Effect of Rice Husk Addition on the Hygrothermal, Mechanical, and Acoustic Properties of Lightened Adobe Bricks

Abstract

1. Introduction

2. Materials and Methods

2.1. Geographic Origin of the Studied Soils

2.2. Origin of the Soil Used

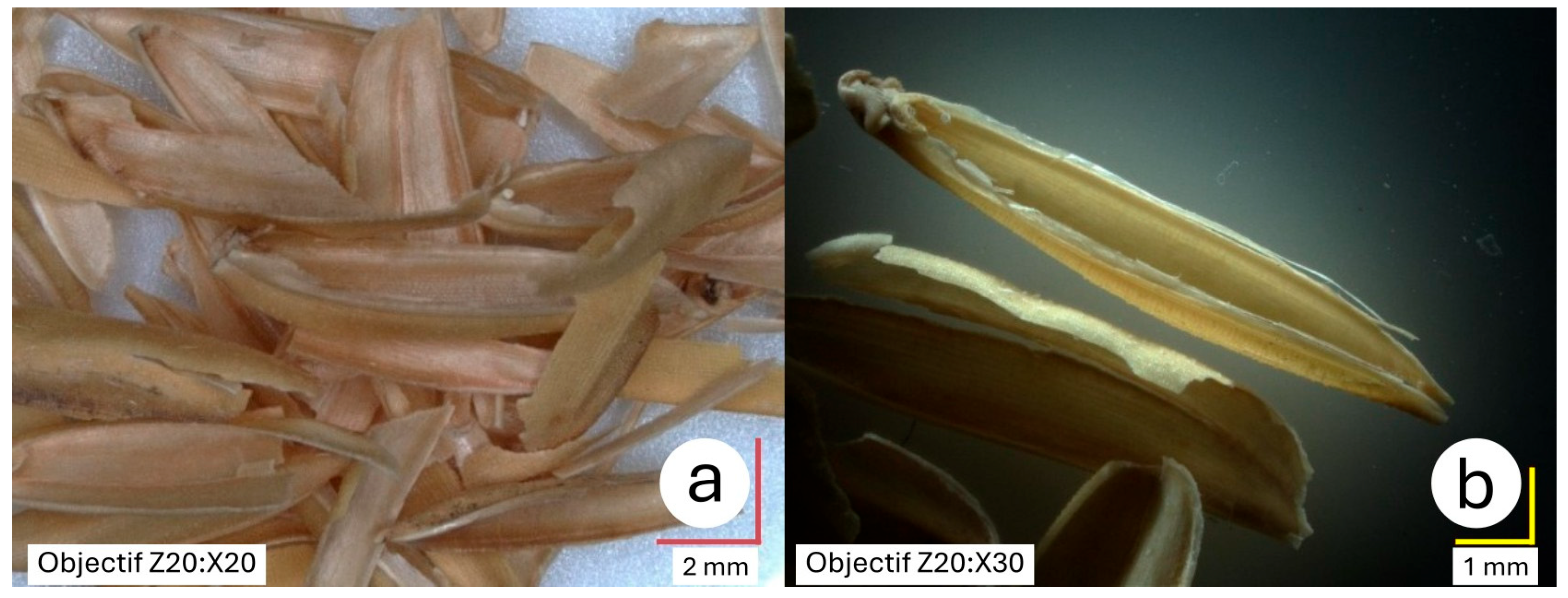

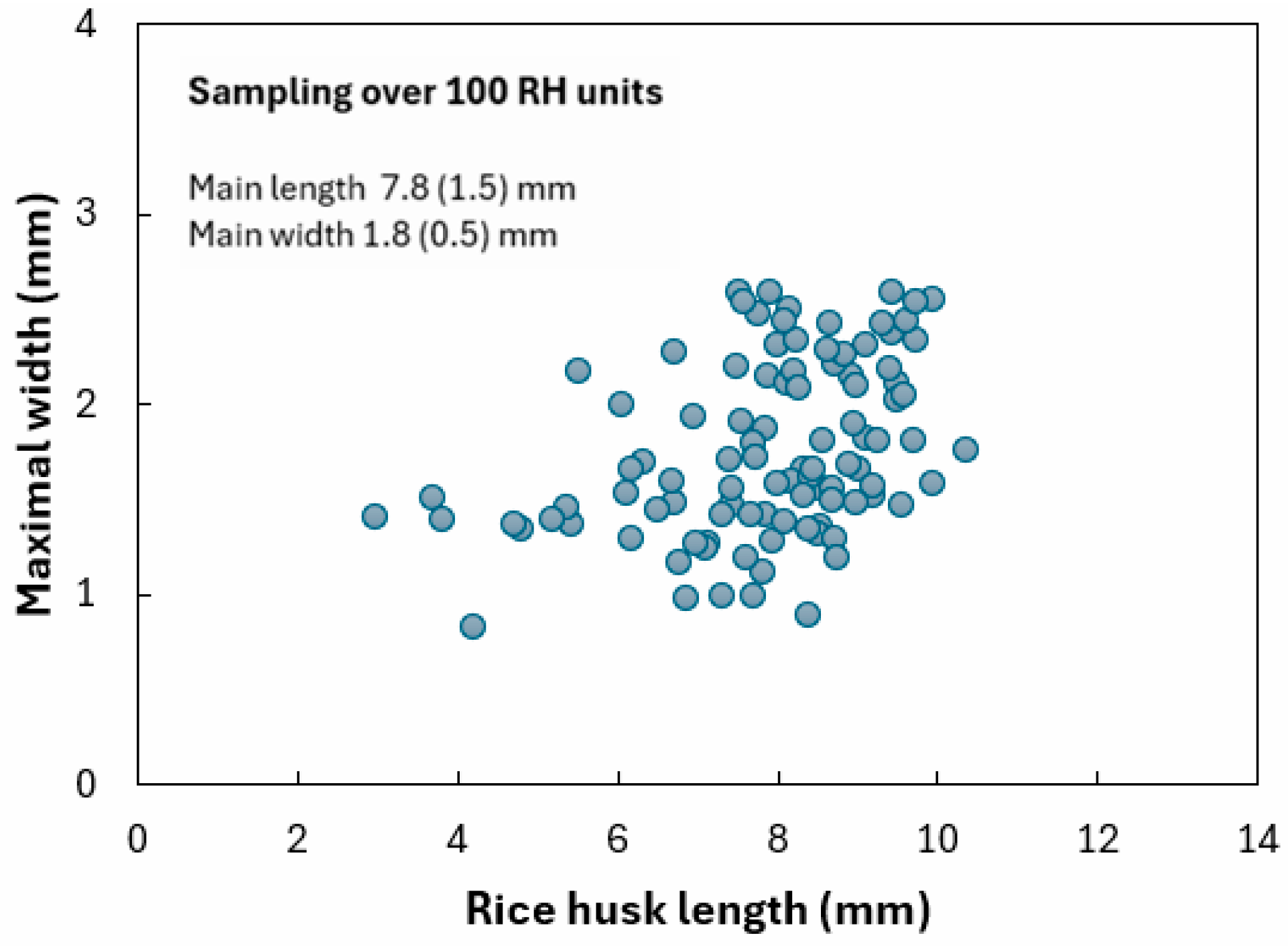

2.3. Overall Characteristics of Rice Husk

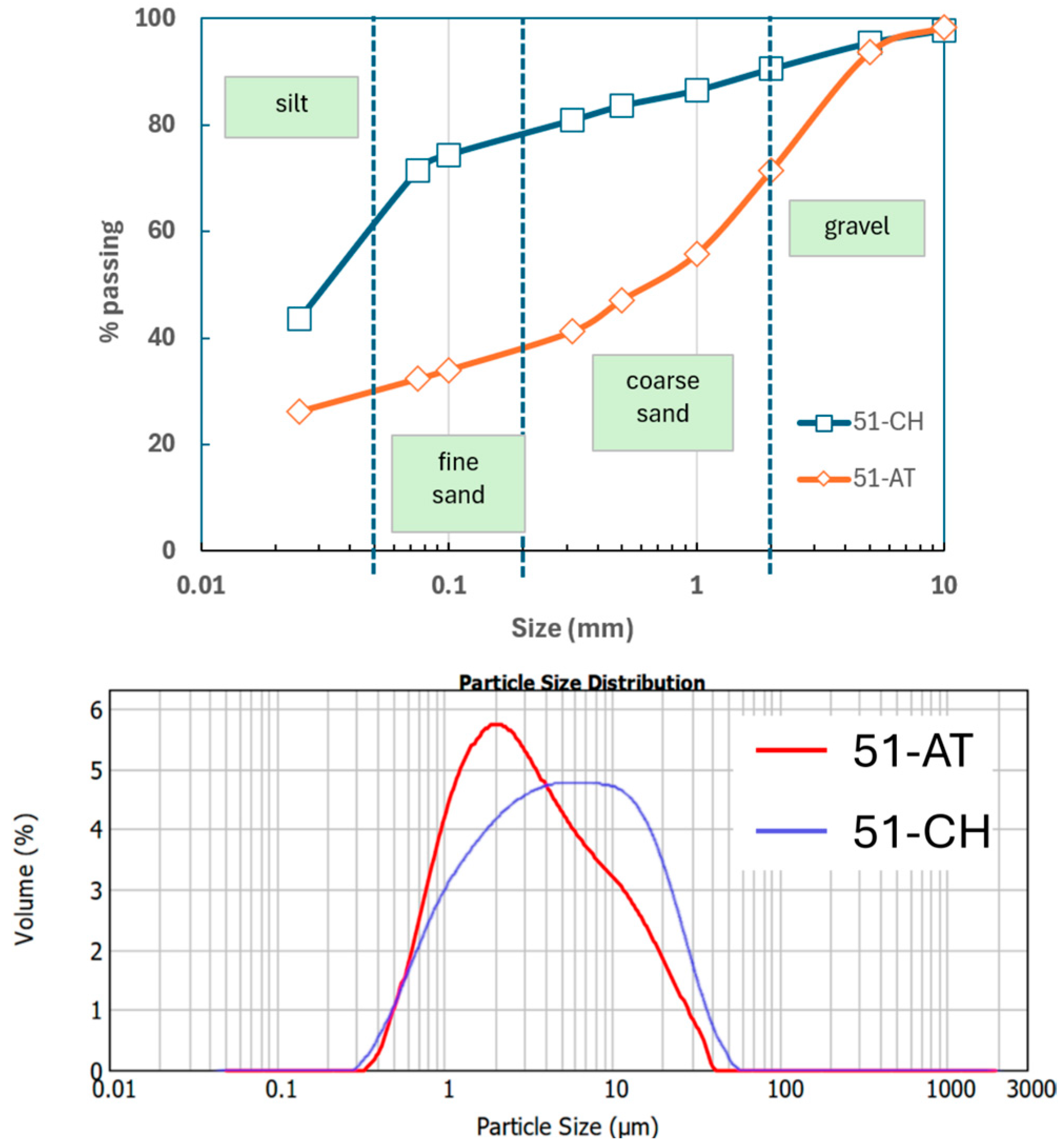

2.4. Granulometry of Soil Samples

2.5. Morphology and Elemental Composition of Soil Samples and Rice Husk

2.6. Measurements of CaCO3 and Water Contents

2.7. Adobe Manufacturing and Drying

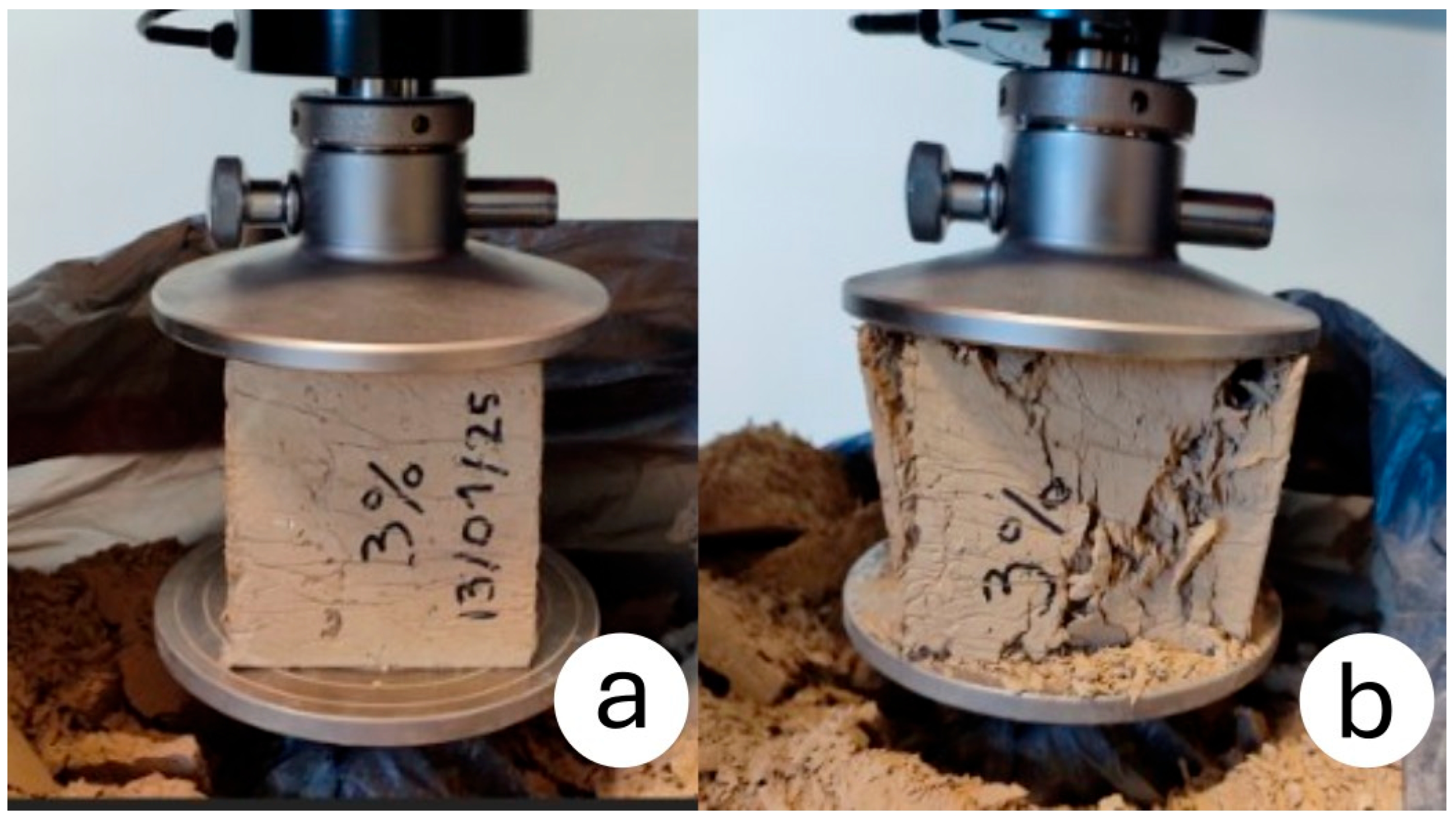

2.8. Compression Tests

2.9. Thermal Tests

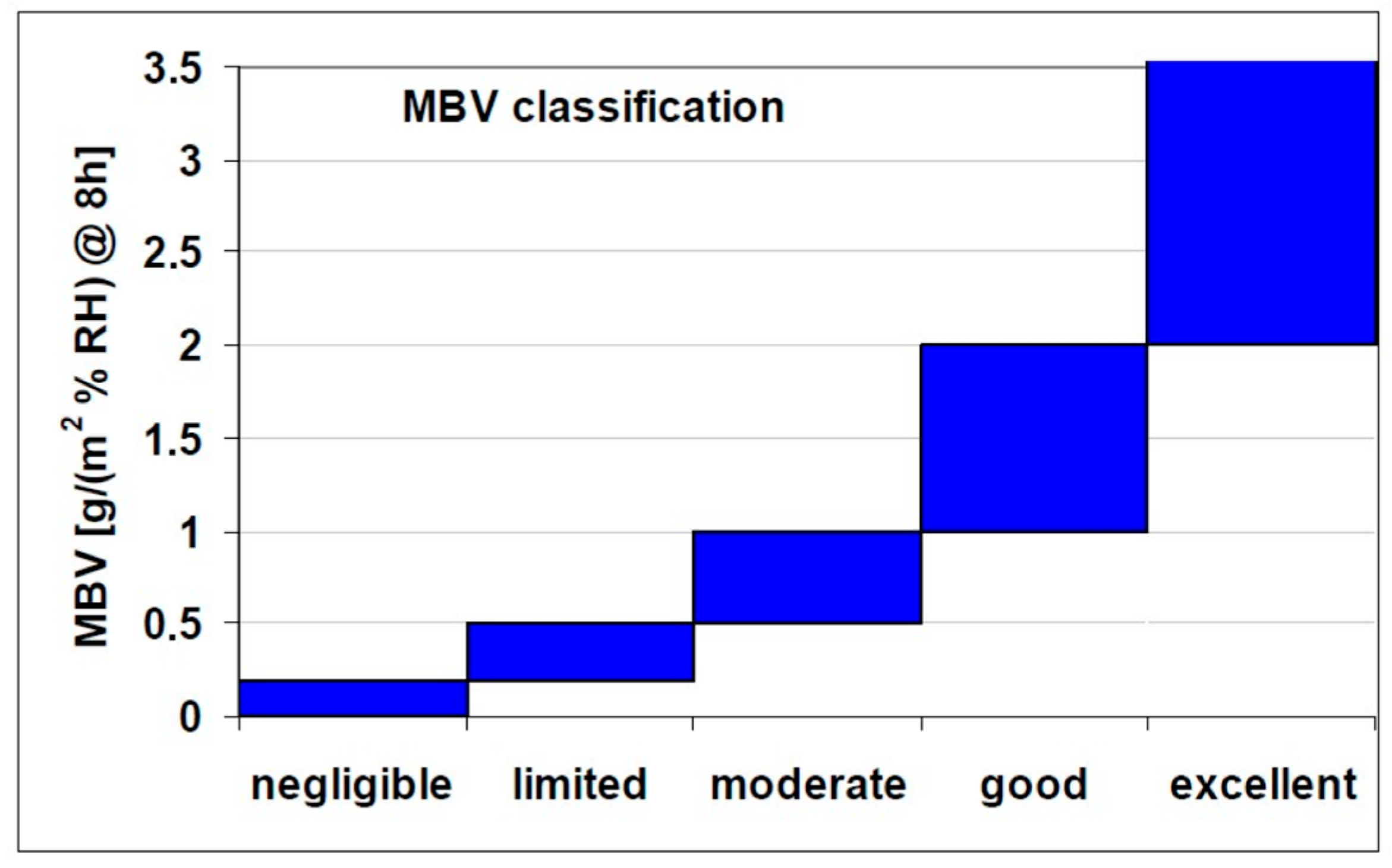

2.10. Moisture Buffer Value (MBV)

2.11. Acoustic Tests

3. Results and Discussion

3.1. Particle Size Distribution of Soil and Rice Husk

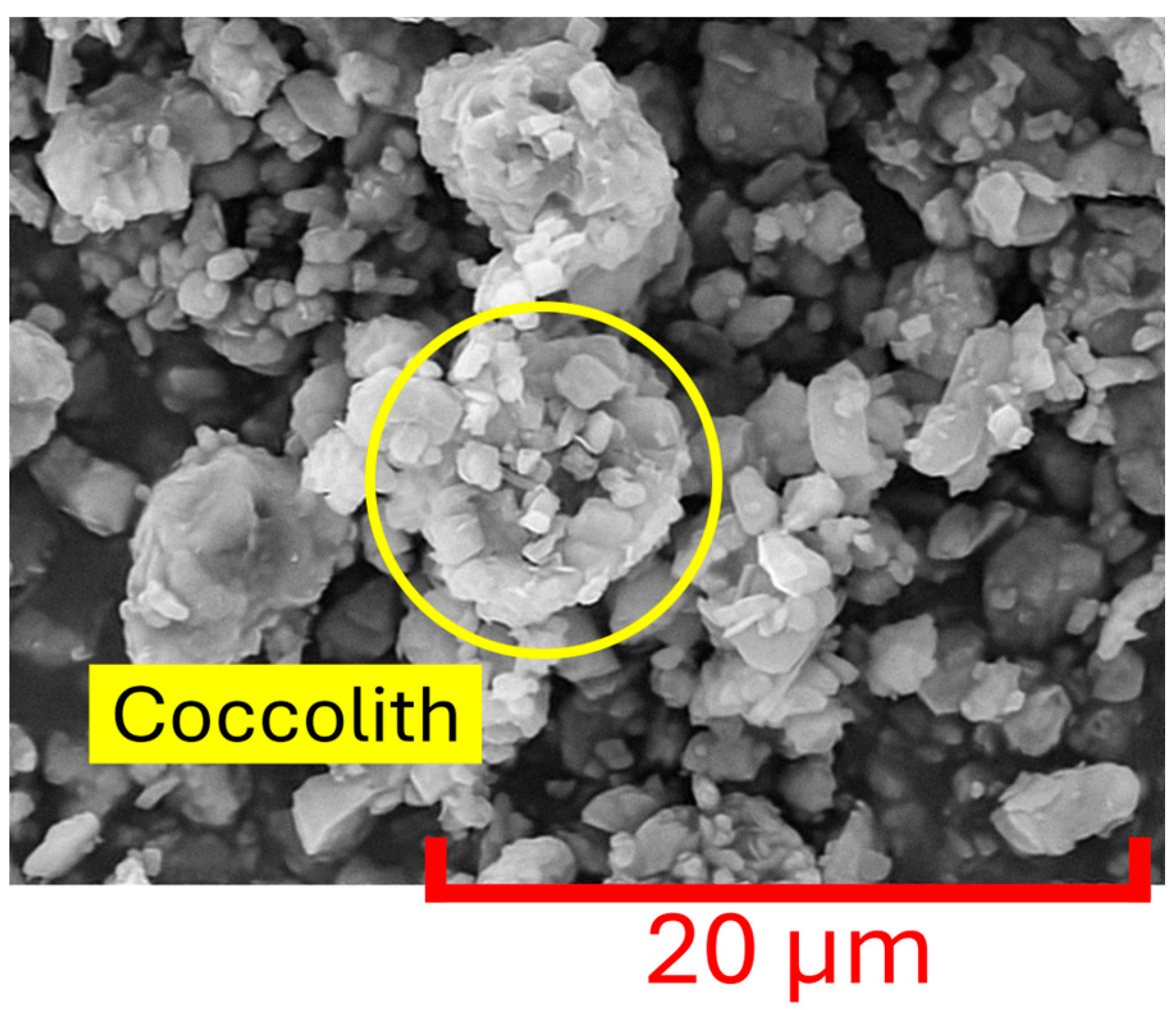

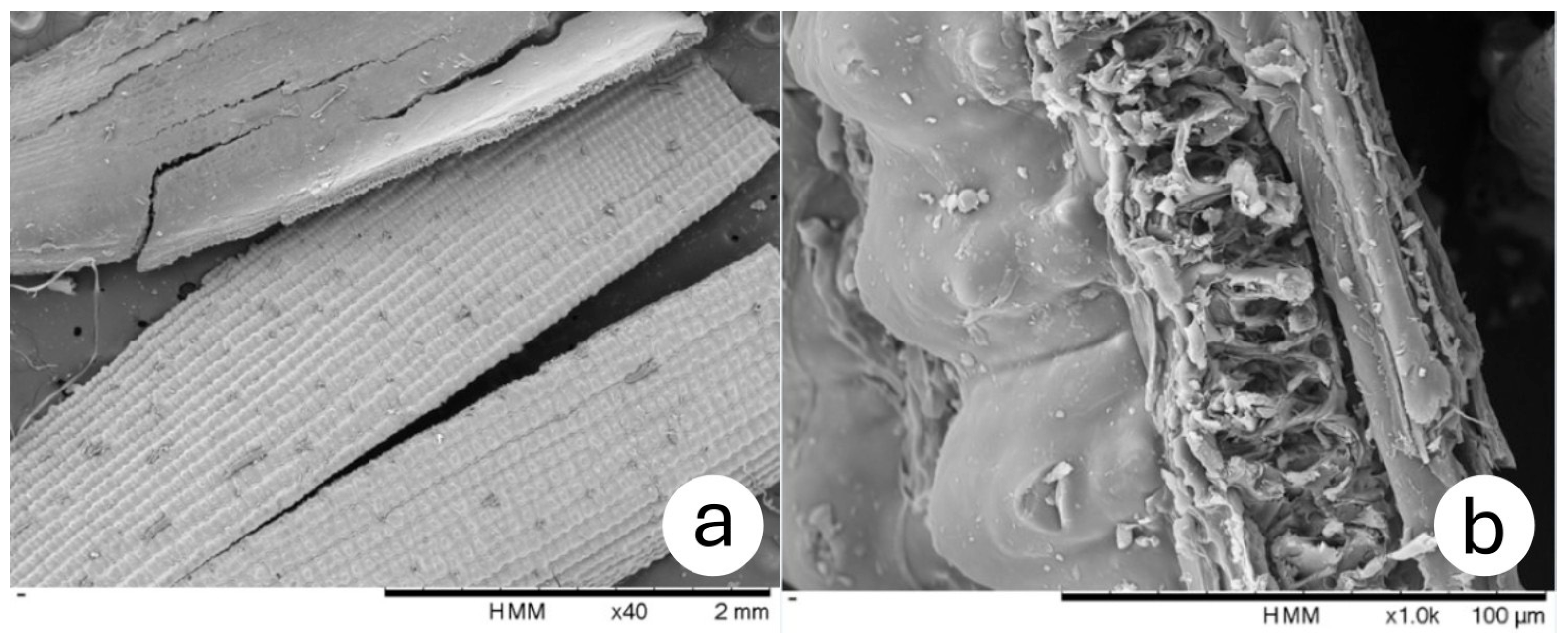

3.2. SEM Morphology Analysis of Soil and Rice Husk

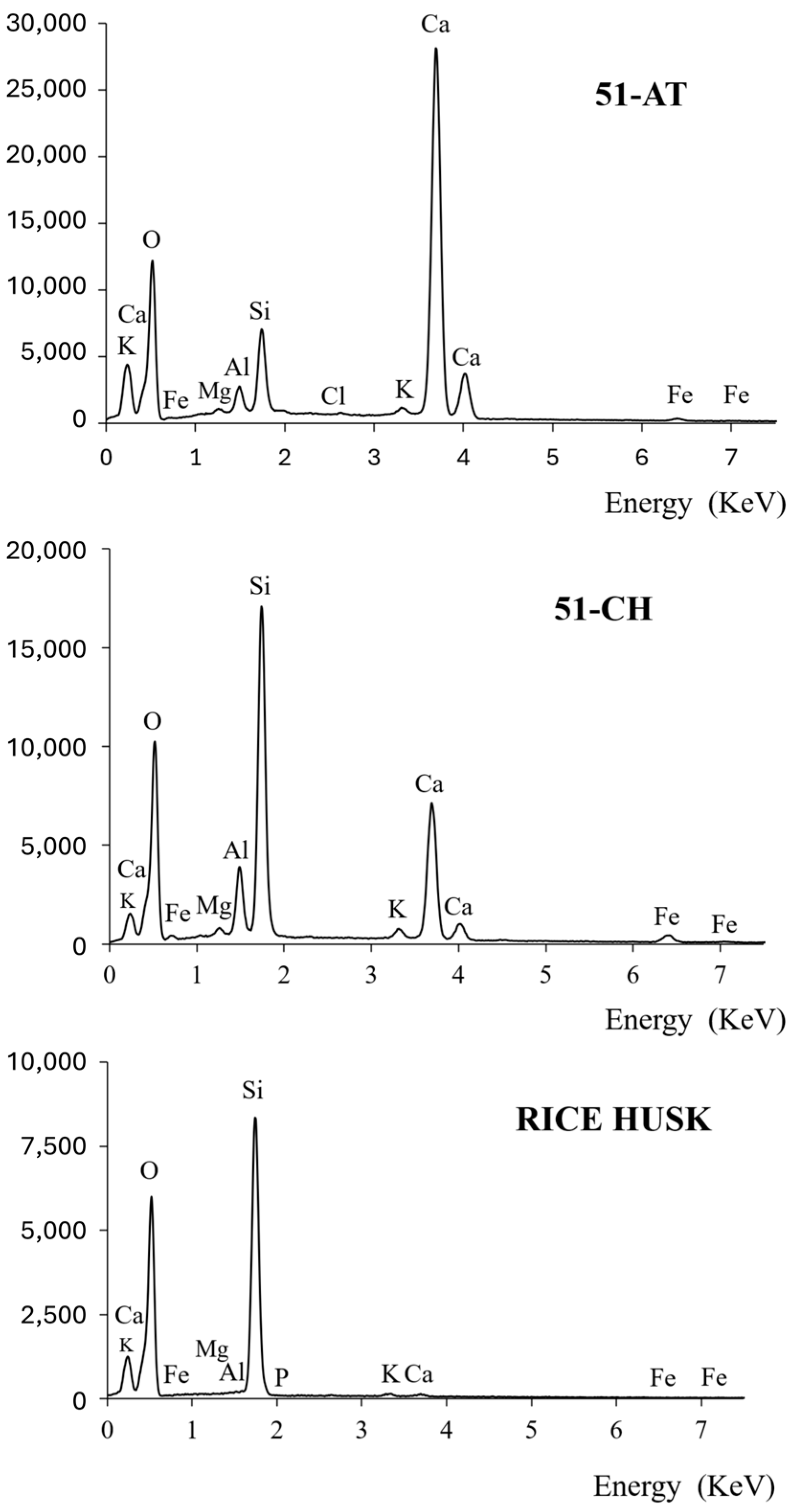

3.3. Elemental Chemical Composition of Soil and Rice Husk Samples

3.4. Physico-Chemical Characteristics of Rice Husk and Soil Samples

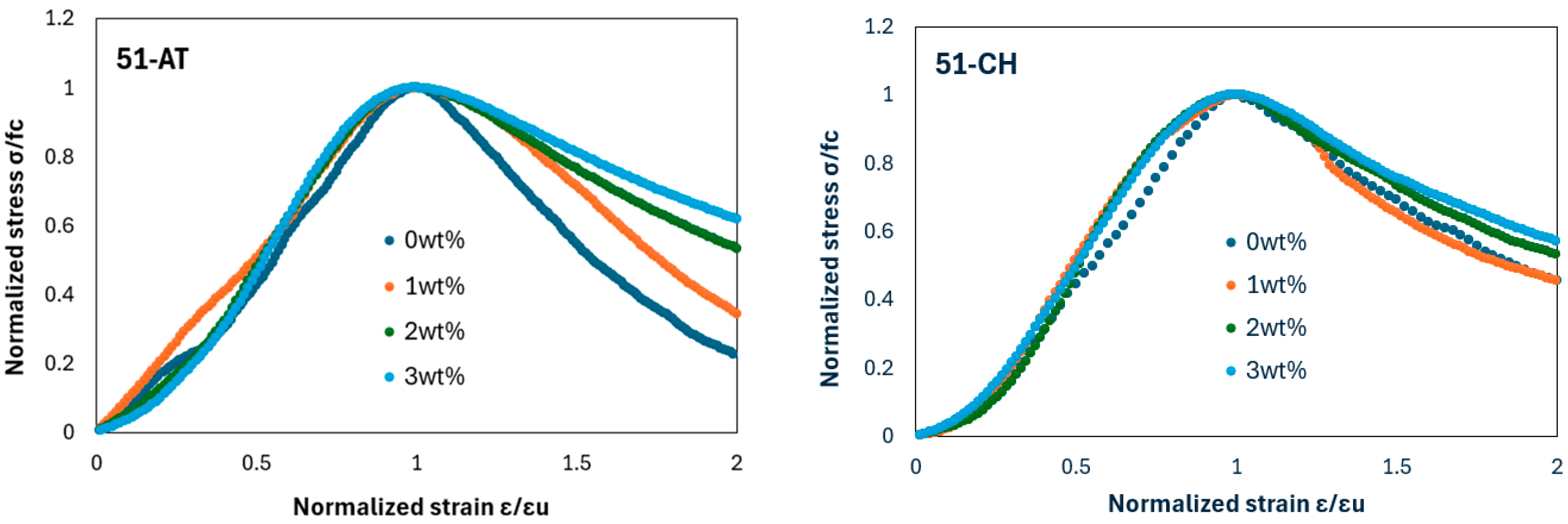

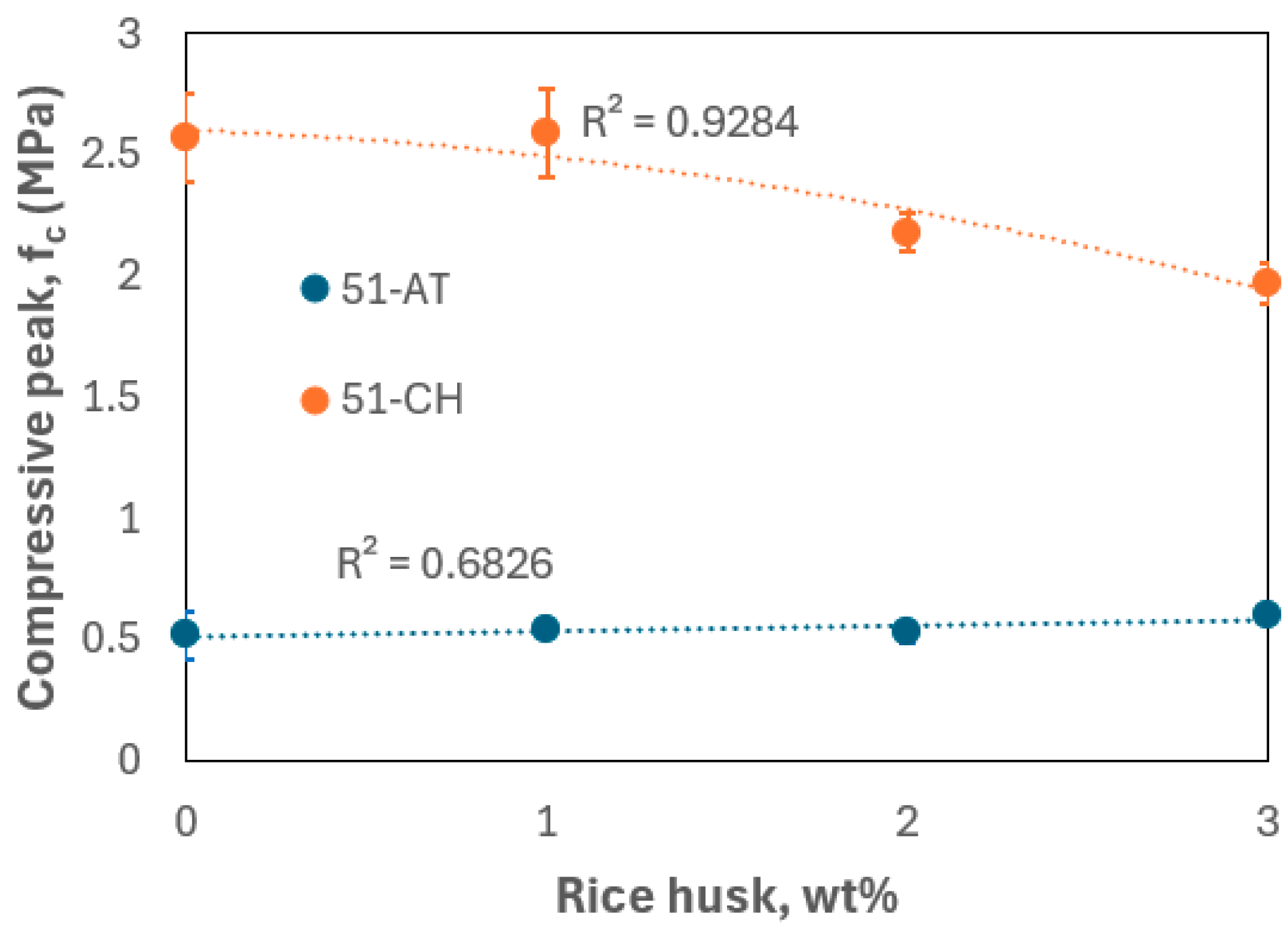

3.5. Compressive Test

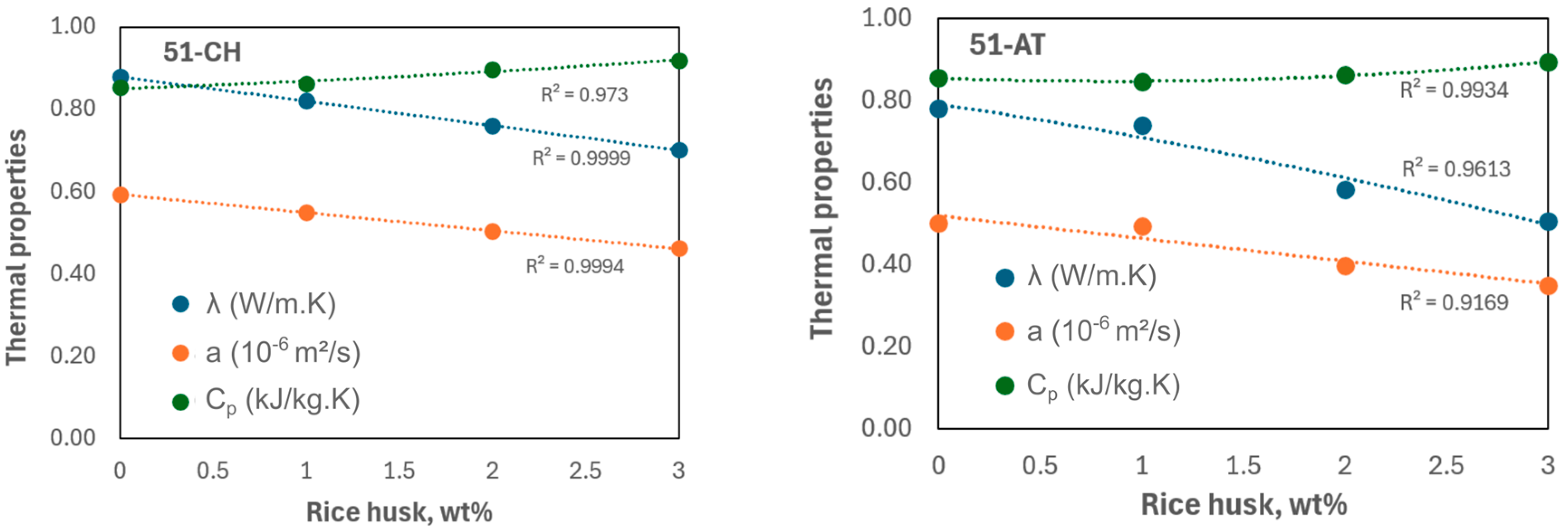

3.6. Thermal and Hydric Analyses

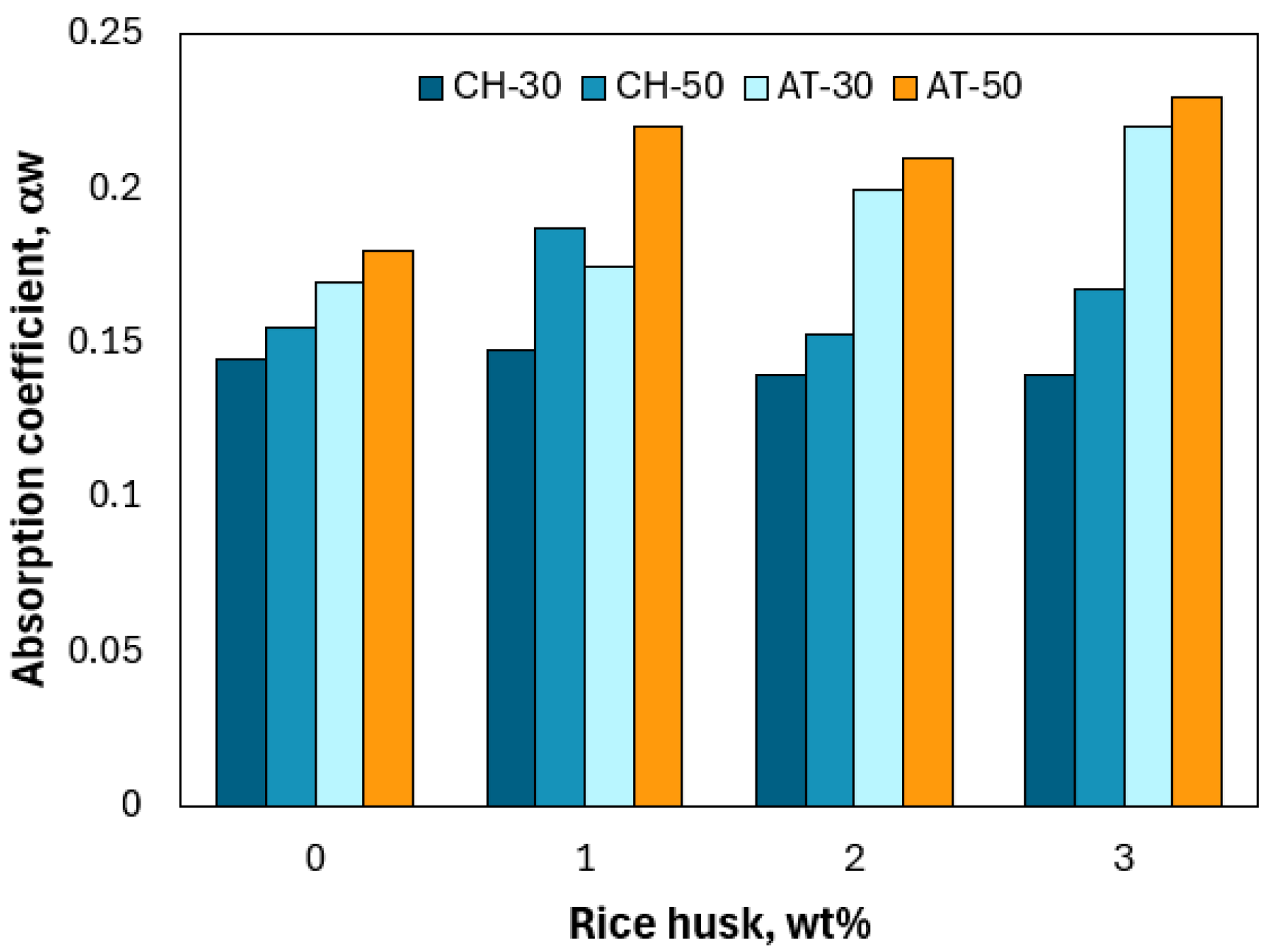

3.7. Acoustic Tests

3.8. Comparison of Rice Husk and Other Natural Fibers

3.9. Comments on Agricultural Waste Management

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Doat, P.; Hays, A.; Houben, H.; Matuk, S.; Vitoux, F. Construire en Terre; Parenthèses: Paris, France, 1979. [Google Scholar]

- Marsh, A.T.M.; Kulshreshtha, Y. The state of earthen housing worldwide: How development affects attitudes and adoption. Build. Res. Inf. 2022, 50, 485–501. [Google Scholar] [CrossRef]

- Ness, D.A.; Xing, K. Toward a Resource-Efficient Built Environment: A Literature Review and Conceptual Model. J. Ind. Ecol. 2017, 21, 572–592. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J.B. Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr. Build. Mater. 2015, 101, 797–809. [Google Scholar] [CrossRef]

- Van Damme, H.; Houben, H. Earth concrete. Stabilization revisited. Cem. Concr. Res. 2018, 114, 90–102. [Google Scholar] [CrossRef]

- Vissac, A.; Bourgès, A.; Gandreau, D.; Anger, R.; Fontaine, L. Argiles & Biopolymères—Les Stabilisants Naturels Pour la Construction en Terre; CRAterre: Villefontaine, France, 2017. [Google Scholar]

- Amziane, S.; Sonebi, M. Overview on Biobased Building Material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Peñaloza, D. The Role of Biobased Building Materials in the Climate Impacts of Construction. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2017. [Google Scholar]

- Arduin, D.; Caldas, L.R.; Claro, C.C.; Rocha, F.; Andrejkovicová, S. Comparative study on stabilized oyster shells adobes: Mechanical resistance, durability and GHG emissions assessment. MATEC Web Conf. 2024, 403, 06001. [Google Scholar] [CrossRef]

- Mohajerani, A.; Hui, S.Q.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; Kadir, A.A.; Rahman, M.T.; Maghool, F. Amazing Types, Properties, and Applications of Fibres in Construction Materials. Materials 2019, 12, 2513. [Google Scholar] [CrossRef] [PubMed]

- Lagouin, M.; Magniont, C.; Sénéchal, P.; Moonen, P.; Aubert, J.E.; Laborel-préneron, A. Influence of types of binder and plant aggregates on hygrothermal and mechanical properties of vegetal concretes. Constr. Build. Mater. 2019, 222, 852–871. [Google Scholar] [CrossRef]

- Paul, S.C.; Mbewe, P.B.K.; Kong, S.Y.; Šavija, B. Agricultural Solid Waste as Source of Supplementary Cementitious Materials in Developing Countries. Materials 2019, 12, 1112. [Google Scholar] [CrossRef] [PubMed]

- Anger, R. Approche Granulaire et Colloïdale du Matériau Terre Pour la Construction; INSA: Lyon, France, 2011. [Google Scholar]

- Ouedraogo, M.; Bamogo, H.; Sanou, I.; Dao, K.; Ouedraogo, K.A.J.; Aubert, J.E.; Millogo, Y. Microstructure, Physical and Mechanical Properties of Adobes Stabilized with Rice Husks. Int. J. Archit. Herit. 2023, 17, 1348–1363. [Google Scholar] [CrossRef]

- Samson, M.; Edgar, N.G.; Tikri, B.; Akana, T.F.; Bobet, O. Thermal Characteristics of Earth Blocks Stabilized by Rice Husks. Open J. Appl. Sci. 2023, 13, 1796–1819. [Google Scholar] [CrossRef]

- Ige, O.; Danso, H. Experimental Characterization of Adobe Bricks Stabilized with Rice Husk and Lime for Sustainable Construction. J. Mater. Civ. Eng. 2021, 34, 04021420. [Google Scholar] [CrossRef]

- Antunes, A.; Faria, P.; Silva, V.; Brás, A. Rice husk-earth based composites: A novel bio-based panel for buildings refurbishment. Constr. Build. Mater. 2019, 221, 99–108. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lascaro, E.; Merli, F.; Ricciardi, P. Rice husk panels for building applications: Thermal, acoustic and environmental characterization and comparison with other innovative recycled waste materials. Constr. Build. Mater. 2018, 171, 338–349. [Google Scholar] [CrossRef]

- Vatani Oskouei, A.; Afzali, M.; Madadipour, M. Experimental investigation on mud bricks reinforced with natural additives under compressive and tensile tests. Constr. Build. Mater. 2017, 142, 137–147. [Google Scholar] [CrossRef]

- Akinyele, J.; Olateju, O.; Oikelome, O. Rice Husk as Filler in the Production of Bricks Using Gboko Clay. Niger. J. Technol. 2015, 34, 672–678. [Google Scholar] [CrossRef]

- Sutas, J.; Mana, A.; Pitak, L. Effect of Rice Husk and Rice Husk Ash to Properties of Bricks. Procedia Eng. 2012, 32, 1061–1067. [Google Scholar] [CrossRef]

- Bazuhair, R.W. Laboratory evaluation of the effect of rice husk fiber on soil properties and behaviors. J. Umm Al-Qura Univ. Eng. Archit. 2023, 14, 166–171. [Google Scholar] [CrossRef]

- Sasui, S.; Jinwuth, W.; Hengrasmee, S. Investigating the Effects of Straw & Rice Husk on the Compressive Strength & Tensile Strength of Adobe Brick. J. Sustain. Constr. Mater. Technol. 2025, 3, 1. [Google Scholar]

- Lertwattanaruk, P.; Tungsirisakul, J. Effect of Natural Materials on Properties of Adobe Brick for Earth Construction. J. Archit./Plan. Res. Stud. (JARS) 2007, 5, 185–200. [Google Scholar]

- Polidori, G.; Aras-Gaudry, A.; Rousse, C.; Beaumont, F.; Bogard, F.; Murer, S.; Moussa, T.; Bliard, C.; Fronteau, G.; Hamard, E. Analysis of adobes from vernacular raw earth buildings in the Champagne region (France). Constr. Build. Mater. 2025, 470, 140582. [Google Scholar] [CrossRef]

- Chabannes, M. Formulation et Étude Des Propriétés Mécaniques d’Agrobétons Légers Isolants à Base de Balles de Riz et de Chènevotte Pour l’éco-construction. Ph.D. Thesis, Université de Montpellier, Montpellier, France, 2015. [Google Scholar]

- Laftah, W.A.; Wan Abdul Rahman, W.A. Rice waste–based polymer composites for packaging applications: A review. Polym. Polym. Compos. 2021, 29, S1621–S1629. [Google Scholar] [CrossRef]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crops Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Chabannes, M.; Bénézet, J.C.; Clerc, L.; Garcia-Diaz, E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: An innovative application. Constr. Build. Mater. 2014, 70, 428–438. [Google Scholar] [CrossRef]

- AFNOR NF EN ISO 11277:2020; Qualité du Sol—Détermination de la Répartition Granulométrique de la Matière Minérale des Sols—Méthode par Tamisage et Sédimentation. AFNOR: Paris, France, 2020.

- AFNOR NF EN ISO 10693:1995; Qualité du Sol—Détermination de la Teneur en Carbonate—Méthode Volumétrique. AFNOR: Paris, France, 1995.

- AFNOR XP P13-901:2022; Blocs de Terre Comprimée Pour Murs et Cloisons: Définitions—Spécifications—Méthodes D’essais—Conditions de Réception. AFNOR: Paris, France, 2022.

- Rode, C.; Peuhkuri, R.H.; Hansen, K.K.; Time, B.; Svennberg, K.; Arfvidsson, J.; Ojanen, T. NORDTEST Project on Moisture Buffer Value of Materials. In Proceedings of the AIVC 26th Conference: Ventilation in Relation to the Energy Performance of Buildings Air Infiltration and Ventilation, APA, Brussels, Belgium, 21–23 September 2005; pp. 47–52. [Google Scholar]

- AFNOR ISO 10534-2:2023; Acoustique—Détermination des Propriétés Acoustiques Aux Tubes D’impédance—Partie 2: Méthode à Deux Microphones Pour le Coefficient D’absorption Sonore Normal et L’impédance de Surface Normale. AFNOR: Paris, France, 2023. Available online: https://www.iso.org/fr/standard/81294.html (accessed on 30 April 2025).

- Garcia-Gaines, R.A.; Frankenstein, S. USCS and the USDA Soil Classification System: Development of a Mapping Scheme. March 2015. Available online: https://usace.contentdm.oclc.org/digital/collection/p266001coll1/id/3757/ (accessed on 4 December 2024).

- Abhilash, H.N.; Hamard, E.; Beckett, C.T.S.; Morel, J.C.; Varum, H.; Silveira, D.; Ioannou, I.; Illampas, R. Mechanical Behaviour of Earth Building Materials. In Testing and Characterisation of Earth-Based Building Materials and Elements: State-of-the-Art Report of the RILEM TC 274-TCE; Fabbri, A., Morel, J.C., Aubert, J.E., Bui, Q.B., Gallipoli, D., Reddy, B.V.V., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 127–180. [Google Scholar]

- Jiménez Delgado, M.C.; Guerrero, I.C. The selection of soils for unstabilised earth building: A normative review. Constr. Build. Mater. 2007, 21, 237–251. [Google Scholar] [CrossRef]

- Kerry, R.; Rawlins, B.G.; Oliver, M.A.; Lacinska, A.M. Problems with determining the particle size distribution of chalk soil and some of their implications. Geoderma 2009, 152, 324–337. [Google Scholar] [CrossRef]

- Park, B.D.; Gon Wi, S.; Ho Lee, K.; Singh, A.P.; Yoon, T.H.; Soo Kim, Y. Characterization of anatomical features and silica distribution in rice husk using microscopic and micro-analytical techniques. Biomass Bioenergy 2003, 25, 319–327. [Google Scholar] [CrossRef]

- Do Prado, K.D.S.; Spinacé, M.A.D.S. Characterization of Fibers from Pineapple’s Crown, Rice Husks and Cotton Textile Residues. Mater. Res. 2015, 18, 530–537. [Google Scholar] [CrossRef]

- Jauberthie, R.; Rendell, F.; Tamba, S.; Cisse, I. Origin of the pozzolanic effect of rice husks. Constr. Build. Mater. 2000, 14, 419–423. [Google Scholar] [CrossRef]

- Walter, L.; Medjigbodo, G.; Claudot, L.; Nait-Rabah, O.; Linguet, L. Influence of metal oxides and particle size on earthen mortar built with tropical soils. Acad. J. Civ. Eng. 2022, 40, 1–10. [Google Scholar]

- Hamidu, I.; Afotey, B.; Kwakye-Awuah, B.; Anang, D.A. Synthesis of silica and silicon from rice husk feedstock: A review. Heliyon 2025, 11, e42491. [Google Scholar] [CrossRef] [PubMed]

- Luh, B.S. Utilization. In Rice; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1991; Volume 2. [Google Scholar]

- Sánchez, A.; Varum, H.; Martins, T.; Fernández, J. Mechanical properties of adobe masonry for the rehabilitation of buildings. Constr. Build. Mater. 2022, 333, 127330. [Google Scholar] [CrossRef]

- Confédération de la Construction en Terre Crue. Guide des Bonnes Pratiques de la Construction en Terre Crue; Confédération de la Construction en Terre Crue: Montreuil-Le-Gast, France, 2020. [Google Scholar]

- Bobet, O.; Seynou, M.; Zerbo, L.; Bamogo, H.; Sanou, I.; Sawadogo, M. Propriétés mécanique, hydrique et thermique de briques en terre crue amendées aux coques d’arachide. J. Société Ouest-Afr. Chim. 2020, 49, 54–64. [Google Scholar]

- Babé, C.; Kidmo, D.K.; Tom, A.; Mvondo, R.R.N.; Boum, R.B.E.; Djongyang, N. Thermomechanical characterization and durability of adobes reinforced with millet waste fibers (sorghum bicolor). Case Stud. Constr. Mater. 2020, 13, e00422. [Google Scholar] [CrossRef]

- Zouaoui, Y.; Benmahiddine, F.; Yahia, A.; Belarbi, R. Hygrothermal and Mechanical Behaviors of Fiber Mortar: Comparative Study between Palm and Hemp Fibers. Energies 2021, 14, 7110. [Google Scholar] [CrossRef]

- Niang, I.; Maalouf, C.; Moussa, T.; Bliard, C.; Samin, E.; Thomachot-Schneider, C.; Lachi, M.; Pron, H.; Mai, T.H.; Gaye, S. Hygrothermal performance of various Typha–clay composite. J. Build. Phys. 2018, 42, 316–335. [Google Scholar] [CrossRef]

- Polidori, G.; Aras-Gaudry, A.; Beaumont, F.; Bogard, F.; Murer, S.; Lachi, M.; Maalouf, C.; Moussa, T.; Bliard, C.; Fronteau, G.; et al. Adobe Bricks of the Champagne Region (France): Characterization of a Chalky Raw Earth Construction Material. Materials 2024, 17, 2307. [Google Scholar] [CrossRef] [PubMed]

- Illampas, R.; Ioannou, I.; Charmpis, D.C. Adobe bricks under compression: Experimental investigation and derivation of stress–strain equation. Constr. Build. Mater. 2014, 53, 83–90. [Google Scholar] [CrossRef]

- Bouhicha, M.; Aouissi, F.; Kenai, S. Performance of composite soil reinforced with barley straw. Cem. Concr. Compos. 2005, 27, 617–621. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Bouguerra, A.; Ledhem, A.; De Barquin, F.; Dheilly, R.M.; Quéneudec, M. Effect of microstructure on the mechanical and thermal properties of lightweight concrete prepared from clay, cement, and wood aggregates. Cem. Concr. Res. 1998, 28, 1179–1190. [Google Scholar] [CrossRef]

- Quagliarini, E.; Lenci, S. The influence of natural stabilizers and natural fibres on the mechanical properties of ancient Roman adobe bricks. J. Cult. Herit. 2010, 11, 309–314. [Google Scholar] [CrossRef]

- Khedari, J.; Watsanasathaporn, P.; Hirunlabh, J. Development of fibre-based soil–cement block with low thermal conductivity. Cem. Concr. Compos. 2005, 27, 111–116. [Google Scholar] [CrossRef]

- Segetin, M.; Jayaraman, K.; Xu, X. Harakeke reinforcement of soil–cement building materials: Manufacturability and properties. Build. Environ. 2007, 42, 3066–3079. [Google Scholar] [CrossRef]

- Lahouioui, M. Élaboration et Évaluation des Propriétés Physico-Thermiques et Acoustiques de Nouveaux Éco-Composites à Base de Bois de Palmier. Ph.D. Thesis, Université de Gabès, Gabès, Tunisia, 2019. [Google Scholar]

- Ouedraogo, M.; Dao, K.; Millogo, Y.; Seynou, M.; Aubert, J.E.; Gomina, M. Influence des fibres de kenaf (Hibiscus altissima) sur les propriétés physiques et mécaniques des adobes. J. Société Ouest-Afr. Chim. 2017, 43, 63. [Google Scholar]

- Ouedraogo, M.; Dao, K.; Millogo, Y.; Aubert, J.E.; Messan, A.; Seynou, M.; Zerbo, L.; Gomina, M. Physical, thermal and mechanical properties of adobes stabilized with fonio (Digitaria exilis) straw. J. Build. Eng. 2019, 23, 250–258. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Silica extraction from rice husk: Comprehensive review and applications. Hybrid. Adv. 2023, 4, 100111. [Google Scholar] [CrossRef]

- Modjonda, S.; Etienne, Y.; Raidandi, D. Thermal and Mechanical Characterization of Compressed Clay Bricks Reinforced by Rice Husks for Optimizing Building in Sahelian Zone. Adv. Mater. Phys. Chem. 2023, 13, 177–196. [Google Scholar] [CrossRef]

- Al Rim, K.; Ledhem, A.; Douzane, O.; Dheilly, R.M.; Queneudec, M. Influence of the proportion of wood on the thermal and mechanical performances of clay-cement-wood composites. Cem. Concr. Compos. 1999, 21, 269–276. [Google Scholar] [CrossRef]

- Ledhem, A.; Dheilly, R.M.; Benmalek, M.L.; Quéneudec, M. Properties of wood-based composites formulated with aggregate industry waste. Constr. Build. Mater. 2000, 14, 341–350. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.C.; Aubert, J.E.; Ghavami, K. Experimental analysis of Pressed Adobe Blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Standard DIN 4108; Thermal Insulation and Energy Economy in Buildings. Deutsches Institut für Normung (DIN): Berlin, Germany, 2024. Available online: https://www.boutique.afnor.org/en-gb/standard/din-41084/thermal-insulation-and-energy-economy-in-buildings-part-4-hygrothermal-desi/eu167388/261822 (accessed on 4 April 2024).

- Demir, I. Effect of organic residues addition on the technological properties of clay bricks. Waste Manag. 2008, 28, 622–627. [Google Scholar] [CrossRef] [PubMed]

- Delot, P. Balle de Riz—Compilation D’éléments Techniques en Vue de Son Utilisation en Isolation Thermique. 2015. Available online: www.ballederiz.fr (accessed on 29 April 2025).

- McGregor, F.; Heath, A.; Maskell, D.; Fabbri, A.; Morel, J.C. A review on the buffering capacity of earth building materials. Proc. Inst. Civ. Eng.-Constr. Mater. 2016, 169, 241–251. [Google Scholar] [CrossRef]

- AFNOR NF EN ISO 11654:1997; Acoustique—Absorbants Pour L’utilisation dans les Bâtiments—Évaluation de L’absorption Acoustique. AFNOR: Paris, France, 1997.

- Mcgrory, M.; Castro Cirac, D.; Gaussen, O.; Cabrera, D. Sound absorption coefficient measurement: Re-examining the relationship between impedance tube and reverberant room methods. In Proceedings of the Acoustics 2012, Nantes, France, 23–27 April 2012; Australian Acoustical Society: Fremantle, Australia, 2012. [Google Scholar]

- Badouard, C. Valorisation des Sous-Produits de Pressurage du Raisin: Caractérisation Thermomécanique d’un Nouveau Matériau Biosourcé à Base D’aignes. Ph.D. Thesis, Université de Reims Champagne-Ardenne, Reims, France, 2023. [Google Scholar]

- Yetgin, Ş.; Çavdar, Ö.; Çavdar, A. The effects of the fiber contents on the mechanic properties of the adobes. Constr. Build. Mater. 2008, 22, 222–227. [Google Scholar] [CrossRef]

- Alioui, A.; Idrissi Kaitouni, S.; Azalam, Y.; Al armouzi, N.; Bendada, E.M.; Mabrouki, M. Effect of straw fibers addition on hygrothermal and mechanical properties of carbon-free adobe bricks: From material to building scale in a semi-arid climate. Build. Environ. 2024, 255, 111380. [Google Scholar] [CrossRef]

- Da Silva, N.A.; Cecchin, D.; Rocha, C.A.A.; Toledo Filho, R.D.; Pessin, J.; Rossi, G.; Bambi, G.; Conti, L.; Ferraz, P.F.P. Influence of coconut fiber incorporation on the mechanical behavior of adobe blocks. Agron. Res. 2024, 22, 1504–1516. [Google Scholar]

- Khrissi, Y.; Tilioua, A. Development and characterization of eco-friendly earth bricks stabilized with date palm waste fibers for sustainable construction. Clean. Waste Syst. 2025, 11, 100283. [Google Scholar] [CrossRef]

- Rocco, A.; Vicente, R.; Rodrigues, H.; Ferreira, V. Adobe Blocks Reinforced with Vegetal Fibres: Mechanical and Thermal Characterisation. Buildings 2024, 14, 2582. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural waste management strategies for environmental sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef] [PubMed]

- Delot, P.; Association Bâtir en Balles. Balle de riz de Camargue. 2017. Available online: https://www.google.com.hk/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.enviroboite.net/IMG/pdf/1710_fiche_balle_riz_web.pdf&ved=2ahUKEwic8IrCtbuOAxWMSWwGHTznACcQFnoECB8QAQ&usg=AOvVaw2zVzoHY3eT_fmZuprt67oG (accessed on 11 July 2025).

- Datchossa, A.T.; Doko, V.K.; Houanou, K.A.; Olodo, E.E.T. 2022 Study of the ecological interest of a rice husk ash mortar. Aust. J. Basic Appl. Sci. 2022, 16, 8–16. [Google Scholar]

| O | Ca | Si | Al | Fe | K | P | Mg | Si/Ca | |

|---|---|---|---|---|---|---|---|---|---|

| 51-AT | 71.9 | 21.5 | 3.2 | 0.7 | 0.3 | 0.26 | - | 0.32 | 0.15 |

| 51-CH | 70.16 | 9.17 | 15.77 | 3.25 | 0.93 | 0.8 | - | 0.43 | 1.72 |

| Rice husk | 74.8 | 0.27 | 24.25 | 0.03 | 0.02 | 0.47 | 0.1 | 0.1 | 89.81 |

| Rice Husk | 51-CH | 51-AT | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 wt% | 1 wt% | 2 wt% | 3 wt% | 0 wt% | 1 wt% | 2 wt% | 3 wt% | ||

| Apparent density (kg/m3) | 150.9 | 1736.87 | 1714.65 | 1680.06 | 1651.43 | 1814.73 | 1763.61 | 1693.02 | 1618.90 |

| Dry density (kg/m3) | 137.6 | 1704.91 | 1687.73 | 1655.53 | 1624.19 | 1784.42 | 1748.97 | 1681.24 | 1608.48 |

| Absolute density (kg/m3) | 1284 | 2720.17 | 2705.81 | 2691.45 | 2677.09 | 2651.00 | 2637.33 | 2623.66 | 2609.99 |

| Moisture content (%) | 8.27 | 1.84 | 1.57 | 1.46 | 1.65 | 1.67 | 0.83 | 0.70 | 0.64 |

| Porosity (%) | 88.32 | 36.15 | 36.63 | 37.58 | 38.31 | 31.55 | 33.13 | 35.47 | 37.97 |

| Clay content (%) | - | 11.3 | - | - | - | 10.27 | - | - | - |

| pH | 6.87 | 7.9 | - | - | - | 7.7 | - | - | - |

| CaCO3 (%) | - | 41.60 | - | - | - | 83.62 | - | - | - |

| Organic matter (%) | - | 0.24 | - | - | - | 1.50 | - | - | - |

| MBV g/(m2·%RH) | - | 2.15 | 2.18 | 2.23 | 2.26 | 1.55 | 2.09 | 2.74 | 2.97 |

| 51-CH | 51-AT | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 wt% | 1 wt% | 2 wt% | 3 wt% | 0 wt% | 1 wt% | 2 wt% | 3 wt% | |

| (MPa) | 2.57 (0.18) | 2.59 (0.18) | 2.18 (0.08) | 1.97 (0.08) | 0.52 (0.10) | 0.54 (0.02) | 0.53 (0.04) | 0.60 (0.02) |

| (%) | 2.32 (0.79) | 2.39 (0.60) | 3.18 (0.76) | 2.84 (0.67) | 2.76 (0.06) | 2.92 (0.33) | 2.39 (0.49) | 3.29 (1.16) |

| Mean tangent modulus E (MPa) | 146.38 (44.63) | 151.83 (41.85) | 98.58 (17.68) | 95.81 (26.08) | 20.60 (5.21) | 19.70 (2.84) | 27.99 (6.18) | 27.02 (12.06) |

| Rice Husk | 51-AT | 51-CH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 wt% | 1 wt% | 2 wt% | 3 wt% | 0 wt% | 1 wt% | 2 wt% | 3 wt% | ||

| Thermal conductivity (W/m·K) | 0.066 (0.001) | 0.782 (0.021) | 0.740 (0.045) | 0.583 (0.042) | 0.508 (0.034) | 0.879 (0.029) | 0.821 (0.015) | 0.760 (0.026) | 0.701 (0.022) |

| Diffusivity (10−6 m2/s) | 0.354 (0.009) | 0.503 (0.030) | 0.496 (0.020) | 0.399 (0.029) | 0.351 (0.023) | 0.593 (0.031) | 0.550 (0.008) | 0.503 (0.014) | 0.462 (0.010) |

| Specific heat capacity (kJ/kg·K) | 1.234 (0.057) | 0.856 (0.033) | 0.846 (0.020) | 0.863 (0.014) | 0.94 (0.004) | 0.853 (0.015) | 0.863 (0.011) | 0.898 (0.009) | 0.919 (0.012) |

| Compressive Peak | Thermal Conductivity | Acoustic Absorption | Moisture Buffering Value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH, wt% | 1% | 2% | 3% | 1% | 2% | 3% | 1% | 2% | 3% | 1% | 2% | 3% |

| 51-AT | ↗ | ↗ | ↗ | ↘ | ↘ | ↘ | → | → | → | ↗ | ↗ | ↗ |

| 51-CH | ↗ | ↘ | ↘ | ↘ | ↘ | ↘ | → | → | → | → | → | → |

| Fiber Used | wt% | Dry Density (kg/m3) | Compressive Strength (MPa) | Thermal Conductivity (W/m·K) | MBV (kg/(m2·%RH)) | Weighted Sound Absorption Coefficient | References |

|---|---|---|---|---|---|---|---|

| Reference (raw soil) | 0 | 1705–1784 | 0.52–2.57 | 0.782–0.879 | 1.5–2.2 | 0.14–0.18 | Present study |

| Rice husk | 0.2–1 | 1770–1900 | 2.4–3.65 | 0.8–1.1 | - | - | [14] |

| 0.75 | - | 3.93 | - | - | - | [16] | |

| Rice husk studied | 1–3 | 1608–1749 | 0.52–2.59 | 0.51–0.821 | 2.09–2.97 | 0.16–0.23 | Present study |

| Wheat straw | 0.72–3.84 | 1430–1830 | 0.5–1.5 | - | - | - | [75] |

| 1–4 | 1393–1701 | 3.08–4.93 | 0.294–0.411 | - | - | [76] | |

| Fonio straw | 0.2–1 | - | 2.3–2.8 | 0.35–1.1 | - | - | [61] |

| Coconut fiber | 0.25–1 | 1795–1857 | 1.4–2.7 | - | - | - | [4] |

| 1–2 | 1675–1715 | 1.95–2.05 | - | - | - | [77] | |

| Sugarcane bagasse | 0.25–1 | 1808–1867 | 1.1–2.05 | - | - | - | [4] |

| Harakeke (flax) | 0.6–0.8 | - | 2.0–3.5 | - | - | - | [58] |

| Date palm | 1–5 | 1250–1679 | 2.1–3.6 | 0.316–0.514 | - | - | [78] |

| Bunho and junco | 1–3 | 1278–1445 | 0.355–1.617 | 0.30–0.55 | - | - | [79] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banaba, G.; Murer, S.; Rousse, C.; Beaumont, F.; Bliard, C.; Chatelet, É.; Polidori, G. Effect of Rice Husk Addition on the Hygrothermal, Mechanical, and Acoustic Properties of Lightened Adobe Bricks. Materials 2025, 18, 3364. https://doi.org/10.3390/ma18143364

Banaba G, Murer S, Rousse C, Beaumont F, Bliard C, Chatelet É, Polidori G. Effect of Rice Husk Addition on the Hygrothermal, Mechanical, and Acoustic Properties of Lightened Adobe Bricks. Materials. 2025; 18(14):3364. https://doi.org/10.3390/ma18143364

Chicago/Turabian StyleBanaba, Grégoire, Sébastien Murer, Céline Rousse, Fabien Beaumont, Christophe Bliard, Éric Chatelet, and Guillaume Polidori. 2025. "Effect of Rice Husk Addition on the Hygrothermal, Mechanical, and Acoustic Properties of Lightened Adobe Bricks" Materials 18, no. 14: 3364. https://doi.org/10.3390/ma18143364

APA StyleBanaba, G., Murer, S., Rousse, C., Beaumont, F., Bliard, C., Chatelet, É., & Polidori, G. (2025). Effect of Rice Husk Addition on the Hygrothermal, Mechanical, and Acoustic Properties of Lightened Adobe Bricks. Materials, 18(14), 3364. https://doi.org/10.3390/ma18143364