Research on the Pavement Performance of Slag/Fly Ash-Based Geopolymer-Stabilized Soil

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Ratios of Slag-Based Geopolymer-Stabilized Soils

2.3. Specimen Preparation

2.4. Testing Methods

2.4.1. Compaction Test

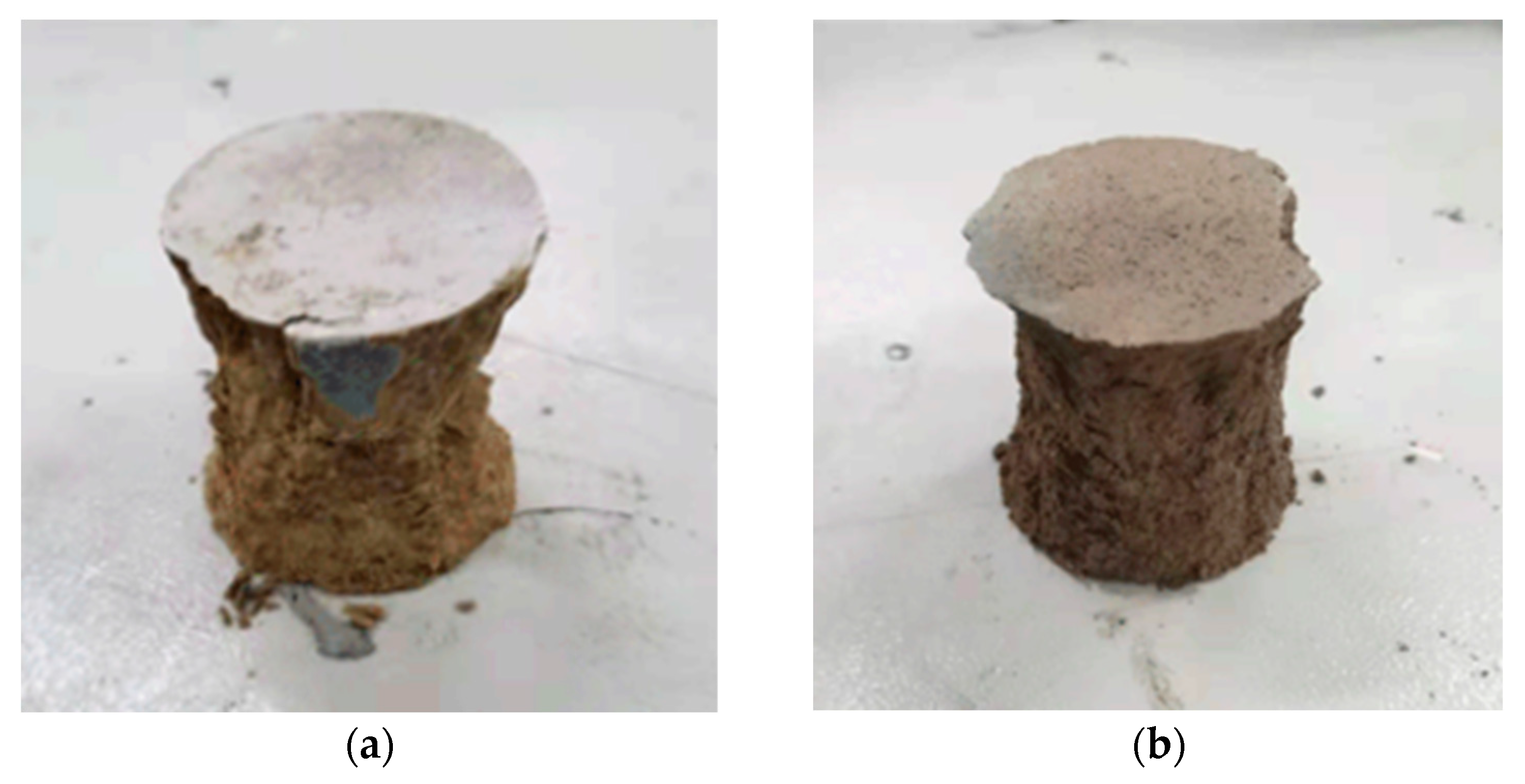

2.4.2. Unconfined Compressive Strength Test

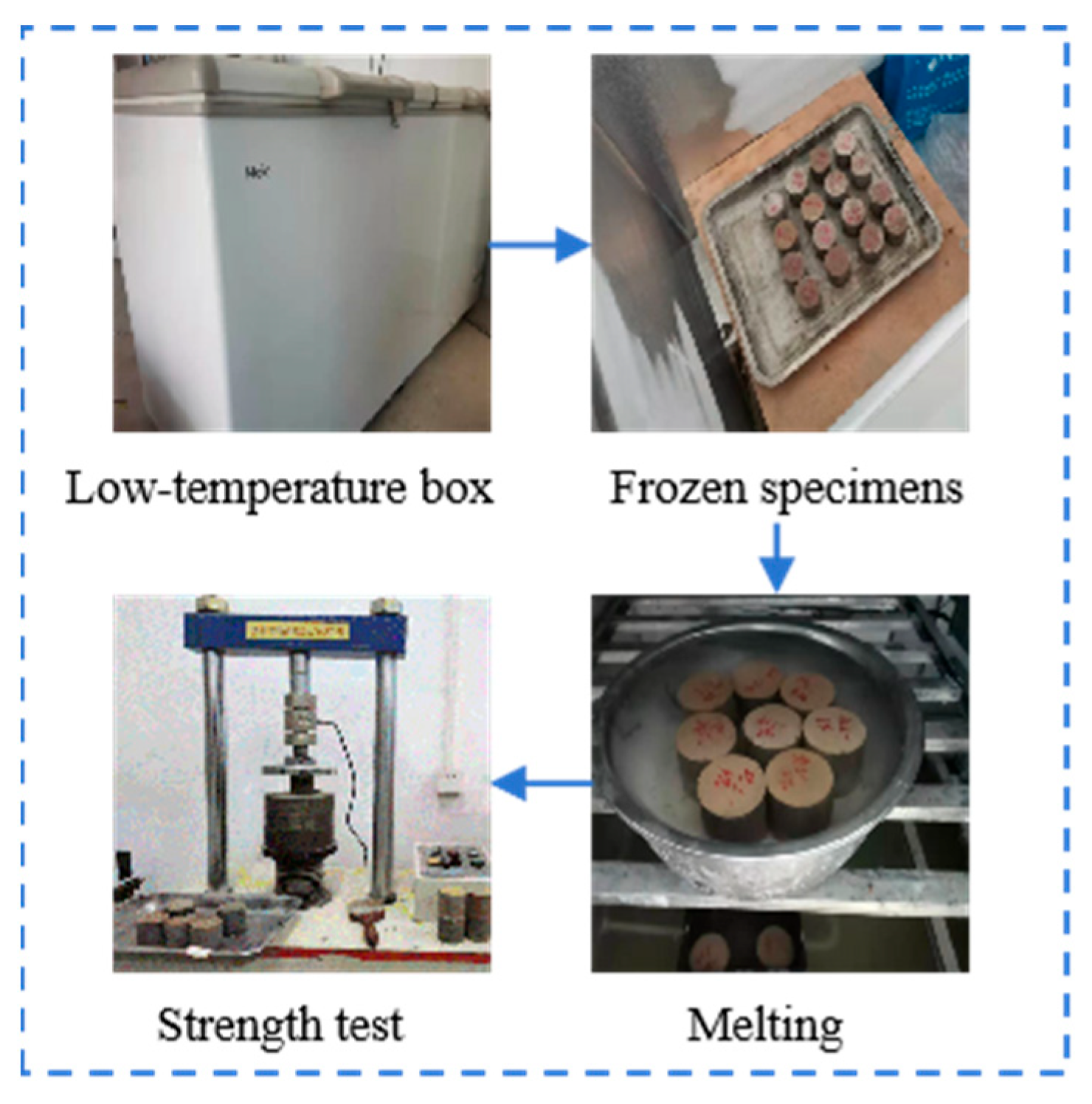

2.4.3. Freeze–Thaw Cycle Test

3. Results and Discussion

3.1. Compaction Test

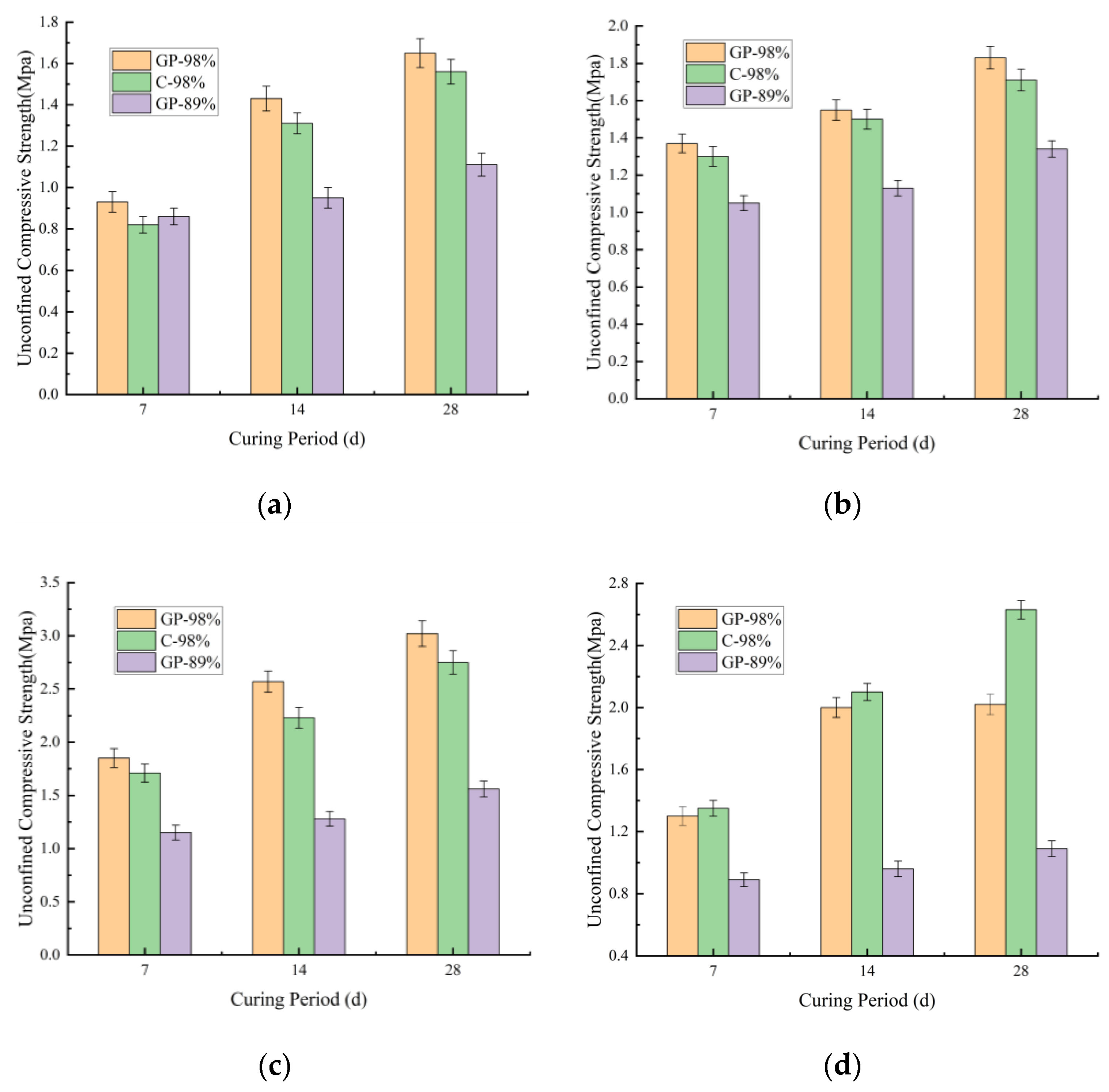

3.2. Unconfined Compressive Strength Test

3.2.1. Unconfined Compressive Strength of Geopolymer-Stabilized Soil Sample 1

3.2.2. Unconfined Compressive Strength of Geopolymer-Stabilized Soil Sample 2

3.2.3. Effect of Fly Ash on the Unconfined Compressive Strength of Geopolymer-Stabilized Various Soil Samples

3.2.4. Effect of Compaction Degree on the Unconfined Compressive Strength of Geopolymer-Stabilized Various Soil Samples

3.3. Freeze–Thaw Cycle Test

4. Conclusions

- (1)

- Slag-based geopolymer significantly enhanced the compressive strength of both soils, with strength positively correlated to dosage. At a 98% compaction degree, soil sample 1 (7-day: 3.4 MPa, 28-day: 5.2 MPa) and soil sample 2 (7-day: 2.61 MPa, 28-day: 4.5 MPa) exhibited higher strength than cement-stabilized soils at equivalent dosages. The stabilized soils can satisfy the strength requirements for subbase layers in extremely heavy/special heavy traffic roads and base courses in light traffic roads.

- (2)

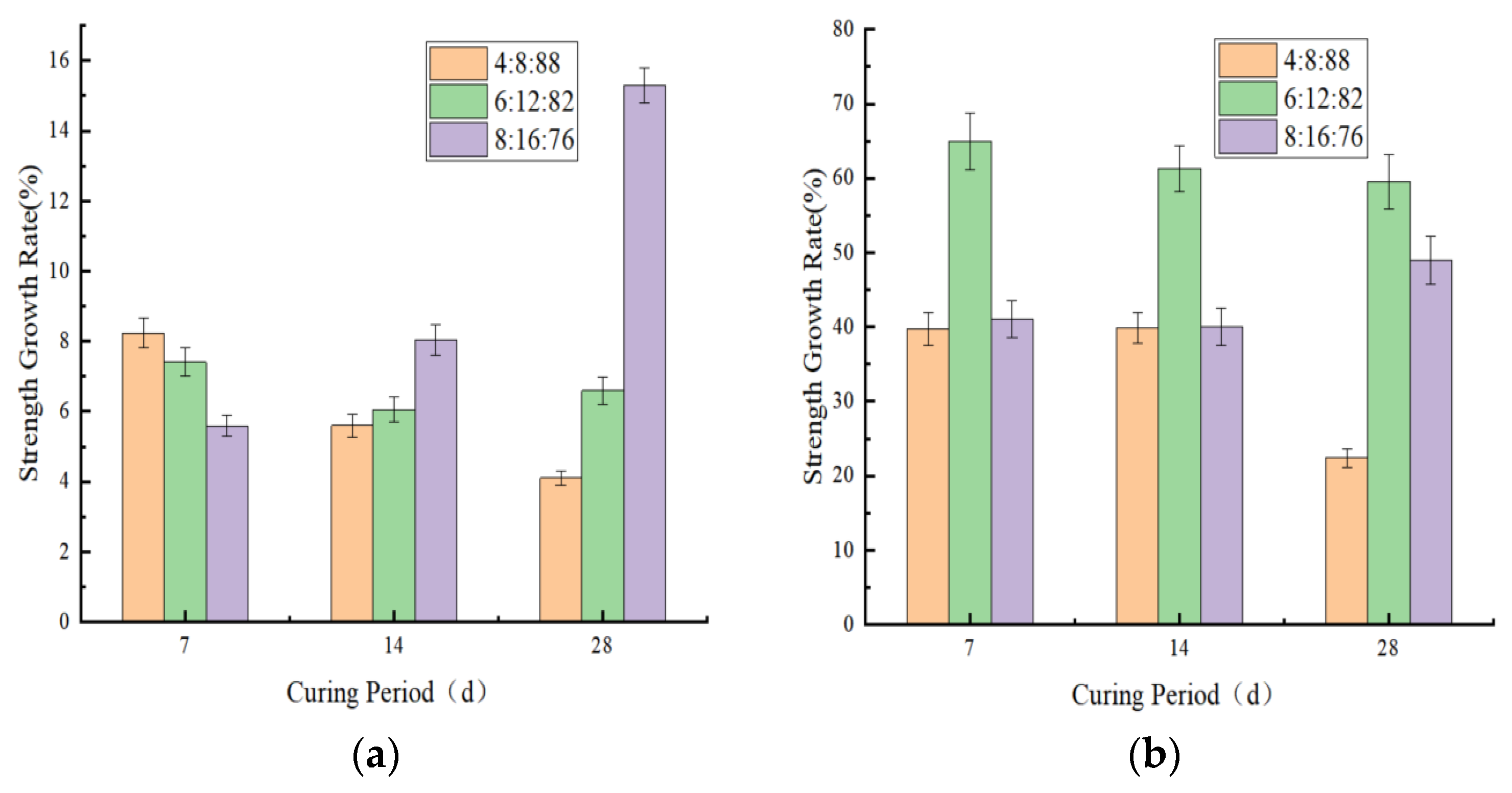

- Fly ash incorporation significantly enhanced the compressive strength of both soils, with more pronounced reinforcement effects on soil sample 2. Under a 98% compaction degree, fly ash addition generally increased the compressive strength enhancement rate of geopolymer-stabilized soil sample 2 by over 40%. Notably, specimens with a 6% stabilizer dosage achieved a 65% strength increase at 7-day curing. In contrast, the maximum strength improvement for soil sample 1 under identical conditions was limited to 15%.

- (3)

- Compaction degree elevation substantially improved the unconfined compressive strength of stabilized soils. The unconfined compressive strength enhancement rate of geopolymer-stabilized soil sample 1 remained stable at approximately 50%, while soil sample 2 achieved a maximum strength increase of 129%, demonstrating significantly higher compaction sensitivity than soil sample 1. Consequently, the comprehensive stabilization of soil sample 2 using geopolymer–fly ash systems required enhanced compaction quality control during rolling operations to ensure target density attainment.

- (4)

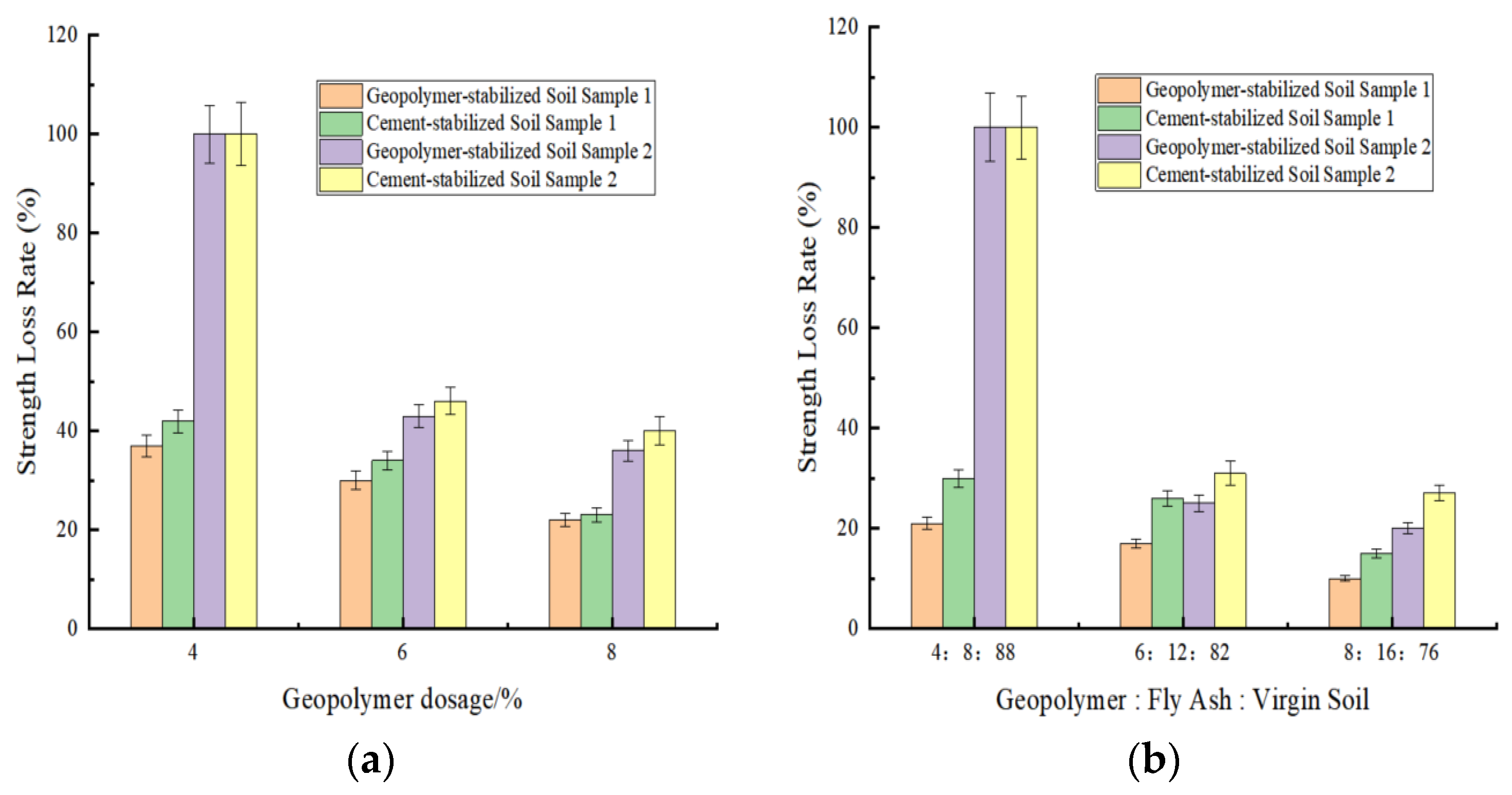

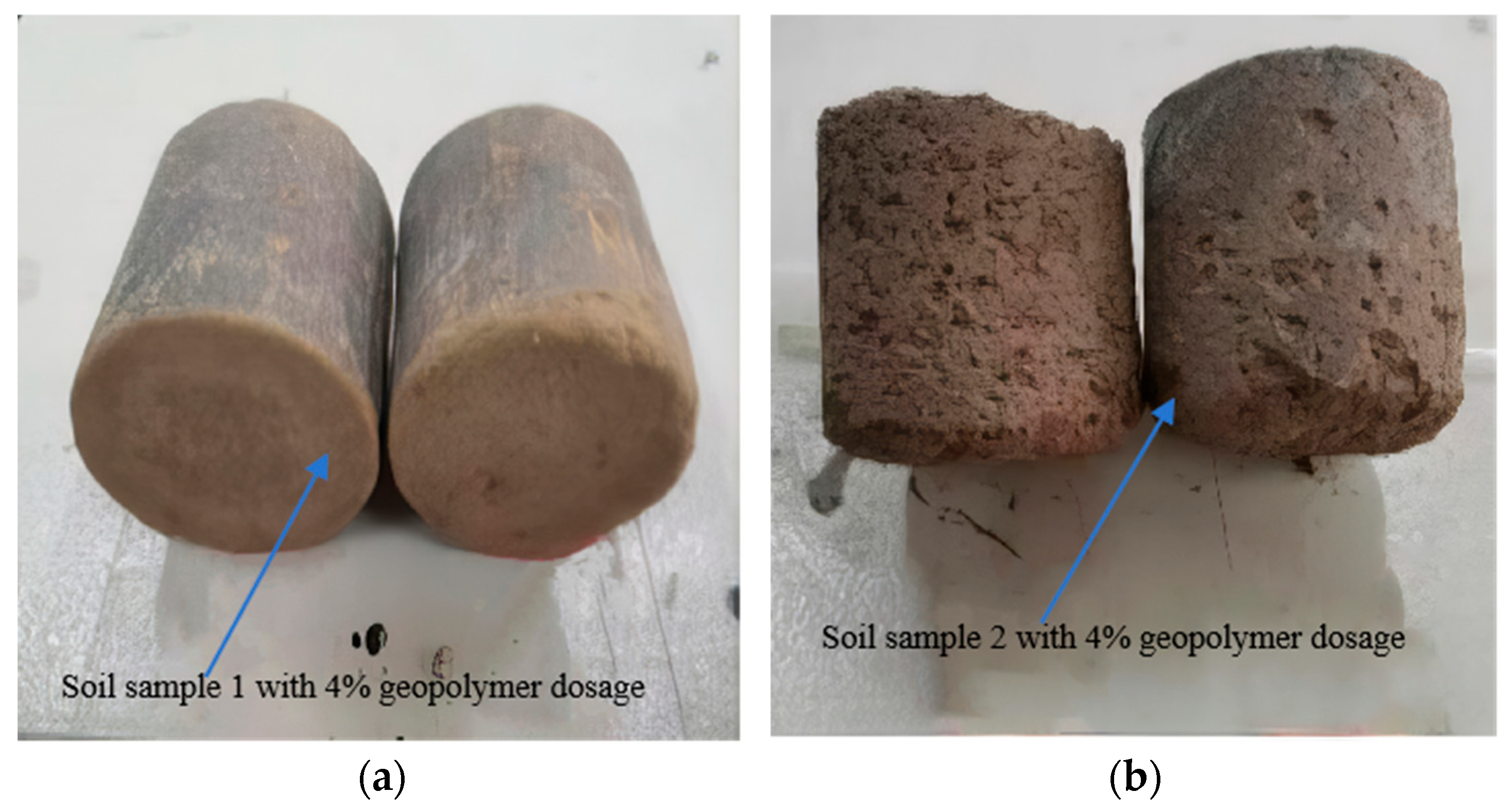

- Synergistic effects of stabilizer dosage and fly ash co-stabilization collectively improved freeze–thaw resistance. Soil sample 1 demonstrated superior frost durability (BDR: 78%) compared to soil sample 2 (BDR: 64%). With combined stabilization, their BDR values increased to 90% and 80%, respectively. Although composite stabilization significantly enhanced the frost resistance of soil sample 2, particular attention remains necessary regarding its initial strength and freeze–thaw susceptibility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liao, Z.; Xue, W.; Liao, L.; Hao, R.; Shen, L.; Cui, D. A Study on the Effect of Different Cementitious Materials on the Mechanical Properties and Microscopic Characteristics of Alkali-Activated Green Ultra-High Performance Concrete (GUHPC). Materials 2025, 18, 2163. [Google Scholar] [CrossRef] [PubMed]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U.; Ahmad, N.; Ahmad, F.; Ahmad, A. Reusing biochar as a filler or cement replacement material in cementitious composites: A review. Construct. Build. Mater. 2021, 300, 124295. [Google Scholar] [CrossRef]

- Badkul, A.; Paswan, R.; Singh, S.K.; Tegar, J.P. A comprehensive study on the performance of alkali activated fly ash/GGBFS geopolymer concrete pavement. Road Mater. Pavement Des. 2021, 23, 1815–1835. [Google Scholar] [CrossRef]

- Zhang, Z.; Su, T.; Zhang, L.; Zheng, R.; Ma, K.; Zhang, L.; Amaechi, C.V.; Wang, C. The Influence of Fly Ash and Slag on the Mechanical Properties of Geopolymer Concrete. Buildings 2024, 14, 2720. [Google Scholar] [CrossRef]

- Thomas, R.; Ye, H.; Radlińska, A.; Peethamparan, A. Alkali-Activated Slag Cement Concrete: A closer look at a sustainable alternative to portland cement. Concr. Int. 2016, 38, 33–38. [Google Scholar]

- Mclellan, B.C.; Williams, R.P.; Lay, J.; Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Chen, Q.; Chen, L. Synthesis and heavy metal immobilization behaviors of slag based geopolymer. J. Hazard. Mater. 2007, 143, 206–213. [Google Scholar] [CrossRef]

- Reddy, D.V.; Edouard, J.-B.; Sobhan, K. Durability of fly ash–based geopolymer structural concrete in the marine environment. J. Mater. Civil Eng. 2013, 25, 781–787. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Chanprasert, P.; Sukmak, P.; Arulrajah, A. Compressive strength development in fly ash geopolymer masonry units manufactured from water treatment sludge. Constr. Build. Mater. 2015, 82, 20–30. [Google Scholar] [CrossRef]

- Yu, L.; Wu, Y.; Meng, Y.; Huang, G.; Li, R.; Pei, J. Study on fatigue crack propagation failure in semi-rigid base. Constr. Build. Mater. 2023, 409, 134007. [Google Scholar] [CrossRef]

- Shen, C.; Wu, Z.; Xiao, P.; Kang, A.; Wang, Y. Experimental Research on the Anti-Reflection Crack Performance of Basalt Fiber Modified Rubber Asphalt Stress-Absorbing Layer. Materials 2024, 17, 2013. [Google Scholar] [CrossRef] [PubMed]

- Hanegbi, N.; Katra, I. A Clay-Based Geopolymer in Loess Soil Stabilization. Appl. Sci. 2020, 10, 2608. [Google Scholar] [CrossRef]

- Hou, Y.; Ji, X.; Zou, L.; Liu, S.; Su, X. Performance of cement-stabilised crushed brick aggregates in asphalt pavement base and subbase applications. Road Mater. Pavement Des. 2015, 17, 120–135. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Sun, Z. Shrinkage performance of cement-treated macadam base materials. Int. Conf. Traffic Transp. Stud. 2010, 378–386. [Google Scholar] [CrossRef]

- Yue, J.; Nie, X.; Wang, Z.; Liu, J.; Huang, Y. Research on the Pavement Performance of Slag/Fly Ash-Based Geopolymer-Stabilized Macadam. Appl. Sci. 2022, 12, 10000. [Google Scholar] [CrossRef]

- Zhou, P.; Alireza, B.; Gan, B.; Zhou, W. Synthesis of Sustainable OPC-Blended Geopolymer Concrete: Experimental and Modeling Study. Adv. Civ. Eng. 2024, 17, 7854488. [Google Scholar] [CrossRef]

- Hu, W.; Nie, Q.; Huang, B.; Su, A.; Du, Y.; Shu, X.; He, Q. Mechanical property characteristics of geopolymer stabilized aggregate base. Constr. Build. Mater. 2018, 191, 1120–1127. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhu, X.; Zhu, W.; Yue, J. Synergistic effect of red mud, desulfurized gypsum and fly ash in cementitious materials: Mechanical performances and microstructure. Constr. Build. Mater. 2023, 404, 133302. [Google Scholar] [CrossRef]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction—Recent developments. Construct. Build. Mater. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Castañón, A.M.; Gómez-Fernández, F.; Corpas-Iglesias, F.A. Retention of Pollutants Elements from Mine Tailings of Lead in Geopolymers for Construction. Materials 2021, 14, 6184. [Google Scholar] [CrossRef]

- Sharmin, S.; Biswas, W.K.; Sarker, P.K. Exploring the Potential of Using Waste Clay Brick Powder in Geopolymer Applications: A Comprehensive Review. Buildings 2024, 14, 2317. [Google Scholar] [CrossRef]

- Arulrajah, A.; Mohammadinia, A.; Phummiphan, I.; Horpibulsuk, S.; Samingthong, W. Stabilization of recycled demolition aggregates by geopolymers comprising calcium carbide residue, fly ash and slag precursors. Constr. Build. Mater. 2016, 114, 864–873. [Google Scholar] [CrossRef]

- Ahirwar, J.; Kaur, M.; Eet, A. Compare the strength of fly ash based geopolymer concrete with demolition waste. Int. J. Civ. Eng. 2018, 5, 20–24. [Google Scholar] [CrossRef]

- Khodair, Y.; Bommareddy, B. Self-consolidating concrete using recycled concrete aggregate and high volume of fly ash, and slag. Constr. Build. Mater. 2017, 153, 307–316. [Google Scholar] [CrossRef]

- Shen, W.; Zhou, M.; Ma, W.; Hu, J.; Cai, Z. Investigation on the application of steel slag–fly ash–phosphogypsum solidified material as road base material. J. Hazard. Mater. 2009, 164, 99–104. [Google Scholar] [CrossRef]

- Hayder, M.R.; Ziari, H.; Shaban, A.M. Characterizing geotechnical properties of sand subgrade soilsstabilized with geopolymer based on metakaolin. Case Stud. Constr. Mater. 2025, 22, e04389. [Google Scholar] [CrossRef]

- Li, Y.; Shen, J.; Lin, H.; Lv, J.; Feng, S.; Ci, J. Properties and environmental assessment of eco-friendly brick powder geopolymer binders with varied alkali dosage. J. Build. Eng. 2022, 58, 105020. [Google Scholar] [CrossRef]

- Teerawattanasuk, C.; Voottipruex, P. Comparison between cement and fly ash geopolymer for stabilized marginal lateritic soil as road material. Int. J. Pavement Eng. 2018, 20, 1264–1274. [Google Scholar] [CrossRef]

- Jiang, W.; He, L.; Zhao, L.; Gao, Y.; Chen, J. Experimental Study on Mechanical Properties of Polypropylene Fiber Cement Stabilized Soil for Highway Base. J. China Foreign Highway 2018, 38, 237–241. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, L. Study of the mechanical properties of stabilized soil containing PPF under freezing and thawing cycles. J. Glaciol. Geocryol. 2017, 39, 850–857. [Google Scholar]

- Wang, Z.; Yang, J.; Wu, Y. Durability Performance of CGF Stone Waste Road Base Materials under Dry–Wet and Freeze–Thaw Cycles. Materials 2024, 17, 4272. [Google Scholar] [CrossRef] [PubMed]

- Horpibulsuk, S.; Phetchuay, C.; Chinkulkijniwat, A. Soil Stabilization by Calcium Carbide Residue and Fly Ash. J. Mater. Civ. Eng. 2012, 24, 184–193. [Google Scholar] [CrossRef]

- Lv, Q.; Wang, Z.; He, J.; Wang, S.; Zhou, G. Microstmcture of Saline Soil Solidified with Alkali-activated Geopolymer. J. Yangtze River Sci. Res. Inst. 2020, 37, 79–83. [Google Scholar] [CrossRef]

- He, B.; Zhang, W.; Tong, G.; Tang, X.; Liu, C. Compressive strength and microstructure of fly ash geopolymer. China Powder Sci. Technol. 2023, 29, 38–46. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Zhang, D.; Tian, X.; Hou, H.; Liu, H.; Tan, S. Mechanical behavior and mechanism of stabilizing soft soil by slag cementitious material. Rock. Soil. Mech. 2005, 28, 1987–1991. [Google Scholar]

- Zhu, X.; Liu, H.; Ma, X.; Xing, Q.; Lin, X.; Man, T. Study on modification of lake deposition high liquid limit clay in the Yellow River flood area. J. Shandong Univ. 2019, 49, 83–90+113. [Google Scholar]

- Zhang, S.; Xie, X.; Xie, R.; Tong, X.; Wu, Y.; Li, J.; Li, Y. Preparation and interface state of phosphate tailing-based geopolymers. J. Cent. South. Univ. 2024, 31, 1900–1914. [Google Scholar] [CrossRef]

- Aghaeipour, A.; Madhkhan, M. Effect of ground granulated blast furnace slag (GGBFS) on RCCP durability, Construction and Building. Construct. Build. Mater. 2017, 141, 533–541. [Google Scholar] [CrossRef]

| Soil Sample | Liquid Limit | Plastic Limit | Plasticity Index |

|---|---|---|---|

| 1 | 26.7 | 18.9 | 7.9 |

| 2 | 46.1 | 29.1 | 17 |

| Material | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Slag | 0 | 3.06 | 5.10 | 17.56 | 0.43 | 2.65 | 1.35 | 63.45 | 0.39 | 4.10 |

| Fly ash | 0.888 | 1.08 | 32.06 | 53.94 | 0.64 | 0.73 | 2.10 | 4.11 | 1.14 | 4.15 |

| Cement | 0.20 | 1.85 | 6.34 | 18.23 | 0.22 | 2.41 | 0.74 | 65.57 | 0.295 | 3.32 |

| Number | Mixing Ratio% | Optimal Moisture Content | Maximum Dry Density | |||

|---|---|---|---|---|---|---|

| Geopolymer | Fly Ash | Soil Sample 1 | Soil Sample 2 | |||

| 1 | 4 | 0 | 0 | 96 | 16.1 | 1.881 |

| 2 | 4 | 0 | 96 | 0 | 10.9 | 1.952 |

| 3 | 6 | 0 | 0 | 94 | 16.6 | 1.872 |

| 4 | 6 | 0 | 94 | 0 | 11.5 | 1.934 |

| 5 | 8 | 0 | 0 | 92 | 15.4 | 1.863 |

| 6 | 8 | 0 | 92 | 0 | 11.7 | 1.926 |

| 7 | 4 | 8 | 0 | 88 | 12.8 | 1.895 |

| 8 | 4 | 8 | 88 | 0 | 12.1 | 1.933 |

| 9 | 6 | 12 | 0 | 82 | 15.2 | 1.852 |

| 10 | 6 | 12 | 82 | 0 | 12.3 | 1.892 |

| 11 | 8 | 16 | 0 | 76 | 15.4 | 1.818 |

| 12 | 8 | 16 | 76 | 0 | 12.8 | 1.855 |

| Dosage | Geopolymer-Stabilized Soil Sample 1 | Cement-Stabilized Soil Sample 1 | ||||

|---|---|---|---|---|---|---|

| Strength Before Freeze–Thaw/MPa | Strength After Freeze–Thaw/MPa | BDR/% | Strength Before Freeze–Thaw/MPa | Strength After Freeze–Thaw/MPa | BDR/% | |

| 4 | 2.5 | 1.67 | 67 | 2.32 | 1.35 | 58 |

| 6 | 3.3 | 2.30 | 70 | 3.14 | 2.06 | 66 |

| 8 | 3.98 | 3.11 | 78 | 3.61 | 2.76 | 77 |

| 4:8:88 | 2.64 | 2.08 | 79 | 2.76 | 1.93 | 70 |

| 6:12:82 | 3.5 | 2.89 | 83 | 3.34 | 2.48 | 74 |

| 8:16:76 | 4.3 | 3.85 | 90 | 4.08 | 3.45 | 85 |

| Dosage | Geopolymer-Stabilized Soil Sample 2 | Cement-Stabilized Soil Sample 2 | ||||

|---|---|---|---|---|---|---|

| Strength Before Freeze–Thaw/MPa | Strength After Freeze–Thaw/MPa | BDR/% | Strength Before Freeze–Thaw/MPa | Strength After Freeze–Thaw/MPa | BDR/% | |

| 4 | 1.43 | / | / | 1.31 | / | / |

| 6 | 1.55 | 0.88 | 57 | 1.45 | 0.78 | 54 |

| 8 | 2.57 | 1.64 | 64 | 2.23 | 1.34 | 60 |

| 4:8:88 | 2 | / | / | 2.1 | / | / |

| 6:12:82 | 2.5 | 1.87 | 75 | 2.22 | 1.53 | 69 |

| 8:16:76 | 3.6 | 2.88 | 80 | 3.11 | 2.28 | 73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Jiang, Y.; Li, Z.; Huang, Y.; Yue, J. Research on the Pavement Performance of Slag/Fly Ash-Based Geopolymer-Stabilized Soil. Materials 2025, 18, 3173. https://doi.org/10.3390/ma18133173

Yang C, Jiang Y, Li Z, Huang Y, Yue J. Research on the Pavement Performance of Slag/Fly Ash-Based Geopolymer-Stabilized Soil. Materials. 2025; 18(13):3173. https://doi.org/10.3390/ma18133173

Chicago/Turabian StyleYang, Chenyang, Yan Jiang, Zhiyun Li, Yibin Huang, and Jinchao Yue. 2025. "Research on the Pavement Performance of Slag/Fly Ash-Based Geopolymer-Stabilized Soil" Materials 18, no. 13: 3173. https://doi.org/10.3390/ma18133173

APA StyleYang, C., Jiang, Y., Li, Z., Huang, Y., & Yue, J. (2025). Research on the Pavement Performance of Slag/Fly Ash-Based Geopolymer-Stabilized Soil. Materials, 18(13), 3173. https://doi.org/10.3390/ma18133173