3.1. Analysis of Orthogonal Experimental Results

The orthogonal experimental results are presented in

Table 5. Based on the experimental data, the mean (K) and range (R) for each influencing factor were calculated to quantify their impacts on thixotropic slurry performance. Through range analysis, the factors were then ranked by significance, and the optimal combination within the three-factor concentration range was determined.

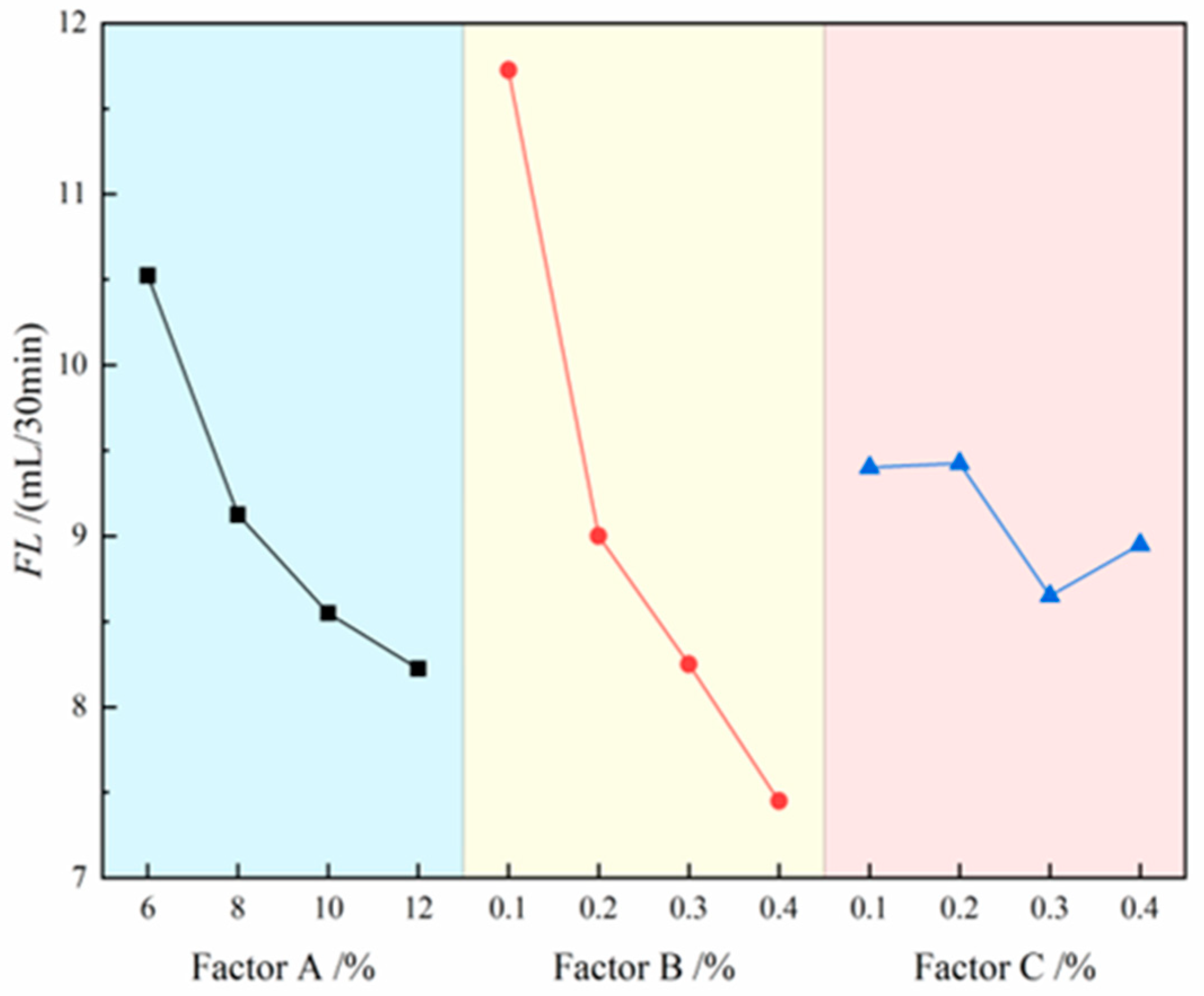

The contribution effects of three factors on FL are illustrated in

Figure 7, where the four level values of each factor are represented on the

x-axis and the FL values are indicated on the

y-axis. The analysis results demonstrate that the degree of influence of each factor on slurry FL follows the following order: CMC > bentonite > Na

2CO

3. Specifically, FL shows a significant decreasing trend with increasing CMC and bentonite content, while it initially decreases and then increases with rising Na

2CO

3 content. The range analysis in

Table 6 further confirms this conclusion, with the range values ranking as follows: CMC (R = 4.275) > bentonite (R = 2.3) > Na

2CO

3 (R = 0.775). Notably, FL exhibits a negative correlation with slurry performance, meaning that lower FL corresponds to better slurry performance. Therefore, when optimizing the slurry formulation, priority should be given to increasing the dosage of CMC and bentonite, while the Na

2CO

3 content needs to be controlled within an optimal range to achieve the best slurry performance. Ultimately, under the dual criteria of maintaining FL below 25 mL/30 min and prioritizing minimal values, the optimal combination for minimizing slurry fluid loss was determined to be A

4B

4C

3.

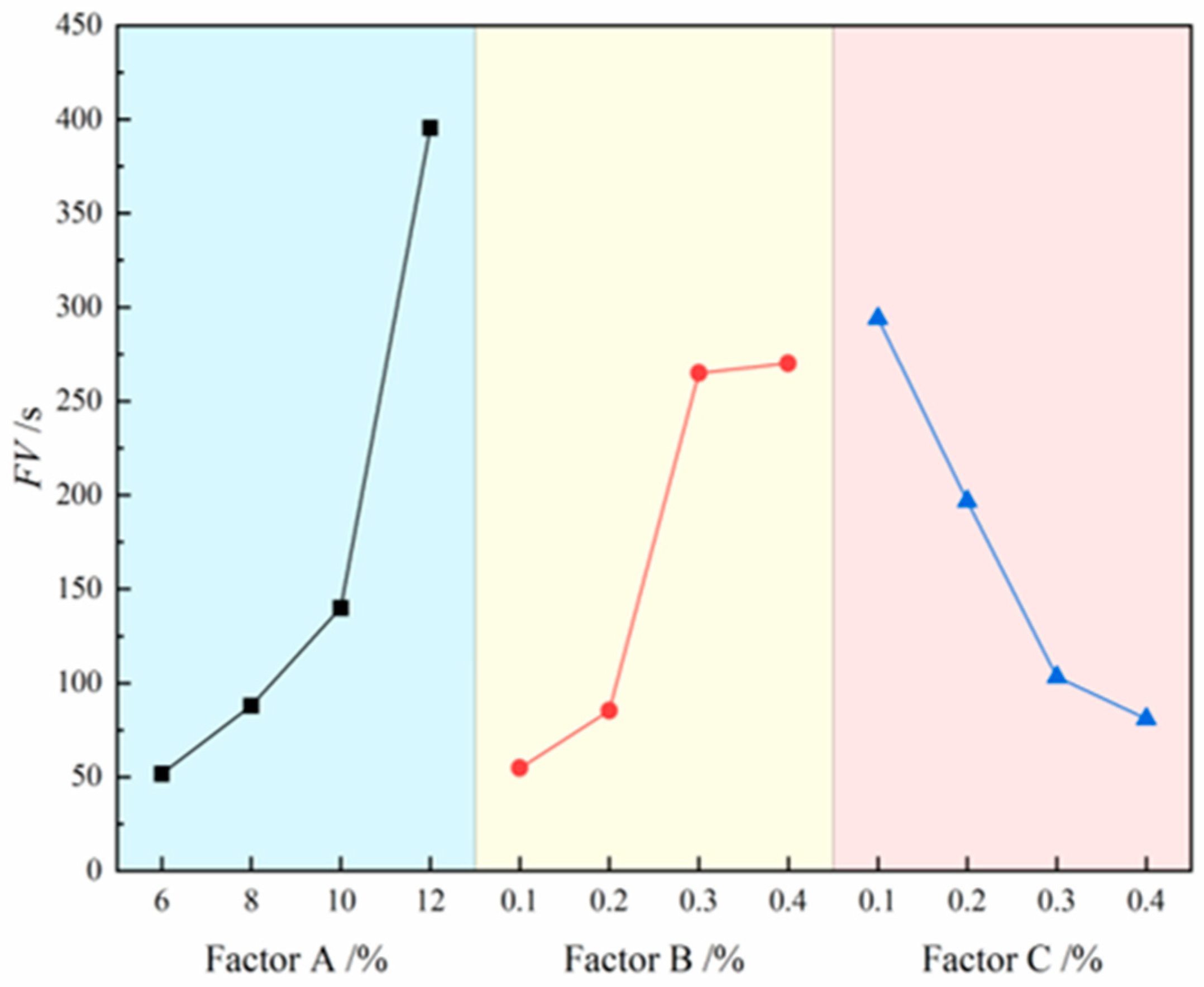

The contribution effects of three factors on FV are illustrated in

Figure 8, where the four level values of each factor are represented on the

x-axis and the FV values are indicated on the

y-axis. The analysis results reveal that the degree of influence of each factor on slurry FV follows the following order: bentonite > CMC > Na

2CO

3. Specifically, FV shows a significant increasing trend with rising bentonite and CMC content, while it exhibits a clear decreasing trend with increasing Na

2CO

3 content. The range analysis in

Table 7 further confirms this conclusion, with the range values ranking as follows: bentonite (R = 343.75) > CMC (R = 215.5) > Na

2CO

3 (R = 213). Notably, bentonite demonstrates the most pronounced effect on FV enhancement, as evidenced by its significantly higher range value compared to other factors, indicating its dominant role in regulating slurry viscosity. Although CMC and Na

2CO

3 show relatively smaller effects, their influence remains non-negligible. Ultimately, the A

3B

2C

3 formulation was identified as the optimal composition for maintaining slurry FV within the target range of 100–120 s, achieving balanced rheological properties and stability.

The contribution effects of three factors on FCT are illustrated in

Figure 9, where the four level values of each factor are represented on the

x-axis and the FCT values are indicated on the

y-axis. The analysis results demonstrate that the degree of influence of each factor on FCT follows the following order: bentonite > CMC > Na

2CO

3. Specifically, FCT shows a significant increasing trend with rising bentonite content, while it exhibits a fluctuating pattern of initial decrease followed by increase with increasing CMC content. For Na

2CO

3, the FCT displays a more complex trend of increase, decrease, and subsequent increase. The range analysis in

Table 8 further confirms this conclusion, with the range values ranking as follows: bentonite (R = 0.55) > CMC (R = 0.275) > Na

2CO

3 (R = 0.2). The range values indicate that bentonite has the most pronounced effect on FCT, with its range value approximately twice that of CMC and 2.75 times that of Na

2CO

3, highlighting its dominant role in regulating FCT. Although both CMC and Na

2CO

3 exhibit relatively minor overall effects, their complex variation trends suggest potentially significant impacts on FCT within specific concentration ranges. Ultimately, through comprehensive analysis of optimal FL and FV combinations under the constraint of maintaining FCT within the 0.5–1 mm range, the A

3B

2C

3 formulation was identified as achieving this target thickness criterion, despite multiple formulations meeting the basic FCT engineering requirements.

Based on orthogonal experimental results, the A

3B

3C

4 formulation (10 wt.% bentonite, 0.3 wt.% CMC, and 0.4 wt.% Na

2CO

3) demonstrated compliance with all six performance criteria within the specified control ranges (pH 11.09 ≈ 11) and exhibited superior overall performance compared to the other 15 tested formulations, thereby establishing it as the optimal slurry formulation.

Figure 10 shows the prepared slurry under this formulation. Notably, range analysis revealed that none of the three factors exhibited significant effects on either slurry SG or pH, and all 16 experimental groups achieved zero WSR, demonstrating that all formulations met the fundamental stability requirements. Consequently, these parameters were not subjected to further detailed analysis in this study.

3.2. Analysis of Comparative Experimental Results

3.2.1. Effect of HEC Content on Slurry Performance

According to the experimental data on the performance of thixotropic slurry with varying HEC dosages in

Table 9, the incorporation of HEC exerts a significant regulatory effect on the rheological properties and stability of the system. The experimental results reveal that as the HEC dosage increases from 0.2% to 1%, the slurry SG exhibits a linear growth from 1.035 to 1.041, while the FV simultaneously rises from 43 s to 121 s, demonstrating a significant positive correlation. Notably, within this dosage range, the WSR of the slurry remains consistently at 0%, and the FCT is maintained within the ideal range of 0.8 to 1 mm, indicating excellent suspension stability and dense film-forming capability. Simultaneously, the evolution of the system’s pH value displays a non-linear characteristic of initially decreasing, then increasing, and finally decreasing again, which is primarily attributed to the dynamic influence of polar groups in HEC molecules on the double-electric layer structure of the slurry colloid.

Regarding key performance parameters, the FL exhibits an exponential decline with increasing HEC dosage, significantly decreasing from 15.5 mL in the 0.2% dosage group to 9.5 mL in the 1% dosage group (a reduction of 38.7%). This is closely related to the molecular structure characteristics of HEC. As a non-ionic water-soluble cellulose ether, the numerous hydroxyl (−OH) and hydroxyethyl (−CH2CH2OH) groups in its molecular chains form a three-dimensional hydration network through hydrogen bonding: (i) Hydrophilic groups strongly associate with water molecules, significantly enhancing the water-retention capacity of the system; (ii) Long-chain molecules entangle to create spatial steric hindrance, effectively inhibiting the sedimentation and separation of solid particles; (iii) The formation of hydration films effectively seals filtration channels, reducing permeability. These multiple mechanisms synergistically improve the fluid loss control performance of the slurry.

Experimental analysis confirms that HEC significantly enhances the rheological properties and stability of the slurry through its unique molecular structure and hydration mechanisms. Its thickening effect, fluid loss reduction characteristics, and colloidal stability advantages provide potential applications for thixotropic slurries in complex engineering environments.

3.2.2. Effect of CMC Content on Slurry Performance

According to the experimental data on performance parameters of thixotropic slurry with varying CMC dosages in

Table 10, as the CMC dosage increases from 0.2% to 1%, the SG of slurry rises from 1.036 to 1.041, and the FV significantly increases from 45 s to 112 s. This phenomenon indicates that CMC effectively enhances the structural strength of the slurry through molecular chain entanglement, thereby significantly improving the rheological properties of the slurry. The increase in FV further validates the thickening effect of CMC in the thixotropic slurry, providing essential assurance for the stability and fluidity of the slurry during construction.

Regarding the key performance parameters, the FL shows a clear negative correlation with increasing CMC dosage, decreasing from 14.6 mL at a 0.2% dosage to 9.2 mL at a 1% dosage (a reduction of 37.0%). This result confirms the adsorption and stabilization effects of the hydroxyl and carboxyl groups in CMC molecules on bentonite particles, significantly reducing the fluid loss of the slurry. Additionally, the pH value gradually decreases from 10.43 to 10.35, indicating that as an anionic cellulose ether, CMC dosage has a certain influence on the pH value of the thixotropic slurry. Notably, under all formulations, the WSR remains stable at 0%, and the FCT stays consistent at 1 mm. This demonstrates that the three-dimensional network structure formed by CMC and bentonite particles exhibits excellent anti-segregation stability and interfacial sealing properties. This stable structure not only effectively prevents stratification and water separation in the slurry but also provides reliable support for the long-term stability of the slurry during construction.

The findings highlight that CMC, as an additive for thixotropic slurry, demonstrates significant advantages in thickening, reducing fluid loss, and colloid stability. The three-dimensional network structure formed by CMC and bentonite particles not only enhances the structural strength of the slurry but also improves its rheological properties and construction stability. This conclusion further confirms the widespread applicability of CMC in thixotropic slurries.

3.2.3. Comparison of the Effects of HEC and CMC on Slurry Performance

Graphs were plotted to show the variations in FV, FL, pH, and SG of the slurry with HEC and CMC contents. Polynomial fitting was applied to these curves to visualize the influence trends of both admixtures on slurry performance indicators. The comparative curves and analysis between HEC and CMC are summarized below. All fitted curves achieved R2 values greater than 0.9, indicating good model fitting.

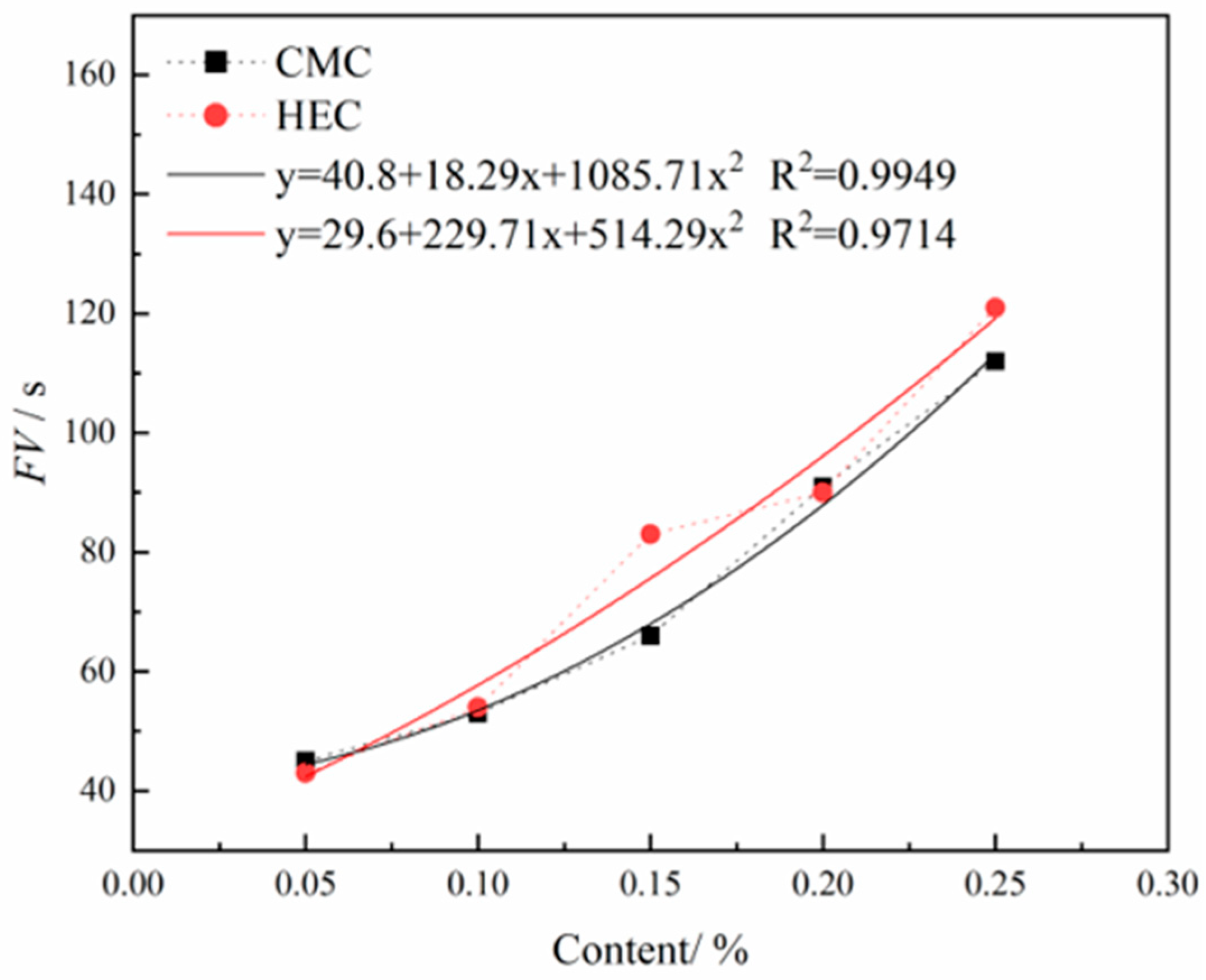

As shown in

Figure 11, the effects of HEC and CMC content on the FV of thixotropic slurry reveal the following trends: both cellulose derivatives exhibit a significant positive correlation between concentration and FV in their thickening effects. At dosages of 2–4% and 8%, there is no notable difference in FV between HEC and CMC. However, within the dosage ranges of 4–8% and 8–10%, HEC demonstrates a more pronounced enhancement in FV compared to CMC, indicating that HEC possesses a more significant thickening capability within certain dosage ranges.

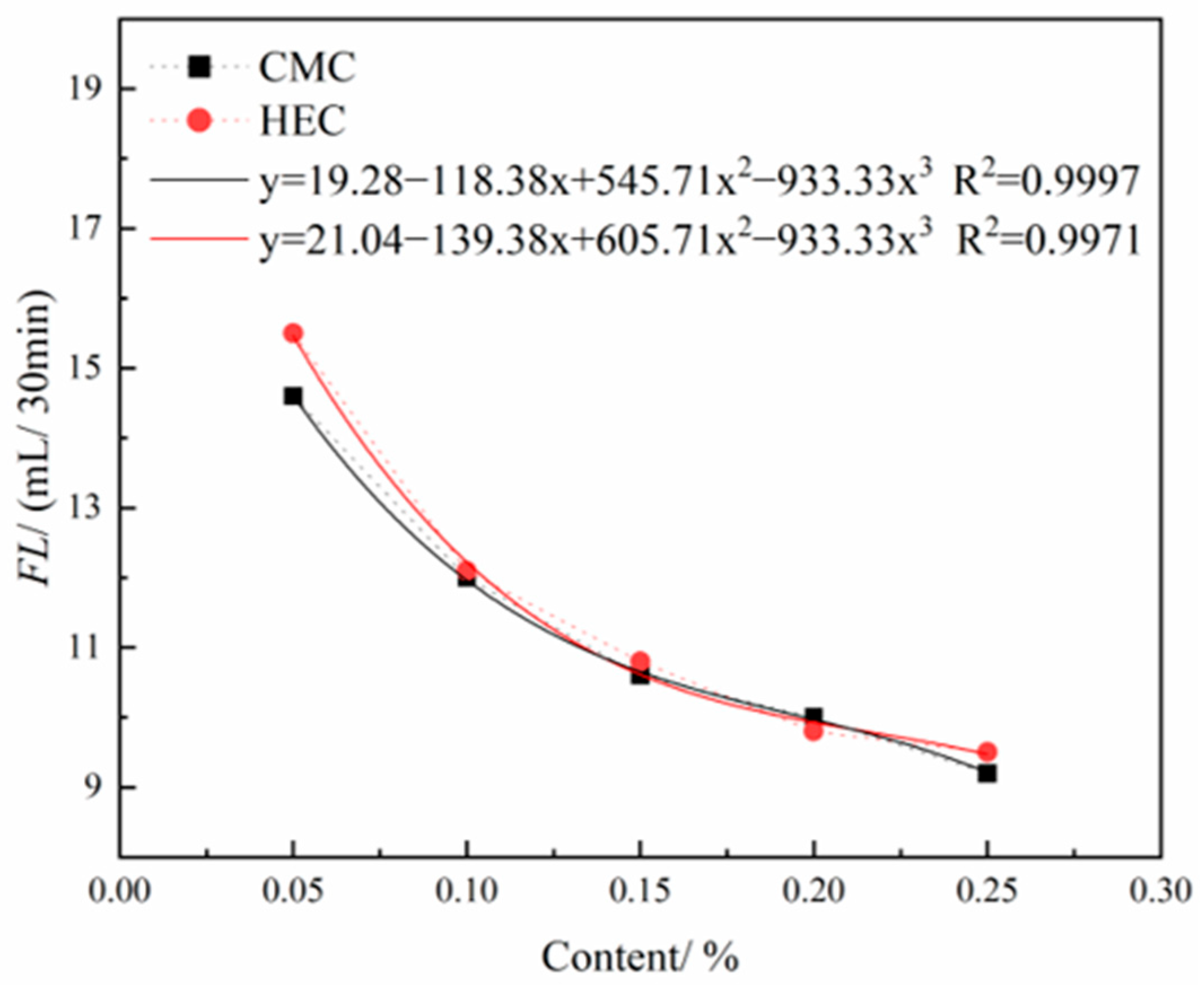

As shown in

Figure 12, the FL of the thixotropic slurry system shows a significant downward trend as the content of both cellulose-based admixtures gradually increases. The improvement effects of the two cellulose derivatives on the water-retention performance of the slurry are similar. Analysis indicates that this stems from the three-dimensional network structure formed by the polymer segments during hydration, which effectively blocks the microporous channels in the slurry system and inhibits the exudation of free water. Furthermore, curve fitting indicates that the FL of slurries containing either CMC or HEC additives both exhibit a negative correlation with additive content. Initially, the FL of the HEC-containing slurry is slightly higher than that of the CMC-containing slurry, but later becomes generally comparable. This phenomenon may be attributed to the increased viscosity of the system, which reduces the uniformity of dispersion. Therefore, in engineering practice, either CMC or HEC can be flexibly selected as water-retention enhancers based on material supply conditions and economic indicators.

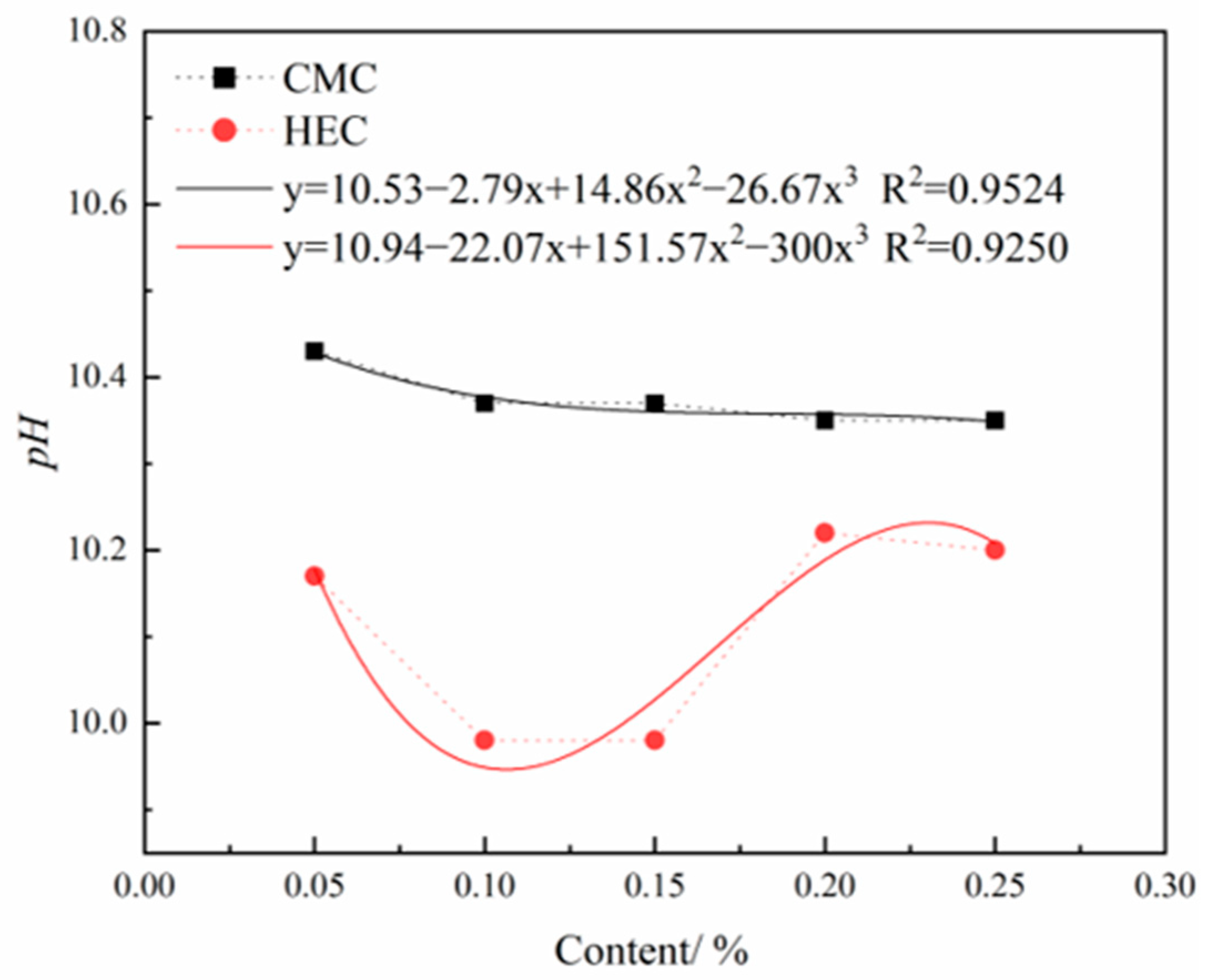

As shown in

Figure 13, under the same dosage conditions, the pH value of the slurry system incorporating CMC is significantly higher than that incorporating HEC. With increasing CMC dosage, the slurry pH exhibits a downward trend, while changes in HEC dosage result in a nonlinear pH variation, characterized by an initial decrease, followed by an increase, and then another decrease. Notably, throughout the entire dosage range, the pH value of the HEC slurry system remains consistently lower than that of the CMC slurry system. This discrepancy in mechanisms primarily stems from the differences in charge response characteristics in solution between non-ionic HEC and anionic CMC.

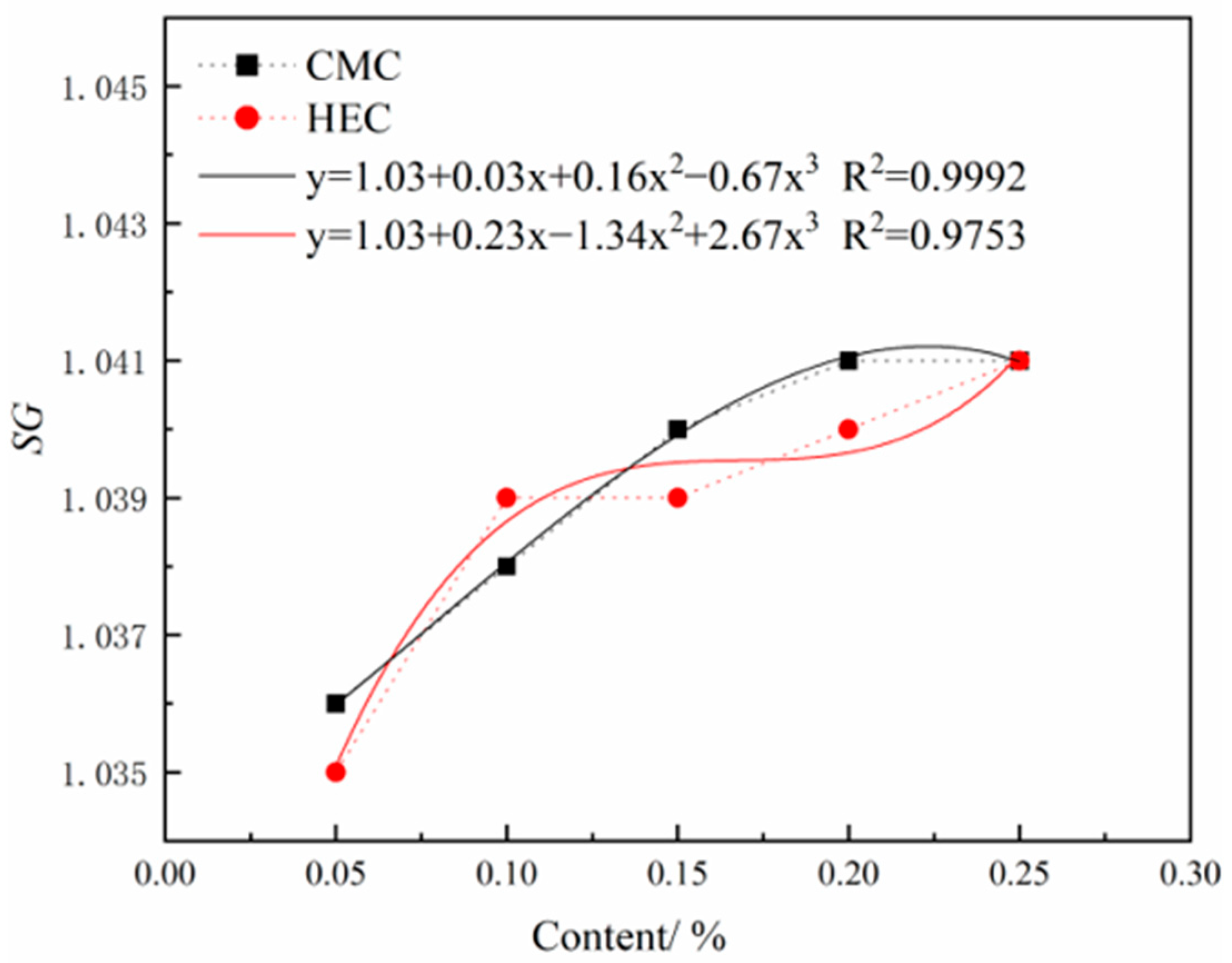

As shown in

Figure 14, the incorporation of both cellulose-based admixtures exerts a certain influence on the SG regulation of the slurry system, manifested by an increase in slurry SG with the rising dosage of the admixture. This phenomenon of SG enhancement is closely related to the molecular structures of the cellulose derivatives: the hydroxyethyl groups (−CH

2CH

2OH) in HEC molecules and the carboxymethyl groups (−CH

2COO

−) in CMC molecules can form stable associations with water molecules through hydrogen bonding. Meanwhile, their long-chain molecules generate steric hindrance effects in the slurry, significantly enhancing the suspension stability of solid particles, thereby inhibiting slurry sedimentation and improving overall compactness, ultimately leading to an increase in SG.

In conclusion, HEC and CMC exhibit similar rheological regulation characteristics in thixotropic slurries, but there are certain differences between the two in terms of thickening efficiency, FL control, pH influence, and SG regulation: HEC slightly outperforms CMC in thickening efficiency, while the two show significant differences in their impact on pH; in terms of FL control and SG enhancement, the effects of the two are comparable, effectively improving the construction performance and stability of the slurry. These findings provide an important basis for the selection of cellulose-based admixtures in engineering practice and also lay the foundation for the potential application of HEC in thixotropic slurries for pipe jacking construction.

3.3. Friction Test Results and Analysis

Based on orthogonal experiments and comparative experiments, five representative formulation combinations were selected, including orthogonal experiment groups A3B4C3 (FV 225 s), A3B3C4 (FV 119 s), A1B1C1 (FV 36 s), as well as comparative experiment groups CMC-0.25 (FV 112 s) and HEC-0.25 (FV 121 s).

As shown in

Figure 15a, the frictional characteristic tests of different viscosity formulations revealed that with increasing slurry viscosity, both the slope (friction coefficient) and intercept (adhesion force) of the fitted linear curve showed an upward trend. Specifically, the friction coefficient demonstrated an increasing progression of 0.45 → 0.56 → 0.62, while the adhesion force increased from 0.07 N to 1.06 N, which aligns with the theoretical expectation that viscosity affects interfacial friction characteristics. Further experimental observations indicated that while high-viscosity slurries (>200 s) could provide excellent support, they led to increased frictional resistance and reduced friction-reduction efficiency; whereas low-viscosity slurries (<50 s) showed significant friction-reduction effects but caused test block settlement due to insufficient support capacity. Therefore, slurry formulation optimization requires balancing friction-reduction performance and support capacity—maintaining medium viscosity (100–120 s) can achieve effective friction reduction while preserving stable support for pipe jacking. Within this optimal range, the A

3B

3C

4 formulation (FV 119 s) demonstrated the best comprehensive performance.

As shown in

Figure 15b, when bentonite content was fixed at 8%, CMC-0.25 (FV 112 s) and HEC-0.25 (FV 121 s) showed no significant differences in either friction coefficient (0.48 vs. 0.45) or adhesion force (0.57 N vs. 0.60 N), which also conformed to theoretical expectations.

3.4. Microstructure Analysis

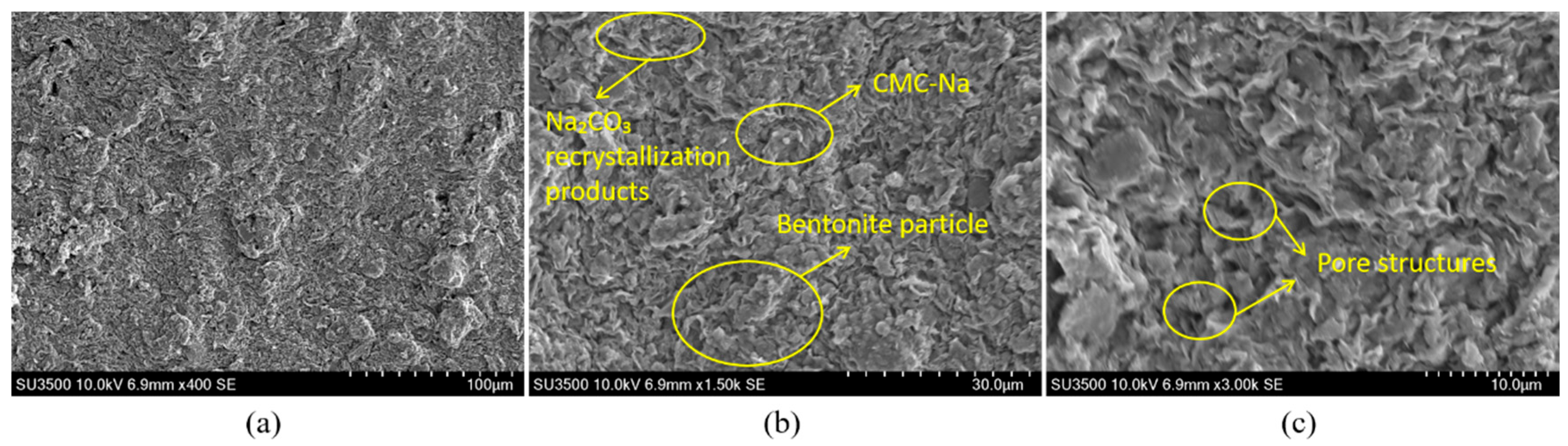

Figure 16 illustrates the microstructural morphology of the thixotropic slurry in the bentonite-CMC-Na

2CO

3 ternary system. Under 400× magnification (

Figure 16a), the sample exhibits a typical montmorillonite lamellar stacking structure, consistent with the morphological characteristics of layered silicate minerals. When magnified to 1500× (

Figure 16b), the edges of the montmorillonite lamellae become more distinct. CMC molecules are uniformly coated on the bentonite surface via electrostatic adsorption and hydrogen bonding, while micron-sized crystalline particles, identified as Na

2CO

3 recrystallization products, are observed at partial pores and lamellar edges. Further magnification to 3000× (

Figure 16c) reveals clearly distinguishable monolayer montmorillonite structures. CMC forms a continuous wrapping network through molecular chain crosslinking, constructing a uniform organic–inorganic composite interface on the bentonite surface. The regularly distributed pore structures provide effective channels for moisture migration.

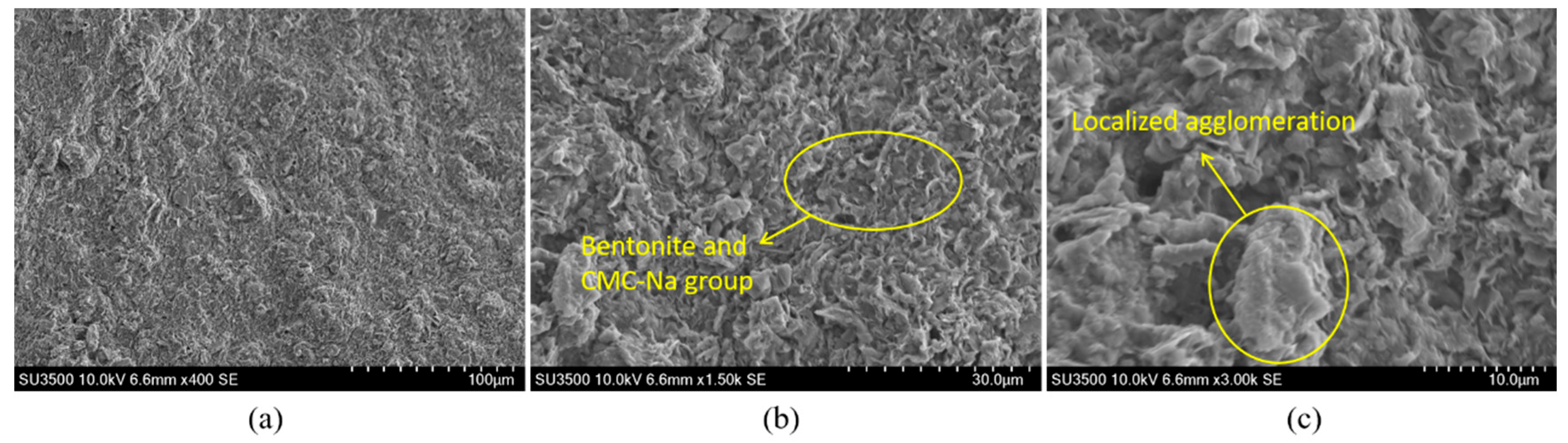

For comparative analysis,

Figure 17 shows the microstructural features of the bentonite-CMC binary system for comparison. Under 400× and 1500× magnifications (

Figure 17a,b), its macroscopic structure remains largely consistent with that of the Na

2CO

3-containing system. However, under 3000× high-resolution imaging (

Figure 17c), localized agglomeration phenomena become apparent, accompanied by loosely stacked bentonite lamellae and uneven pore size distribution. This phenomenon can be attributed to the absence of two key mechanisms: (i) insufficient montmorillonite lamellar dispersion due to the lack of ion exchange induced by soda ash, and (ii) disordered entanglement of CMC molecular chains caused by charge imbalance. Such microstructural defects may lead to reduced water-retention capacity and impaired thixotropic performance.

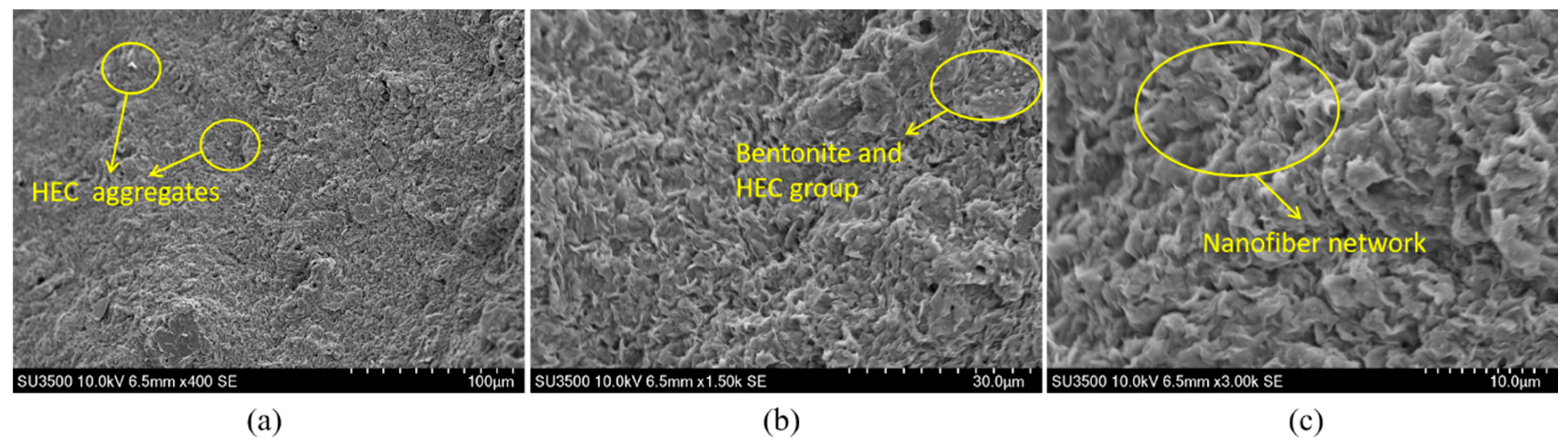

Figure 18 presents the microstructural morphology of the bentonite-HEC binary thixotropic slurry. Under 400× magnification (

Figure 18a), bentonite retains its typical lamellar stacking morphology, while HEC molecular chains form localized bright white aggregates due to incomplete dispersion. Under 1500× magnification (

Figure 18b), partial exfoliation of bentonite lamellae is observed, with HEC forming a thin film coating on the bentonite surface via intermolecular hydrogen bonding, exhibiting similarities to the CMC systems in

Figure 13 and

Figure 14. Further magnification to 3000× (

Figure 18c) reveals three critical structural features: (i) HEC forming a continuous nanofiber network uniformly coating the bentonite surface and extending into interlayer spaces; and (ii) uniform overall pore distribution interspersed with localized fiber fractures and agglomerations. This composite structure endows the material with pronounced thixotropic properties through synergistic hydrogen-bonded networks and physical entanglement.

Further analysis indicates that CMC (existing as CMC-Na), an anionic cellulose ether, adsorbs onto bentonite particles via electrostatic interactions and hydrogen bonding to form a three-dimensional network, enhancing interparticle cohesion and improving slurry thixotropy [

43]. In contrast, HEC, a non-ionic cellulose ether, establishes hydrogen bonds between its hydroxyl groups and surface hydroxyls or interlayer cations of bentonite lamellae, strengthening particle adhesion. These distinct properties enable targeted applications of the two cellulose ethers in different engineering scenarios. Additionally, the incorporation of appropriate soda ash facilitates uniform bentonite dispersion and promotes the formation of a more continuous three-dimensional network. This not only enhances slurry stability but also effectively retards the sedimentation rate of solid particles.