Effects of Stacking Configuration on Impact Resistance of Electric Locomotive Coupling Protective Covers Reinforced by CFRP, GFRP, and Their Hybrids

Abstract

1. Introduction

2. Finite-Element Model Development

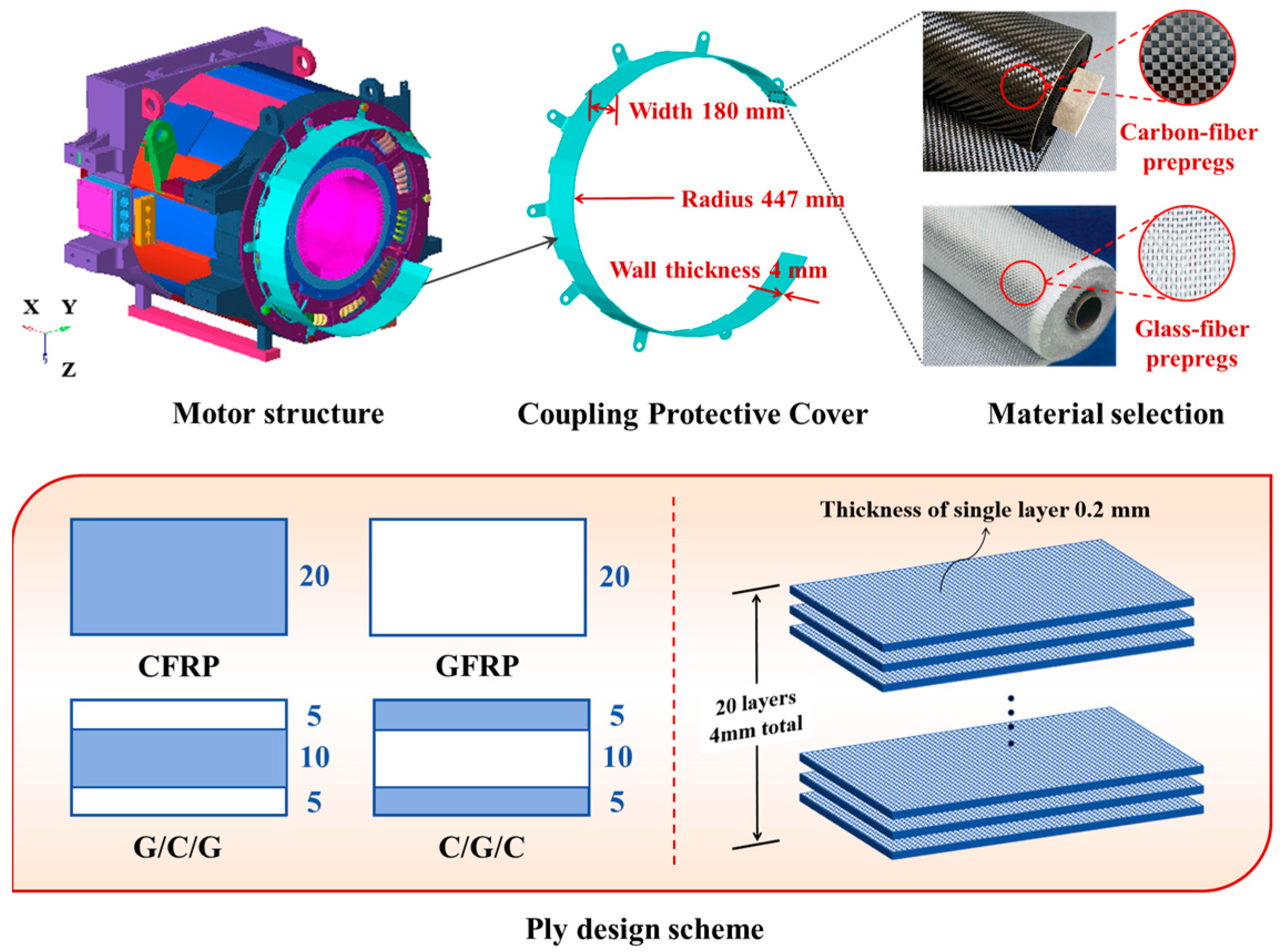

2.1. Geometric Model and Layering Design

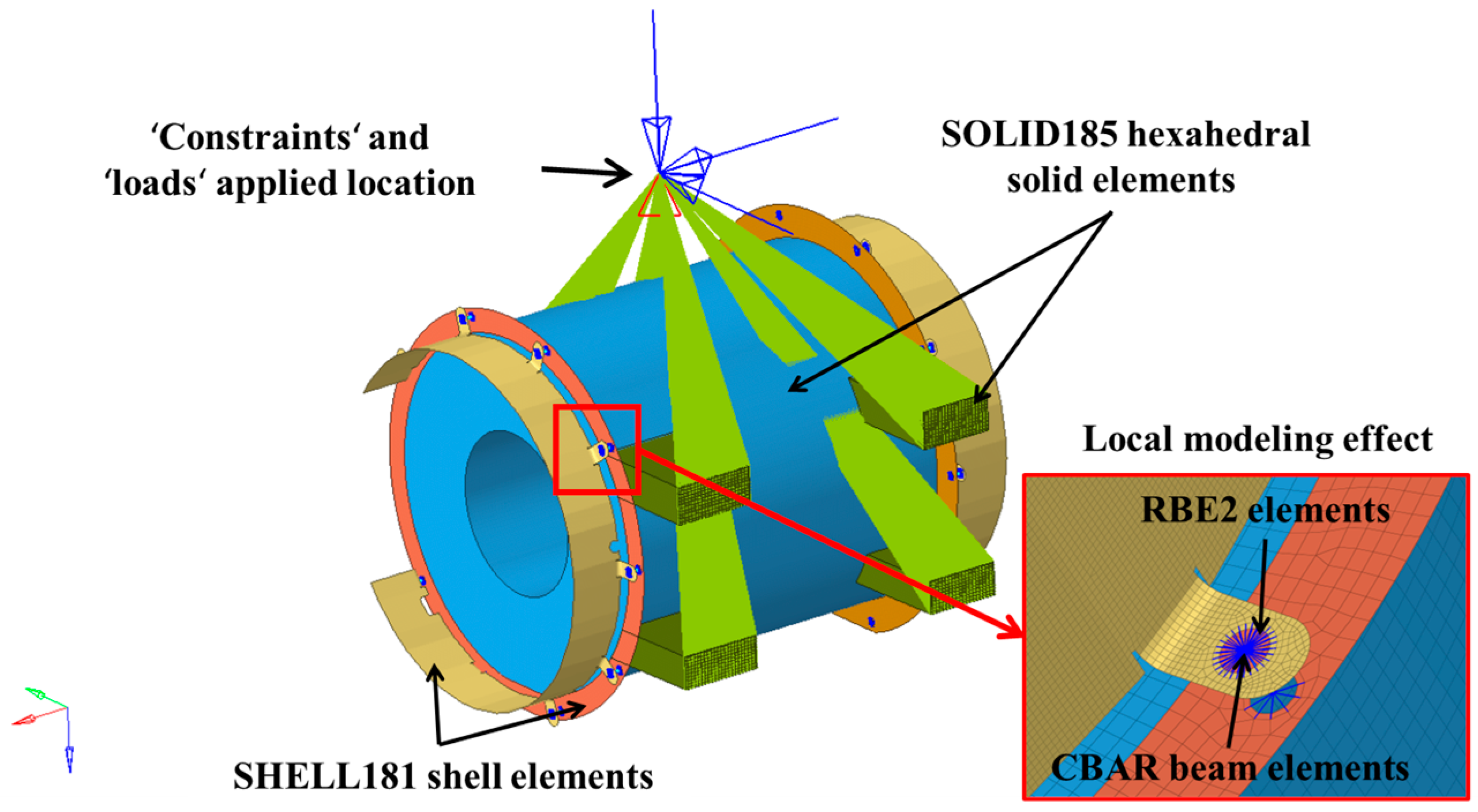

2.2. Structural Impact Finite-Element Model

2.3. Gravel Impact Finite-Element Model

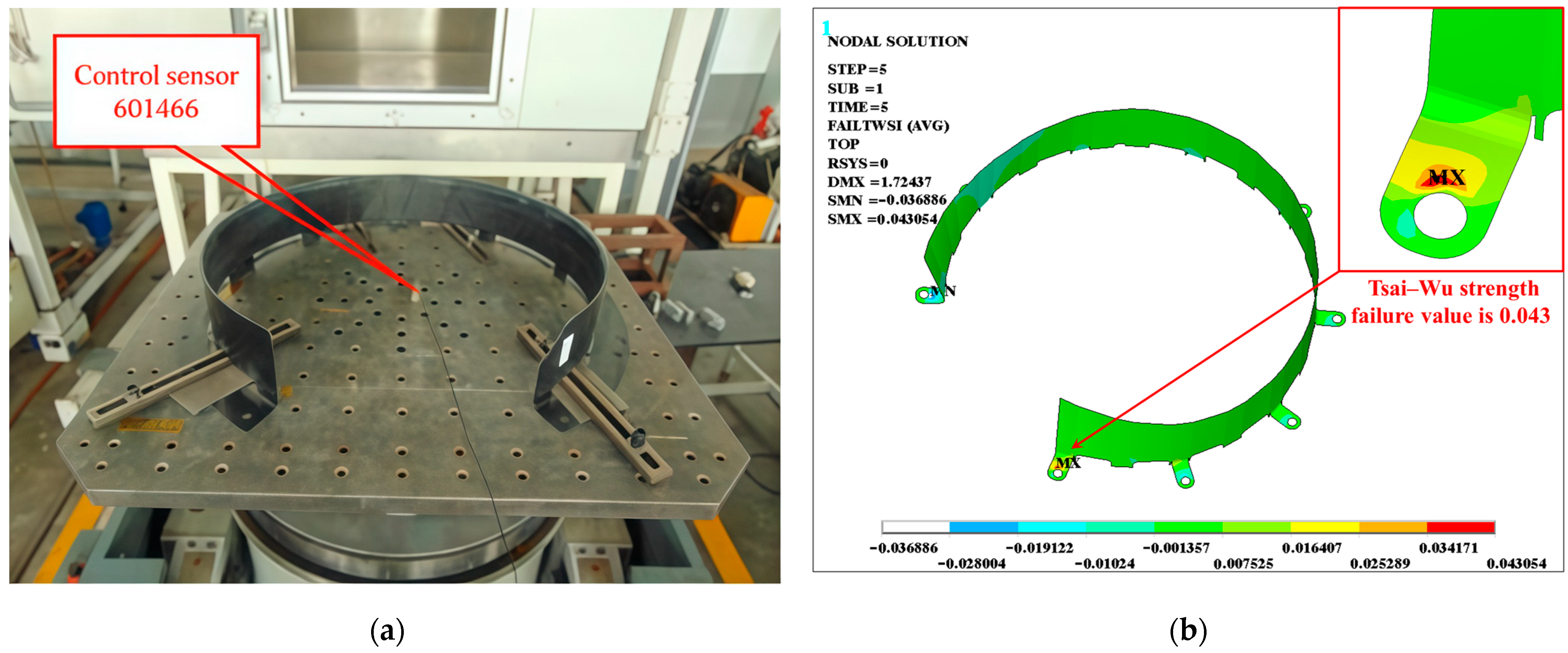

2.4. Model Verification

3. Results Analysis

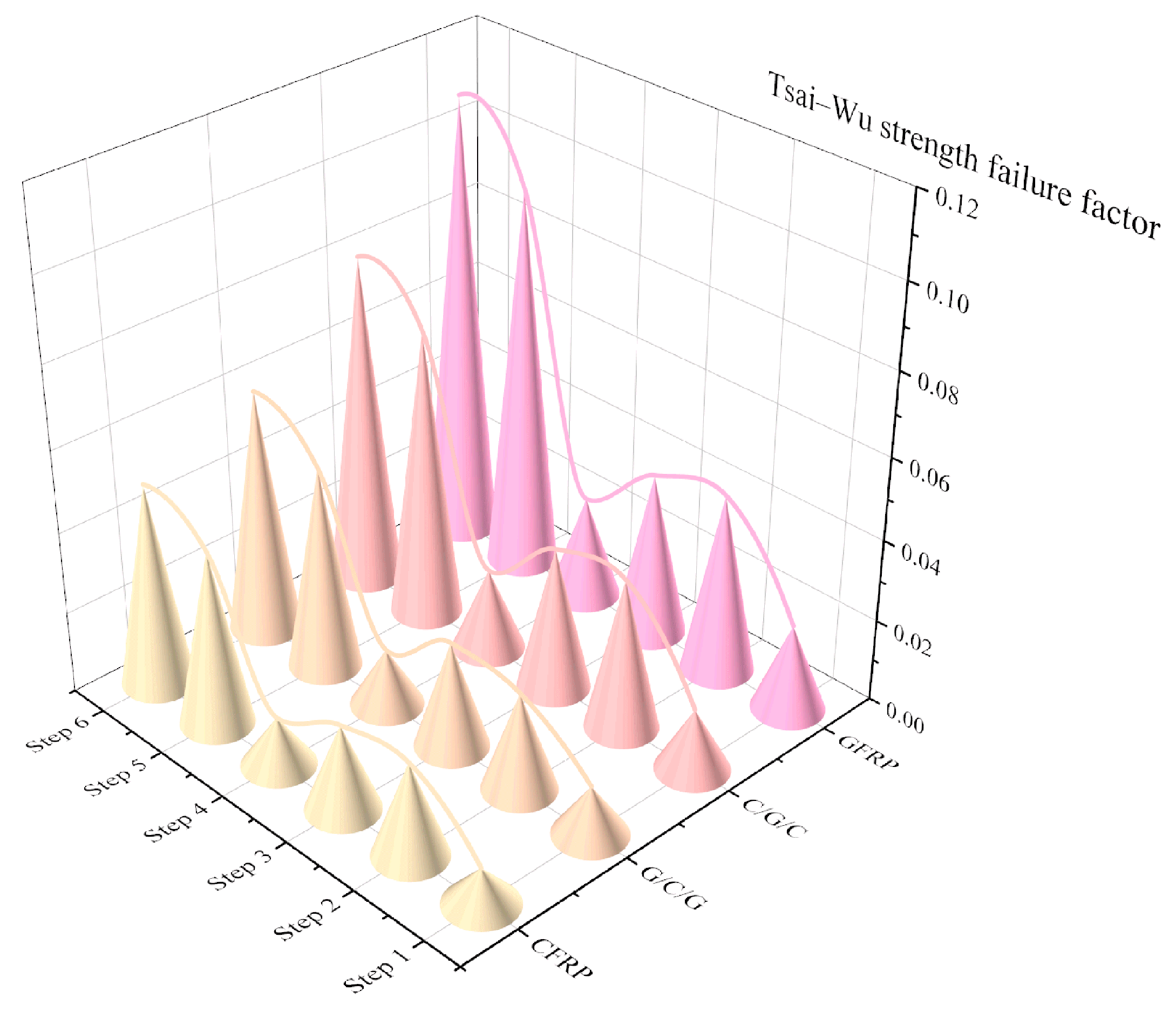

3.1. Structural-Impact Conditions

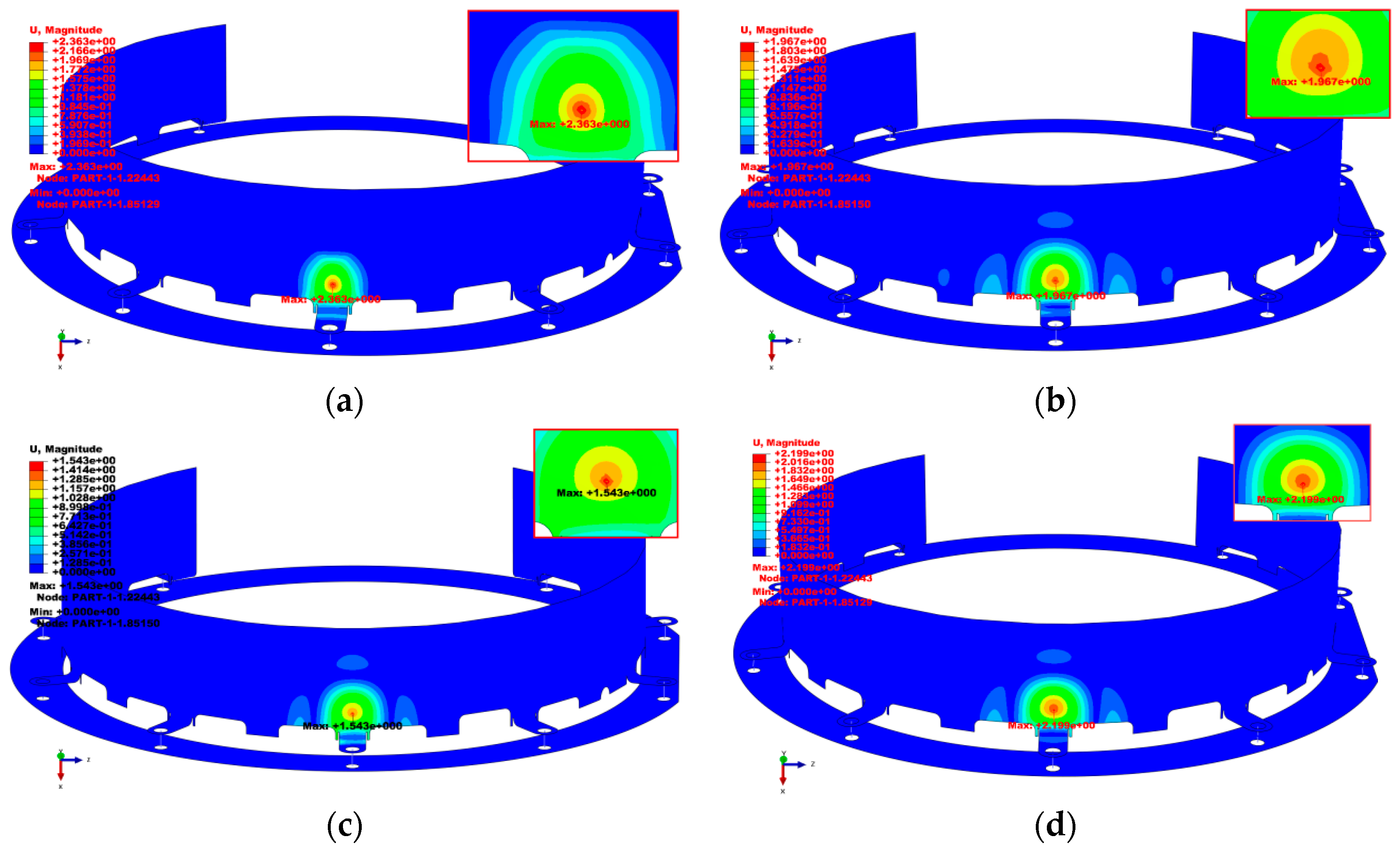

3.2. Ballast Impact Conditions

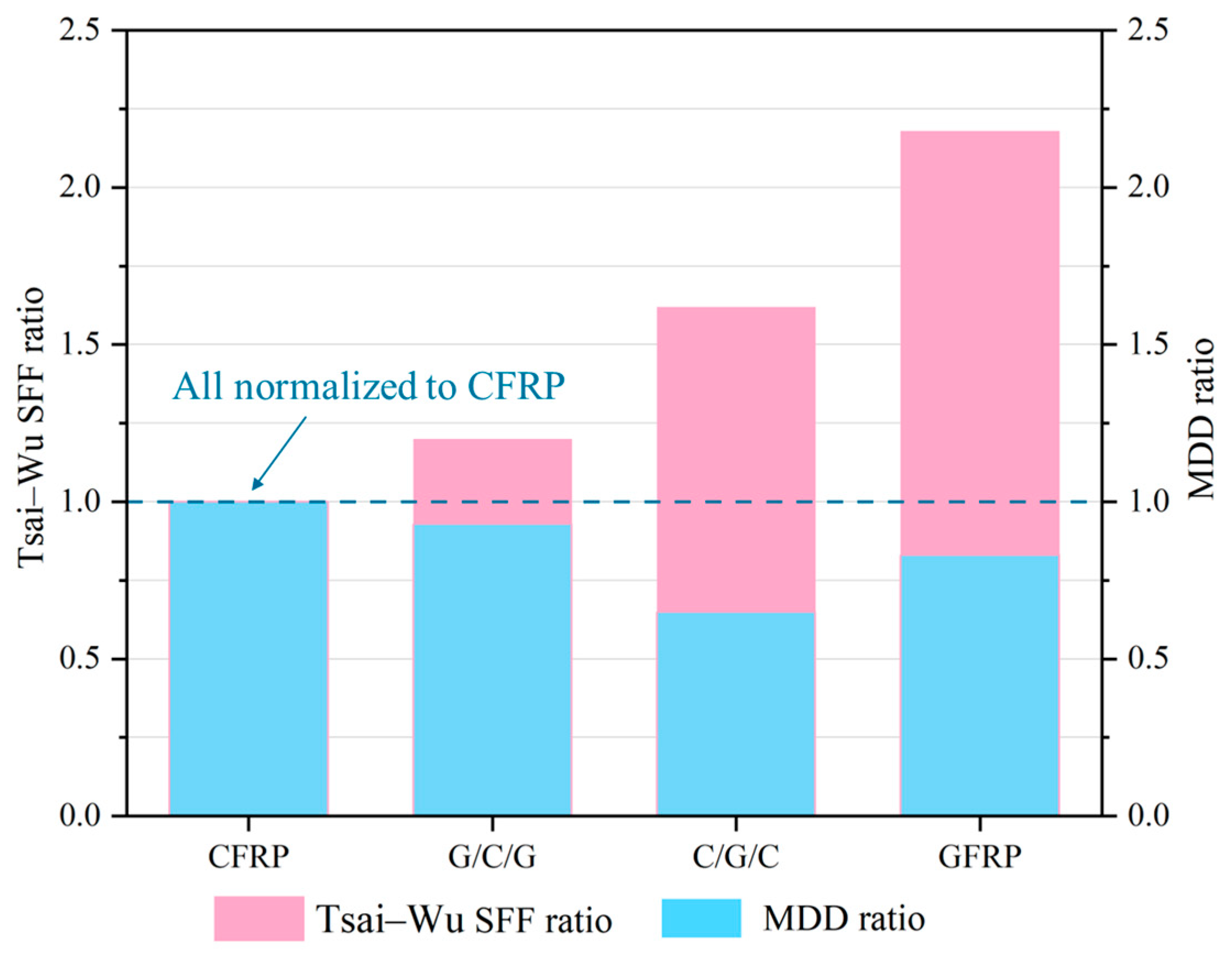

3.3. Discussion

4. Conclusions and Perspectives

- (1)

- Under structural impact conditions, the maximum Tsai–Wu coefficient values for all stacking configurations were concentrated at the bolt connection between the protective cover and the motor body but remained below one, indicating that the protective-cover structure met the safety requirements. The CFRP configuration had the smallest maximum Tsai–Wu coefficient, corresponding to the highest structural safety, whereas the GFRP configuration had the highest Tsai–Wu coefficient, making it the most vulnerable structural design. The hybrid stacking configurations fell between these two extremes;

- (2)

- Under ballast-impact conditions, none of the protective covers were penetrated, confirming that they met the requirement for safe operation. The maximum deformation displacement of the CFRP protective cover was close to that of the GFRP configuration, but its deformation area was smaller. The maximum deformation displacements for the C/G/C and G/C/G hybrid stacking configurations were 1.54 and 1.97 mm, respectively, which were lower than those of both the CFRP and GFRP configurations. This indicated that hybridizing CFRP and GFRP improved the impact resistance of the structure;

- (3)

- A comprehensive comparison of the simulation results under two operating conditions showed that incorporating GFRP into the CFRP protective-cover structure enhanced its ballast-impact resistance but reduced its overall structural-impact resistance. Furthermore, in the hybrid material design, using CFRP as the outer layer helped improve the structure’s ballast-impact resistance (with the lowest maximum impact deformation) but this led to the deterioration of the structural-impact resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Toro, S.A.; González, C.; Fernández-Blázquez, J.P.; Ridruejo, A. Fabrication and mechanical properties of a high-performance PEEK-PEI hybrid multilayered thermoplastic matrix composite reinforced with carbon fiber. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108308. [Google Scholar] [CrossRef]

- Chen, Y.; Prasad, V.; Yasar, M.; Murphy, N.; Ivankovic, A. Enhancing interfacial performance and fracture toughness of carbon fibre reinforced thermoplastic composites. Part A Appl. Sci. Manuf. 2024, 187, 108434. [Google Scholar] [CrossRef]

- Ridha, M.; Su, Z.; Tran, L.Q.N.; Yek, W.M.A.; Narayanaswamy, S.; Tay, T.E. Effect of geometry and adhesion on the performance of fiber reinforced thermoplastic composite joints with metal inserts. Part A Appl. Sci. Manuf. 2024, 187, 108482. [Google Scholar] [CrossRef]

- Quan, Z.; Liu, C.; Li, J.; Qin, X.; Yu, J. Fiber bundle deposition model and variable speed printing strategy for in-situ impregnation 3D printing of continuous fiber reinforced thermoplastic composites. Compos. Sci. Technol. 2024, 255, 110723. [Google Scholar] [CrossRef]

- Xian, G.; Zhou, P.; Li, C.; Dong, S.; Du, H.; Tian, J.; Guo, R.; Peng, Z.; Zhang, Z.; He, T. Mechanical properties evaluation of glass fiber reinforced thermoplastic composite plate under combined bending loading and water immersion. Constr. Build. 2024, 440, 137470. [Google Scholar] [CrossRef]

- Liu, Z.; Hui, W.; Chen, G.; Cao, P. Multiscale analyses of the damage of composite rocket motor cases. Front. Mater. 2023, 10, 1198493. [Google Scholar] [CrossRef]

- Wasti, S.; Kore, S.; Yeole, P.; Tekinalp, H.; Ozcan, S.; Vaidya, U. Bamboo fiber reinforced polypropylene composites for transportation applications. Front. Mater. 2022, 9, 967512. [Google Scholar] [CrossRef]

- Souza, M.C.D.; Moroz, I.; Cesarino, I.; Leão, A.L.; Jawaid, M.; Dias, O.A.T. A Review of Natural Fibers Reinforced Composites for Railroad Applications. Appl. Sci. Eng. Prog. 2022, 15, 5800. [Google Scholar]

- Jagadeesh, P.; Puttegowda, M.; Oladijo, O.P.; Lai, C.W.; Gorbatyuk, S.; Matykiewicz, D.; Rangappa, S.M.; Siengchin, S. A comprehensive review on polymer composites in railway applications. Polym. Compos. 2022, 43, 1238–1251. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, X.; Li, Z.; Dai, P.; Zan, H.; Cai, D.; Du, C. Design and application of carbon fiber composite material in end box of rail transit vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2019, 612, 032200. [Google Scholar] [CrossRef]

- Ding, S.; Chen, D.; Liu, J. Research, development and prospect of China high-speed train. CJTAM 2021, 53, 35–50. [Google Scholar]

- Chen, D.; Sun, G.; Meng, M.; Li, G.; Li, Q. Residual crashworthiness of CFRP structures with pre-impact damage–an experimental and numerical study. Int. J. Mech. Sci. 2018, 149, 122–135. [Google Scholar] [CrossRef]

- Sun, G.; Tong, S.; Chen, D.; Gong, Z.; Li, Q. Mechanical properties of hybrid composites reinforced by carbon and basalt fibers. Int. J. Mech. Sci. 2018, 148, 636–651. [Google Scholar] [CrossRef]

- Hayashi, T. On the improvement of mechanical properties of composites by hybrid composition. In Proceedings of the 8th International Reinforced Plastics Conference, Brighton, UK, 10–12 October 1972; pp. 149–152. [Google Scholar]

- Dong, C.; Davies, I.J. Flexural strength of bidirectional hybrid epoxy composites reinforced by E glass and T700S carbon fibres. Compos. Part B Eng. 2015, 72, 65–71. [Google Scholar] [CrossRef]

- de Camargo, F.V.; Pavlovic, A.; Schenal, E.C.; Fragassa, C. Explicit stacked-shell modelling of aged basalt fiber reinforced composites to low-velocity impact. Compos. Struct. 2021, 256, 113017. [Google Scholar] [CrossRef]

- de Camargo, F.V.; Pavlovic, A. Fracture evaluation of the falling weight impact behaviour of a basalt/vinylester composite plate through a multiphase finite element model. Key Eng. Mater. 2017, 754, 59–62. [Google Scholar] [CrossRef]

- Sorini, C.; Chattopadhyay, A.; Goldberg, R. Multiscale Modeling of Adiabatic Heating and Fiber Breakage in Polymer Matrix Composites Subjected to Impact Loading. Am. Soc. Compos. 2019, 34, 31263. [Google Scholar]

- Sencu, R.M.; Yang, Z.; Wang, Y.C.; Withers, P.J.; Soutis, C. Multiscale image-based modelling of damage and fracture in carbon fibre reinforced polymer composites. Compos. Sci. Technol. 2020, 198, 108243. [Google Scholar] [CrossRef]

- Antin, K.N.; Laukkanen, A.; Andersson, T.; Smyl, D.; Vilaça, P. A Multiscale Modelling Approach for Estimating the Effect of Defects in Unidirectional Carbon Fiber Reinforced Polymer Composites. Materials 2019, 12, 1885. [Google Scholar] [CrossRef]

- Ghosh, S.; Raghavan, P. Multiscale model for damage analysis in fiber-reinforced composites with interfacial debonding. Int. J. Multiscale Comput. Eng. 2004, 2, 621–645. [Google Scholar] [CrossRef]

- Cascino, A.; Meli, E.; Rindi, A. A strategy for lightweight designing of a railway vehicle car body including composite material and dynamic structural optimization. Railw. Eng. Sci. 2023, 31, 340–350. [Google Scholar] [CrossRef]

- Graupner, N.; Hohe, J.; Schober, M.; Rohrmüller, B.; Weber, D.; Bruns, L.; Bruns, A.; Müssig, J. A competitive study of the static and fatigue performance of flax, glass, and flax/glass hybrid composites on the structural example of a light railway axle tie. Front. Mater. 2022, 9, 837289. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Y.; Meng, M.; Li, B.; Sun, X.; Yang, B.; Xiao, S.; Wang, T. Dynamic axial crushing behaviors of circular composite tubes with different reinforcing fibers and triggers. Int. J. Mech. Sci. 2023, 244, 108083. [Google Scholar] [CrossRef]

- Tian, A.; Sun, K.; Che, Q.; Jiang, B.; Song, X.; Guo, L.; Chen, D.; Xiao, S. Axial Impact Response of Carbon Fiber-Reinforced Polymer Structures in High-Speed Trains Based on Filament Winding Process. Materials 2024, 17, 4970. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Ren, H.; Wang, Z.; Wei, L.; Zhao, X. Low-velocity impact response and damage mechanism of cosine function cell-based lattice core sandwich panels. Thin-Walled Struct. 2024, 205, 112499. [Google Scholar] [CrossRef]

- Hazell, P.J.; Appleby-Thomas, G. A study on the energy dissipation of several different CFRP-based targets completely penetrated by a high velocity projectile. Compos. Struct. 2009, 91, 103–109. [Google Scholar] [CrossRef]

- Grujicic, M.; Pandurangan, B.; Koudela, K.L.; Cheeseman, B.A. A computational analysis of the ballistic performance of light-weight hybrid composite armors. Appl. Surf. Sci. 2006, 253, 730–745. [Google Scholar] [CrossRef]

- Ma, B.; Cao, X.; Feng, Y.; Song, Y.; Yang, F.; Li, Y.; Zhang, D.; Wang, Y.; He, Y. A comparative study on the low velocity impact behavior of UD, woven, and hybrid UD/woven FRP composite laminates. Compos. Part B 2024, 271, 111133. [Google Scholar] [CrossRef]

- Liu, X.; Kong, W.; Song, S.; Wang, A. Impact properties and damage assessment of unidirectional aramid/carbon fiber hybrid reinforced polymer composites. Thin-Walled Struct. 2025, 209, 112898. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, Z.; Bai, Y.; Fang, S.; Ma, D.; Zhang, C. Intralaminar hybrid configurations on the impact resistance of Carbon/Kevlar plain-woven composite plates. Thin-Walled Struct. 2025, 209, 112895. [Google Scholar] [CrossRef]

- Hamza, S.S.; Ismail, A.E.; Yuhazri, M.Y.; Ariffin, A.H.; Sultan, M.T.H. Hybridization effect on crashworthiness parameters of natural composite. Front. Mater. 2021, 8, 619245. [Google Scholar]

- Guerfala, W.; Rozycki, P.; Binetruy, C. Development of flax/basalt/PA11 bio-composites: Optimal formulation and modelling of the quasi-static behaviour. Front. Mater. 2023, 10, 1176408. [Google Scholar] [CrossRef]

- Zhu, G.; Zhang, Y.; Niu, X.; Duan, C.; Wang, Z.; Zhao, X. Novel multiscale modeling strategy for hybrid fiber reinforced composites. Int. J. Mech. Sci. 2025, 287, 109997. [Google Scholar] [CrossRef]

- Cao, X.; Zhu, G.; Wang, Z.; Zhao, X. On flexural behavior of 3D-printed continuous hybrid fiber reinforced composites: Experimental and multiscale modeling study. Compos. Struct. 2025, 359, 119034. [Google Scholar] [CrossRef]

- Rajaneesh, A.; Ponthot, J.P.; Bruyneel, M. High velocity impact response of composite laminates using modified meso-scale damage models. Int. J. Mech. Sci. 2021, 147, 103701. [Google Scholar] [CrossRef]

- Johnson, A.F.; Holzapfel, M. Influence of delamination on impact damage in composite structures. Compos. Sci. Technol. 2006, 66, 807–815. [Google Scholar] [CrossRef]

- Lombarkia, R.; Gakwaya, A.; Nandlall, D.; Dano, M.L.; Lévesque, J.; Vachon-Joannette, P. Experimental investigation and finite-element modeling of the crushing response of hat shape open section composite. Int. J. Crashworthiness 2022, 27, 772–783. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Coelho, C.A.C.P.; Reis, P.N.B. Numerical simulations of the low-velocity impact response of semicylindrical woven composite shells. Materials 2023, 16, 3442. [Google Scholar] [CrossRef]

- GB/T 21563-2018; Railway Applications—Rolling Stock Equipment—Shock and Vibration Tests. National Standard of the People’s Republic of China: Beijing, China, 2018.

- Jin, W.; Zhang, Y.; Yang, G.; Chen, J.; Wang, M.; Li, G. Deterioration mechanism and influence of temperature and humidity on structural performance of braided CFRP carbody. J. Cent. South Univ. 2022, 53, 1582–1591. (In Chinese) [Google Scholar]

- Zhang, K.; Tang, W.; Ran, X. Constitutive relationship of anisotropic CFRP material and its application in planar plate impact simulation. J. Vib. Shock. 2019, 38, 101–106. (In Chinese) [Google Scholar]

- Chen, D.; Luo, Q.; Meng, M.; Li, Q.; Sun, G. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres. Compos. Part B Eng. 2019, 176, 107191. [Google Scholar] [CrossRef]

- EN 12663-1:2010+A1:2014; Railway Applications—Structural Requirements of Railway Vehicle Bodies Part 1: Locomotives and Passenger Rolling Stock (and Alternative Method for Freight Wagons). European Standard: Brussels, Belgium, 2014.

| Material | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio | Strength (MPa) |

|---|---|---|---|---|

| CFRP | 1400 | EX: 75.6 EY: 75.6 EZ: 9 GXY: 4.82 | 0.05 | Tensile strength: 800 Compressive strength: 500 |

| GFRP | 2600 | EX: 24 EY: 24 EZ: 9 GXY: 4.82 | 0.1 | Tensile strength: 414 Compressive strength: 331 |

| Condition | Acceleration | ||

|---|---|---|---|

| Transverse X | Longitude Y | Vertical Z | |

| 1 | +30 g | - | −1 g |

| 2 | −30 g | - | −1 g |

| 3 | - | +30 g | −1 g |

| 4 | - | −30 g | −1 g |

| 5 | - | - | +(30 − 1) g |

| 6 | - | - | −(30 + 1) g |

| Material Parameter | CFRP | GFRP |

|---|---|---|

| Stress in Tension | X: 800 MPa | X: 414 MPa |

| Y: 800 MPa | Y: 414 MPa | |

| Z: 54 MPa | Z: 54 MPa | |

| Stress in Compression | X: −500 MPa | X: −331 MPa |

| Y: −500 MPa | Y: −331 MPa | |

| Z: −240 MPa | Z: −240 MPa | |

| Stress in Shear | XY: 60 MPa | XY: 60 MPa |

| YZ:60 MPa | YZ:60 MPa | |

| XZ: 60 MPa | XZ: 60 MPa | |

| Stress Coupling Coefficients | XY: −1 | XY: −1 |

| YZ: −1 | YZ: −1 | |

| XZ: −1 | XZ: −1 |

| Condition | Ballast-Stone Diameter (mm) | Ballast-Stone Strength (MPa) | Impact Velocity (m/s) |

|---|---|---|---|

| 1 | 20 | 300 | 33 |

| Condition | CFRP | G/C/G | C/G/C | GFRP | ||||

|---|---|---|---|---|---|---|---|---|

| Tsai–Wu Strength Failure Value | Failure Location | Tsai–Wu Strength Failure Value | Failure Location | Tsai–Wu Strength Failure Value | Failure Location | Tsai–Wu Strength Failure Value | Failure Location | |

| 1 | 0.01 | Bolt hole | 0.01 | Bolt hole | 0.02 | Bolt hole | 0.02 | Bolt hole |

| 2 | 0.02 | Bolt hole | 0.02 | Bolt hole | 0.04 | Bolt hole | 0.04 | Bolt hole |

| 3 | 0.02 | Bolt hole | 0.03 | Bolt hole | 0.04 | Bolt hole | 0.04 | Bolt hole |

| 4 | 0.01 | Bolt hole | 0.01 | Bolt hole | 0.02 | Bolt hole | 0.03 | Bolt hole |

| 5 | 0.04 | Bolt hole | 0.05 | Bolt hole | 0.07 | Bolt hole | 0.09 | Bolt hole |

| 6 | 0.05 | Bolt hole | 0.06 | Bolt hole | 0.08 | Bolt hole | 0.11 | Bolt hole |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Chen, J.; Guan, M.; Xiao, S.; Yang, G.; Chen, D. Effects of Stacking Configuration on Impact Resistance of Electric Locomotive Coupling Protective Covers Reinforced by CFRP, GFRP, and Their Hybrids. Materials 2025, 18, 3133. https://doi.org/10.3390/ma18133133

Xu Y, Chen J, Guan M, Xiao S, Yang G, Chen D. Effects of Stacking Configuration on Impact Resistance of Electric Locomotive Coupling Protective Covers Reinforced by CFRP, GFRP, and Their Hybrids. Materials. 2025; 18(13):3133. https://doi.org/10.3390/ma18133133

Chicago/Turabian StyleXu, Yanhui, Jiyong Chen, Mingzhu Guan, Shoune Xiao, Guangwu Yang, and Dongdong Chen. 2025. "Effects of Stacking Configuration on Impact Resistance of Electric Locomotive Coupling Protective Covers Reinforced by CFRP, GFRP, and Their Hybrids" Materials 18, no. 13: 3133. https://doi.org/10.3390/ma18133133

APA StyleXu, Y., Chen, J., Guan, M., Xiao, S., Yang, G., & Chen, D. (2025). Effects of Stacking Configuration on Impact Resistance of Electric Locomotive Coupling Protective Covers Reinforced by CFRP, GFRP, and Their Hybrids. Materials, 18(13), 3133. https://doi.org/10.3390/ma18133133