1. Introduction

The steady growth in world population with the consequent increase in anthropogenic activity has led to the overexploitation of the natural resources on which the quality of life is based: water, soil, and air. Intensive agriculture leads to serious consequences such as deforestation, desertification, groundwater pollution due to the massive use of pesticides and fertilizers, air pollution due to high ammonia emissions, etc. [

1]. The environmental and social consequences of land degradation such as desertification, especially in the Mediterranean regions, have been known and analyzed for some time now [

2,

3,

4]. Soil erosion is more pronounced during periods of heavy rainfall as topsoil is carried elsewhere and there is a loss of nutrients and reduced infiltration. There is a need to increase or maintain vegetation cover in these areas to mitigate the problem [

5].

Rethinking the entire global agricultural system becomes mandatory; we need to discard the idea of intensive agriculture and focus on a system to make soils fertile and increase infiltration at the expense of surface runoff.

Based on these assumptions, many studies have been conducted in recent years on the production of porous ceramic materials such as artificial lightweight aggregates (hereafter referred to only as lightweight aggregates or LWAs). Due to their chemical and physical properties, lightweight aggregates are suitable for numerous applications, such as energy conversion and storage [

6], heat transfer [

7], green roofs, rooftop gardens, urban greening, and hydroponics [

8]. The technical reference definition for lightweight aggregates (LWAs) is contained in the standard for concrete [

9] and it defines lightweight aggregates as any “aggregate of mineral origin having a density of granular particles [

10] less than 2000 kg/m

3 or having a loose bulk density [

11] less than 1200 kg/m

3”. The main constituent is (almost) always clay: if it is subjected to high temperatures (commercial LWAs are manufactured by firing in rotary kilns at maximum temperatures of 1000 to 1300 °C, the temperature will vary depending on the specific material being processed and the desired reaction [

12]), it tends to expand its starting volume a lot (even up to 6–7 times), releasing gas phase components (organic substances and reduced metal oxides), resulting in a honeycomb-like internal structure. According to a study conducted by the authors, the increase in volume is more related to the formation of an adequate viscous phase than to the release of gas [

13].

In the agronomic field, the usefulness of LWAs is mainly related to the open porosity of their structure, which allows water to drain efficiently, preventing water stagnation and thus the possible proliferation of mold and/or fungal diseases; it can also be useful for reducing the weight of the substrate (by about 10%), in the case of green roof use, and for mulching [

14].

This work stems from the idea of obtaining a green alternative to current commercially available LWAs for agricultural purposes. This alternative would use less virgin clay, partially replacing it with reclaimed materials. The effect of static or rotary firing on the physical and chemical properties of the prototypes will also be compared. The raw materials used are Italian red clay, pumice, and spent coffee grounds. The authors have previously used pumice stone to manufacture LWAs through powder sintering in a static electric furnace [

15]. Pumice scraps were selected to enhance the light weight and the porous structure compared to red clay LWAs. It should be noted that developing lightweight aggregates for agronomic applications presents several challenges. Controlling the porosity and water absorption is essential to ensure a proper balance between drainage and water retention, thus avoiding stagnation, which is harmful to roots. Maintaining a neutral–sub-acidic pH (pH = 6.0–6.9) and low electrical conductivity is also necessary to avoid hindering the absorption of nutrients. The aggregates must be light yet resistant and stable over time, as well as being compatible with different cultivation systems, including hydroponics. Although the use of waste materials is sustainable, it involves variability in quality and behavior during sintering, which must be optimized to ensure consistent performance and low environmental impact. Compliance with agronomic regulations is essential for the safe and legal use of the product.

Clay and volcanic ash have always been used for the production of LWAs due to the characteristics of the material obtained after firing. There are studies in the literature evaluating the geotechnical properties of clay LWAs [

16,

17,

18], the mechanisms of expansion during firing [

13,

19], the effects of adding sand to smectite-rich Tunisian clay rocks [

20], the use of zeolitic tuffs [

21], and the use of volcanic pumice and lapillus [

15]. There are also studies that used wastes of various kinds such as spent coffee grounds [

8,

22], fly ash [

23,

24,

25], sewage sludge [

26], rice husk ash [

27], cattle bone flour ash [

28], and waste from municipal and industrial origins [

29]. Further examples include the use of diatomite waste [

30], red ceramic waste [

31], industrial residues rich in aluminosilicates and carbonates [

32], paraffin/titanium-bearing blast furnace slag phase change aggregate [

33], PET plastic waste and byproduct additives [

34], as well as slag and fly ash for the stabilization of organic clay [

35].

The literature is rich in insights into the design of lightweight aggregates using waste, and this has enabled the design of new environmentally friendly materials with a matrix consisting of clay and pumice and with spent coffee ground as the pore-forming agent. Thanks to the raw materials used, the aggregates could be defined as eco-friendly. The advantages of using pumice include its consistent chemical and mineralogical composition over time and the fact that it is a national byproduct with limited marketing potential that risks becoming waste. The benefit of using spent coffee grounds is that they are a waste that is easily available in any geographical area and burned during the cooking process, increasing the porosity of the material. Two different forms of firing for LWAs were evaluated, in a static kiln and in a rotational kiln, to highlight the advantages and disadvantages of the two sintering processes. The production of expanded clay involves a high-temperature firing process that transforms raw clay into a lightweight, porous material. The choice between a static and a rotary kiln for this process affects several aspects of production. In a static kiln, the clay LWAs are placed on fixed supports in a stationary firing chamber, and heat can be distributed by natural or forced convection; there can be temperature variability within the kiln, with some areas hotter than others. Thus, when firing in a static kiln, the expanded clay may have variations in porosity and density due to the uneven heat distribution. In this case, firing may take longer to achieve an optimum balance between densification degree and interconnected pores available for water retention. In a rotary kiln, the clay is placed in a drum that constantly rotates, ensuring that the material is continuously mixed and evenly exposed to heat. The final product tends to have a more uniform porosity and density, and firing is generally faster and more efficient. In general, rotary kilns are preferred for high volume production and to achieve uniform product quality, while static kilns can be used in smaller production environments or where uniform firing is not critical. Static firing has been considered, since there are many ceramic tile production plants in the national territory. In this context, if production is to be diversified or converted, the production of lightweight aggregates (LWAs) could be evaluated using equipment that is already available.

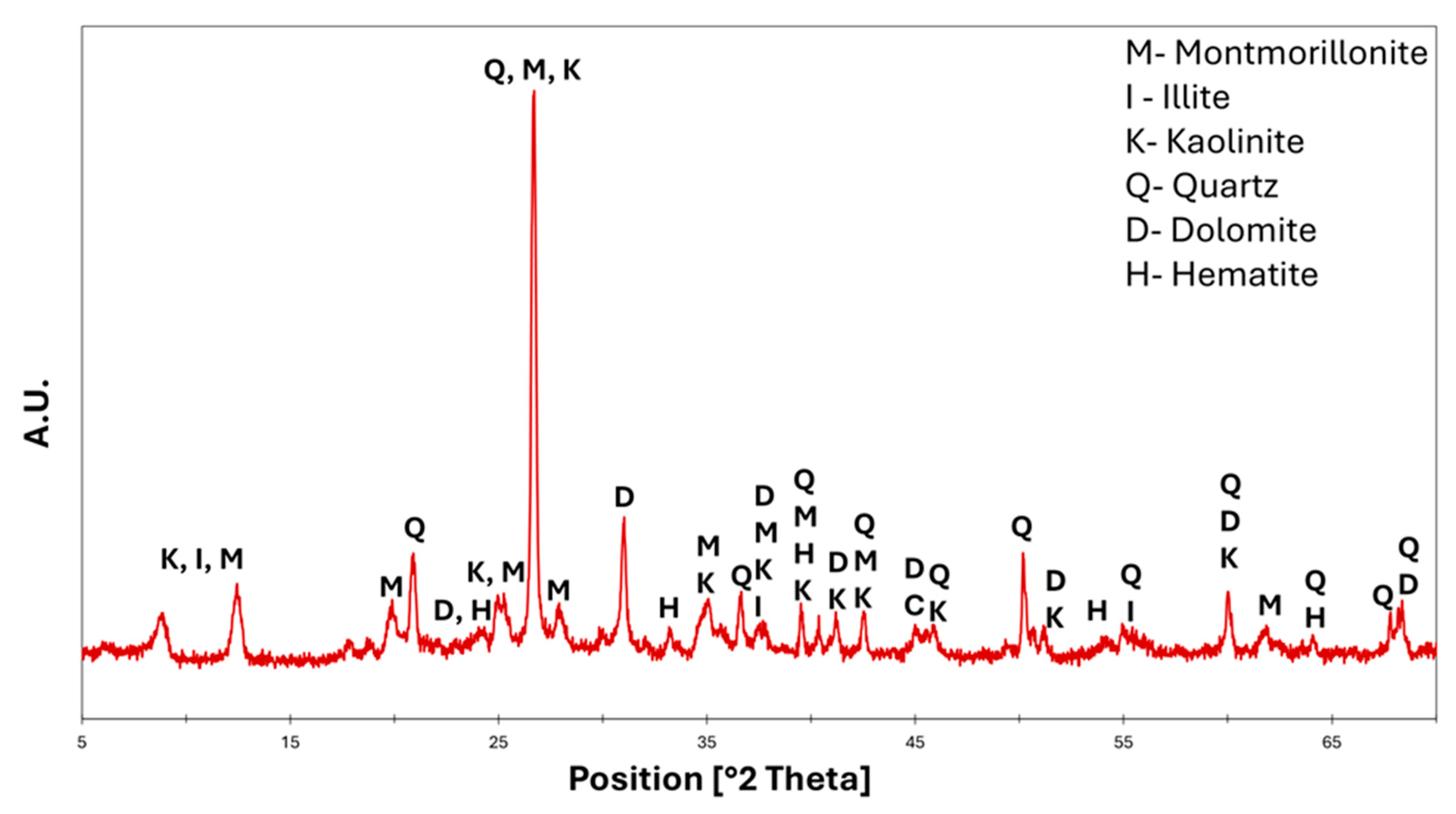

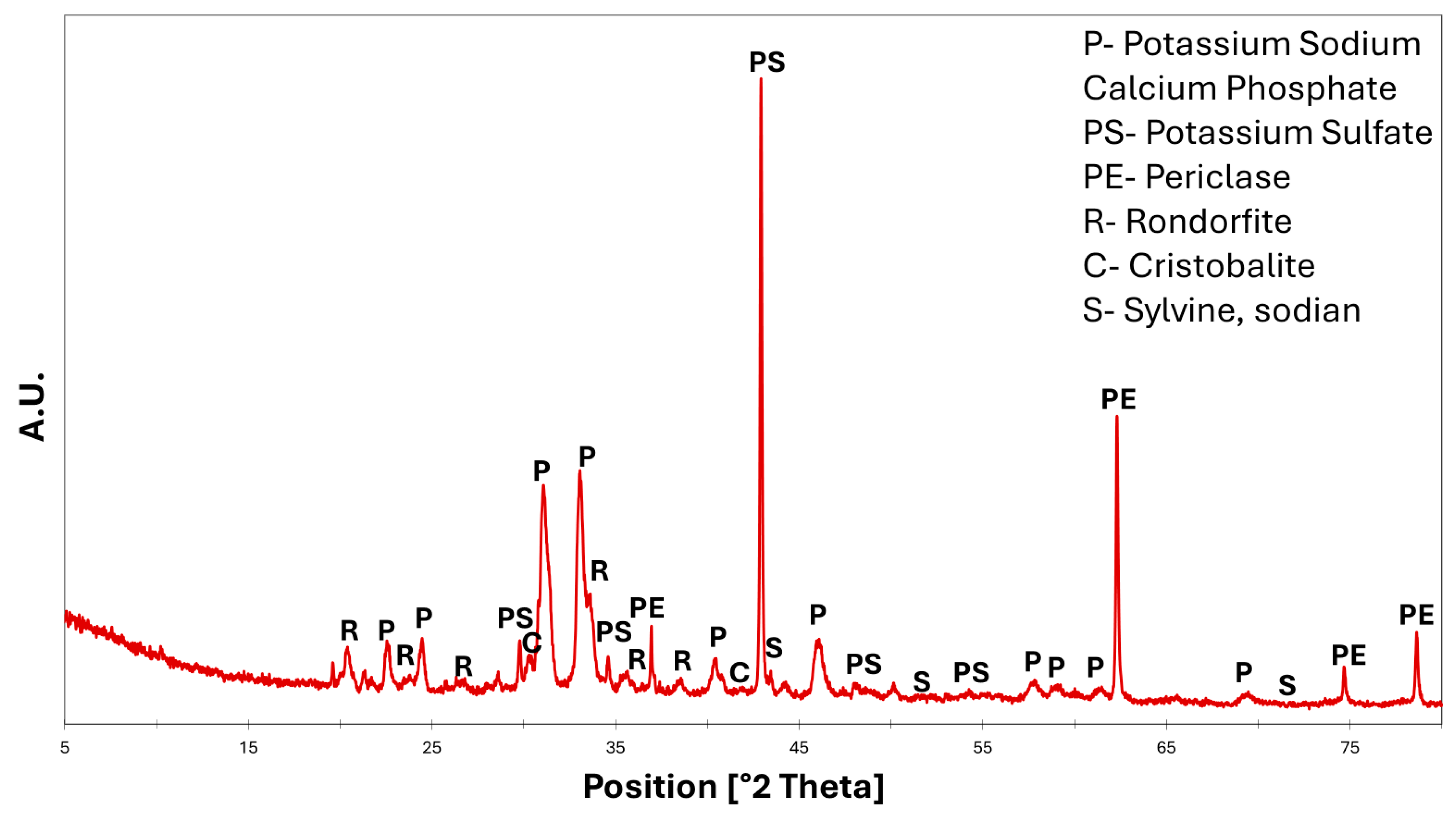

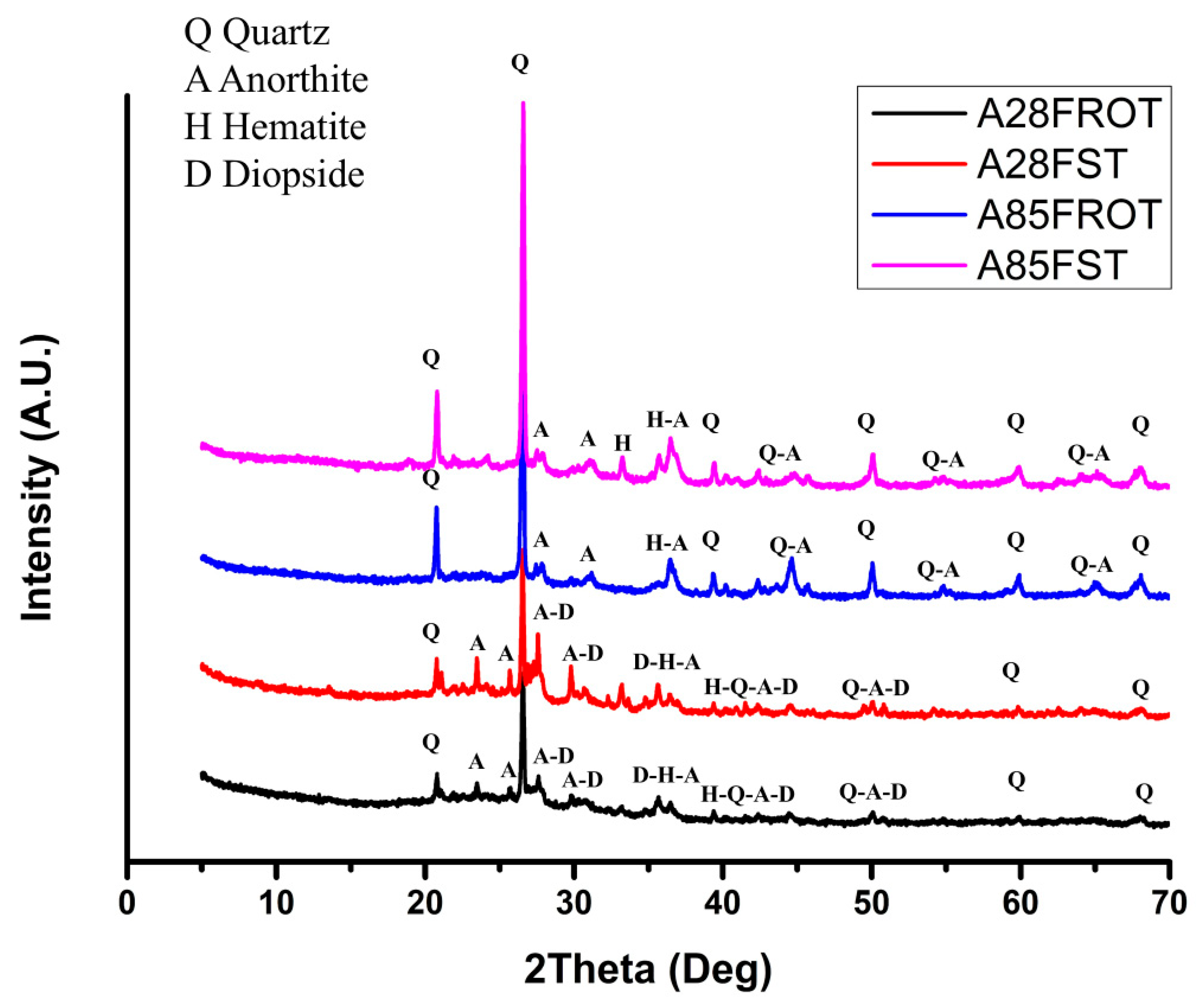

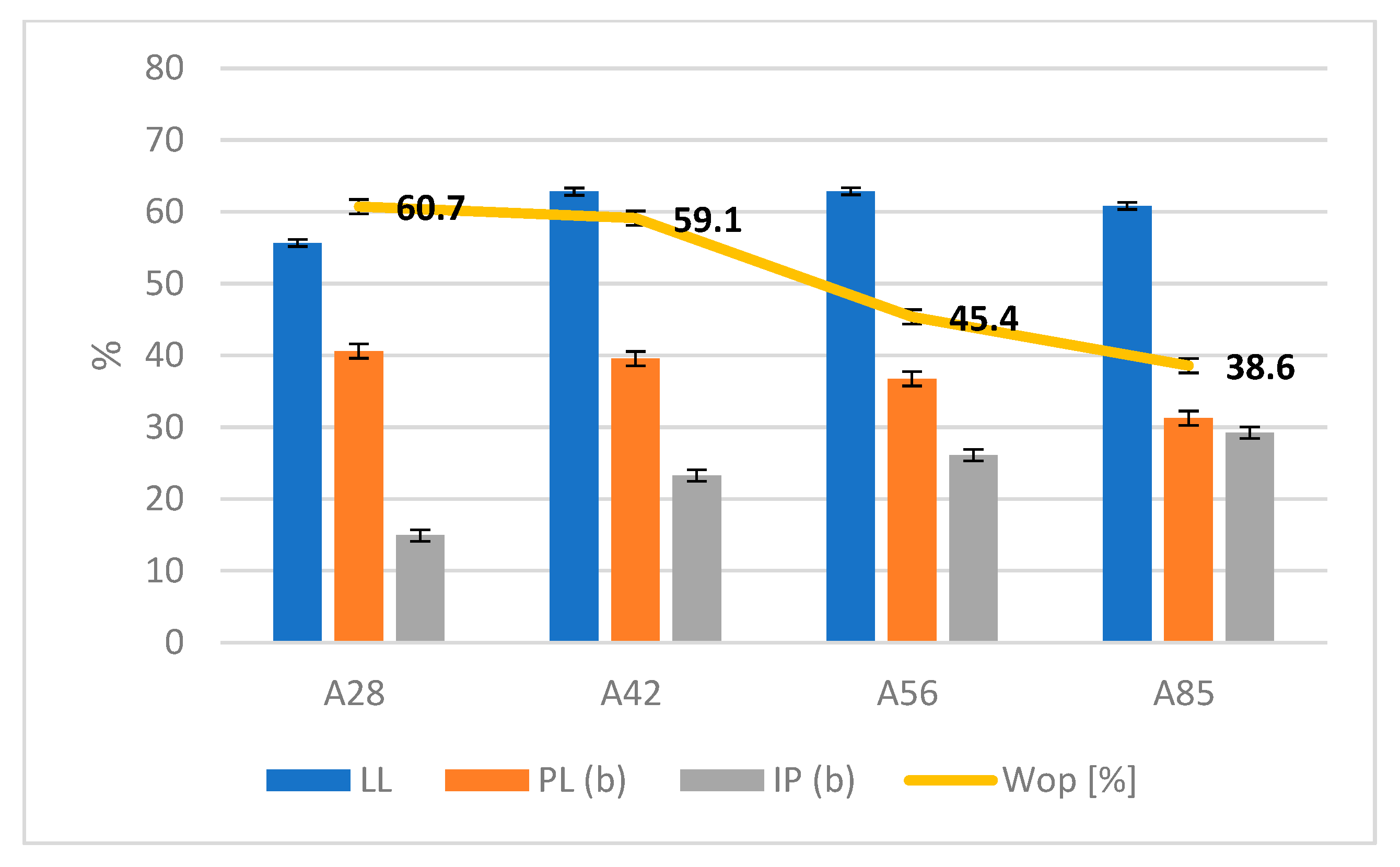

The scope of this work has been to characterize the new LWA formulations in terms of their physical, chemical, and mechanical properties in order to evaluate the best sintering process. The raw materials underwent characterization in terms of particle size distribution, moisture content, chemical composition (XRF and CHNS), mineralogical phases (XRD), and thermal behavior (TG/DTA for clay and pumice; calorimetry for SCGs). Formulations with varying clay contents (28–100 wt%) were prepared, mixed with water based on their consistency limits (liquid limit, plastic limit, and plasticity index), shaped into spherical pellets, and fired using both rotary and static kilns. The LWAs were then characterized by measuring their loss on ignition (LOI); bloating index (BI); bulk and particle densities; loose bulk density; total, open, and closed porosity; water absorption after 24 h (WA24h); compressive strength (CS); pH; and electrical conductivity (EC).

4. Conclusions

This study investigated the influence of two different firing methods—using a rotary kiln and static kiln—on the production and performance of lightweight aggregates (LWAs) made from red clay, pumice scraps, and spent coffee grounds. The aim was to explore the feasibility of creating eco-friendly, high-performing materials that could reduce the use of virgin clay while incorporating byproducts and waste and to evaluate the effect of firing method on the LWAs’ properties.

The aggregates obtained using both firing methods demonstrated physical and chemical properties suitable for construction and agronomic applications. In particular, the compressive strength of all the formulations exceeded that of pure clay-based aggregates, although this was accompanied by an increase in the dry particle density. Notably, the A42 formulation, in which 50% of the clay was replaced with pumice, achieved a favorable balance between strength, porosity, and weight. This study demonstrated that using pumice scraps in the composition, instead of clay, could reduce the firing temperature below the conventional range (1100–1300 °C). This further contributes to reducing energy consumption and gas emissions.

Firing in a rotary kiln resulted in aggregates with a more uniform structure, a higher WA% and compressive strength, and a greater dry particle density, largely due to the consistent rotation and improved heat distribution during the sintering process. However, it also produced a negative bloating index, meaning that the aggregates shrank rather than expanded, which led to denser and mechanically stronger materials but with less internal porosity than commercial lightweight aggregates. This method is advantageous for industrial-scale production thanks to its efficiency and ability to deliver consistent quality.

On the other hand, static kiln firing yielded aggregates with even higher compressive strength in some formulations and better resolution of the crystalline phases. However, due to the less uniform heating and longer thermal exposure, this process can lead to more variable porosity and internal structures. Despite this, the mechanical properties of the static kiln-fired aggregates remained excellent, making this method suitable for smaller-scale production or specific applications where uniformity is less critical but mechanical performance is a priority.

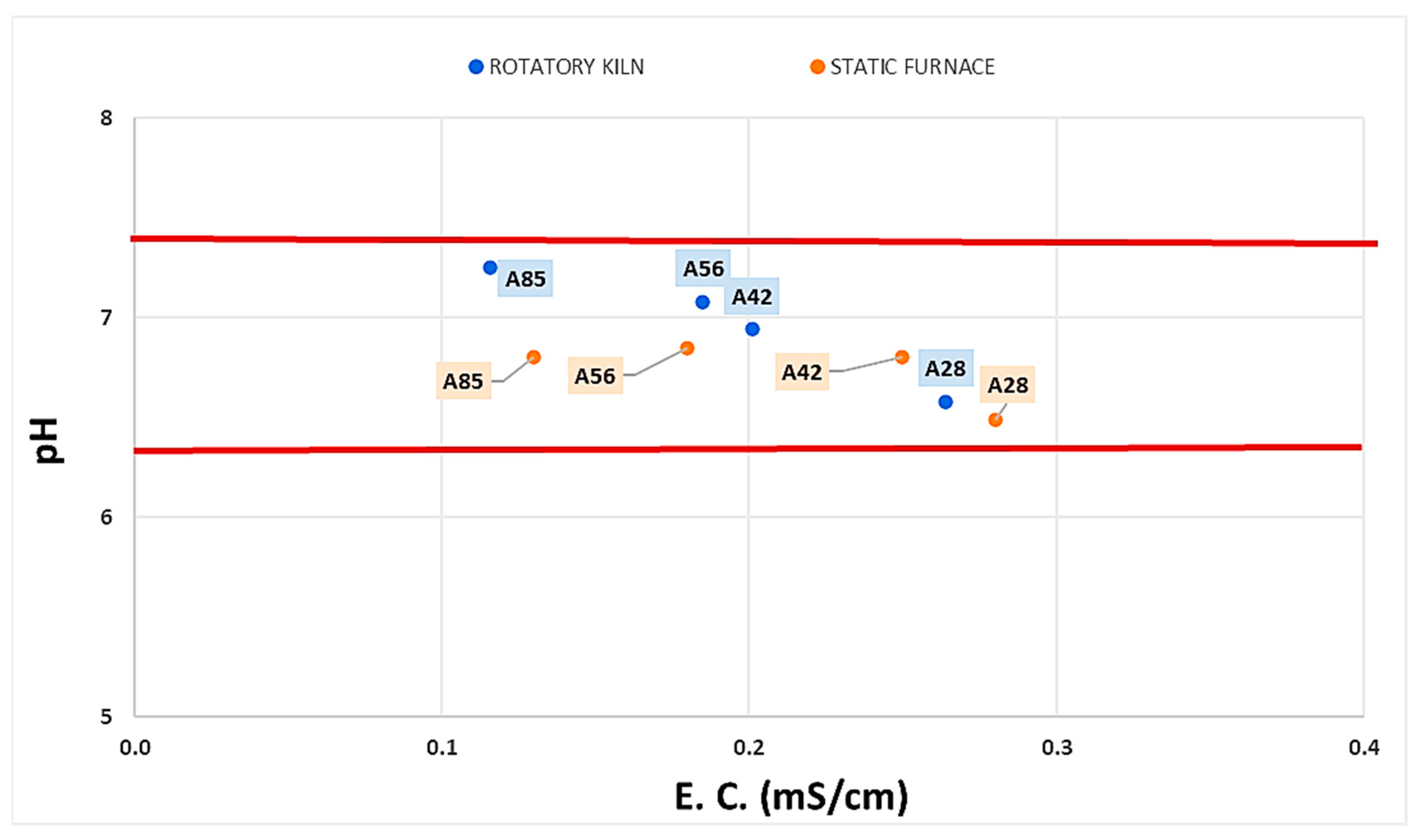

Across all the samples, the pH values ranged between 6.5 and 7.3, and the electrical conductivity remained well below agronomic thresholds, indicating the LWAs are safe and effective for use in soil conditioning, green roofs, and hydroponic systems. These properties, combined with their acceptable density and porosity values, confirm compliance with standards for lightweight aggregates and support their suitability for multiple uses.

In addition to the influence of firing conditions, the composition of the aggregates—particularly the proportions of of pumice and spent coffee grounds—was found to significantly impact the final properties. The addition of pumice, a porous and predominantly amorphous material, increased the total and open porosity, thereby enhancing the water absorption capacity. However, it also reduced the bloating index and compressive strength, revealing a trade-off between porosity and structural performance. SCGs, incorporated at a constant 15 wt% in all the formulations, acted as an effective pore-forming agent due to their high organic content, contributing to higher losses on ignition during firing. Despite promoting porosity, the SCGs did not significantly compromise the mechanical strength and helped maintain the pH and electrical conductivity within ranges suitable for agronomic use. Their dual function—as structural modifiers and sources of plant-beneficial nutrients—underscores the value of integrating organic waste into aggregate production. Overall, the combined use of pumice and SCGs enables fine-tuning of LWA properties to meet diverse functional requirements across the construction and agricultural sectors, while also supporting waste valorization and circular economy principles.

In conclusion, lightweight aggregates produced with recycled materials and processed through either rotary or static kiln sintering represent a sustainable and technically reliable alternative to traditional aggregates. The choice of firing method should be guided by the intended application, production scale, and performance requirements: while a rotary kiln is more suitable for industrial-scale, uniform production, a static kiln can yield superior mechanical properties in specific formulations where high strength is needed. These materials contribute to circular economy practices by transforming waste into valuable, multifunctional resources for both construction and agriculture. Future research could further enhance their performance by exploring alternative pore-forming agents or adjusting the ratios of the raw materials.