Investigation of the Evolutionary Patterns of Pore Structures and Mechanical Properties During the Hydration Process of Basalt-Fiber-Reinforced Concrete

Abstract

1. Introduction

2. Material and Experimental Method

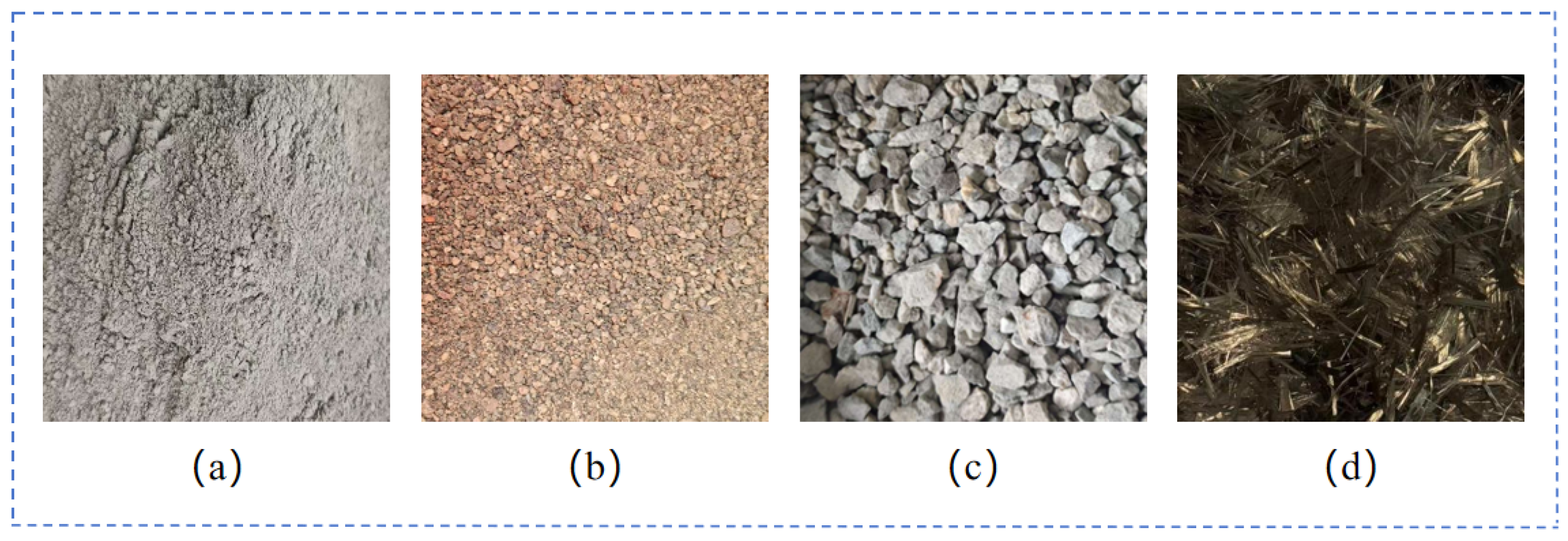

2.1. Materials

2.2. Specimen Preparation

2.3. Experimental Scheme

2.3.1. Mechanical Strength Test

- is the compressive strength (Mpa);

- is maximum load at destruction of the test piece (kN);

- is pressurized area of the specimen in mm2;

- is the compression reduction factor, 0.95 for a specimen with a side length of 100 mm.

- is the splitting tensile of concrete (MPa);

- is the splitting-surface area of specimens (mm2);

- is the splitting tensile strength reduction factor, which is 0.85 for a specimen with the side length of a 100 mm reduction factor, which is 0.85 for a specimen with the side length of 100 mm.

2.3.2. CT Scan

2.3.3. General Experimental Scheme

3. Mechanical Properties

3.1. Failure Mechanism

3.2. Mechanical Strength

4. Pore Analysis

4.1. Gray-Scale Value

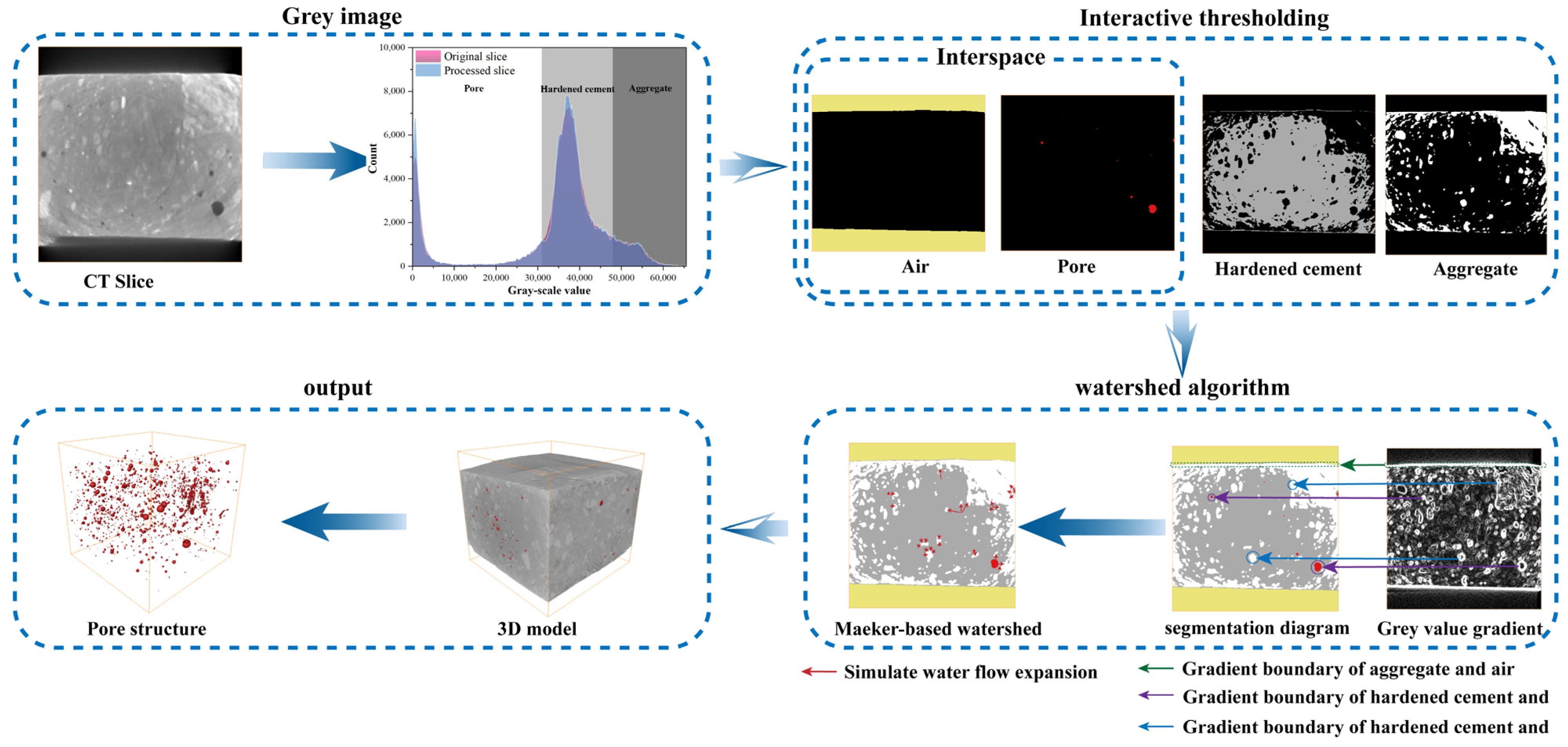

4.2. Watershed Algorithm

4.3. Macroscopic Pore Analysis

4.3.1. Pore Data Extraction Methodology

4.3.2. Porosity Analysis

- is rate of change in porosity;

- is porosity of concrete at period t1;

- is porosity of concrete at period t2.

- is porosity (%);

- is time (days);

- is the initial porosity (the y-value as x approaches 0);

- is the final stable porosity (the y-value as x approaches infinity);

- is a time-scale parameter that denotes the midpoint of the porosity change rate;

- is a shape parameter that quantifies the degree of steepness of the curve.

- is the residual associated with the i-th observed value;

- is the i-th observed value, and represents the i-th predicted value

4.4. Microscale Analysis of Pore Structure Evolution

4.4.1. The Variation Pattern of Pore Size Distribution

4.4.2. Analysis of the Evolutionary of Pore Structure

- is the data matrix of aperture distribution, with dimensions n × m, where n is to the number of rows and m corresponds to the number of columns.

- is the matrix element corresponding to the measurement value of the aperture unknown in the j-th spatial dimension for the i-th sample.

- is the total number of independently observed samples.

- is the total number of unique pore types.

- is an indicator function, characterizing the cumulative probability distribution of aperture values that are less than or equal to the threshold τ.

- is the cumulative frequency of the aperture at the J-column position where the aperture is less than or equal to τ.

- is the aperture screening threshold.

- For each τk, calculate the m-dimensional relative content vector RC (τk), represented as τk = RC (τk) = [RC1 (τk), …, RCm (τk)].

- Assess the monotonicity conditions between adjacent positions as defined in Equation (10).

- c.

- Select the first τk that fulfills the specified conditions as the optimal threshold τ*, ensuring that it aligns with the predefined criteria for selection.

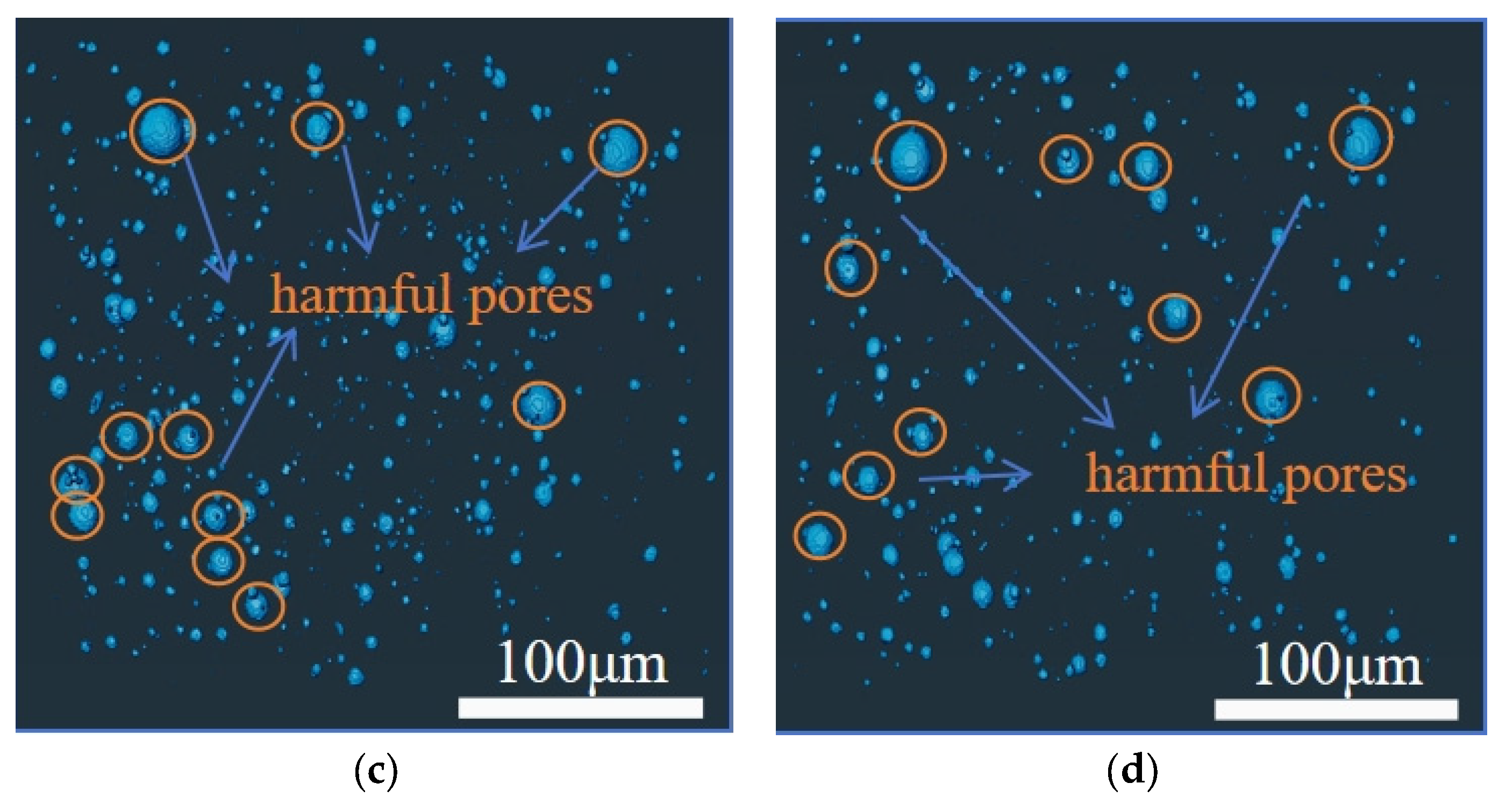

4.4.3. Visualization Analysis of Pore Structure

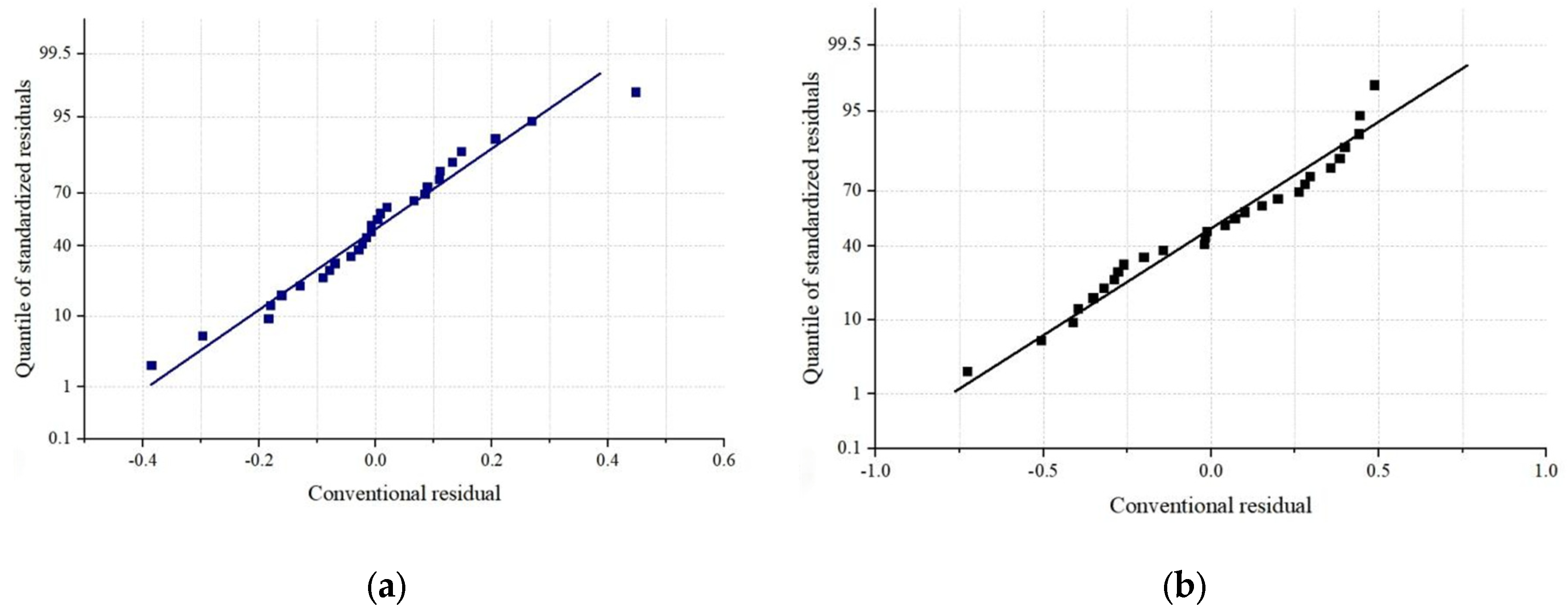

5. Correlation Analysis Between Porosity and Mechanical Properties

- is the strength of the concrete (MPa);

- is the regression coefficient;

- is the intercept coefficient;

- is the time (days);

- is the porosity (%).

- is the compressive strength of concrete, MPa;

- is the splitting tensile strength of concrete, MPa.

6. Conclusions

- (1)

- BFRC exhibited superior ductility, characterized by a yielding-like phase before fracture, contrasting the brittle failure of NC. The three-dimensional fiber network effectively bridged micro-cracks, redistributed stress, and enhanced energy dissipation, thereby improving structural resilience.

- (2)

- The incorporation of 0.2% basalt fiber significantly improved the splitting tensile strengths of concrete. At 28 days, BFRC exhibited a compressive strength of 50.78 MPa and splitting tensile strength of 4.07 MPa, surpassing ordinary concrete by 19.88% and 43.3%, respectively. Early strength reduction in BFRC (13.13 MPa vs. 22.81 MPa for NC at 3 days) was attributed to fiber-induced interference during initial hydration, which diminished as hydration progressed, leading to accelerated strength gain post 7 days.

- (3)

- The integration of CT scanning with the watershed algorithm enabled the precise segmentation of pores and the concrete matrix, overcoming the subjectivity of traditional threshold methods. This approach provided critical insights into the development of the pore structure over the hydration age, validated by high-resolution imaging and statistical analysis.

- (4)

- BFRC demonstrated a 64.83% lower porosity (5.13%) compared to NC (11.66%) at 28 days. Microscopic analysis revealed that harmless pores (<1.104 × 107 μm3) dominated BFRC, increasing from 42.8% to 77.5%, whereas NC showed a rise from 33.1% to 67.6%. This refinement was driven by the densification of inter-facial transition zones, where basalt fibers promoted the directional growth of hydration products, effectively filling capillary pores and suppressing harmful pore formation.

- (5)

- A two-dimensional strength-porosity model and a three-dimensional age-dependent multi-factor model were developed. The latter achieved exceptional predictive accuracy (R2 up to 0.9968) by incorporating the curing time and porosity interactions, offering a robust tool for optimizing the fiber-reinforced concrete design.

- (6)

- Future research directions: (1) Study the hydration process of concrete mixed with different fibers and the effect of different fibers on the hydration process of concrete. (2) Employ experimental methodologies to systematically examine the correlation between mechanical properties and pore structures in recycled aggregate basalt-fiber-reinforced concrete, with the objective of facilitating its industrial implementation in the context of global energy conservation and carbon emission reduction initiatives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, L.; Sun, X.J.; Yu, Z.P.; Guan, Z.X.; Long, A.X.; Lian, H.H.; Lian, Y.J. Experimental study and theoretical analysis on dynamic mechanical properties of basalt fiber reinforced concrete. J. Build. Eng. 2022, 62, 105334. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.L.; Xie, C.P.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.Y.; Qi, Y.Z. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.S.; Pham, T.M.; Hao, H. Effect of aggregate size on bond behaviour between basalt fibre reinforced polymer sheets and concrete. Compos. Part B Eng. 2019, 158, 459–474. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y.L. Experimental study on basic mechanical properties of basalt fiber reinforced concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Y.L.; Yang, Y.X.; Su, L.; Xie, S.J. Splitting tensile strength of basalt fiber reinforced coral aggregate concrete: Optimized XGBoost models and experimental validation. Constr. Build. Mater. 2024, 416, 135133. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, mechanical and dynamic properties of basalt fiber reinforced concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef]

- Qin, S.H.; Wu, L. Study on mechanical properties and mechanism of new basalt fiber reinforced concrete. Case Stud. Constr. Mater. 2025, 22, e04290. [Google Scholar] [CrossRef]

- Deng, Y.G.; Zhao, B.J.; Dai, T.T.; Li, G.Q. Study on the dispersibility of modified basalt fiber and its influence on the mechanical properties of concrete. Constr. Build. Mater. 2022, 350, 128839. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.R. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Shen, Y.J.; Lv, Y.; Yang, H.W.; Ma, W.; Zhang, L.; Wei, X. Pore development and mechanical properties of iced concrete during hydration. Constr. Build. Mater. 2022, 353, 129077. [Google Scholar] [CrossRef]

- Deng, G.Y.; Guo, R.Q.; Ma, L.J.; Long, Z.L.; Xu, F.; Yin, C.J.; Xu, X. Study on dynamic mechanical properties and microstructure of basalt fiber reinforced coral sand cement composite. Constr. Build. Mater. 2024, 425, 136024. [Google Scholar] [CrossRef]

- Huang, D.G.; Wang, X.Z.; Li, X.F.; Su, L.; Tian, J.B.; Li, Y.; Liu, Y.H. Research on the mechanical properties and pore structure deterioration of Basalt-polyvinyl alcohol hybrid fiber concrete under the coupling effects of sulfate attack and freeze-thaw cycles. Constr. Build. Mater. 2025, 473, 140949. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Chen, X.D.; Wu, S.; Zhou, J. Influence of porosity on compressive and tensile strength of cement mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Wang, K.D.; Wang, W.J.; Guo, Y.D.; Liu, Y.; Duan, P.; Shi, W.; Liu, Y. Grey modeling study on mechanical properties and pore structure of concrete with different basalt fiber contents based on NMR. J. Build. Eng. 2024, 89, 109287. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Lv, Z.Y.; Duan, Z.H.; Zhang, C.Z. Pore structure characteristics, modulation and its effect on concrete properties: A review. Constr. Build. Mater. 2023, 397, 132430. [Google Scholar] [CrossRef]

- Choi, H.B.; Park, J.O.; Lee, H.D.; Lee, K.R. Mechanical and pore properties of concrete using basalt-based recycled aggregates according to mixture conditions. Materials 2022, 15, 5677. [Google Scholar] [CrossRef]

- Li, D.; Niu, D.T.; Fu, Q.; Luo, D.M. Fractal characteristics of pore structure of hybrid Basalt–Polypropylene fibre-reinforced concrete. Cement Concr. Compos. 2020, 109, 103555. [Google Scholar] [CrossRef]

- Dong, X.X.; Bao, X.H.; Cui, H.Z.; Xu, C.J.; Chen, X.S. Macro-porosity and skeleton of a cement-gravel-treated granite residual soil for subgrade from CT scanning. Constr. Build. Mater. 2023, 371, 130703. [Google Scholar] [CrossRef]

- Ren, D.Y.; Wu, P.F.; Yang, H.B.; Xu, J.R.; Wang, Z.L.; Huang, Y.Q.; Chen, X.; Kong, L. Mesoscopic evaluation of dynamic water scour resistance of basalt fiber-reinforced porous asphalt concrete using CT scanning technology. Constr. Build. Mater. 2025, 465, 140186. [Google Scholar] [CrossRef]

- Liang, Z.W.; Rao, C.M.; Zhu, Y.C.; Rabczuk, T.; Wang, J.M. Numerical simulation on the three-dimension mesoscopic model of aerated ceramsite concrete based on CT scan. Case Stud. Constr. Mater. 2024, 21, e04068. [Google Scholar] [CrossRef]

- Trussell, N.; Hårr, M.S.; Kjeka, G.; Asadi, I.; Endrerud, P.E.; Jacobsen, S. Anisotropy and macro porosity in wet sprayed concrete: Laminations, fibre orientation and macro pore properties measured by image analysis, PF test, water penetration and CT scanning. Constr. Build. Mater. 2023, 389, 131715. [Google Scholar] [CrossRef]

- Vicente, M.A.; Ruiz, G.; González, D.C.; Mínguez, J.; Tarifa, M.; Zhang, X.X. CT-Scan study of crack patterns of fiber-reinforced concrete loaded monotonically and under low-cycle fatigue. Int. J. Fatigue 2018, 114, 138–147. [Google Scholar] [CrossRef]

- Wang, M.Z.; Yang , Y.; Wang, W. Establishing a 3D aggregates database from X-ray CT scans of bulk concrete. Constr. Build. Mater. 2022, 315, 125740. [Google Scholar] [CrossRef]

- Tian, W.; Han, N. Pore characteristics (>0.1 mm) of non—Air entrained concrete destroyed by freeze—Thaw cycles based on CT scanning and 3D printing. Cold Reg. Sci. Technol. 2018, 151, 314–322. [Google Scholar] [CrossRef]

- Li, N.; Zhao, Y.R.; Xing, Y.M.; He, X.Y.; Li, H.X. Meso-damage analysis of concrete based on X-ray CT in-situ compression and using deep learning method. Case Stud. Constr. Mater. 2023, 18, e02118. [Google Scholar] [CrossRef]

- Ren, Q.F.; Pacheco, J.; de Brito, J. Calibration of wall effects in mesostructure modelling of concrete using marker-controlled watershed segmentation. Constr. Build. Mater. 2023, 398, 132505. [Google Scholar] [CrossRef]

- Zhang, M.; Yao, X.H.; Guan, J.F.; Li, L.L.; Wang, J.; Qing, L.B. Study of Concrete Strength and Pore Structure Model Based on Grey Relation Entropy. Materials 2021, 14, 432. [Google Scholar] [CrossRef]

- Xu, F.W.; Pan, H.K. Research on Quantitative Characterization Model of Compressive Strength or Elastic Modulus of Recycled Concrete Based on Pore Grading. Materials 2025, 18, 3. [Google Scholar] [CrossRef]

- Li, D.Q.; Li, Z.L.; Lv, C.C.; Zhang, G.H.; Yin, Y.M. A predictive model of the effective tensile and compressive strengths of concrete considering porosity and pore size. Constr. Build. Mater. 2018, 170, 520–526. [Google Scholar] [CrossRef]

- Bian, P.F.; Zhang, M.; Yu, Q.J.; Zhan, B.G.; Gao, P.; Guo, B.L.; Chen, Y.Y. Prediction model of compressive strength of foamed concrete considering pore size distribution. Constr. Build. Mater. 2023, 409, 133705. [Google Scholar] [CrossRef]

- Yu, P.; Qiu, H.F.; He, S.; Qin, Y.; Zhou, Y.T. Pore structure and prediction of mechanical properties by ANN of concrete mixed MK and SF under hydrochloric acid corrosion. Constr. Build. Mater. 2023, 409, 133665. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.Q.; Wang, L.H. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Cui, S.G.; Liu, P.; Cui, E.Q.; Su, J.; Huang, B. Experimental study on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high geothermal tunnels. Constr. Build. Mater. 2018, 173, 124–135. [Google Scholar] [CrossRef]

- Song, Z.; Xiao, K.; Xiao, S.; Du, K.F.; Mao, Z.B.; Li, T.; Wang, B. Effect of porosity on the tensile strength and micromechanisms of laminated stitched C/C-SiC composites. Mater. Des. 2024, 247, 113429. [Google Scholar] [CrossRef]

- JC/T 60018-2023; Technical Specification for Curing of Cast-in-place Concrete. China Architecture & Building Press: Beijing, China, 2023.

- GB-50010-2010; Code for design of concrete structures. Standardization Administration of China: Beijing, China, 2010.

- GB/T-50081-2019; Standard for test methods of concrete physical and mechanical properties. Standardization Administration of China: Beijing, China, 2019.

- Hong, S.; Jiang, R.G.; Zheng, F.; Fan, S.X.; Dong, B.Q. Quantitative characterization of carbonation of cement-based materials using X-ray imaging. Cement Concr. Compos. 2022, 134, 104794. [Google Scholar] [CrossRef]

- Cui, H.T.; Ke, D.Y.; Gao, Q.F.; Li, S.L. Mesoscopic pore characteristics analysis of aged bridge concrete based on X-ray computed tomography. J. Build. Eng. 2023, 78, 107739. [Google Scholar] [CrossRef]

- Feng, X.H.; Gong, B.; Tang, C.A.; Zhao, T. Study on the non-linear deformation and failure characteristics of EPS concrete based on CT-scanned structure modelling and cloud computing. Eng. Fract. Mech. 2022, 261, 108214. [Google Scholar] [CrossRef]

- Patra, S.; Gautam, R.; Singla, A. A novel context sensitive multilevel thresholding for image segmentation. Appl. Soft Comput. 2014, 23, 122–127. [Google Scholar] [CrossRef]

- Kornilov, A.; Safonov, I.; Yakimchuk, I. A review of watershed implementations for segmentation of volumetric images. J. Imaging 2022, 8, 127. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, Y.; Liu, K.; Zhan, T.; Liu, S.L.; Liang, Y.L.; Hu, Y.L.; Li, M.F.; Lei, G.P.; Zhou, S.Y.; et al. WC electron microscopy image segmentation based on improved watershed and Hu—Moment edge matching algorithms. Comput. Mater. Sci. 2025, 246, 113401. [Google Scholar] [CrossRef]

- Tong, L.; Cai, Y.; Liu, Q. Carbonation modelling of hardened cementitious materials considering pore structure characteristics: A review. J. Build. Eng. 2024, 96, 110547. [Google Scholar] [CrossRef]

- Yang, W.R.; Tang, Z.Y.; Wu, W.W.; Zhang, K.; Yuan, J.; Li, H.Y.; Feng, Z.M. Effect of different fibers on impermeability of steam cured recycled concrete. Constr. Build. Mater. 2022, 328, 127063. [Google Scholar] [CrossRef]

- Jin, S.S.; Zhang, J.X.; Han, S. Fractal analysis of relation between strength and pore structure of hardened mortar. Constr. Build. Mater. 2017, 135, 1–7. [Google Scholar] [CrossRef]

| Experimental Group (1 m3) | Water | Cement | Sand | Stone | Basalt Fiber |

|---|---|---|---|---|---|

| NC | 197.8 | 394.4 | 632.73 | 1175.07 | 0 |

| BFRC | 197.8 | 394.4 | 632.73 | 1175.07 | 0.2%/5.3 kg |

| Experimental Group | Compressive Strength Test | Splitting Tensile Test | CT Scan |

|---|---|---|---|

| NC | 24 | 24 | 3 |

| BFRC | 24 | 24 | 3 |

| Type | Compressive Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|

| 3 Days | 5 Days | 7 Days | 9 Days | 11 Days | 14 Days | 21 Days | 28 Days | |

| BFRC | 13.13 | 29.75 | 35.45 | 40.35 | 42.83 | 46.2 | 48.1 | 50.78 |

| NC | 22.81 | 27.53 | 31.23 | 35.68 | 37.84 | 39.51 | 41.53 | 42.36 |

| Type | Splitting Tensile Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|

| 3 Days | 5 Days | 7 Days | 9 Days | 11 Days | 14 Days | 21 Days | 28 Days | |

| BFRC | 1.87 | 2.89 | 3.47 | 3.63 | 3.69 | 3.80 | 3.88 | 4.07 |

| NC | 1.53 | 1.75 | 1.93 | 2.21 | 2.42 | 2.61 | 2.72 | 2.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Wang, X.; Yan, F.; Cai, X.; Xiao, S.; Cui, S.; Liu, P. Investigation of the Evolutionary Patterns of Pore Structures and Mechanical Properties During the Hydration Process of Basalt-Fiber-Reinforced Concrete. Materials 2025, 18, 3212. https://doi.org/10.3390/ma18143212

Zhao J, Wang X, Yan F, Cai X, Xiao S, Cui S, Liu P. Investigation of the Evolutionary Patterns of Pore Structures and Mechanical Properties During the Hydration Process of Basalt-Fiber-Reinforced Concrete. Materials. 2025; 18(14):3212. https://doi.org/10.3390/ma18143212

Chicago/Turabian StyleZhao, Junqin, Xuewei Wang, Fuheng Yan, Xin Cai, Shengcai Xiao, Shengai Cui, and Ping Liu. 2025. "Investigation of the Evolutionary Patterns of Pore Structures and Mechanical Properties During the Hydration Process of Basalt-Fiber-Reinforced Concrete" Materials 18, no. 14: 3212. https://doi.org/10.3390/ma18143212

APA StyleZhao, J., Wang, X., Yan, F., Cai, X., Xiao, S., Cui, S., & Liu, P. (2025). Investigation of the Evolutionary Patterns of Pore Structures and Mechanical Properties During the Hydration Process of Basalt-Fiber-Reinforced Concrete. Materials, 18(14), 3212. https://doi.org/10.3390/ma18143212