Hybrid Laser Cleaning of Carbon Deposits on N52B30 Engine Piston Crowns: Multi-Objective Optimization via Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

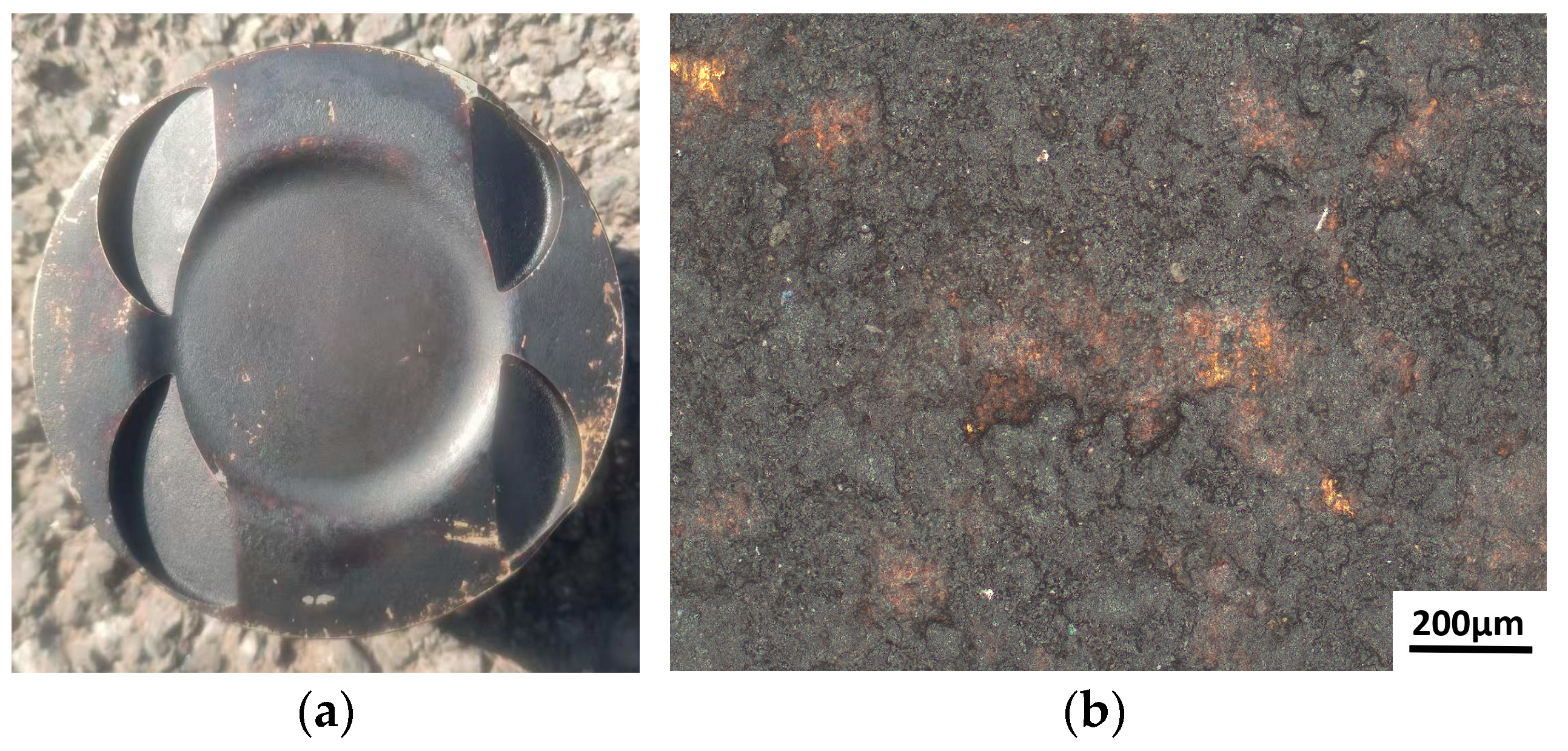

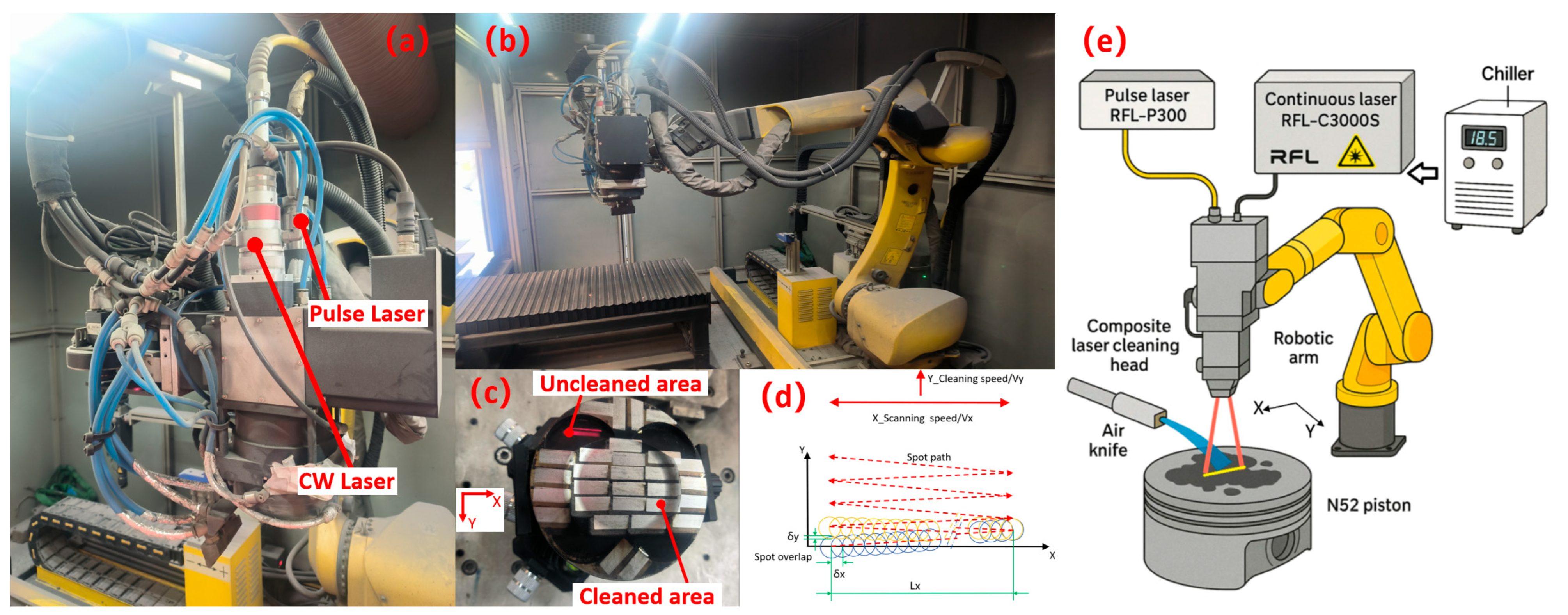

2.1. Experimental Materials and Equipment

2.2. Experimental Methods

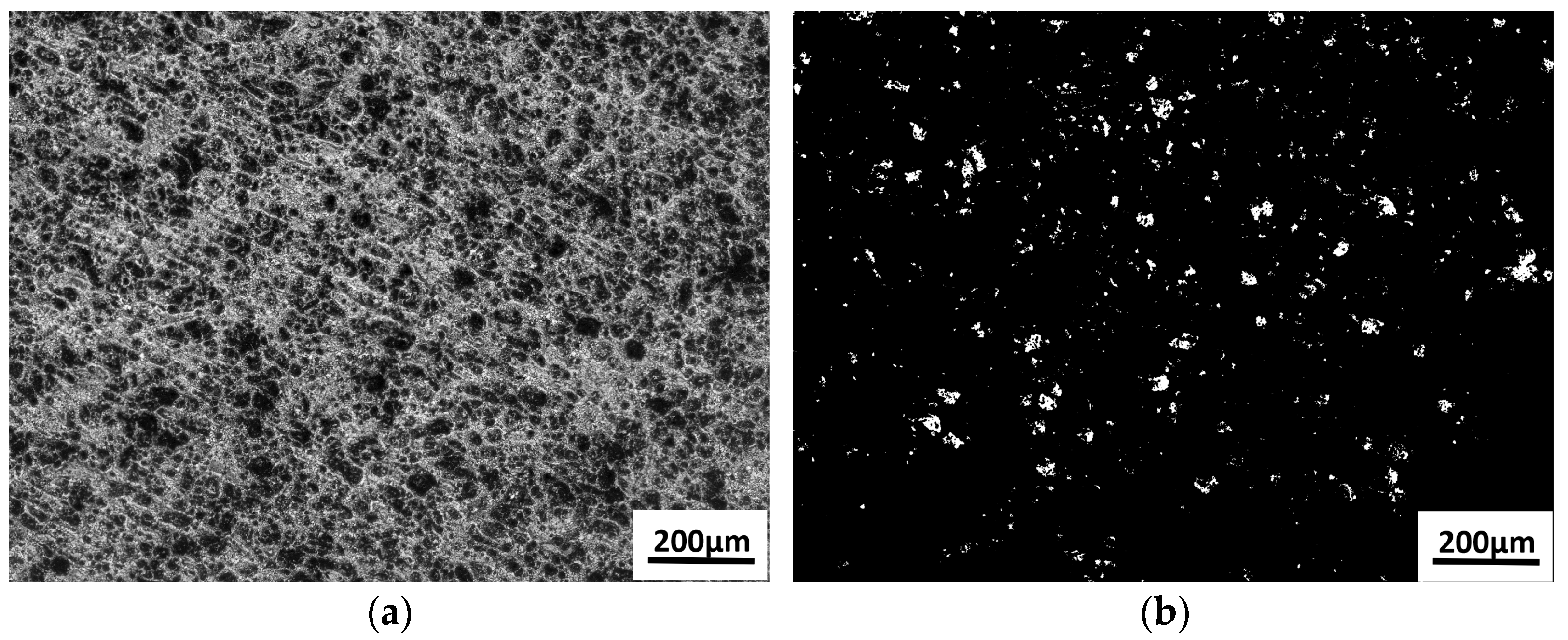

2.2.1. Characterization Method for Surface Roughness and Carbon Residue Rate

2.2.2. Single-Factor Experiment

- 1.

- Effect of X-Direction Scanning Speed on Surface Roughness (Sa)

- 2.

- Effect of Pulse Repetition Frequency on Surface Roughness (Sa)

- 3.

- Effect of Y-Direction Cleaning Speed on Surface Roughness (Sa)

- 4.

- Effect of Pulsed Laser Power on Surface Roughness (Sa)

- 5.

- Effect of CW Laser Power on Surface Roughness (Sa)

2.2.3. Plackett–Burman Design

2.2.4. The Steepest Ascent Test

2.2.5. The Box–Behnken Design

3. Results and Analysis

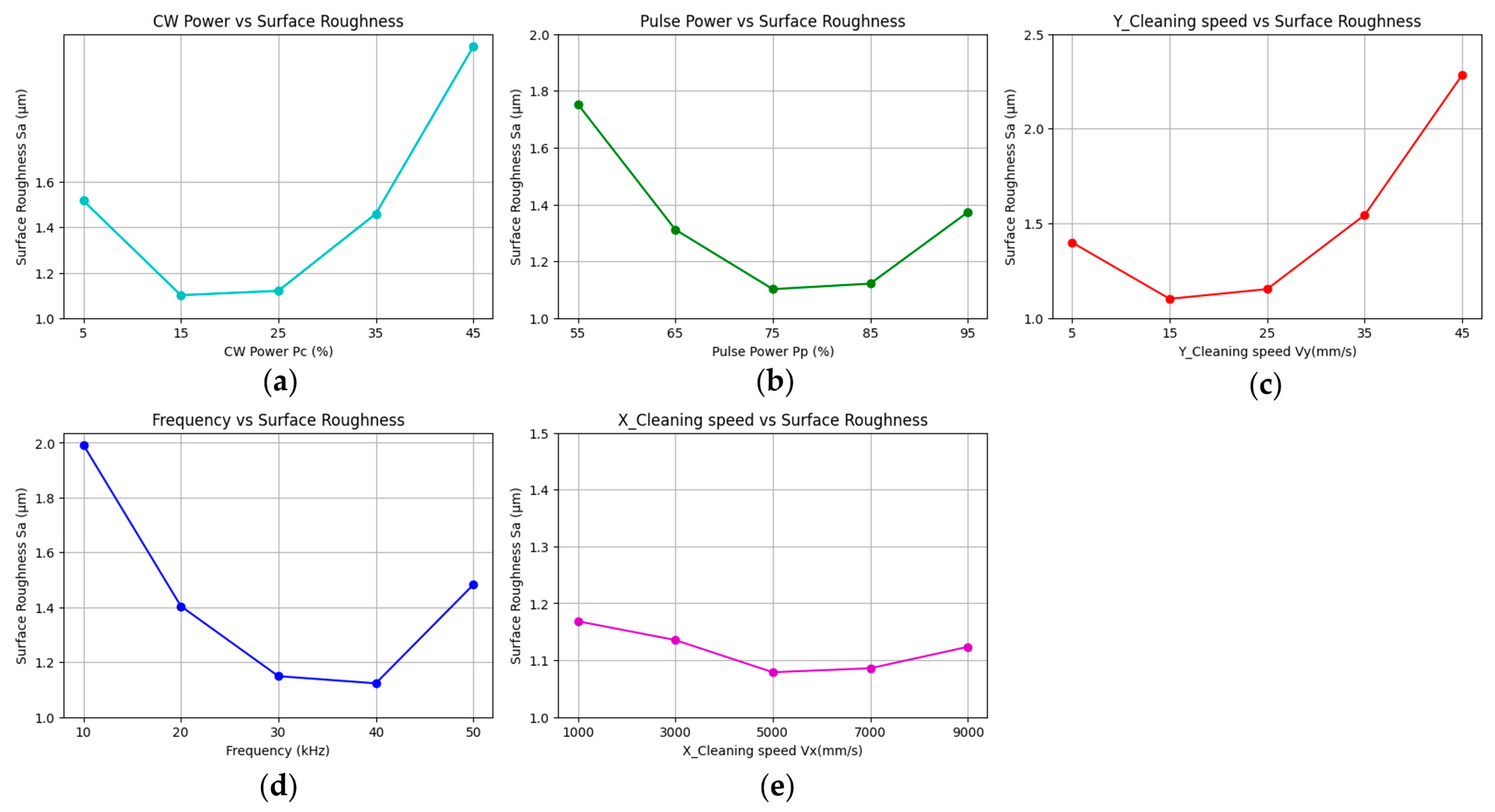

3.1. Results and Analysis of Single-Factor Experiment

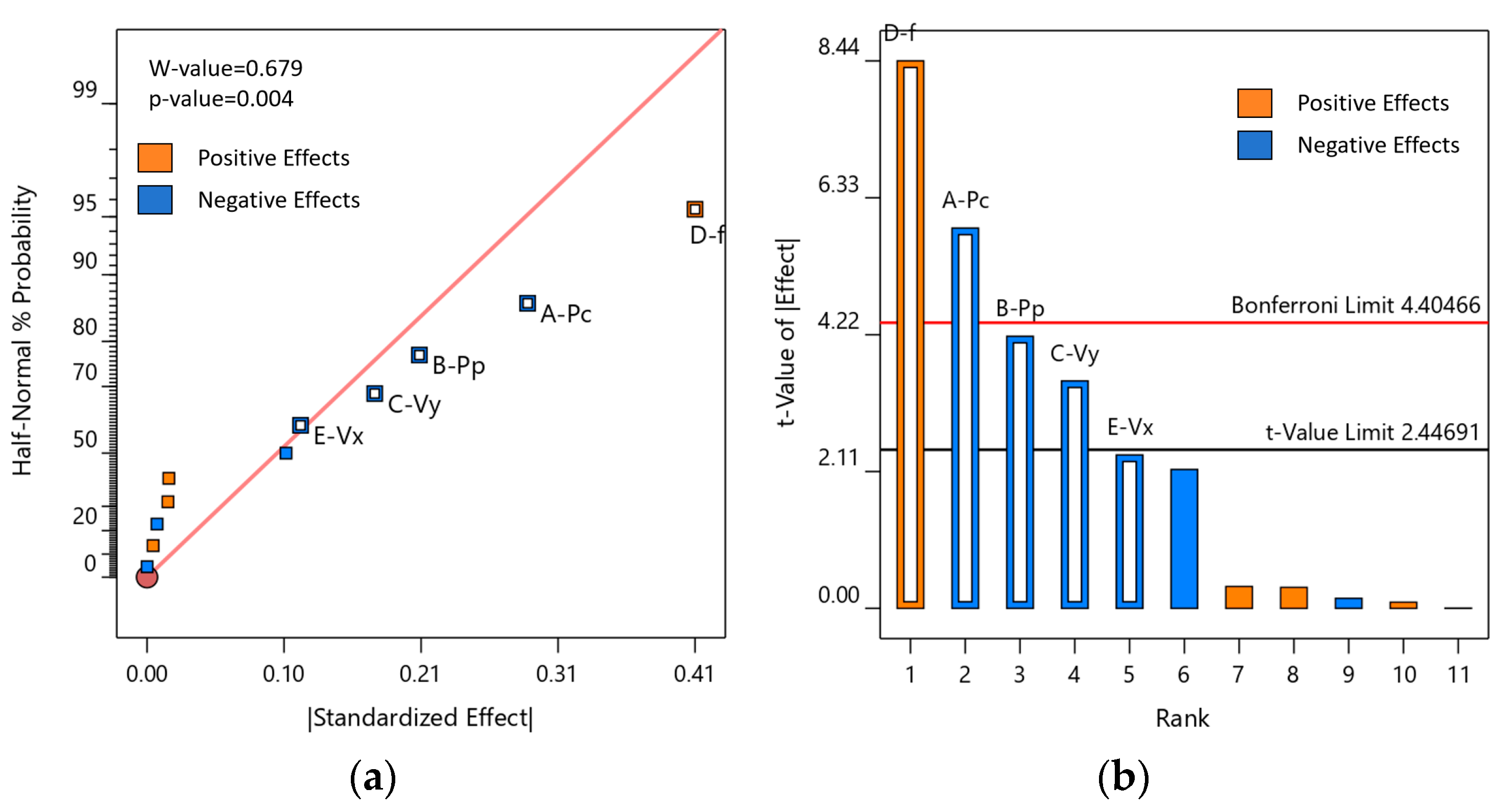

3.2. Results of the Plackett–Burman Design

3.3. Analysis of the Results of the Steepest Ascent Test

3.4. Analysis of the Results of the Box–Behnken Design

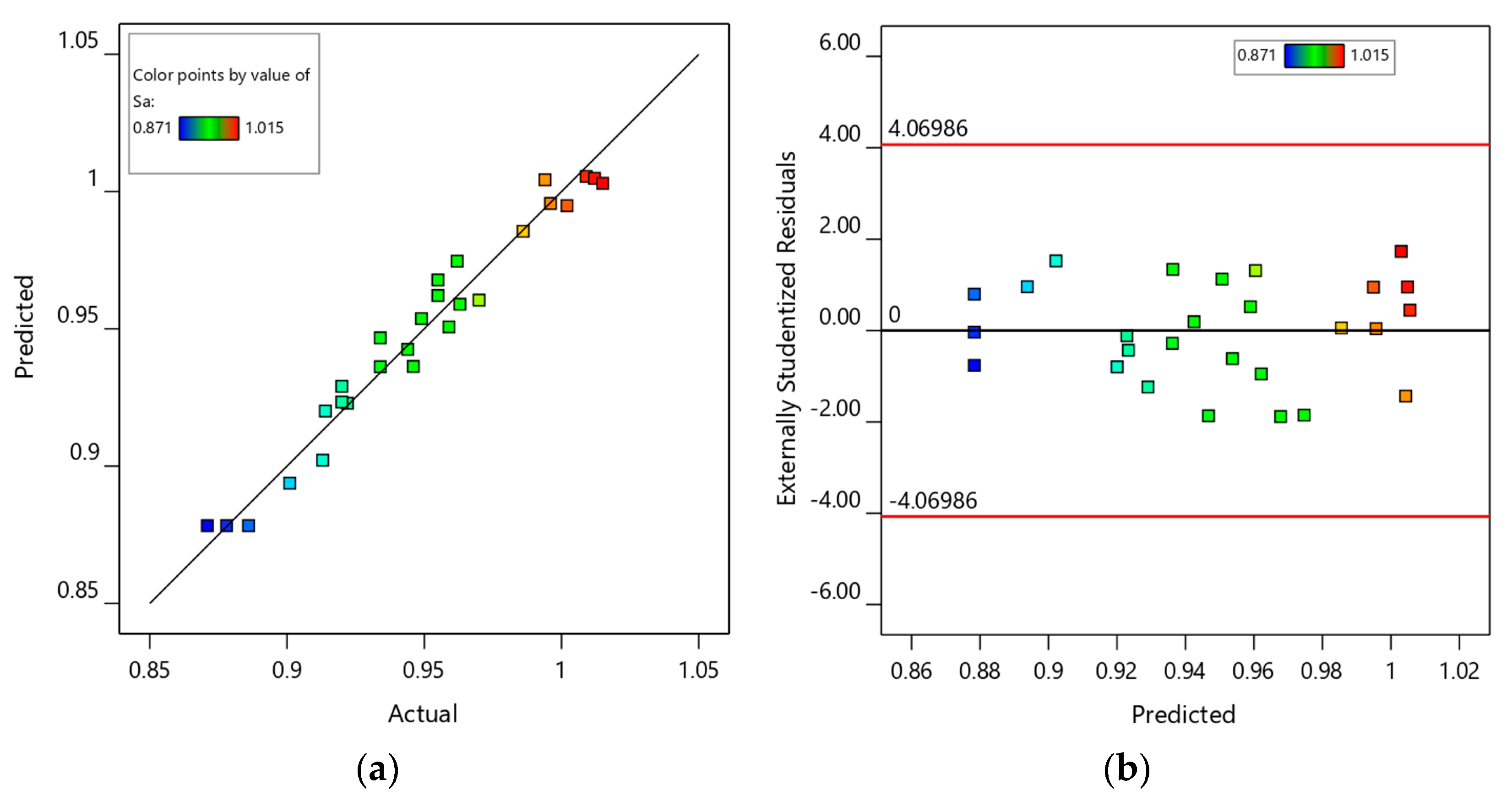

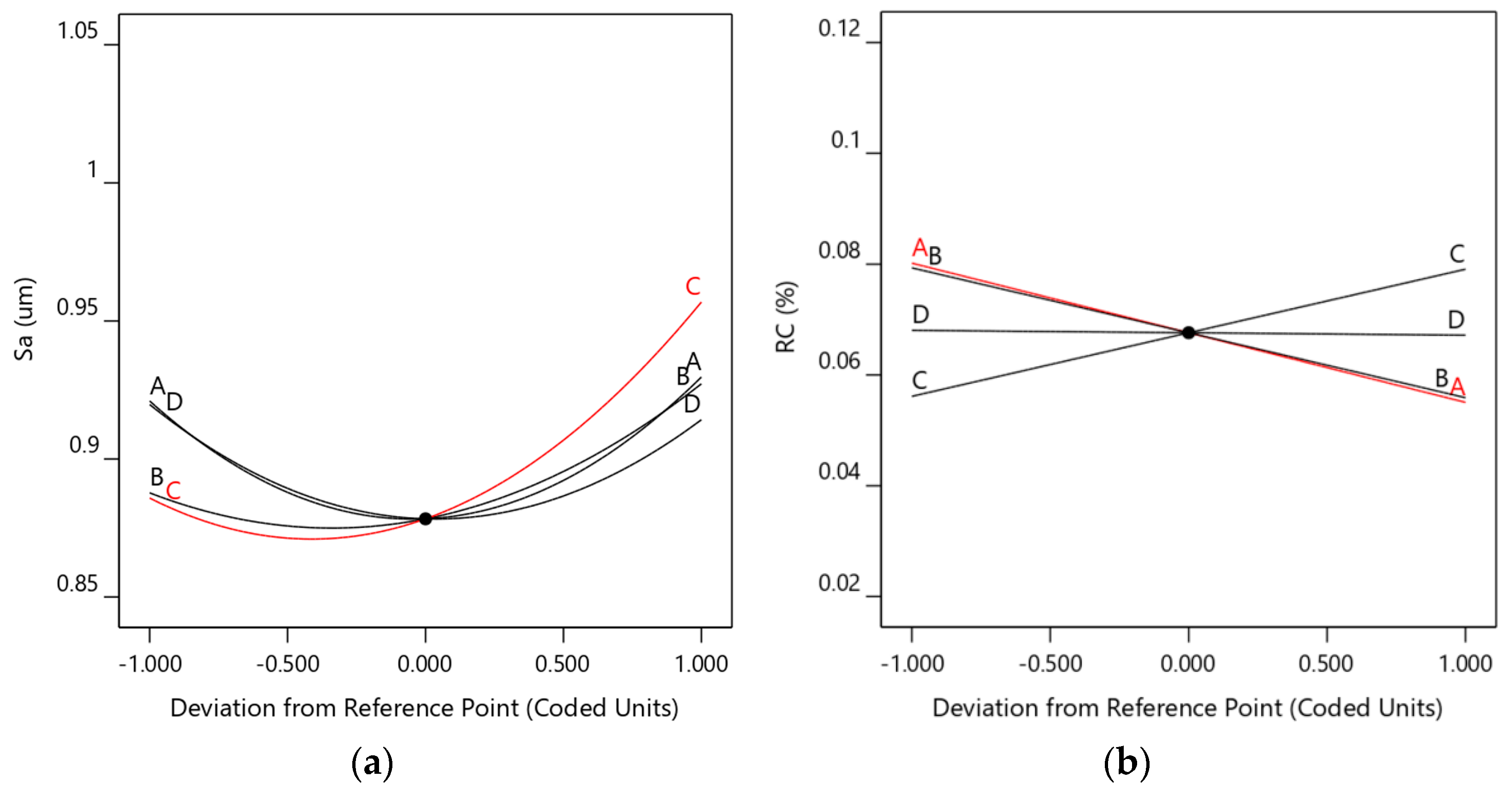

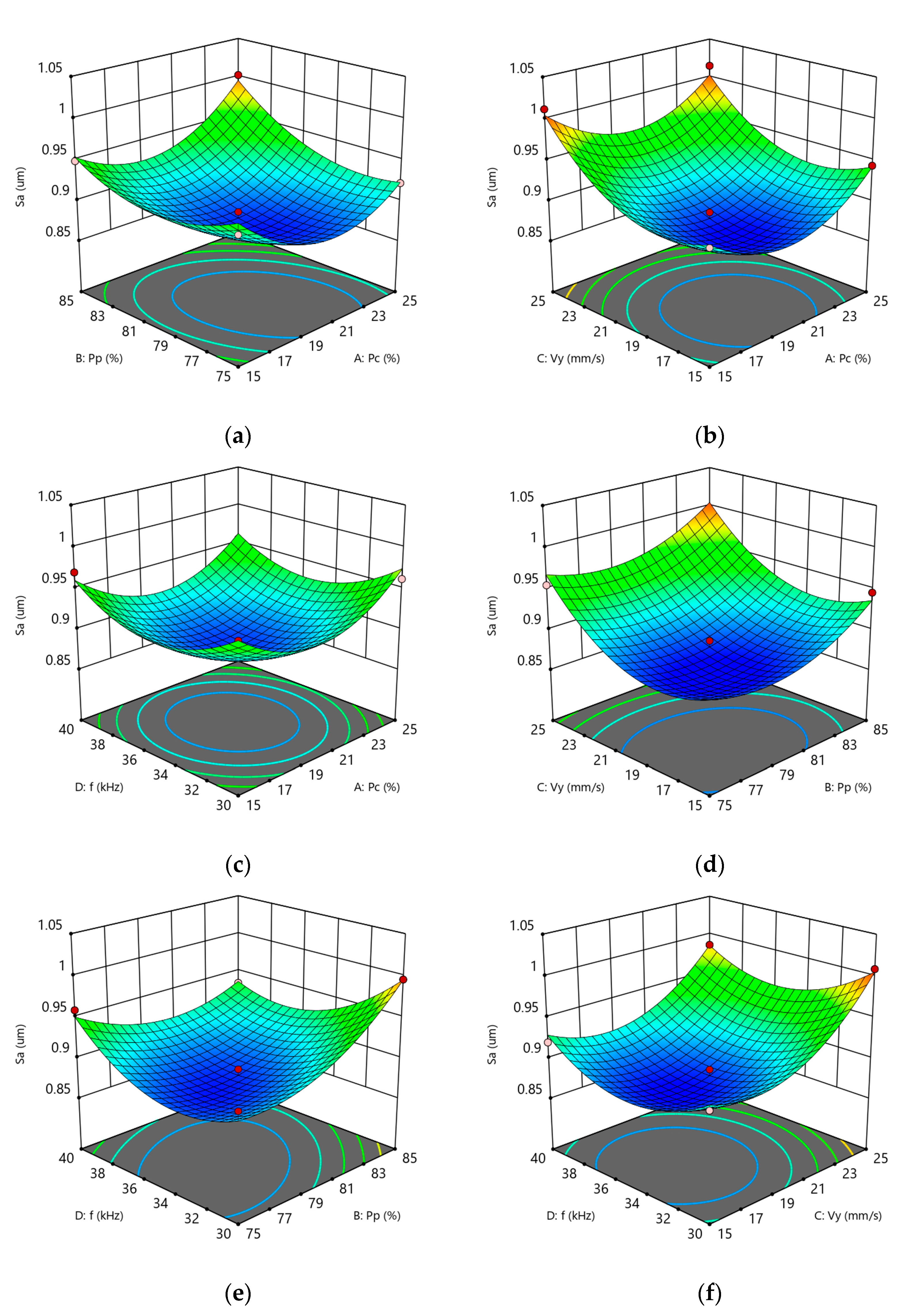

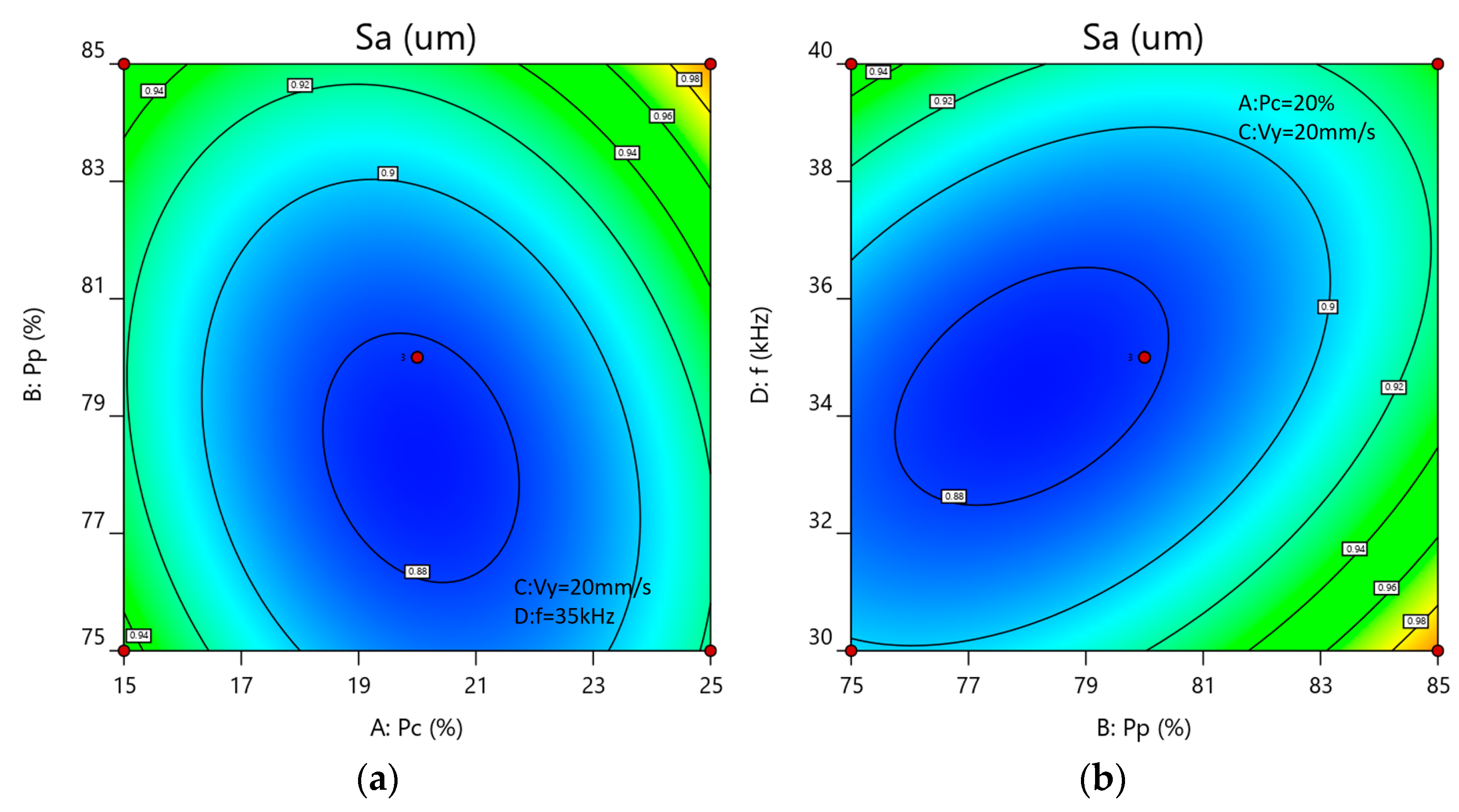

3.4.1. Analysis of Surface Roughness (Sa) Using the Box–Behnken Design

− 0.00006BC − 0.00108BD − 0.00029CD + 0.001882A2 + 0.001167B2 + 0.001722C2 + 0.001547D2

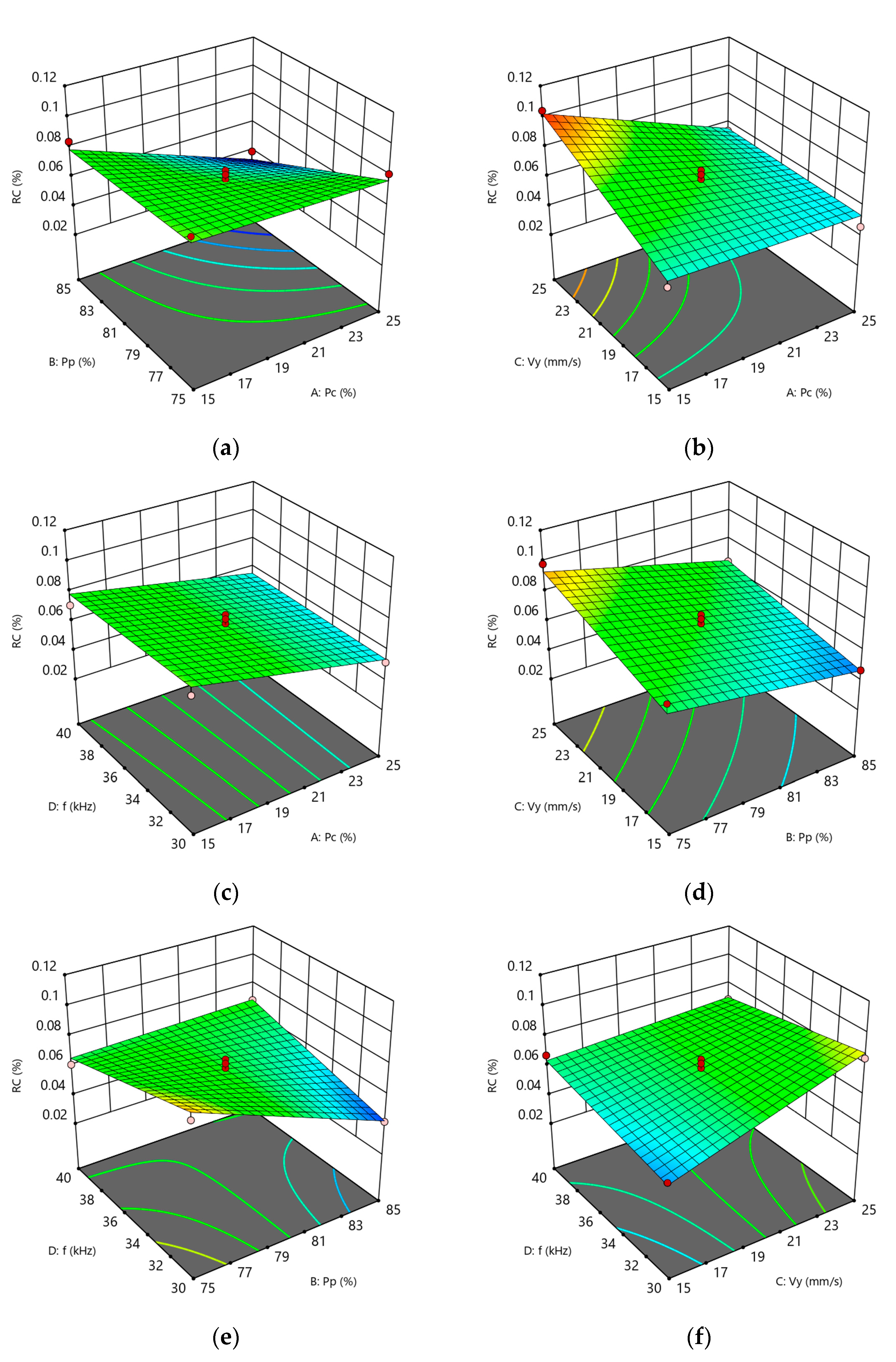

3.4.2. Analysis of Carbon Residue Rate (RC) Using the Box–Behnken Design

+ 0.000043AD − 0.000096BC + 0.000535BD − 0.000323CD

3.5. Multi-Objective Optimization of Process Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kay, J.A.; Green, G. Dry Ice Cleaning of Electrical Equipment: Revitalize Electrical Assets with Precision Cleaning. IEEE Ind. Appl. Mag. 2024, 30, 14–23. [Google Scholar] [CrossRef]

- Liu, W.; Qing, X.; Li, M.; Liu, L.; Zhang, H. Supercritical CO2 Cleaning of Carbonaceous Deposits on Diesel Engine Valve. Procedia CIRP 2015, 29, 828–832. [Google Scholar] [CrossRef]

- Long, Y.; Li, J.; Timmer, D.H.; Jones, R.E.; Gonzalez, M.A. Modeling and Optimization of the Molten Salt Cleaning Process. J. Clean. Prod. 2014, 68, 243–251. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, Z.; Jin, Y.; Chen, X.; Yang, L.; Xu, J.; Shan, D.; Chen, Y.; Guo, B. Mechanism and Application of Laser Cleaning: A Review. Opt. Lasers Eng. 2022, 157, 107130. [Google Scholar] [CrossRef]

- Guan, Y.; Ng, G.; Zheng, H.; Hong, M.; Hong, X.; Zhang, Z. Laser Surface Cleaning of Carbonaceous Deposits on Diesel Engine Piston. Appl. Surf. Sci. 2013, 270, 526–530. [Google Scholar] [CrossRef]

- Wang, W.; Wang, X.; Liu, W.; Xing, F.; Wang, J. Effect of spot overlapping rate on surface area carbon and oxide cleaning quality of GH3030 alloy. Infrared Laser Eng. 2023, 52, 20220164. [Google Scholar] [CrossRef]

- Qiao, Y.; Huang, K.; Liang, X.; Hu, Z.; Zhang, G.; Zhang, J. Effect of Laser Cleaning Speed on Morphology and Composition of Carbon-Deposited Surface of Titanium Alloy. Appl. Laser 2017, 37, 859–864. [Google Scholar]

- Qiu, C.; Chen, Z.; Zhou, W.; Martynenko, S.; Yanovskiy, L. Experimental Investigation on Carbon Deposition Characteristics of Aeroengine Swirl Nozzle and Its Effect on Spray Behaviors. Fuel 2022, 324, 124431. [Google Scholar] [CrossRef]

- Eskandari, M.J.; Karimi, M.; Araghchi, M.; Hadipour, A. Laser Cleaning Process of High-Pressure Turbine Blade: Characterization and Removal of Surface Contaminants. Surf. Coat. Technol. 2023, 470, 129885. [Google Scholar] [CrossRef]

- Fox, J.A. A Method for Improving Continuous Wave Laser Penetration of Metal Targets. Appl. Phys. Lett. 1975, 26, 682–684. [Google Scholar] [CrossRef]

- Pouli, P.; Nevin, A.; Andreotti, A.; Colombini, P.; Georgiou, S.; Fotakis, C. Laser Assisted Removal of Synthetic Painting-Conservation Materials Using UV Radiation of Ns and Fs Pulse Duration: Morphological Studies on Model Samples. Appl. Surf. Sci. 2009, 255, 4955–4960. [Google Scholar] [CrossRef]

- Chen, G.X.; Kwee, T.J.; Tan, K.P.; Choo, Y.S.; Hong, M.H. Laser Cleaning of Steel for Paint Removal. Appl. Phys. A 2010, 101, 249–253. [Google Scholar] [CrossRef]

- Pan, Y.; Lv, X.; Zhang, H.; Chen, J.; Han, B.; Shen, Z.; Lu, J.; Ni, X. Millisecond Laser Machining of Transparent Materials Assisted by a Nanosecond Laser with Different Delays. Opt. Lett. 2016, 41, 2807–2810. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.; Pan, Y.; Jia, Z.; Li, Z.; Ni, X. Surface Damage Induced by a Combined Millisecond and Nanosecond Laser. Appl. Opt. 2017, 56, 5060–5067. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, H.; Chen, J.; Han, B.; Shen, Z.; Lu, J.; Ni, X. Millisecond Laser Machining of Transparent Materials Assisted by Nanosecond Laser. Opt. Express 2015, 23, 765–775. [Google Scholar] [CrossRef]

- Yuan, B.-S.; Wang, D.; Dong, Y.; Zhang, W.; Jin, G.-Y. Experimental Study of the Morphological Evolution of the Millisecond-Nanosecond Combined-Pulse Laser Ablation of Aluminum Alloy. Appl. Opt. 2018, 57, 5743–5748. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Zhou, Y.; Zhang, X.; Jin, G. Experimental Study of the Damage Morphology Induced by the Millisecond-Nanosecond Combined-Pulse Laser with Different Pulse Delay on Silicon. Optik 2021, 226, 165904. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Zhou, Y.; Yuan, B.; Cai, J.; Jin, G. The Acceleration Mechanism of Shock Wave Induced by Millisecond-Nanosecond Combined-Pulse Laser on Silicon. Plasma Sci. Technol. 2021, 23, 055507. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.; Zhang, W.; Zhou, Y.; Zhao, C.; Jin, G. Theoretical Simulation of Laser-Supported Absorption Wave Induced by Millisecond-Nanosecond Combined-Pulse Laser on Silicon. In Proceedings of the AOPC 2021: Advanced Laser Technology and Applications, Beijing, China, 24 November 2021; pp. 241–245. [Google Scholar] [CrossRef]

- Xia, S.; Cai, J.; Zhang, X.; Li, J.; Jin, G.; Chang, X. Study on Thermal Stress of the the Fused Silica Irradiated by Millisecond-Nanosecond Combined Pulse Laser. Pramana 2021, 95, 171. [Google Scholar] [CrossRef]

- Pozo-Antonio, J.S.; Papanikolaou, A.; Melessanaki, K.; Rivas, T.; Pouli, P. Laser-Assisted Removal of Graffiti from Granite: Advantages of the Simultaneous Use of Two Wavelengths. Coatings 2018, 8, 124. [Google Scholar] [CrossRef]

- Pouli, P.; Papakonstantinou, E.; Frantzikinaki, K.; Panou, A.; Frantzi, G.; Vasiliadis, C.; Fotakis, C. The Two-Wavelength Laser Cleaning Methodology; Theoretical Background and Examples from Its Application on CH Objects and Monuments with Emphasis to the Athens Acropolis Sculptures. Herit. Sci. 2016, 4, 9. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, C.; Mi, G.; Zhang, W.; Wang, J. Influence of Compound Laser on Paint Removal Depth and Performance of 6005A Aluminum Alloy. J. Mater. Eng. Perform. 2024, 33, 8666–8675. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, J.; Jin, G. Simulation Study on Rubber Removal by Continuous Nanosecond Combined Laser. In Proceedings of the AOPC 2021: Advanced Laser Technology and Applications, Beijing, China, 24 November 2021; pp. 383–386. [Google Scholar] [CrossRef]

- Dong, H.; Sun, Z.; Li, J.; Li, Y.; Zhang, W.; Jin, G. Study on Removal of Aluminum Alloy Oxide Film by Continuous-Nanosecond Combined Laser with Different Pulse Delays. Opt. Commun. 2024, 552, 130112. [Google Scholar] [CrossRef]

- Wang, G.; Deng, J.; Lei, J.; Tang, W.; Zhou, W.; Lei, Z. Multi-Objective Optimization of Laser Cleaning Quality of Q390 Steel Rust Layer Based on Response Surface Methodology and NSGA-II Algorithm. Materials 2024, 17, 3109. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, P.; Li, Z.; Zhang, J.; Liu, W. Multi-Objective Optimization of Laser Cladding Process Parameters for Q345B Steel. Mater. Today Commun. 2024, 39, 108679. [Google Scholar] [CrossRef]

- Arsha, A.; Jayakumar, E.; Rajan, T.; Antony, V.; Pai, B. Design and Fabrication of Functionally Graded In-Situ Aluminium Composites for Automotive Pistons. Mater. Des. 2015, 88, 1201–1209. [Google Scholar] [CrossRef]

- Natesan, E.; Meyer, K.A.; Eriksson, S.; Ahlström, J.; Persson, C. Effects of Dwell Time on the Deformation and Fatigue Behaviour of A356-T7 Cast Aluminium Alloys Used in High Specific Power IC Engine Cylinder Heads. Materials 2020, 13, 2727. [Google Scholar] [CrossRef] [PubMed]

- Slavchov, R.I.; Mosbach, S.; Kraft, M.; Pearson, R.; Filip, S.V. An Adsorption-Precipitation Model for the Formation of Injector External Deposits in Internal Combustion Engines. Appl. Energy 2018, 228, 1423–1438. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, G.; Du, G.; Sun, X.; Jiang, G.; Zeng, X.; Sun, P.; Deng, B.; Xie, H.; Wu, Z.; et al. Investigating the Microstructures of Piston Carbon Deposits in a Large-Scale Marine Diesel Engine Using Synchrotron X-Ray Microtomography. Fuel 2015, 142, 173–179. [Google Scholar] [CrossRef]

- Gu, Z.; Wang, T.; Feng, W.; Zhang, X.; Yao, T. Experimental and Process Parameter Optimization Study of Laser Cleaning of Aluminum Alloy Surface Paint Layers. J. Optoelectron. Laser 2025, 36, 208–215. [Google Scholar]

- Hu, J.; Heidari, A.A.; Zhang, L.; Xue, X.; Gui, W.; Chen, H.; Pan, Z. Chaotic Diffusion-Limited Aggregation Enhanced Grey Wolf Optimizer: Insights, Analysis, Binarization, and Feature Selection. Int. J. Intell. Syst. 2022, 37, 4864–4927. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, L.; Piao, Y.; Tao, S.; Xu, W.; Gao, T.; Wu, X. Blind Remote Sensing Image Deblurring Using Local Binary Pattern Prior. Remote Sens. 2022, 14, 1276. [Google Scholar] [CrossRef]

- Basavanna, M.; Shivakumara, P.; Srivatsa, S.K.; Kumar, G.H. Adaptive Histogram Analysis for Scene Text Binarization and Recognition. Malays. J. Comput. Sci. 2016, 29, 74–85. [Google Scholar] [CrossRef]

- Lv, X.-G.; Li, F. Binary Image Deblurring with Automatic Binary Value Estimation. J. Electron. Imaging 2018, 27, 033043. [Google Scholar] [CrossRef]

- Yang, L.; Wu, H.; Chen, Q.; Zhou, X. Effects of Preparation Parameters on SiO2 Aerogels by Single-Factor and Orthogonal Experiments. Mater. Res. Innov. 2015, 19 (Suppl. 2), S90–S95. [Google Scholar] [CrossRef]

- Filgueiras, A.V.; Gago, J.; García, I.; León, V.M.; Viñas, L. Plackett Burman Design for Microplastics Quantification in Marine Sediments. Mar. Pollut. Bull. 2021, 162, 111841. [Google Scholar] [CrossRef]

- Beres, D.L.; Hawkins, D.M. Plackett-Burman Techniques for Sensitivity Analysis of Many-Parametered Models. Ecol. Model. 2001, 141, 171–183. [Google Scholar] [CrossRef]

- Joyce, A.P.; Leung, S.S. Use of Response Surface Methods and Path of Steepest Ascent to Optimize Ligand-Binding Assay Sensitivity. J. Immunol. Methods 2013, 392, 12–23. [Google Scholar] [CrossRef]

- Qin, X.; Zhao, Y.; Wang, Y.; Zeng, J.; Zhou, L.; Ge, J.; Liu, Q.; Zhou, J.; Long, Y. Optimization and GRA Prediction of Al-Cu Pulsed Laser Welding Process Based on RSM. J. Laser Appl. 2024, 36, 022012. [Google Scholar] [CrossRef]

- Nguyen, V.; Altarazi, F.; Tran, T.; Hu, J. Optimization of Process Parameters for Laser Cutting Process of Stainless Steel 304: A Comparative Analysis and Estimation with Taguchi Method and Response Surface Methodology. Math. Probl. Eng. 2022, 2022, 6677586. [Google Scholar] [CrossRef]

- Vilanova, M.; Escribano-García, R.; Guraya, T.; San Sebastian, M. Optimizing Laser Powder Bed Fusion Parameters for IN-738LC by Response Surface Method. Materials 2020, 13, 4879. [Google Scholar] [CrossRef] [PubMed]

| Major Alloying Elements (wt%) | Minor Alloying Elements (wt%) | Al Content (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Si | Cu | Mg | Fe | Mn | Zn | Cr | Ni | Ti | |

| 19.14 | 3.28 | 0.62 | 0.42 | 0.05 | 0.04 | 0.01 | 0.01 | 0.014 | 76.443 |

| Carbon Deposit Layer | Thickness Range (μm) | Main Components |

|---|---|---|

| Surface layer (Loose layer) | 10–50 | Hydrocarbons (HC); Resin and asphalt |

| Intermediate layer (Dense layer) | 50–150 | Graphitic carbon (C); Metal oxides (Fe2O3, Al2O3); Sulfides (SOx) |

| Base layer (Oxidized/sulfurized layer) | 5–20 | Metal particles (Fe, Ni, Cr); Nitrogen oxides (NOx); Sulfides (FeS, CuS) |

| Equipment | Model |

|---|---|

| Pulsed lasers | RFL-P300 (Raycus Fiber Laser Technologies Co., Ltd., Wuhan, China) |

| CW fiber lasers | RFL-C3000 (Raycus Fiber Laser Technologies Co., Ltd., Wuhan, China) |

| Smoke purifiers | DB2400 (S&A Industrial Equipment Co., Ltd., Guangzhou, China) |

| Laser cleaning head | FH1-ACiF1-2K0300DZ2-23M01 (Han’s Laser Technology Industry Group Co., Ltd., Shenzhen, China) |

| Laser water cooler | TFLW-3000WDR (Tongfei Technology Co., Ltd., Suzhou, China) |

| Robotic arm | FANUC M-20ID (FANUC Corporation, Yamanashi, Japan) |

| Pulsed Laser | Semiconductor Laser | ||

|---|---|---|---|

| Power/W | 0–300 | Power/W | 0–3000 |

| X-Scanning speed/mm·s−1 | 5000 | X_Scanning speed/mm·s−1 | 5000 |

| Spot diameter/μm | 350 | Spot diameter/μm | 2100 |

| Line width/mm | 16 | Line width/mm | 16 |

| Frequency/kHz | 10–50 | Frequency/kHz | 2 |

| Pulse width/ns | 150 | Duty cycle/% | 100 |

| Center wavelength/nm | 1064 ± 5 | Center wavelength/nm | 1080 ± 5 |

| Core diameter/μm | 100 | Core diameter/μm | 600 |

| Y_Cleaning speed/mm·s−1 | 0–2400 | ||

| Defocus amount/mm | 0 | ||

| Axial moving speed of laser head/mm·s−1 | 19.5 | ||

| Spot spacing/mm | 1 | ||

| Name | Units | Low | High |

|---|---|---|---|

| A:Pc | % | 5 | 25 |

| B:Pp | % | 65 | 85 |

| C:Vy | mm/s | 5 | 25 |

| D:f | kHz | 30 | 50 |

| E:Vx | mm/s | 3000 | 7000 |

| Name | Units | Level | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| A:Pc | % | 15 | 20 | 25 |

| B:Pp | % | 75 | 80 | 85 |

| C:Vy | mm/s | 15 | 20 | 25 |

| D:f | kHz | 30 | 35 | 40 |

| Std | Run | A:Pc | B:Pp | C:Vy | D:f | E:Vx | Sa |

|---|---|---|---|---|---|---|---|

| % | % | mm/s | kHz | mm/s | μm | ||

| 10 | 1 | 5 | 85 | 25 | 50 | 3000 | 1.753 |

| 4 | 2 | 5 | 85 | 5 | 50 | 7000 | 1.88 |

| 11 | 3 | 25 | 65 | 25 | 50 | 7000 | 1.705 |

| 5 | 4 | 5 | 65 | 25 | 30 | 7000 | 1.495 |

| 6 | 5 | 5 | 65 | 5 | 50 | 3000 | 2.329 |

| 1 | 6 | 25 | 85 | 5 | 50 | 7000 | 1.61 |

| 3 | 7 | 25 | 65 | 25 | 50 | 3000 | 1.765 |

| 9 | 8 | 25 | 85 | 25 | 30 | 3000 | 1.145 |

| 2 | 9 | 5 | 85 | 25 | 30 | 7000 | 1.423 |

| 8 | 10 | 25 | 85 | 5 | 30 | 3000 | 1.374 |

| 7 | 11 | 25 | 65 | 5 | 30 | 7000 | 1.341 |

| 12 | 12 | 5 | 65 | 5 | 30 | 3000 | 1.783 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1.02 | 5 | 0.2032 | 28.20 | 0.0004 | significant |

| A-Pc | 0.2474 | 1 | 0.2474 | 34.34 | 0.0011 | |

| B-Pp | 0.1267 | 1 | 0.1267 | 17.58 | 0.0057 | |

| C-Vy | 0.0886 | 1 | 0.0886 | 12.30 | 0.0127 | |

| D-f | 0.5129 | 1 | 0.5129 | 71.20 | 0.0002 | |

| E-Vx | 0.0403 | 1 | 0.0403 | 5.59 | 0.0560 | |

| Residual | 0.0432 | 6 | 0.0072 | |||

| Cor Total | 1.06 | 11 |

| Sample | A | B | C | D | Sa |

|---|---|---|---|---|---|

| % | % | mm/s | kHz | μm | |

| 1 | 15 | 75 | 15 | 40 | 1.020 |

| 2 | 20 | 80 | 20 | 35 | 0.878 |

| 3 | 25 | 85 | 25 | 30 | 1.145 |

| 4 | 30 | 90 | 30 | 25 | 1.821 |

| 5 | 35 | 95 | 35 | 20 | 2.906 |

| Std | Run | A:Pc | B:Pp | C:Vy | D:f | Sa | RC |

|---|---|---|---|---|---|---|---|

| % | % | mm/s | kHz | μm | |||

| 12 | 1 | 25 | 80 | 20 | 40 | 0.955 | 0.0512 |

| 22 | 2 | 20 | 85 | 20 | 30 | 0.996 | 0.0423 |

| 15 | 3 | 20 | 75 | 25 | 35 | 0.955 | 0.0983 |

| 14 | 4 | 20 | 85 | 15 | 35 | 0.946 | 0.047 |

| 17 | 5 | 15 | 80 | 15 | 35 | 0.92 | 0.0542 |

| 21 | 6 | 20 | 75 | 20 | 30 | 0.913 | 0.0884 |

| 25 | 7 | 20 | 80 | 20 | 35 | 0.886 | 0.0742 |

| 13 | 8 | 20 | 75 | 15 | 35 | 0.901 | 0.0714 |

| 11 | 9 | 15 | 80 | 20 | 40 | 0.97 | 0.0711 |

| 5 | 10 | 20 | 80 | 15 | 30 | 0.914 | 0.0501 |

| 26 | 11 | 20 | 80 | 20 | 35 | 0.878 | 0.0683 |

| 3 | 12 | 15 | 85 | 20 | 35 | 0.949 | 0.084 |

| 20 | 13 | 25 | 80 | 25 | 35 | 1.015 | 0.0543 |

| 9 | 14 | 15 | 80 | 20 | 30 | 0.963 | 0.0765 |

| 23 | 15 | 20 | 75 | 20 | 40 | 0.959 | 0.0611 |

| 19 | 16 | 15 | 80 | 25 | 35 | 1.012 | 0.1041 |

| 4 | 17 | 25 | 85 | 20 | 35 | 1.002 | 0.039 |

| 8 | 18 | 20 | 80 | 25 | 40 | 0.986 | 0.0691 |

| 7 | 19 | 20 | 80 | 15 | 40 | 0.92 | 0.0674 |

| 6 | 20 | 20 | 80 | 25 | 30 | 1.009 | 0.0841 |

| 18 | 21 | 25 | 80 | 15 | 35 | 0.944 | 0.0464 |

| 1 | 22 | 15 | 75 | 20 | 35 | 0.934 | 0.0853 |

| 10 | 23 | 25 | 80 | 20 | 30 | 0.962 | 0.0523 |

| 16 | 24 | 20 | 85 | 25 | 35 | 0.994 | 0.0643 |

| 27 | 25 | 20 | 80 | 20 | 35 | 0.871 | 0.0714 |

| 2 | 26 | 25 | 75 | 20 | 35 | 0.922 | 0.0812 |

| 24 | 27 | 20 | 85 | 20 | 40 | 0.934 | 0.0685 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 0.0425 | 14 | 0.0030 | 22.61 | <0.0001 | significant |

| A-Pc | 0.0002 | 1 | 0.0002 | 1.68 | 0.2196 | |

| B-Pp | 0.0047 | 1 | 0.0047 | 34.85 | <0.0001 | |

| C-Vy | 0.0151 | 1 | 0.0151 | 112.58 | <0.0001 | |

| D-f | 0.0001 | 1 | 0.0001 | 0.6756 | 0.4271 | |

| AB | 0.0011 | 1 | 0.0011 | 7.86 | 0.0159 | |

| AC | 0.0001 | 1 | 0.0001 | 0.8208 | 0.3828 | |

| AD | 0.0000 | 1 | 0.0000 | 0.3648 | 0.5571 | |

| BC | 9.0 × 10−6 | 1 | 9.0 × 10−6 | 0.0670 | 0.8001 | |

| BD | 0.0029 | 1 | 0.0029 | 21.71 | 0.0006 | |

| CD | 0.0002 | 1 | 0.0002 | 1.57 | 0.2347 | |

| A2 | 0.0118 | 1 | 0.0118 | 87.86 | <0.0001 | |

| B2 | 0.0045 | 1 | 0.0045 | 33.78 | <0.0001 | |

| C2 | 0.0099 | 1 | 0.0099 | 73.56 | <0.0001 | |

| D2 | 0.0080 | 1 | 0.0080 | 59.36 | <0.0001 | |

| Residual | 0.0016 | 12 | 0.0001 | |||

| Lack of Fit | 0.0015 | 10 | 0.0001 | 2.66 | 0.3039 | not significant |

| Pure Error | 0.0001 | 2 | 0.0001 | |||

| Cor Total | 0.0441 | 26 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 0.0070 | 10 | 0.0007 | 23.44 | <0.0001 | significant |

| A-Pc | 0.0019 | 1 | 0.0019 | 63.57 | <0.0001 | |

| B-Pp | 0.0016 | 1 | 0.0016 | 55.26 | <0.0001 | |

| C-Vy | 0.0016 | 1 | 0.0016 | 53.01 | <0.0001 | |

| D-f | 2.341 × 10−6 | 1 | 2.341 × 10−6 | 0.0785 | 0.7829 | |

| AB | 0.0004 | 1 | 0.0004 | 14.03 | 0.0018 | |

| AC | 0.0004 | 1 | 0.0004 | 14.79 | 0.0014 | |

| AD | 4.622 × 10−6 | 1 | 4.622 × 10−6 | 0.1551 | 0.6989 | |

| BC | 0.0000 | 1 | 0.0000 | 0.7729 | 0.3923 | |

| BD | 0.0007 | 1 | 0.0007 | 24.00 | 0.0002 | |

| CD | 0.0003 | 1 | 0.0003 | 8.75 | 0.0093 | |

| Residual | 0.0005 | 16 | 0.0000 | |||

| Lack of Fit | 0.0005 | 14 | 0.0000 | 3.77 | 0.2293 | not significant |

| Pure Error | 0.0000 | 2 | 8.71 × 10−6 | |||

| Cor Total | 0.0075 | 26 |

| Name | Goal | Limits | Weights |

|---|---|---|---|

| CW laser power Pc/% | In range | 15–25 | 1 |

| Pulsed laser power Pp/% | In range | 75–85 | 1 |

| Y_Scanning speed/mm·s−1 | In range | 15–25 | 1 |

| Repetition frequency f/kHz | In range | 30–40 | 1 |

| Carbon residue rate RC | Minimize | 0–0.05 | 1 |

| Surface roughness Sa/μm | Minimize | 0.4–1 | 1 |

| Sample | Surface Roughness/Sa (μm) | Carbon Residue Rate/RC | ||||

|---|---|---|---|---|---|---|

| Optimize Values | Experimental Values | Relative Errors | Optimize Values | Experimental Values | Relative Errors | |

| 1 | 0.947 | 0.970 | 2.37% | 3.65% | 3.87% | 5.68% |

| 2 | 0.947 | 0.935 | 1.28% | 3.65% | 3.58% | 1.96% |

| 3 | 0.947 | 0.959 | 1.25% | 3.65% | 3.47% | 5.19% |

| Prediction Range | 0.915–0.978 | 0.0225–0.0509 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Wang, L.; Yao, Z.; Zhang, Q.; Chen, Z.; Duan, J.; Ye, T.; Yao, J. Hybrid Laser Cleaning of Carbon Deposits on N52B30 Engine Piston Crowns: Multi-Objective Optimization via Response Surface Methodology. Materials 2025, 18, 3626. https://doi.org/10.3390/ma18153626

Su Y, Wang L, Yao Z, Zhang Q, Chen Z, Duan J, Ye T, Yao J. Hybrid Laser Cleaning of Carbon Deposits on N52B30 Engine Piston Crowns: Multi-Objective Optimization via Response Surface Methodology. Materials. 2025; 18(15):3626. https://doi.org/10.3390/ma18153626

Chicago/Turabian StyleSu, Yishun, Liang Wang, Zhehe Yao, Qunli Zhang, Zhijun Chen, Jiawei Duan, Tingqing Ye, and Jianhua Yao. 2025. "Hybrid Laser Cleaning of Carbon Deposits on N52B30 Engine Piston Crowns: Multi-Objective Optimization via Response Surface Methodology" Materials 18, no. 15: 3626. https://doi.org/10.3390/ma18153626

APA StyleSu, Y., Wang, L., Yao, Z., Zhang, Q., Chen, Z., Duan, J., Ye, T., & Yao, J. (2025). Hybrid Laser Cleaning of Carbon Deposits on N52B30 Engine Piston Crowns: Multi-Objective Optimization via Response Surface Methodology. Materials, 18(15), 3626. https://doi.org/10.3390/ma18153626