Multiphysics-Coupled Simulation of Ultrasound-Assisted Tailing Slurry Sedimentation

Abstract

1. Introduction

2. Experimental Overview

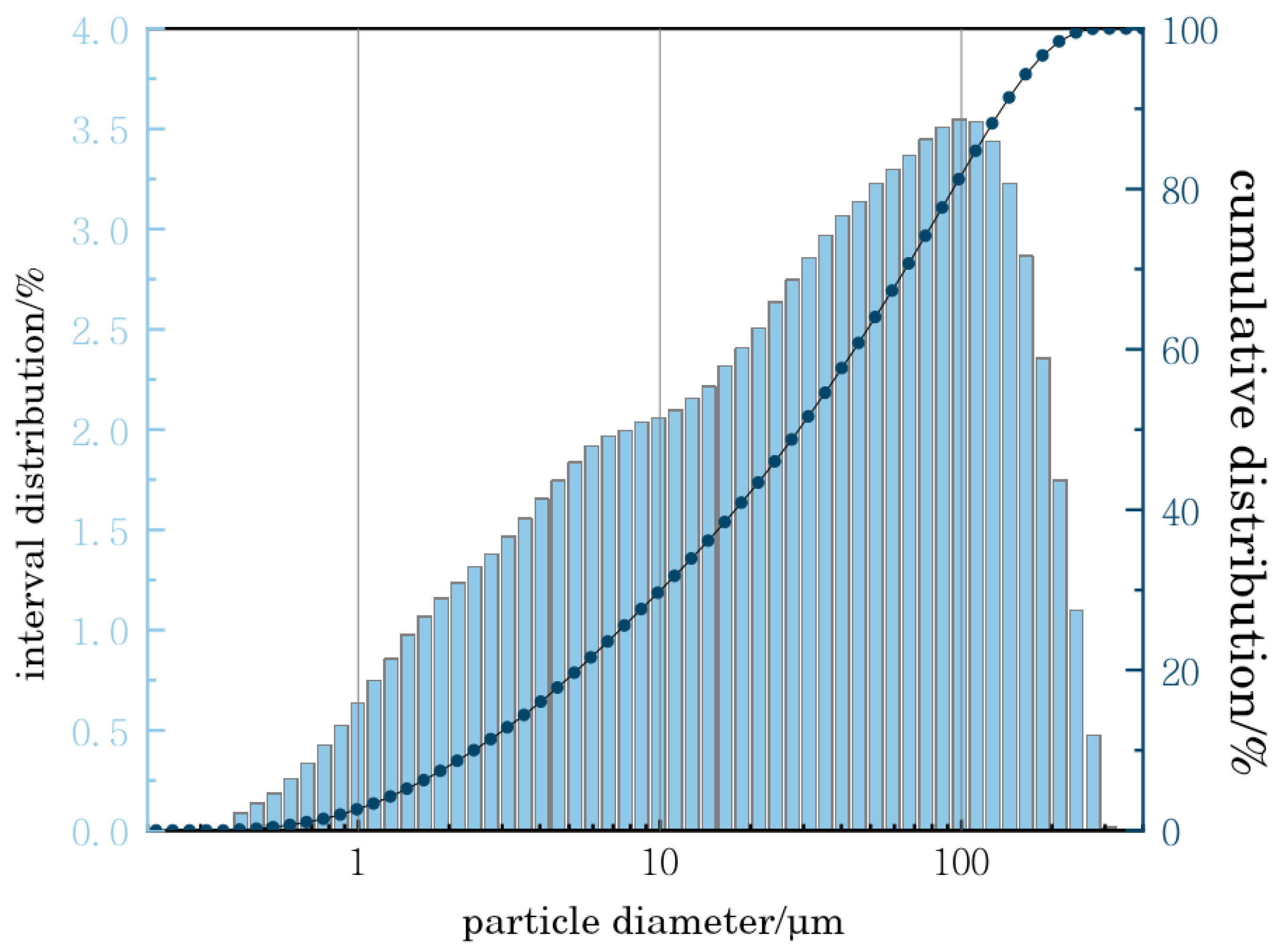

2.1. Tailing Material

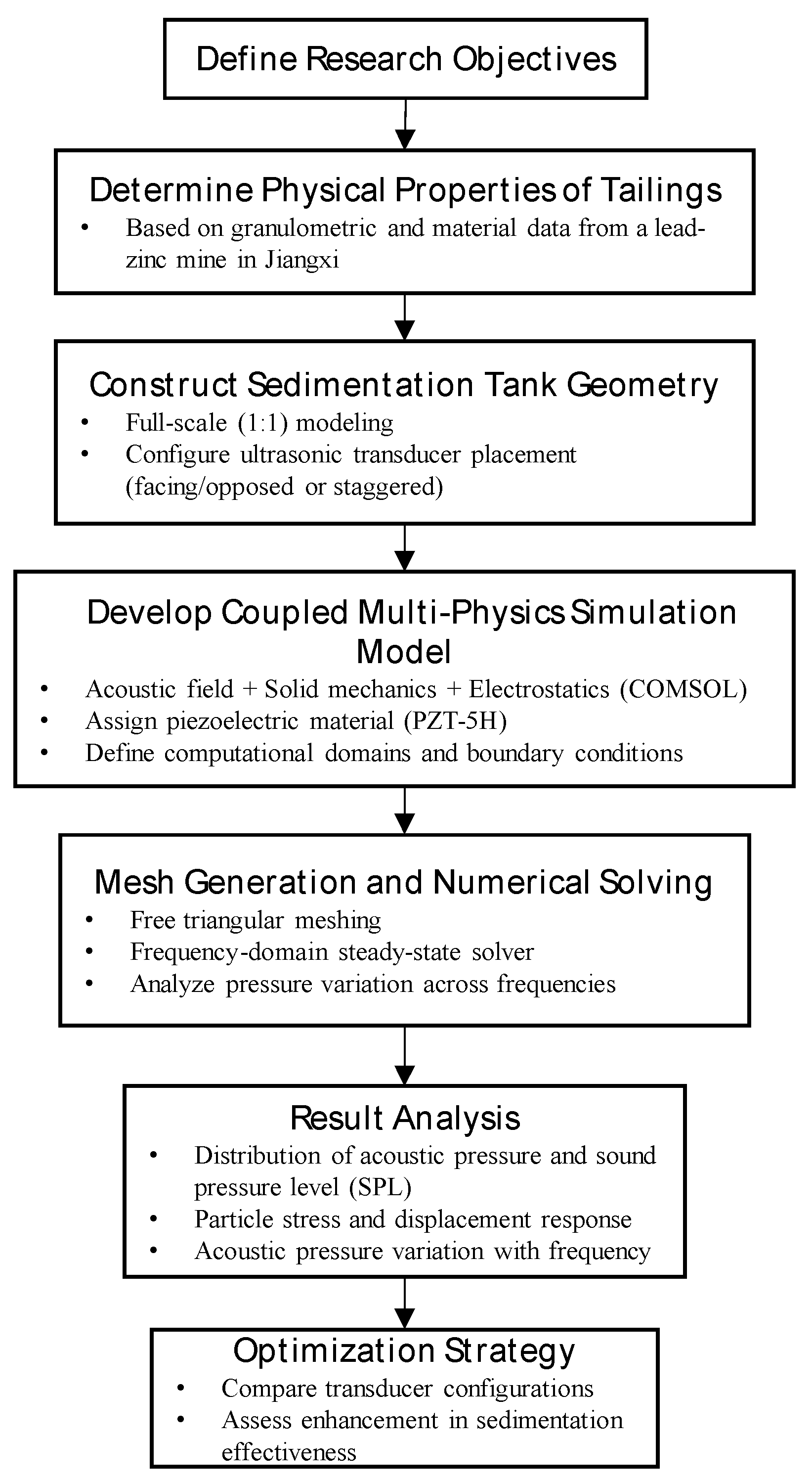

2.2. Research Plan

3. Construction of Numerical Models

3.1. Mathematical Model

- –

- —medium density, kg/m3;

- –

- q—Dipole source, N/m3;

- –

- —Angular frequency, rad/s;

- –

- —Speed of sound, m/s;

- –

- —Time, s;

- –

- —The sound pressure changes at different times, Pa;

- –

- —Equivalent wave velocity.

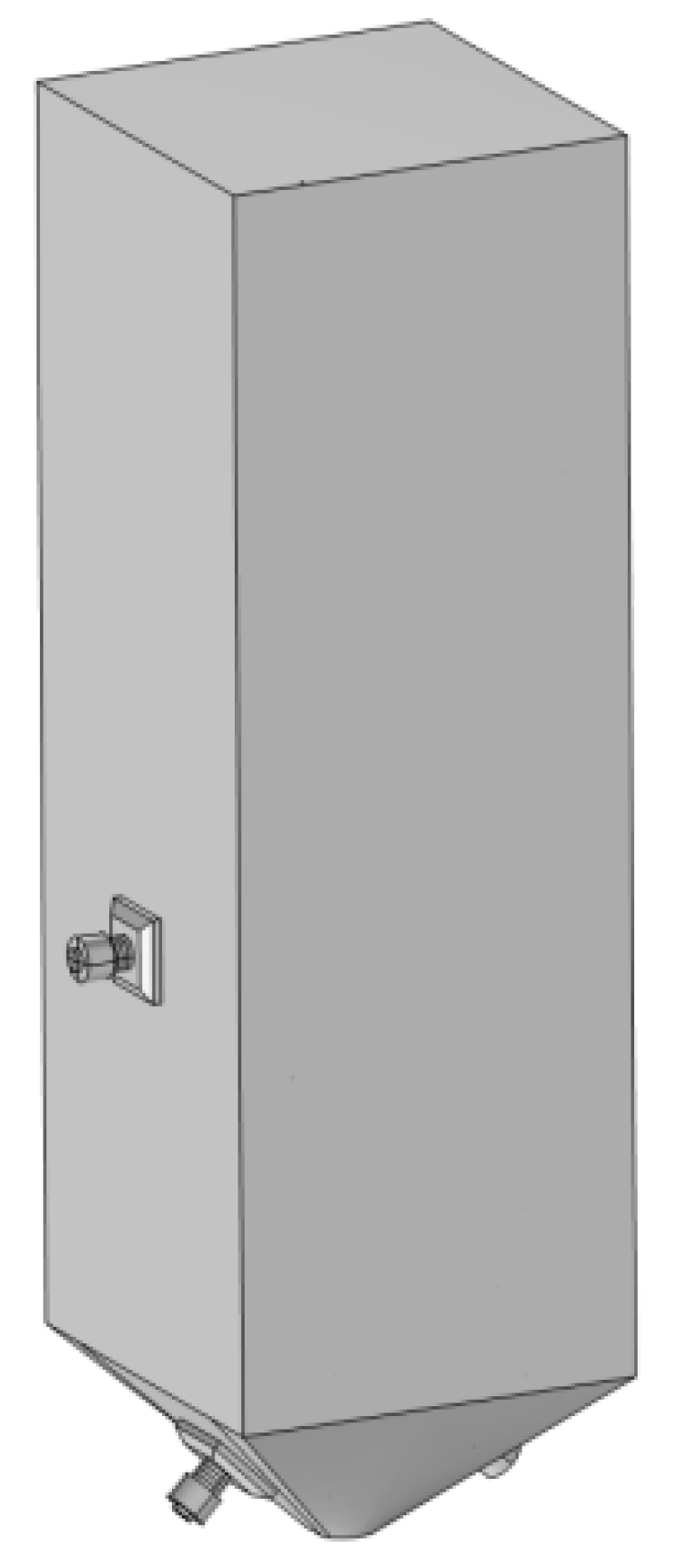

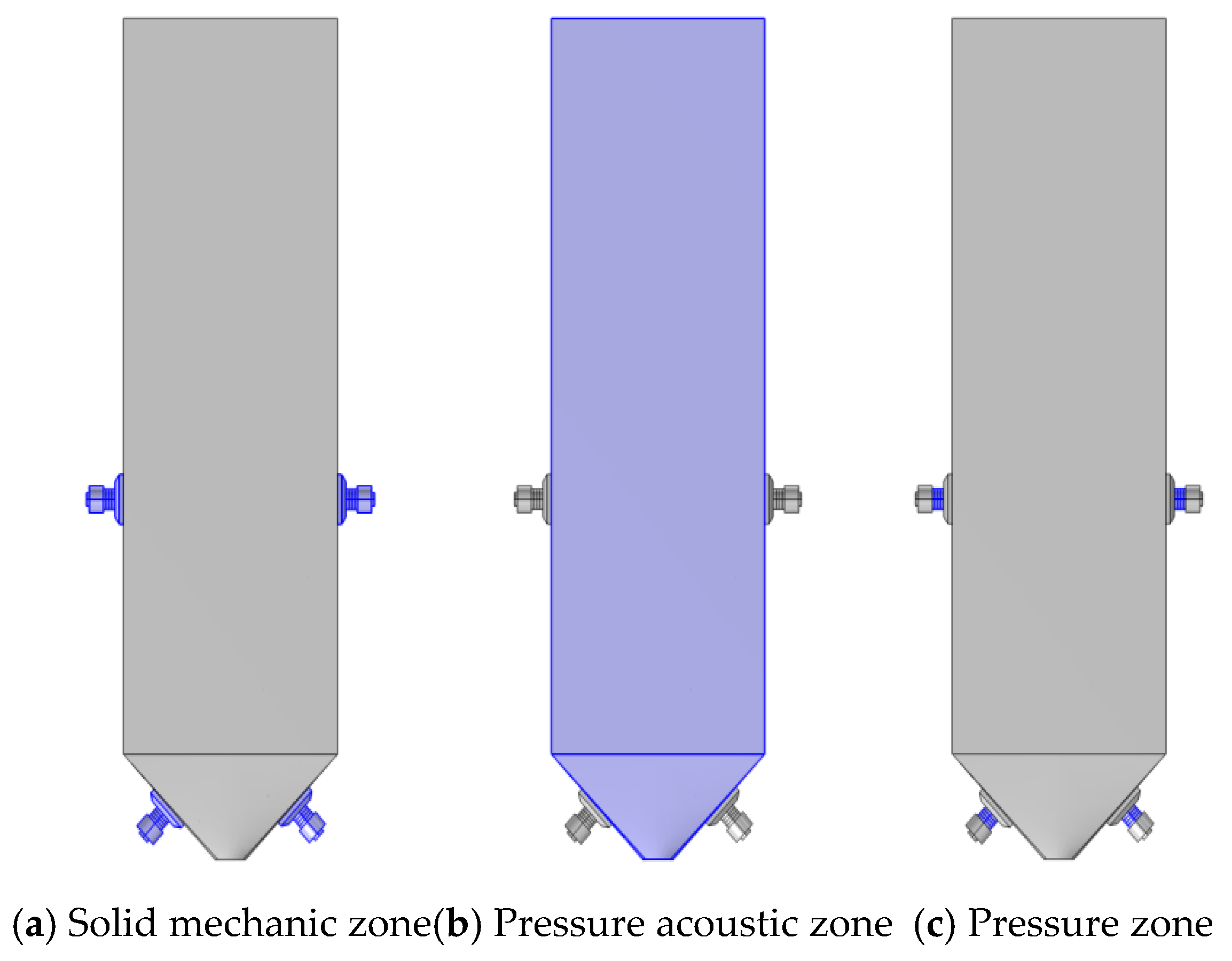

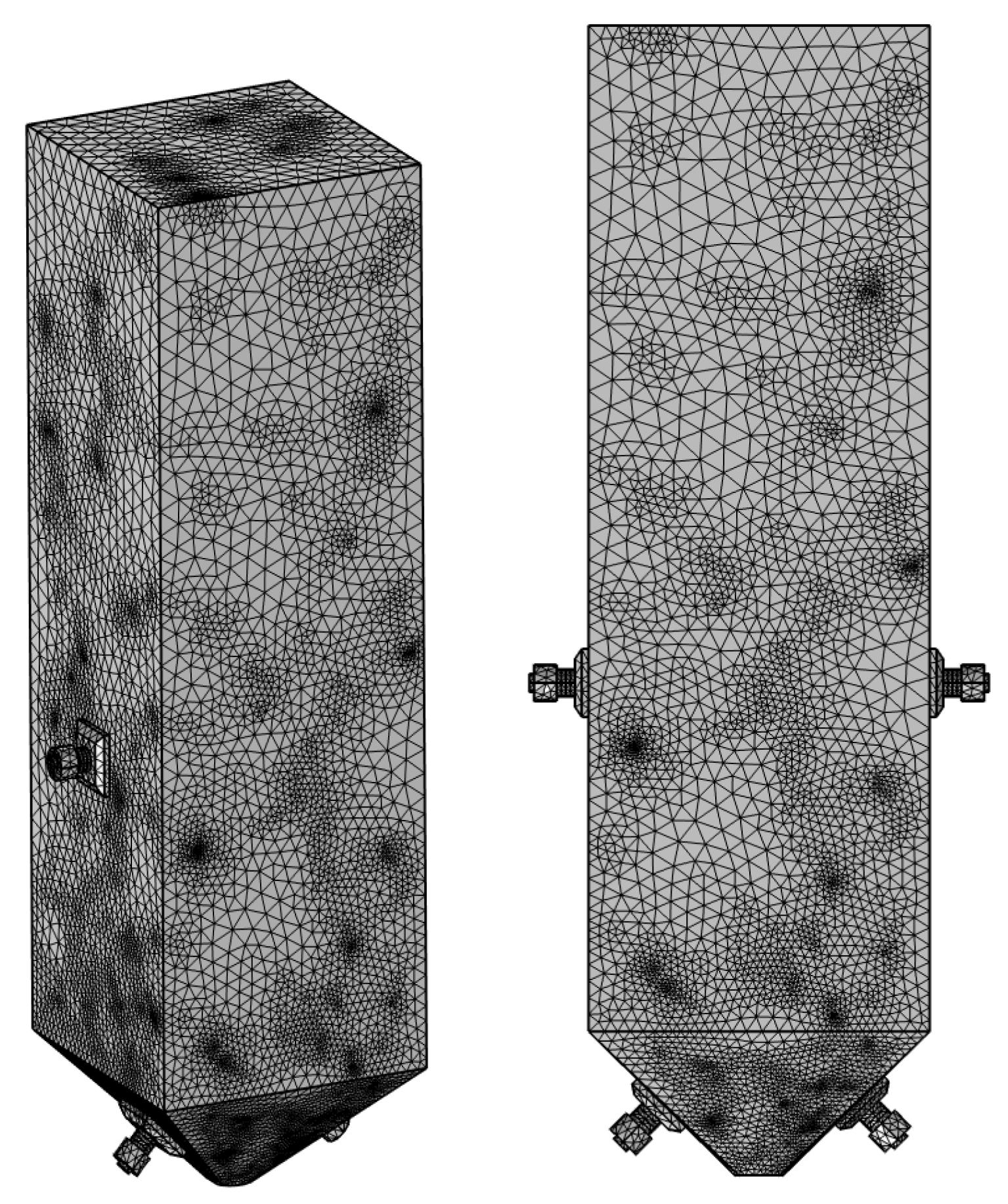

3.2. Sand Silo Model

3.2.1. Condition Setting

- Piezoelectric materials

- Tail mortar

3.2.2. Grid Division

4. Results’ Analysis

4.1. Analysis of Sound Intensity Results

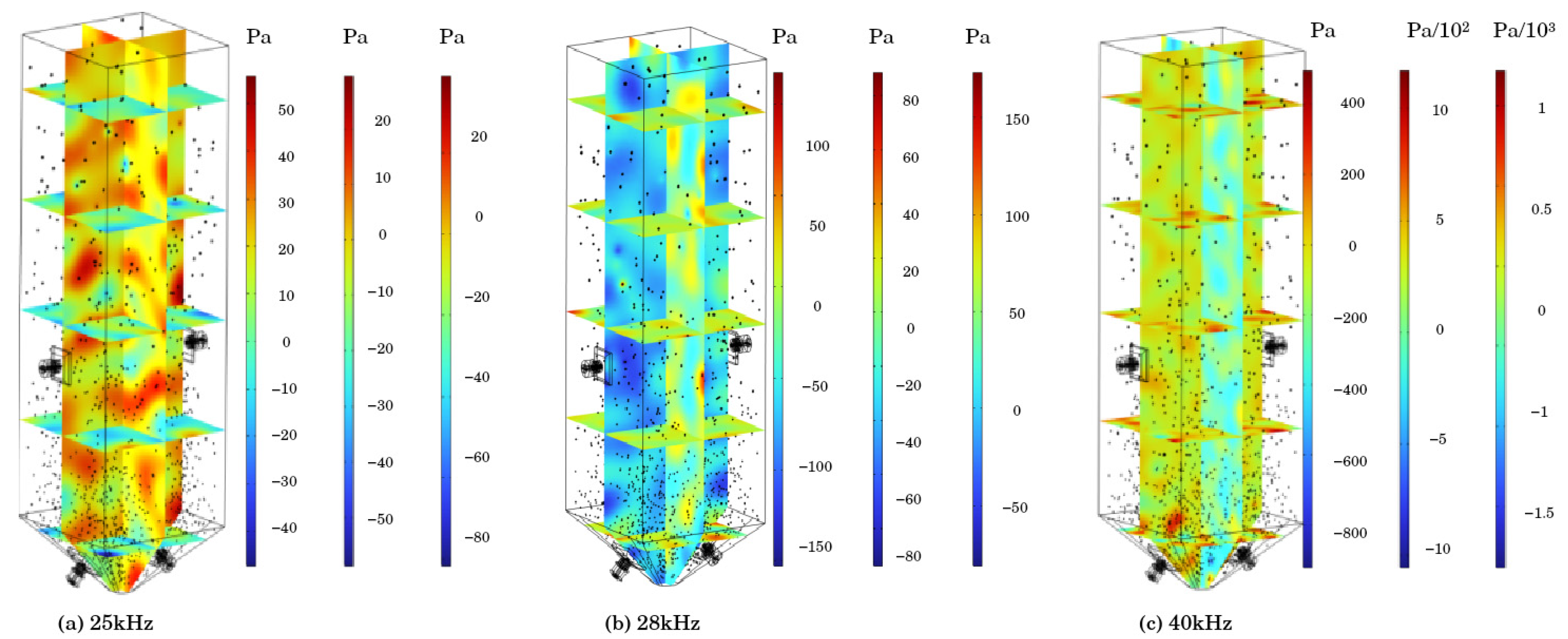

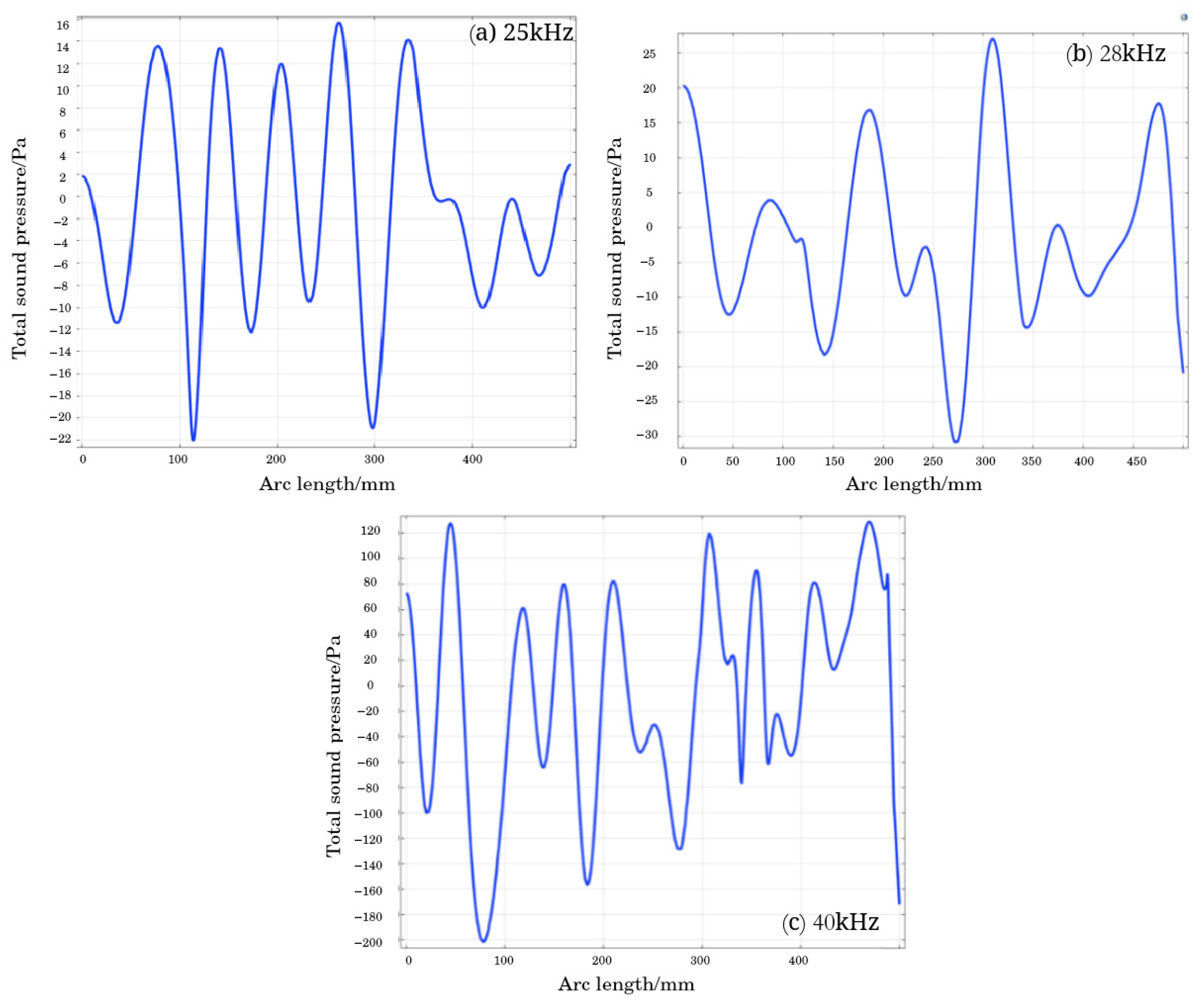

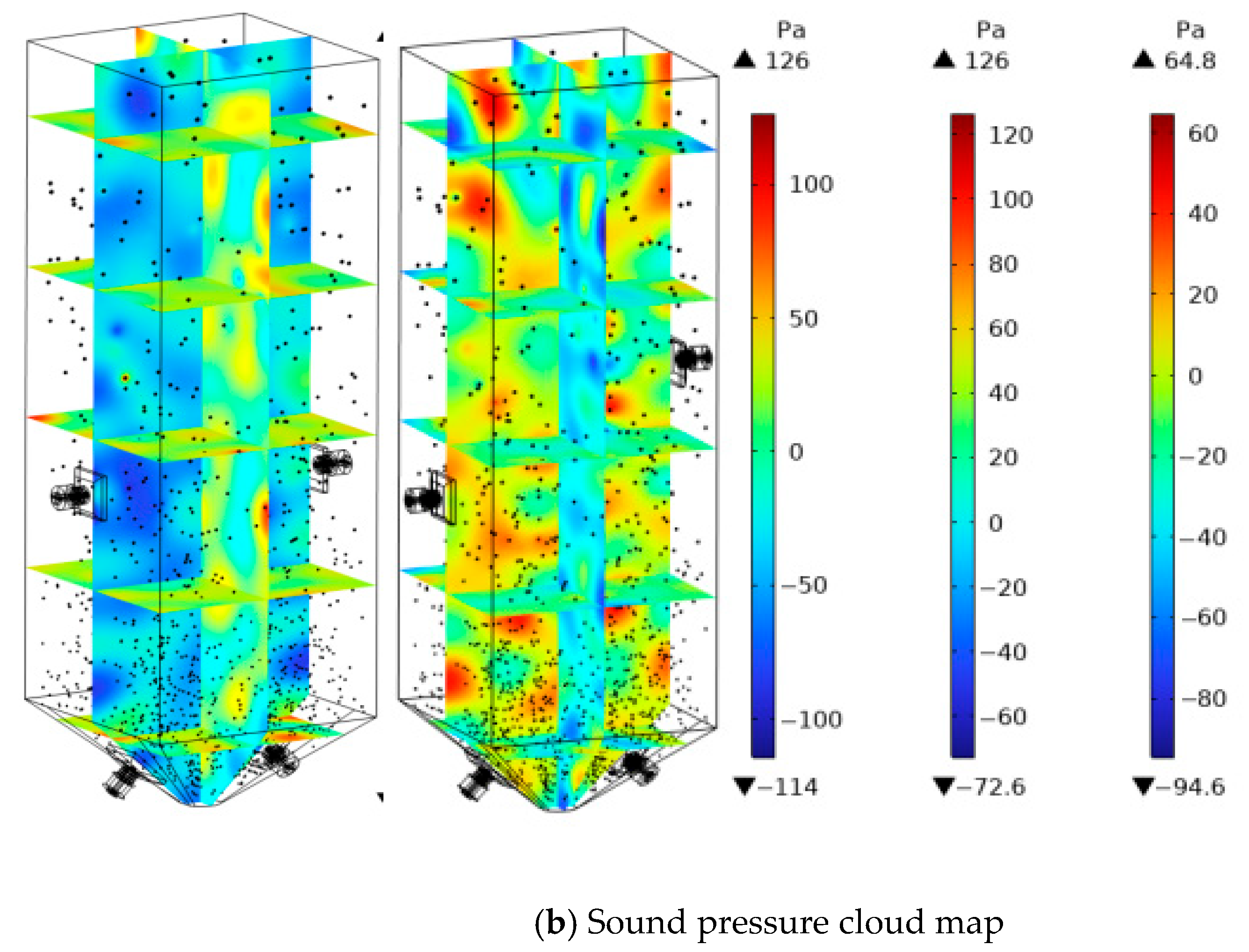

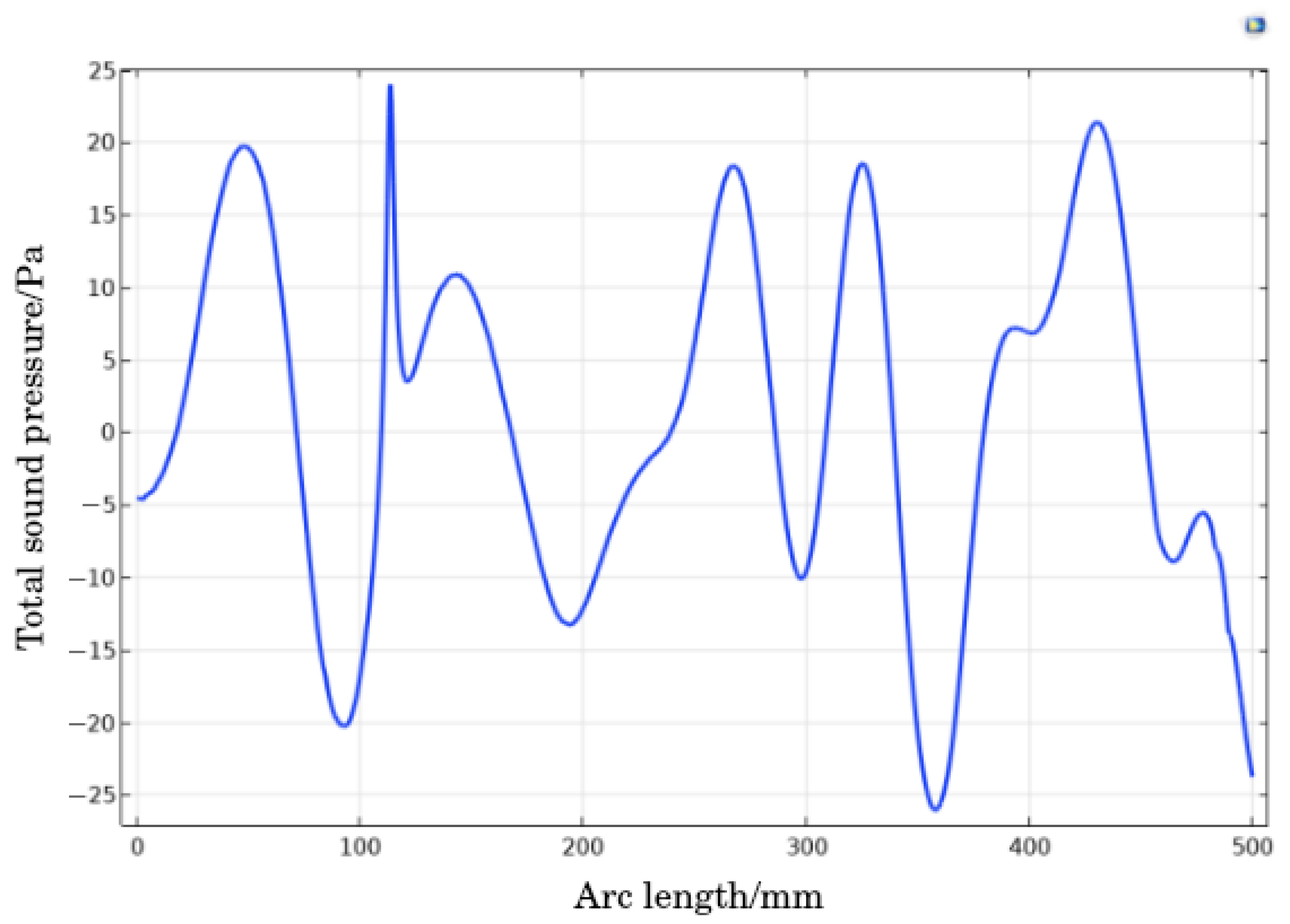

4.1.1. Sound Pressure

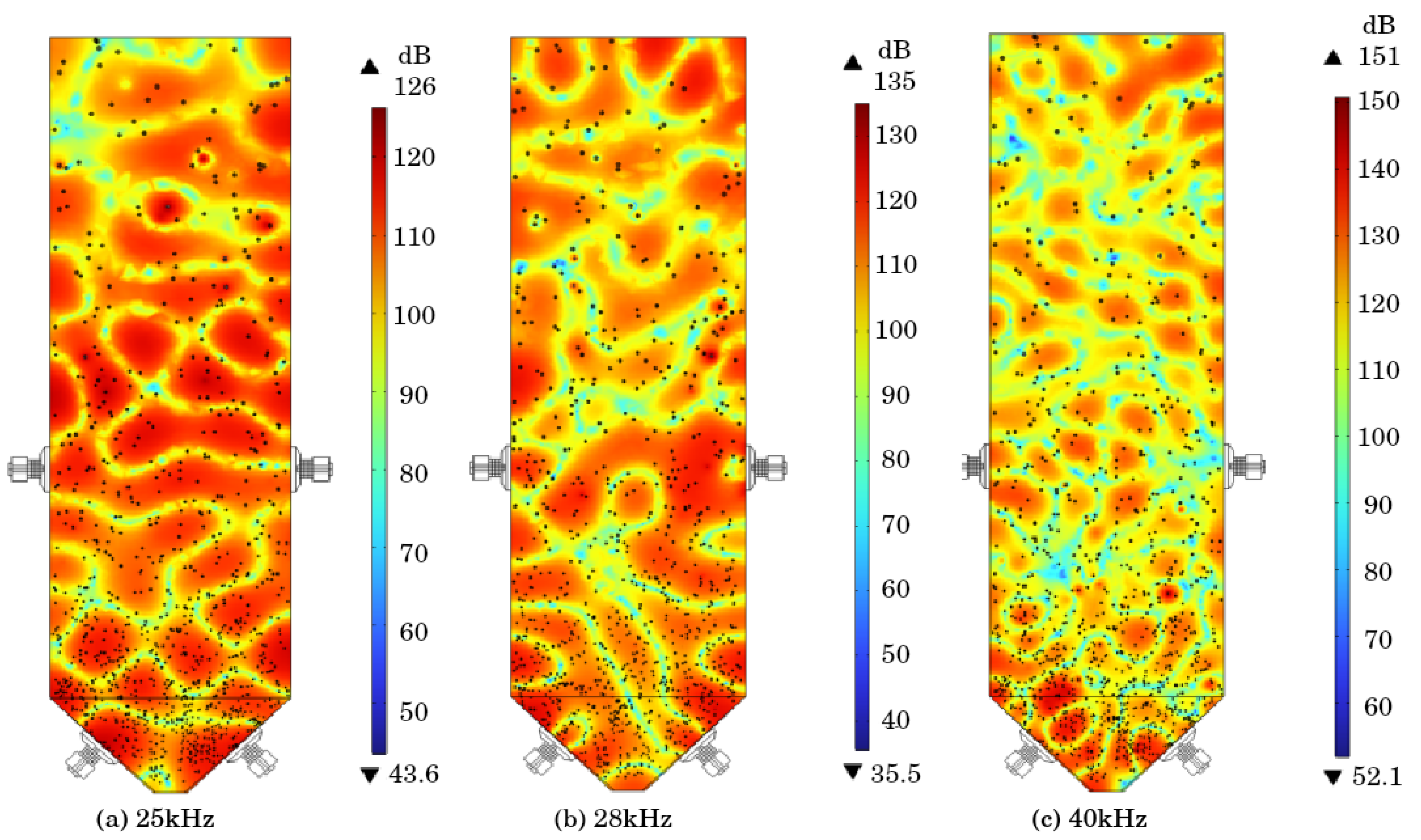

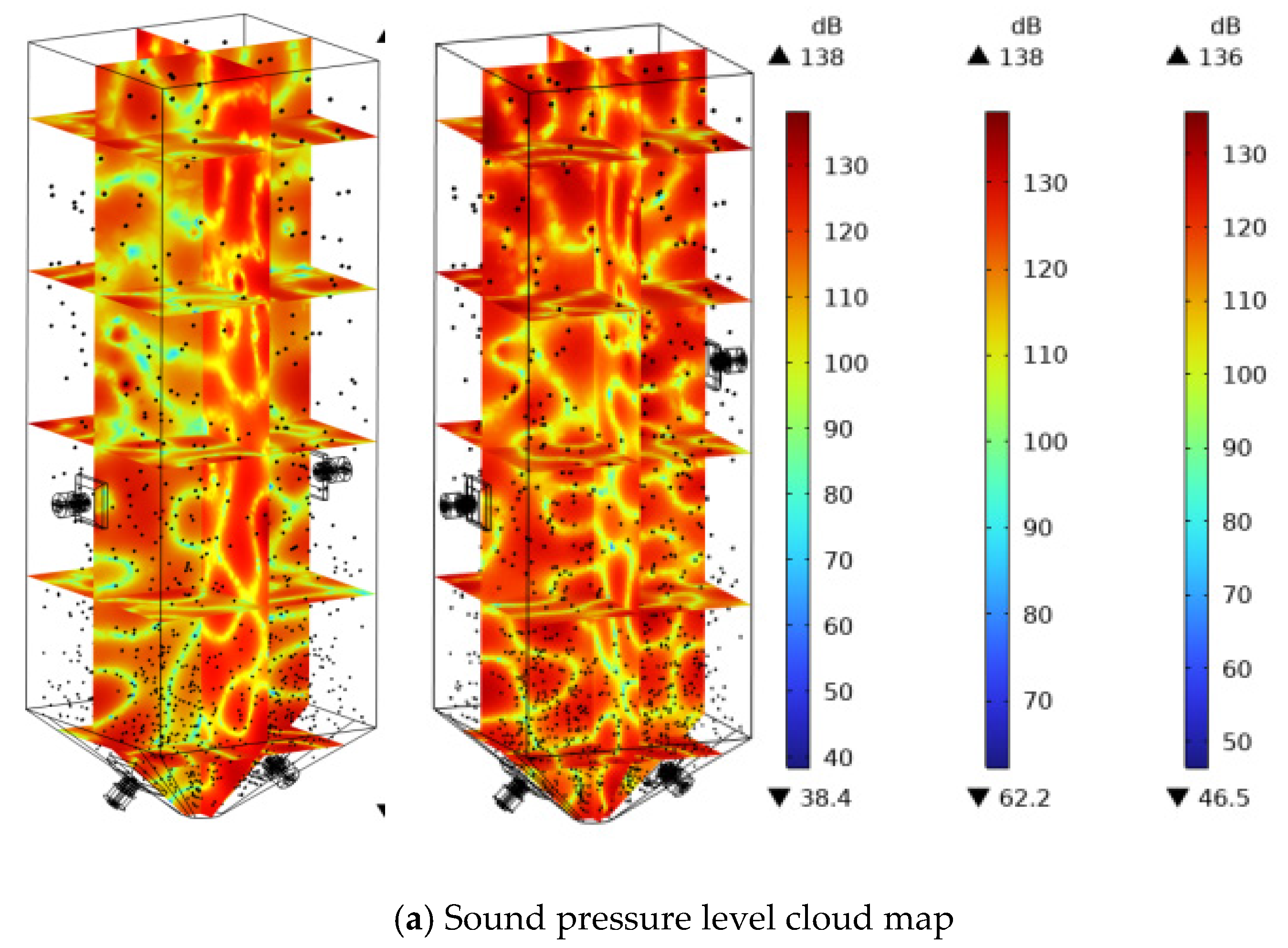

4.1.2. Sound Pressure Level

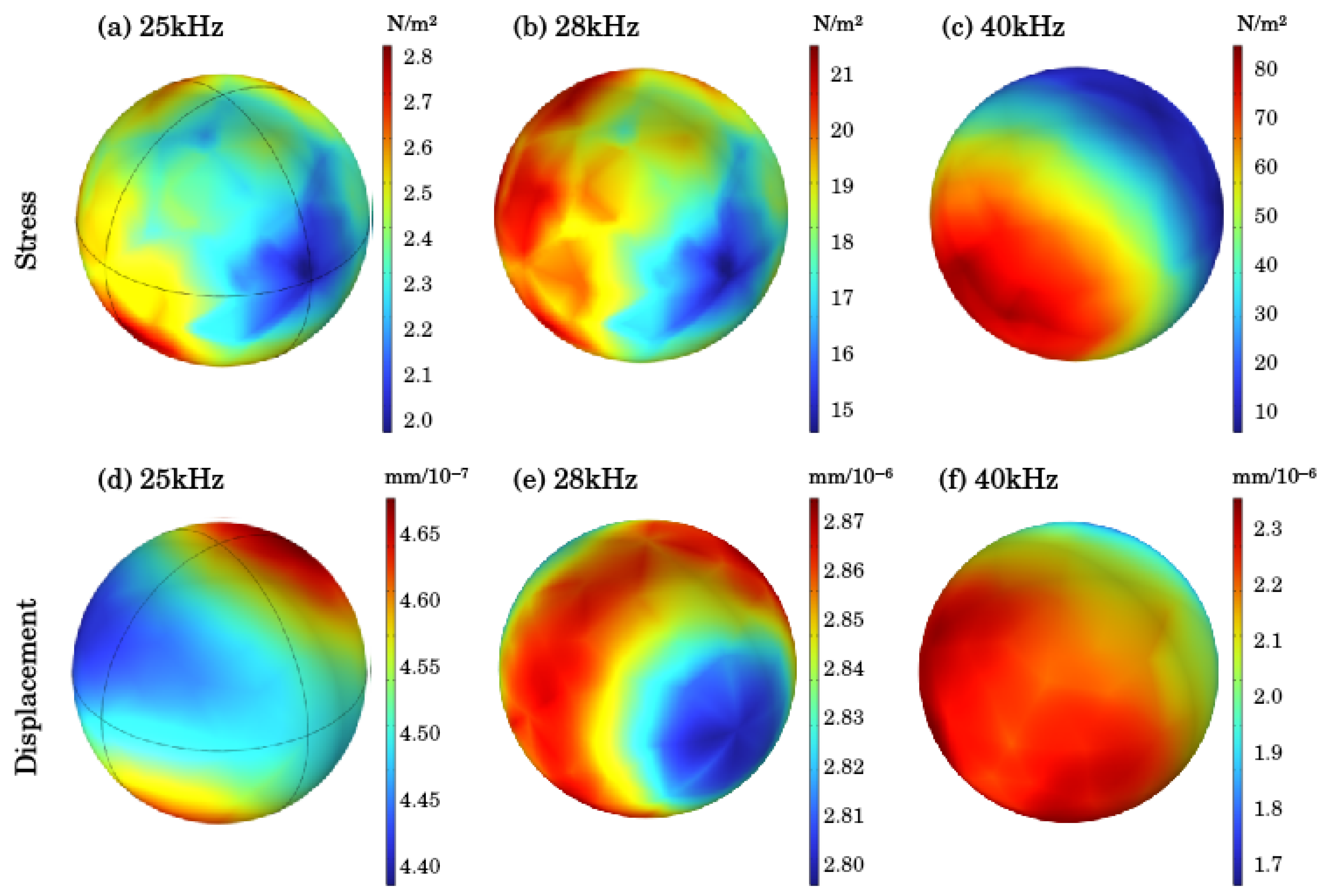

4.2. Analysis of Particle Force Results

4.3. Comparison of Sound Intensity Characteristics: Taking Sound Pressure Collection as an Example

4.4. Effect Improvement: Transducer Position Transformation

5. Conclusions

- (1)

- Under the same power input, the energy density per unit area is positively correlated with the sound pressure level. In the scenario of dense tailings in mines, this energy concentration directly affects the strength of the effect on tailing particles. Specific data shows that when the frequency is increased from 25 KHz to 40 KHz, the maximum sound pressure level in the sand silo increases from 130 dB to 157 dB. High-frequency sound waves can generate stronger energy impact on the tailings in local areas of the sand silo, which can quickly act on the locally accumulated tailing particles.

- (2)

- In the sand silo filled with dense tailings in the mine, the longitudinal sound pressure distribution of different frequency sound waves shows periodic fluctuations, but the effect on tailings settlement varies significantly. The maximum sound pressure of a 40 kHz sound wave reaches 1220 Pa. In tailing thickening operations, excessively high sound pressure can excessively disturb the settling tailing particles, which is not conducive to rapid thickening of tailings. Compared with 25 kHz, although the amplitude increase in sound pressure is limited at 28 kHz, the periodic fluctuation in longitudinal sound pressure is more severe, which significantly increases the tensile and compressive stress borne by tailing particles during the settling process. This can effectively promote particle aggregation and settling, which is more in line with the requirements of rapid and efficient settling in mining tailing filling and thickening projects and has better engineering applicability.

- (3)

- In the process of filling tailings and thickening operations in mines, the technical adjustment of changing the longitudinal opposition of resonant sound waves to oblique propagation has brought significant positive effects. It not only eliminates the interference of upward sound field and avoids the tail sand particles being lifted upwards and unable to settle smoothly, but it also reduces energy loss so that the sound pressure level and sound pressure distribution density in the sand silo are synchronously increased. From the perspective of optimizing sound field characteristics, this directly enhances the settling driving effect on tailing particles, allowing for faster and more uniform settling of tailings in the sand silo. It is a key technological improvement to improve the settling efficiency during the process of filling tailings in mines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, S.Y.; Lai, W. Research on Comprehensive Utilization Technology of Tailings for Green Mines. Gold 2024, 45, 8–11. [Google Scholar] [CrossRef]

- Li, W.P. Research on the Application of Infill Mining Technology in Metal Mine Mining Engineering. Metall. Mater. 2024, 44, 121–123. [Google Scholar]

- Li, M.; Li, Q.X.; Wu, X.R.; Wu, Z. Study on Influencing Factors of Working Performance of Fly Ash Paste Filling Materials. Min. Res. Dev. 2024, 44, 65–71. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, B.; Li, T.; Fan, C.; Yu, H. Effect and Mechanism of Activators on the Properties of Yellow River sediment/fly ash/cement-based Alkali-activated Cementitious Materials Used for Coal Mine Filling. Constr. Build. Mater. 2024, 445, 137955. [Google Scholar] [CrossRef]

- Chen, W.; Chen, L.; Yin, S. Effect of Bacteria-fly-ash Based Binder on Cemented Tailings Backfill: Mechanical Strength, Solidified Mechanism and Economic Benefits. Constr. Build. Mater. 2024, 448, 138292. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Hudson-Edwards, K.A.; Yang, P.; Zhu, L.; Yang, X.; Chen, Z. Properties, Disasters, and Resource Potential of Mine Waste Tailings. Metal Mine 2024, 8, 216–227. [Google Scholar] [CrossRef]

- Chen, X.Z.; Guo, L.J. Engineering Practice and Development Trend of Metal of Metal Mine Backfill Technology. Copp. Eng. 2024, 4, 130–141. [Google Scholar] [CrossRef]

- Xi, B.; Wa, J.; Ru, Z.; Wu, A. Research and Application Development of the Green and Efficient Paste-fill Cementitious Materials. Nonferrous Met. 2024, 76, 1–13. [Google Scholar] [CrossRef]

- Chen, Q.L.; Liu, Q.L.; Huang, B.; Wang, F.; Li, W.; Liu, F.; Zhao, S. Study on the Treatment of M-Cresol Wastewater by Ultrasound and Potassium Ferrate Combined Process. Henan Chem. Ind. 2024, 41, 1–3. [Google Scholar] [CrossRef]

- Zhao, F.Y.; Xiang, S.F.; Zhao, S.J.; Fu, F.Y.; Liu, X.D. Research Progress of Pretreated Straw Fibers for the Fabrication of Composites with a Polymer Matrix. J. Zhejiang Sci.-Tech. Univ. 2024, 51–52, 809–819. Available online: https://xuebao.zstu.edu.cn/oa/darticle.aspx?type=view&id=20241109 (accessed on 16 July 2025).

- Huang, S.M.; Zhu, X.H.; Wang, W.B.; Heng, Z.H.; Hong, H.O. U-Sodar: Noncontact Vital Sign Detection Technology Based on Ultrasonic Radar. J. Radars 2024, 14, 168–188. [Google Scholar] [CrossRef]

- Zou, Q.; Liao, Y.; An, M.; Cao, Y.; Su, H.; Wang, K.; Luo, G. Effect of Ultrasonic Pretreatment on the Flocs Characteristics in the Flocculation Filtration Process of Coal Slurry Water. Colloids Surf. A Physicochem. Eng. Asp. 2024, 692, 134010. [Google Scholar] [CrossRef]

- Vikulina, V.; Vikulin, P. Effect of Ultrasound on Sedimentation of Suspended Solids in Water. Iop Conf. Ser. Mater. Sci. Eng. 2018, 365, 032001. [Google Scholar] [CrossRef]

- Wang, J.L. Experimental Study on Low-Intensity Ultrasonic Enhanced SBR Treatment of Low-Temperature Domestic Sewage. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2022. [Google Scholar]

- Jiang, P.G.; Bai, T.F.; Wei, D.F.; Zhang, A.; Wang, Y. Experimental Study on Steady Tailings Discharge Technology Based on Ultrasonic Activation of High-concentration Fine Tailings. Gold 2023, 44, 10–12. [Google Scholar] [CrossRef]

- Peng, Q.; Wang, H.; Xing, P.; Yang, L.; Wang, Z. Influence of Ultrasonic Irradiation on Thickening Effect and Rheology of Tailings Underflow. Chin. J. Nonferrous Met. 2021, 31, 1377–1387. [Google Scholar] [CrossRef]

- Jin, R. Mechanism and Application of Vibration to Remove the Bonded Material on the Plate Surface of Inclined Plate Thickener. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2022. [Google Scholar]

- Park, J.; Chun, Y.W.; Trung, H.T.; Kim, Y.U. Effect of Ultrasonic Energy on Self-Weight Consolidation of Clay Minerals. KSCE Journal of Civil Engineering. KSCE J. Civ. Eng. 2014, 18, 971–974. [Google Scholar] [CrossRef]

- Samchenko, S.; Kozlova, I.; Zemskova, O.; Baskakova, E. Increase of Aggregative and Sedimentation Stability of Slag Suspensions by Ultrasound. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 110, p. 01061. [Google Scholar] [CrossRef]

- Du, J.; Mcloughlin, R.; Smart, R.S.C. Improving Thickener Bed Density by Ultrasonic Treatment. Int. J. Miner. Process. 2014, 133, 91–96. [Google Scholar] [CrossRef]

- Tian, X.; Wu, X.; Wang, Y. Optimization design of high-efficiency grading dewatering and filling process for whole tailings and research on sand silo performance. Nonferrous Equip. 2025, 39, 92–97. [Google Scholar]

- Chen, Q.; Dai, Z.; Wang, X. Research on the Settlement Law of Tailings with Different Fine Particle Contents and Their Pore Distribution Characteristics in Sedimentary Bodies. China Saf. Prod. Sci. Technol. 2023, 19, 79–85. [Google Scholar]

- Ruan, Z.; Wu, A.; Jiao, H. Research progress and development trend of full tailings slurry thickening in China. Chin. J. Nonferrous Met. 2022, 32, 286–301. [Google Scholar]

- Yang, J.; Qi, Z.; Kou, Y. Experimental study and application of graded fine tailings thickening for filling in a certain gold mine. Min. Res. Dev. 2021, 41, 27–32. [Google Scholar]

- Zhu, L.; Lv, W.; Yang, P. The influence of ultrasonic waves on the rheological properties of whole tailings mortar. Mater. Rev. 2020, 34, 6088–6094. [Google Scholar]

- Wang, J. Research on the Flow Behavior Characteristics of Vertical Pipe Self Flow Transportation of Whole Tailings Paste. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2022. [Google Scholar]

- Feng, J. Research on Safety Evaluation and Failure Control Methods of Metal Mine Deep Well Filling System. Ph.D. Thesis, Central South University, Changsha, China, 2005. [Google Scholar]

- Li, W. Research on the Thickening Technology of Ultra Fine Whole Tailings Paste for Phosphate Ore. Mater’s Thesis, Changsha Mining Research Institute, Changsha, China, 2023. [Google Scholar]

- Xiao, C. Research on Intelligent Prediction Model Based on the Deductive Mechanism of Full Tailings Depth Thickening. Ph.D. Thesis, Central South University, Changsha, China, 2022. [Google Scholar]

- Zhuen, R. Study on Thickness Law and Rheological Properties of Tailings Slurry Under Ultrasonic. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2021. [Google Scholar]

| Group | G1 | G2 | G3 |

|---|---|---|---|

| Power/W | 100 | 100 | 100 |

| Frequency | 25 kHz | 28 kHz | 40 kHz |

| Attribute | Name | Value | Unit |

|---|---|---|---|

| Density | Rho | 7500 | kg/m3 |

| Elastic matrix | cE | {1.27205 × 1011, 8.02122 × 1010, 1.27205 × 1011, 0, 0, 0, 2.29885 × 1010, 0, 0, 0, 0, 2.29885 × 1010, 0, 0, 0, 0, 0, 2.34742 × 1010} | Pa |

| Coupling matrix | eEs | {0, 0, −6.62281, 0, 0, −6.62281, 0, 0, 23.2403, 0, 17.0345, 0, 17.0345, 0, 0, 0, 0, 0} | C/m2 |

| Relative dielectric constant | Eps | {1704.4, 1704.4, 1433.6} | 1 |

| Heat capacity at constant pressure | Cp | 440 | J/(kg·K) |

| Thermal conductivity | k | 1.3 | W/(m·K) |

| Attribute | Name | Value | Unit |

|---|---|---|---|

| Density | Rho | 1800 | Kg/m3 |

| Dynamic viscosity | mu | 2 | Pa·s |

| Specific heat rate | ga | 1 | 1 |

| Conductivity | sig | 5.5 × 10−6 | S/m |

| Thermal conductivity | k | K(T[1/K]) | W/(m·K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, L.; Zhao, C. Multiphysics-Coupled Simulation of Ultrasound-Assisted Tailing Slurry Sedimentation. Materials 2025, 18, 3430. https://doi.org/10.3390/ma18153430

Peng L, Zhao C. Multiphysics-Coupled Simulation of Ultrasound-Assisted Tailing Slurry Sedimentation. Materials. 2025; 18(15):3430. https://doi.org/10.3390/ma18153430

Chicago/Turabian StylePeng, Liang, and Congcong Zhao. 2025. "Multiphysics-Coupled Simulation of Ultrasound-Assisted Tailing Slurry Sedimentation" Materials 18, no. 15: 3430. https://doi.org/10.3390/ma18153430

APA StylePeng, L., & Zhao, C. (2025). Multiphysics-Coupled Simulation of Ultrasound-Assisted Tailing Slurry Sedimentation. Materials, 18(15), 3430. https://doi.org/10.3390/ma18153430