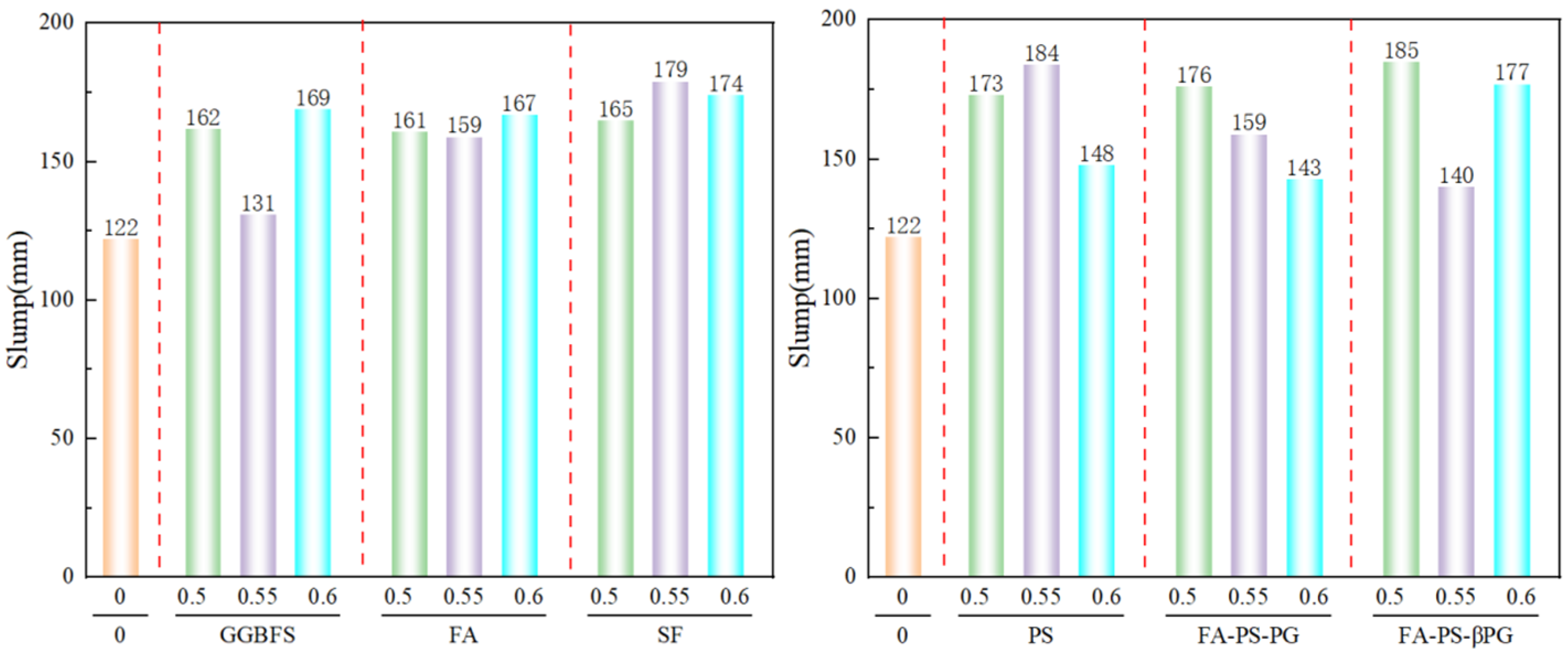

3.1. Workability

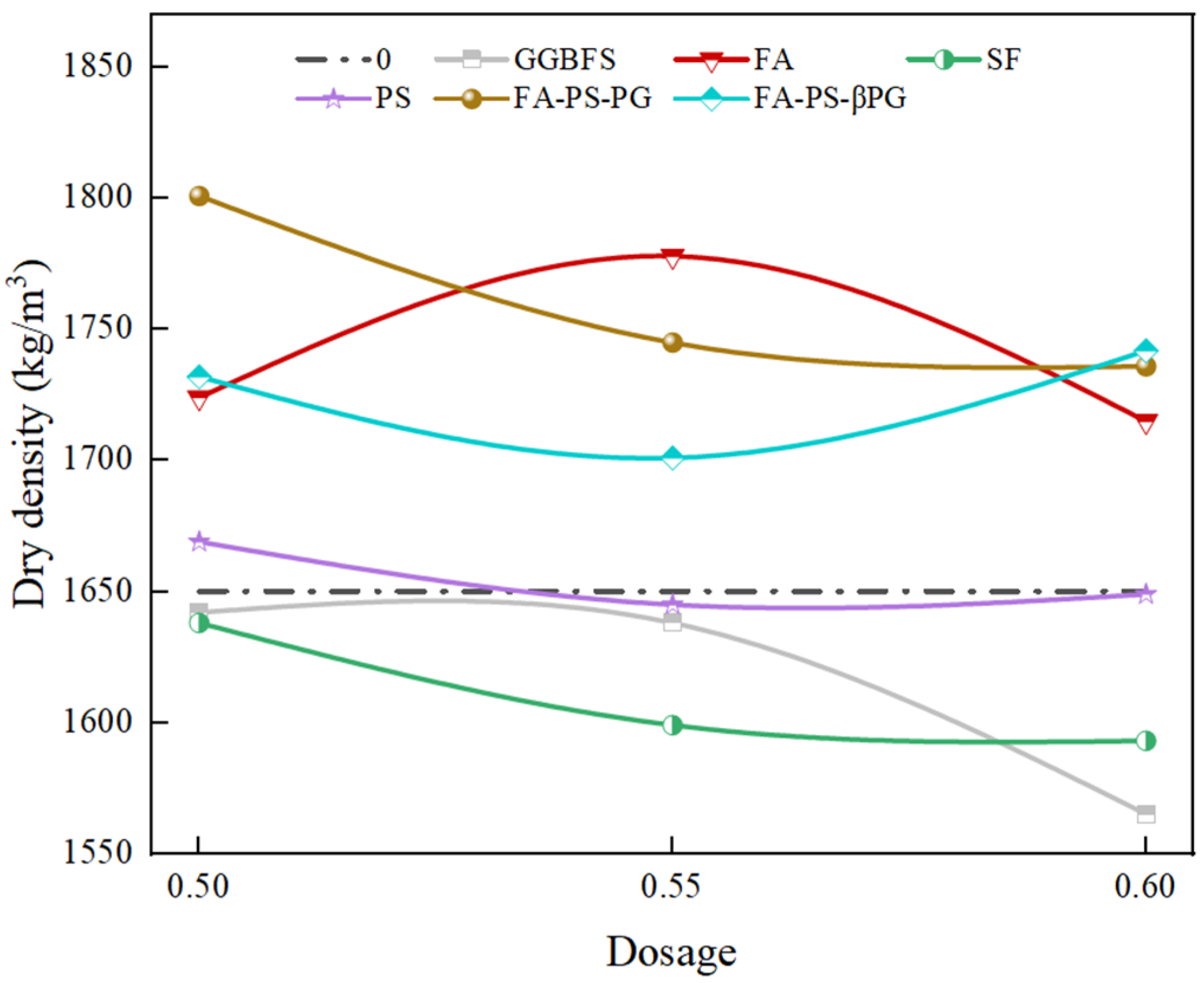

3.2. Dry Density

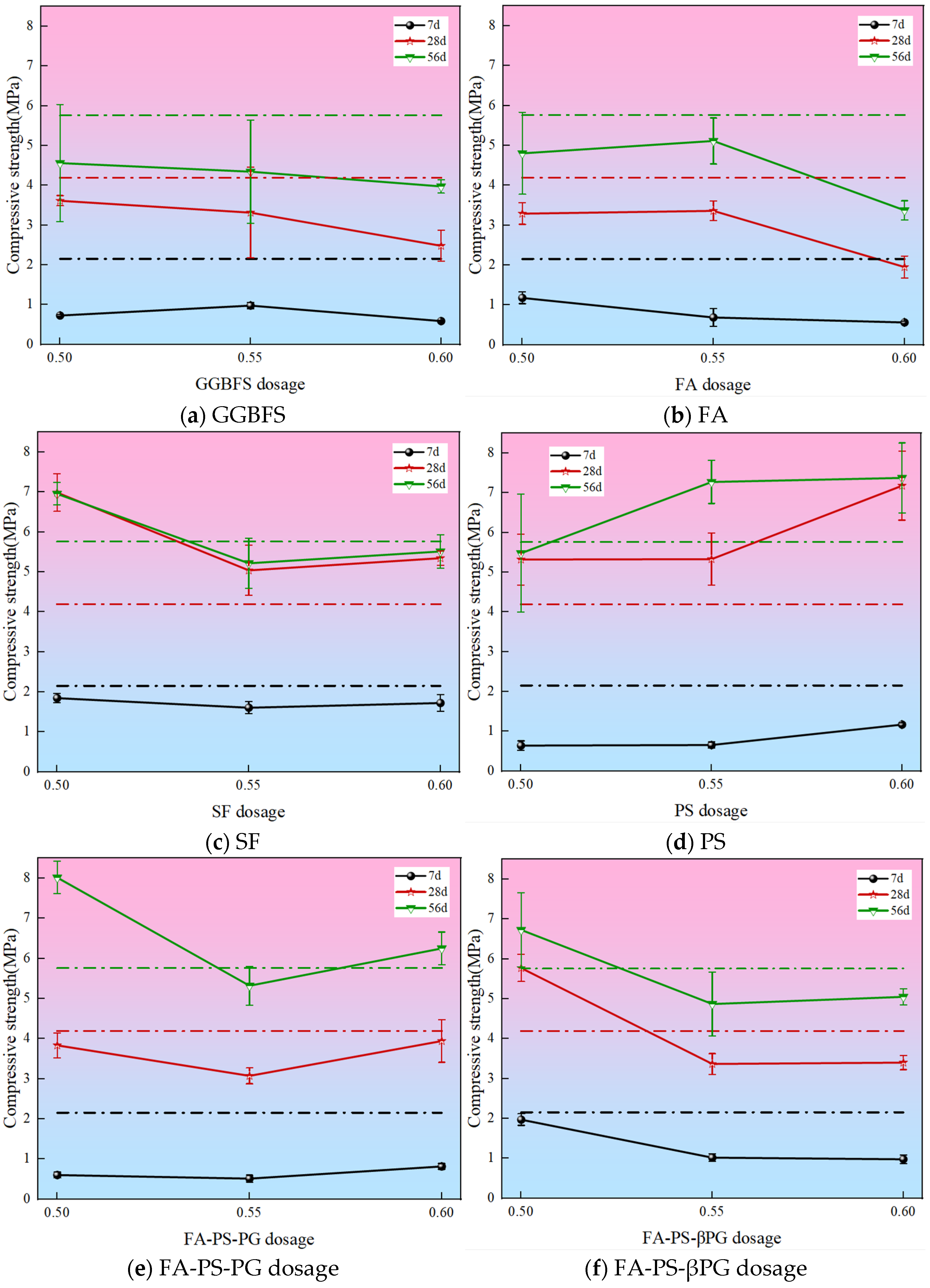

3.3. Compressive Strength

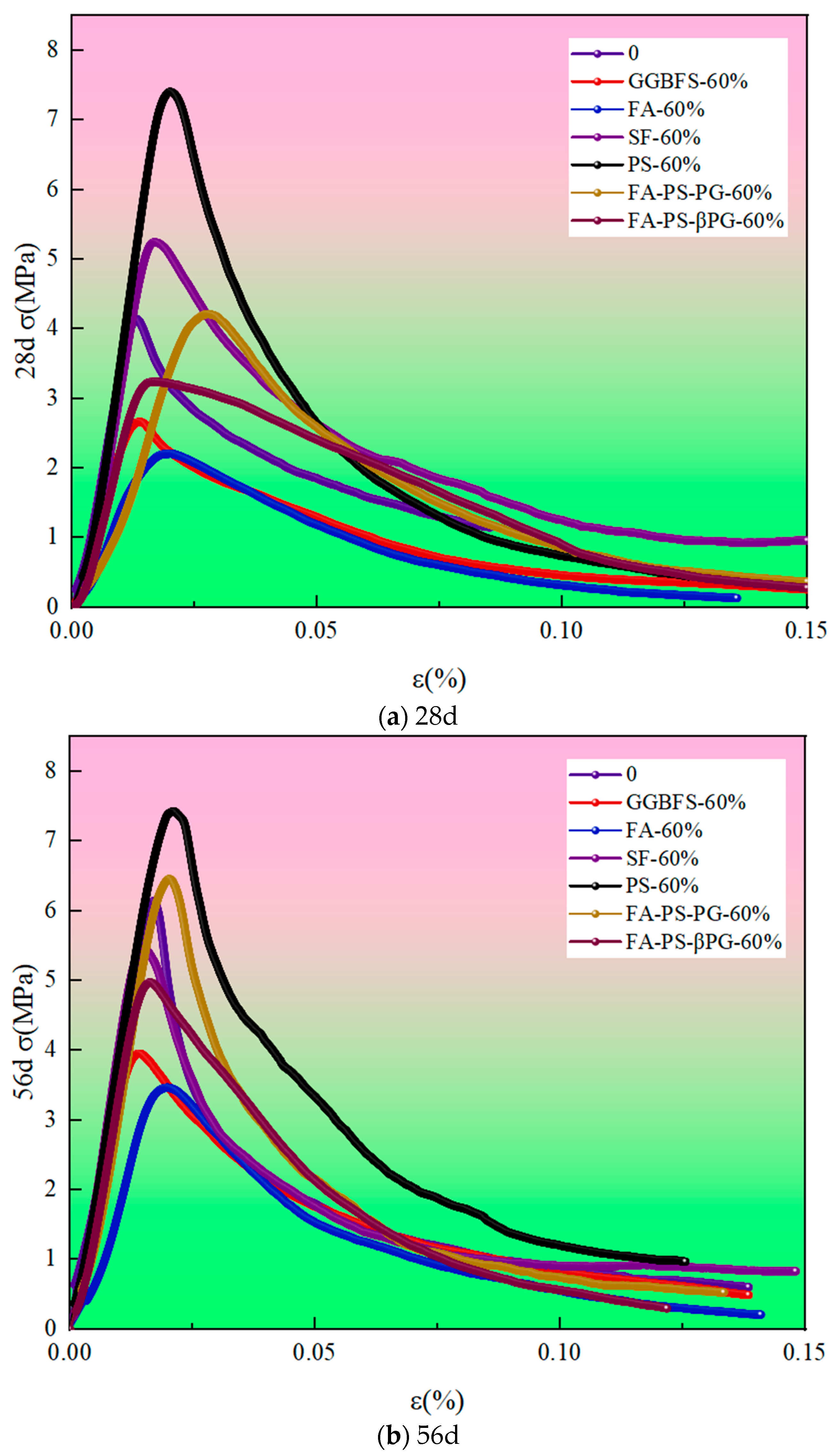

3.4. Constitutive Model

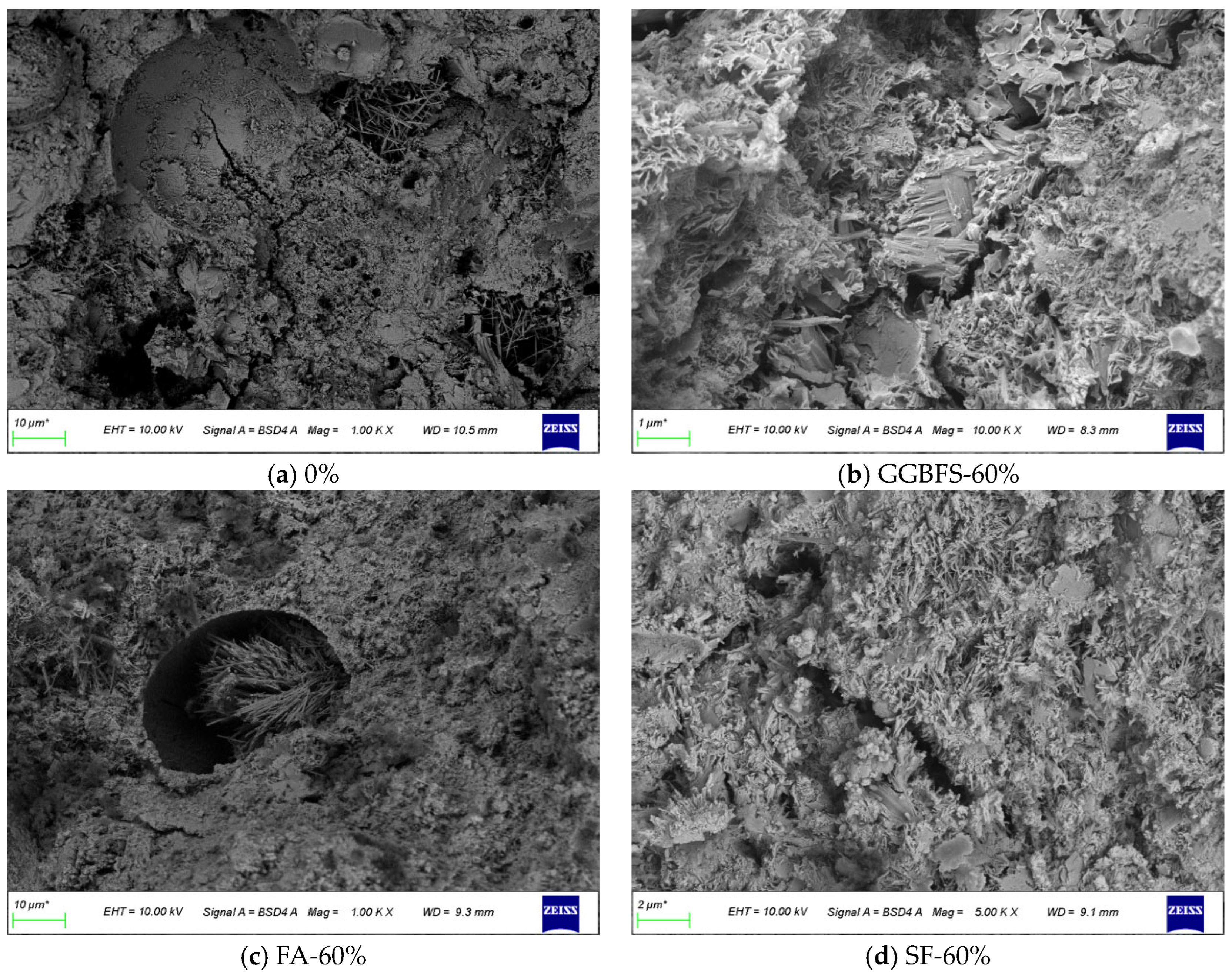

3.5. Microstructure of Backfill Material

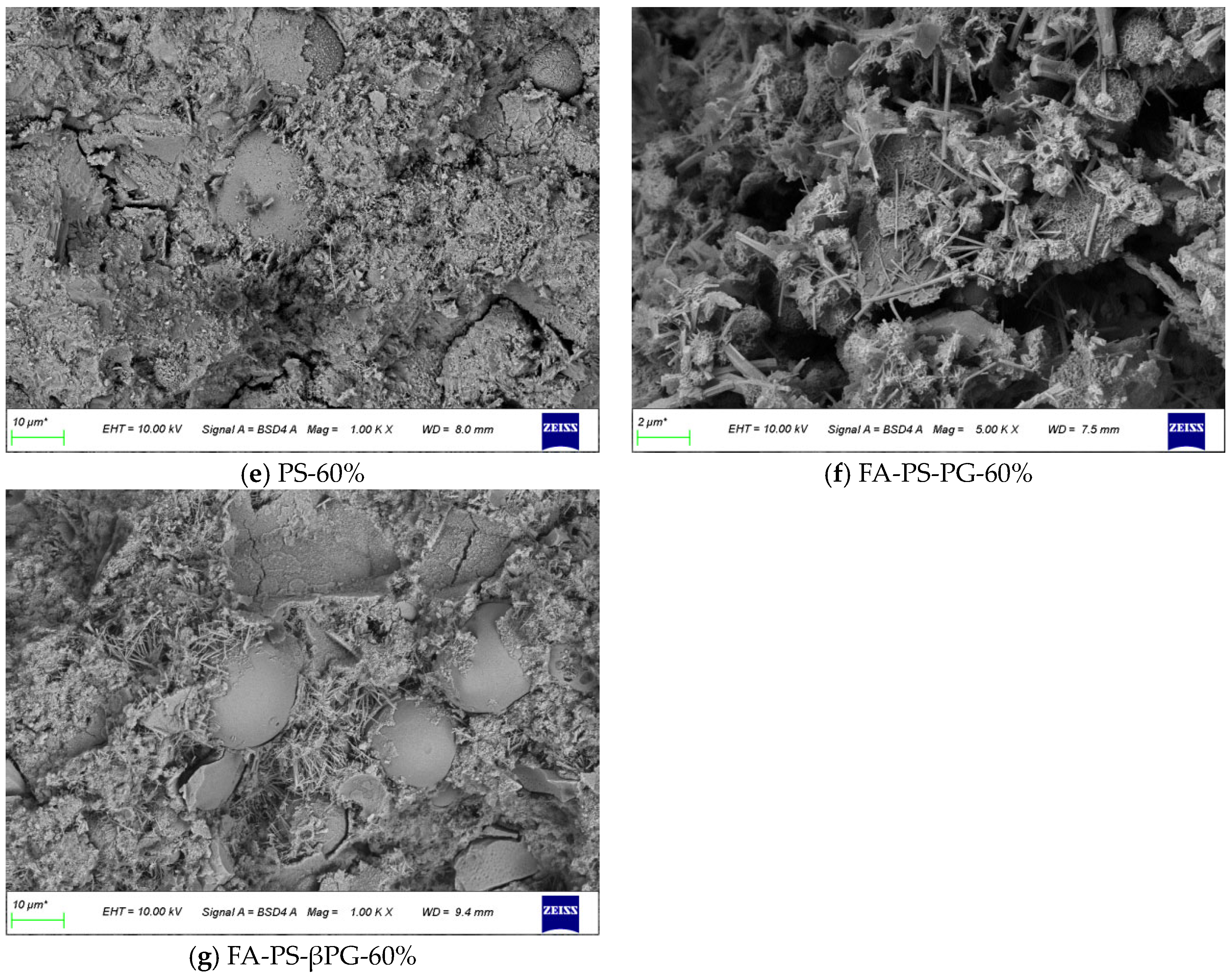

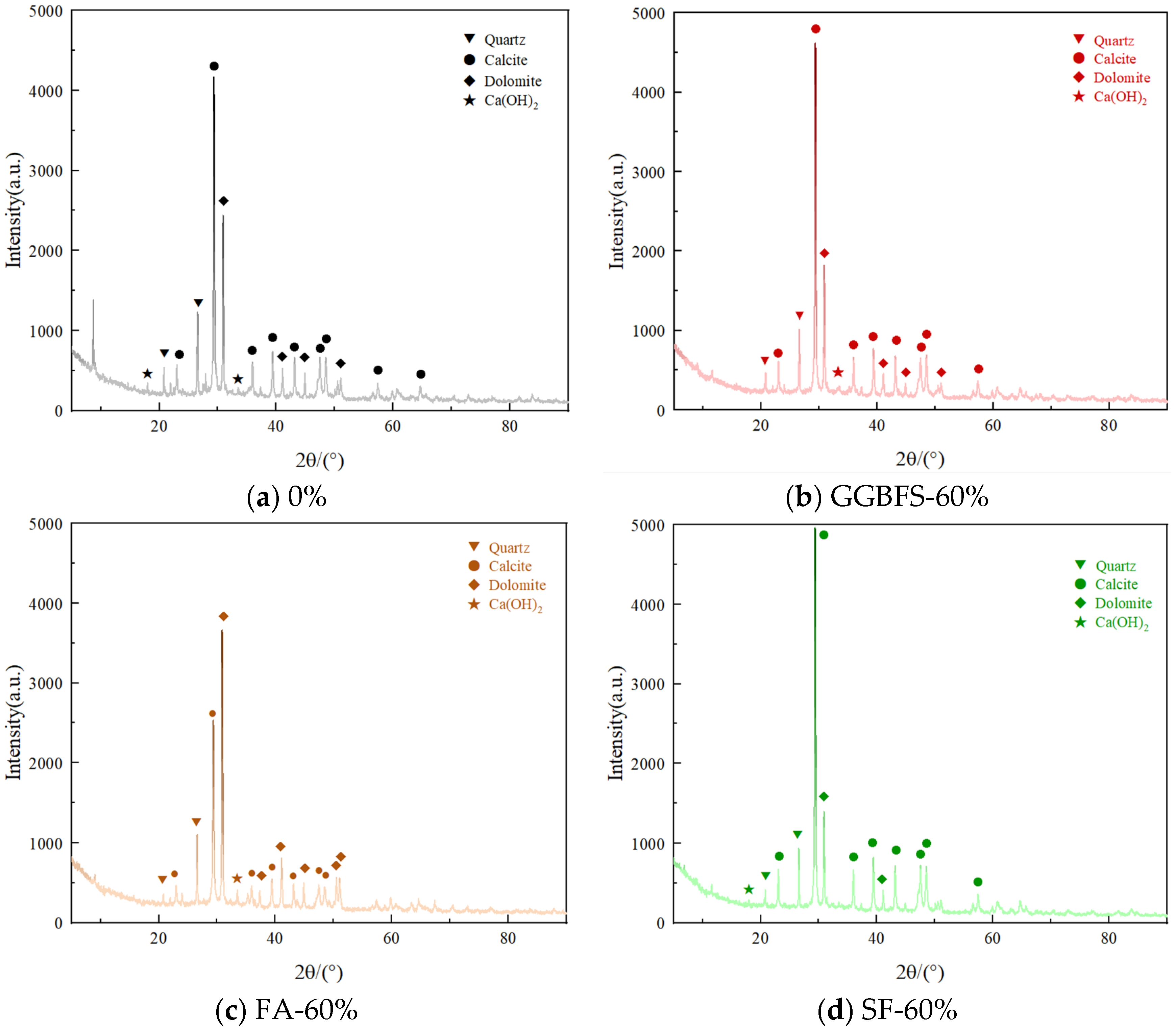

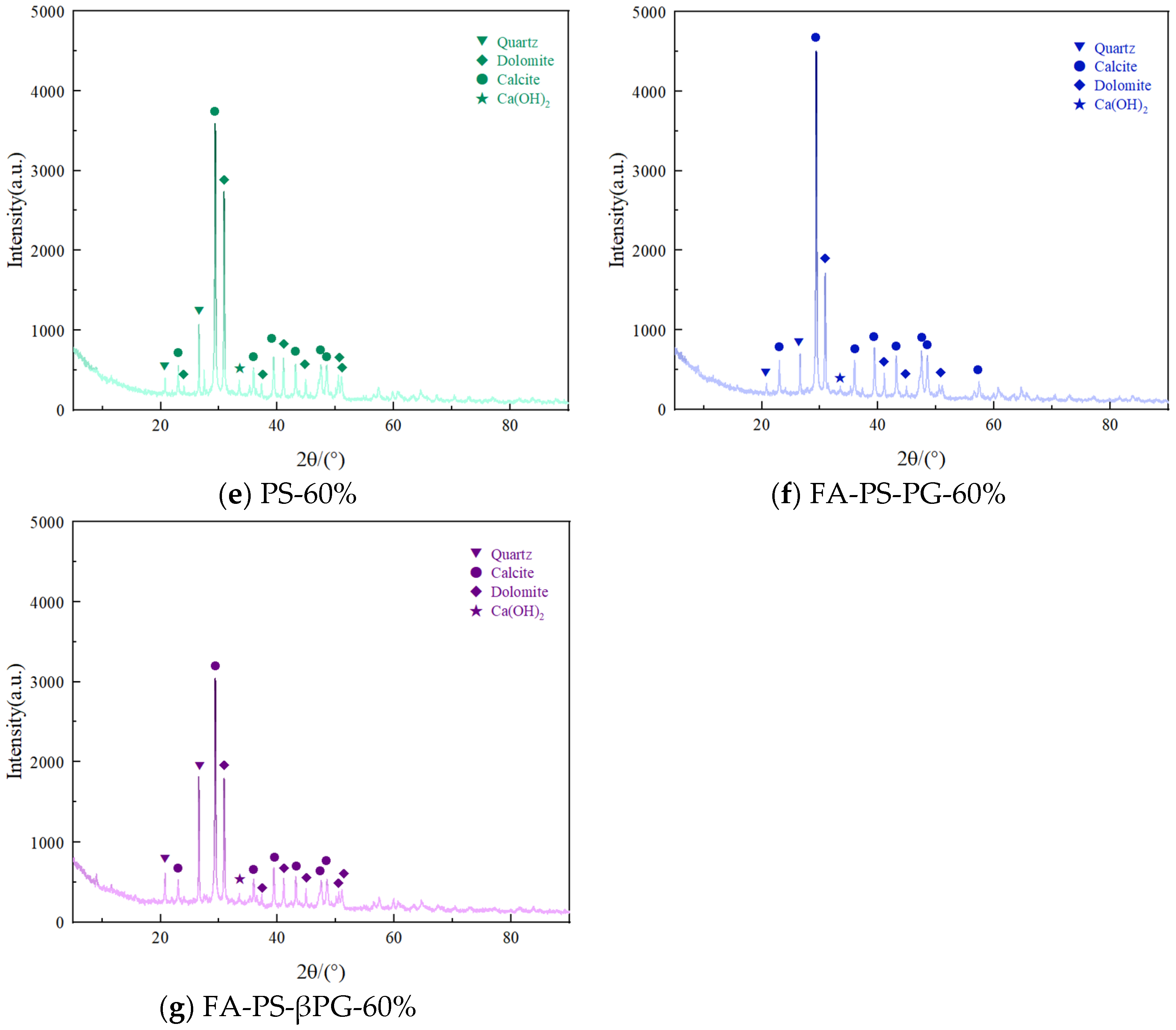

3.6. Hydration Products of Backfill Materials

4. Conclusions

- (1)

- The incorporation of industrial solid waste increased the slump of backfill materials by 7.38–51.64%. The minimum slump was observed when GGBFS was added at 55%, while the maximum slump occurred with FA-PS-βPG at a 50% dosage. This enhanced fluidity facilitates the preparation of backfill materials.

- (2)

- The incorporation of industrial solid wastes resulted in the dry density of the backfill materials ranging from 1565 to 1801 kg/m3. The dry density exhibited a decreasing trend with increasing dosages of GGBFS, SF, PS, and FA-PS-PG. However, the addition of FA alone led to an initial increase followed by a decrease in dry density. In contrast, the incorporation of FA-PS-βPG caused the dry density to first decrease and then increase.

- (3)

- Comparative analysis of the compressive strength of backfill materials with different mix proportions revealed the following: Specimens incorporating PS exhibited higher compressive strength across all replacement ratios. Mixtures containing SF showed negligible strength development at later ages. The lowest 56-days compressive strength (3.37 MPa) was observed at a 60% FA replacement level. The highest 56-days compressive strength (8.02 MPa) was achieved with FA-PS-PG at a 50% replacement rate.

- (4)

- Compared with the control group, the incorporation of industrial solid wastes resulted in varying degrees of increase in parameter a and decrease in parameter b of the 56-days constitutive model, indicating enhanced elasticity. All mixtures demonstrated good fitting performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, S.; Niu, Z.; Liu, Y.; Wang, P. Research progress on performance enhancement of construction waste recycled aggregate. J. Archit. Civ. Eng. 2022, 39, 1–13. [Google Scholar] [CrossRef]

- Ma, Z.; Hu, R.; Shen, J.; Wang, C.; Wu, H. Chloride diffusion and binding capacity of sustainable cementitious materials with construction waste powder as cement replacement. Constr. Build. Mater. 2023, 368, 130352. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Zhang, F. Research progress on strengthening and modification of construction waste recycled aggregate. Bull. Chin. Ceram. Soc. 2020, 39, 2486–2491. [Google Scholar] [CrossRef]

- Yu, X.; Wang, J.; Wang, H.; Zeng, B.; Tang, F.; Wang, M. Effect of construction waste recycled powder on properties of C30–C40 recycled concrete. Concrete 2024, 147–151+156. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, S. Study on strength mechanism of construction waste-fly ash based cemented backfill. Non-Met. Mines 2023, 46, 82–87. [Google Scholar]

- Feng, S.; Jin, J.; Wang, X.; Zhao, N.; He, Z. Performance study and hydration mechanism of mineral admixtures combined with construction waste filling materials. Min. Res. Dev. 2023, 43, 77–82. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

- Wei, H. High-Value Preparation of FS Filling Cementitious Materials from Low-Quality Solid Waste and Application Research. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2021. [Google Scholar] [CrossRef]

- Yang, X. Collaborative Preparation of Filling Slurry from Low-Quality Multi-Solid Waste and Study on Pipeline Transportation Resistance. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2020. [Google Scholar] [CrossRef]

- Zhang, S. Study on Axial Compressive Mechanical Properties and Constitutive Model of Fly Ash-Slag-Carbide Slag Recycled Concrete. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2024. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Zhou, S.; Peng, D.; Tan, C. Application research of construction waste recycled aggregate in sponge city construction. New Build. Mater. 2019, 46, 170–173. [Google Scholar] [CrossRef]

- Hassani, F.; Razavi, S.; Isagon, I. A study of physical and mechanical behaviour of gelfill. C. Bull. 2007, 100. [Google Scholar]

- Liu, S.; Wang, Y.; Wu, A.; Gao, Y.; Li, C.; Ruan, Z. Development of low-carbon cemented phosphogypsum backfill utilizing carbide slag and industrial solid wastes: Workability, mechanical properties, and microstructure. J. Environ. Chem. Eng. 2025, 13, 116881. [Google Scholar] [CrossRef]

- Yılmaz, T.; Ercikdi, B.; Deveci, H. Utilisation of construction and demolition waste as cemented paste backfill material for underground mine openings. J. Environ. Manag. 2018, 222, 250–259. [Google Scholar] [CrossRef]

- Ji, Y.; Xie, L.; Xiao, J.; Zheng, Y.; Ma, S.; Pan, T. Mechanical properties and acoustic emission characteristics of microbial cemented backfill with various particle size distributions of recycled aggregates. Constr. Build. Mater. 2024, 417, 135269. [Google Scholar] [CrossRef]

- Sarici, T.; Geckil, T.; Ok, B.; Aksoy, H.S. An Investigation of the Usability of Alkali-Activated Blast Furnace Slag-Additive Construction Demolition Waste as Filling Material. Materials 2025, 18, 398. [Google Scholar] [CrossRef] [PubMed]

- Khandani, F.S.; Atapour, H.; Rad, M.Y.; Khosh, B. An experimental study on the mechanical properties of underground mining backfill materials obtained from recycling of construction and demolition waste. Case Stud. Constr. Mater. 2023, 18, e02046. [Google Scholar] [CrossRef]

- Figiela, B.; Brudny, K.; Lin, W.; Korniejenko, K. Investigation of mechanical properties and microstructure of construction-and demolition-waste-based geopolymers. J. Compos. Sci. 2022, 6, 191. [Google Scholar] [CrossRef]

- Wu, H.; Kang, S.; Zhang, H.; Sun, Q.; Shen, R.; Shu, Z. Research of the workability, mechanical and hydration mechanism of coal gangue-construction solid waste backfilling materials. Constr. Build. Mater. 2023, 408, 133833. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Method of Mechanical Properties of Ordinary Concrete. China architecture and building press: Beijing, China, 2019.

- Zhang, Q.; Dong, S.; Wu, F.; Cai, Y.; Xie, L.; Huang, C.; Zhao, J.; Yang, S.; Xu, F.; Zhu, Z.; et al. Investigation of the macro performance and mechanism of biochar modified ultra-high performance concrete. Case Stud. Constr. Mater. 2024, 21, e03595. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, F.; Dong, S.; Zhang, Q.; Huang, C.; Chen, L. A Low-Carbon Composite Cementitious Material Manufactured by a Combined Process of Red Mud. Buildings 2024, 14, 1729. [Google Scholar] [CrossRef]

- Rößler, C.; Steiniger, F.; Ludwig, H. Characterization of C–S–H and C–A–S–H phases by electron microscopy imaging, diffraction, and energy dispersive X-ray spectroscopy. J. Am. Ceram. Soc. 2017, 100, 1733–1742. [Google Scholar] [CrossRef]

- Li, C. Preparation and Properties of Phosphorous Slag-Fly Ash-Phosphogypsum-Cement Lightweight Concrete. Master’s Thesis, Guizhou University, Guiyang, China, 2016. [Google Scholar]

- Xiao, J. Experimental study on complete stress-strain curve of recycled concrete under uniaxial compression. J. Tongji Univ. (Nat. Sci.) 2007, 11, 1445–1449. [Google Scholar]

- Guo, Z. Strength and Deformation of Concrete: Experimental Basis and Constitutive Relation; Tsinghua University Press: Beijing, China, 1992. [Google Scholar]

- Wu, F.; Yang, B.; Luo, P.; Dong, S.; Wang, H.; Zhang, Q.; Huang, Z.; Jiang, J.; Cai, Y.; Yang, S.; et al. Improving the Performance of Mortar under Carbonization Curing by Adjusting the Composition of Ternary Binders. Materials 2024, 17, 5037. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y. Experimental study on fluidity and mechanical properties of alkali-activated slag/fly ash system. Min. Res. Dev. 2022, 42, 141–147. [Google Scholar] [CrossRef]

| Name | SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 | TiO2 | Na2O | K2O | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 15.62 | 5.69 | 3.63 | 68.54 | 2.23 | 2.26 | 0 | 0.40 | 0.43 | 1.20 |

| GGBFS | 39.36 | 1.26 | 7.75 | 45.70 | 3.86 | 0 | 1.07 | 0 | 0 | 1.00 |

| FA | 48.32 | 7.97 | 24.78 | 7.75 | 0.82 | 0.55 | 0 | 0.54 | 3.79 | 5.48 |

| SF | 92.30 | 1.56 | 1.78 | 1.71 | 0.89 | 0 | 0 | 0.53 | 0 | 1.23 |

| PS | 38.17 | 1.72 | 3.48 | 44.13 | 1.87 | 0 | 0 | 0 | 0 | 10.63 |

| Mix Code | Cement | Industrial Solid Waste | CDW | Water | SP | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| GGBS | FA | SF | PS | PG | βPG | |||||

| 0 | 234 | 1170 | 363 | 4.68 | ||||||

| GGBFS-50% | 115 | 115 | 1150 | 357 | 4.6 | |||||

| GGBFS-55% | 104 | 127 | 1156 | 358 | 4.62 | |||||

| GGBFS-60% | 92 | 138 | 1150 | 357 | 4.6 | |||||

| FA-50% | 115 | 115 | 1150 | 357 | 4.6 | |||||

| FA-55% | 104 | 127 | 1156 | 358 | 4.62 | |||||

| FA-60% | 92 | 138 | 1150 | 357 | 4.6 | |||||

| SF-50% | 115 | 115 | 1150 | 357 | 4.6 | |||||

| SF-55% | 104 | 127 | 1156 | 358 | 4.62 | |||||

| SF-60% | 92 | 138 | 1150 | 357 | 4.6 | |||||

| PS-50% | 115 | 115 | 1150 | 357 | 4.6 | |||||

| PS-55% | 104 | 127 | 1156 | 358 | 4.62 | |||||

| PS-60% | 92 | 138 | 1150 | 357 | 4.6 | |||||

| FA-PS-PG-50% | 115 | 54.25 | 54.25 | 7 | 1150 | 357 | 4.6 | |||

| FA-PS-PG-55% | 104 | 59.96 | 59.96 | 7 | 1156 | 358 | 4.62 | |||

| FA-PS-PG-60% | 92 | 65.09 | 65.09 | 8 | 1150 | 356 | 4.6 | |||

| FA-PS-βPG-50% | 115 | 54.25 | 54.25 | 7 | 1150 | 357 | 4.6 | |||

| FA-PS-βPG-55% | 104 | 59.96 | 59.96 | 7 | 1156 | 358 | 4.62 | |||

| FA-PS-βPG-60% | 92 | 65.09 | 65.09 | 8 | 1150 | 356 | 4.6 | |||

| Mix Code | Ascent Stage | Descent Stage | ||

|---|---|---|---|---|

| a | R2 | b | R2 | |

| 28d-0 | −0.14 | 0.99 | 0.85 | 0.9 |

| 28d-GGBFS-60% | 0.53 | 0.99 | 0.63 | 0.94 |

| 28d-FA-60% | 0.8 | 0.99 | 1.03 | 0.99 |

| 28d-SF-60% | −0.11 | 0.99 | 0.8 | 0.99 |

| 28d-PS-60% | −0.01 | 0.99 | 2.15 | 0.99 |

| 28d-FA-PS-PG-60% | −0.03 | 0.99 | 1.74 | 0.99 |

| 28d-FA-PS-βPG-60% | 0.44 | 0.99 | 0.27 | 0.99 |

| 56d-0 | −0.03 | 0.98 | 2.84 | 0.93 |

| 56d-GGBFS-60% | 0.55 | 0.99 | 0.69 | 0.99 |

| 56d-FA-60% | −0.04 | 0.99 | 1.23 | 0.99 |

| 56d-SF-60% | 0.37 | 0.99 | 1.58 | 0.98 |

| 56d-PS-60% | 0.57 | 0.99 | 1.78 | 0.97 |

| 56d-FA-PS-PG-60% | 0.02 | 0.99 | 2.65 | 0.98 |

| 56d-FA-PS-βPG-60% | 0.25 | 0.99 | 0.91 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Liu, Q.; Wu, F.; Dong, S.; Zhang, Q.; Wang, J.; Luo, P.; Yang, X. Performance Study on Preparation of Mine Backfill Materials Using Industrial Solid Waste in Combination with Construction Waste. Materials 2025, 18, 3716. https://doi.org/10.3390/ma18153716

Cai Y, Liu Q, Wu F, Dong S, Zhang Q, Wang J, Luo P, Yang X. Performance Study on Preparation of Mine Backfill Materials Using Industrial Solid Waste in Combination with Construction Waste. Materials. 2025; 18(15):3716. https://doi.org/10.3390/ma18153716

Chicago/Turabian StyleCai, Yang, Qiumei Liu, Fufei Wu, Shuangkuai Dong, Qiuyue Zhang, Jing Wang, Pengfei Luo, and Xin Yang. 2025. "Performance Study on Preparation of Mine Backfill Materials Using Industrial Solid Waste in Combination with Construction Waste" Materials 18, no. 15: 3716. https://doi.org/10.3390/ma18153716

APA StyleCai, Y., Liu, Q., Wu, F., Dong, S., Zhang, Q., Wang, J., Luo, P., & Yang, X. (2025). Performance Study on Preparation of Mine Backfill Materials Using Industrial Solid Waste in Combination with Construction Waste. Materials, 18(15), 3716. https://doi.org/10.3390/ma18153716