Advances in Interfacial Engineering and Structural Optimization for Diamond Schottky Barrier Diodes

Abstract

1. Introduction

2. Diamond Schottky Barrier Diodes (SBDs)

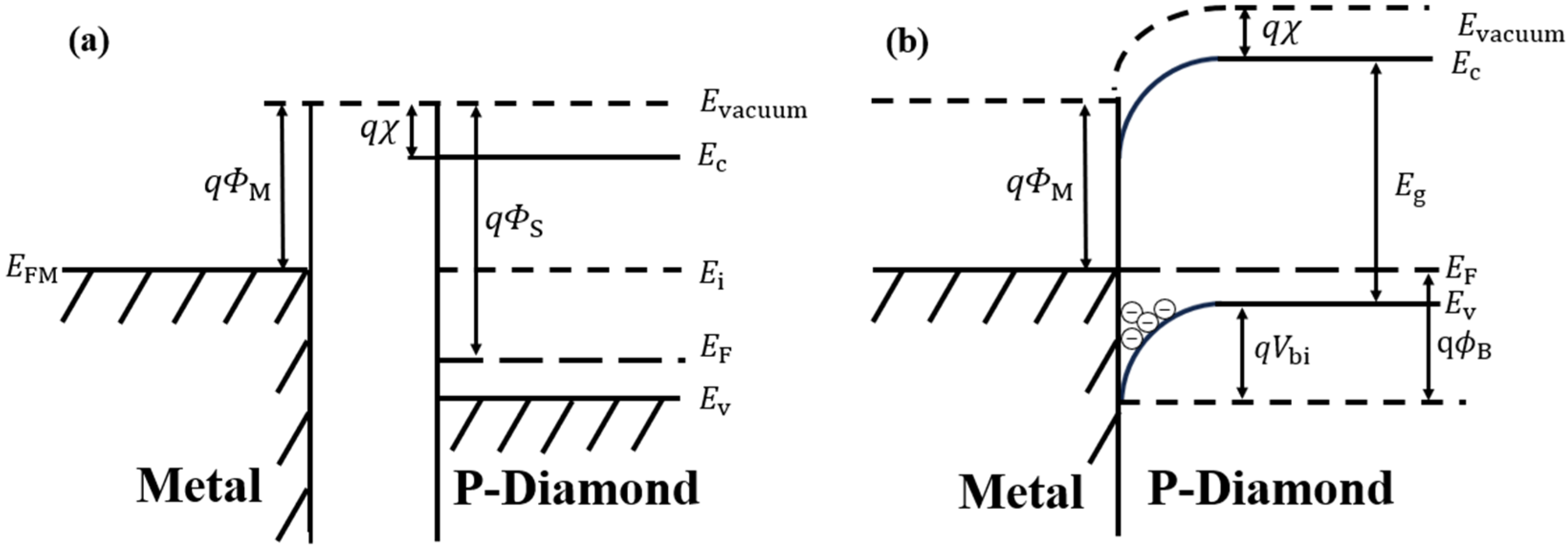

2.1. Energy Band Contacts in Diamond SBDs

2.2. Extraction of Key Parameters in SBDs

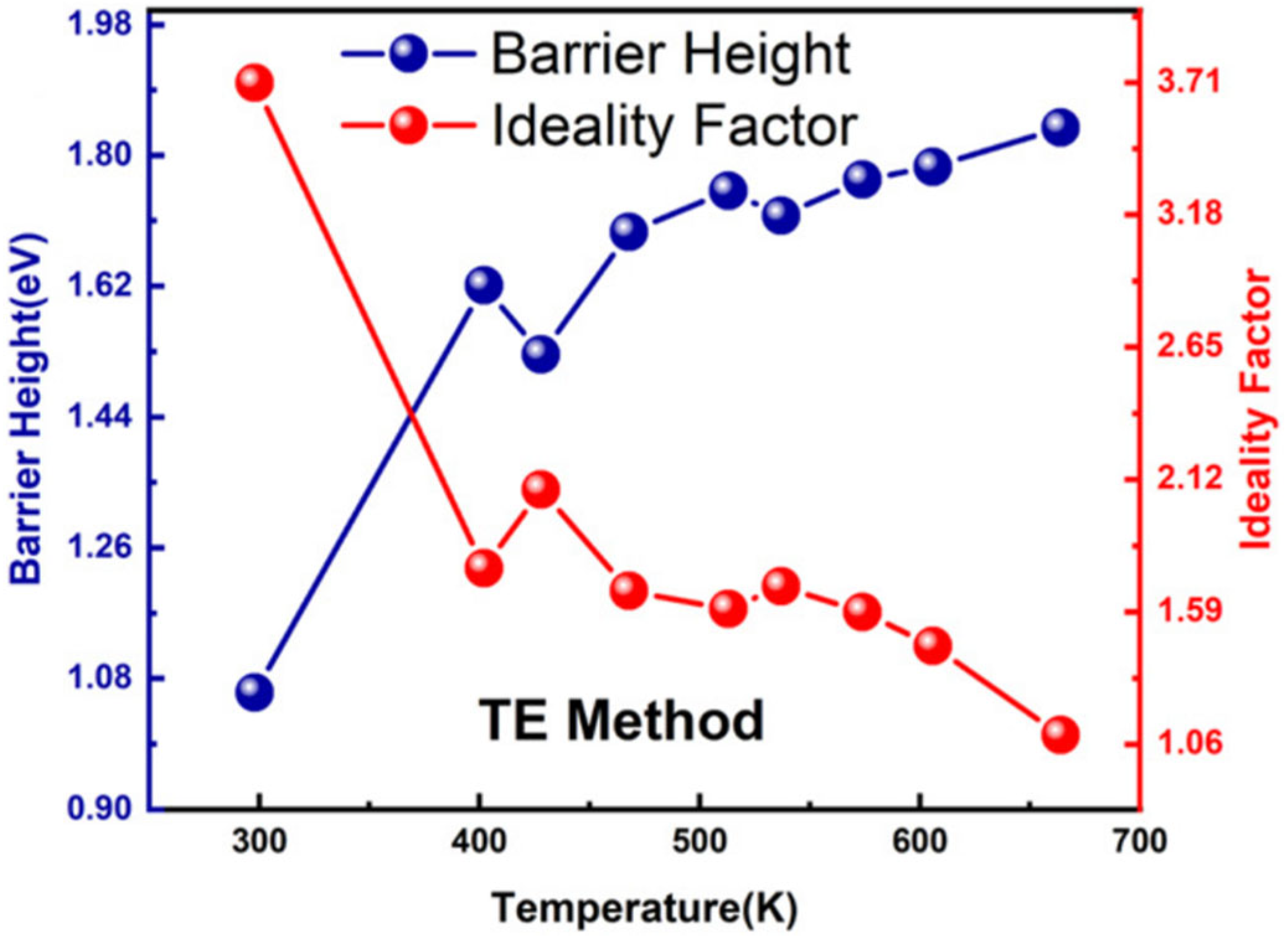

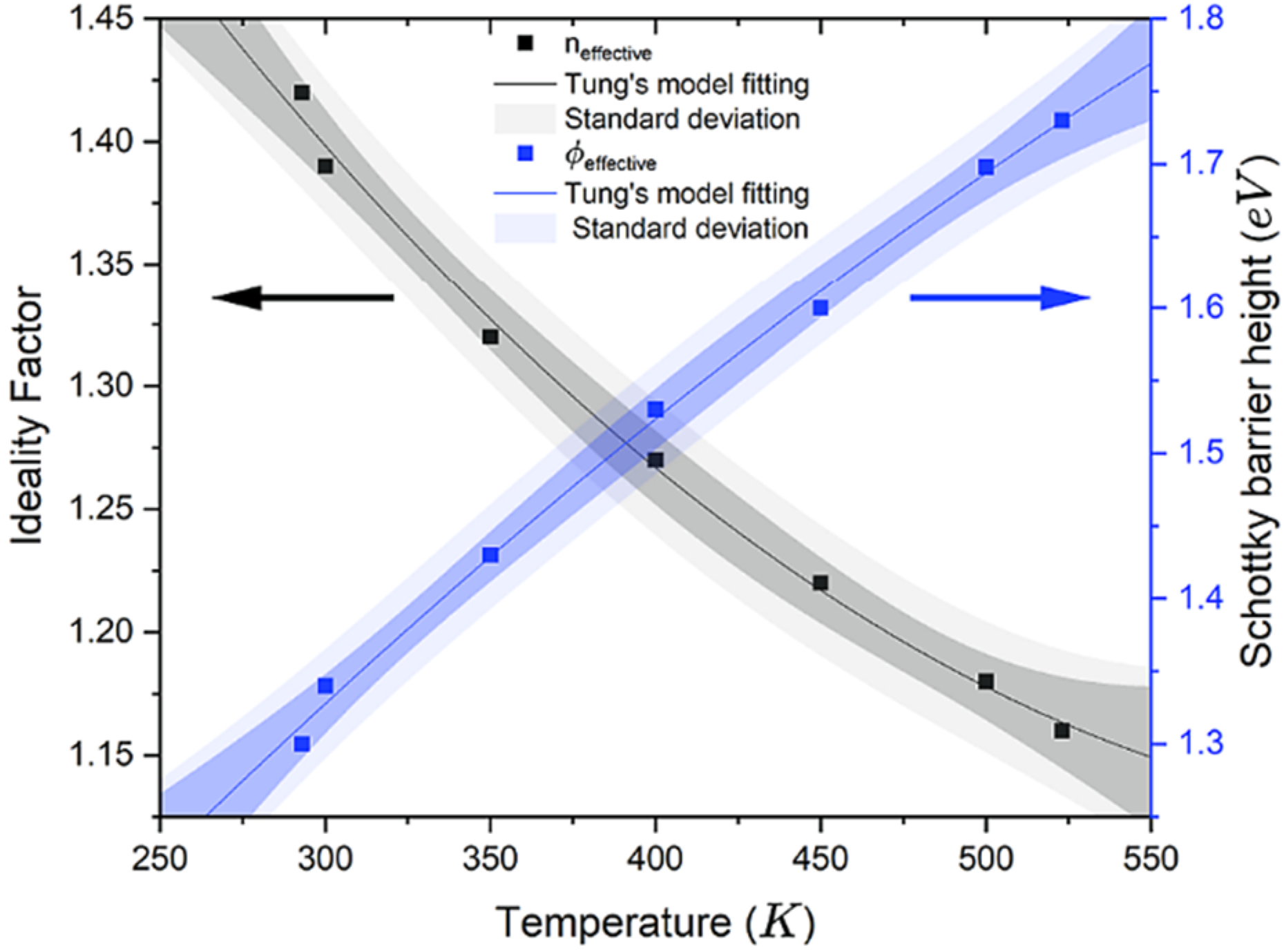

2.3. Barrier Inhomogeneity Modeling and Temperature Dependence in Diamond SBDs

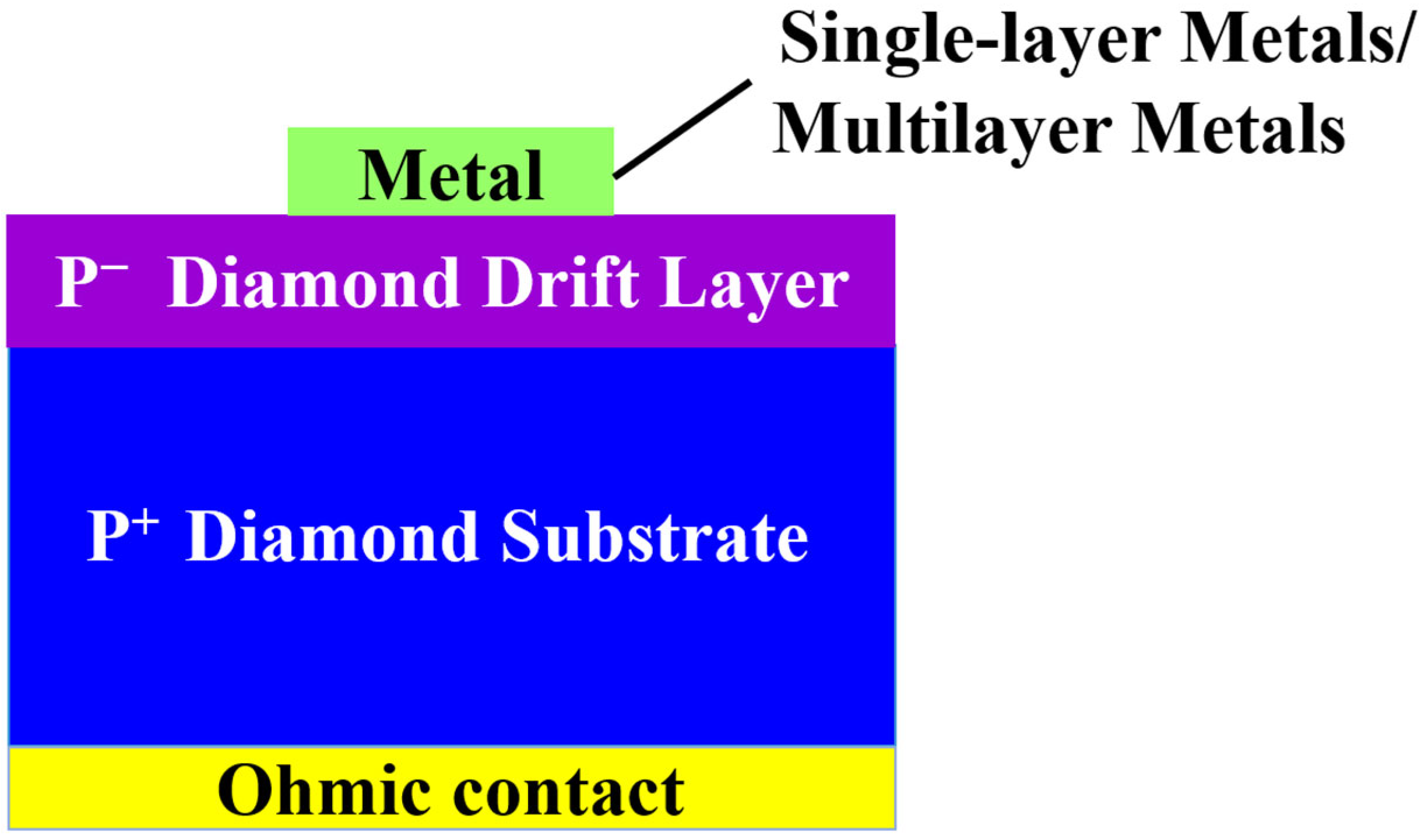

3. Research Progress of Diamond MS SBDs

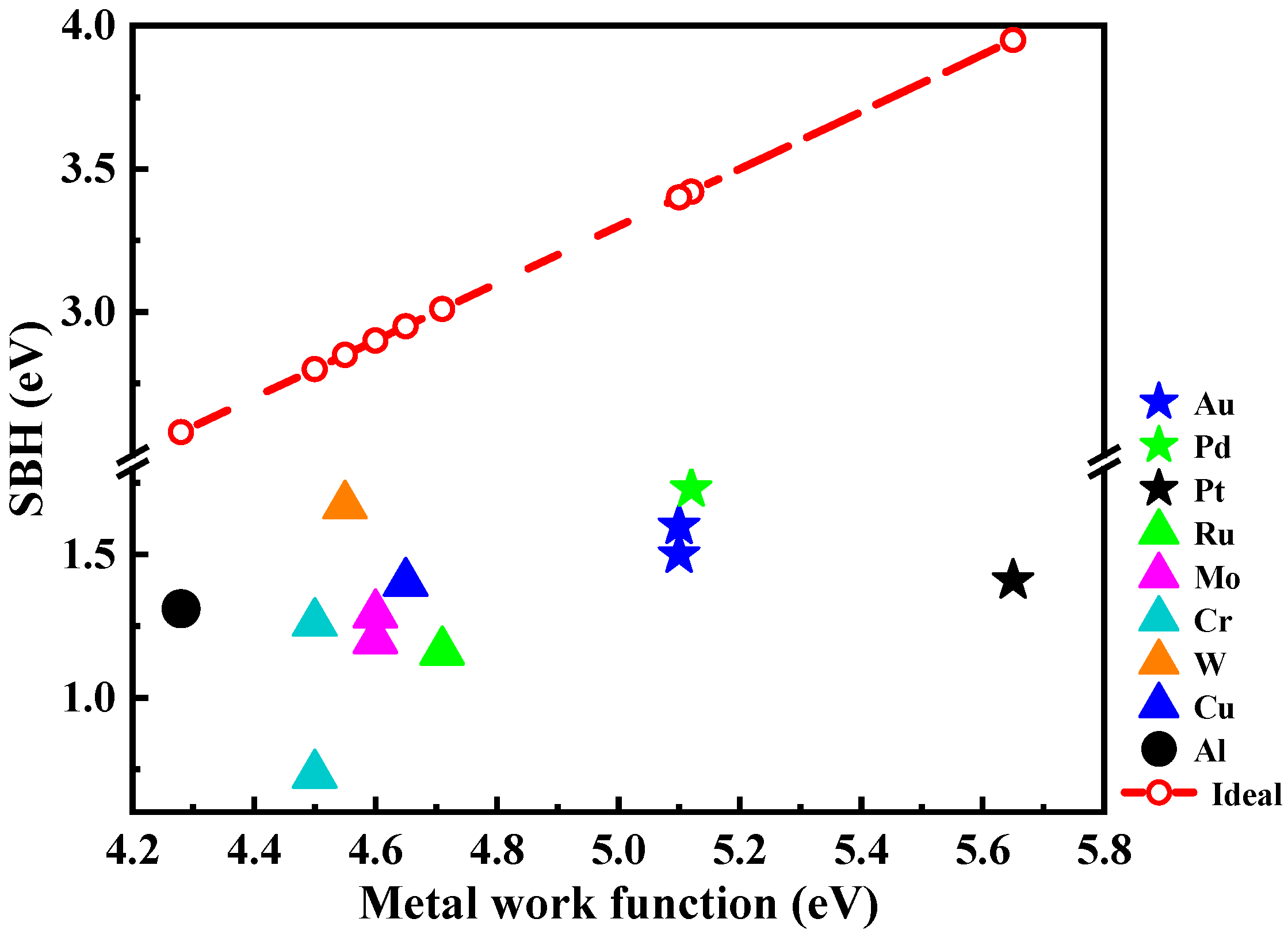

3.1. Single-Layer Metals/Diamond SBDs

3.1.1. Nobel Metals/Diamond SBDs

3.1.2. Transition Metals/Diamond SBDs

3.1.3. Other Metals/Diamond SBDs

3.2. Multilayer Metals/Diamond SBDs

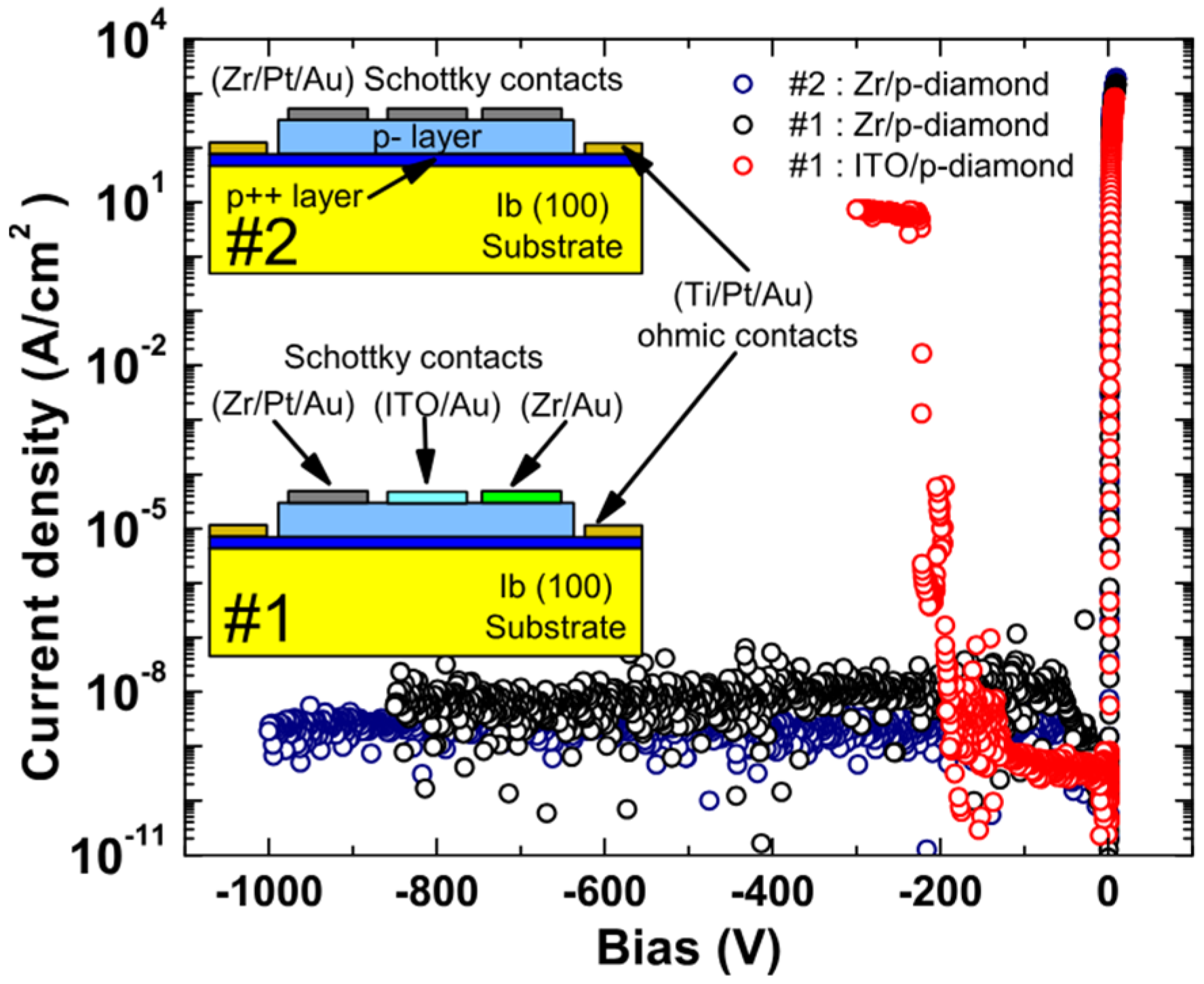

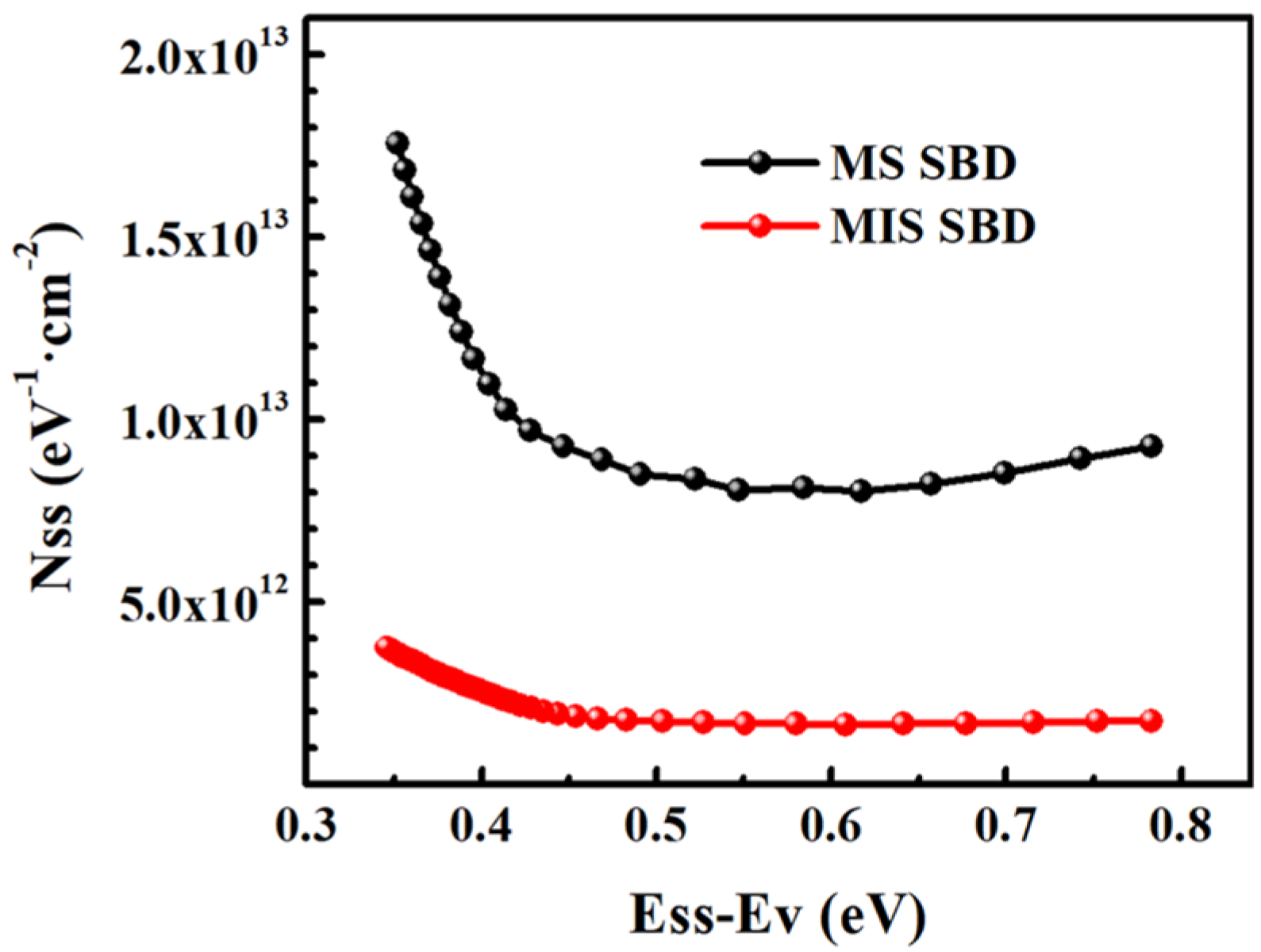

4. Research Progress of Diamond MIS SBDs

4.1. Interface Passivation Interlayers

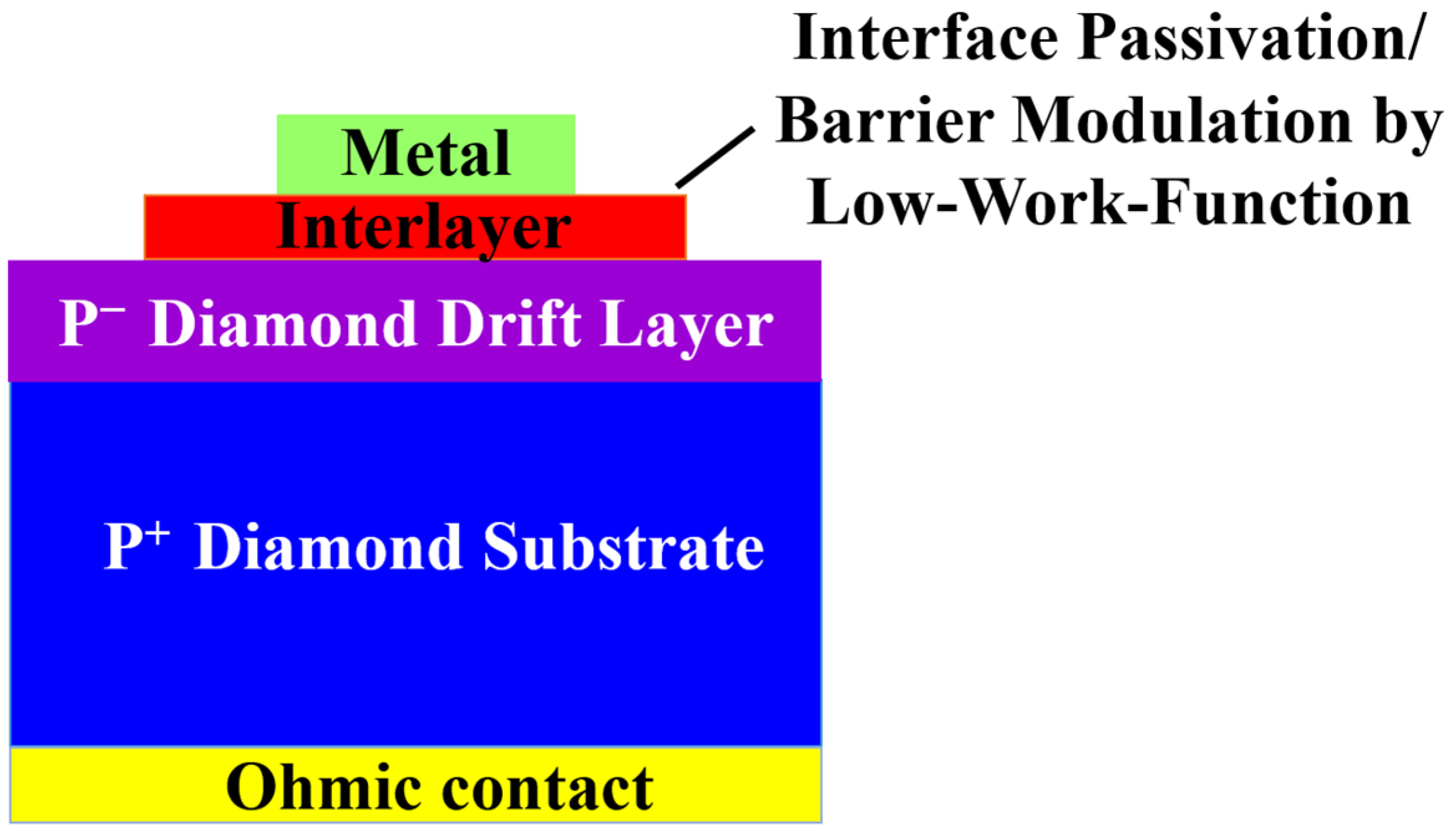

4.2. Barrier Modulation by Low-Work-Function Interlayers

4.3. Terminal Electric Field Control Interlayers

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pernot, J.; Koizumi, S. Electron mobility in phosphorous doped {111} homoepitaxial diamond. Appl. Phys. Lett. 2008, 93, 052105. [Google Scholar] [CrossRef]

- Davies, G. Properties and Growth of Diamond; The Institution of Electrical Engineers: London, UK, 1994; p. 438. [Google Scholar]

- Butler, J.; Geis, M.; Krohn, K.; Lawless, J., Jr.; Deneault, S.; Lyszczarz, T.; Flechtner, D.; Wright, R. Exceptionally high voltage Schottky diamond diodes and low boron doping. Semicond. Sci. Technol. 2003, 18, S67. [Google Scholar] [CrossRef]

- Isberg, J.; Hammersberg, J.; Johansson, E.; Wikstrom, T.; Twitchen, D.J.; Whitehead, A.J.; Coe, S.E.; Scarsbrook, G.A. High carrier mobility in single-crystal plasma-deposited diamond. Science 2002, 297, 1670–1672. [Google Scholar] [CrossRef] [PubMed]

- Landstrass, M.; Plano, M.; Moreno, M.; McWilliams, S.; Pan, L.; Kania, D.; Han, S. Device properties of homoepitaxially grown diamond. Diam. Relat. Mater. 1993, 2, 1033–1037. [Google Scholar] [CrossRef]

- Huang, A.Q. New unipolar switching power device figures of merit. IEEE Electron. Device Lett. 2004, 25, 298–301. [Google Scholar] [CrossRef]

- Funaki, T.; Kodama, K.; Umezawa, H.; Shikata, S. Characterization of fast switching capability for diamond Schottky barrier diode. Mater. Sci. Forum 2011, 679, 820–823. [Google Scholar] [CrossRef]

- Umezawa, H.; Mokuno, Y.; Yamada, H.; Chayahara, A.; Shikata, S.-i. Characterization of Schottky barrier diodes on a 0.5-inch single-crystalline CVD diamond wafer. Diam. Relat. Mater. 2010, 19, 208–212. [Google Scholar] [CrossRef]

- Tsao, J.; Chowdhury, S.; Hollis, M.; Jena, D.; Johnson, N.; Jones, K.; Kaplar, R.; Rajan, S.; Van de Walle, C.; Bellotti, E.; et al. Ultrawide-bandgap semiconductors: Research opportunities and challenges. Adv. Electron. Mater. 2018, 4, 1600501. [Google Scholar] [CrossRef]

- Baumann, P.; Bozeman, S.; Ward, B.; Nemanich, R. Characterization of metal-diamond interfaces: Electron affinity and Schottky barrier height. Diam. Relat. Mater. 1997, 6, 398–402. [Google Scholar] [CrossRef]

- Baumann, P.; Nemanich, R. Characterization of copper-diamond (100), (111), and (110) interfaces: Electron affinity and Schottky barrier. Phys. Rev. B 1998, 58, 1643. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, J.; Liu, J.; Wei, J.; Da, B.; Li, C.; Koide, Y. Reliable Ohmic Contact Properties for Ni/Hydrogen-Terminated Diamond at Annealing Temperature up to 900 °C. Coatings 2021, 11, 470. [Google Scholar] [CrossRef]

- Takeuchi, D.; Ogura, M.; Ri, S.G.; Kato, H.; Okushi, H.; Yamasaki, S. Electron emission suppression from hydrogen-terminated n-type diamond. Diam. Relat. Mater. 2008, 17, 986–988. [Google Scholar] [CrossRef]

- Gaowei, M.; Muller, E.M.; Rumaiz, A.K.; Weiland, C.; Cockayne, E.; Jordan-Sweet, J.; Smedley, J.; Woicik, J. Annealing dependence of diamond-metal Schottky barrier heights probed by hard x-ray photoelectron spectroscopy. Appl. Phys. Lett. 2012, 100, 201606. [Google Scholar] [CrossRef]

- Garino, Y.; Teraji, T.; Koizumi, S.; Koide, Y.; Ito, T. p-type diamond Schottky diodes fabricated by vacuum ultraviolet light/ozone surface oxidation: Comparison with diodes based on wet-chemical oxidation. Phys. Status Solidi A 2009, 206, 2082–2085. [Google Scholar] [CrossRef]

- Glover, G. The CV characteristics of Schottky barriers on laboratory grown semiconducting diamonds. Solid-State Electron. 1973, 16, 973–978. [Google Scholar] [CrossRef]

- Kiyota, H.; Matsushima, E.; Sato, K.; Okushi, H.; Ando, T.; Kamo, M.; Sato, Y.; Iida, M. Electrical properties of Schottky barrier formed on as-grown and oxidized surface of homoepitaxially grown diamond (001) film. Appl. Phys. Lett. 1995, 67, 3596–3598. [Google Scholar] [CrossRef]

- Kono, S.; Kodama, H.; Ichikawa, K.; Yoshikawa, T.; Abukawa, T.; Sawabe, A. Electron spectro-microscopic determination of barrier height and spatial distribution of Au and Ag Schottky junctions on boron-doped diamond (001). Jpn. J. Appl. Phys. 2014, 53, 05FP03. [Google Scholar] [CrossRef]

- Mead, C.; McGill, T. Schottky barrier heights on p-type diamond and silicon carbide (6H). Phys. Lett. A 1976, 58, 249–251. [Google Scholar] [CrossRef]

- Takeuchi, D.; Yamanaka, S.; Watanabe, H.; Okushi, H. Device Grade B-Doped Homoepitaxial Diamond Thin Films. Phys. Status Solidi A 2001, 186, 269–280. [Google Scholar] [CrossRef]

- Teraji, T.; Garino, Y.; Koide, Y.; Ito, T. Low-leakage p-type diamond Schottky diodes prepared using vacuum ultraviolet light/ozone treatment. J. Appl. Phys. 2009, 105, 126109. [Google Scholar] [CrossRef]

- Yamanaka, S.; Takeuchi, D.; Watanabe, H.; Okushi, H.; Kajimura, K. Low-compensated boron-doped homoepitaxial diamond films. Diam. Relat. Mater. 2000, 9, 956–959. [Google Scholar] [CrossRef]

- Zhen, C.; Wang, X.; Wu, X.; Liu, C.; Hou, D. Au/p-diamond ohmic contacts deposited by RF sputtering. Appl. Surf. Sci. 2008, 255, 2916–2919. [Google Scholar] [CrossRef]

- Li, F.; Liu, J.; Zhang, J.; Wang, X.; Wang, W.; Liu, Z.; Wang, H. Measurement of barrier height of Pd on diamond (100) surface by X-ray photoelectron spectroscopy. Appl. Surf. Sci. 2016, 370, 496–500. [Google Scholar] [CrossRef]

- Umezawa, H.; Ikeda, K.; Kumaresan, R.; Tatsumi, N.; Shikata, S.I. Increase in reverse operation limit by barrier height control of diamond Schottky barrier diode. IEEE Electron. Device Lett. 2009, 30, 960–962. [Google Scholar] [CrossRef]

- Tsugawa, K.; Noda, H.; Hirose, K.; Kawarada, H. Schottky barrier heights, carrier density, and negative electron affinity of hydrogen-terminated diamond. Phys. Rev. B 2010, 81, 045303. [Google Scholar] [CrossRef]

- Kumaresan, R.; Umezawa, H.; Shikata, S. Vertical structure Schottky barrier diode fabrication using insulating diamond substrate. Diam. Relat. Mater. 2010, 19, 1324–1329. [Google Scholar] [CrossRef]

- Nawawi, A.; Tseng, K.; Amaratunga, G.; Umezawa, H.; Shikata, S. Characterization of vertical Mo/diamond Schottky barrier diode from non-ideal I–V and C–V measurements based on MIS model. Diam. Relat. Mater. 2013, 35, 1–6. [Google Scholar] [CrossRef]

- Umezawa, H.; Ikeda, K.; Tatsumi, N.; Ramanujam, K.; Shikata, S.I. Device scaling of pseudo-vertical diamond power Schottky barrier diodes. Diam. Relat. Mater. 2009, 18, 1196–1199. [Google Scholar] [CrossRef]

- Ueda, K.; Kawamoto, K.; Soumiya, T.; Asano, H. High-temperature characteristics of Ag and Ni/diamond Schottky diodes. Diam. Relat. Mater. 2013, 38, 41–44. [Google Scholar] [CrossRef]

- Chen, Y.; Ogura, M.; Okushi, H. Temperature dependence on current–voltage characteristics of nickel/diamond Schottky diodes on high quality boron-doped homoepitaxial diamond film. Appl. Phys. Lett. 2003, 82, 4367–4369. [Google Scholar] [CrossRef]

- Koné, S.; Civrac, G.; Schneider, H.; Isoird, K.; Issaoui, R.; Achard, J.; Gicquel, A. CVD diamond Schottky barrier diode, carrying out and characterization. Diam. Relat. Mater. 2010, 19, 792–795. [Google Scholar] [CrossRef]

- Ohmagari, S.; Teraji, T.; Koide, Y. Non-destructive detection of killer defects of diamond Schottky barrier diodes. J. Appl. Phys. 2011, 110, 056105. [Google Scholar] [CrossRef]

- Liao, M.; Koide, Y.; Alvarez, J. Crystallographic and electrical characterization of tungsten carbide thin films for Schottky contact of diamond photodiode. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2006, 24, 185–189. [Google Scholar] [CrossRef]

- Alba, G.; Leinen, D.; Villar, M.; Alcántara, R.; Piñero, J.; Fiori, A.; Teraji, T.; Araujo, D. Comprehensive nanoscopic analysis of tungsten carbide/Oxygenated-diamond contacts for Schottky barrier diodes. Appl. Surf. Sci. 2021, 537, 147874. [Google Scholar] [CrossRef]

- Uehigashi, Y.; Ohmagari, S.; Umezawa, H.; Yamada, H.; Liang, J.; Shigekawa, N. Fabrication of p+-Si/p-diamond heterojunction diodes and effects of thermal annealing on their electrical properties. Diam. Relat. Mater. 2021, 120, 108665. [Google Scholar] [CrossRef]

- Ri, S.G.; Takeuchi, D.; Tokuda, N.; Okushi, H.; Yamasaki, S. Fermi level pinning-free interface at metals/homoepitaxial diamond (111) films after oxidation treatments. Appl. Phys. Lett. 2008, 92, 112112. [Google Scholar] [CrossRef]

- Baumann, P.; Nemanich, R. Electron affinity and Schottky barrier height of metal–diamond (100), (111), and (110) interfaces. J. Appl. Phys. 1998, 83, 2072–2082. [Google Scholar] [CrossRef]

- Tachibana, T.; Glass, J.; Nemanich, R. Effect of surface hydrogen on metal-diamond interface properties. J. Appl. Phys. 1993, 73, 835–842. [Google Scholar] [CrossRef]

- Lim, W.; Jeong, J.H.; Lee, J.H.; Hur, S.B.; Ryu, J.K.; Kim, K.S.; Kim, T.H.; Song, S.Y.; Yang, J.I.; Pearton, S. Temperature dependence of current-voltage characteristics of Ni–AlGaN/GaN Schottky diodes. Appl. Phys. Lett. 2010, 97, 242103. [Google Scholar] [CrossRef]

- Chen, Y.; Ogura, M.; Yamasaki, S.; Okushi, H. Ohmic contacts on p-type homoepitaxial diamond and their thermal stability. Semicond. Sci. Technol. 2005, 20, 860–863. [Google Scholar] [CrossRef]

- Baliga, B.J. Fundamentals of Power Semiconductor Devices; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Sze, S.M.; Li, Y.; Ng, K.K. Physics of Semiconductor Devices; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Taşçıoğlu, İ.; Aydemir, U.; Altındal, Ş. The explanation of barrier height inhomogeneities in Au/n-Si Schottky barrier diodes with organic thin interfacial layer. J. Appl. Phys. 2010, 108, 064506. [Google Scholar] [CrossRef]

- Tung, R.T. Formation of an electric dipole at metal-semiconductor interfaces. Phys. Rev. B 2001, 64, 205310. [Google Scholar] [CrossRef]

- Rhoderick, E.H. Metal-semiconductor contacts. IEE Proc. I 1982, 129, 1–14. [Google Scholar] [CrossRef]

- Sze, S.; Ng, K. Chapter 3 Metal-Semiconductors Contacts. In Physics of Semiconductor Devices, 3rd ed.; John Wiley & Sons: Hoboken NJ, USA, 2007; pp. 134–196. [Google Scholar]

- Cheung, S.; Cheung, N. Extraction of Schottky diode parameters from forward current-voltage characteristics. Appl. Phys. Lett. 1986, 49, 85–87. [Google Scholar] [CrossRef]

- Sze, S. Semiconductor Devices Physics and Technology; John Wiley & Sons: Hoboken, NJ, USA, 1985. [Google Scholar]

- Cova, P.; Singh, A. Temperature dependence of IV and CV characteristics of Ni/n-CdF2 Schottky barrier type diodes. Solid-State Electron. 1990, 33, 11–19. [Google Scholar] [CrossRef]

- Kar, S.; Panchal, K.; Bhattacharya, S.; Varma, S. On the mechanism of carrier transport in metal-thin-oxide semiconductor diodes on Polycrystalline silicon. IEEE Trans. Electron. Devices 2005, 29, 1839–1845. [Google Scholar] [CrossRef]

- Maeda, K.; Kitahara, E. Metal-induced gap states model of nonideal Au/Si Schottky barrier with low defect density. Appl. Surf. Sci. 1998, 130, 925–929. [Google Scholar] [CrossRef]

- Norde, H. A modified forward IV plot for Schottky diodes with high series resistance. J. Appl. Phys. 1979, 50, 5052–5053. [Google Scholar] [CrossRef]

- Muret, P.; Traoré, A.; Maréchal, A.; Eon, D.; Pernot, J.; Pinẽro, J.; Villar, M.d.P.; Araujo, D. Potential barrier heights at metal on oxygen-terminated diamond interfaces. J. Appl. Phys. 2015, 118, 204505. [Google Scholar] [CrossRef]

- Sato, K.; Yasumura, Y. Study of forward IV plot for Schottky diodes with high series resistance. J. Appl. Phys. 1985, 58, 3655–3657. [Google Scholar] [CrossRef]

- Türüt, A.; Bati, B.; Kökçe, A.; Sağlam, M.; Yalçin, N. The bias-dependence change of barrier height of Schottky diodes under forward bias by including the series resistance effect. Phys. Scr. 1996, 53, 118. [Google Scholar] [CrossRef]

- Card, H.; Rhoderick, E. Studies of tunnel MOS diodes I. Interface effects in silicon Schottky diodes. J. Phys. D Appl. Phys. 1971, 4, 1589. [Google Scholar] [CrossRef]

- Heine, V. Theory of surface states. Phys. Rev. 1965, 138, A1689. [Google Scholar] [CrossRef]

- Werner, J.H.; Güttler, H.H. Barrier inhomogeneities at Schottky contacts. J. Appl. Phys. 1991, 69, 1522–1533. [Google Scholar] [CrossRef]

- Werner, J.H. HH Güttler. J. Appl. Phys. 1991, 69, 1523. [Google Scholar]

- Werner, J.; Levi, A.; Tung, R.; Anzlowar, M.; Pinto, M. Origin of the excess capacitance at intimate Schottky contacts. Phys. Rev. Lett. 1988, 60, 53–56. [Google Scholar] [CrossRef]

- Brezeanu, G.; Pristavu, G.; Draghici, F.; Pascu, R.; Della Corte, F.; Rascuna, S. Enhanced non-uniformity modeling of 4H-SiC Schottky diode characteristics over wide high temperature and forward bias ranges. IEEE J. Electron Devices Soc. 2020, 8, 1339–1344. [Google Scholar] [CrossRef]

- Schroder, D.K. Semiconductor Material and Device Characterization; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Werner, J.; Ploog, K.; Queisser, H. Interface-state measurements at Schottky contacts: A new admittance technique. Phys. Rev. Lett. 1986, 57, 1080. [Google Scholar] [CrossRef]

- Card, H. On the direct currents through interface states in metal-semiconductor contacts. Solid-State Electron. 1975, 18, 881–883. [Google Scholar] [CrossRef]

- Türüt, A.; Yalçin, N.; Saǧlam, M. Parameter extraction from non-ideal C−V characteristics of a Schottky diode with and without interfacial layer. Solid-State Electron. 1992, 35, 835–841. [Google Scholar] [CrossRef]

- Werner, J.; Tung, R.; Levi, A.; Anzlowar, M. Admittance Measurements at Epitaxial and Nonepitaxial Silicide Schottky Contacts. MRS Online Proc. Libr. 1987, 91, 433. [Google Scholar] [CrossRef]

- Werner, J.H. Electrical characterization of interface states at Schottky contacts and MIS tunnel diodes. In Metallization and Metal-Semiconductor Interfaces; Springer: Cham, Switzerland, 1989; pp. 235–256. [Google Scholar]

- Ho, P.S.; Yang, E.S.; Evans, H.L.; Wu, X. Electronic states at silicide-silicon interfaces. Phys. Rev. Lett. 1986, 56, 177–180. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Yang, E.S. Interface capacitance in metal-semiconductor junctions. J. Appl. Phys. 1989, 65, 3560–3567. [Google Scholar] [CrossRef]

- Singh, A. Characterization of interface states at Ni/nCdF2 Schottky barrier type diodes and the effect of CdF2 surface preparation. Solid-State Electron. 1985, 28, 223–232. [Google Scholar] [CrossRef]

- Rouger, N.; Maréchal, A. Design of diamond power devices: Application to Schottky barrier diodes. Energies 2019, 12, 2387. [Google Scholar] [CrossRef]

- Schlamp, G. Noble metals and noble metal alloys. In Handbook of Materials Data; Springer: Cham, Switzerland, 2018; pp. 339–412. [Google Scholar]

- Nasr-Esfahani, P.; Ensafi, A.A. Noble metals and nonnoble metal oxides based electrochemical sensors. In Functionalized Nanomaterial-Based Electrochemical Sensors; Woodhead Publishing: Cambridge, UK, 2022; pp. 115–140. [Google Scholar]

- Pan, M.; Yang, J.; Liu, K.; Yin, Z.; Ma, T.; Liu, S.; Xu, L.; Wang, S. Noble metal nanostructured materials for chemical and biosensing systems. Nanomaterials 2020, 10, 209. [Google Scholar] [CrossRef]

- Teraji, T.; Koide, Y.; Ito, T. Schottky barrier height and thermal stability of p-diamond (100) Schottky interfaces. Thin Solid Films 2014, 557, 241–248. [Google Scholar] [CrossRef]

- Liang, B.; Liu, B.; Fan, S.; Li, C.; Zhang, W.; Xue, J.; Yang, S.; Zhang, S.; Liu, K.; Dai, B.; et al. High sensitivity DTSs based on diamond with a low doping drift layer. IEEE Sens. J. 2024, 24, 20368–20374. [Google Scholar] [CrossRef]

- Tersoff, J.; Harrison, W.A. Transition-metal impurities in semiconductors—Their connection with band lineups and Schottky barriers. Phys. Rev. Lett. 1987, 58, 2367. [Google Scholar] [CrossRef]

- Mönch, W. Barrier heights of metal contacts on H-terminated diamond: Explanation by metal-induced gap states and interface dipoles. Europhys. Lett. 1994, 27, 479. [Google Scholar] [CrossRef]

- Tung, R. Electron transport at metal-semiconductor interfaces: General theory. Phys. Rev. B 1992, 45, 13509–13523. [Google Scholar] [CrossRef]

- Abdelrahman, A.; Ohmagari, S.; Yoshitake, T. Enhancing the Reverse Threshold Limit for Heteroepitaxial Diamond-Based Pseudovertical Schottky Diodes: Dependency on the Metal Contact Size. ACS Appl. Electron. Mater. 2024, 6, 6303–6312. [Google Scholar] [CrossRef]

- Chen, Y.; Ogura, M.; Okushi, H. Schottky junction properties on high quality boron-doped homoepitaxial diamond thin films. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2004, 22, 2084–2086. [Google Scholar] [CrossRef]

- Ikeda, K.; Umezawa, H.; Ramanujam, K.; Shikata, S.-i. Thermally stable Schottky barrier diode by Ru/diamond. Appl. Phys. Express 2009, 2, 011202. [Google Scholar] [CrossRef]

- Koné, S.; Schneider, H.; Isoird, K.; Thion, F.; Achard, J.; Issaoui, R.; Msolli, S.; Alexis, J. An assessment of contact metallization for high power and high temperature diamond Schottky devices. Diam. Relat. Mater. 2012, 27, 23–28. [Google Scholar] [CrossRef]

- VanderWeide, J.; Nemanich, R. Interface reactions of titanium on single crystal and thin film diamond analyzed by UV photoemission spectroscopy. Mater. Sci. Monogr. 1991, 73, 359–364. [Google Scholar]

- Eon, D.; Traoré, A.; Pernot, J.; Gheeraert, E. Recent progress on diamond Schottky diode. In Proceedings of the 2016 28th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Prague, Czech Republic, 12–16 June 2016; pp. 55–58. [Google Scholar]

- Tung, R.T. Recent advances in Schottky barrier concepts. Mater. Sci. Eng. R Rep. 2001, 35, 1–138. [Google Scholar] [CrossRef]

- Zhao, D.; Hu, C.; Liu, Z.; Wang, H.-X.; Wang, W.; Zhang, J. Diamond MIP structure Schottky diode with different drift layer thickness. Diam. Relat. Mater. 2017, 73, 15–18. [Google Scholar] [CrossRef]

- Murooka, T.; Yaita, J.; Makino, T.; Ogura, M.; Kato, H.; Yamasaki, S.; Natal, M.; Saddow, S.E.; Iwasaki, T.; Hatano, M. Characterization of Schottky barrier diodes on heteroepitaxial diamond on 3C-SiC/Si substrates. IEEE Trans. Electron Devices 2019, 67, 212–216. [Google Scholar] [CrossRef]

- Wade, M.; Muret, P.; Omnès, F.; Deneuville, A. Technology and electrical properties of ohmic contacts and Schottky diodes on homoepitaxial layers grown on (100) diamond surfaces. Diam. Relat. Mater. 2006, 15, 614–617. [Google Scholar] [CrossRef]

- Teraji, T.; Fiori, A.; Kiritani, N.; Tanimoto, S.; Gheeraert, E.; Koide, Y. Mechanism of reverse current increase of vertical-type diamond Schottky diodes. J. Appl. Phys. 2017, 122, 135304. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Wang, J.; Yi, W.; Wang, R.; Wang, W.; Wang, K.; Wang, H.-X. Schottky barrier diode fabricated on oxygen-terminated diamond using a selective growth approach. Diam. Relat. Mater. 2019, 99, 107529. [Google Scholar] [CrossRef]

- Maier, F.; Ristein, J.; Ley, L. Electron affinity of plasma-hydrogenated and chemically oxidized diamond (100) surfaces. Phys. Rev. B 2001, 64, 165411. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, J.; Zhu, E.; Liao, L.; Lee, S.J.; Ding, M.; Shakir, I.; Gambin, V.; Huang, Y.; Duan, X. Approaching the Schottky–Mott limit in van der Waals metal–semiconductor junctions. Nature 2018, 557, 696–700. [Google Scholar] [CrossRef] [PubMed]

- Bardeen, J. Surface states and rectification at a metal semi-conductor contact. Phys. Rev. 1947, 71, 717. [Google Scholar] [CrossRef]

- Saidi, W.A. Influence of strain and metal thickness on metal-MoS2 contacts. J. Chem. Phys. 2014, 141, 094707. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, K.; Liu, B.; Zhang, X.; Qiao, P.; Zhao, J.; Li, Y.; Hao, X.; Liang, Y.; Liang, B.; et al. Surface potential pinning study for oxygen terminated IIa diamond. Carbon 2023, 205, 69–75. [Google Scholar] [CrossRef]

- Volpe, P.N.; Muret, P.; Pernot, J.; Omnès, F.; Teraji, T.; Jomard, F.; Planson, D.; Brosselard, P.; Dheilly, N.; Vergne, B.; et al. High breakdown voltage Schottky diodes synthesized on p-type CVD diamond layer. Phys. Status Solidi (A) 2010, 207, 2088–2092. [Google Scholar] [CrossRef]

- Asano, H.; Nishiwaki, M.; Kawamoto, K.; Ueda, K. High-temperature characteristics of diamond Schottky diodes using various Schottky metals. In Extended Abstracts of the 2013 International Conference on Solid State Devices and Materials; The Japan Society of Applied Physics: Fukuoka, Japan, 2013. [Google Scholar]

- Chiu, F.C. A review on conduction mechanisms in dielectric films. Adv. Mater. Sci. Eng. 2014, 2014, 578168. [Google Scholar] [CrossRef]

- Ashok, S.; Srikanth, K.; Badzian, A.; Badzian, T.; Messier, R. Space-charge-limited current in thin-film diamond. Appl. Phys. Lett. 1987, 50, 763–765. [Google Scholar] [CrossRef]

- Matsumae, Y.; Akiba, Y.; Hirose, Y.; Kurosu, T.K.T.; Iida, M.I.M. Space charge limited current in semiconducting diamond films. Jpn. J. Appl. Phys. 1994, 33, L702. [Google Scholar] [CrossRef]

- Mort, J.; Machonkin, M.; Okumura, K. Density of states distribution in diamond thin films. Appl. Phys. Lett. 1991, 59, 455–457. [Google Scholar] [CrossRef]

- Sang, D.; Li, H.; Cheng, S.; Wang, Q.; Yu, Q.; Yang, Y. Electrical transport behavior of n-ZnO nanorods/p-diamond heterojunction device at higher temperatures. J. Appl. Phys. 2012, 112, 036101. [Google Scholar] [CrossRef]

- Rose, A. Space-charge-limited currents in solids. Phys. Rev. 1955, 97, 1538. [Google Scholar] [CrossRef]

- Traoré, A.; Muret, P.; Fiori, A.; Eon, D.; Gheeraert, E.; Pernot, J. Zr/oxidized diamond interface for high power Schottky diodes. Appl. Phys. Lett. 2014, 104, 052105. [Google Scholar] [CrossRef]

- Nikolenko, A.; Strelchuk, V.; Kudryk, Y.; Danylenko, I.; Belyaev, A.; Kovalenko, T.; Lysakovskyi, V.; Ivakhnenko, S.; Dub, M.; Sai, P.; et al. Peculiarities of current transport in boron-doped diamond Schottky diodes with hysteresis in current–voltage characteristics. Diam. Relat. Mater. 2024, 143, 110897. [Google Scholar] [CrossRef]

- Guo, W.; Huang, J.; Hwang, J. Hysteresis loop in the current—Voltage characteristic of Al/boron-doped polycrystalline diamond Schottky contact. Diam. Relat. Mater. 1997, 6, 12–16. [Google Scholar] [CrossRef]

- Erlbacher, T.; Huerner, A.; Zhu, Y.L.; Bach, L.; Schletz, A.; Zuerbig, V.; Pinti, L.; Kirste, L.; Giese, C.; Nebel, C.E.; et al. Electrical properties of Schottky-diodes based on B doped diamond. Mater. Sci. Forum 2018, 924, 931–934. [Google Scholar] [CrossRef]

- Evans, D.; Roberts, O.; Williams, G.; Vearey-Roberts, A.R.; Bain, F.; Evans, S.; Langstaff, D.; Twitchen, D. Diamond–metal contacts: Interface barriers and real-time characterization. J. Phys. Condens. Matter 2009, 21, 364223. [Google Scholar] [CrossRef]

- Ihm, J.; Louie, S.G.; Cohen, M.L. Diamond-metal interfaces and the theory of Schottky barriers. Phys. Rev. Lett. 1978, 40, 1208. [Google Scholar] [CrossRef]

- Cheng, C.; Zhang, Z.; Sun, X.; Gui, Q.; Wu, G.; Dong, F.; Zhang, D.; Guo, Y.; Liu, S. Ab-initio study of Schottky barrier heights at metal-diamond (111) interfaces. Appl. Surf. Sci. 2023, 615, 156329. [Google Scholar] [CrossRef]

- Hasegawa, H. Fermi level pinning and Schottky barrier height control at metal-semiconductor interfaces of InP and related materials. Jpn. J. Appl. Phys. 1999, 38, 1098. [Google Scholar] [CrossRef]

- Duboz, J.; Binet, F.; Laurent, N.; Rosencher, E.; Scholz, F.; Harle, V.; Briot, O.; Gil, B.; Aulombard, R. Influence of surface defects on the characteristics of GaN Schottky diodes. MRS Proc. Libr. 1996, 449, 1085. [Google Scholar] [CrossRef]

- Altındal, Ş.; Karadeniz, S.; Tuğluoğlu, N.; Tataroğlu, A. The role of interface states and series resistance on the I–V and C–V characteristics in Al/SnO2/p-Si Schottky diodes. Solid-State Electron. 2003, 47, 1847–1854. [Google Scholar] [CrossRef]

- Bampoulis, P.; van Bremen, R.; Yao, Q.; Poelsema, B.; Zandvliet, H.J.; Sotthewes, K. Defect dominated charge transport and fermi level pinning in MoS2/metal contacts. ACS Appl. Mater. Interfaces 2017, 9, 19278–19286. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.; Sun, X.; He, X.; Xu, E.; Wang, Q.; Cao, R.; Shen, W.; Dong, F.; Guo, Y.; Zhang, Z.; et al. Atomic and electronic properties of the metal/diamond (100) interfaces by first-principles calculations. Surf. Interfaces 2024, 52, 104916. [Google Scholar] [CrossRef]

- Kim, G.S.; Kim, S.W.; Kim, S.H.; Park, J.; Seo, Y.; Cho, B.J.; Shin, C.; Shim, J.H.; Yu, H.Y. Effective Schottky barrier height lowering of metal/n-Ge with a TiO2/GeO2 interlayer stack. ACS Appl. Mater. Interfaces 2016, 8, 35419–35425. [Google Scholar] [CrossRef]

- Song, S.; Kim, S.H.; Kim, S.G.; Han, K.H.; Kim, H.J.; Yu, H.Y. Effective Schottky barrier height and interface trap density reduction engineering using 2-dimensional reduced graphene oxide interlayer for metal-interlayer-semiconductor contact structure. J. Alloys Compd. 2023, 937, 168327. [Google Scholar] [CrossRef]

- Lee, H.K.; Jyothi, I.; Janardhanam, V.; Shim, K.H.; Yun, H.-J.; Lee, S.N.; Hong, H.; Jeong, J.C.; Choi, C.J. Effects of Ta-oxide interlayer on the Schottky barrier parameters of Ni/n-type Ge Schottky barrier diode. Microelectron. Eng. 2016, 163, 26–31. [Google Scholar] [CrossRef]

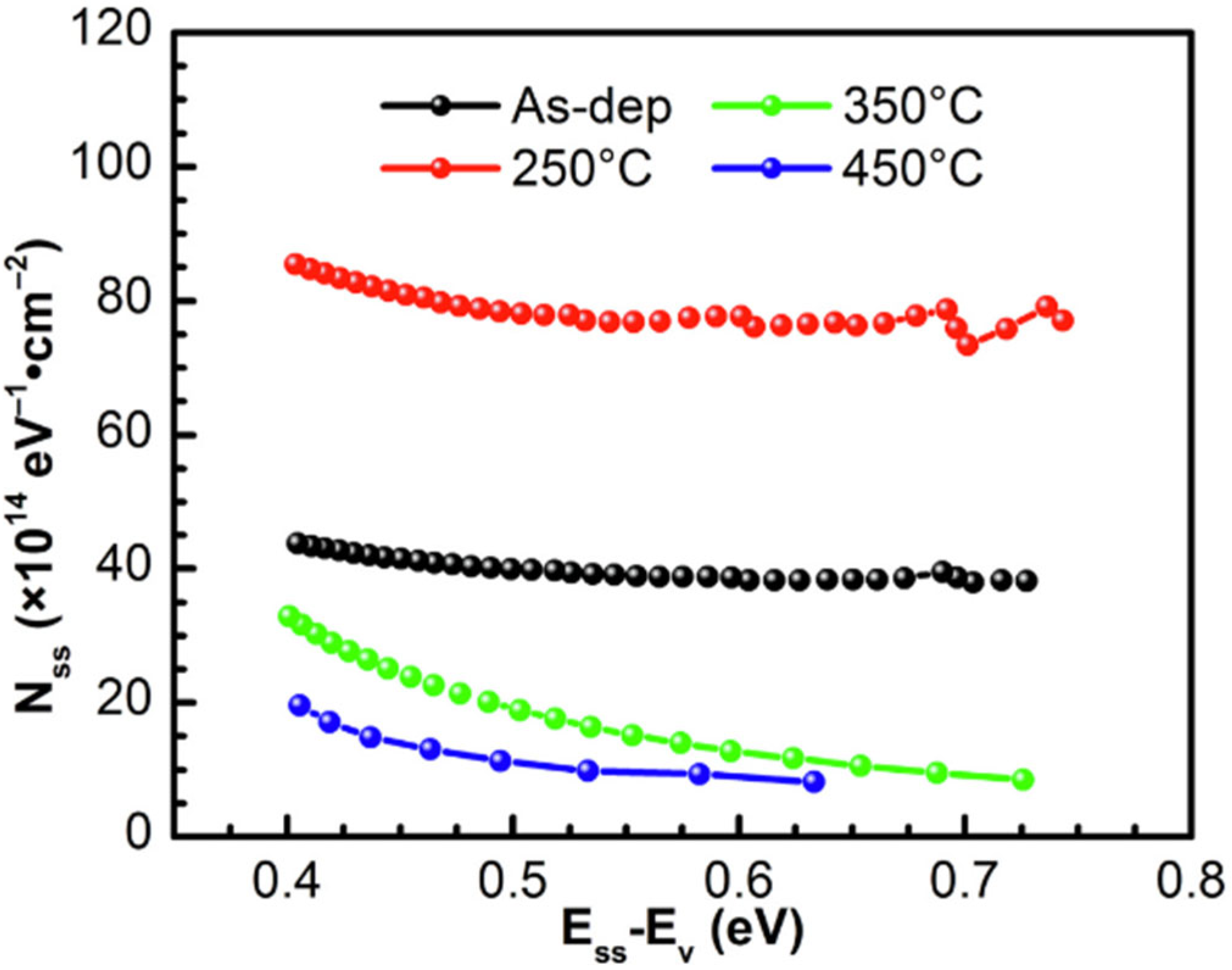

- Zhang, X.; Matsumoto, T.; Sakurai, U.; Makino, T.; Ogura, M.; Yamasaki, S.; Sometani, M.; Okamoto, D.; Yano, H.; Iwamuro, N.; et al. Energy distribution of Al2O3/diamond interface states characterized by high temperature capacitance-voltage method. Carbon 2020, 168, 659–664. [Google Scholar] [CrossRef]

- Hiraiwa, A.; Saito, T.; Matsumura, D.; Kawarada, H. Isotope analysis of diamond-surface passivation effect of high-temperature H2O-grown atomic layer deposition-Al2O3 films. J. Appl. Phys. 2015, 117, 215304. [Google Scholar] [CrossRef]

- Itoh, Y.; Sumikawa, Y.; Umezawa, H.; Kawarada, H. Trapping mechanism on oxygen-terminated diamond surfaces. Appl. Phys. Lett. 2006, 89, 203503. [Google Scholar] [CrossRef]

- Choi, G.; Yoon, H.H.; Jung, S.; Jeon, Y.; Lee, J.Y.; Bahng, W.; Park, K. Schottky barrier modulation of metal/4H-SiC junction with thin interface spacer driven by surface polarization charge on 4H-SiC substrate. Appl. Phys. Lett. 2015, 107, 252101. [Google Scholar] [CrossRef]

- Wang, J.; Shao, G.; Chen, G.; Yan, X.; Li, Q.; Song, W.; Wang, Y.; Liu, Z.; Fan, S.; Zhang, C.; et al. Schottky barrier height modulation of Zr/p-diamond Schottky contact by inserting ultrathin atomic layer-deposited Al2O3. IEEE Trans. Electron Devices 2021, 68, 5995–6000. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Li, Q.; Shao, G.; Chen, G.; He, S.; Wang, R.; Wang, W.; Bu, R.; Wen, F.; et al. Improved-performance Diamond Schottky barrier diode with tin oxide interlayer. IEEE Trans. Electron Devices 2022, 69, 6260–6264. [Google Scholar] [CrossRef]

- Seçkin, A.; Koralay, H. Electrical Properties of Schottky Devices from HfO2 and ZnO/HfO2 Thin Films: Morphological, Structural, and Optical Investigations. ACS Omega 2025, 10, 6520–6533. [Google Scholar] [CrossRef]

- Han, S.; Kwak, T.; Choi, U.; Kang, H.; Yoo, G.; Kim, S.-w.; Nam, O. Electrical characteristics of metal–insulator diamond semiconductor Schottky barrier diode grown on heteroepitaxial diamond substrate. Phys. Status Solidi (A) 2023, 220, 2200680. [Google Scholar] [CrossRef]

- Tekeli, Z.; Gökçen, M.; Altındal, Ş.; Özçelik, S.; Özbay, E. On the profile of frequency dependent dielectric properties of (Ni/Au)/GaN/Al0. 3Ga0. 7N heterostructures. Microelectron. Reliab. 2011, 51, 581–586. [Google Scholar] [CrossRef]

- Gökçen, M.; Altındal, Ş.; Karaman, M.; Aydemir, U. Forward and reverse bias current–voltage characteristics of Au/n-Si Schottky barrier diodes with and without SnO2 insulator layer. Phys. B Condens. Matter 2011, 406, 4119–4123. [Google Scholar] [CrossRef]

- Balaram, N.; Reddy, V.R.; Reddy, P.S.; Janardhanam, V.; Choi, C.J. Microstructural, chemical states and electrical properties of Au/CuO/n-InP heterojunction with a cupric oxide interlayer. Vacuum 2018, 152, 15–24. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Ranga, P.; Saleh, M.; Roy, S.; Scarpulla, M.A.; Lynn, K.G.; Krishnamoorthy, S. Schottky barrier height engineering in β-Ga2O3 using SiO2 interlayer dielectric. IEEE J. Electron Devices Soc. 2020, 8, 286–294. [Google Scholar] [CrossRef]

- Herniter, M.E.; Getty, W. High current density results from a LaB6 thermionic cathode electron gun. IEEE Trans. Plasma Sci. 2002, 18, 992–1001. [Google Scholar] [CrossRef]

- Ebihara, K.; Hiramatsu, S. High-current-density gun with a LaB6 cathode. Rev. Sci. Instrum. 1996, 67, 2765–2769. [Google Scholar] [CrossRef]

- Qi, K.; Lin, Z.; Chen, W.; Cao, G.; Cheng, J.; Sun, X. Formation of extremely high current density LaB6 field emission arrays via e-beam deposition. Appl. Phys. Lett. 2008, 93, 093503. [Google Scholar] [CrossRef]

- Shao, G.; Wang, J.; Liu, Z.; Wang, Y.; Wang, W.; Wang, H.-X. Performance-improved vertical Zr/diamond Schottky barrier diode with lanthanum hexaboride interfacial layer. IEEE Electron Device Lett. 2021, 42, 1366–1369. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Zhang, M.; Wang, R.; Chen, G.; Chang, X.; Lin, F.; Wen, F.; Jia, K.; Wang, H.-X. An enhancement-mode hydrogen-terminated diamond field-effect transistor with lanthanum hexaboride gate material. IEEE Electron Device Lett. 2020, 41, 585–588. [Google Scholar] [CrossRef]

- Shao, G.; Wang, J.; Zhang, S.; Wang, Y.; Wang, W.; Wang, H.-X. Effect of rapid thermal annealing on performances of vertical boron-doped diamond Schottky diode with LaB6 interlayer. Diam. Relat. Mater. 2023, 132, 109678. [Google Scholar] [CrossRef]

- Berrada, A.; Mercurio, J.; Etourneau, J.; Alexandre, F.; Theeten, J.; Duc, T.M. Thermionic emission properties of LaB6 and CeB6 in connection with their surface states, examination by XPS, Auger spectroscopy and the Kelvin method. Surf. Sci. 1978, 72, 177–188. [Google Scholar] [CrossRef]

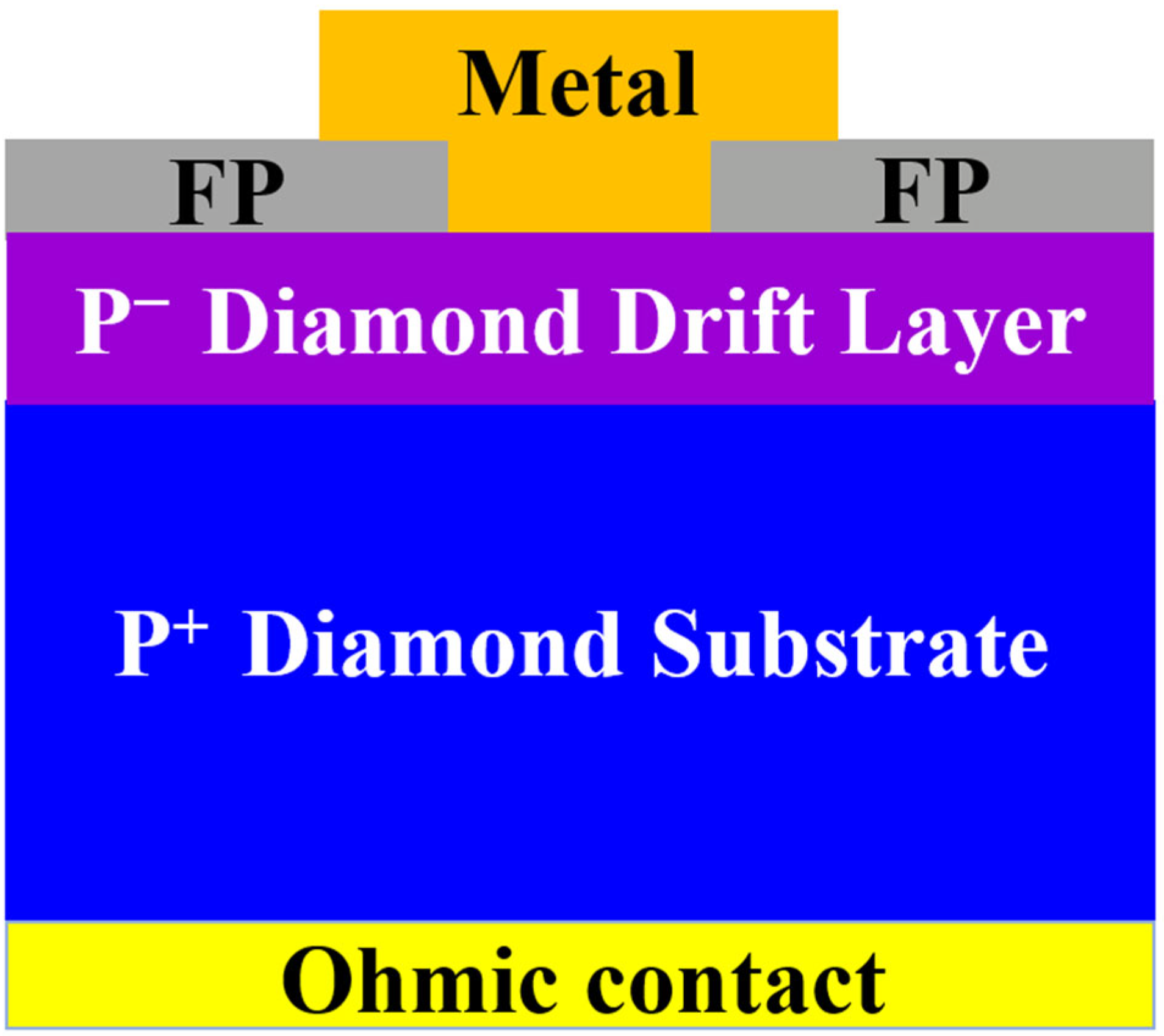

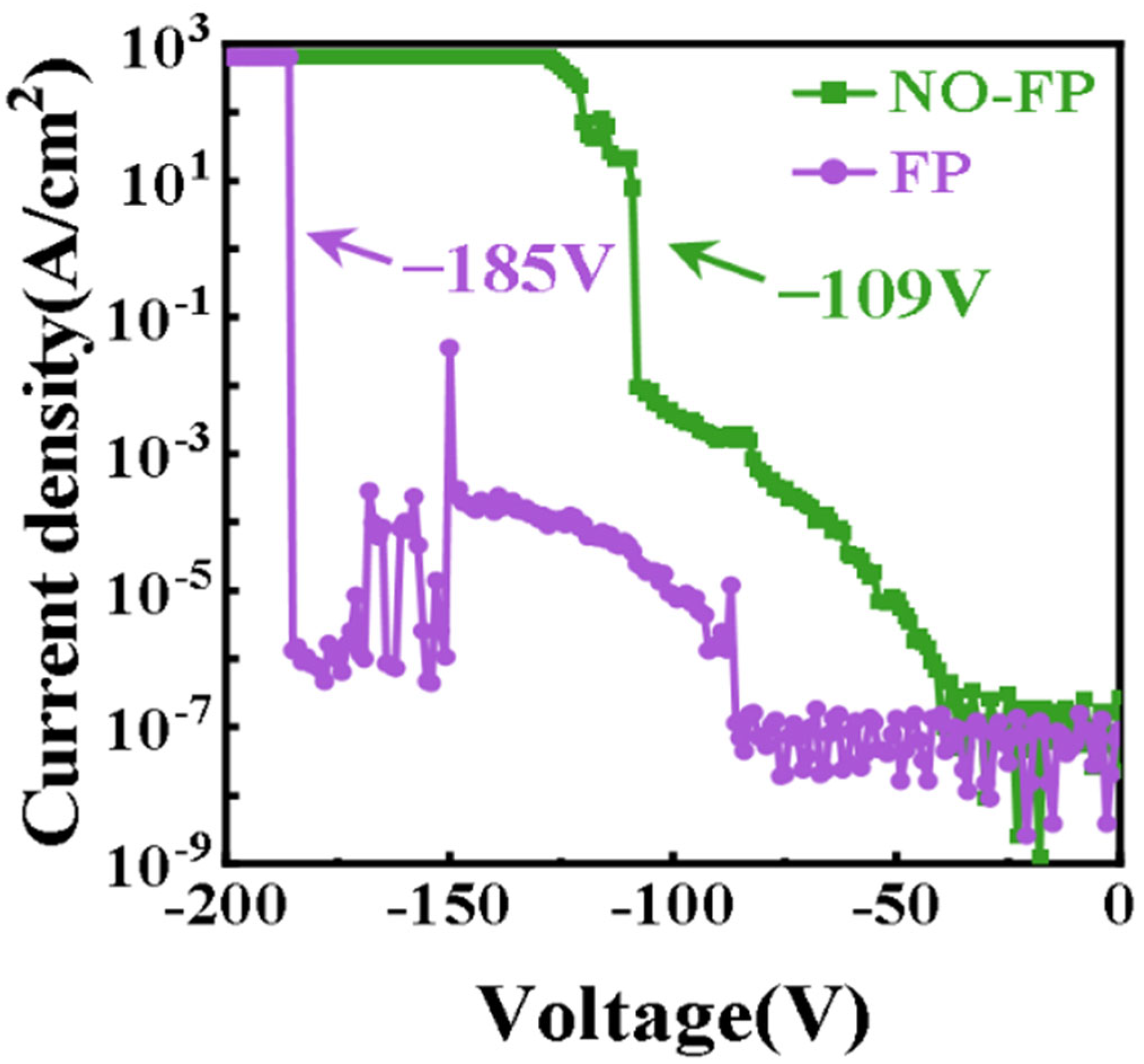

- Zhang, S.; Li, Q.; Wang, J.; Wang, R.; Shao, G.; Chen, G.; He, S.; Wang, W.; Bu, R.; Wang, H.-X. High Breakdown Electric Field Diamond Schottky Barrier Diode with SnO2 Field Plate. IEEE Trans. Electron Devices 2022, 69, 6917–6921. [Google Scholar] [CrossRef]

- Araujo, D.; Suzuki, M.; Lloret, F.; Alba, G.; Villar, P. Diamond for electronics: Materials, processing and devices. Materials 2021, 14, 7081. [Google Scholar] [CrossRef]

- Song, Q.; Tang, X.; Yuan, H.; Han, C.; Zhang, Y.; Zhang, Y. Design, simulation, and fabrication of 4H-SiC power SBDs with SIPOS FP structure. IEEE Trans. Device Mater. Reliab. 2015, 15, 543–551. [Google Scholar] [CrossRef]

- Song, Q.W.; Zhang, Y.M.; Zhang, Y.M.; Tang, X.Y. Simulation study on 4H–SiC power devices with high-k dielectric FP terminations. Diam. Relat. Mater. 2012, 22, 42–47. [Google Scholar] [CrossRef]

- Li, Q.; Liang, Y.; Chen, G.; Liu, Z.; Zhang, S.; Zeng, J.; Zhang, Q.; Wang, R.; Zhang, Z.; Fan, S.; et al. Vertical diamond Schottky barrier diodes with curved field plates. Appl. Phys. Lett. 2024, 124, 233502. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Wang, J.; Yi, W.; Wang, R.; Wang, W.; Wang, K.; Wang, H. Reduction in reverse leakage current of diamond vertical Schottky barrier diode using SiNX field plate structure. Results Phys. 2019, 13, 102250. [Google Scholar] [CrossRef]

- Saxena, V.; Su, J.N.; Steckl, A.J. High-voltage Ni-and Pt-SiC Schottky diodes utilizing metal field plate termination. IEEE Trans. Electron Devices 1999, 46, 456–464. [Google Scholar] [CrossRef]

- Hanawa, H.; Onodera, H.; Horio, K. Analysis of lags and current collapse in source-field-plate AlGaN/GaN high-electron-mobility transistors. Jpn. J. Appl. Phys. 2013, 52, 08JN21. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Shao, G.; Chen, G.; He, S.; Zhang, Q.; Zhang, S.; Wang, R.; Fan, S.; Wang, H.-X. Breakdown voltage enhancement of vertical diamond Schottky barrier diode with annealing method and Al2O3 field plate structure. IEEE Electron Device Lett. 2022, 43, 1937–1940. [Google Scholar] [CrossRef]

- Marron, T.; Takashima, S.; Li, Z.; Chow, T.P. Impact of annealing on ALD Al2O3 gate dielectric for GaN MOS devices. Phys. Status Solidi C Curr. Top. 2012, 9, 907–910. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Wang, J.; Yi, W.; Wang, R.; Wang, K.; Wang, H. Performance improved vertical diamond Schottky barrier diode with fluorination-termination structure. IEEE Electron Device Lett. 2019, 40, 1229–1232. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Z.; Wang, J.; Liang, Y.; Nauman, M.; Fu, J.; Wang, Y.-F.; Fan, S.; Wang, W.; Wang, H.-X. Fabrication of dual-termination Schottky barrier diode by using oxygen-/fluorine-terminated diamond. Appl. Surf. Sci. 2018, 457, 411–416. [Google Scholar] [CrossRef]

- Hanada, T.; Ohmagari, S.; Kaneko, J.H.; Umezawa, H. High yield uniformity in pseudo-vertical diamond Schottky barrier diodes fabricated on half-inch single-crystal wafers. Appl. Phys. Lett. 2020, 117, 262107. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, S.; Shao, G.; Wang, J.; Wang, R.; Zhang, Q.; Chen, G.; He, S.; Fan, S.; Wang, H.X. High breakdown electric field diamond Schottky barrier diode with HfO2 field plate. Appl. Phys. Lett. 2023, 122, 202101. [Google Scholar] [CrossRef]

- Umezawa, H.; Nagase, M.; Kato, Y.; Shikata, S. Diamond vertical Schottky barrier diode with Al2O3 field plate. Mater. Sci. Forum 2012, 717, 1319–1321. [Google Scholar] [CrossRef]

| Material | FP | SBH (eV) | n | BV (V) | Ref |

|---|---|---|---|---|---|

| HfO2 | w/ | 1.55 | 1.48 | 280 | [153] |

| w/o | 1.57 | 1.46 | 183 | ||

| Al2O3 | w/ | \ | \ | 1800 | [154] |

| w/o | \ | \ | 900 | ||

| SiNx | w/ | 1.6 | 2 | 133 | [145] |

| w/o | 1.8 | 1.6 | 122 | ||

| SnO2 | w/ | 1.65 | 1.31 | 185 | [140] |

| w/o | 1.66 | 1.30 | 109 | ||

| SiO2 | w/ | 0.47–1.44 | 1.02–1.52 | 407 | [152] |

| FT−Diamond | w/ | 0.82–1.44 | 2.12–2.66 | 97–117 | [150] |

| w/o | 0.69–1.83 | 1.55–3.55 | 73.5–85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Zhang, X.; Wang, S.; Li, M.; Jiao, S.; Liang, Y.; Wang, W.; Zhang, J. Advances in Interfacial Engineering and Structural Optimization for Diamond Schottky Barrier Diodes. Materials 2025, 18, 3657. https://doi.org/10.3390/ma18153657

Lu S, Zhang X, Wang S, Li M, Jiao S, Liang Y, Wang W, Zhang J. Advances in Interfacial Engineering and Structural Optimization for Diamond Schottky Barrier Diodes. Materials. 2025; 18(15):3657. https://doi.org/10.3390/ma18153657

Chicago/Turabian StyleLu, Shihao, Xufang Zhang, Shichao Wang, Mingkun Li, Shuopei Jiao, Yuesong Liang, Wei Wang, and Jing Zhang. 2025. "Advances in Interfacial Engineering and Structural Optimization for Diamond Schottky Barrier Diodes" Materials 18, no. 15: 3657. https://doi.org/10.3390/ma18153657

APA StyleLu, S., Zhang, X., Wang, S., Li, M., Jiao, S., Liang, Y., Wang, W., & Zhang, J. (2025). Advances in Interfacial Engineering and Structural Optimization for Diamond Schottky Barrier Diodes. Materials, 18(15), 3657. https://doi.org/10.3390/ma18153657