Investigation of Buckling and Failure in Thin-Walled Columns Fabricated from PLA and PETG Using FDM 3D Printing

Abstract

1. Introduction

2. Literature Review

- PLA exhibits higher tensile strength;

- PETG surpasses PLA in impact strength and heat resistance;

- Higher nozzle temperatures and lower layer heights improve strength and interlayer adhesion for both materials;

- PETG retains dimensional stability better at elevated temperatures.

3. Materials and Methods

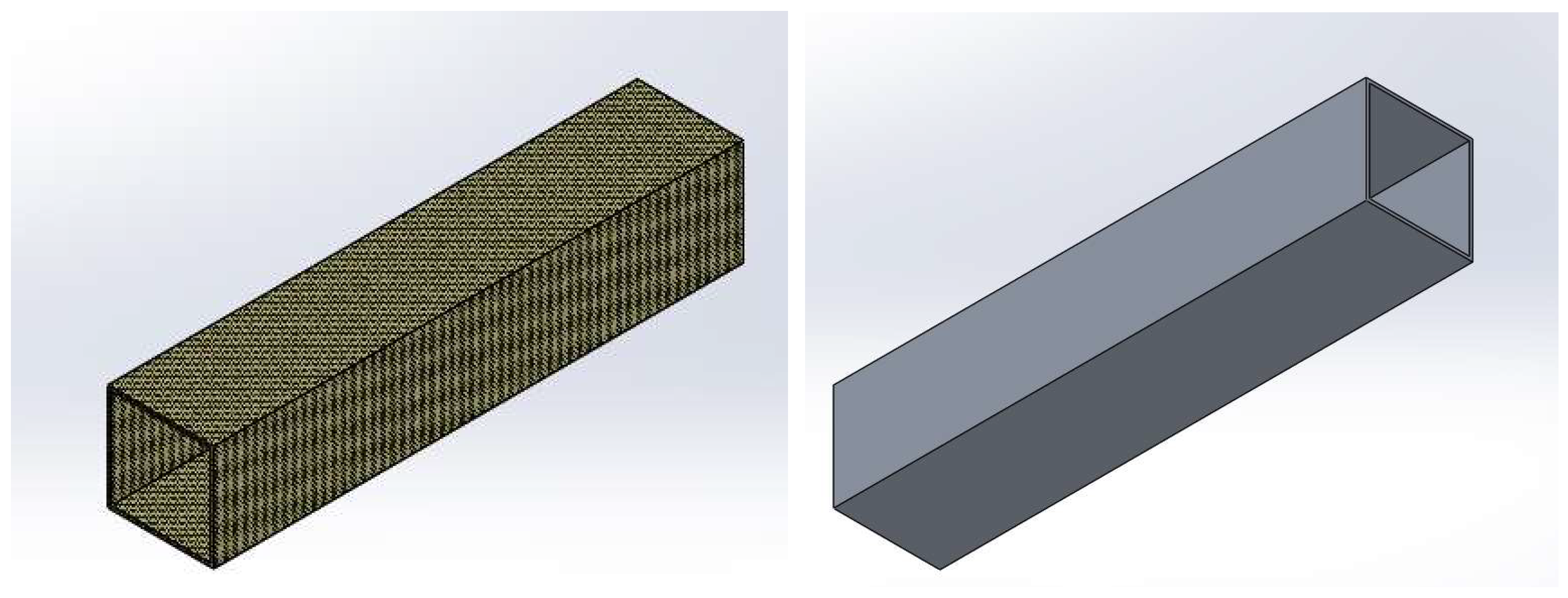

3.1. Three-Dimensional Model

3.2. Three-Dimensional Printing Machine, Printing Materials and Test Specimens

- -

- PLA—45.17 ± 0.14 g.

- -

- PETG—46.34 ± 0.17 g.

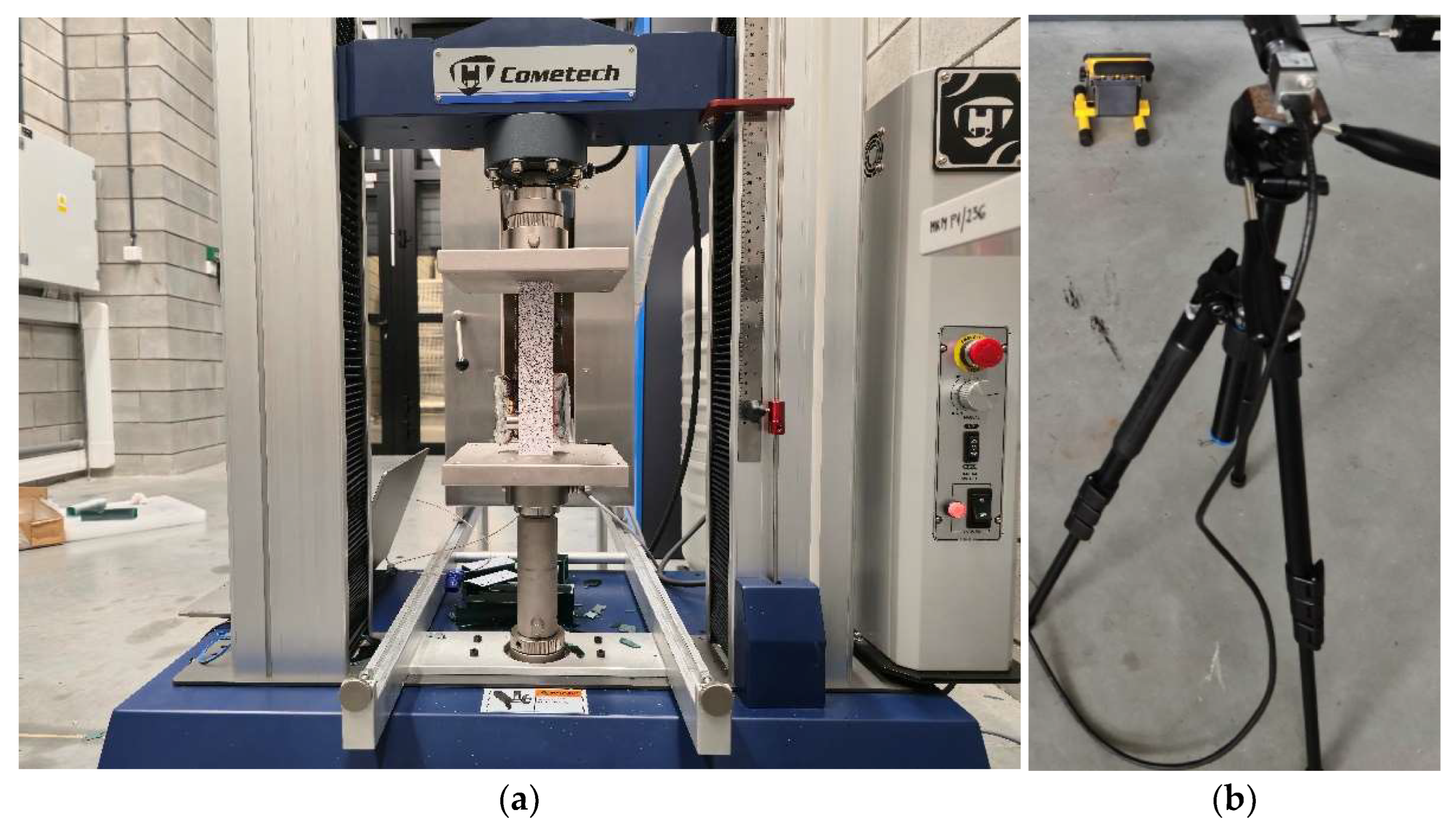

3.3. Equipment Used for Research

- -

- Cometech QC-505M2F universal testing machine (Cometech Testing Machines Co., Ltd., Fengyuan District, Taichung City, Taiwan) (Figure 3a). This machine is designed to perform static compression tests; it is controlled by Amis Plus software (1.5.6); maximum load is 50 kN; initial load is 100 N; test speed is 4 mm/min.

- -

- Aramis 2D optical strain measurement system (Figure 3b). This equipment is a digital image correlation (DIC) technology; it provides visualization of strain distribution over the specimen surface and allows to determine zones with maximum stress and potential damage.

- -

- SpotWave 201 acoustic emission system (Vallen Systeme GmbH, Wolfratshausen, Germany). This equipment is presented as a single-channel system with a VS150-L piezoelectric sensor (Vallen Systeme GmbH, Wolfratshausen, Germany) (Figure 3a); it is used to record signals accompanying material damage. As a result, the obtained data were analyzed using Vallen AE software (R2023.1218.2).

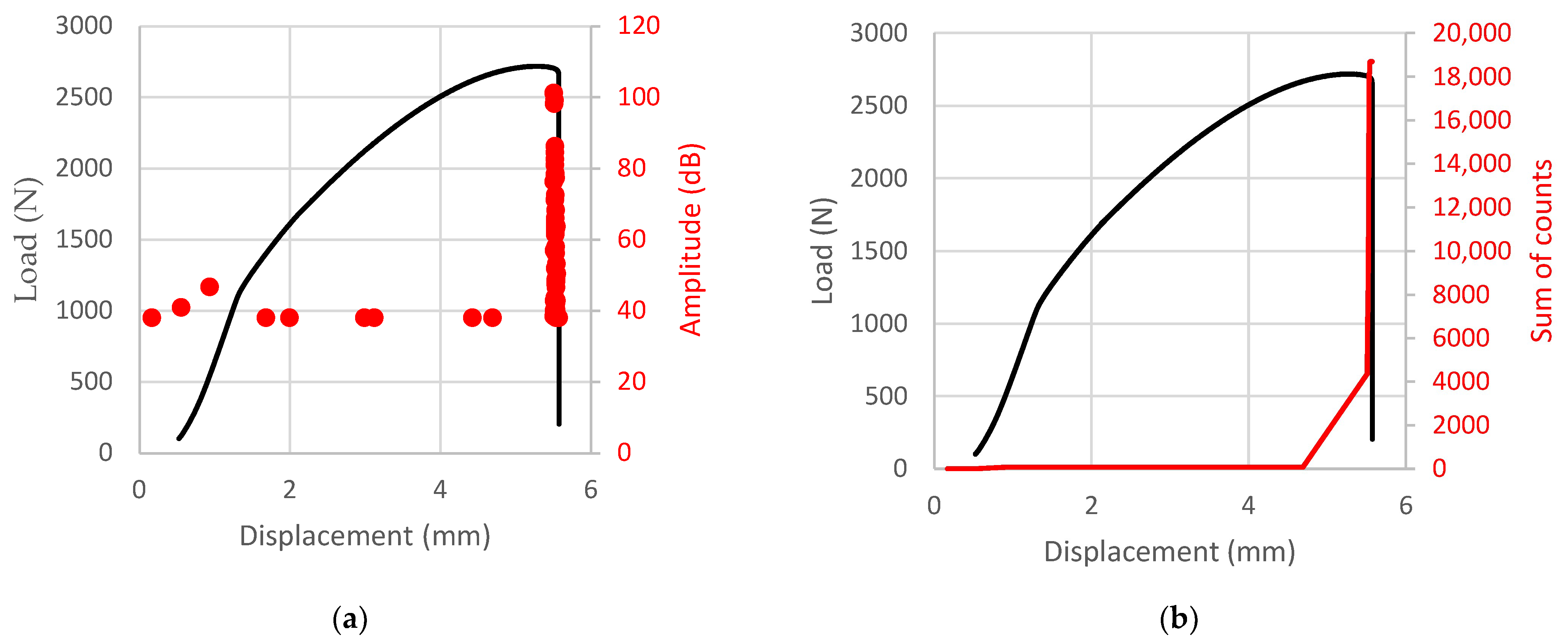

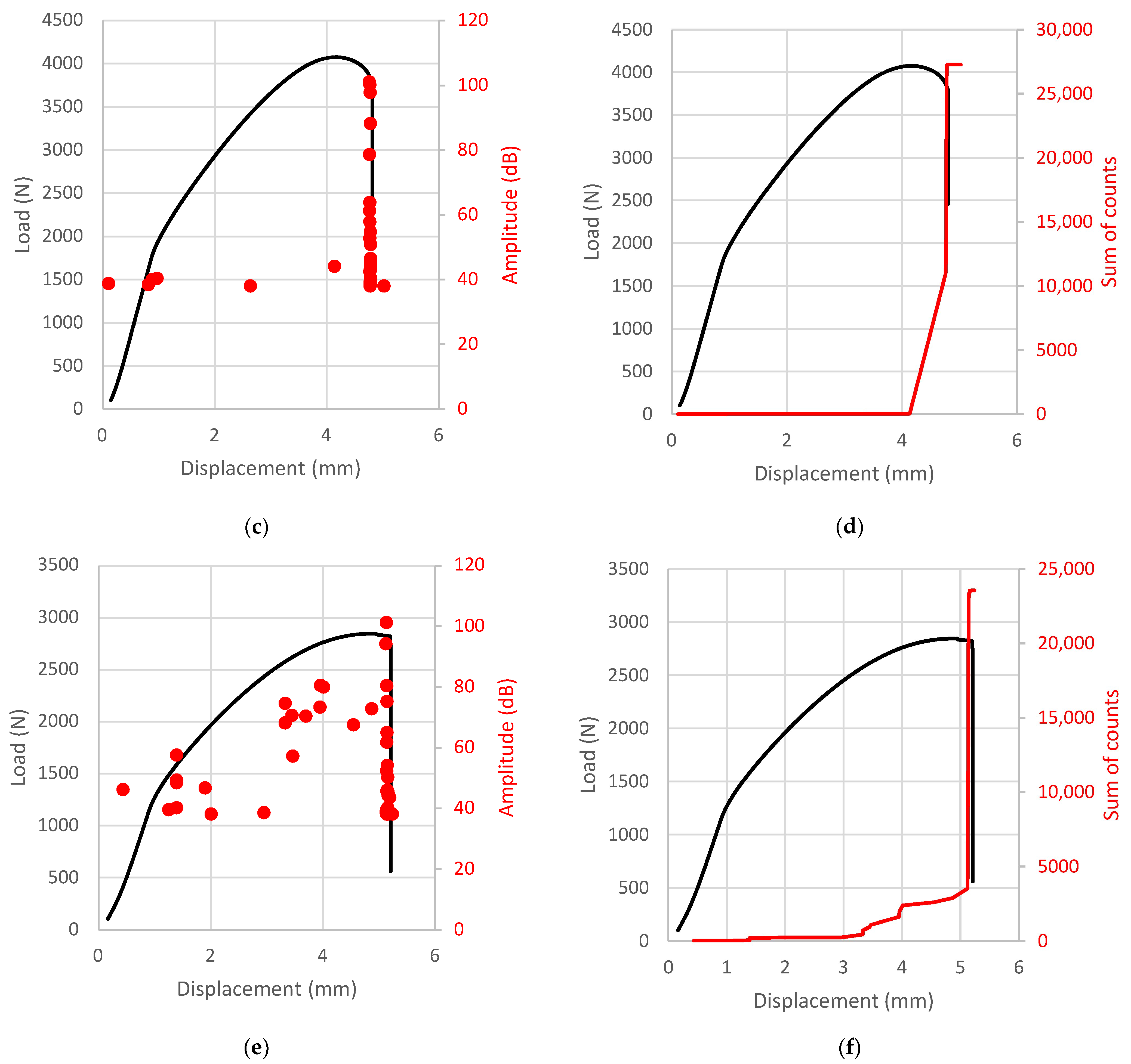

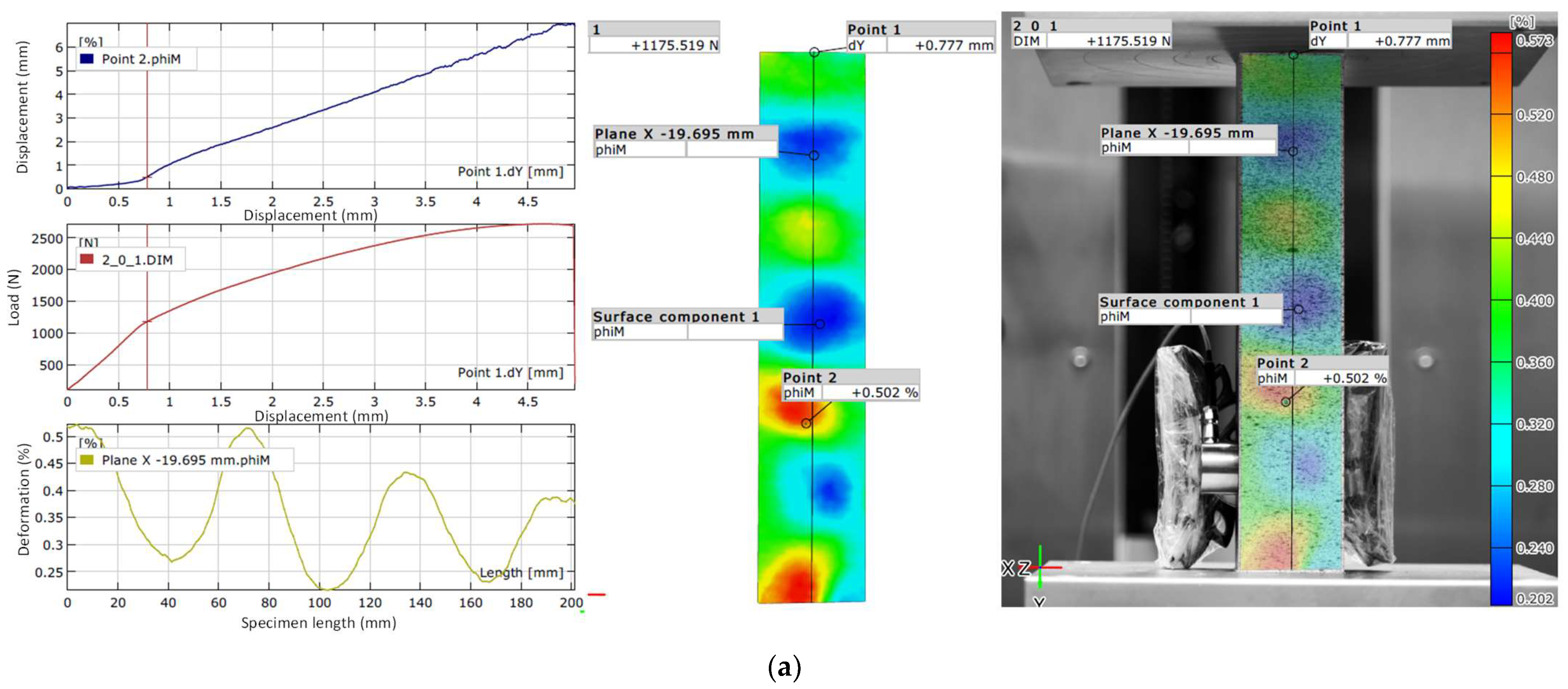

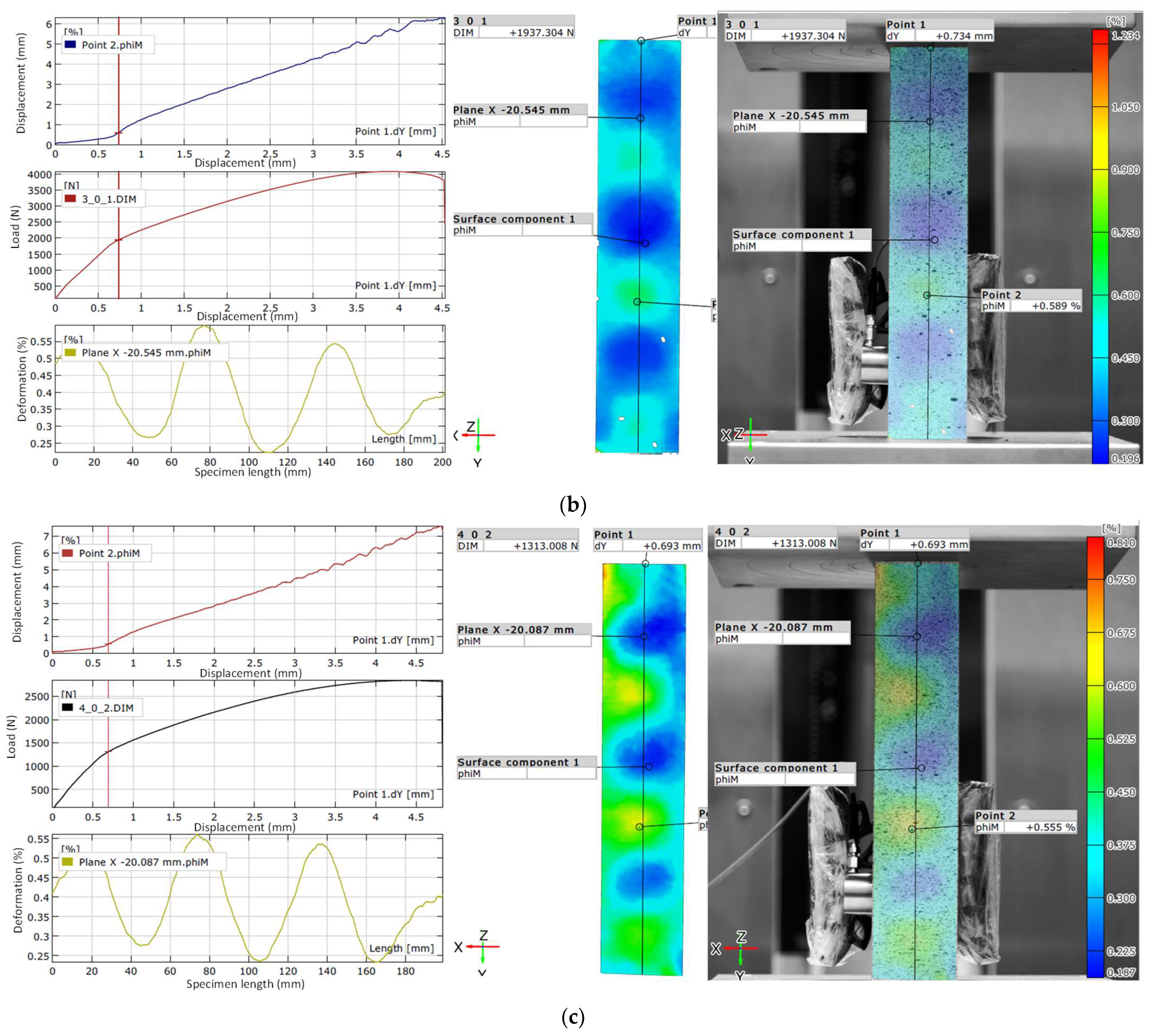

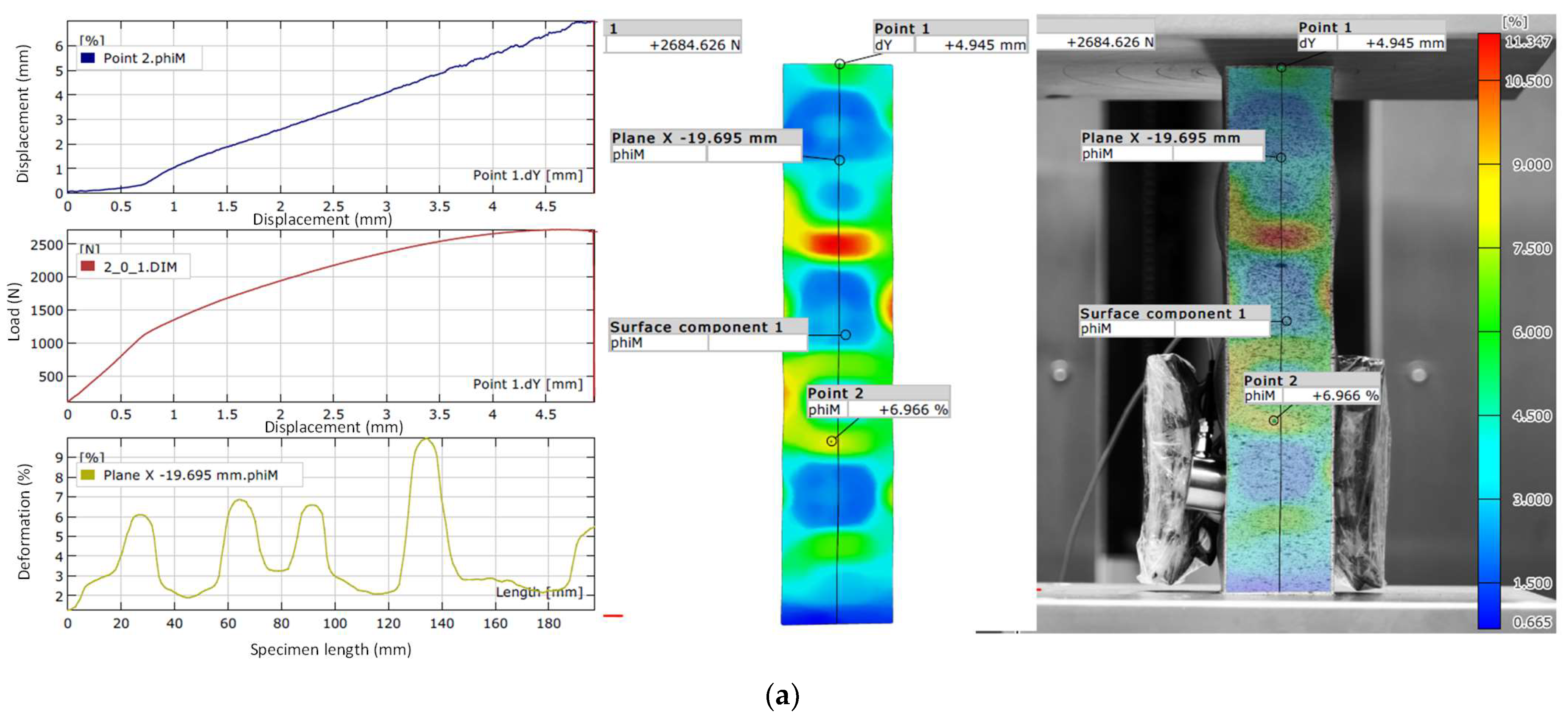

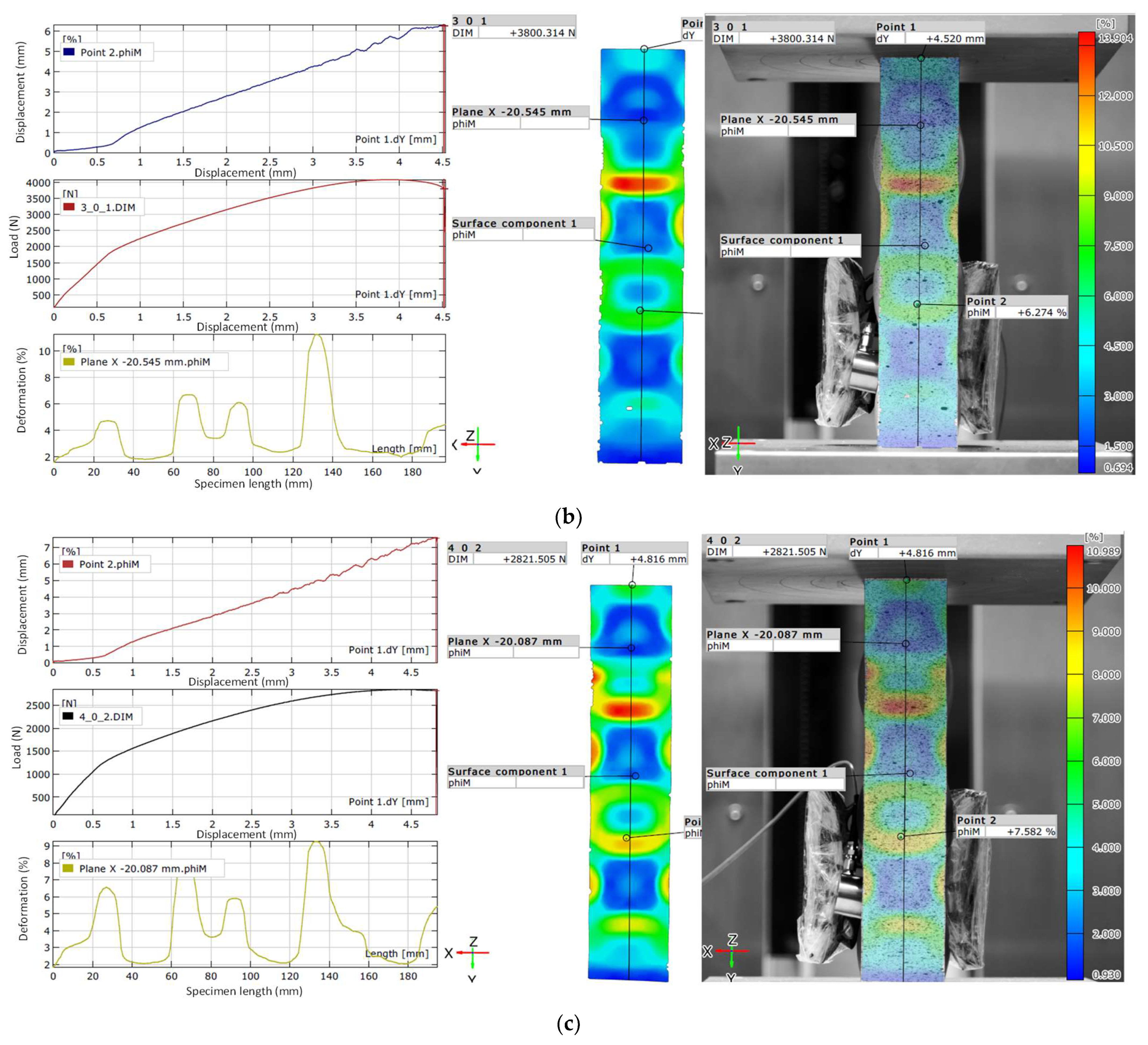

4. Results and Discussion

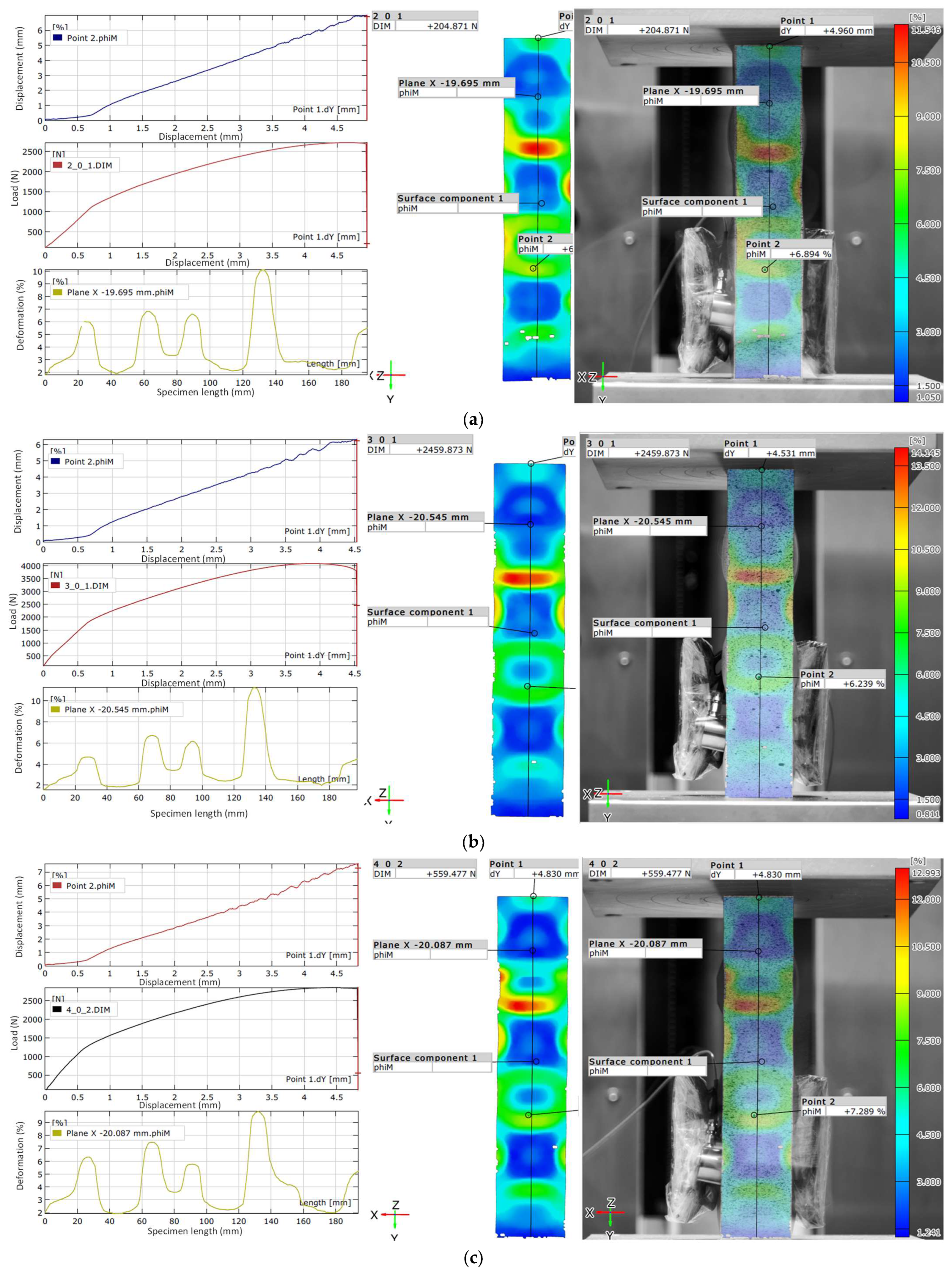

- PLA—2684.6 N

- PETG1—3800.3 N

- PETG2—2821.5 N

- PLA—5.1 mm

- PETG1—4.6 mm

- PETG2—5.2 mm

- PLA—11.347%

- PETG1—13.904%

- PETG2—10.989%

5. Conclusions

Prospects for Future Research

- Effect of Printing Parameters: A more detailed analysis will be conducted on how FDM printing parameters—such as extruder temperature, layer orientation, printing speed, and infill density—affect the mechanical properties and stability of thin-walled columns. This will support the development of recommendations for optimizing printing settings to maximize the strength and stability of the printed structures.

- Analysis of Geometries and Cross-Sections: Subsequent experiments will explore columns with various cross-sectional shapes, wall thicknesses, and element lengths to determine the most effective configurations for different loading conditions.

- Cyclic and Impact Loading: The performance of PLA and PETG structures under cyclic and dynamic loads will be examined. Investigating their fatigue resistance and impact toughness will help expand their practical applications, particularly in the transportation and construction sectors.

- Incorporation of Reinforcing Fillers: Future studies will explore the use of modified composite materials based on PLA and PETG, reinforced with fibers such as carbon, glass, or Kevlar. The influence of these fillers on critical load capacity and failure mechanisms will be a key focus.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rozylo, P.; Falkowicz, K.; Wysmulski, P.; Debski, H.; Pasnik, J.; Kral, J. Experimental-Numerical Failure Analysis of Thin-Walled Composite Columns Using Advanced Damage Models. Materials 2021, 14, 1506. [Google Scholar] [CrossRef] [PubMed]

- Daliri, O.; Farahani, M.; Farhang, M. A combined numerical and statistical analysis for prediction of critical buckling load of the cylindrical shell with rectangular cutout. Eng. Solid Mech. 2019, 7, 35–46. [Google Scholar] [CrossRef]

- Musa, A.E.; Al-Shugaa, M.A.; Al-Gahtani, H.J. The upper bound of the buckling stress of axially compressed carbon steel circular cylindrical shells. J. Press. Vessel Technol. 2024, 146, 061302. [Google Scholar] [CrossRef]

- Bin Kamarudin, M.N.; Mohamed Ali, J.S.; Aabid, A.; Ibrahim, Y.E. Buckling Analysis of a Thin-Walled Structure Using Finite Element Method and Design of Experiments. Aerospace 2022, 9, 541. [Google Scholar] [CrossRef]

- Rozylo, P.; Debski, H. Stability and load carrying capacity of thin-walled composite columns with square cross-section under axial compression. Compos. Struct. 2024, 329, 117795. [Google Scholar] [CrossRef]

- Aldhafeeri, T.; Alotaibi, M.; Barry, C.F. Impact of Melt Processing Conditions on the Degradation of Polylactic Acid. Polymers 2022, 14, 2790. [Google Scholar] [CrossRef]

- Benamira, M.; Benhassine, N.; Ayad, A.; Dekhane, A. Investigation of printing parameters effects on mechanical and failure properties of 3D printed PLA. Eng. Fail. Anal. 2023, 148, 107218. [Google Scholar] [CrossRef]

- Bouzouita, A.; Notta-Cuvier, D.; Raquez, J.M.; Lauro, F.; Dubois, P. Poly(lactic acid)-Based Materials for Automotive Applications. In Industrial Applications of Poly(lactic acid); Di Lorenzo, M., Androsch, R., Eds.; Advances in Polymer Science; Springer: Cham, Switzerland, 2017; p. 282. [Google Scholar] [CrossRef]

- Chmielowiec, A.; Sikorska-Czupryna, S.; Klich, L.; Woś, W.; Kuraś, P. Optimization of Quality Control Processes Using the NPGA Genetic Algorithm. Adv. Sci. Technol. Res. J. 2024, 18, 264–276. [Google Scholar] [CrossRef]

- Chmielowiec, A.; Woś, W.; Czyżewski, J. Numerical Analysis of Inertia Forces in the Connecting Rod and Their Impact on Stress Formation. Materials 2025, 18, 1385. [Google Scholar] [CrossRef]

- Vladov, S.; Scislo, L.; Sokurenko, V.; Muzychuk, O.; Vysotska, V.; Osadchy, S.; Sachenko, A. Neural Network Signal Integration from Thermogas-Dynamic Parameter Sensors for Helicopters Turboshaft Engines at Flight Operation Conditions. Sensors 2024, 24, 4246. [Google Scholar] [CrossRef]

- Vladov, S.; Vysotska, V.; Sokurenko, V.; Muzychuk, O.; Nazarkevych, M.; Lytvyn, V. Neural Network System for Predicting Anomalous Data in Applied Sensor Systems. Appl. Syst. Innov. 2024, 7, 88. [Google Scholar] [CrossRef]

- Mazurkow, A.; Chmielowiec, A.; Homik, W. The Issue of Hydrodynamic Friction in the Context of the Operational Properties of Ring-Shaped Torsional Vibration Dampers. Appl. Sci. 2025, 15, 6528. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Vikneswaran, S.K.; Nagarajan, P.; Dinesh, S.K.; Senthil Kumar, K.L.; Megalingam, A. Investigation of the tensile behaviour of PolyLactic Acid, Acrylonitrile Butadiene Styrene, and Polyethylene Terephthalate Glycol materials. Mater. Today Proc. 2022, 66, 1093–1098. [Google Scholar] [CrossRef]

- Sandanamsamy, L.; Harun, W.S.W.; Tsumori, F. A comprehensive review on fused deposition modelling of polylactic acid. Prog. Addit. Manuf. 2023, 8, 775–799. [Google Scholar] [CrossRef]

- Shekhar, N.; Mondal, A. Synthesis, properties, environmental degradation, processing, and applications of Polylactic Acid (PLA): An overview. Polym. Bull. 2024, 81, 11421–11457. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Zhang, Y.; Cao, W.; Liu, X.; Bao, J.; Zhang, X.; Chen, W. Fabrication of novel macromolecular P-S synergistic flame retardants and its applications in biodegradable poly (lactic acid): Combustibility, anti-melt dripping behavior, crystallization, and mechanical properties. Polymer 2023, 289, 126475. [Google Scholar] [CrossRef]

- Horvath, T.; Kalman, M.; Kollar, M. Szabone The mechanical properties of polyethylene-terephthalate (PET) and polylactic-acid (PDLLA and PLLA), the influence of material structure on forming. IOP Conf. Ser. Mater. Sci. Eng. 2018, 426, 012018. [Google Scholar] [CrossRef]

- Fang, C.C.; Zhang, Y.; Wang, P. Influence of structural design on mechanical and thermal properties of jute reinforced polylactic acid (PLA) laminated composites. Cellulose 2020, 27, 9397–9407. [Google Scholar] [CrossRef]

- Rahman, A.N.M.M.; Zhang, X.; Qin, X.; Alamgir Sayeed, M.M.; Islam, S.R. Novel okra woven fabric reinforced polylactic acid composites: Mechanical, morphological, and thermal properties. Polym. Compos. 2023, 44, 8819–8837. [Google Scholar] [CrossRef]

- Somsuk, N.; Pramoonmak, S.; Chongkolnee, B.; Tipboonsri, P.; Memon, A. Enhancing Mechanical Properties of 3D-Printed PLA Composites Reinforced with Natural Fibers: A Comparative Study. J. Compos. Sci. 2025, 9, 180. [Google Scholar] [CrossRef]

- Cao, D. Increasing strength and ductility of extruded polylactic acid matrix composites using short polyester and continuous carbon fibers. Int. J. Adv. Manuf. Technol. 2024, 130, 3631–3641. [Google Scholar] [CrossRef]

- Wach, R.A.; Wolszczak, P.; Adamus-Wlodarczyk, A. Enhancement of Mechanical Properties of FDM-PLA Parts via Thermal Annealing. Macromol. Mater. Eng. 2018, 303, 1800169. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F.; Ko, Y.G. Mechanical properties and compatibility of polylactic acid/polystyrene polymer blend. Mater. Lett. 2016, 164, 409–412. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Future trends of plastic bottle recycling: Compatibilization of PET and PLA. Polym. Test. 2020, 81, 106160. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3D-Printed PLA and PETG, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef]

- Selvan, S.T.; Mohandass, M. An experimental analysis of mechanical properties for a dissimilar pattern structure in the 3-D printing of a PLA5F filament using the Taguchi method. Mater. Res. Express 2024, 11, 105304. [Google Scholar] [CrossRef]

- Selwin, M.; Nagarajan, R.; Mohammad, F. Optimization of wear behavior of additively manufactured green biocomposites from printed polylactic acid (PLA) and microcrystalline cellulose. Wood Mater. Sci. Eng. 2025, 1–10. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, X.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers 2023, 15, 3096. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Tamimi, Z.A.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive manufacturing: A comprehensive review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.W.; Qi, C.Z.; Tao, H.Y. The degradation investigation of biodegradable PLA/PBAT blend: Thermal stability, mechanical properties and PALS analysis. Radiat. Phys. Chem. 2021, 180, 109239. [Google Scholar] [CrossRef]

- Csótár, H.; Szalai, S.; Kurhan, D.; Sysyn, M.; Fischer, S. Evaluating 3D-Printed Polylactic Acid (PLA)-Reinforced Materials: Mechanical Performance and Chemical Stability in Concrete Mediums. Appl. Sci. 2025, 15, 2165. [Google Scholar] [CrossRef]

- Dana, H.R.; Ebrahimi, F. Synthesis, properties, and applications of polylactic acid-based polymers. Polym. Eng. Sci. 2023, 63, 22–43. [Google Scholar] [CrossRef]

- Shih, Y.-F.; Lin, C.-W.; Cai, Y.-L.; Jahan, K.; Chen, Y.-H. Effects of Bio-Based Polyelectrolyte Complex on Thermal Stability, Flammability, and Mechanical Properties Performance Utilization in PLA/PBS Composites. Buildings 2023, 13, 154. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.; Singh, H. PLA based biocomposites for sustainable products: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Flanagan, T.; Modi, V.; Finnegan, W.; Harrison, N.; Ghabezi, P. Composite upcycling: An experimental study on mechanical behaviour of injection moulded parts prepared from recycled material extrusion printed parts, previously prepared using glass fibre polypropylene composite industry waste. J. Clean. Prod. 2025, 499, 145280. [Google Scholar] [CrossRef]

- Kyriakidis, I.F.; Kladovasilakis, N.; Pechlivani, E.M.; Tsongas, K. Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review. J. Compos. Sci. 2024, 8, 215. [Google Scholar] [CrossRef]

- ASTM E9-19; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International: West Conshohocken, PA, USA, 2025.

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

| Parameter | PLA | PETG1 | PETG2 |

|---|---|---|---|

| Filament type | Print-Me PLA (PPHU POLIGRAF Wiesław Kasprowiak, under their PRINT-ME brand, Gorzów Wielkopolski, Poland) | Print-Me Swift PETG (PPHU POLIGRAF Wiesław Kasprowiak, under their PRINT-ME brand, Gorzów Wielkopolski, Poland) | ROSA 3D CarbonLook PET-G (ROSA PLAST Sp. Z o.o., Warsaw, Poland) |

| Filament diameter | 1.75 mm | 1.75 mm | 1.75 mm |

| Nozzle temperature | ~210 °C | ~240 °C | ~240 °C |

| Bed temperature | 60 °C | 80 °C | 80 °C |

| Layer height | 0.3 mm | 0.3 mm | 0.3 mm |

| Print speed | 0.30 mm/s | 0.30 mm/s | 0.20 mm/s |

| Bed cooling | On | Off | Off |

| Printing orientation | Vertical (Z-axis) | Vertical (Z-axis) | Vertical (Z-axis) |

| Adhesion method | Framed base | Framed base | Framed base |

| Material | Maximum Load (N) | Cross-Sectional Area (mm2) | Compressive Strength (MPa) |

|---|---|---|---|

| PLA | 2720 | 192.25 | 14.15 |

| PETG1 | 4077 | 192.25 | 21.21 |

| PETG2 | 2847 | 192.25 | 14.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baranovskyi, D.; Wysmulski, P.; Rozylo, P.; Debski, H.; Bulakh, M.; Kopyść, M.; Myamlin, S. Investigation of Buckling and Failure in Thin-Walled Columns Fabricated from PLA and PETG Using FDM 3D Printing. Materials 2025, 18, 3346. https://doi.org/10.3390/ma18143346

Baranovskyi D, Wysmulski P, Rozylo P, Debski H, Bulakh M, Kopyść M, Myamlin S. Investigation of Buckling and Failure in Thin-Walled Columns Fabricated from PLA and PETG Using FDM 3D Printing. Materials. 2025; 18(14):3346. https://doi.org/10.3390/ma18143346

Chicago/Turabian StyleBaranovskyi, Denys, Pawel Wysmulski, Patryk Rozylo, Hubert Debski, Maryna Bulakh, Marcin Kopyść, and Sergey Myamlin. 2025. "Investigation of Buckling and Failure in Thin-Walled Columns Fabricated from PLA and PETG Using FDM 3D Printing" Materials 18, no. 14: 3346. https://doi.org/10.3390/ma18143346

APA StyleBaranovskyi, D., Wysmulski, P., Rozylo, P., Debski, H., Bulakh, M., Kopyść, M., & Myamlin, S. (2025). Investigation of Buckling and Failure in Thin-Walled Columns Fabricated from PLA and PETG Using FDM 3D Printing. Materials, 18(14), 3346. https://doi.org/10.3390/ma18143346