Effect of Plate Thickness on Residual Stress Distribution of GH3039 Superalloy Subjected to Laser Shock Peening

Highlights

- A modified method for parameter C of J-C constitutive model is proposed at ultra-high strain rate.

- An analytical model for laser impact induced plate bending is put forward.

- Plate thickness has an obvious effect on residual stress field in LSP GH3039 at the same parameters.

- Residual stress in GH3039 is the superposition of two stress fields induced by LSP and plate bending.

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and the Specimen Preparation

2.2. LSP Procedure

2.3. Residual Stress Measurement

2.4. Selection of Constitutive Mode

2.5. Quasi-Static Tensile Test at Different Temperatures

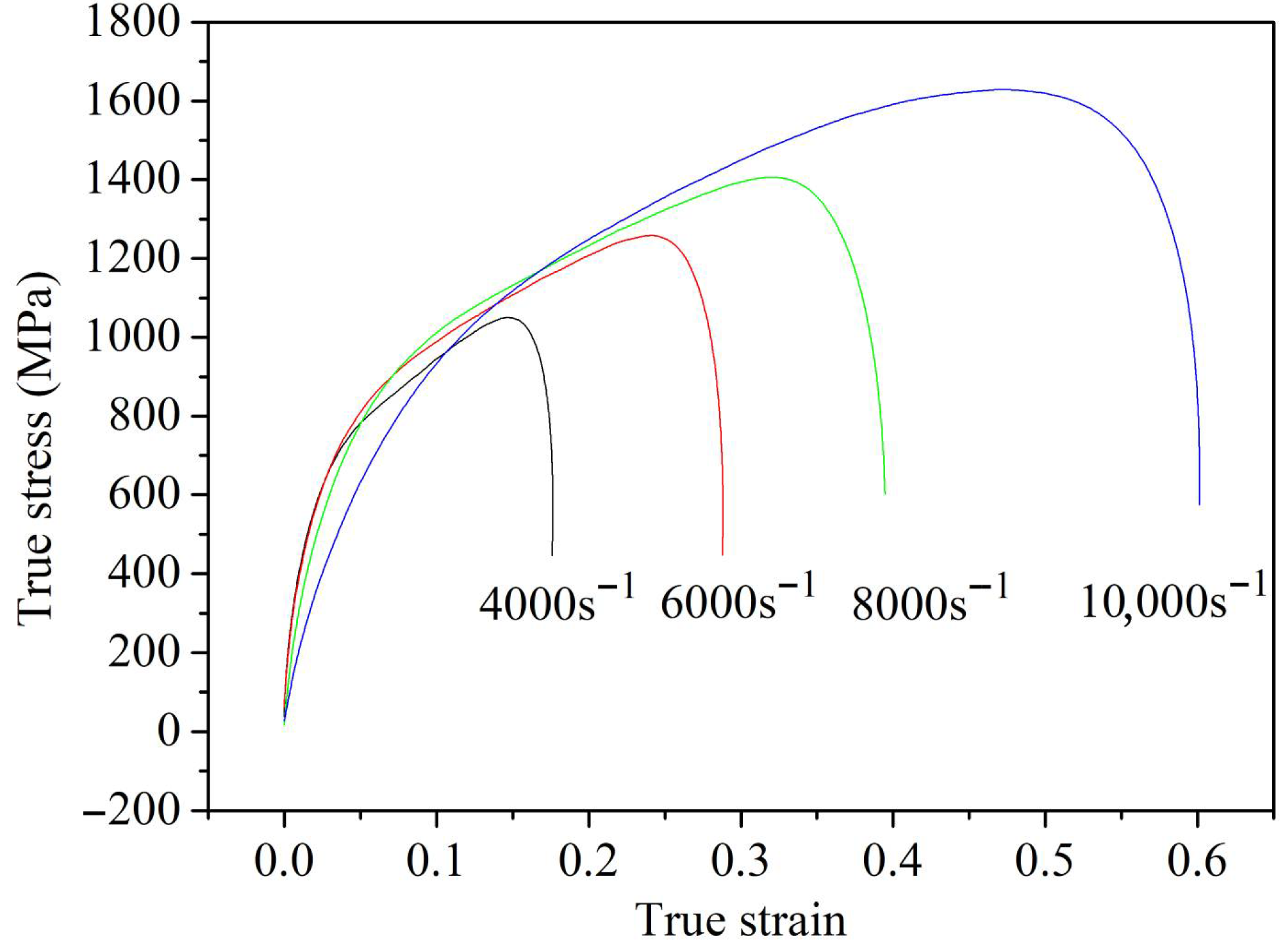

2.6. SHPB Test

2.7. LSP Numerical Simulation

3. Results and Discussion

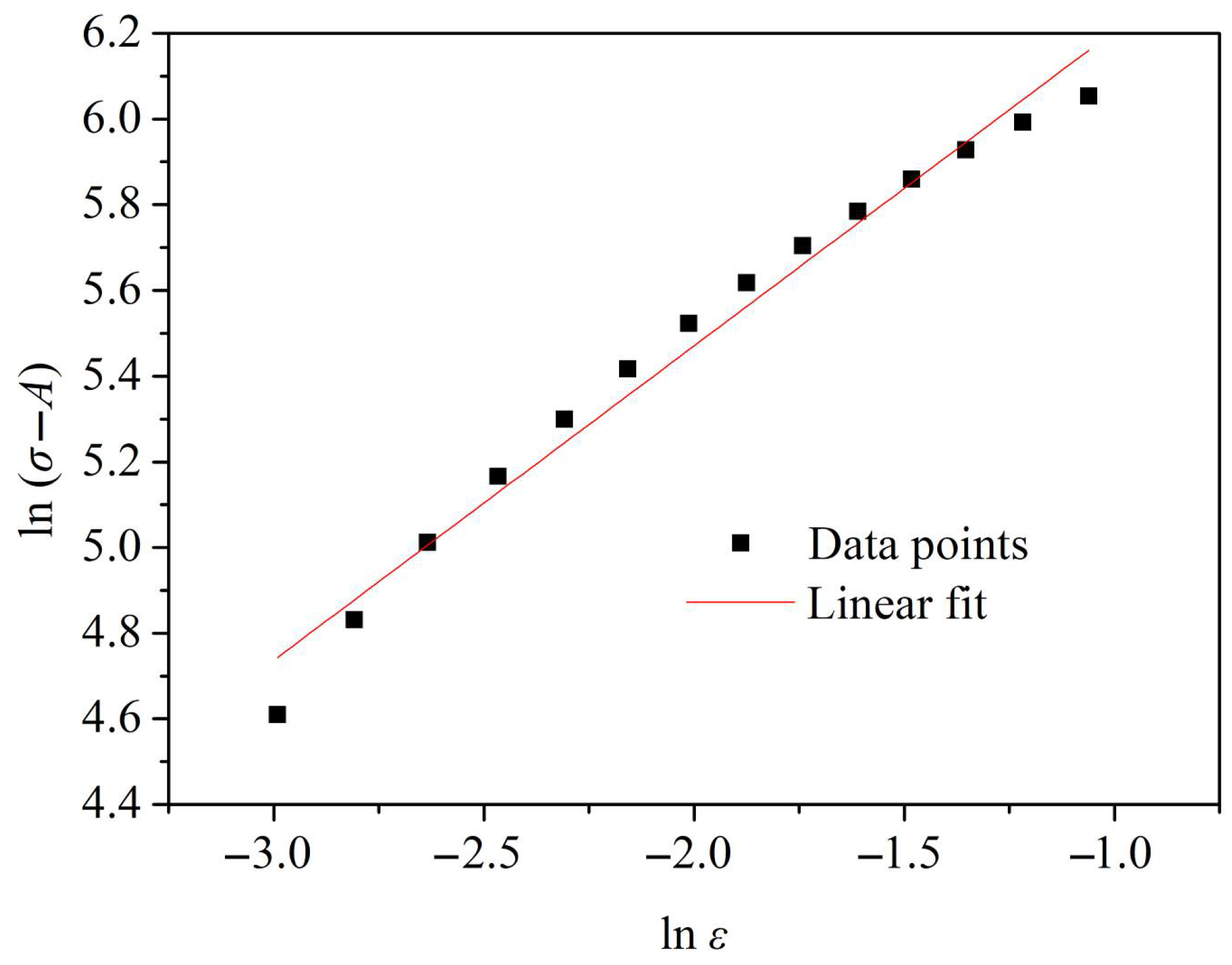

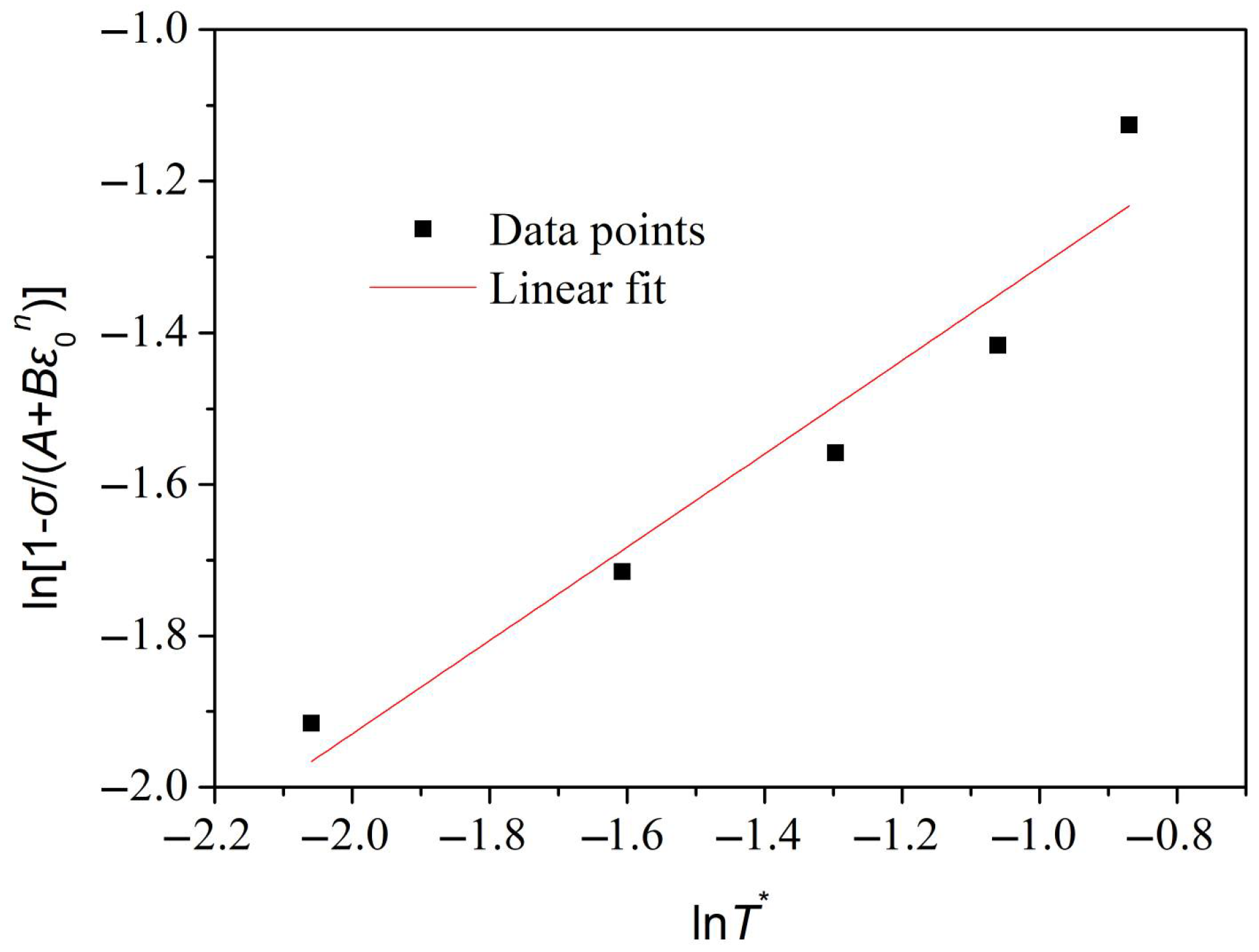

3.1. Establishment and Validation of J-C Constitutive Equation of LSP-Processed GH3039

3.1.1. Establishment of J-C Constitutive Equation of GH3039 at Strain Rate of 104 s−1

3.1.2. Establishment of J-C Constitutive Equation of GH3039 at Ultra-High Strain Rate

3.1.3. Validation of J-C Constitutive Equation of GH3039 at Ultra-High Strain Rate

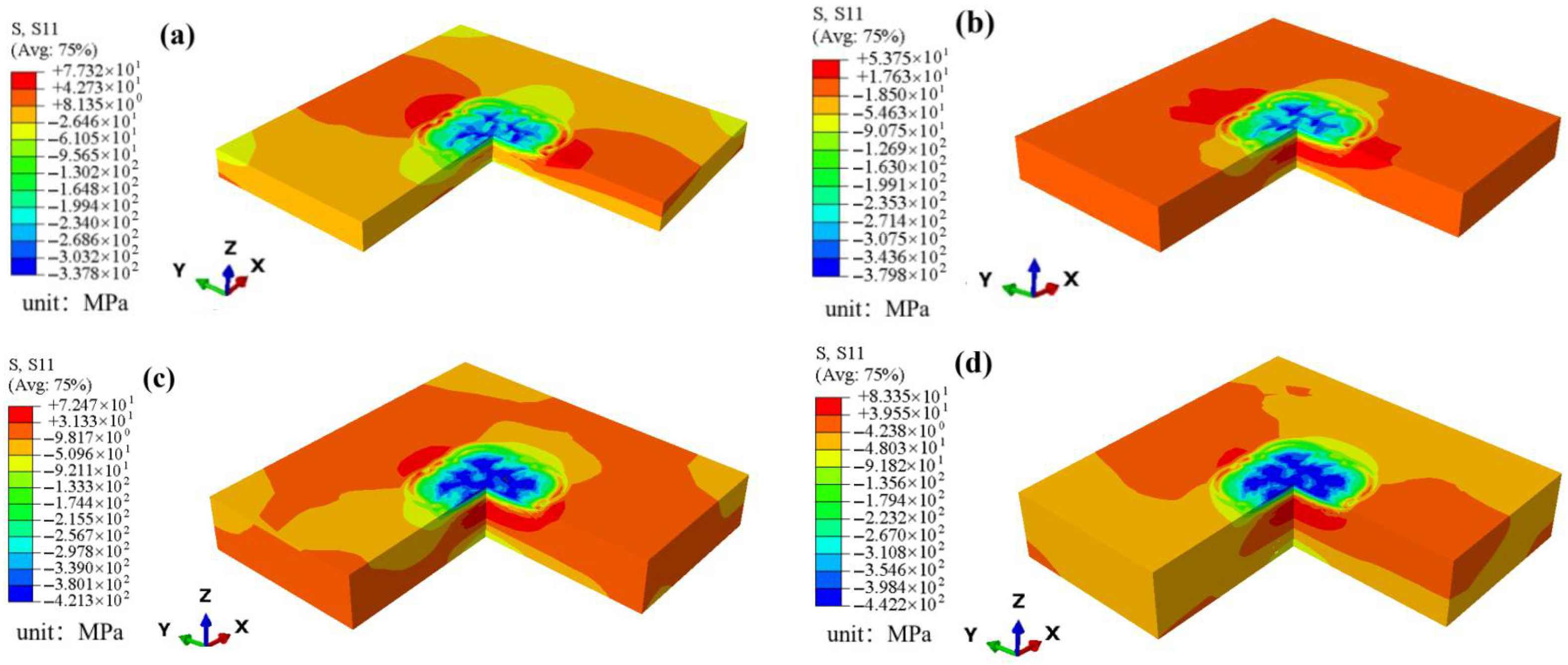

3.2. Residual Stress Distributions as a Function of Plate Thickness After One-Sided LSP

3.3. Bending Deformation Degree as a Function of Plate Thickness After One-Sided LSP

3.4. Influence Mechanism of Plate Thickness on the Residual Stress Field of LSP-Processed GH3039

4. Conclusions

- (1)

- Based on the results of quasi-static tensile tests and separated Hopkinson bar tests, the J-C constitutive equation for GH3039 under a given strain rate was derived through data fitting.

- (2)

- By comparing finite element simulations with LSP experimental results, the strain-rate coefficient C in the GH3039 J-C constitutive equation was modified. A constitutive equation for GH3039 at ultra-high strain rates is .

- (3)

- The final residual stress distribution in the laser-shocked GH3039 alloy plate is the linear superposition of the initial stress field induced by LSP in the thickness direction and the stress field caused by the plate bending.

- (4)

- The residual stress field in GH3039 alloy plates is significantly influenced by plate thickness under the same LSP conditions. As the plate thickness increases, both the magnitude and the distribution depth of the residual compressive stress on the laser-treated surface of the GH3039 plates exhibit an increasing trend. This is primarily attributed to the higher bending stiffness of thicker plates, which reduces the harmful coupling effect caused by the reflected tensile wave.

- (5)

- With the help of the GH3039 J-C constitutive model and numerical method, the ideal residual stress field distribution of GH3039 superalloy can be obtained by adjusting the laser processing parameters to meet the service requirements of aerospace components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nie, X.F.; He, W.F.; Zhou, L.C.; Li, Q.P.; Wang, X.D. Experiment investigation of LSP on TC6 titanium alloy to improve high cycle fatigue performance. Mater. Sci. Eng. A 2014, 594, 161–167. [Google Scholar] [CrossRef]

- Ge, M.Z.; Tang, Y.; Zhang, Y.K.; Wang, Y. Enhancement in fatigue property of Ti-6Al-4V alloy remanufactured by combined laser cladding and LSP processes. Surf. Coat. Tech. 2022, 444, 128671. [Google Scholar] [CrossRef]

- Wu, J.F.; Zou, S.K.; Zhang, Y.K.; Gong, S.L.; Sun, G.F.; Ni, Z.H.; Cao, Z.W.; Che, Z.G.; Feng, A.X. Microstructures and mechanical properties of β forging Ti17 alloy under combined laser shock processing and shot peening. Surf. Coat. Tech. 2017, 328, 283–291. [Google Scholar] [CrossRef]

- Luong, H.; Hill, M.R. The effects of laser peening and shot peening on high cycle fatigue in 7050-T7451 aluminum alloy. Mater. Sci. Eng. A 2010, 527, 699–707. [Google Scholar] [CrossRef]

- Tang, Y.; Ge, M.Z.; Zhang, Y.K.; Wang, T.M.; Wang, Y. Improvement of Fatigue Life of GH3039 Superalloy by Laser Shock Peening. Materials 2020, 13, 3489. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.D.; Zhou, W.F.; Ren, Y.P.; Xu, S.D.; Liu, F.F.; Yuan, S.Q.; Ren, N.F.; Huang, J.J. Dislocation evolution and properties enhancement of GH2036 by laser shock processing: Dislocation dynamics simulation and experiment. Mater. Sci. Eng. A 2016, 654, 184–192. [Google Scholar] [CrossRef]

- Kattoura, R.; Keller, S.; Qian, D.; Kashaev, N. Identification of Johnson-Cook. material model parameters for laser shock peening process simulation for AA2024, Ti–6Al–4V and Inconel 718. J. Meter. Res. Technol. 2024, 28, 1975–1989. [Google Scholar]

- Fang, Y.W.; Li, Y.H.; He, W.F.; Lu, Y.J.; Li, P.Y. Numerical simulation of residual stresses fields of DD6 blade during laser shock processing. Mater. Des. 2013, 43, 170–176. [Google Scholar] [CrossRef]

- Wu, J.J.; Zhao, J.B.; Qiao, H.C.; Lu, Y.; Sun, B.Y.; Hu, X.L.; Yang, Y. A method to determine the material constitutive model parameters of FGH4095 alloy treated by laser shock processing. Appl. Surf. Sci. Adv. 2020, 1, 100029. [Google Scholar] [CrossRef]

- Ge, M.Z.; Xiang, J.Y. Effect of LSP on microstructure and fatigue crack growth rate of AZ31B magnesium alloy. J. Alloy. Compd. 2016, 680, 544–552. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Steinberg, D.J.; Cochran, S.G.; Guinan, M.W. A constitutive model for metals applicable at high-strain rate. J. Appl. Phys. 1980, 51, 1498–1504. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculation. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef]

- Vasu, A.; Gobal, K.; Grandhi, R.V. A computational methodology for determining the optimum re-peening schedule to increase the fatigue life of laser peened aircraft components. Int. J. Fatigue 2015, 70, 395–405. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Wang, X.G.; Huang, C.Z.; Zou, B.; Liu, H.L.; Zhu, H.T.; Wang, J. Dynamic behavior and a modified Johnson-Cook. constitutive model of Inconel 718 at high strain rate and elevated temperature. Mater. Sci. Eng. A 2013, 580, 385–390. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Huang, Z.W.; Chen, B.; Zhang, Y.W.; Tong, J.Y.; Fang, G.W.; Duan, S.W. Investigation on residual stress distribution in thin plate subjected to two-sided laser shock processing. Opt. Laser Technol. 2019, 111, 146–155. [Google Scholar] [CrossRef]

- Ocaña, J.L.; Correa, C.; García-Beltrán, A.; Porro, J.A.; Díaz, M.; Ruiz-de-Lara, L.; Peral, D. Laser shock processing of thin Al2024-T351 plates for induction of through-thickness compressive residual stresses fields. J. Mater. Process. Technol. 2015, 223, 8–15. [Google Scholar] [CrossRef]

- Meng, X.K.; Leng, X.M.; Shan, C.; Zhou, L.C.; Zhou, J.Z.; Huang, S.; Lu, J.Z. Vibration fatigue performance improvement in 2024-T351 aluminum alloy by ultrasonic-assisted LSP. Int. J. Fatigue 2023, 168, 107471. [Google Scholar] [CrossRef]

| C | Cr | Al | Ti | Mo | Nb | Fe | Si | S | Mn | P | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.051 | 21.00 | 0.57 | 0.59 | 2.10 | 1.11 | 3.00 | 0.80 | 0.012 | 0.40 | 0.020 | Bal. |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Val. | −319.3 | −326.5 | −324.1 | −309.5 | −318.1 | −324.8 | −311.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Ge, M.; Zhang, Y. Effect of Plate Thickness on Residual Stress Distribution of GH3039 Superalloy Subjected to Laser Shock Peening. Materials 2025, 18, 3682. https://doi.org/10.3390/ma18153682

Ma Y, Ge M, Zhang Y. Effect of Plate Thickness on Residual Stress Distribution of GH3039 Superalloy Subjected to Laser Shock Peening. Materials. 2025; 18(15):3682. https://doi.org/10.3390/ma18153682

Chicago/Turabian StyleMa, Yandong, Maozhong Ge, and Yongkang Zhang. 2025. "Effect of Plate Thickness on Residual Stress Distribution of GH3039 Superalloy Subjected to Laser Shock Peening" Materials 18, no. 15: 3682. https://doi.org/10.3390/ma18153682

APA StyleMa, Y., Ge, M., & Zhang, Y. (2025). Effect of Plate Thickness on Residual Stress Distribution of GH3039 Superalloy Subjected to Laser Shock Peening. Materials, 18(15), 3682. https://doi.org/10.3390/ma18153682