Experimental Crack Width Quantification in Reinforced Concrete Using Ultrasound and Coda Wave Interferometry

Abstract

1. Introduction

2. Ultrasonic Investigation of Reinforced Concrete Under Tensile Loading

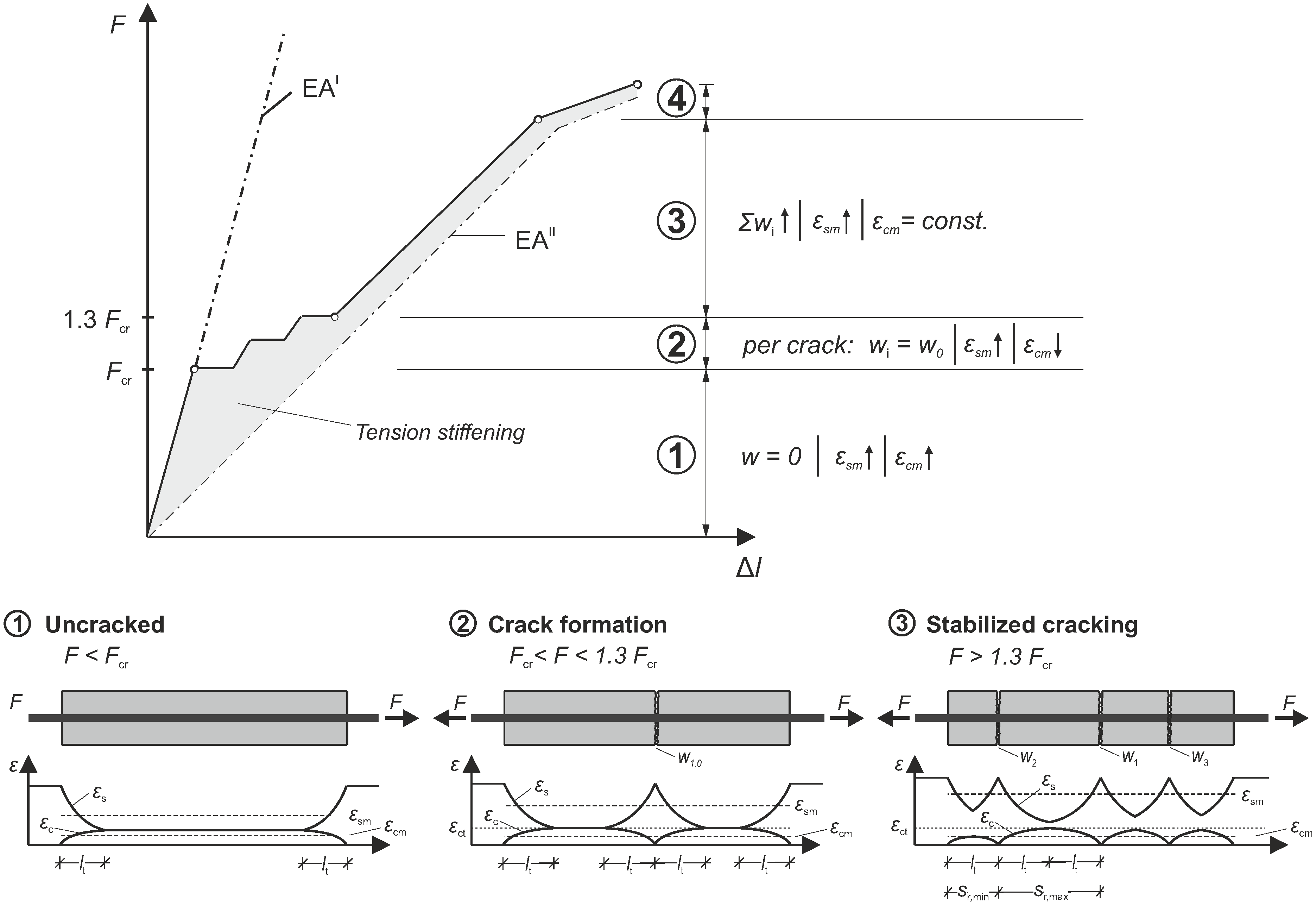

2.1. Load-Bearing Behavior of Reinforced Concrete Tension Members

2.2. Sensing Reinforced Concrete with Ultrasound and Coda Wave Interferometry

3. Experiments

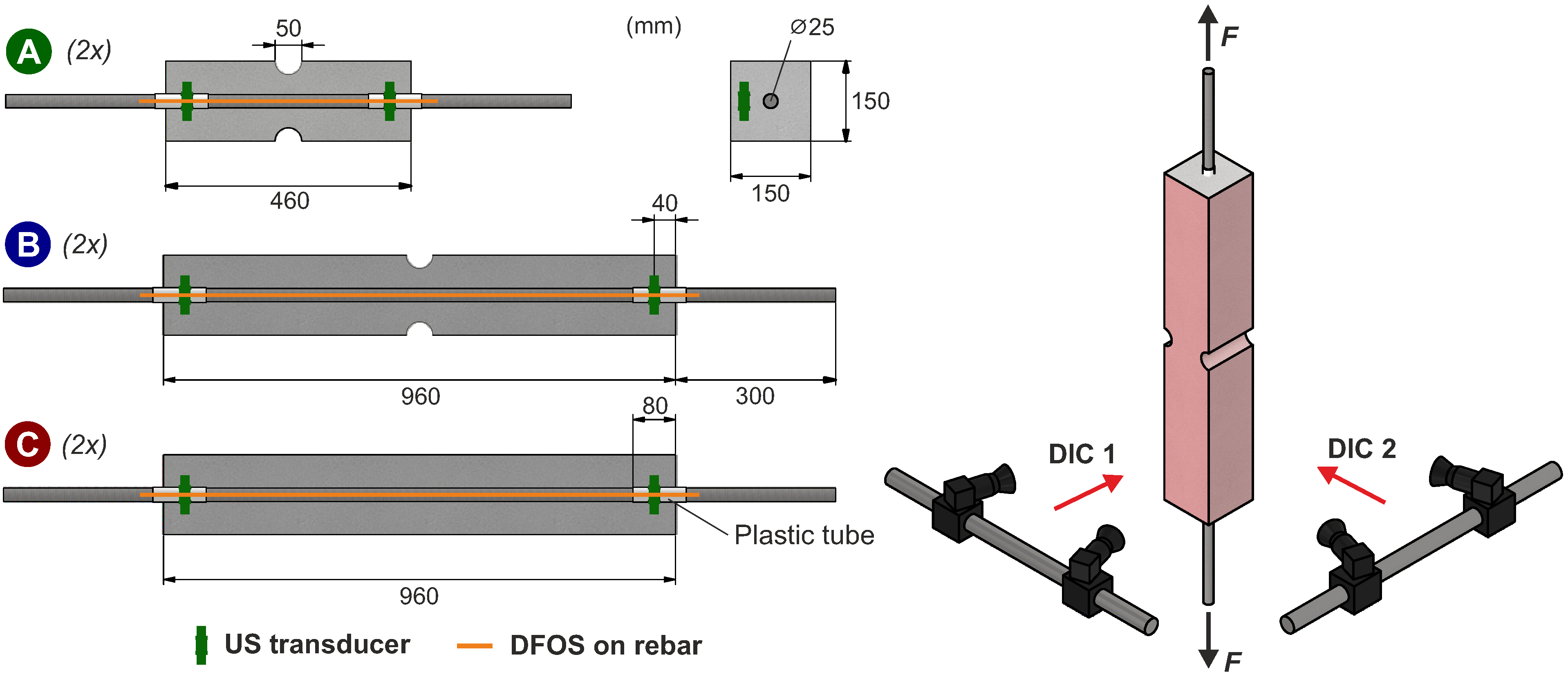

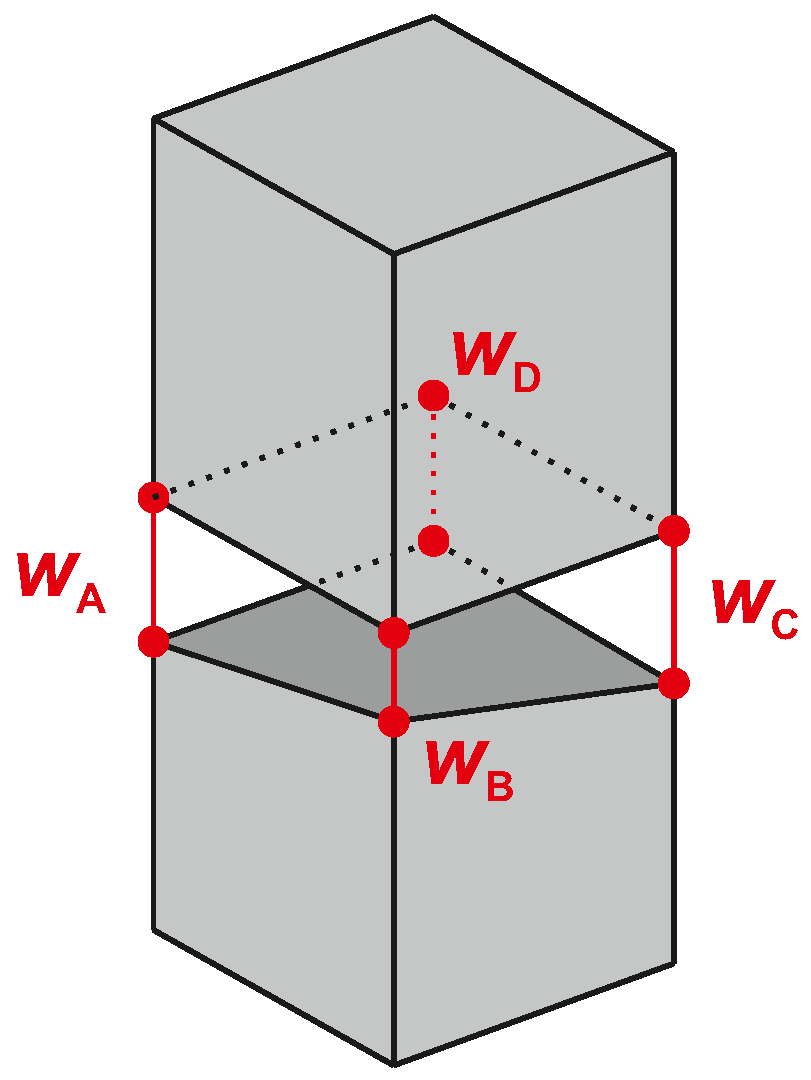

3.1. Experimental Setup

- Predefined and easily repeatable crack patterns by specifying the position of the first crack notching the cross-section

- Limitation of the initial crack width by selecting a high reinforcement ratio

- Control of the maximum number of cracks in the specimen via its length in relation to the transfer length

| Cement | w/c | Agg 0/2 | Agg 2/4 | Agg 4/8 | Agg 8/16 | |

|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | ||

| CEM I 32.5 R | 350 | 0.60 | 674 | 222 | 410 | 412 |

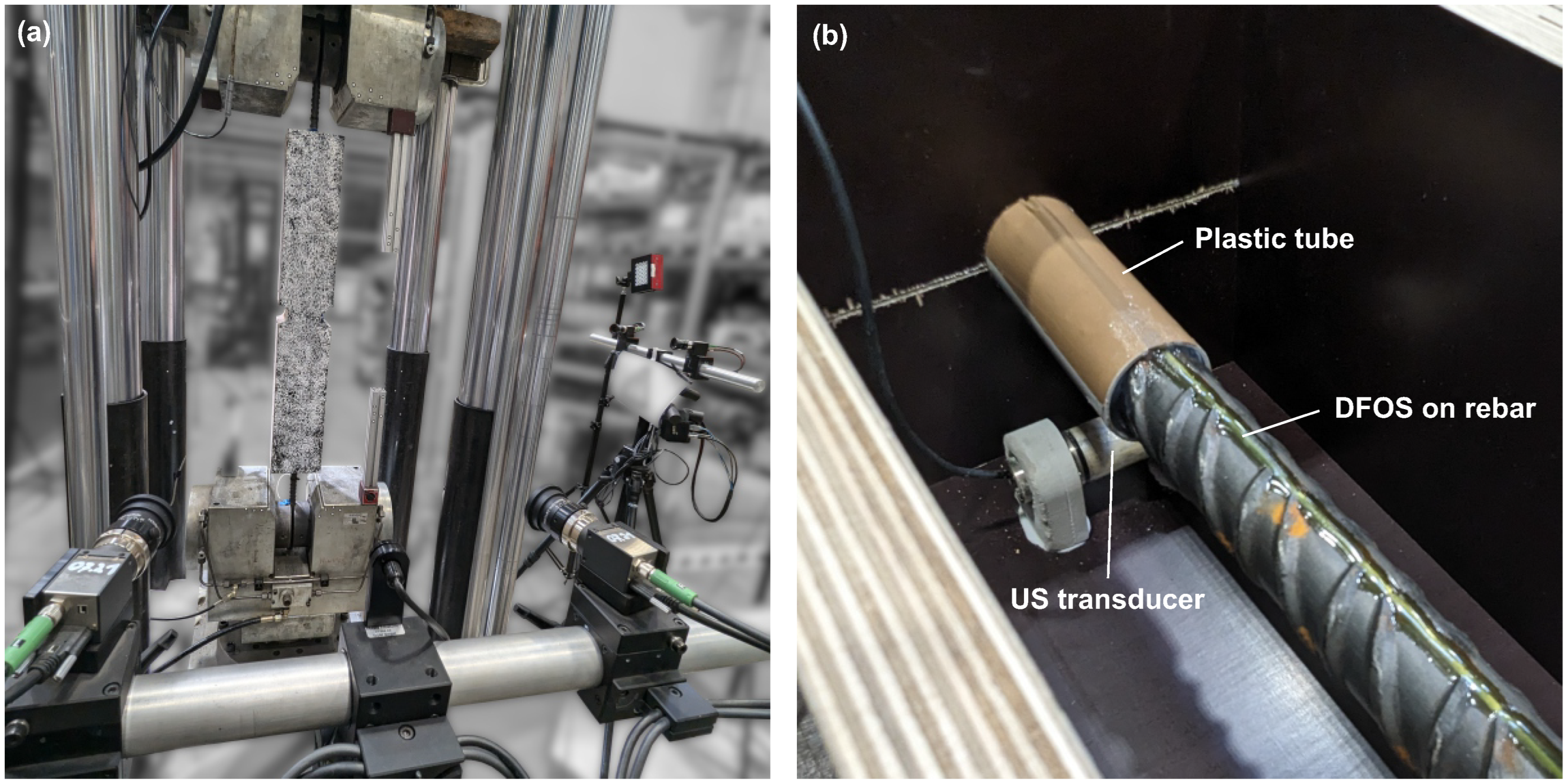

3.2. Measuring Equipment

3.3. Test Procedure

4. Results

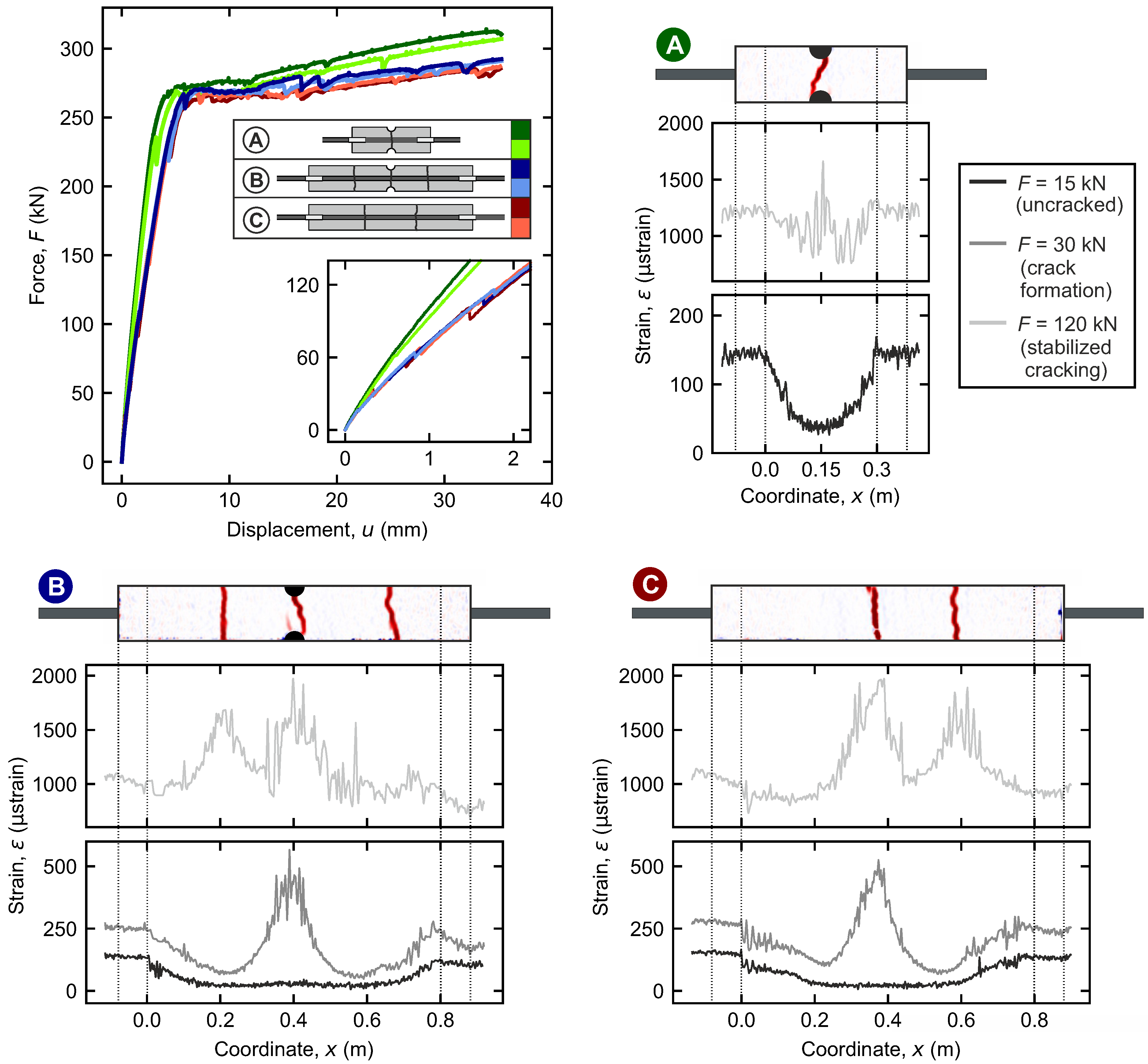

4.1. Load, Crack Pattern, and Strain

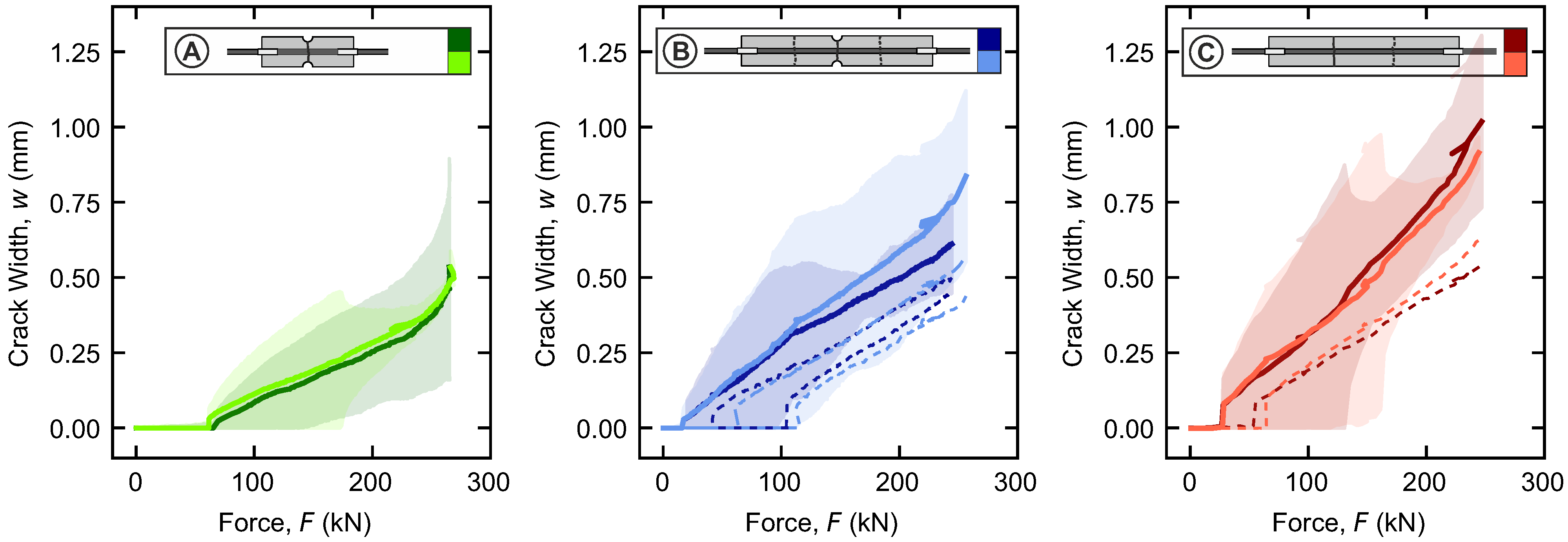

4.2. Crack Widths

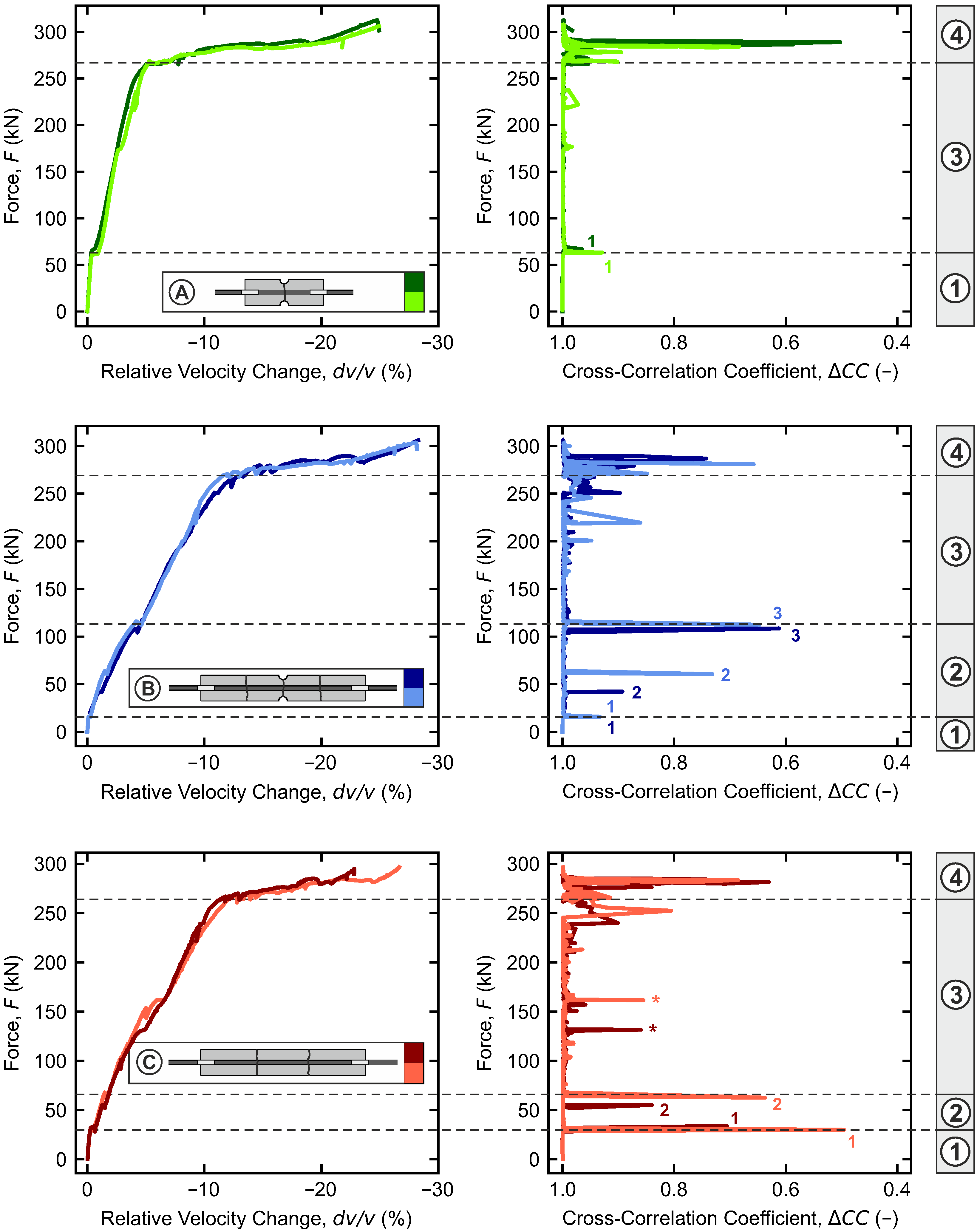

4.3. Ultrasound

5. Discussion

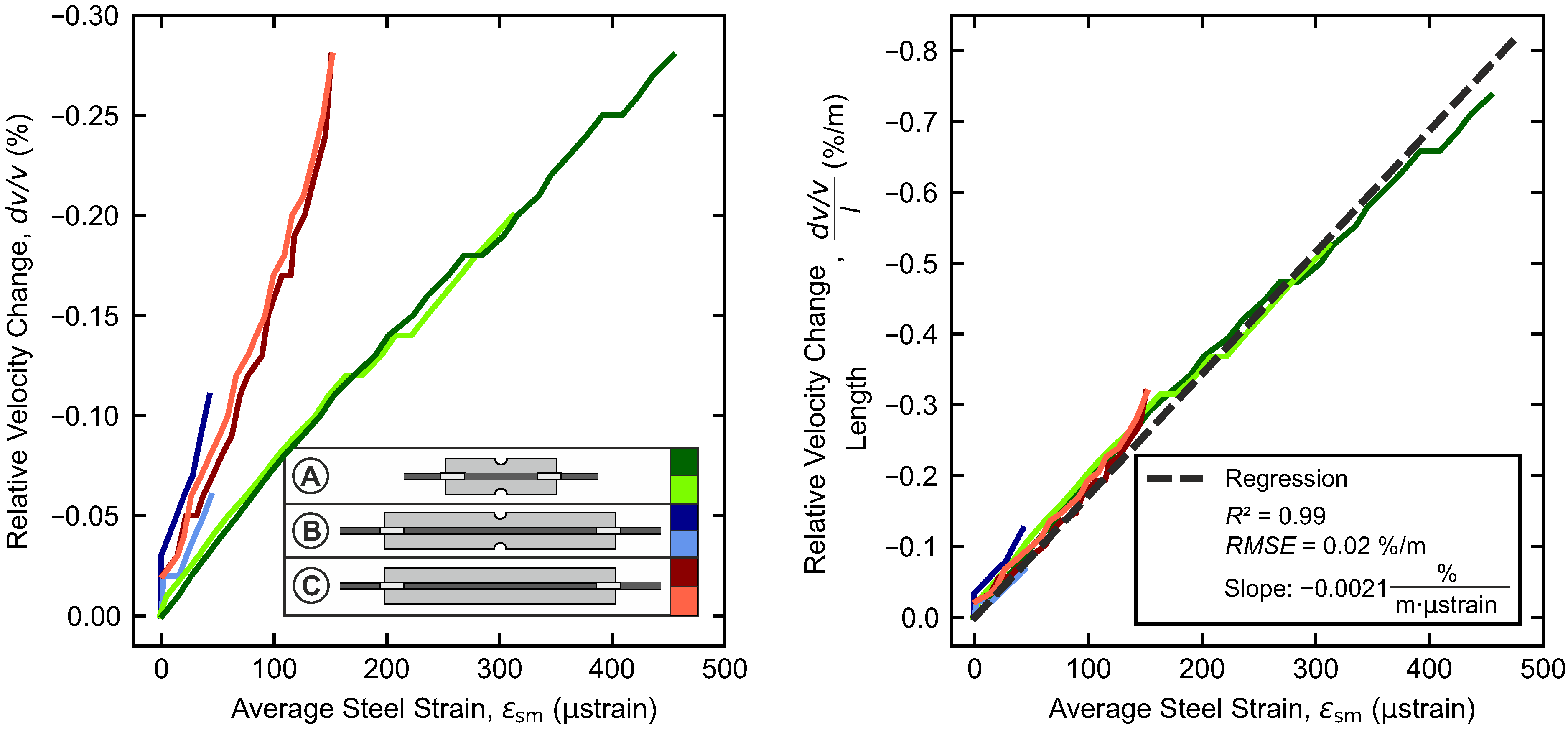

5.1. Uncracked Range

5.2. Crack Formation Range

5.3. Stabilized Cracking

6. Conclusions

- In the uncracked state, the changes in the relative velocity and the average (steel) strain are linearly correlated. A statistically well-determined () length-normalized relationship with a rate of µstrain is established.

- In the crack formation range, each crack causes the relative velocity to drop. In size, the drop is medium-correlated () with the initial crack width, with a rate of –5.71%/mm.

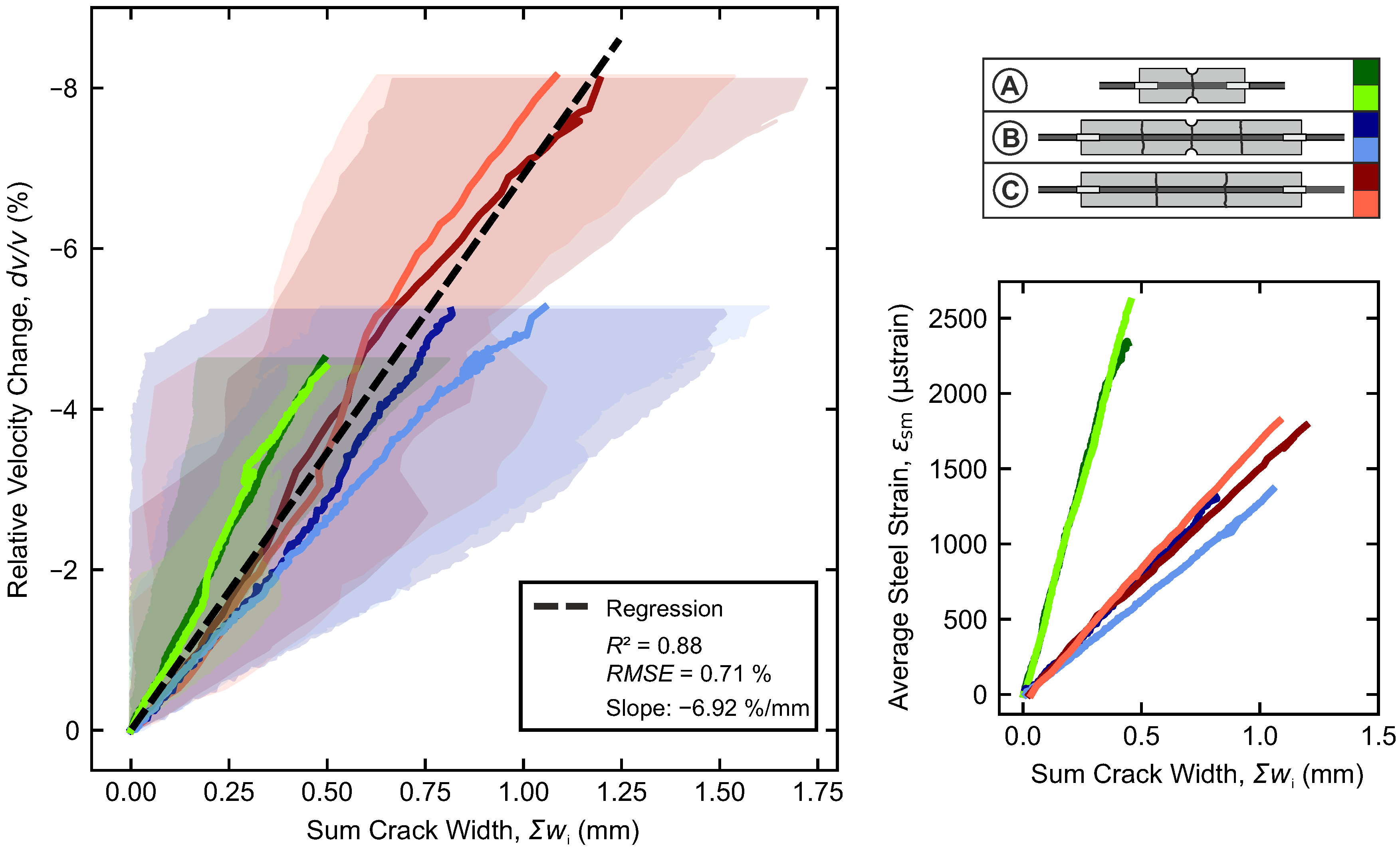

- In the stabilized cracking range, the crack width significantly determines the relative velocity change in the ultrasonic signal. Here, a proportional relationship of to the sum of the averaged crack widths is established, with a rate of –6.92%/mm ( = 0.88). This correlation is independent of the specimen length. The ultrasonic signal integrates all cracks, and the distribution of crack widths and feeds, into one quantity .

- In contrast to the stable states observed in the uncracked and the stabilized cracking ranges, the crack formation range is characterized by system rearrangements, rendering it less quantifiable by ultrasound.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CWI | Coda Wave Interferometry |

| DFOS | Distributed Fiber Optic Sensor |

| DIC | Digital Image Correlation |

References

- McCormac, J.; Brown, R.H. Design of Reinforced Concrete: ACI 318-11 Code Edition, 9th ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Zilch, K.; Zehetmaier, G. Bemessung im Konstruktiven Betonbau; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- DIN 1076:1999-11; Ingenieurbauwerke im Zuge von Straßen und Wegen–Überwachung und Prüfung. DIN Media GmbH: Berlin, Germany, 1999. [CrossRef]

- Fischer, O.; Thoma, S.; Crepaz, S. Distributed fiber optic sensing for crack detection in concrete structures. Civ. Eng. Des. 2019, 1, 97–105. [Google Scholar] [CrossRef]

- Speck, K.; Vogdt, F.; Curbach, M.; Petryna, Y. Faseroptische Sensoren zur kontinuierlichen Dehnungsmessung im Beton. Beton- Und Stahlbetonbau 2019, 114, 160–167. [Google Scholar] [CrossRef]

- Paul, A.; Sanio, D.; Mark, P. Detektion innerer Spannstahlbrüche durch faseroptische Messungen an Betonoberflächen. Beton- Und Stahlbetonbau 2025, 120, 330–342. [Google Scholar] [CrossRef]

- Zhang, Y.; Abraham, O.; Le Duff, A.; Lascoup, B.; Tournat, V.; Larose, E.; Planes, T.; Guerjouma, R.E.; Durand, O. Monitoring the Stress Level of Concrete Structures with CODA Wave Interferometry: Experimental Illustration of an Investigated Zone. In Nondestructive Testing of Materials and Structures; Büyüköztürk, O., Taşdemir, M.A., Güneş, O., Akkaya, Y., Eds.; RILEM Bookseries; Springer Netherlands: Dordrecht, The Netherlands, 2013; Volume 6, pp. 233–238. [Google Scholar] [CrossRef]

- Jiang, H.; Zhan, H.; Zhang, J.; Jiang, R.; Zhuang, C.; Fan, P. Detecting Stress Changes and Damage in Full-Size Concrete T-Beam and Slab with Ultrasonic Coda Waves. J. Struct. Eng. 2021, 147, 04021140. [Google Scholar] [CrossRef]

- Larose, E.; Hall, S. Monitoring stress related velocity variation in concrete with a 2 x 10(-5) relative resolution using diffuse ultrasound. J. Acoust. Soc. Am. 2009, 125, 1853–1856. [Google Scholar] [CrossRef] [PubMed]

- Stähler, S.C.; Sens-Schönfelder, C.; Niederleithinger, E. Monitoring stress changes in a concrete bridge with coda wave interferometry. J. Acoust. Soc. Am. 2011, 129, 1945–1952. [Google Scholar] [CrossRef]

- Hafiz, A.; Schumacher, T. Monitoring of Stresses in Concrete Using Ultrasonic Coda Wave Comparison Technique. J. Nondestruct. Eval. 2018, 37, 73. [Google Scholar] [CrossRef]

- Clauß, F.; Epple, N.; Ahrens, M.A.; Niederleithinger, E.; Mark, P. Comparison of Experimentally Determined Two-Dimensional Strain Fields and Mapped Ultrasonic Data Processed by Coda Wave Interferometry. Sensors 2020, 20, 4023. [Google Scholar] [CrossRef]

- Clauß, F.; Epple, N.; Ahrens, M.A.; Niederleithinger, E.; Mark, P. Correlation of Load-Bearing Behavior of Reinforced Concrete Members and Velocity Changes of Coda Waves. Materials 2022, 15, 738. [Google Scholar] [CrossRef]

- Epple, N.; Barroso, D.F.; Niederleithinger, E. Towards Monitoring of Concrete Structures with Embedded Ultrasound Sensors and Coda Waves—First Results of DFG for CoDA. In European Workshop on Structural Health Monitoring; Rizzo, P., Milazzo, A., Eds.; Lecture notes in civil engineering; Springer International Publishing: Cham, Switzerland, 2021; Volume 127, pp. 266–275. [Google Scholar] [CrossRef]

- Diewald, F.; Denolle, M.; Timothy, J.J.; Gehlen, C. Impact of temperature and relative humidity variations on coda waves in concrete. Sci. Rep. 2024, 14, 18861. [Google Scholar] [CrossRef] [PubMed]

- Legland, J.; Thery, R.; Abraham, O.; Villain, G.; Durand, O.; Larose, E.; Tournat, V. Influence of moisture on the estimation of nonlinear parameters in concrete with Nonlinear ultrasonic Coda Wave Interferometry. e-J. Nondestruct. Test. 2018, 23. [Google Scholar]

- Larose, E.; Obermann, A.; Digulescu, A.; Planès, T.; Chaix, J.F.; Mazerolle, F.; Moreau, G. Locating and characterizing a crack in concrete with diffuse ultrasound: A four-point bending test. J. Acoust. Soc. Am. 2015, 138, 232–241. [Google Scholar] [CrossRef]

- Zhang, Y.; Planès, T.; Larose, E.; Obermann, A.; Rospars, C.; Moreau, G. Diffuse ultrasound monitoring of stress and damage development on a 15-ton concrete beam. J. Acoust. Soc. Am. 2016, 139, 1691. [Google Scholar] [CrossRef]

- Grabke, S.; Clauß, F.; Bletzinger, K.U.; Ahrens, M.A.; Mark, P.; Wüchner, R. Damage Detection at a Reinforced Concrete Specimen with Coda Wave Interferometry. Materials 2021, 14, 5013. [Google Scholar] [CrossRef]

- Grabke, S.; Bletzinger, K.U.; Wüchner, R. Development of a finite element-based damage localization technique for concrete by applying coda wave interferometry. Eng. Struct. 2022, 269, 114585. [Google Scholar] [CrossRef]

- Finger, C.; Saydak, L.; Vu, G.; Timothy, J.J.; Meschke, G.; Saenger, E.H. Sensitivity of Ultrasonic Coda Wave Interferometry to Material Damage-Observations from a Virtual Concrete Lab. Materials 2021, 14, 4033. [Google Scholar] [CrossRef] [PubMed]

- Sträter, N.; Clauß, F.; Ahrens, M.A.; Mark, P. Detection of tendon breaks in prestressed concrete structures using coda wave interferometry. Struct. Concr. 2024, 26, 3319–3332. [Google Scholar] [CrossRef]

- Bompan, K.F.; Haach, V.G. Ultrasonic tests in the evaluation of the stress level in concrete prisms based on the acoustoelasticity. Constr. Build. Mater. 2018, 162, 740–750. [Google Scholar] [CrossRef]

- Haach, V.G.; Juliani, L.M.; Da Roz, M.R. Ultrasonic evaluation of mechanical properties of concretes produced with high early strength cement. Constr. Build. Mater. 2015, 96, 1–10. [Google Scholar] [CrossRef]

- Lillamand, I.; Chaix, J.F.; Ploix, M.A.; Garnier, V. Acoustoelastic effect in concrete material under uni-axial compressive loading. NDT E Int. 2010, 43, 655–660. [Google Scholar] [CrossRef]

- Nogueira, C.L.; Willam, K.J. Ultrasonic testing of damage in concrete under uniaxial compression. ACI Mater. J. 2001, 98, 265–275. [Google Scholar] [CrossRef]

- Popovics, S.; Popovics, J.S. Effect of stresses on the ultrasonic pulse velocity in concrete. Mater. Struct. 1991, 24, 15–23. [Google Scholar] [CrossRef]

- Shah, A.A.; Ribakov, Y.; Hirose, S. Nondestructive evaluation of damaged concrete using nonlinear ultrasonics. Mater. Des. 2009, 30, 775–782. [Google Scholar] [CrossRef]

- Shokouhi, P.; Zoëga, A.; Wiggenhauser, H.; Fischer, G. Surface wave velocity-stress relationship in uniaxially loaded concrete. ACI Mater. J. 2012, 109, 141–148. [Google Scholar] [CrossRef][Green Version]

- Diewald, F.; Epple, N.; Kraenkel, T.; Gehlen, C.; Niederleithinger, E. Impact of External Mechanical Loads on Coda Waves in Concrete. Materials 2022, 15, 5482. [Google Scholar] [CrossRef]

- Zhan, H.; Jiang, H.; Zhuang, C.; Zhang, J.; Jiang, R. Estimation of Stresses in Concrete by Using Coda Wave Interferometry to Establish an Acoustoelastic Modulus Database. Sensors 2020, 20, 4031. [Google Scholar] [CrossRef]

- Zhong, B.; Zhu, J. Applications of Stretching Technique and Time Window Effects on Ultrasonic Velocity Monitoring in Concrete. Appl. Sci. 2022, 12, 7130. [Google Scholar] [CrossRef]

- He, Y.; Song, L.; Xue, K.; Liu, S.; Li, H.; Yang, W.; Huang, J. Ultrasonic Coda Wave Experiment and Simulation of Concrete Damage Process under Uniaxial Compression. Buildings 2022, 12, 514. [Google Scholar] [CrossRef]

- Zhang, Y.; Abraham, O.; Grondin, F.; Loukili, A.; Tournat, V.; Le Duff, A.; Lascoup, B.; Durand, O. Study of stress-induced velocity variation in concrete under direct tensile force and monitoring of the damage level by using thermally-compensated Coda Wave Interferometry. Ultrasonics 2012, 52, 1038–1045. [Google Scholar] [CrossRef]

- Croppi, J.I.; Ahrens, M.A.; Palmeri, A.; Piccinin, R.; Mark, P. Experimental investigation on post-installed lap splices in ordinary and steel fiber-reinforced concrete. Mater. Struct. 2024, 57, 180. [Google Scholar] [CrossRef]

- Fib Model Code for Concrete Structures 2010; fib CEB-FIP, Ernst & Sohn: Berlin, Germany, 2013.

- Wu, H.; Gilbert, R.I. An Experimental Study of Tension Stiffening in Reinforced Concrete Members under Short-Term and Long-Term Loads; The University of New South Wales, Australia: Sydney, Australia, 2008. [Google Scholar]

- Forth, J.P.; Beeby, A.W. Study of composite behavior of reinforcement and concrete in tension. ACI Struct. J. 2014, 111, 397–406. [Google Scholar] [CrossRef]

- Rimkus, A.; Gribniak, V. Experimental investigation of cracking and deformations of concrete ties reinforced with multiple bars. Constr. Build. Mater. 2017, 148, 49–61. [Google Scholar] [CrossRef]

- Clauß, F.; Ahrens, M.A.; Mark, P. A comparative evaluation of strain measurement techniques in reinforced concrete structures–A discussion of assembly, application, and accuracy. Struct. Concr. 2021, 22, 2992–3007. [Google Scholar] [CrossRef]

- Yager, J.; Woods, J.E.; Hoult, N.A.; Bentz, E.C. Characterization of concrete tension modulus, softening, and stiffening using distributed sensing. Mater. Struct. 2025, 58, 131. [Google Scholar] [CrossRef]

- Murnaghan, F.D. Finite deformations of an elastic solid. Am. J. Math. 1937, 59, 235–260. [Google Scholar] [CrossRef]

- Hughes, D.S.; Kelly, J.L. Second-Order Elastic Deformation of Solids. Phys. Rev. 1953, 92, 1145–1149. [Google Scholar] [CrossRef]

- Snieder, R. The Theory of Coda Wave Interferometry. Pure Appl. Geophys. 2006, 163, 455–473. [Google Scholar] [CrossRef]

- Planès, T.; Larose, E. A review of ultrasonic Coda Wave Interferometry in concrete. Cem. Concr. Res. 2013, 53, 248–255. [Google Scholar] [CrossRef]

- Sens-Schönfelder, C.; Wegler, U. Passive image interferometry and seasonal variations of seismic velocities at Merapi Volcano, Indonesia. Geophys. Res. Lett. 2006, 33, L21302. [Google Scholar] [CrossRef]

- Niederleithinger, E.; Wang, X.; Herbrand, M.; Müller, M. Processing Ultrasonic Data by Coda Wave Interferometry to Monitor Load Tests of Concrete Beams. Sensors 2018, 18, 1971. [Google Scholar] [CrossRef]

- Wolf, J.; Niederleithinger, E.; Mielentz, F.; Grothe, S.; Wiggenhauser, H. Überwachung von Betonkonstruktionen mit eingebetteten Ultraschallsensoren. Bautechnik 2014, 91, 783–796. [Google Scholar] [CrossRef]

- Niederleithinger, E.; Wolf, J.; Mielentz, F.; Wiggenhauser, H.; Pirskawetz, S. Embedded ultrasonic transducers for active and passive concrete monitoring. Sensors 2015, 15, 9756–9772. [Google Scholar] [CrossRef]

- Fröjd, P.; Ulriksen, P. Frequency selection for coda wave interferometry in concrete structures. Ultrasonics 2017, 80, 1–8. [Google Scholar] [CrossRef]

- Bassil, A.; Wang, X.; Chapeleau, X.; Niederleithinger, E.; Abraham, O.; Leduc, D. Distributed Fiber Optics Sensing and Coda Wave Interferometry Techniques for Damage Monitoring in Concrete Structures. Sensors 2019, 19, 356. [Google Scholar] [CrossRef] [PubMed]

- Schreier, H.; Orteu, J.J.; Sutton, M.A. Image Correlation for Shape, Motion and Deformation Measurements; Springer: Boston, MA, USA, 2009. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Clauß, F.; Ahrens, M.A.; Mark, P. Thermo–mechanical experiments on reinforced concrete beams: Assessing thermal, mechanical, and mixed impacts on fiber optic measurements. Struct. Concr. 2022, 23, 3521–3537. [Google Scholar] [CrossRef]

- DIN EN 12390-1:2021-09; Prüfung von Festbeton_- Teil_1: Form, Maße und Andere Anforderungen für Probekörper und Formen. DIN Media GmbH: Berlin, Germany, 2021. [CrossRef]

| 28.4 | 34.4 | 2.8 | 26,200 | 532 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sträter, N.; Clauß, F.; Ahrens, M.A.; Mark, P. Experimental Crack Width Quantification in Reinforced Concrete Using Ultrasound and Coda Wave Interferometry. Materials 2025, 18, 3684. https://doi.org/10.3390/ma18153684

Sträter N, Clauß F, Ahrens MA, Mark P. Experimental Crack Width Quantification in Reinforced Concrete Using Ultrasound and Coda Wave Interferometry. Materials. 2025; 18(15):3684. https://doi.org/10.3390/ma18153684

Chicago/Turabian StyleSträter, Noah, Felix Clauß, Mark Alexander Ahrens, and Peter Mark. 2025. "Experimental Crack Width Quantification in Reinforced Concrete Using Ultrasound and Coda Wave Interferometry" Materials 18, no. 15: 3684. https://doi.org/10.3390/ma18153684

APA StyleSträter, N., Clauß, F., Ahrens, M. A., & Mark, P. (2025). Experimental Crack Width Quantification in Reinforced Concrete Using Ultrasound and Coda Wave Interferometry. Materials, 18(15), 3684. https://doi.org/10.3390/ma18153684