A Review of Grain Refinement and Texture Engineering in Aluminum Alloy Magnetron Sputtering Targets

Abstract

1. Introduction

2. Aluminum and Its Alloy Sputtering Targets

2.1. High-Purity Aluminum Target

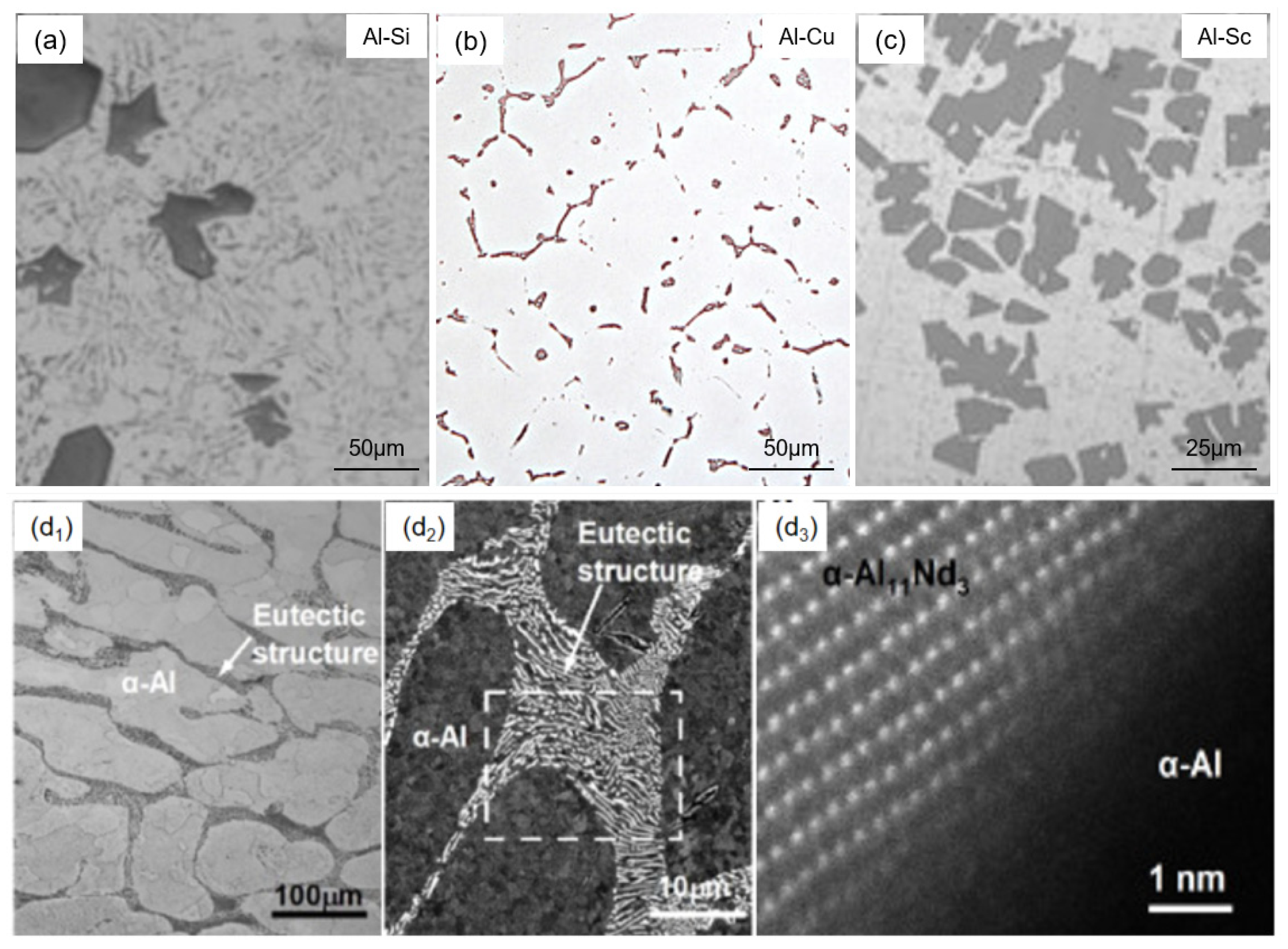

2.2. Al-Si Sputtering Target

2.3. Al-Cu Sputtering Targets

2.4. Al-RE Sputtering Targets

3. Processing and Preparation Methods

3.1. Melting and Casting

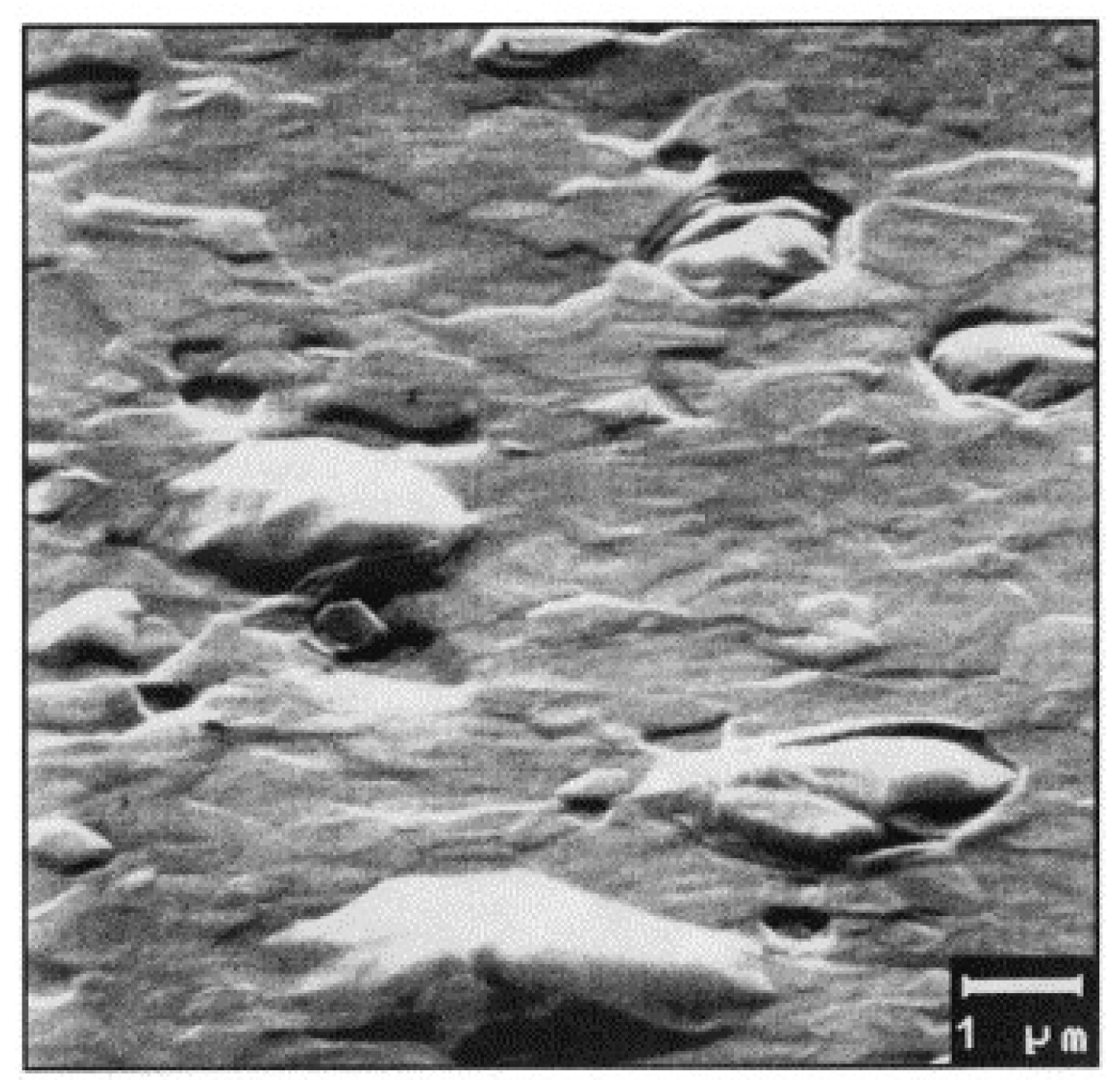

3.2. Powder Metallurgy

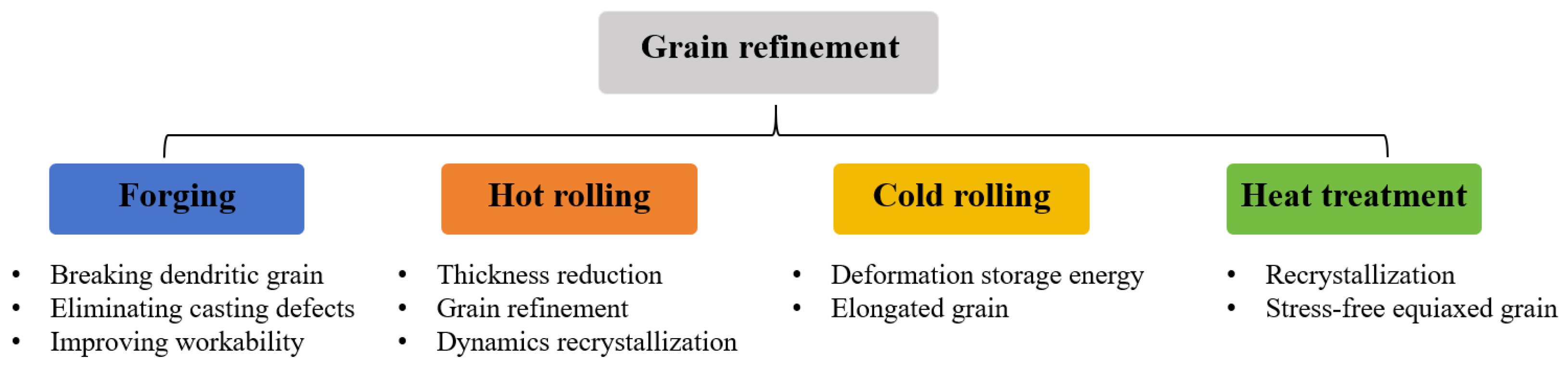

4. Grain Refinement

4.1. Forging

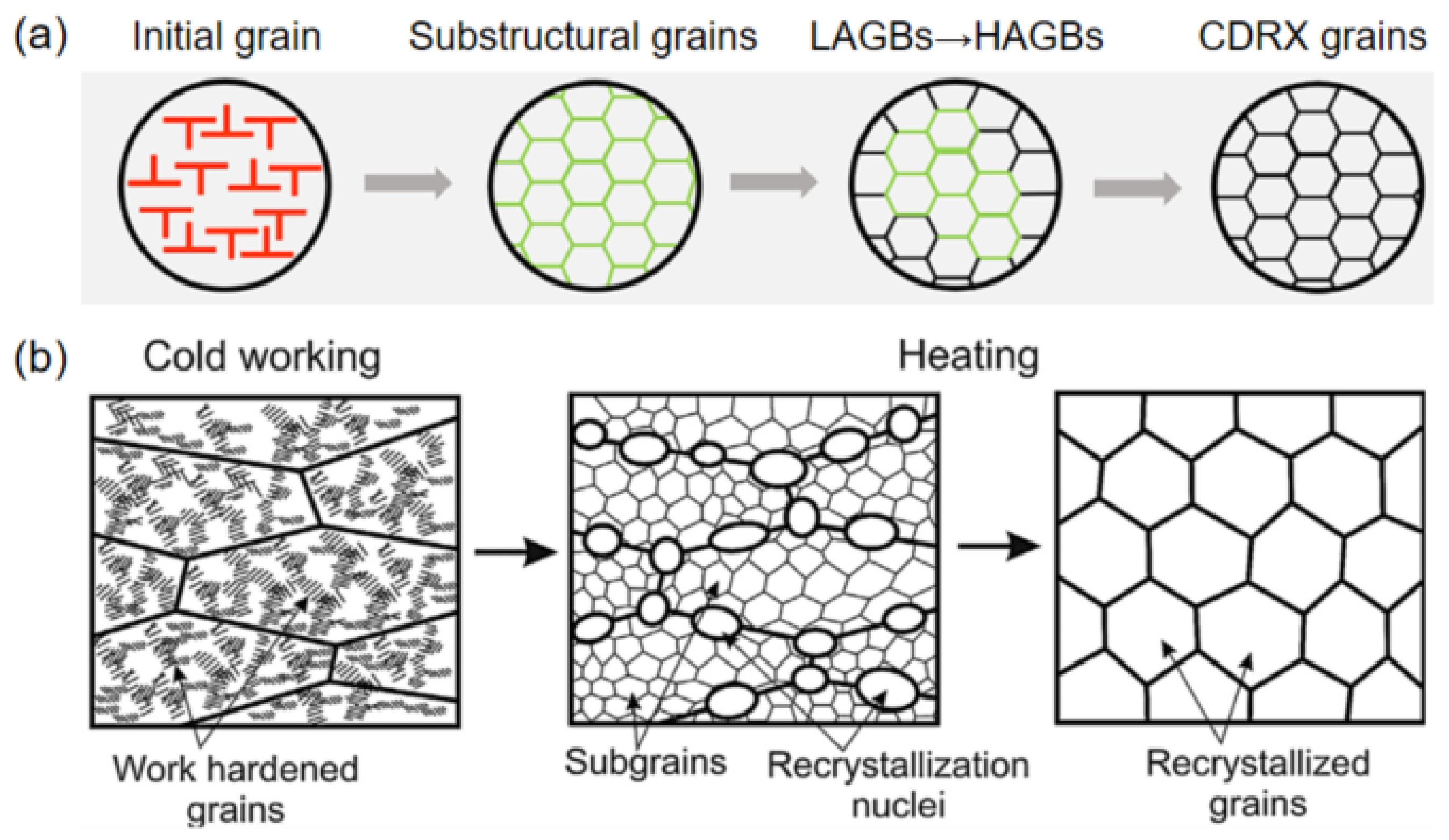

4.2. Hot Rolling

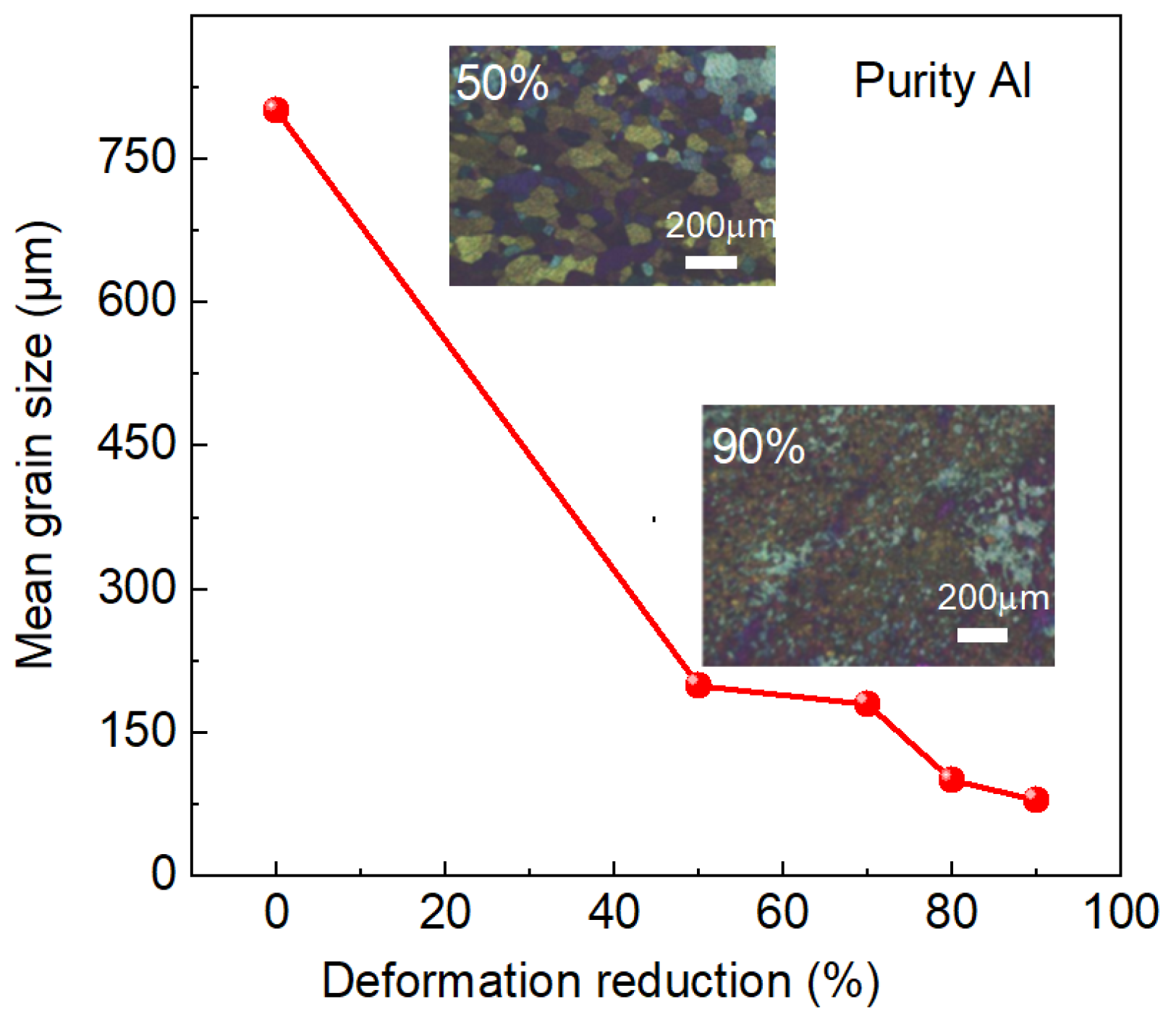

4.3. Cold Rolling

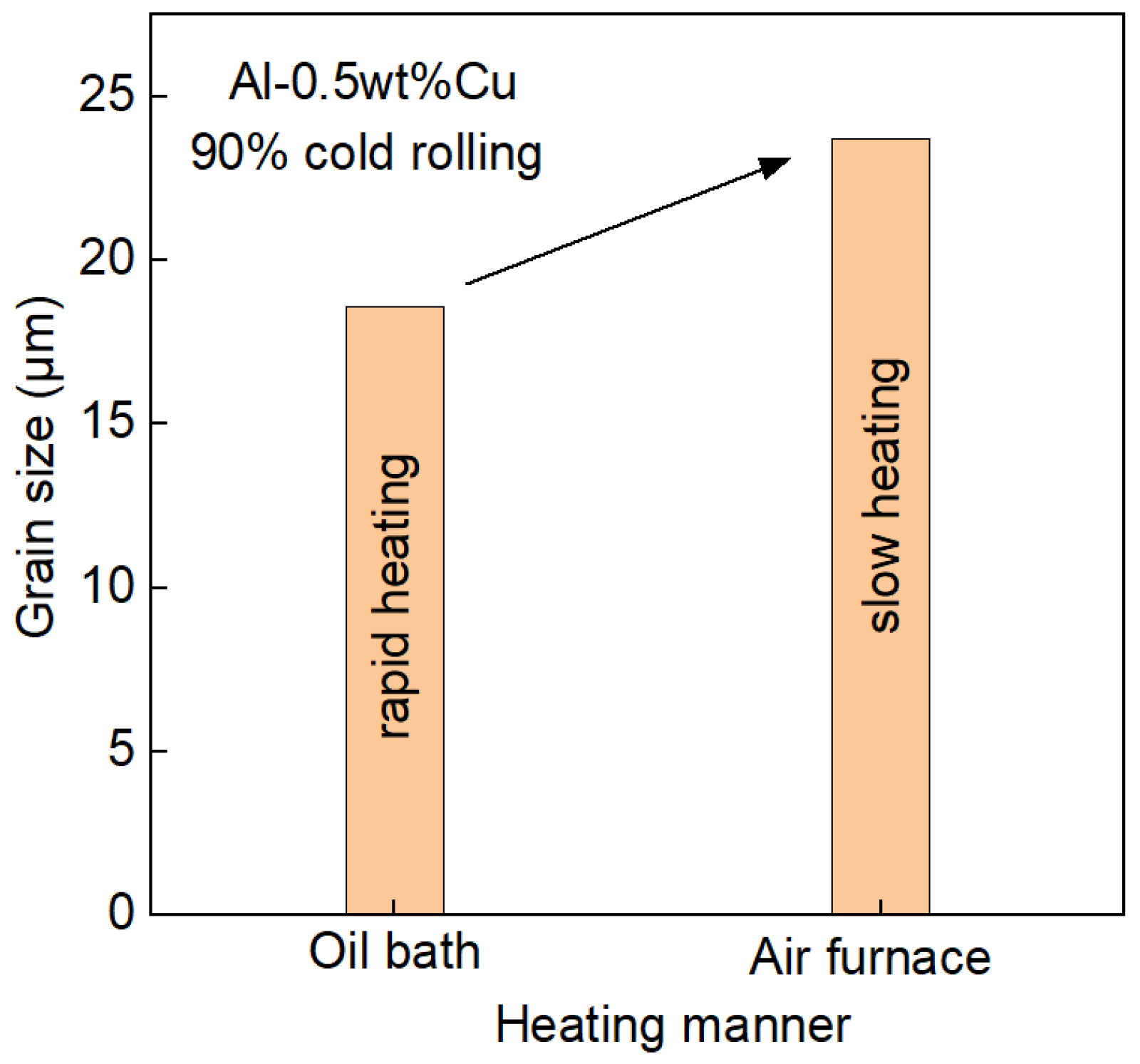

4.4. Heat Treatment

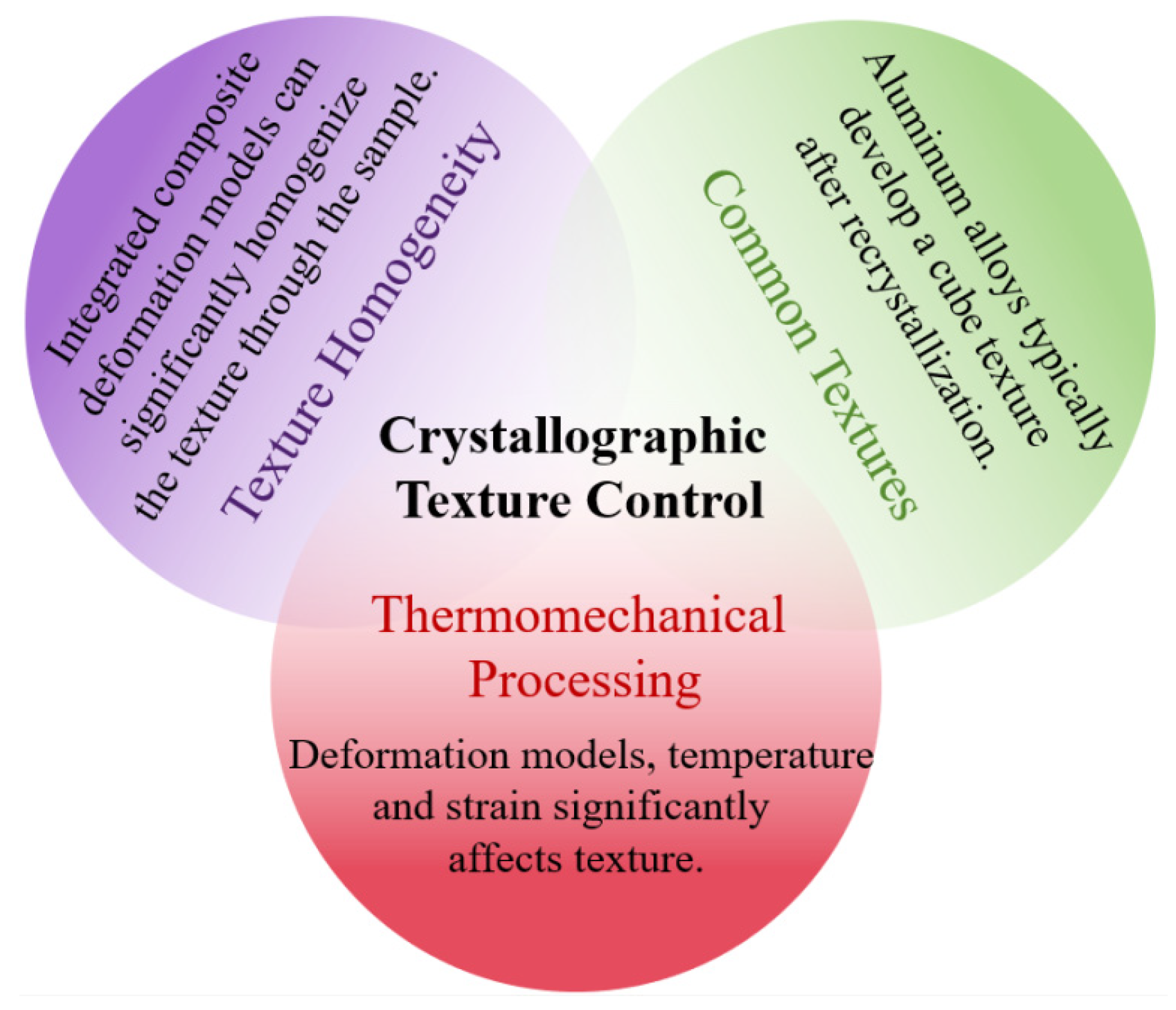

5. Crystallographic Texture Control

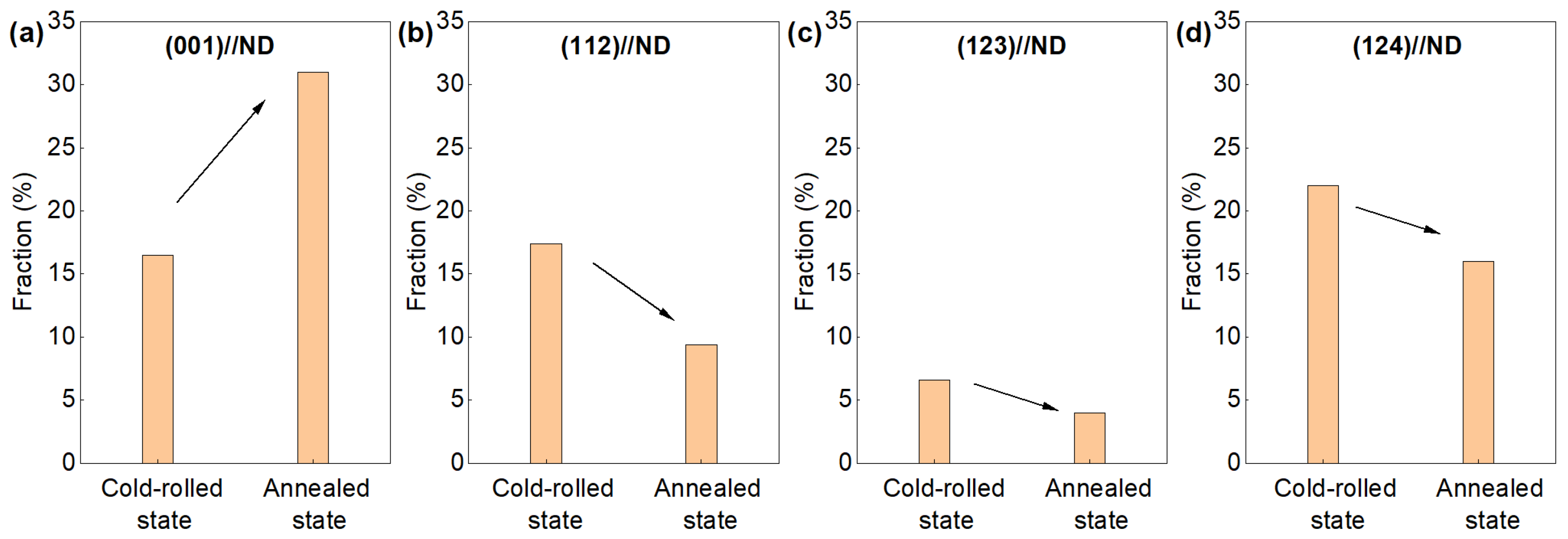

5.1. Common Textures in Aluminum Alloys

5.2. Effect of Thermomechanical Processing on Texture

5.3. Dependence of Texture on the Sample Thickness

6. Summary

Funding

Data Availability Statement

Conflicts of Interest

References

- Janarthanan, B.; Thirunavukkarasu, C.; Maruthamuthu, S.; Manthrammel, M.A.; Shkir, M.; AlFaify, S.; Selvakumar, M.; Reddy, V.R.M.; Park, C. Basic deposition methods of thin films. J. Mol. Struct. 2021, 1214, 130606. [Google Scholar]

- Liu, Z.J.; Chen, Y.X.; Huang, W.J.; Huang, H.J. Manufacture and application of splattering target materials. South. Met. 2003, 135, 23–24. [Google Scholar]

- Kowalska, A.; Kaczmarski, M.; Czerski, K.; Dubey, R.; Haridas, G.D.; Valat, M.; Targosz-Sleçzka, N.; Figiel, P.; Slowik, J.; Baranowska, J. Electron screening in deuteron-deuteron reactions on a Zr target with oxygen and carbon contamination. Materials 2025, 18, 1331. [Google Scholar] [PubMed]

- Yang, B.C.; Cui, H.L. Manufacture and application of sputtering target materials. Vacuum 2001, 3, 11–15. [Google Scholar]

- Tong, L.H.; Zhong, W.P.; Li, F.L. Research and prospect of ultra-high purity aluminum and alloys for semiconductor sputtering targets. World Nonferrous Metals 2023, 8, 141–143. [Google Scholar]

- Zhang, Q.L.; He, J.H. Review of sputtering targets. Shanghai Steel Res. 2002, 4, 30–41. [Google Scholar]

- Chu, Z.Q. The present status and development trend of magnetron sputtering target at home and abroad. Met. Mater. Metall. Eng. 2011, 39, 44–49. [Google Scholar]

- Shang, Z.Y.; Jiang, X.; Li, Y.J.; Yang, Y.G. Sputtering targets used in integrated circuit. Chin. J. Rare Met. 2005, 29, 475–477. [Google Scholar]

- Wu, L.J. Aluminum alloy films and sputtering targets. Chin. J. Vac. Sci. Technol. 2000, 20, 347–351. [Google Scholar]

- He, J.J.; Lyu, B.G.; Jia, Q.; Ding, Z.C.; Liu, S.Q.; Luo, J.F.; Wang, X.Q. Development of high-purity metal sputtering targets for integrated circuits. Eng. Sci. China 2023, 25, 79–87. [Google Scholar]

- Zhang, W.J.; Yi, W.B.; Wu, J. Electromigration in Al interconnects and the challenges in ultra-deepsubmicron technology. Acta Phys. Sin. 2006, 55, 5424–5434. [Google Scholar]

- Zaborowski, M.; Dumania, P. Kinetics of hillock growth in Al and Al-alloys. Microelectron. Eng. 2000, 50, 301–309. [Google Scholar]

- Ma, X.Y.; Chen, J.B.; Huang, G.J. Ultra-high purity aluminum alloy interconnect and sputtering targets. Light Alloy Fabr. Technol. 2011, 39, 56–60. [Google Scholar]

- Yang, Y.G.; Yang, Y.Z.; Liao, Z.; Wang, X.P.; Jiang, X. Effect of annealing temperature on microstructure and performance of high purity Al-1wt% Si alloy. Heat Treat. Met. 2009, 34, 81–83. [Google Scholar]

- Jouhari, C.; Liu, Y.C. Investigation of self-diffusion and specific heat capacity of eutectic al-si systems using molecular dynamics simulations with ADP. Int. J. Comput. Methods Eng. Sci. Mech. 2024, 25, 489–501. [Google Scholar]

- Manani, S.; Pradhan, A.K. Effects of melt thermal treatment on cast Al-Si alloys: A review. Mater. Today Proc. 2022, 62, 6568–6572. [Google Scholar]

- Schöbel, M.; Fernández, R.; Koos, R.; Bernardi, J. Elasto-plastic deformation in Al-Cu cast alloys for engine components. J. Alloys Compd. 2019, 775, 617–627. [Google Scholar]

- He, J.J.; Jia, Q.; Ding, Z.C.; Wang, X.Q.; Cao, X.M.; Cao, Z.Q.; Gu, X.F. Cast Microstructure and Crystallographic Features of Al3Sc Dendrites in High Sc-Contained Al-Sc Alloys. Crystals 2024, 14, 200. [Google Scholar]

- Wang, X.Q.; Song, R.X.; Wang, D.; Guan, X.; Li, S.; Sun, S.C.; Yang, H.B.; Wang, X.J.; Wu, D.G.; Tu, G.F.; et al. Deformability, inherent mechanical properties and chemical bonding of Al11Nd3 in Al-Nd target material. J. Mater. Sci. Technol. 2025, 214, 278–291. [Google Scholar]

- Jin, L.; Yang, J.Q.; Yang, F.Z.; Zhan, D.P.; Tian, Z.Q.; Zhou, S.M. Research progresses of copper interconnection in chips. J. Electrochem. 2020, 26, 521–530. [Google Scholar]

- Wu, F.S.; Zhang, J.S.; Wu, Y.P.; Zheng, Z.L.; Wang, L.; Qiao, K. Progress of electromigration in IC interconnect metallic line. Semicond. Technol. 2004, 9, 15–21. [Google Scholar]

- Wang, J.; Shang, S.L.; Wang, Y.; Mei, Z.G.; Liang, Y.F.; Du, Y.; Liu, Z.K. First-principles calculations of binary Al compounds: Enthalpies of formation and elastic properties. Calphad 2011, 35, 562–573. [Google Scholar]

- Arai, T.; Iiyori, H.; Hiromasu, Y.; Atsumi, M.; Ioku, S.; Furuta, K. Aluminum-based gate structure for active-matrix liquid crystal displays. IBM J. Res. Dev. 1998, 42, 491–499. [Google Scholar]

- Wang, X.Q.; Wang, Y.; He, J.; Ding, Z.C.; Luo, J.F.; Hui, S.X. Application and research progress of AlSc material for high frequency filter. Chin. J. Rare Met. 2023, 47, 303–314. [Google Scholar]

- Zhang, W.Y.; Liu, H.; Wang, Z.J.; Huang, M.S.; Wen, K.; Ma, X.B.; Zhou, H. Study on preparation and annealing process of aluminum-scandium alloy target material. Rare Met. Cem. Carbides 2020, 48, 73–76. [Google Scholar]

- Wang, X.Q.; Zhao, Y.; Liu, H.X.; Sun, S.C.; Yang, H.B.; Zhong, J.M.; Tu, G.F.; Li, S.; Zhang, Y.D.; Esling, C.; et al. Finite-temperature ductility-brittleness and electronic structures of AlnSc (n = 1, 2 and 3). Rare Met. 2024, 43, 3974–3989. [Google Scholar]

- Takatsuji, H.; Colgan, E.G.; Cabral, C.; Harper, J.M. Evaluation of Al(Nd)-alloy films for application to thin-film-transistor liquid crystal displays. IBM J. Res. Dev. 1998, 42, 501–508. [Google Scholar]

- Onishi, T.; Iwamura, E.; Takagi, K.; Watanabe, T. Effects of Nd content in Al thin films on hillock formation. J. Vac. Sci. Technol. A Vac. Surf. Film. 1997, 15, 2339–2348. [Google Scholar]

- Wu, L.J. Magnetron sputtering target materials. Chin. J. Vac. Sci. Technol. 2001, 21, 342–347. [Google Scholar]

- Wen, Y.L.; Hui, Z.; Zhang, X.Z. Preparation Method of Ultra-High Purity Equiaxed Fine-Grained Aluminum Target. Chinese Patent CN109518140A, 26 May 2019. [Google Scholar]

- Cheng, Y.B.; Gu, Z.H.; Zhuang, Z.J.; Zhu, B. Preparation Process of Al-Sc Alloy Target Material. Chinese Patent CN115595540A, 13 January 2023. [Google Scholar]

- Zhao, Z.Z.; Fang, Q.; Xie, Y. Production Method of Al-Nd Alloy Target. Chinese Patent CN103184419A, 3 July 2013. [Google Scholar]

- Tian, Y.; Wang, X.F.; Liu, L.X.; Xiang, C.S. Research status of powder metallurgy technology in preparation of sputtering target materials. Hot Work. Technol. 2024, 53, 7–10. [Google Scholar]

- Jin, Y.Z.; Liu, D.L.; Chen, J. Studying on manufacture and application of sputtering target materials. J. Sichuan Univ. Sci. Eng. (Nat. Sci. Ed.) 2005, 18, 22–24. [Google Scholar]

- Yu, K.; Zhao, J. Si-Al Alloy Target with High Silicon Content for Sputtering Coating and Preparation Method. Chinese Patent CN101403088A, 8 April 2009. [Google Scholar]

- Wang, K.; Zhao, C.F.; Song, Y.H.; Wang, M.J.; Wang, F. Dual grain refinement effect for pure aluminum with the addition of micrometer-sized TiB2 particles. Materials 2024, 17, 4337. [Google Scholar] [PubMed]

- Yao, L.J.; Pan, J.; Bian, Y.J.; Wang, X.Z.; Zhang, L.N.; Luo, M.H. An Aluminum-Silicon Target Material and Its Fabrication Method. Chinese Patent CN113774339, 28 February 2023. [Google Scholar]

- Liu, M.X.; Li, S.Z.; Ding, Z.Q. High-Purity Copper-Aluminum Alloy Target and Its Preparation Method. Chinese Patent CN119753596A, 4 April 2024. [Google Scholar]

- Wang, Q.J.; Ren, X.L.; Wang, L.; Yan, T.R.; Wang, K.S.; Xu, B.F. Study on hot deformation behavior and dynamic recrystallization mechanism of Cu-Ti-Fe Alloy. Adv. Eng. Mater. 2024, 26, 2301618. [Google Scholar]

- Zhou, Y.C.; Yang, L.; Wang, Y.; Li, P.; Xia, Y.F.; Fan, H. Annealed microstructure of high pure aluminum target. Heat Treat. Met. 2016, 41, 34–37. [Google Scholar]

- Huang, Y.; Li, Y.; Shi, D.C. High-Purity Al-Nd Alloy Target for Sputtering and Manufacturing Method. Chinese Patent CN107619972A, 23 January 2022. [Google Scholar]

- Dong, J.F. Study on Technology and Structure Homogeneity of High Purity Aluminum and Its Alloy with Large Size Processed by Equal Channel Angular Pressing. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2017. [Google Scholar]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar]

- Doherty, R.D.; Hughes, D.A.; Humphreys, F.J.; Jonas, J.J.; Jensen, D.J.; Kassner, M.E.; King, W.E.; McNelley, T.R.; McQueen, H.J.; Rollett, A.D. Current issues in recrystallization: A review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar]

- Ahlborn, H.; Hornbogen, E.; Köster, U. Recrystallisation mechanism and annealing texture in aluminium-copper alloys. J. Mater. Sci. 1969, 4, 944–950. [Google Scholar]

- Li, H.Q.; Han, Q.; Ma, Y.L.; Xing, S.Q.; Jiang, L.P. Experimental study on recrystallization law of high pure aluminum target. Light Alloy Fabr. Technol. 2011, 39, 49–60. [Google Scholar]

- Wang, L.Q. Effect of Cold Rolling and Annealing Process on Structure and Property of High Purity Al-0.5wt%Cu Alloy. Master’s Thesis, Harbin Institute of Technology University, Harbin, China, 2018. [Google Scholar]

- Lyu, Y.Y. Study on Microstructure and Properties in Preparing of High Purity Aluminum Target. Master’s Thesis, Henan University of Science and Technology, Luoyang, China, 2017. [Google Scholar]

- Wu, G.L.; Huang, T.L.; Li, X.R.; Qing, L.; Huang, X.X. Preparation Method of High-Purity Aluminum-Silicon Target Material. Chinese Patent CN104451566A, 25 May 2015. [Google Scholar]

- Yang, Y.Z.; Shang, Z.Y.; Sun, X.L.; He, J.J.; Wang, X.P. Effect of heat treatment on the second phase in Al-Si alloy with 99.9995% purity. Foundry Technol. 2008, 29, 64–67. [Google Scholar]

- Zhao, H. Effect of Heating Rate on Recrystallization Behavior and Microstructure of Ultra-High Purity Al-0.5wt%Cu Alloy. Master’s Thesis, Chongqing University, Chongqing, China, 2015. [Google Scholar]

- Haupt, G.R.; Wickersham, C.E. Drift in film thickness uniformity arising from sputtering target recrystallization. J. Vac. Sci. Technol. A Vac. Surf. Film. 1989, 7, 2355–2358. [Google Scholar]

- Rollett, A.D. Materials Processing and Texture; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Lücke, K. The orientation dependence of grain boundary motion and the formation of recrystallization textures. Can. Metall. Q. 1974, 13, 261–274. [Google Scholar]

- Cho, H.G.; Kim, Y.D.; Kim, M.S. Prediction of grain structure and texture in twin-roll cast aluminum alloys using cellular automaton-finite element method. Materials 2025, 18, 1075. [Google Scholar] [PubMed]

- Tu, T.Y.; Li, F.; He, H.; Xu, W.J.; Yuan, M.Q.; Jiang, J.Q. Preparation Method of Fine-Grained Ultra-Pure Aluminum Target with High Preferred Orientation. Chinese Patent CN107119244A, 1 September 2017. [Google Scholar]

- Li, F. Study on Preparation Technology of Fine-Grained and High-Purity Aluminum Target with High Preferred Orientation. Master’s Thesis, Southeast China University, Nanjing, China, 2018. [Google Scholar]

- Han, Q.; Li, H.Q.; Ma, Y.L.; Xing, S.Q. Recrystallization texture analysis of annealed high purity aluminum target material. Light Alloy Fabr. Technol. 2012, 40, 59–62. [Google Scholar]

- Huang, G.J.; Chen, J.B.; Huang, T.L.; Zou, B. EBSD analysis of microstructure and texture of ultra-high pure Al-0.5wt%Cu alloy sputtering target. J. Chin. Electron Microsc. Soc. 2010, 29, 750–753. [Google Scholar]

- Chen, J.B. Investigation on Texture and Microstructure Evolution of Ultra-High Purity Al-0.5wt%Cu Alloy During Rolling and Annealing. Master’s Thesis, Chongqing University, Chongqing, China, 2010. [Google Scholar]

- Li, X.R. Investigation on Microstructure and Texture of Al-Cu Alloy During Deformation and Recrystallization. Master’s Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Sarkar, J.; Saimoto, S.; Mathew, B.; Gilmanet, P.S. Microstructure, texture and tensile properties of aluminum-2at.% neodymium alloy as used in flat panel displays. J. Alloys Compd. 2009, 479, 719–725. [Google Scholar]

- Li, Q.; Lin, Z.C. Preparation Method of High-Purity Aluminum Target with Uniform Orientation. Chinese Patent CN113755801A, 7 December 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, R.-X.; Wang, D.; Yang, Y.; He, J.; Li, S.; Yan, H.-L.; Zuo, L. A Review of Grain Refinement and Texture Engineering in Aluminum Alloy Magnetron Sputtering Targets. Materials 2025, 18, 3235. https://doi.org/10.3390/ma18143235

Song R-X, Wang D, Yang Y, He J, Li S, Yan H-L, Zuo L. A Review of Grain Refinement and Texture Engineering in Aluminum Alloy Magnetron Sputtering Targets. Materials. 2025; 18(14):3235. https://doi.org/10.3390/ma18143235

Chicago/Turabian StyleSong, Run-Xin, Dong Wang, Yiqiao Yang, Jinjiang He, Song Li, Hai-Le Yan, and Liang Zuo. 2025. "A Review of Grain Refinement and Texture Engineering in Aluminum Alloy Magnetron Sputtering Targets" Materials 18, no. 14: 3235. https://doi.org/10.3390/ma18143235

APA StyleSong, R.-X., Wang, D., Yang, Y., He, J., Li, S., Yan, H.-L., & Zuo, L. (2025). A Review of Grain Refinement and Texture Engineering in Aluminum Alloy Magnetron Sputtering Targets. Materials, 18(14), 3235. https://doi.org/10.3390/ma18143235