Axial Compression of BFRP Spiral Strip–PVC Tube Confined Fiber-Recycled Concrete: Experiment and FEM Analysis

Abstract

1. Introduction

2. Experimental Programs

2.1. Design and Fabrication of Specimens

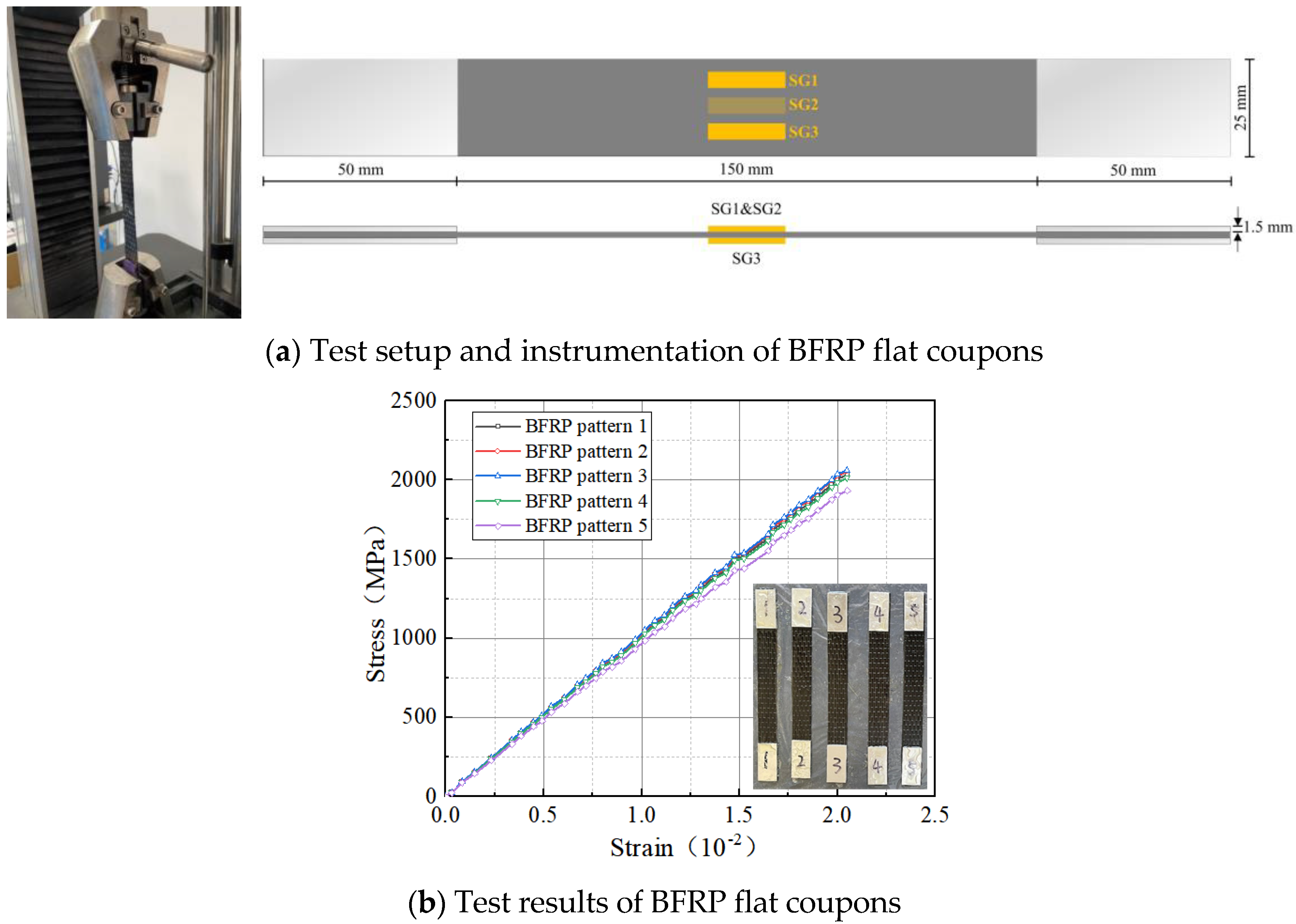

2.2. Material Properties

2.3. Measurement Procedures

3. Experimental Results and Discussion

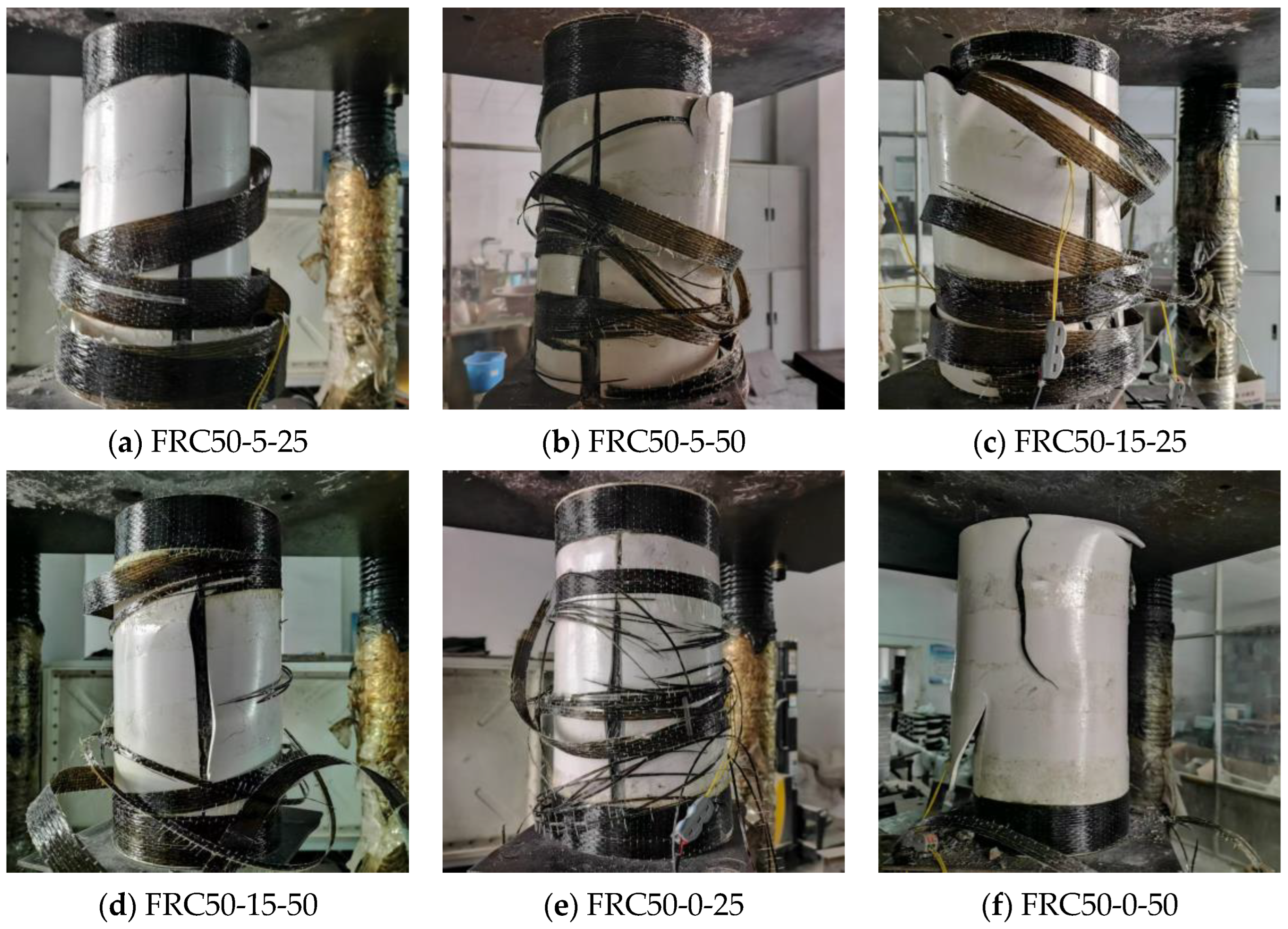

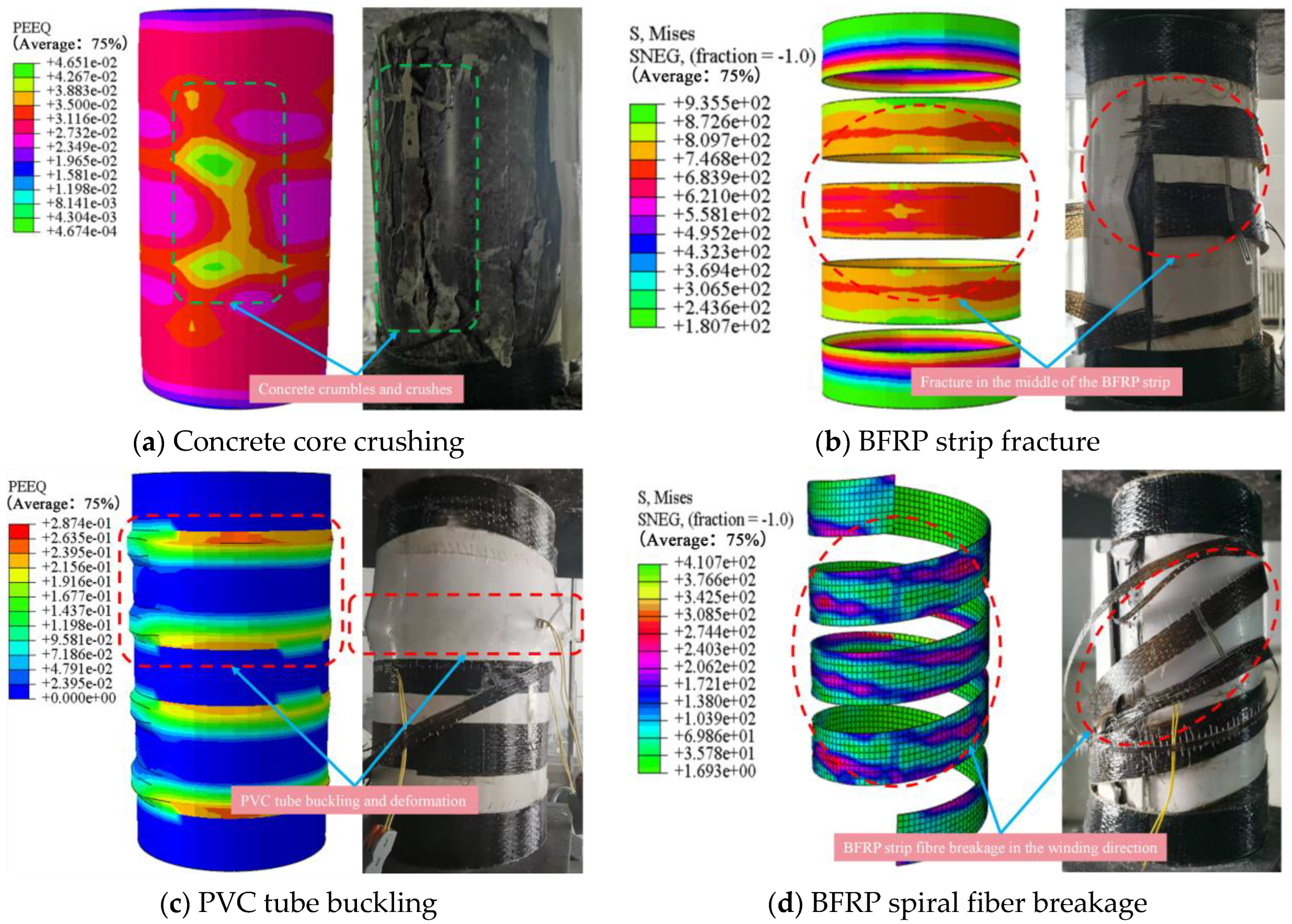

3.1. Failure Model and Experimental Results

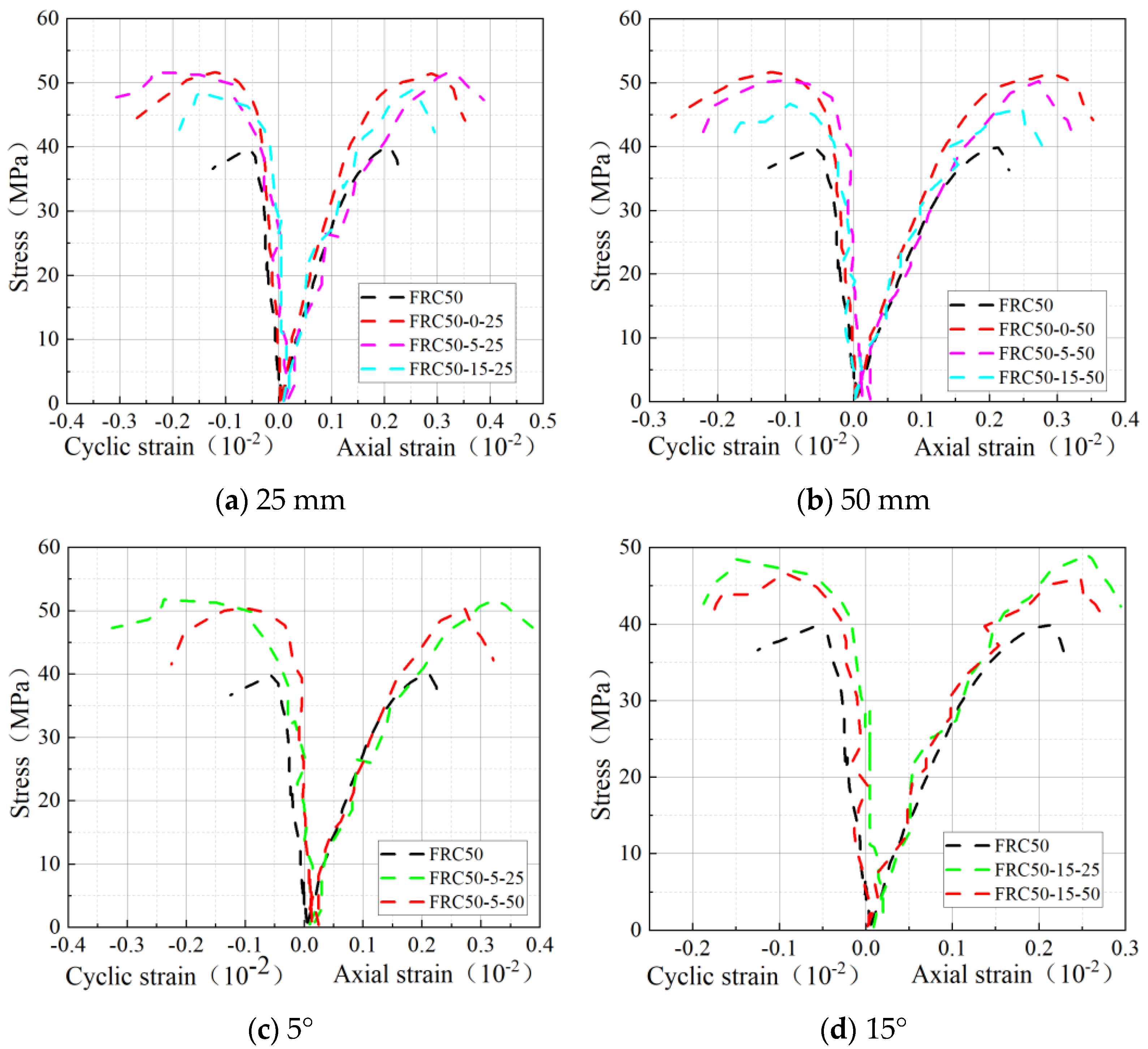

3.2. Stress–Strain Curve of the Specimen

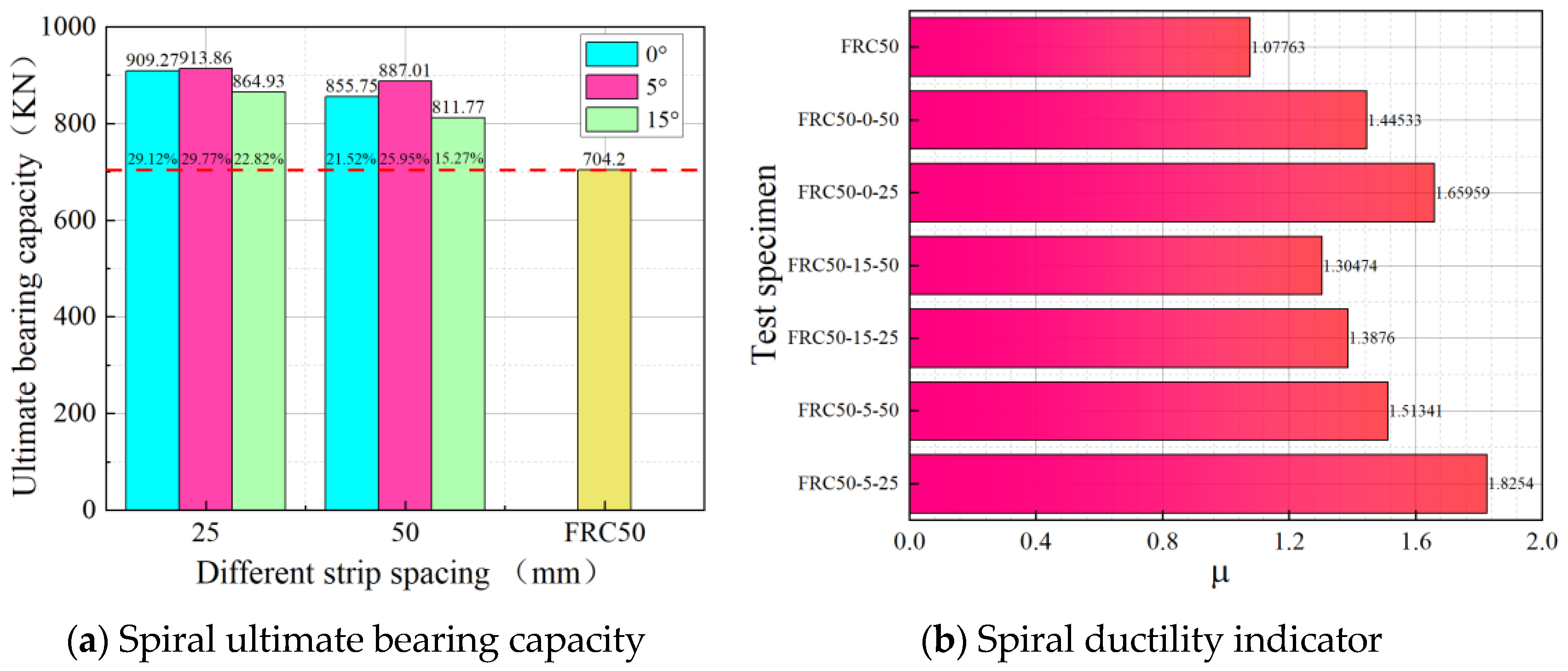

3.3. Bearing Capacity and Ductility

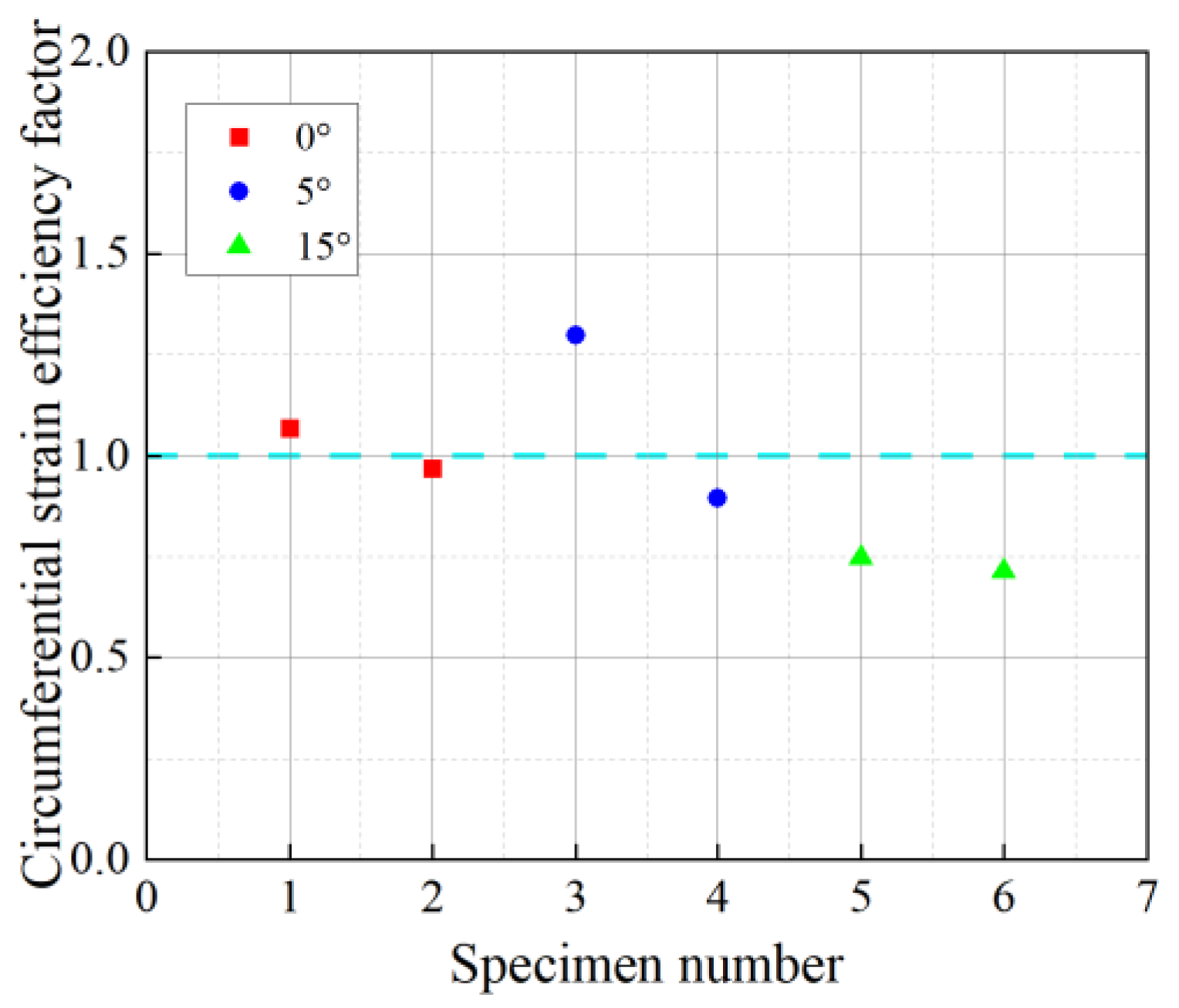

3.4. BFRP Circumferential Strain Utilization

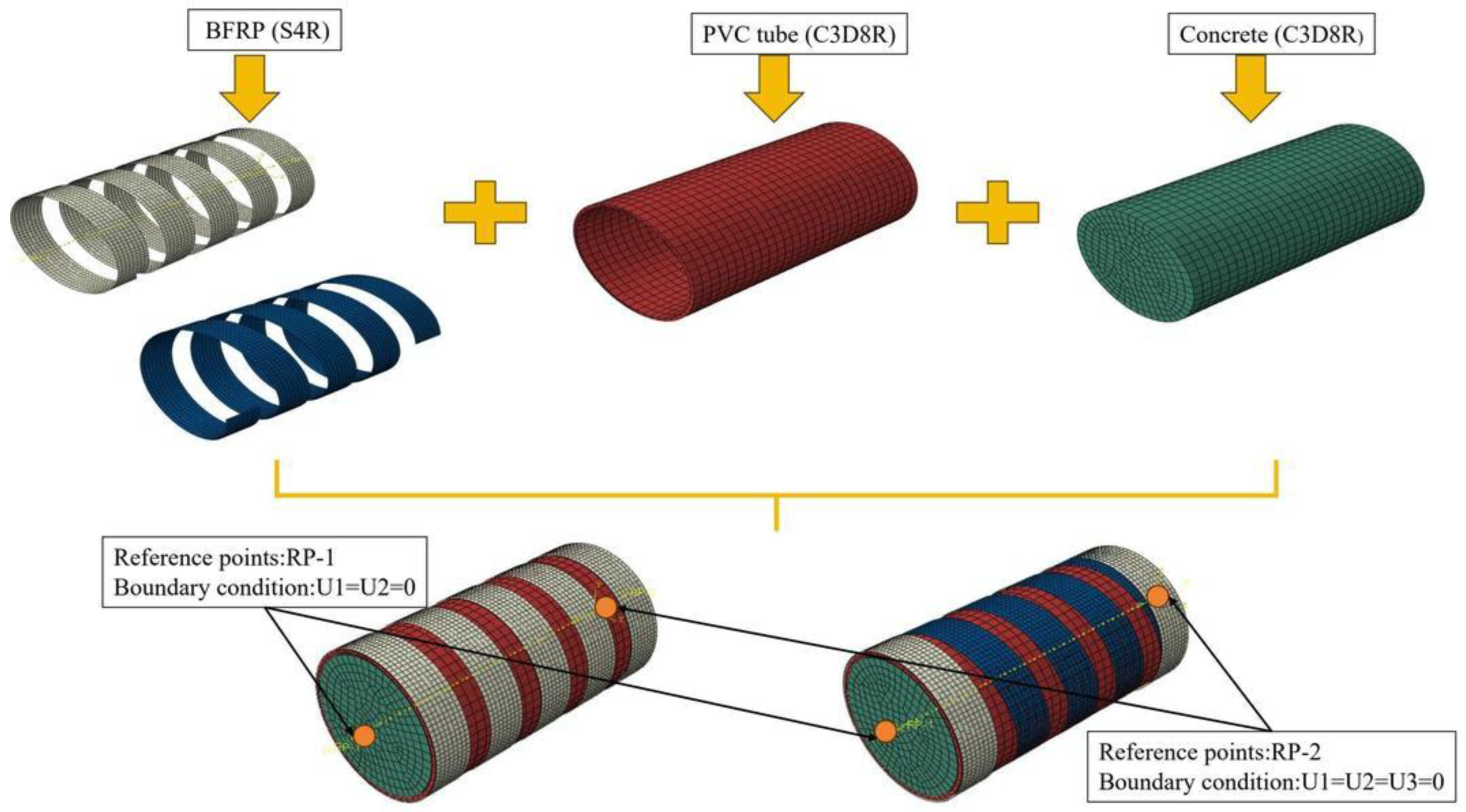

4. FE Analysis

4.1. Constitutive Relations of Materials

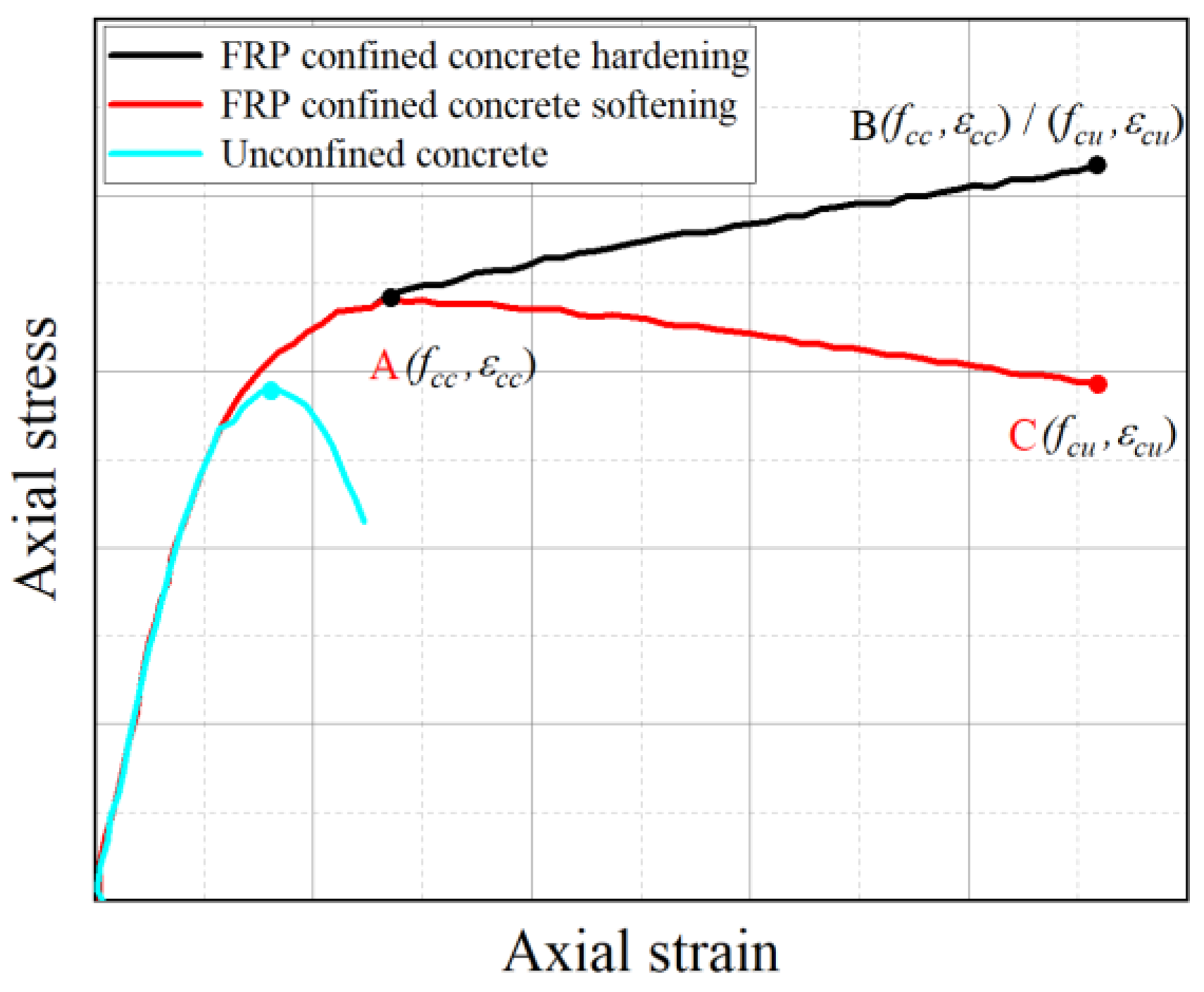

4.1.1. Concrete

4.1.2. PVC Tube

4.1.3. BFRP Strip

4.2. Grid Division and Cell Selection

4.3. Boundary Conditions and Interactions

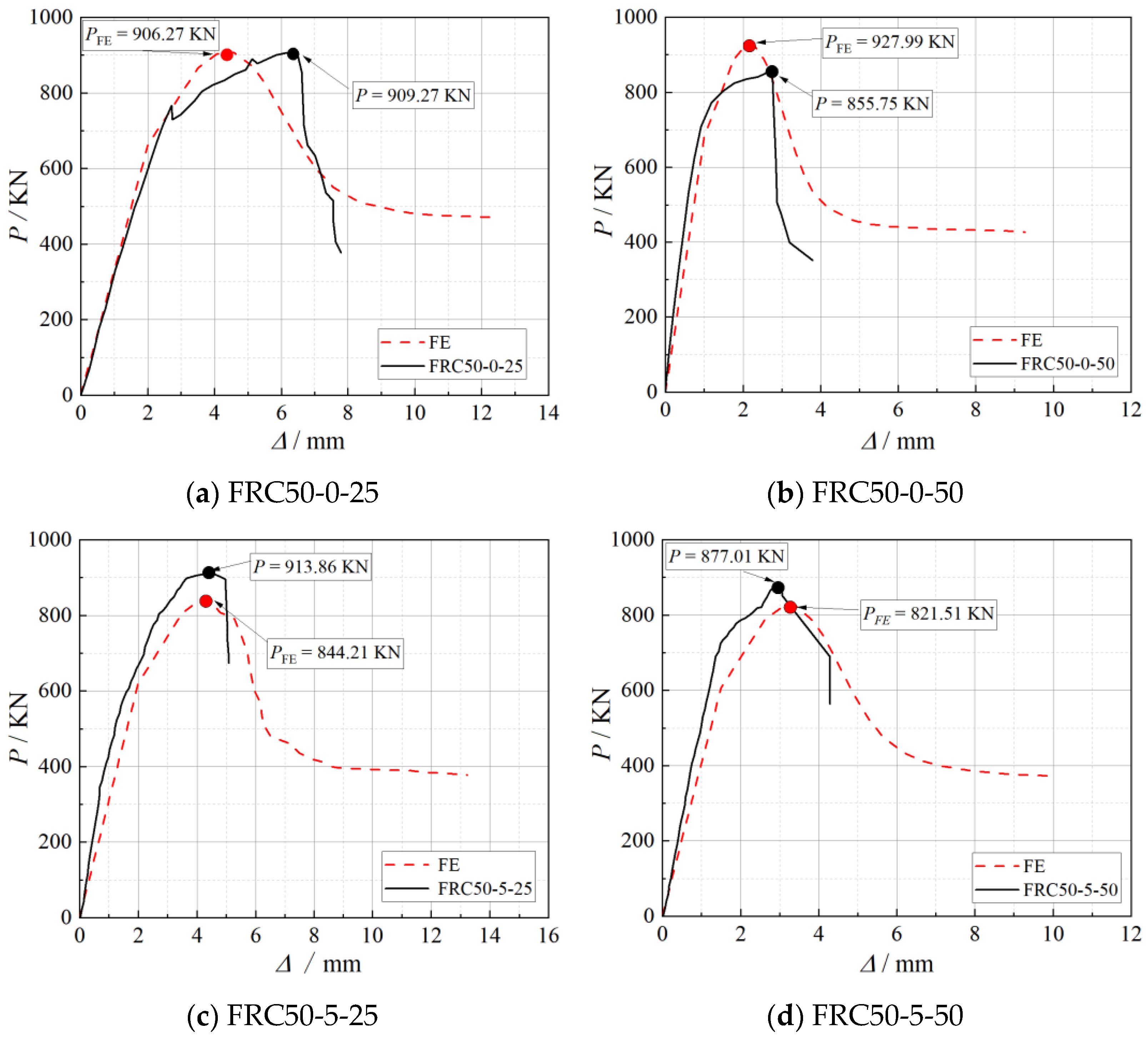

4.4. FE Models Validation

5. Strength Prediction Model

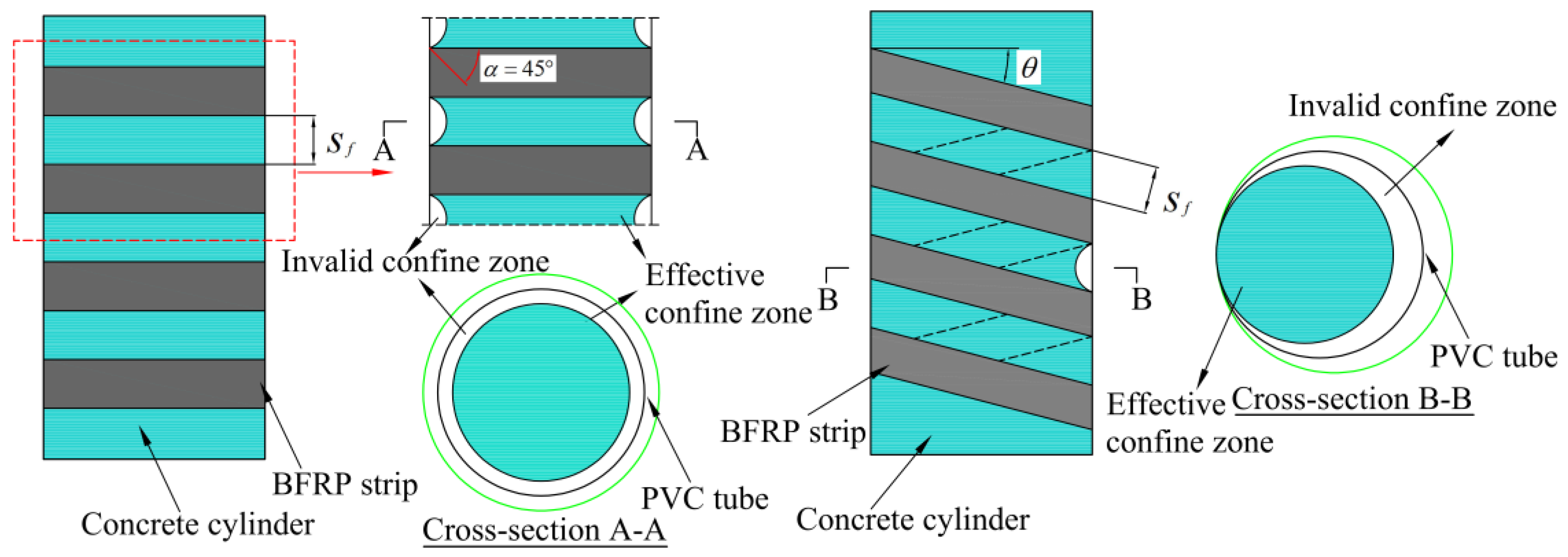

5.1. Calculation of Effective Lateral Restraint Stress

5.2. Strength Modeling of Typically Constrained Concrete Cylinders

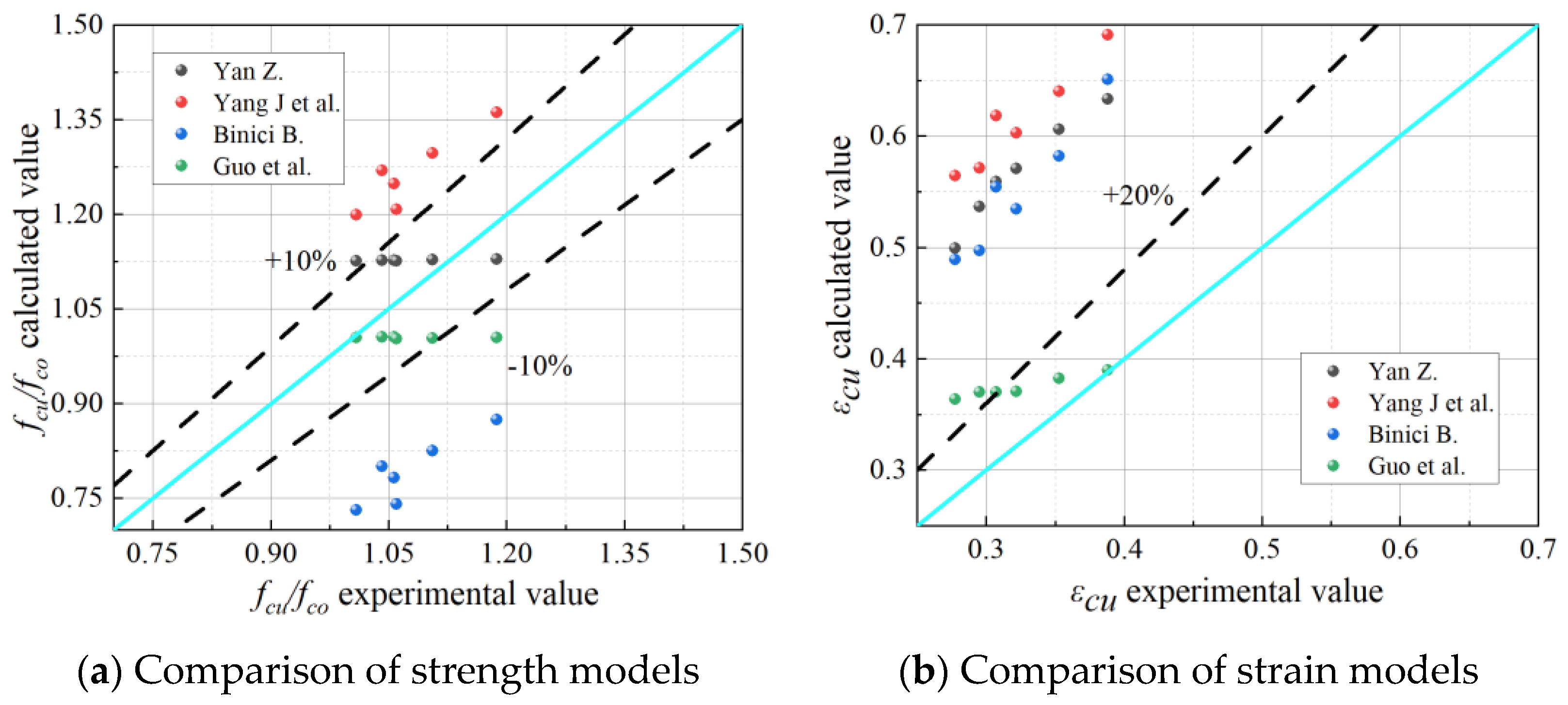

5.3. Evaluation and Analysis of Existing Models

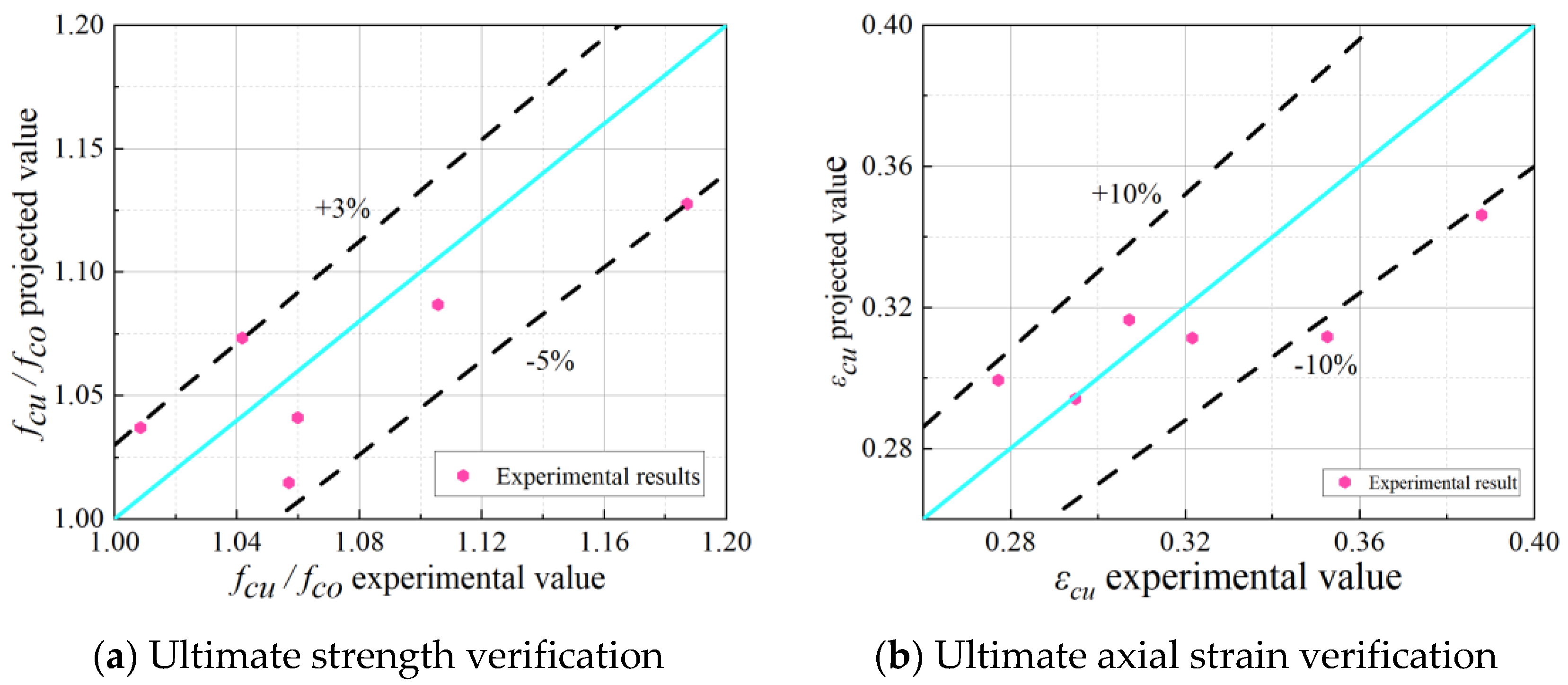

5.4. Model Modification and Validation

6. Conclusions

- (1)

- Under the composite system of the new winding method, a reasonable winding angle and strip spacing effectively enhanced the bearing capacity. Compared to the unconfined specimen, the peak axial bearing capacity of the confined specimen was increased by 15.28% to 29.77%.

- (2)

- The one-piece nature of the spiral wound strip significantly improved the stress–strain curve of the specimen. At a reasonable winding angle, the axial and circumferential strains of the best spirally wound specimen increased by 12.21% and 21.62%, respectively, compared to the best circumferentially wound specimen.

- (3)

- A well-designed winding angle and helix pitch can improve the plastic deformation capacity of the reinforced specimens and enhance structural ductility. The ductility index of the best spirally wound specimen was 1.83, which is 69.39% higher than the unconfined specimen and 10% higher than the best circumferentially wound specimen.

- (4)

- The finite element model of BFRP spiral strip–PVC tube confined RAC was established using ABAQUS finite element analysis software. The simulated damage morphology closely matches the actual observations, validating the modeling approach.

- (5)

- A stress–strain model was developed by correcting existing models and fitting the experimental data. The error of the strength model ranged from +3% to −5%, and the error of the ultimate axial strain model was within ±10%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wilson, D.C.; Rodic, L.; Modak, P.; Soos, R.; Carpintero, A.; Velis, K.; Iyer, M.; Simonett, O. Global Waste Management Outlook; UNEP: Nairobi, Kenya, 2015. [Google Scholar]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Rashad, A.M. Behavior of steel slag aggregate in mortar and concrete—A comprehensive overview. J. Build. Eng. 2022, 53, 104536. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Bazaz, J.B.; Khayati, M. Properties and Performance of Concrete Made with Recycled Low-Quality Crushed Brick. J. Mater. Civ. Eng. 2012, 24, 330–338. [Google Scholar] [CrossRef]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Htet, P.; Chen, W.; Hao, H.; Li, Z.; Shaikh, F. Hybrid fibre reinforced recycled aggregate concrete: Dynamic mechanical properties and durability. Constr. Build. Mater. 2024, 415, 135044. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Abdulla, N.A. A state-of art-review of materials; methods, and applications of PVC-FRP-confined concrete. Constr. Build. Mater. 2023, 363, 129719. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Jin, R.; Kasal, B. Strength and ductility improvement of recycled aggregate concrete by polyester FRP-PVC tube confinement. Compos. Part B Eng. 2019, 162, 178–197. [Google Scholar] [CrossRef]

- Yu, F.; Zhou, H.; Jiang, N.; Fang, Y.; Song, J.; Feng, C.; Guan, Y. Flexural experiment and capacity investigation of CFRP repaired RC beams under heavy pre-damaged level. Constr. Build. Mater. 2020, 230, 117030. [Google Scholar] [CrossRef]

- Ulger, T.; Okeil, A.M. Effect of initial panel slenderness on efficiency of Strengthening-By-Stiffening using FRP for shear deficient steel beams. Thin-Walled Struct. 2016, 105, 147–155. [Google Scholar] [CrossRef]

- Sayed, A.M.; Wang, X.; Wu, Z. Finite element modeling of the shear capacity of RC beams strengthened with FRP sheets by considering different failure modes. Constr. Build. Mater. 2014, 59, 169–179. [Google Scholar] [CrossRef]

- Yu, F.; Bu, S.; Li, D.; Feng, C.; Fang, Y. Experimental investigation and theoretical study on bearing capacity of strong PVC-FRP confined concrete column-weak joint strengthened with core steel tube under axial loading. Constr. Build. Mater. 2021, 271, 121880. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Guo, Y.-C.; Gao, W.-Y.; Li, J.-Z.; Xie, J.-H. Behavior of partially and fully FRP-confined circularized square columns under axial compression. Constr. Build. Mater. 2017, 152, 319–332. [Google Scholar] [CrossRef]

- Khodadadi, N.; Roghani, H.; Harati, E.; Mirdarsoltany, M.; De Caso, F.; Nanni, A. Fiber-reinforced polymer (FRP) in concrete: A comprehensive survey. Constr. Build. Mater. 2024, 432, 136634. [Google Scholar] [CrossRef]

- Liao, J.; Zeng, J.J.; Zhuge, Y.; Zheng, Y.; Ma, G.; Zhang, L. FRP-confined concrete columns with a stress reduction-recovery behavior: A state-of-the-art review, design recommendations and model assessments. Compos. Struct. 2023, 321, 117313. [Google Scholar] [CrossRef]

- Harle, S.M. Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review. Structures 2024, 60, 105881. [Google Scholar] [CrossRef]

- Thong, M.P.; Muhammad, N.S.H.; Youssef, J. Optimized FRP Wrapping Schemes for Circular Concrete Columns under Axial Compression. J. Compos. Constr. 2015, 19, 04015015. [Google Scholar] [CrossRef]

- Garyfalia, G.T.; Theodoros, C.R.; Athanasios, I.K. Axially Loaded Reinforced Concrete Columns with a Square Section Partially Confined by Light GFRP Straps. J. Compos. Constr. 2015, 19, 04014035. [Google Scholar] [CrossRef]

- Liao, J.; Zeng, J.-J.; Jiang, C.; Li, J.-X.; Yuan, J.-S. Stress-strain behavior and design-oriented model for FRP spiral strip-confined concrete. Compos. Struct. 2022, 293, 115747. [Google Scholar] [CrossRef]

- Ismail, R.; Rashid, R.S.M.; Chan, W.C.; Jaafar, M.S.; Hejazi, F. Compressive behavior of concrete cylinder fully and partially confined by carbon fibre-reinforced polymer (CFRP). Constr Build Mater. 2019, 201, 196–206. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Yu, Z.; Han, T.; Yuan, J. Behavior of BFRP strips confined PVC tubes with internal fillers under axial compressive load. J. Build. Eng. 2022, 58, 104999. [Google Scholar] [CrossRef]

- Yu, F.; Xu, G.; Niu, D.; Cheng, A.; Wu, P.; Kong, Z. Experimental study on PVC-CFRP confined concrete columns under low cyclic loading. Constr. Build. Mater. 2018, 177, 287–302. [Google Scholar] [CrossRef]

- Yu, F.; Zhang, N.; Niu, D.; Kong, Z.; Zhu, D.; Wang, S.; Fang, Y. Strain analysis of PVC-CFRP confined concrete column with ring beam joint under axial compression. Compos. Struct. 2019, 224, 111012. [Google Scholar] [CrossRef]

- Chu, C.; Liu, B.; Xu, W.; Liu, H. Axial compressive behavior of short columns of BFRP strip-PVC tube composite reinforced fiber recycled concrete. Structures 2024, 67, 106983. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.; Zhong, Y.; Liu, G. Axial compressive performance and prediction models of confined concrete cylinders made of BFRP-PVC composite tubes. Arch. Civ. Mech. Eng. 2024, 24, 243. [Google Scholar] [CrossRef]

- ASTM International. ASTM D3039M-17: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials (Metric); ASTM International: Washington, DC, USA, 2017. [Google Scholar]

- GB/T 8804.1-2003; Determination of Tensile Properties of Thermoplastic Tube Materials—Part 1: General Principles for Testing. China Standards Press: Beijing, China, 2003.

- 50010-2010; Code for Design of Concrete Structures, 2015 ed. China Architecture & Building Press: Beijing, China, 2015.

- Chen, Z.; Xu, R. Experimental and numeral investigation on self-compacting concrete column with CFRP-PVC spiral reinforcement. Earthq. Struct. 2022, 22, 39–51. [Google Scholar] [CrossRef]

- Issa, C.A.; Chami, P.; Saad, G. Compressive strength of concrete cylinders with variable widths CFRP wraps: Experimental study and numerical modeling. Constr. Build. Mater. 2009, 23, 2306–2318. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Triantafillou, T.; Matthys, S.; Audenaert, K.; Balázs, G.; Blaschko, M.; Blontrock, H.; Czaderski, C.; David, E.; Di Tomasso, A.; Duckett, W.; et al. Externally Bonded FRP Reinforcement for RC Structures; International Federation for Structural Concrete (FIB): Lausanne, Switzerland, 2001. [Google Scholar]

- Jiang, T.; Teng, J.G. Analysis-oriented stress–strain models for FRP–confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Gao, W.Y.; Zeng, J.J.; Duan, Z.J.; Ni, X.Y.; Peng, K.D. Compressive behavior of FRP ring-confined concrete in circular columns: Effects of specimen size and a new design-oriented stress-strain model. Constr. Build. Mater. 2019, 201, 350–368. [Google Scholar] [CrossRef]

- Yan, Z.Z.; Pantelides, C.P. Design-oriented model for concrete columns confined with bonded FRP jackets or post-tensioned FRP shells. In Proceedings of the 8th International Symposium on Fiber Reinforced Polymer Reinforcement for Concrete Structures, Patras, Greece, 16–18 July 2007. [Google Scholar]

- Binici, B. Design of FRPs in circular bridge column retrofits for ductility enhancement. Eng. Struct. 2008, 30, 766–776. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wang, Z. Axial compressive behavior of partially CFRP confined seawater sea-sand concrete in circular columns—Part I: Experimental study. Compos. Struct. 2020, 246, 112373. [Google Scholar] [CrossRef]

| Test Specimen | Recycled Aggregate Substitution Rate (%) | Helix Pitch (mm) | Strip Layer | PVC Tube | Number of Individuals | Winding Angle (◦) |

|---|---|---|---|---|---|---|

| FRC50-5-25 | 50 | 25 | 1 | 1 | 3 | 5 |

| FRC50-5-50 | 50 | 50 | 1 | 1 | 3 | 5 |

| FRC50-15-25 | 50 | 25 | 1 | 1 | 3 | 15 |

| FRC50-15-50 | 50 | 50 | 1 | 1 | 3 | 15 |

| FRC50-0-25 | 50 | 25 | 1 | 1 | 3 | 0 |

| FRC50-0-50 | 50 | 50 | 1 | 1 | 3 | 0 |

| FRC50 | 50 | / | / | / | 3 | / |

| Classify | Clinker (kg/m3) | Granule (kg/m3) | Natural Aggregate (kg/m3) | Recycled Aggregate (kg/m3) | Coal Ash (kg/m3) | Water-Reducing Agent (kg/m3) | Water (kg/m3) | Fiber Content (%) |

|---|---|---|---|---|---|---|---|---|

| FRC50 | 414 | 626 | 556 | 556 | 138 | 1.81 | 160 | 0.2 |

| Model Number | Density (kg/m3) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Elongation at Break (10−2) | Poisson’s Ratio | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|

| D160 × 4 | 1350–1550 | 34.11 | 3.32 | 1.03 | 0.38 | 48.3 |

| Test Specimen | (KN) | (MPa) | (MPa) | (MPa) | (10−2) | (10−2) | (10−2) | (10−2) |

|---|---|---|---|---|---|---|---|---|

| FRC50-5-25 | 913.86 | 51.74 | 47.33 | 39.87 | 0.21254 | 0.32420 | 0.38797 | 0.32589 |

| FRC50-5-50 | 887.01 | 50.22 | 42.15 | 39.87 | 0.21254 | 0.27306 | 0.32166 | 0.22466 |

| FRC50-15-25 | 864.93 | 48.97 | 42.26 | 39.87 | 0.21254 | 0.25568 | 0.29492 | 0.18729 |

| FRC50-15-50 | 811.77 | 45.96 | 40.21 | 39.87 | 0.21254 | 0.24845 | 0.27731 | 0.17935 |

| FRC50-0-25 | 909.27 | 51.48 | 44.09 | 39.87 | 0.21254 | 0.28891 | 0.35273 | 0.26796 |

| FRC50-0-50 | 855.75 | 48.45 | 41.54 | 39.87 | 0.21254 | 0.27818 | 0.30719 | 0.24282 |

| FRC50 | 704.20 | 39.87 | 36.27 | 39.87 | 0.21254 | 0.21254 | 0.22904 | 0.12506 |

| Swell Angle | Eccentricity | Biaxial to Uniaxial Compressive Strength Ratio | Yield Surface Parameters | Coefficient of Viscosity |

|---|---|---|---|---|

| 30 | 0.1 | 1.16 | 0.667 | 10−5 |

| Specimens | Experimental Peak Load (KN) | FE Simulation Peak Load (KN) | Discrepancy (%) |

|---|---|---|---|

| FRC50-0-25 | 906.27 | 909.27 | 0.33 |

| FRC50-0-50 | 927.99 | 855.75 | 7.79 |

| FRC50-5-25 | 913.86 | 844.21 | 7.63 |

| FRC50-5-50 | 877.01 | 821.51 | 6.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, J.; Liu, H.; Liu, G.; Wang, W.; Bao, J. Axial Compression of BFRP Spiral Strip–PVC Tube Confined Fiber-Recycled Concrete: Experiment and FEM Analysis. Materials 2025, 18, 3431. https://doi.org/10.3390/ma18153431

Tian J, Liu H, Liu G, Wang W, Bao J. Axial Compression of BFRP Spiral Strip–PVC Tube Confined Fiber-Recycled Concrete: Experiment and FEM Analysis. Materials. 2025; 18(15):3431. https://doi.org/10.3390/ma18153431

Chicago/Turabian StyleTian, Jiaxing, Huaxin Liu, Genjin Liu, Wenyu Wang, and Jiuwen Bao. 2025. "Axial Compression of BFRP Spiral Strip–PVC Tube Confined Fiber-Recycled Concrete: Experiment and FEM Analysis" Materials 18, no. 15: 3431. https://doi.org/10.3390/ma18153431

APA StyleTian, J., Liu, H., Liu, G., Wang, W., & Bao, J. (2025). Axial Compression of BFRP Spiral Strip–PVC Tube Confined Fiber-Recycled Concrete: Experiment and FEM Analysis. Materials, 18(15), 3431. https://doi.org/10.3390/ma18153431